东方马达RK系列

- 格式:pdf

- 大小:1.85 MB

- 文档页数:64

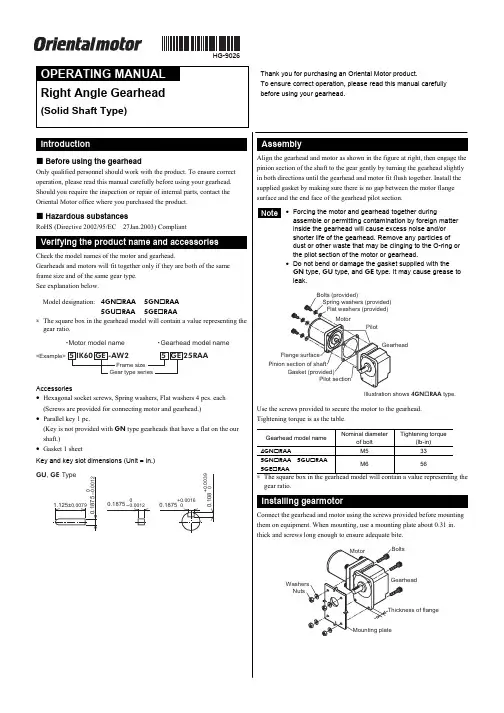

HG-9026Right Angle Gearhead(Solid Shaft Type)Thank you for purchasing an Oriental Motor product.To ensure correct operation, please read this manual carefully before using your gearhead.Before using the gearhead Only qualified personnel should work with the product. To ensure correct operation, please read this manual carefully before using your gearhead. Should you require the inspection or repair of internal parts, contact the Oriental Motor office where you purchased the product.Hazardous substances RoHS (Directive 2002/95/EC 27Jan.2003) CompliantCheck the model names of the motor and gearhead.Gearheads and motors will fit together only if they are both of the same frame size and of the same gear type. See explanation below.Model designation: 4GN RAA 5GN RAA5GU RAA 5GE RAA∗ The square box in the gearhead model will contain a value representing the gear ratio.<Example>5 IK60 GE -AW25 GE 25RAAFrame size Gear type series䊶Motor model name䊶Gearhead model nameAccessories• Hexagonal socket screws, Spring washers, Flat washers 4 pcs. each (Screws are provided for connecting motor and gearhead.)• Parallel key 1 pc.(Key is not provided with GN type gearheads that have a flat on the our shaft.)• Gasket 1 sheetKey and key slot dimensions (Unit = in.)GU , GE Type1.125±0.00790.1875+0.00160.18750-0.00120.18750-0.00120.108+0.0039Installation hole dimensions (Unit: in.)A±0.010A±0.0104×ØEB ±0.010C ±0.010ØDo r mo r eGearheadmodel nameScrew type Thicknessof flangeA B C ØDØE 4GN RAA No.10-24UNC 0.35 1.10 2.17 0.98 1.380.225GN RAA 1/4-20UNC 0.39 1.14 2.24 1.30 1.460.275GU RAA5GE RAA5/16-18UNC 0.47 1.18 2.64 1.30 1.380.33∗ The square box in the gearhead model will contain a value representing the gear ratio.The shaft of the gearhead has been machined to an outer diameter tolerance of h7 and is provided with a key slot for connecting the transmission parts. When connecting the transmission parts, ensure that the shaft and parts have a clearance fit, and secure with a screw to prevent the parts from wobbling. Use a screw hole (No.10-24UNC, effective depth 0.39 in.) provided at the tip of the output shaft of 5GU RAA and 5GE RAA as an auxiliary means for preventing the transfer mechanism from disengaging.< The example of output axistip screw hole use >Note • Do not use excessive force, or hammerthe transmission parts onto the gearmotor shaft as damage may occur. • Output shaft of 5GU120RAA to 5GU180RAA , 5GE120RAA to5GE180RAA cannot be turned by hand.For position alignment, turn on the motor.• Use your gearmotor under ambient temperature of +14 to +122 °F and85% humidity.• Do not use your gearmotor where it may be exposed direct sunlight waterand/or oil.• Do not use your gearmotor in locations subject to severe vibration or shock,a large amount of dust, inflammable gas and or corrosive gas.• On rare occasions, a small amount of grease may ooze out from thegearhead. If there is concern over possible environmental damage resulting from the leakage of grease, check for grease stains during regular inspections. Alternatively, install an oil pan or other device to prevent leakage from causing further damage. Oil leakage may lead to problems in the customer’s equipment or products.• If the ambient temperature is low, the motor may take a longer time to startor its speed may drop. This is caused, among others, by an increased friction torque of the oil seal used on the gearhead output shaft. As the motor continues to operate and the sliding part of the oil seal breaks in, the friction torque will drop and the motor will operate at the specified speed.• Direction of rotation of the gearhead output shaftThe motor and gearhead output shaft rotate in opposite directions.• Maximum permissible torqueSince the output torque of the gearhead increases proportionally with the reduction of speed, a high reduction ratio of the gearhead will result in anoutput torque that cannot be taken up by the physical construction of the gearhead. Use gearheads within the maximum permissible torque set for each speed reduction ratio. Also, be sure shaft rotation is not stopped by an external force or load obstruction. The resulting shock may damage the gearhead.• Permissible overhung load and permissible thrust load“Overhung load” refers to load placed on the output shaft of the gearhead in a direction perpendicular to the shaft as shown in the Figure below. The “Thrust load” is a load applied in the axial direction of the output shaft. Since the overhung load and thrust load have a great influence on the life of the bearings and strength of the shaft, be careful not to exceed the maximum values shown in the table at following.< Permissible overhung load and permissible thrust load >Permissibleoverhung load (lb)From the endof shaftGearhead model nameGear ratioMaximum permissibletorque(lb-in)0.39 in. 0.79 in.Permissible thrust load(lb)3 to 18 22 334GN RAA 25 to 18070 45 67 223 to 18 56 785GN RAA25 to 18088 67 101 453 to 9 90 11212.5 to 25101 135 5GU RAA 5GE RAA30 to 180177 112 15756∗ The square box in the gearhead model will contain a value representing thegear ratio.• Unauthorized reproduction or copying of all or part of this OperatingManual is prohibited.• Oriental Motor shall not be liable whatsoever for any patent-relatedproblem arising in connection with the use of any information, circuit, equipment or device described in the manual.• Characteristics, specifications and dimensions are subject to changewithout notice.• While we make every effort to offer accurate information in the manual,we welcome your input. Should you find unclear descriptions, errors or omissions, please contact the nearest office.•is a trademark of Oriental Motor Co., Ltd.© Copyright ORIENTAL MOTOR CO., LTD. 2006• Please contact your nearest Oriental Motor office for further information.ORIENTAL MOTOR U.S.A. CORP .Technical Support Line Tel:(800)468-3982Available from 7:30 AM to 5:00 PM, P .S.T.E-mail:*****************************ORIENTAL MOTOR CO., LTD.Headquarters Tokyo, JapanTel:(03)3835-0684 Fax:(03)3835-1890Printed on Recycled Paper。

ORIENTALMOTOR⽇本东⽅马达及驱动选型RKSeries RoHS-Compliant5-Phase Stepping Motor and Driver Package RK SeriesⅷStandard Type ⅷTH Geared TypeⅷPL Geared Type ⅷPN Geared TypeⅷHarmonic Geared Type2RoHS-Compliant5-Phase Stepping Motor and Driver PackageRK SeriesThe RK Series incorporates new functions and state-of-the-art technologies to achieve the ultimate use of a control motor. The seriesoffers various types including the standard type, electromagnetic brake type, IP65 rated motor type, and four geared types. Three frame sizes of 42 mm, 60 mm and 85 (90) mm are available. The wide range of motor variations and affordable prices make the RK Series a perfect solution for your various applications.ⅥFeaturesv bz Smooth Drive FunctionThe smooth drive function ensures low-vibration andlow-noise operation at low speeds by internally executing microstepping within the driver, working independently of the inputpulse frequency of your controller.V i b r a t i o n C o m p o n e n t V o l t a g e V p -p [V ]Speed [r/min]The smooth drive function of the RK Series improves the settling performance.S p e e d [r /m i n ]S p e e d [r /m in ]Conventional Model RK (Smooth Drive: ON)100 ms/div100 ms/divStep Angle: 0.72?/stepStep Angle: 0.72?/stepx Microstep Drive SystemThe motor's basic step angle is divided by a maximum of 1/250 without the use of a reduction mechanism or other mechanical elements. 16 resolution levels are available to set the desired resolution. This enables fine positioning and the further reduction of vibration and noise. A motion sequence of "low-speed transfer ? high-speed return" can easily be performed without the need for changing from a microstep pulse frequency to a full step pulse frequency. The RK Series can also be used in full-step operation.c 100-115 VAC, 200-230 VAC Power Source Variation The RK Series can be used with most common power supplies available around the world.They also comply with the international standards, ensuring safe operation.v Improved Angle AccuracyAngle accuracy may decrease during use of microstep drivers, due to the effect of current control. However, the drivers used in the RK Series are designed to ensure that the motor operates at maximum accuracy.A n g l e E rr o r [d e g ]0.0720.036-0.072-0.036Power Supply Voltage: 100-115 VAC b Improved ResponseThe RK Series, with its high starting frequency, shortens the machine cycle without affecting acceleration/deceleration rates. This produces a significant savings in time for an operation in which the same cycle is repeated thousands of times each day.Rise Time [ms]S p e e d [r /m i n ]3Features Line-upSystem ConfigurationProduct LineSpecifications and Characteristics DimensionsConnection and Operation List of Motor and Driver CombinationsAccessoriesBefore Using a Stepping MotorControllersⅷEnvironmentally Friendly Energy-Saving Mode In the energy-saving mode, the supply of current to the motor is stopped and the load is held only with the electromagnetic brake while the motor remains at a standstill. Stopping the supply of current to the motor extends the motor life by limiting the consumption of energy.(Available only with electromagnetic brake type)P o w e r C o n s u m p t i o n [k W ]Automatic Current-Cutback Modein Energy-Saving ModeComparison of Annual Power Consumption at ⅷSafe Operation in Major Countries around the World Compliance with Safety StandardsThe RK Series complies with the UL/CSA and ENstandards. (With the RK54Ⅺ type, only the driver conforms to the CSA standard.) The CE marking certifies compliance with the EMC Directive and Low-Voltage Directive.Additionally, the RK Series conforms to the EMC Directive only through its use of surge arrester. The RK Seriesdoesn't require an external ferrite core or filter in the motor line or power line.ⅷProtective Earth Terminal(Excluding motors with a frame size of 42 mm)The life of a motor is affected by its bearing. The RK Series achieves approx. twice the life of a conventional motor by adopting a modified bearing. (Available only with the standard type and standard electromagnetic-brake type with a frame size of 60 or 85 mm.)ⅷNew IP65 Rated Motor Conforming to the IP65 Standard for Ingress Protection against Dust and WaterTerminal-Block Connection DesignThe motor can be wired directly from its terminal block.No Motor/Driver RelaySince the motor cable can be connected directly with the driver terminals, there is no need for wire connection orsoldering on a relay terminal block.DriverRoHS-CompliantThe RK Series conforms to the RoHS Directive thatprohibits the use of six chemical substances including lead and cadmium.ⅥWide VarietyThe RK Series offers a range of motor frame sizes depending on the motor type and power supply voltage specification, as shown below.□ⅷStandard Type/Standard Type IP65 Rated MotorEasy-to-use standard types offer balanced performance. The IP65 rated motor conforms to the IP65 standard for ingress protectionagainst dust and water.ⅷStandard Type with Electromagnetic BrakeA motor combines with power off activated type electromagnetic brake.TH Geared Type (Low backlash)A low-cost geared motor offers low backlash.ⅷPL Geared Type (Low backlash)A geared motor offers low backlash, high strength and wide gear ratios.ⅷPNGeared Type (Non-backlash)A high-accuracy geared motor achieves a backlash of 3 arc minutes or less. It also provides high strength and wide gear ratios.Harmonic Geared Type(Non-backlash)A high-accuracy, backlash-free geared motor adopts a newly developed harmonic gear. It ensures high strength in a compact body.45FeaturesLine-upSystem ConfigurationProduct LineSpecifications and CharacteristicsDimensionsConnection and Operation List of Motor and Driver Combinations Accessories Before Using a Stepping Motor ControllersTH (Parallel Shaft)PL (Harmonic Drive)ⅥSystem ConfigurationAn example of a system configuration with the SG8030 Series controller.Mounting Brackets (Accessories)Connector-Terminal BlockDriverⅷThe system configuration shown above is an example. Other combinations are available.67Features Line-upSystem ConfigurationProduct LineSpecifications and CharacteristicsDimensionsConnection and Operation List of Motor and Driver CombinationsAccessoriesBefore Using a Stepping Motor ControllersⅥProduct Number Codeqw e r t y u io !0RK 5 6 6 B A E - N 5Series RK :RK Series 5: 5-PhaseMotor Frame Size 4: 42 mm6: 60 mm 9: 85 mm (90 mm sq. for Geared Type)Motor Case LengthMotor Shaft Type A : Single Shaft B : Double ShaftElectromagnetic Brake Blank : Without Electromagnetic Brake M : With Electromagnetic Brake Power Supply Voltage A : Single-Phase 100-115 VAC C : Single-Phase 200-230 VAC Motor Classi? c ation TypeBlank : Standard Type T :TH Geared TypeP :PL Geared Type N :PN Geared Type H : Harmonic Geared TypeGear RatioⅥProduct Line89 Features Line-up System ConfigurationProduct LineSpecifications and CharacteristicsDimensionsConnection and Operation List of Motor and Driver CombinationsAccessoriesBefore Using a Stepping Motor ControllersStandard Type Motor Frame Size 42 mmⅥSpecificationsⅷWith the RK54Ⅺ type, only the driver conforms to the CSA standard.RK543AA RK544AA RK545AA RK543BA RK544BA RK545BAHow to Read Specifications Table ?See the following descriptions.Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK543AA/RK543BAPulse Speed [kHz](0)(300)(200)(100)(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]132Current: 0.75 A/Phase Step Angle: 0.72?/step 2RK544AA/RK544BAPulse Speed [kHz]0(0)30(300)20(200)10(100)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]132Current: 0.75 A/Phase Step Angle: 0.72?/step 2RK545AA/RK545BAPulse Speed [kHz]0(0)30(300)20(200)10(100)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]132Current: 0.75 A/Phase Step Angle: 0.72?/step 2ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.ⅥHow to Read Specifications TablePlease read the following information before examining the specifications on pages 9 to 23.10Standard Type Motor Frame Size 60 mm, 85 mmHow to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK564ⅪAE RK564ⅪCEPulse Speed [kHz]0(0)10(100)20(200)30(300) Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]462Current: 1.4 A/Phase Step Angle: 0.72?/step 2RK566ⅪAE RK566ⅪCEPulse Speed [kHz](0)10(100)20(200)30(300) Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2RK569ⅪAE RK569ⅪCEPulse Speed [kHz]0(0)10(100)20(200)30(300) Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2ⅷEnter A (Single shaft) or B (Double shaft) in the box (Ⅺ) within the model name.ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.RK596ⅪAE RK596ⅪCEPulse Speed [kHz](0)(100)(200) Speed [r/min](Resolution 10)T o r q u e [N ?m ]C u r r e n t [A ]510Current: 1.4 A/Phase Step Angle: 0.72?/step 2 RK599ⅪAE RK599ⅪCEPulse Speed [kHz]Speed [r/min](Resolution 10)(0)(50)(100)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2 RK5913ⅪAERK5913ⅪCEPulse Speed [kHz](0)(50)(100) Speed [r/min](Resolution 10)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2 11FeaturesLine-upSystem ConfigurationProduct LineSpecifications and Characteristics DimensionsConnection and Operation List of Motor and Driver CombinationsAccessoriesBefore Using a Stepping Motor ControllersStandard Type IP65 Rated Motor Motor Frame Size 60 mm, 85 mmⅥSpecificationsHow to Read Specifications Table ?Page 91Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.2Excluding the gap between the shaft and the flangeⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK564AAT/RK564ACTPulse Speed [kHz]0(0)10(100)20(200)30(300)Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]462Current: 1.4 A/Phase Step Angle: 0.72?/step 2RK566AAT/RK566ACTPulse Speed [kHz]0(0)10(100)20(200)30(300) Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2RK569AAT/RK569ACTPulse Speed [kHz]0(0)10(100)20(200)30(300) Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.RK596AAT/RK596ACTPulse Speed [kHz]0(0)10(100)20(200) Speed [r/min]Resolution 1(Resolution 10)T o r q u e [N ?m ]C u r r e n t [A ]510Current: 1.4 A/Phase Step Angle: 0.72?/step2RK599AAT/RK599ACTPulse Speed [kHz]Speed [r/min]Resolution 1(Resolution 10)0(0)5(50)10(100)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2RK5913AAT/RK5913ACTPulse Speed [kHz]0(0)5(50)10(100) Speed [r/min]Resolution 1(Resolution 10)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 212Standard Type with Electromagnetic Brake Motor Frame Size 42 mm ⅥSpecificationsⅷWith the RK54Ⅺtype, only the driver conforms to the CSA standard.How to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK543AMAPulse Speed [kHz]0(0)30(300)20(200)10(100)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]132Current: 0.75 A/Phase Step Angle: 0.72?/step 2RK544AMAPulse Speed [kHz]0(0)30(300)20(200)10(100)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]132Current: 0.75 A/Phase Step Angle: 0.72?/step 2RK545AMAPulse Speed [kHz]0(0)30(300)20(200)10(100)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]132Current: 0.75 A/Phase Step Angle: 0.72?/step 2ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.13FeaturesLine-upSystem Configuration Product LineSpecifications and CharacteristicsDimensionsConnection and Operation List of Motor and Driver CombinationsAccessoriesBefore Using a Stepping Motor ControllersStandard Type with Electromagnetic Brake Motor Frame Size 60 mm, 85 mmⅥSpecificationsHow to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK564AMAE RK564AMCEPulse Speed [kHz]0(0)10(100)20(200)30(300)Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]462Current: 1.4 A/Phase Step Angle: 0.72?/step 2RK566AMAE RK566AMCEPulse Speed [kHz]0(0)10(100)20(200)30(300) Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2RK569AMAE RK569AMCEPulse Speed [kHz]0(0)10(100)20(200)30(300) Speed [r/min]T o r q u e [N ?m ]Resolution 1(Resolution 10)C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.RK596AMAE RK596AMCEPulse Speed [kHz]0(0)10(100)20(200) Speed [r/min]Resolution 1(Resolution 10)T o r q u e [N ?m ]C u r r e n t [A ]510Current: 1.4A/Phase Step Angle: 0.72? step 2RK599AMAE RK599AMCEPulse Speed [kHz]0(0)Speed [r/min]Resolution 1(Resolution 10)5(50)10(100)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2 RK5913AMAE RK5913AMCEPulse Speed [kHz]0(0)5(50)10(100) Speed [r/min]Resolution 1(Resolution 10)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.72?/step 2 14TH Geared Type Motor Frame Size 42 mmⅥSpecificationsⅷWith the RK54Ⅺtype, only the driver conforms to the CSA standard.How to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.Note:ⅷDirection of rotation of the motor and that of the gear output shaft are the same for models with gear ratios of 1:3.6, 1:7.2 and 1:10. It is opposite for 1:20 and 1:30 gear ratio models.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK543AA-T3.6/RK543BA-T3.6Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.2?/step 2RK543AA-T7.2/RK543BA-T7.2Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.1?/step 2RK543AA-T10/RK543BA-T10Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.072?/step 2ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.RK543AA-T20/RK543BA-T20Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.036?/step 2RK543AA-T30/RK543BA-T30T o rq u e [N ?m ]C u r r e n t [A ]12Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)Current: 0.75 A/Phase Step Angle: 0.024?/step 215FeaturesLine-upSystemConfiguration Product LineSpecifications and CharacteristicsDimensionsConnection and Operation List of Motor and Driver Combinations AccessoriesBefore Using a Stepping MotorControllersTH Geared Type Motor Frame Size 60 mmⅥSpecificationsHow to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.Note:ⅷDirection of rotation of the motor and that of the gear output shaft are the same for models with gear ratios of 1:3.6, 1:7.2 and 1:10. It is opposite for 1:20 and 1:30 gear ratio models.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK564ⅪAE-T3.6 RK564ⅪCE-T3.6Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]24Current: 1.4 A/Phase Step Angle: 0.2?/step 2RK564ⅪAE-T7.2 RK564ⅪCE-T7.2Pulse Speed [kHz]0(0)15(150)10(100)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.1?/step 2RK564ⅪAE-T10 RK564ⅪCE-T10Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)T o r q u e [N ?m ]C u r r e n t [A ]24Current: 1.4 A/Phase Step Angle: 0.072?/step 2ⅷEnter A (Single shaft) or B (Double shaft) in the box (Ⅺ) within the model name.ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.RK564ⅪAE-T20 RK564ⅪCE-T20Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)15(150)T o r q u e [N ?m ]C u r r e n t [A ]24Current: 1.4 A/Phase Step Angle: 0.036?/step 2RK564ⅪAE-T30 RK564ⅪCE-T30Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)T o r q u e [N ?m ]C u r r e n t [A ]24Current: 1.4 A/Phase Step Angle: 0.024?/step 216TH Geared Type Motor Frame Size 90 mmⅥSpecificationsHow to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.Note:ⅷDirection of rotation of the motor and that of the gear output shaft are the same for models with gear ratios of 1:3.6, 1:7.2 and 1:10. It is opposite for 1:20 and 1:30 gear ratio models.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK596ⅪAE-T3.6 RK596ⅪCE-T3.6Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]2.55Current: 1.4 A/Phase Step Angle: 0.2?/step 2 RK596ⅪAE-T7.2 RK596ⅪCE-T7.2Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]2.55Current: 1.4 A/Phase Step Angle: 0.1?/step 2 RK596ⅪAE-T10 RK596ⅪCE-T10Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)T o r q u e [N ?m ]C u r r e n t [A ]264Current: 1.4 A/Phase Step Angle: 0.072?/step 2ⅷEnter A (Single shaft) or B (Double shaft) in the box (Ⅺ) within the model name.ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.RK596ⅪAE-T20 RK596ⅪCE-T20C u r r e n t [A ]Pulse Speed [kHz](Resolution 10)(0)(50)(100)(150)Current: 1.4 A/Phase Step Angle: 0.036?/step 2RK596ⅪAE-T30 RK596ⅪCE-T30C u r r e n t [A ]Pulse Speed [kHz](Resolution 10)(0)(50)(150)Current: 1.4 A/Phase Step Angle: 0.024?/step 217FeaturesLine-upSystem ConfigurationProduct LineSpecifications and CharacteristicsDimensionsConnection and Operation List of Motor and Driver CombinationsAccessoriesBefore Using a Stepping Motor ControllersPL Geared Type Motor Frame Size 42 mmⅥSpecificationsⅷWith the RK54Ⅺ type, only the driver conforms to the CSA standard.How to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.Note:ⅷDirection of rotation of the motor and that of the gear output shaft are the same.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK545AA-P5 RK545BA-P5Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)15(150)T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.144?/step 2RK545AA-P7.2RK545BA-P7.2Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.1?/step 2RK545AA-P10RK545BA-P10Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.072?/step 2ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Besure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)ⅷWhen using the motor with the dedicated driver, the driver’s automatic current cutback function at motor standstill reduces maximum holding torque by approximately 50%.RK543AA-P25 RK543BA-P25Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min](0)(50)(100)(150)T o r q u e [N ?m ]C u r r e n t [A ]12Current: 0.75 A/Phase Step Angle: 0.0288?/step2RK543AA-P36 RK543BA-P36Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]21Current: 0.75 A/Phase Step Angle: 0.02?/step2RK543AA-P50 RK543BA-P50Pulse Speed [kHz]0(0)15(150)10(100)5(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]21Current: 0.75 A/Phase Step Angle: 0.0144?/step 218PL Geared Type Motor Frame Size 60 mmⅥSpecificationsHow to Read Specifications Table ?Page 9Sixteen resolutions are available, where n=1, 2, 2.5, 4, 5, 8, 10, 20, 25, 40, 50, 80, 100, 125, 200 and 250.Note:ⅷDirection of rotation of the motor and that of the gear output shaft are the same.ⅥSpeed – Torque Characteristics fs: Maximum Starting FrequencyRK566ⅪAE-P5 RK566ⅪCE-P5Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min]0(0)5(50)10(100)15(150)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.144?/step 2RK566ⅪAE-P7.2 RK566ⅪCE-P7.2Pulse Speed [kHz](0)(150)(100)(50)Resolution 1(Resolution 10)Speed [r/min]T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.1?/step 2RK566ⅪAE-P10 RK566ⅪCE-P10Pulse Speed [kHz]Resolution 1(Resolution 10)Speed [r/min](0)(50)(100)(150)T o r q u e [N ?m ]C u r r e n t [A ]48Current: 1.4 A/Phase Step Angle: 0.072?/step 2ⅷEnter A (Single shaft) or B (Double shaft) in the box (Ⅺ) within the model name.ⅷThe pulse input circuit responds to approximately 200 kHz with a pulse duty of 50%.Notes:ⅷPay attention to heat dissipation from motor as there will be a considerable amount of heat under certain conditions.Be sure to keep the temperature of the motor case under 100?C.(Under 75?C is required to comply with UL or CSA standards.)。

RKD514L-C东方步进电动机驱动器原理与检修RKD514L-C东方步进电动机驱动器(以下简称RKD514L-C驱动器),可驱动五相步进电动机,电源电压AC200~230V,输出电流3.5A(可调),输出电压约150V。

设备端子及调整部件功能、控制端子、主端子接线等见以下图表。

1、RKD514L-C驱动器端子、调整部件功能、端子接线图1 RKD514L-C驱动器接线端子及调整部件图RKD514L-C驱动器接线端子及调整部件功能说明(见表4-1)上述(图1、图2、图3)图表(表4-1),是在检修设备之前,要尽量掌握的相关“知识储备”,如控制端子功能和相关调整部件的作用,则是检修中必须要掌握的,检修内容将与之发生紧密的关联。

输出状态取决于部件的设置与调整,有时人为的调错,会使机器产生“故障”,检修人员应该区分故障的真假,可以通过调试手段,将一些“伪故障”排除掉。

2、MCU主板电路之一如图4所示电路,包含了MCU基本工作电路、控制端子信号输入/输出电路和功能整定电路。

〔MCU基本电路〕+5V电源,接入MCU的相关供电引脚;晶振元件XL101与振荡电路IC106、IC110生成的脉冲信号,做为时钟信号输入MCU的120脚;R184、D103、C136和IC108(HC14)内部两组反相器电路,组成上电复位电路,在CPU上电瞬间提供一个低电平的复位脉冲,输入MCU的122脚,使MCU内部计数器、寄存器清零。

以上电路提供MCU正常工作的基本条件。

〔控制端子信号输入/输出电路〕外部输入的4路控制信号经CN101插座进入。

高速光耦合器件PC101、表4-1 RKD514L-C驱动器接线端子及调整部件功能说明图2 RKD514L-C驱动器电源、步进电动机接线图PC102(TLP750)承担着对转速(脉冲)信号和正/反转控制信号的传输任务,输出信号再经两级反相器电路,输入至MCU的7、8脚。

这是两路基本控制信号;另两路控制信号经光耦合器PC103、PC104(P781)进行隔离传输,其中一路控制信号为调机信号ON/OFF指令,确定停车时马达处于直流刹车还是自由停车状态,两路信号输入至MCU的5、6脚。

AS系列闭环控制步进马达组合产品规格一览表组合型号一览表电动机单体型号一览表驱动器型号一览表ASC系列闭环控制步进马达组合产品规格一览表组合型号一览表电动机单体型号一览表驱动器型号一览表RK系列5相步进马达组合产品规格一览表组合型号一览表电动机单体型号一览表驱动器型号一览表UPK · W系列5相步进马达组合具有东方步进马达的一般特性,为5相步进马达与专用驱动器的组合。

2. 具有易操作性的特点。

3. 种类齐全,有两百多种可供选择。

组合型号一览表电动机单体型号一览表驱动器型号一览表PMU系列5相步进马达组合具有东方步进马达的一般特性,为5相步进马达与专用驱动器的组合。

2. 安装尺寸为28*28mm,为小型,轻便型而推出的系列规格一览表组合型号一览表电动机单体型号一览表驱动器型号一览表UMK系列2相步进马达组合步进角为1.8°的2相步进马达与专用AC驱动器的组合。

2. 拥有内藏自动电流OFF,脉冲输入方式切换,步距角切换,过热输出逻辑切换功能,另配有用于检测机构原点时使用的激磁时序输出(TIMING)功能规格一览表组合型号一览表电动机单体型号一览表驱动器型号一览表CFKⅡ系列5相步进马达组合. 马达最小安装尺寸仅为20mm的微型设计,小型基板型驱动器,符合设备小型化的趋势。

2. 驱动器对应DC24~36V电压输入。

3. 低速情况下仍能保持低振荡的特性,适用于低速精密执行的场合。

规格一览表组合型号一览表电动机单体型号一览表驱动器型号一览表CRK系列5相步进马达组合1. 5相高性能步进马达与具备平滑驱动功能的小型,低振动,低噪音的驱动器的组合,2 .DC24V光耦合器输入,单/双脉冲输入规格。

3. CRK系列在保留前部品的优点情况下,推出追求定位精密的高分辨型规格一览表组合型号一览表电动机单体型号一览表驱动器型号一览表CSK系列5相步进马达组合1. 5相高性能步进马达与具备平滑驱动功能的小型,低振动,低噪音的驱动器的组合,2 .为东方步进马达的基本型组合。