LED恒温加热平台说明书(英文版)

- 格式:doc

- 大小:66.50 KB

- 文档页数:3

Star Manufacturing International Inc.10 Sunnen DriveS t. Louis, MO 63143Phone: (314) 781-2777Fax: (314) 781-3636Installation and Operating Instructions STAR-MAXELECTRIC HOT PLATEMODELS502A AND 502FA2M-Z1436 Rev. B 6/25/02Model 502AModel 502FASAFETY SYMBOLThis symbol is intended to alert the user to the presence of Arrayimportant operating and maintenance instructions in the manualaccompanying the appliance.RETAIN THIS MANUAL FOR FUTURE REFERENCENOTICEUsing any part other than genuine Star factory suppliedparts relieves the manufacturer of all liability.NOTICEStar reserves the right to change specifications and productdesign without notice. Such revisions do not entitle thebuyer to corresponding changes, improvements, additionsor replacements for previously purchased equipment.MAINTENANCE AND REPAIRSContact your local authorized service agent for service or required maintenance. Refer to the authorizedservice center listing provided with the unit. The Star Service Help Desk (1-800-807-9054) is available duringnormal business hours to answer any questions that may arise. Please have your model number and serialnumber for faster service.CAUTION CAUTIONThis equipment is designed and sold for commercialuse only by personnel trained and experienced in itsoperation and is not sold for consumer use in andaround the home nor for use directly by the generalpublic in food service locations. For equipment tobe used by the general public, please contact thefactory.The Star-Max models 502A and 502FA Electric HotPlates are equipped for the voltage indicated on thenameplate mounted on the front panel. This unit isdesigned to operate on alternating current (A.C.),two wire single phase service only. DO NOTCONNECT TO DIRECT CURRENT (D.C.).Total Connected Load502FA - at 240 Volts, Wattage is 5200.at 208 Volts, Wattage is 3900.502A - at 240 Volts, Wattage is 4200.at 208 Volts, Wattage is 3150.INSTALLATIONFor your protection, we recommend that aqualified electrician install this appliance. Theelectrician should be familiar with electricalinstallations and your local electrical requirements.The external wiring should be in conduit or anapproved type of flexible cable and of suitable sizeto carry the load. The supply circuit should beproperly fused and equipped with a means ofdisconnecting as required by local electrical code.The body of the hot plate should be grounded (Donot ground to a gas supply pipe). The connectionsare made in this unit at the pigtail leads located inthe junction box on the back of the unit. To gainaccess to the pigtail leads remove cover on junctionbox.LEVELING UNIT Level unit by adjusting the (4) feet for accurate and perfect line up with other Star-Max series units.CAUTION GENERAL OPERATING INSTRUCTIONSUSE ONLY FLAT BOTTOM PANS AND POTS! DO NOT USE RAISED BOTTOM UTENSILS OR BUCKETS! GOOD HEAT TRANSFER DEPENDS UPON GOOD CONTACT BETWEEN THE ELEMENT AND POT.Two (2) heating elements are used. For the 502FA each element draws 2600 watts on 240 Volts and 1950 watts on 208 Volts. For the 502A each element draws 2100 watts on 240 Volts and 1575watts on 208 Volts. Each element is controlled by an infinite position switch. The right control knob controls the rear cooking element and the left control knob controls the front cooking element.On "HI" the element delivers uninterrupted full heat. Between "LO" and "5" any desired amount of heat can be obtained between 6% and 60% of full heat.Signal lights are provided above the control knobs to give a visual check if either one or both heating units are turned on.OPERATING PROCEDURE DO NOT INSTALL WITHOUT FEET.LOCATE THE UNIT Do not install the unit closer than 1 inch from a side wall and/or closer than 1 inch from a rear wall.CLEANINGThe exterior surfaces can be kept clean and attractive by regularly wiping with a clean soft cloth. Any discoloration can be removed with a non-abrasive cleaner.For model 502A, the heating elements may be raised for access to the drip pans, which may be removed for cleaning and the bottom pan may be removed by sliding pan forward. REPLACEMENT OF INFINITE CONTROLBE SURE POWER IS DISCONNECTED BEFORE ATTEMPTING TO SERVICE UNIT.1.Pull control knobs on front panel forward toremove.2.Remove 4 screws from front panel and tiltfront panel forwards.3.Remove the nut that mounts the inoperativecontrol and pull the control to the side.4.Remove one wire at a time from theinoperative control and connect at the sameterminal on the new control. Carefully checkto see that proper wires have been connected to the terminals of the control. See attachedwiring diagram.5.Assemble new control to the front panel. MAINTENANCE AND REPAIRSContact the factory or one of its representatives or a local service company for service or maintenance if required.RETAIN THIS MANUAL FOR FUTURE REFERENCE Part No. 2M-Z1436 Rev. B 6/25/02Part# 2M-4497-2 01/02The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.FOR ASSISTANCEShould you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.ALL:* Pop-Up Toasters * Butter Dispensers * Pretzel Merchandisers * Pastry Display Cabinets * Nacho Chip Merchandisers * Accessories of any kind * Sneeze Guards * Pizza Ovens * Heat Lamps * Hot Cups * Pumps Visit our Website at: Email: **********************************************:(800) 807-9814THOROUGHLY INSPECT YOUR UNIT ON ARRIVALThis unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of the unit.LIMITED EQUIPMENT WARRANTYAll workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below)should be taken to the closest Star service agency, transportation prepaid.>Star will not assume any responsibility for loss of revenue.>On all shipments outside the United States and Canada, see International Warranty.*The warranty period for the JetStar series six (6) ounce popcorn machines is two (2) years.*The warranty period for the Chrome-Max Griddles is five (5) years on the griddle surface. See detailed warranty provided with unit.* The warranty period for Teflon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to Teflon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners. This warranty does not apply to the “non-stick” properties of such materials.>This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts and ninety (90) days on labor.>This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or the Service Center's sub-agency.>This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and Operating instructions.PARTS WARRANTYParts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is chargeable to the customer.SERVICES NOT COVERED BY WARRANTYPORTABLE EQUIPMENTStar will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.These products should be taken to the Service Agency for repair:1.Travel time and mileage rendered beyond the 50 mile radius limit 2.Mileage and travel time on portable equipment (see below) 3.Labor to replace such items that can be replaced easily during a daily cleaning routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc. 4.Installation of equipment 5.Damages due to improper installation 6.Damages from abuse or misuse 7.Operated contrary to the Operating and Installation Instructions 8.Cleaning of equipment 9.Seasoning of griddle plates10.Voltage conversions 11.Gas conversions 12.Pilot light adjustment 13.Miscellaneous adjustments 14.Thermostat calibration and by-pass adjustment 15.Resetting of circuit breakers or safety controls 16.Replacement of bulbs 17.Replacement of fuses 18.Repair of damage created during transit, delivery, &installation OR created by acts of God * The Model 510F Fryer.* The Model CFS Series Food Steamer.* The Model 526TO Toaster Oven.* The Model 526WO Warming Oven.* The Model J4R, 4 oz. Popcorn Machine.* The Model 518CM & 526CM Cheese Melter.* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmers.* All Condiment Dispensers except the Model CSD Series Chili/Cheese Dispenser.* All Specialty Food Warmers except Model 130R, 500, 11RW Series, and 11WSA Series.March 18, 2009 RB W/Ceramic Block。

Thermostatic Heater IllustrationI.Item description:Adopted by original Yudian Automation PDI economic type temperature controller, its high-accuracy, operation is safe, simple, clear and convenience.Adopted by multiple high-quality metal heating pipes, maintenance is convenience and low failure-rate.The aluminum top surface is high thermal conductivity, heat fast and evenly.The whole case is made by high-quality SUS304 stainless to ensure it against from rusted and peeling off in the usual condition.II. SpecfationPower Supply:220V (50HZ);Controllable Temperature Range:Basic Type (Ordinary Temperature~350℃); Elevated TemperatureType( Ordinary Temperature~450℃),Ultra Temperature Type (Ordinary Temperature~500℃), Each type of the item hasUnitary Type (Model A), Splitting Type (Model B) and Guardrail Type ( Model C).E,F。

Fan coil units3PictogrammesManual cool/heat changeoverAutomatic cool/heat changeover based on water temperatureAutomatic cool/heat changeover based on air temperatureControl of the 3-way/4-port ON/OFF valve. The water valve shut-off once the desired temperature is reached.The controller controls the electric heater as integration or replacement of the hot water heating system. When the operating mode selector witch is turned on “electric heater” and the electric heater is turned on, the fan runs continuously at medium speed.The fan speed can be set at one of the 3 speeds (low, medium or maximun) by turning the operation mode selector.The fan speed is switched automatically based on the difference between the temperature set on the thermostat and the room temperature.Optimised comfort cooling. When the fan coil has reached the desired setpoint, the fan will operate at medium speed and at regular intervals to ensure constant room temperature and lower sound.The controller prevents the fan coil unit from operating in one mode, if the required water temperature is not achieved to operate in the selected mode.The dead zone is a temperature interval close to the set temperature. When the air is warmer/cooler than the top/lower limit of the neutral zone, the cooling/ heating mode is selected.FWV FWL FWM01234567891011kWFWD24681012141618202224kWFWB24681012141618202224kWFan Coil Reference 2-pipe4-pipeProduct portfolioFan Coil Reference 2-pipe4-pipeCooling HeatingFan Coil Reference 2-pipe4-pipeDaikin fan coil units deliver quiet, reliable, controllable comfort of air conditioning without all the noise of other central systems.Fan coil units are a highly efficient means of turning a water chiller or hot water boiler into an efficient, quiet air conditioning system.The units are super quiet because the only moving part is the fan; making them ideal for use in offices, hotels and the home.The new range of fan coil units offers 5 models, of which 3 in flexible application. A wide range of accessories is available.For the ultimate in quiet, controllable air conditioning with all the comfort but none of the bulk or noise, the clear choice is Daikin.Easy to installFast and easy field set up, ready for use!KEY HOLE SYSTEM / LEVELLING•Quick fixing system for wall/ceiling mounting Advantage : No need to unscrew the nut •Units just need to be perfectly leveledAdvantage : No need to calculate the condensate drainageWATER CONNECTION •Pre-assembled 3-way/4-port ON/OFF valves are available •Valve packages are insulated, no extra drain pan required •Valve packages contain balancing valves and sensor pocket •Valve packages can be factory-mounted and are leak tested•Same valve package can be installed vertically and horizontally, on the right or on the left side of the unit without changeAdvantage : Easy to connect even when space is limitedCONDENSATE DRAINAGE•Condensate drain pan features slopes to reduce water accumulation •Supplied with flexible rubber hose pipe for easy connectionAdvantage : Eliminates the need to align drain pan outlet with customer pipingAdvantage : No need for collar if pipe diameter is compatibleQUICK ELECTRICAL CONNECTIONS•Fast-on connections for electrical options : no tools needed •Controls are already factory-wired and testedAdvantage : Control panel no longer needs to be opened (external customer connections)•Wiring diagram on the cover of the electrical boxEasy to maintainLow maintenance and high effeciency QUICK REMOVAL OF WASHABLE FILTER•No tools needed•Same system on vertical and horizontal unitsAdvantage: very fast filter removalELECTRIC HEATER RESETTING•No relay up to 2kW capacityAdvantage: even quieter operation•Manual reset easily accessible•Equipped with two overheat cut-out thermostats(manual & automatic reset)Advantage: anticipates the upcoming standardsFAN MOTOR/CONTROL PANEL ACCESSIBILITY• 4 screws to access to the fan motor•Fan board is removable without bringing the unit down•Motor is life-lubricated and has a life span of 40,000 hours•Control panel removable by a single screw•Can be unfolded for a better component access•Removable grilles•Easy access to control valvesSTRUCTURE•Modular concept•Height of the units only 240mm for all the sizes•Cooling coil and fan module is made of:-galvanised sheet steel-internally insulated (with 3mm close-cell polyurethane)•Key-hole system for fast mounting•Rubber anti-vibration damper to isolate the unit from supporting structure •Straight duct connector is mounted to both suction and discharge side (width 30mm)• A template is available in the carton box for easy connection to the ceiling HEAT EXCHANGER•3, 4 or 6 stage row cooling coil•Standard left handed water connections + air-purge(water connections can easily be turned)•Drain pan can to collect the condensate from:-Heat exchanger-Regulating valvesFAN MOTOR ASSEMBLY•1, 2 or 3 centrifugal fans with forward profile blades, dynamically andstatically balanced•7-speed electrical motors (with thermal protection on windings)•All 7 speeds pre-wired in the factory in the terminal block of the switch box •To reduce the requested installation space is the terminal block located onthe same side as the water connectionsAIR FILTER•Located in the air inlet•Removable from the bottom•Made of acrylic fiber, filter class EU2STRUCTURE•Possibility of installation both in horizontal and vertical position•Reduced height 280mm up to model 10•The unit is made of:- galvanised sheet steel- insulated with noise-proof/anti-condensing material(self-extinguishing in Class 1, with a thickness of 10mm)•Key-hole system for fast mounting•Straight duct connector is mounted to discharge side(width 30mm)HEAT EXCHANGER• 1 or 2 stage row cooling coil•Standard left handed water connections + air-purge•System for collecting and discharging condensate setup either for ceiling or wall mounting.FAN MOTOR ASSEMBLY•Dual intake centrifugal fans made of aluminum, dynamically and statically balanced •3-speed electric motor, installed on vibration damping supports(with thermal protection on windings)AIR FILTER•Air-intake module + Filter is standard delivered with each unit•Removable filter from the bottom•Made of acrylic fiber, filter class EU2EPIMSA6EPIA6FWV/L/M FWB FWD01y02y y03y y04y y y05y06y yx /v07y 08yx /v x /v09x /v 10yx /v x /v12v 16v 18vy v /x vEasy to control !The new fan coil units can be operated by 3 different controllers:• electronic control built-in (ECFWEB6)• electronic control remote (ECFWER6)• electromechanical control built-in (ECFWMB6)The electronic control consists of:•Operating mode selector , to turn the fan coil on and off,to choose the type of operating mode (automatic or at fixed speed) and to control the electric heating.•Cooling / Heating selector•Operational LEDs that indicates the current operation mode•Thermostat to control the room temperature•Free contacts for external enabling signal that may switch on or off the unit.• Free contacts for centralized cool/heat changeover • Water temperature probe • Air temperature probeSeveral configurations are possible by changing dip switches.The electromechanical controller includes a fan speed selector (3 speeds + stop) and manual cool/heat changeover. In case of the on/off valves, control can also be done through this controller.Power interface / master slave interfaceAn additional interface is required for units with a current greater than 1,12A.Master slave interface (EPIMSA6: 4x3A)For remote control of up to 4 fan coil units, an optional master/slave interface can be installed. Up to 3 EPIMSA6can be connected in parallel (--> max. 12 fan coils).Power interface (EPIA6: 1x16A)This is absolutely required for connection of ECFWER6 to FWD12 to18. It can be used as an alternative for EPIMSA6for all other fan coils.Master slave interface is only needed in case of remote control of multiple fan coil unitsObigation to use master slave interface or power interface Obligation to use power interfaceControl featuresBasic control functionsOptionsCooling/heating changeover2-p i p e4-p i p eCOOLINGTotal capacity (H)kW Sensible capacity (H)kW Water flow l/h Pressure drop kPa HEATINGHeating capacity (H)kW Water flow l/h Pressure drop kPa Power input HW Coil water volume lAir flowH/M/L m 3/h Sound power level H/M/L dBA WeightFWV kg FWM kg FWL kg COOLINGTotal capacity (H)kW Sensible capacity (H)kW Water flow l/h Pressure drop kPa Cooling coil water volume l HEATINGHeating capacity (H)kW Water flow l/h Pressure drop kPa Heating coil water volume l Power input H W Air flowH/M/L m 3/h Sound power level H/M/L dBA WeightFWV kg FWM kg FWL kgWater connections inch Max. absorbed current WDimensions FWV/FWL mm FWM mmPower supplyV/~/HzFWV/FWL/FWM01-10C**010203040608101.542.09 2.93 4.33 4.77 6.718.711.20 1.51 2.113.15 3.654.91 6.382653595047458201,1541,498131311121412192.14 2.79 3.815.636.367.8311.12653595047458201,1541,498910991091336466287891822440.50.71 1.4 1.4 2.1 2.1319/233/178344/271/211442/341/241706/497/361785/605/4701,011/771/5701,393/1,022/64247/39/3452/44/3650/44/3855/48/4059/52/4459/52/4466/58/481920253031414114151923233232202127323344441.5 1.79 2.87 4.26 4.67 6.648.551.17 1.46 2.07 3.09 3.57 4.85 6.262583084947338031,1421,471131311121412190.50.71 1.4 1.4 2.1 2.12.23 2.07 2.91 4.51 4.677.919.301961822863964656948167851010890.20.20.30.40.40.60.63659628789182244307/225/174327/261/205431/332/238690/490/356763/593/460998/765/5651,362/1,007/63647/39/3454/48/4250/45/3855/48/4059/53/4659/52/4466/58/482021263233444415162025253434212228343546461/2"1/2"1/2"1/2"1/2"3/4"3/4"0.160.210.270.390.380.80 1.12564x774x226564x984x226564x1,194x226564x1,404x251535x584x224535x794x224535x1,004x224535x1,214x249230/1/5001020304060810FWV FWL FWM ESRH02A6ESRH03A6ESRH06A6ESRH10A6x x x EEH01A6EEH02A6EEH03A6EEH06A6EEH10A6x x x E2MV03A6E2MV06A6E2MV10A6x x x E4MV03A6E4MV06A6E4MV10A6x x x YFSTA6xx x EAIDF02A6EAIDF03A6EAIDF06A6EAIDF10A6--x ESFV06A6ESFV10A6x -x ESFVG02A6ESFVG03A6ESFVG06A6ESFVG10A6x --EFA02A6EFA03A6EFA06A6EFA10A6x -x ERPV02A6ERPV03A6ERPV06A6ERPV10A6x x -ECFWMB6x x -ECFWEB6x x -ECFWER6x x x EPIMSA6x x x EDPVA6x x x EDPHA6-xx2-p i p e ( **= T N o r T V )4-p i p e ( **= F N )** = T N (2-p i p e , w i t h o u t v a l v e s ), T V (2-p i p e , w i t h v a l v e s ), F N (4-p i p e , w i t h o u t v a l v e s )Additional single row heat exchanger*Electric heater**2-pipe ON-OFF 3-way motor driven valve with complete mounting kit*4-pipe ON-OFF 3-way motor driven valve with complete mounting kit*(**)Fan stop thermostat**(only for ECFWMB6)Air intake & discharge grille +front filter fixing kit for concealed models Supporting feet(= supporting brackets + covers)Supporting feet + grille Manual fresh air intake louver Rear panel for vertically installed units Controller - electromechanical built-in**Controller - electronic built-in + water probe**Controller - electronic remote + water probe Power interface for connection of up to 4 FCU to a single control panel Vertical drain pan Horizontal drain panOption description * C a n b e o r d e r e d f a c t o r y m o u n t e d ** f a c t o r y m o u n t e d o n r e q u e s tMeasuring conditions (at nominal air flow and ESP) COOLING • Air temperature entering the unit: 27°C/19°C • Water temperature entering the unit 7°C • Water temperature rise 5 KHEATING • Room air temperature 20°C • For 2 pipe units : Water inlet temperature 50°C - Water flow rate same as for the cooling test • For 4 pipe units : - Water inlet temperature 70°C - Water temperature decrease 10 KFWB02-10AT 10Additional heat exchanger 3-way valve std h/e 3-way valve add. h/e 2-way valve std h/e 2-way valve add. h/e Electric heater Fan stop thermostat Power interface (*)Master slave interface (*)Controller electronic - remoteOption description 020304050607080910EAH04A6EAH07A6EAH10A6factory mounted on requestE2MV307A6E2MV310A6factory mounted on requestE2MV207A6E2MV210A6factory mounted on requestYFSTA6-EPIA6EPIMSA6ECFWER60203040506070809104008001,2007165592.61 3.14 3.49 5.08 5.45 6.477.578.6710.341.88 2.16 2.34 3.6 3.87 4.4 5.23 5.96 6.94485395988739361,1111,2991,4881,77481411158142121265.47 6.01 6.4710.3111.3912.2815.0516.8518.784805275679049991,0771,3191,4791,647710812710161518232426313335434548239x1,039x609239x1,389x609239x1,739x6093.14 5.9912.82755261,1233587917239x788x243239x1,138x243239x1,497x3351061922940.510.94 1.28586069230V/1~/50HzFWB2-p i p e /4-p i p e Air flow ratem 3/h Available static pressure Pa COOLINGTotal capacity (H)kW Sensible capacity (H)kW Water flow l/h Pressure drop kPa HEATINGHeating capacity (H)kW Water flow l/h Pressure dropkPa Machine weight kg Dimensions (HxWxD)mm HEATINGHeating capacity (H)kW Water flow l/h Pressure dropkPa Weight kg Dimensions mm Power input (H)W Running curent (H)A Sound power level (H)dBAPower supply2-p i p eA d d . H e a t e x c h a n g e rMeasuring conditionsCOOLING 2-pipe: air: 27°CDB/19°CWB - entering water 7°C - leaving water 12°C HEATING 2-pipe: air: 20°CDB - entering water 70°C - leaving water 60°CSound power level according to ISO3741 - sound pressure calculated at 1.5m distance - Q=2(*) In combination with ECFWER6, EPIMSA6 or EPIA6 must be installed for FWB08-1011Notes:1. The valves for FWD12-16-18 do not contain piping nor drain pan.2. Requires electronic control.3. Neglecting the absolute requirement to install an additional interface (EPIA6 or EPIMSA6) to FWD06 -->18 may cause fire or other damage to the equipment.4. In combination with ECFWER6, EPIMSA6 or EPIA6 must be installed for FWD06-10.5. In combination with ECFWER6, EPIA6 must be installed for FWD12-18.Electric heater: small (2)Electric heater: big (2)2-pipe 3-way valve (1)4-pipe 3-way valve (1)Vertical drain pan Horizontal drain pan Fan stop thermostatFresh air intake louvers (motorised) Controller - electronic remote + water probe (3)Master / Slave Interface (4)Power interface (5)Option description 2- p i p e / 4-p i p eCOOLINGTotal capacity kW Sensible capacity kW Water flow (H)l/h Pressure drop (H)kPa HEATINGHeating capacity kW Water flow (H)l/h Pressure drop (H)kPa Available static pressure Pa Weight kg COOLINGTotal capacity kW Sensible capacity kW Water flow (H)l/h Pressure drop (H)kPa HEATINGHeating capacity kW Water flow (H)l/h Pressure drop (H)kPa Available static pressure Pa Weight kg Air flow rate m 3/h Power input W Water connections inch Max. absorbed current A Dimensions mm Sound power level OveralldBA Power supplyV/~/HzFWD04-18A*2-p i p e ( *= T )4-p i p e ( *= F )Measuring conditions (at nominal air flow and ESP) COOLING • Air temperature entering the unit: 27°C/19°C • Water temperature entering the unit 7°C • Water temperature rise 5 KHEATING • Room air temperature 20°C • For 2 pipe units : Water inlet temperature 50°C - Water flow rate same as for the cooling test • For 4 pipe units : - Water inlet temperature 70°C - Water temperature decrease 10 K040608101216183.90 6.207.808.8211.9016.418.33.08 4.65 6.527.369.3612.814.16741,0641,3391,5142,0562,8333,140172424162634454.057.719.4310.7914.4519.8121.926741,0641,3391,5142,0562,8333,140142020132128376658686497145134334147496577803.90 6.207.808.8211.9016.418.33.08 4.65 6.527.169.3612.814.16741,0641,3391,5142,0562,8333,140172424162634454.49 6.629.219.2115.8621.1521.153495818088081,3921,8561,85691513131216166353635992138128354350527183868001,2501,6001,6002,2003,0003,0001772743153255309911,0013/43/43/43/41110.95 1.58 1.971.97 3.21 5.375.37280x754x559280x964x559280x1,174x559352x1,174x718352x1,384x71866697272747878230/1/5004060810121618EDEH04A6EDEHS06A6EDEHS10A6EDEHS12A6EDEHS18A6EDEH04A6EDEHB06A6EDEHB10A6EDEHB12A6EDEHB18A6ED2MV04A6ED2MV10A6ED2MV12A6ED2MV18A6ED4MV04A6ED4MV10A6 2 x ED2MV12A62 x ED2MV18A6EDDPV10A6EDDPV18A6EDDPH10A6EDDPH18A6YFSTA6EDMFA04A6EDMFA06A6EDMFA10A6EDMFA12A6EDMFA18A6ECFWER6EPIMSA6----EPIA6FWDE P C E 04-25B / C D / 04/06 L a M o v i d a P r i n t e d o n n o n -c h l o r i n a t e d p a p e r / P r i n t e d i n B e l g i u mDaikin products are distributed by:Zandvoordestraat 300B-8400 Oostende, Belgium The present publication is drawn up by way of information only and does not constitute an offer binding upon Daikin Europe N.V .. Daikin Europe N.V . has compiled the content of this publication to the best of its knowledge. No express or implied warranty is given for the completeness, accuracy, reliability or fitness for particular purpose of its content and the products and services presented therein. Specifications are subject to change without prior notice. Daikin Europe N.V . explicitly rejects any liability for any direct or indirect damage, in the broadest sense, arising from or related to the use and/or interpretation of this publication. All content is copyrighted by Daikin Europe N.V .Daikin Europe N.V . is approved by LRQA for its Quality Management System in accordance with the ISO9001standard. ISO9001 pertains to quality assurance regarding design, development, manufacturing as well as to services related to the product.ISO14001 assures an effective environmental management system in order to help protect human health and the environment from the potential impact of our activities, products and services and to assist in maintaining and improving the quality of the environment.Daikin units comply with the European regulations that guarantee the safety of the product.Daikin Europe NV participates in the Eurovent Certification Programme for Air Conditioners (AC),Liquid Chilling Packages (LCP) and Fan Coil Units (FC); the certified data of certified models are listed in the Eurovent Directory.Daikin’s unique position as a manufacturer of air conditioning equipment, compressors and refrigerants has led to its close involvement in environmental issues. For several years Daikin has had the intention to become a leader in the provision of environmental friendly products. This challenge demands the eco design and development of a wide range of products and an energy management system; which involves energy conservation and reduction of waste.。

第8页光源系列 LAMP Series闪射系列 FLASHING SERIES外形设计美观、烟尘式散热排气孔Beautiful and decent appearance design, Smoke-Dust cooling exhaust hole产品特性 PRODUCTS FEATURES灯体采用6063航空铝材,冷锻式一体成型,外形新颖,美观大方;独有烟尘式散热设计,通过散热排气孔能更快的带走热量,散热效率高;电源采用美国BCD方案设计,高精度智能控制电路,具有过载欠压等保护,使用更安全;进口一体化透镜,透光率高达93%,表面鳞面设计,更好的防止眩光;新型EMC超导热大功率灯珠,具有高光效,高显指,采用陶瓷支架,散热效果更好,将低光衰。

The lamp body is made of 6063 aviation aluminum with novel and beautiful appearance. Product Category: Cold Forging, Integrated molding.Cooling Design: Unique Smoke-Dust Type, it can take away heat faster through the vent holes, so the cooling efficiency is very high.Power source: Using BCD solution design from US with precision smart control circuit, overload & under voltage protection, keeps it more secure.Lens: Integrated lens imported from abroad, light transmission rate is as high as 93%, and the surface design uses Scaly surface, so it can prevent glare much better;New EMC Lamp beads: superconducting heat and high power, high luminance, and high color render index.Ceramic bracket: provides better heat dissipation and low light decay.应用范围商业重点照明、酒店重点照明、装饰照明、专卖店、咖啡厅、KTV、超市、写字楼、书房、面包店、书店、家居等场所。

FEATURES• Diamondback 170º Optic Lens• I ntegrated aluminum heatsink• Waterproof IP68• Snap & Peel Qwik Release Tab• 4 different mod styles to perform in a wide variety of sign applications• More light diffusion with a wider batwing resulting in better coverageSPECIFICATIONSBeam Angle 170˚ Ultra-Wide Low Dome Batwing Optic with DiamondbackOptic Lens TechnologyCertifications UL & cUL Recognized (SAM Manual), CE, RoHsDimensions QM1: 0.69”W x 1.4”L x 0.25”HQM2: 0.69”W x 2.2”L x 0.25”HQM3: 0.69”W x 3.14”L x 0.25”HQM4: 1.7”W x 1.77”L x 0.25”HEfficacy See Product OptionsFastening Peel & Stick / Mechanical Screw HoleInput12VDCIntensity See Product OptionsMax Mods (Series)See Product OptionsOperating Temp-30º to +60ºCPackaging QM1: 60 ft. (150 mods) per bag or 600 ft. (1500 mods) per caseQM2: 44.7 ft. (76 mods) per bag or 536.52 ft. (912 mods) per caseQM3: 33.3 ft. (50 mods) per bag or 500 ft. (750 mods) per caseQM4: 25.3 ft. (38 mods) per bag or 608 ft. (912 mods) per casePower See Product OptionsPower Supply P-LED 12VDCProtection Grade IP68Run Footage See Product OptionsSpacing QM1: 2.5 mods/ft. (fully stretched)QM2: 1.7 mods/ft. (fully stretched)QM3: 1.5 mods/ft. (fully stretched)QM4: 1.5 mods/ft. (fully stretched)Warranty 5 Year Product / 5 Year Limited LaborPRODUCT OPTIONSColor Wavelength Efficacy Intensity Power Max Mods (Series)Run Footage Part Number*True White7100K110 LM/W44 LM/mod (110 LM/ft)0.4W/MOD (1.0W/FT)30 ft. (75 mods)60 ft. (150 mods)PL-QM1-TW110-P True White7100K111 LM/W89 LM/mod (150 LM/ft)0.8W/MOD (1.36W/FT)22.3 ft. (38 mods)44.7 ft. (76 mods)PL-QM2-TW150-P True White7100K111 LM/W133.5 LM/mod (200 LM/ft) 1.2W/MOD (1.8W/FT)16.6 ft. (25 mods)33.3 ft. (50 mods)PL-QM3-TW200-P True White7100K109 LM/W174 LM/mod (260 LM/ft) 1.6W/MOD (2.4W/FT)12.6 ft. (19 mods)25.3 ft.(38 mods)PL-QM4-TW260-P•325-227-4577•***************REV20170405WIRING DETAILSWhite/Red PostitiveWhite/Black Negative1234RECOMMENDED COVERAGE CHARTDepth Max. Stroke ProductSingle Row2”6”QM13”8”QM1/QM2/QM3/QM44”12”QM1/QM2/QM3/QM45”16”QM2/QM3/QM46”18”QM2/QM3/QM47”22”QM38”24”QM4Note: Product and depth may vary depending on face material and desiredbrightness. For 2” depths increase module density to 3 mods per foot.Wwarranty5P 5L* “P” denotes lens factory installed.Subject to changes.。

ENMade in Germany1 Included in delivery 32 Adapters 43 Product Description4 Technical specifications 4 Contact information5 Warranty54 Buttons and Displays 6 4.1 Buttons 6 4.2 Boost-Buttons LEDs 7 4.3 LCD 7 Network behavior 8 4.4 Inclusion 9 4.5 Mounting the Spirit Z-Wave Plus 10 4.6 Plus Mechanical Installation 11 4.7 Exclusion 12 4.8 Unmounting the Spirit Z-Wave 13 4.9 Plus Factory Rese 13 5 Operating the device 14 5.1 Setpoint adjustment 14 5.2Child protection14Content5.3 Altering the operating states 14 5.4 Window open detection 15 5.5 Display NodeID 156 Z-Wave 166.1 Assoziation 17 6.2 Basic17 6.3 Configuration 18 6.4 Multilevel Sensor 18 6.5 Multilevel Switch 19 6.6 Notification 19 6.7 Protection 19 6.8 Thermostat Mode 19 6.9 Thermostat Setpoint 207 T roubleshooting201. Spirit Z-Wave Plus energy-saving thermostat2. Screw3. Adapters for Danfoss valves4. 2x AA batteries1. Included in deliveryRASpirit Z-Wave Plusenergy-saving thermostat2x AA batteries Screw for adapter* When using the RAV adapter, you need the RAV Pinfor the extension of the valve stem.WARNING - Remove the connecting pieces of the plastic adapter completely before you use one of the supplied adapters!Additional adapters are available for different valve manufacturers. Please consult the EUROtronic Website for all information about the different adapters at: /Service/FAQFor the following valves no adapter is required:Heimeier, Junkers Landy + Gyr, MNG, Honeywell, Braukmann, as these have a thread of M30 x 1.5mm. The adapters for Danfoss RAV (pin must be plugged on the valve tappet) Danfoss RA and Danfoss RAVL are included.For the following valves an adapter is required:Herz M28 x 1,5 mm, Comap M28 x 1,5 mm, Vaillant 30,5 mm, Oventrop M30 x 1,0 mm, Meges M38 x 1,5 mm, Ondal M38 x 1,5 mm, Giacomini 22,6 mm, Rossweiner M33 x 2,0 mm, Markaryd M28 x 1,0 mm,, Ista M32 x 1,0 mm, Vama M28 x 1,0 mm, Pettinaroli M28 x 1,5 mm, T+A M28 x 1,5 mm, Gampper 1/2/6.If you are not sure which valve you are using, please visit: /Produkte/Adapter for fur-ther Information. Here you will find a list of various valves and adapters.2. AdaptersSpirit Z-Wave Plus is a Z-Wave radio standard compatible energy-saving radiator thermostat. FLiRS (Frequently Listening Receiver Slave):Spirit Z-Wave uses FLiRS to provide short latency and short responding times.3. Product DescriptionIf you wish to receive further technical Support or information about other EUROtronic products, please contact us via E-Mail or telephone.Customer Service:Eurotronic Technology GmbH Südweg 136396 Steinau-Ulmbach GermanyContact informationTelefon: 0 66 67 / 9 18 47-0Servicehotline: 0 66 67 / 9 18 47-17 eMail:*******************Internet: WarrantyThe 24-months warranty period begins at the day of purchase. Please keep the receipt as evidence of pur-chase. During the warranty period, defective radiator thermostats may be sent to your dealer or the address below. Please ensure sufficient postage is paid. A new or repaired device will then be sent to you free of charge.Please note that EUROtronic only grants warranty on the function of the device. EUROtronic will not grant war-ranty for the interaction between the thermostat and the bottom part of the valve. The technical data is only valid for the use of the following valves: Heimeier, Junkers Landys + Gyr, MNG, Honeywell, Braukmann (mea-sure of thread M30 x 1,5), Oventrop (M30 x 1,5) Danfoss RA, RAV and RAVL. Please refer to the combinations of the devices on our website (https:///produkte/adapter-information.html) EUROtronic does not issue a guarantee when using the thermostat with valves which are not mentioned above.Declaration of Conformity:Eurotronic Technology GmbH hereby declares that this device is compliant with the essential require-ments and other relevant provisions. The declaration of conformity is provided at . Advice on environmental protection:From the date of implementation of European guidelines 2002/96/EC and 2006/66/EC, into national law, the following applies: Electric and electronic devices and batteries may not be disposed of in household waste. The consumer is obliged to return electric and electronic devices and batteries to the public col-lection points established for them or to the point of sale. The particulars of this are regulated by the applicable state laws. The symbol on the product, operation instructions or packaging points to these provisions. You make an important contribution to the protection of the environment by reusing or recycling old equipment/bat-teries or making use of them in other ways.WarningDo not use rechargeable batteries!Never recharge batteries, do not short circuit them, do not take them apart - Risk of explosion! Remove dead batteries from the device immediately. Do not use old and new batteries together. Clean battery and device contacts before inserting if necessary.Keep batteries away from children. Avoid contact with skin, eyes and mucous membranes. In case ofcontact with battery acid, rinse the affected areas immediately with plenty of water, and seek medical atten-tion immediately. Do not expose batteries to direct sunlight.Safety Instructions: Spirit Z-Wave Plus is designed for use in buildings. Operate Spirit Z-Wave Plus only as described in the user manual. Spirit Z-Wave Plus should only be put to use in a dry and dust-free place, away from direct sunlight. Do not keep using the device when there is obvious damage. Spirit Z-Wave Plus may not be rebuilt, modified or opened.4.1 Buttons4. Buttons and Display&Minus PlusBoostTechnical specificationsDevice short description Spirit Z-Wave Plus EAN4260012711301Article Number 701003Supply Voltage 2 x 1,5V LR6/Mignon/AA Radio Frequency 868,42 MHz ConnectionM30 x 1,5mmMethod of operation Type 1Dimensions (W x H x D): 56 x 68 x 89 mm Weight176g (incl. batteries)Degree of protection IP20Degree of pollution24.3 LCDColorState MeaningBlinkingOver the Air update of the actuator software in progress. Temperature regulation is not possible during this process. Lights constantly A task has failed.Boost – green Boost – redWrench:Lights up if mechanical tasks are ongoing.Antenna:Displays the Spirit Z-Wave Plus network state. Segment visible: rf-link established Segment turned off: rf-link lostID: Lights up if the Display shows the Z-Wave NodeID.Battery: Lights up if less than 15% battery is remaining Lock: Lights up if child protection is set.Celsius: Displayed if the LCD shows a setpoint temperaturePercent: Displayed instead of °C Icon if the Comet Z Plus is set to direct. control mode.On factory default the device does not belong to any Z-Wave network Spirit Z-Wave Plus needs to be added to an existing wireless network to communicate with the devices of this network. This process is called Inclusion.Spirit Z-Wave Plus can also be removed from a network. This process is called Exclusion. Both processes are initiated by the primary controller of the Z-Wave network. This control-ler is turned into exclusion respective inclusion mode. Please consult the manual of your Z-Wave Controller how to activate Inclusion or Exclusion mode.If Spirit Z-Wave Plus has been added to anetwork, it has to be removed prior to be added to another wireless network.Network behaviorInteroperabilityThis device and every other certified Z-Wave device can be used together with any other certified Z-Wave device regardless of brand and origin as long as both are suited for the same frequency range.SecuritySpirit Z-Wave Plus supports secure communi-cation. Spirit Z-Wave Plus will communicate with other devices secure as long as this device provides the same or a higher level of security. Otherwise Spirit Z-Wave Plus will automatically turn into a lower level of security.Inserting batteriesRemove the battery cover by simply pulling it off. Now insert the batteries. Pay attention to the correctpolarity! At a later battery change, the configuration of your Spirit Z-Wave Plus is maintained.4.4 InclusionStart Inclusion mode of your primary Z-Wave Controller. Press the Boost-Button.Spirit Z-Wave Plus will show the assigned NodeID.After adding the Spirit Z-Wave Plus to a network it is ready to be installed on the radiator. The LCD shows INS. Do not press the boost button yet.4.5 Mounting the Spirit Z-Wave Plus4.6 Mechanical InstallationPress the boost button to start mechanical installation.4.7 ExclusionStart Exclusion mode of your primary Z-Wave Controller.Now press and hold the boost button of the Spirit Z-Wave Plus for at least 5 seconds.Remove the Spirit Z-Wave Plus from the Z-Wave network before unmounting it. Follow the process described in Exclusion and wait until the LCD shows INC. You can now uninstall Spirit Z-Wave Plus from the radiator.Remove batteries.Press and hold boost button.While still holding boost button insert batteries. The LCD shows RES. Release boost button. To perform the factory reset press boost button.2.1.Please use this procedure only when the network primary controller is missing or otherwise inoperable.DEFRES Press Boost button to perform reset.Defaults restoredNode XXX removed4.8 Unmounting the Spirit Z-Wave Plus4.9 Factory Reset5 Operating the deviceThe LCD shows the configured set point or the valve opening percentage if the device is in manufacturer specific mode.5.1 Setpoint adjustmentThe setpoint is adjusted via plus and minus button.Altering the setpoint locally will set the Spirit Z-Wave Plus in heating mode.The energy saving setpoint can only be adjusted via Z-Wave.The configurable setpoint range is 8°C to 28°C.If the setpoint is increased/decreased above/below the set point limits theSpirit Z-Wave Plus will change into boost / off –mode.5.2 Child protectionPress and hold plus and minus button simultaneously for 3 secondsto enable/disable the child protection.If the Spirit Z-Wave Plus is set into the highest protection level it is nolonger possible to operate the device locally.5.3 Altering the operating statesOff-ModePress minus button until OFF is displayed.Boost-ModePush the boost button.Alternatively press the plus button until ON is displayed.Heating-ModeIf the operating state is not heating mode, pressing the plus orminus button will bring the device in heating mode.5.4 Window open detectionIf the roomtemperature drops the window open detection will trigger.Spirit Z-Wave Plus will change temporarily in off mode for 15 minutes.Window open detection will end automatically after 15 minutes and the previously active operating mode will be restored.Window open detection can also be canceled by a button press.The window open detection is disabled during manufacturer specific mode.The sensitivity oft he window open detection can be configured5.5 Display NodeIDPress and hold the boost button for 3 seconds to display the NodeID.6 Z-WaveCommand Class Description Version Control (C)Security *Support (S) Association Allows to associate with other Z-Wave devices.2S U, S0, S2 Allows to group associations. 1S U, S0, S2 Association GroupInformationBasic Provides access to basic functionality.1S U, S0, S2 Battery Returns the current battery level of the device.1S U, S0, S2 Configuration Allows to configure the device settings.1S U, S0, S2 Device Reset Locally Informs the Z-Wave Controller that the device was factory reset. 1S U, S0, S2 Firmware UpdateAllows Over the Air Update of the device.3S U, S0, S2 Meta DataManufacturer Specific Provides information about Manufacturer and Product.1S U, S0, S2 Multilevel Sensor Provides the measured room temperature.5S U, S0, S2 Multilevel Switch Provides or sets the valve opening degree of the valve Controlling1S U, S0, S2 the valve opening degree requires manufacturer specific mode.Notification Informs the controller about critical system events/errors.8S U, S0, S2 Power Level Used to alter the rf-power(required by Z-Wave). 1S U, S0, S2 Protection Allows to lock the device(child protection).1S U, S0, S2 Security Allows encrypted Z-Wave Communication.2S U Thermostat Mode Configures the operation mode. 3S U, S0, S2 Thermostat Setpoint Allows to configure the desired room temperature. 3S U, S0, S2 Transport Service Handles the transmission of large telegrams.2S U Version Returns information about the Firmware.2S U, S0, S2 Z-Wave Plus Info Identifies the device as a Z-Wave Plus Device.1S U*Availability of the Command Class after adding the Spirit Z-Wave Plus to your Z-Wave network.U UnsecureS0 Z-Wave Security standard S0S2 Z-Wave Security standard S26.2 BasicSpirit Z-Wave Plus can only be associated with the Z-Wave controller.Control basic functions of the Spirit Z-Wave Plus via basic command class.Group No Description CommandsMax supported Nodes1LifelineBATTERY_REPORT,DEVICE_RESET_LOCALLY_NOTIFICATION,THERMOSTAT_MODE_REPORT,THERMOSTAT_SETPOINT_REPORT,NOTIFICATION_REPORT,PROTECTION_REPORT,SENSOR_MULTILEVEL_REPORT,SWITCH_MULTILEVEL_REPORT1Value Description Function0x00Energy Save Heating Switches into energy save heating mode. The room temperature will be lowered to the configured setpoint in order to save. energy. 0x0F OFF No Heating. Only Frost-protection.0xF0Full Power HeatingSwitches into Boost mode(Quick heat).0xFE Manufacturer Specific Switches into direct Valve control mode. 0xFFHeatingSwitches into comfort heating mode.The room temperature will be kept at the configured comfortable level.6.4 Multilevel SensorSpirit Z-Wave Plus can be configured during runtime.Spirit Z-Wave Plus measured the room temperature and automatically reports sensor readings to associated devices. Per default the reporting threshold is ±0.5°C. This parameter can be altered via configuration command class.Parameter number Size in Byte Name Description11LCD Invert0x00 LCD-content normal0x01 LCD-content inverted (UK Edition)default: 0x0021LCD Timeout0x00 No Timeout LCD always on0x05-0x1E LCD will turn off after 5 to 30 seconds. default: 0x0031Backlight0x00 Backlight disabled 0x01 Backlight enabled default: 0x0141Battery report0x00 Battery status is only reported as a system notification (Notification CC) 0x01 Send battery status unsolicited once a day. default: 0x0151Measured Temperature report 0x00 Unsolicited Temperature reporting disabled.0x01 – 0x32 report if temperature changed by delta = 0,1°C … 5,0 °Cdefault 0x05 (report on delta T = 0,5°C)61Valve opening percentage report 0x00 Unsolicited valve opening percentage reporting disabled. 0x01-0x64 report if valve opening changed by delta = 1% … 100% default 0x0071Window open detection0x00 Disabled0x01 Sensitivity low 0x02 Sensitivity medium 0x03 Sensitivity high default: 0x02 medium81Measured Temperature offset 0xCE-0x32 Offsets the measured temperature by-5,0°C – (+)5,0°C 0x80 External temperature sensor will be used for regulation.default: 0x00 0,0°C OffsetThe measured room temperature can be adjusted with an offset. Spirit Z-Wave Plus can receive temperature readings from other Z-Wave devices (wall thermostat for example) The external tempera-ture can be used for temperature regulation. This feature has to be enabled via configuration parameter. The Spirit Z-Wave Plus can handle Multilevel Sensor Reports in the following format:Report outgoing:Sensor type: …Air Temperature“Scale: Celsius Precision:2Report incoming:Sensor type: …Air Temperature“Scale: Celsius and Fahrenheit Precision:0, 1 and 26.5 Multilevel Switch6.6 NotificationAllows to request the valve opening in percent. 0% represents a fully shut valve. 100 % a fully open valve. The valve opening can be reported on change. If the configuration parameter is set. Spirit Z-Wave Plus will send notifications on certain events.Notification type ReasonDescriptionPowerManagement Replace battery soonNotification is sent if less than 25% battery remainingPowerManagement Replace battery now Notification is sent if less than 15% battery remainingSystemSystem Hardware failure with manufacturer proprietary failure code Provides manufacturer specific error codes for mechanical problems 0x01 Motor movement not possible 0x02 Not mounted on a valve0x03 Valve closing point could not be detected 0x04 Piston positioning failed6.7 ProtectionSpirit Z-Wave Plus can be locked remotely.Protection level Description0x00Unprotected regular operation possible0x01Restricted: device can be unlocked using a button pattern.0x02No local operation possible.6.8Thermostat ModeSpirit Z-Wave Plus offers the following modes.Mode Name Description0x00Off No heating. Only frost protection.0x01Heat Switches into comfort heating mode. The room temperature will be kept at the configured comfortable level.0x0B Energy Heat Switches into energy save heating mode. The room temperature will be lowe-red to the configured setpoint in order to save energy.0x0FFull PowerSwitches into Boost mode (Quick heat). Spirit Z-Wave Plus heats the room up as fast as possible. The mode is left automatically after 5 minutes or earlier if requested by the user(via Z-Wave or locally on the device).0x1F Manufacturer SpecificSwitches into direct valve control mode. The valve opening percentage can be controlled using the Switch multilevel command class.6.9 Thermostat SetpointThe following setpoints of the Spirit Z-Wave Plus can be altered.Modus Name Precision Scale Temp. Range 0x01Heat0,1 and 2Celsius and Fahrenheit8°C-28°C0x0B Energy Heat0,1 and 2Celsius and Fahrenheit8°C-28°C 7 T roubleshootingProblem Reason SolutionBatterie Icon Batteries do not haveenough power.Replace batteries.Heating element does not warm up.Is the boiler water temperature O.K.?Valve does not open, is it calcifiedafter the summer pause/heatingpause.Adjust the temperature of the boiler water.Remove the Comet Blue, move the valve back and forthper hand or with a tool.Heating element does not cool down.Valve does not close completely.It may be that the closing pointof your valve seat has shifted.Unmount Spirit Z-Wave Plus. Move the valve stem severaltimes by hand, it may be that adaptation is impossiblebecause your valve is calcified or the seat no longerperforms its function.Pressure piece falls out (This can also cause an E1-error)Due to an endless thread thepressure piece, which is situatedat the bottom, can fall out if thedevice has not been affixed on thevalve.Remove batteries. Put in the pressure piece.Insert the batteries. The endless thread is rotatingnow and fixes the pressure piece again.ER1-3 and ERR The error code can be cleared bypressing the boost button.Err Inclusion failed Z-Wave Controller out of range.ER1Valve positioning not possible Check if the valve is jammed.ER2Valve not detected Check if the Spirit Z-Wave Plus is correctly mounted. ER3Valves closing point not detected Check if the Spirit Z-Wave Plus is correctly mounted.。

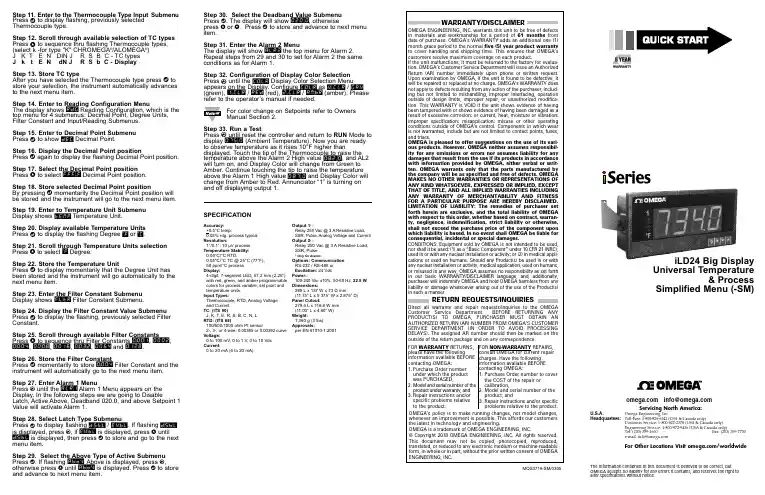

Step 11. Enter to the Thermocouple Type Input Submenu Press d to display flashing, previously selected Thermocouple type.Step 12. Scroll through available selection of TC types Press b to sequence thru flashing Thermocouple types,(select k -for type "K" CHROMEGA ®/ALOMEGA ®)J K T E N DIN J R S B C - TC types J k t E N dN J R S b C - DisplayStep 13. Store TC typeAfter you have selected the Thermocouple type press d to store your selection, the instrument automatically advances to the next menu item.Step 14. Enter to Reading Configuration MenuThe display shows RDG Reading Configuration, which is the top menu for 4 submenus: Decimal Point, Degree Units,Filter Constant and Input/Reading Submenus.Step 15. Enter to Decimal Point Submenu Press d to show DEC Decimal Point.Step 16. Display the Decimal Point positionPress d again to display the flashing Decimal Point position.Step 17. Select the Decimal Point position Press b to select FFF.F Decimal Point position.Step 18. Store selected Decimal Point positionBy pressing d momentarily the Decimal Point position will be stored and the instrument will go to the next menu item.Step 19. Enter to Temperature Unit Submenu Display shows TEMP Temperature Unit.Step 20. Display available Temperature Units Press d to display the flashing Degree °F or °C .Step 21. Scroll through Temperature Units selection Press b to select °F Degree.Step 22. Store the Temperature UnitPress d to display momentarily that the Degree Unit has been stored and the instrument will go automatically to the next menu item.Step 23. Enter the Filter Constant Submenu Display shows FLTR Filter Constant Submenu.Step 24. Display the Filter Constant Value Submenu Press d to display the flashing, previously selected Filter Constant.Step 25. Scroll through available Filter Constants Press b to sequence thru Filter Constants 0001, 0002,0004, 0008, 0016, 0032, 0064and 0128.Step 26. Store the Filter ConstantPress d momentarily to store 0004Filter Constant and the instrument will automatically go to the next menu item.Step 27. Enter Alarm 1 MenuPress a until the ALR1Alarm 1 Menu appears on the Display. In the following steps we are going to DisableLatch, Active Above, Deadband 020.0, and above Setpoint 1Value will activate Alarm 1.Step 28. Select Latch Type SubmenuPress d to display flashing DSBL / ENBL .If flashing DSBL is displayed, press a , if ENBL is displayed, press buntil DSBL is displayed, then press d to store and go to the next menu item.Step 29. Select the Above Type of Active Submenu Press d . If flashing ABoV Above is displayed, press a ,otherwise press b until ABoV is displayed. Press d to store and advance to next menu item.MQS3716-SM/0305iLD24 Big Display Universal Temperature&ProcessSimplified Menu (-SM)WARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 61 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal five (5) year product warranty to cover handling and shipping time. T his ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evalua-tion. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, includ-ing but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modifica-tion. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its vari-ous products. However, OMEGA neither assumes responsibil-ity for any omissions or errors nor assumes liability for any damages that result from the use if its products in accordance with information provided by OMEGA, either verbal or writ-ten. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY W ARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warran-ty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical appli-cations or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANT Y/DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.RETURN REQUESTS/INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RE URNING ANY PRODUC (S) O OMEGA, PURCHASER MUS OB AIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPART MENT (IN ORDER T O AVOID PROCESSING DELAYS). T he assigned AR number should then be marked on the outside of the return package and on any correspondence.FOR WARRANTY RETURNS, please have the followinginformation available BEFORE contacting OMEGA:1. Purchase Order number under which the product was PURCHASED,2.3. Model and serial number of the product under warranty, and Repair instructions and/or specific problems relative to the product.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:1. P urchase Order number to cover the COST of the repair or calibration,2.3.Model and serial number of the product, and R epair instructions and/or specific problems relative to the product.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a trademark of OMEGA ENGINEERING, INC.© Copyright 2018 OMEGA ENGINEERING, INC. All rights reserved. T his document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.***********************Servicing North America:Omega Engineering, Inc.Toll-Free: 1-800-826-6342 (USA & Canada only)Customer Service: 1-800-622-2378 (USA & Canada only) Engineering Service: 1-800-872-9436 (USA & Canada only) Tel: (203) 359-1660 Fax: (203) 359-7700 e-mail:**************For Other Locations Visit /worldwidehis Quick Start Reference provides information on setting up your instrument for basic operation. The latest complete Communication and Operational Manual as well as free Software and ActiveX Controls are available at or on the CD-ROM enclosed with your shipment .SAFETY CONSIDERATIONThe instrument is a panel mount device protected in accordance with EN 61010-1:2001, electrical safetyrequirements for electrical equipment for measurement, control and laboratory.Remember that the unit has no power-on switch. Building installation should include a switch or circuit-breaker that must be compliant to IEC 947-1 and 947-3.SAFETY:•Do not exceed voltage rating on the label located on the back of the instrument housing.•Always disconnect power before changing signal and power connections.•Do not use this instrument on a work bench without its case for safety reasons.•Do not operate this instrument in flammable or explosive atmospheres.EMC:•Whenever EMC is an issue, always use shielded cables. •Never run signal and power wires in the same conduit.•Use signal wire connections with twisted-pair cables.•Install Ferrite Bead(s) on signal wire close to the instrument if EMC problems persist.。

恒温加热台使用方法(一)恒温加热台使用方法详解什么是恒温加热台?恒温加热台是一种专门用于实验室或工业生产中的设备,能够提供恒定的温度环境来加热样品或反应容器。

它具有温度稳定、控制精度高等特点,广泛应用于化学、生物、医药等领域。

恒温加热台的使用方法步骤1:准备工作1.确保恒温加热台的电源线已经连接到稳定可靠的电源插座,电源开关处于关闭状态。

2.检查恒温加热台的加热盘和控制面板是否清洁,并做好相应的清洁工作。

步骤2:设置温度1.打开恒温加热台的电源开关,待显示屏上出现相关信息后,进入温度设置界面。

2.通过控制面板上的温度调节按钮,调整加热台的温度设定值。

通常可通过“上”和“下”按钮进行微调。

3.确定设定值后,按下确认键,开始加热。

步骤3:放置样品1.将需要加热的样品或反应容器放置在恒温加热台的加热盘上。

确保样品平稳并与加热盘接触良好。

2.注意避免样品或容器与恒温加热台的控制面板、电源线等接触,以防影响加热效果或造成安全隐患。

步骤4:加热过程1.恒温加热台开始加热后,会以设定温度作为目标,尽可能保持加热盘上的温度稳定。

2.在加热过程中,可以通过恒温加热台的显示屏上的温度显示,实时监测加热盘上的温度变化。

步骤5:加热结果1.当样品达到所需的温度后,可根据实验需求进行相应的操作。

2.加热结束后,关闭恒温加热台的电源开关,待设备冷却后再进行清洁和存放。

常见问题及解决方法问题1:恒温加热台无法正常加热解决方法:检查电源线是否连接良好,确保电源供应稳定,若问题仍未解决,建议联系售后服务。

问题2:加热盘温度不稳定解决方法:检查加热盘是否有杂物或污垢影响散热,清洁加热盘后再试,若问题仍未解决,建议联系售后服务。

问题3:温度显示与实际温度不一致解决方法:进行温度校准,按照设备说明书中的方法进行校准,若问题仍未解决,建议联系售后服务。

小结恒温加热台是一种功能强大的加热设备,在实验和生产中起到重要作用。

正确使用恒温加热台并掌握常见问题的解决方法,能够提高工作效率和实验数据的可靠性。