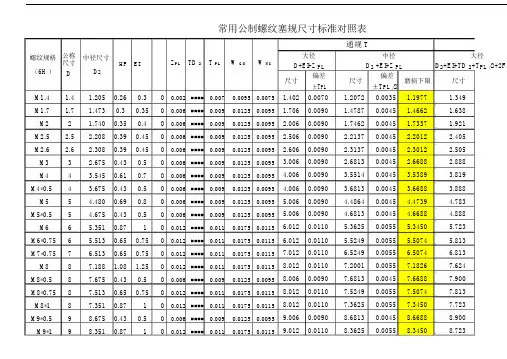

常用公制螺纹环规尺寸标准对照表

- 格式:xls

- 大小:97.00 KB

- 文档页数:25

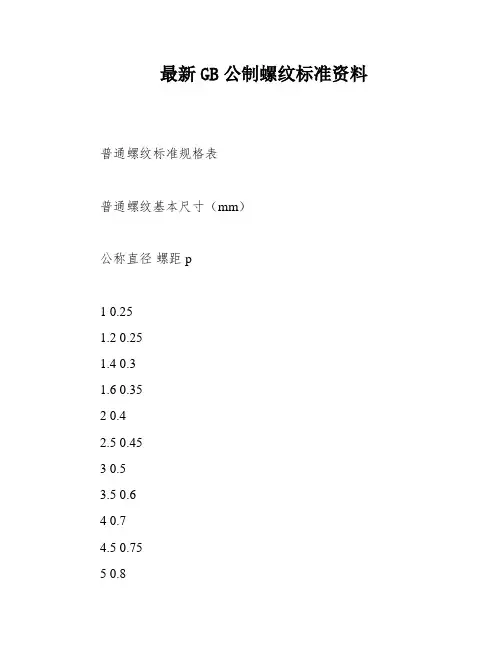

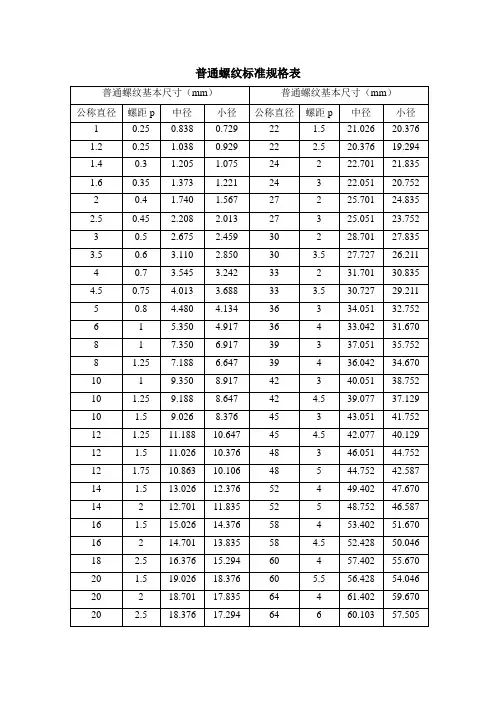

最新GB公制螺纹标准资料普通螺纹标准规格表普通螺纹基本尺寸(mm)公称直径螺距p1 0.251.2 0.251.4 0.31.6 0.352 0.42.5 0.453 0.53.5 0.64 0.74.5 0.755 0.86 18 18 1.25 10 1 10 1.25 10 1.5 12 1.25 12 1.5 12 1.75 14 1.5 14 2 16 1.5 16 2 18 2.5 20 1.5 20 2 20 2.5 22 1.5 22 2.5 24 224 3 27 2 27 3 30 2 30 3.5 33 2 33 3.5 36 3 36 4 39 3 39 4 42 3 42 4.5 45 3 45 4.5 48 3 48 5 52 4 52 5修正后的文章:这是普通螺纹标准规格表,列出了不同公称直径和螺距的基本尺寸(以毫米为单位)。

螺纹是一种常见的连接方式,常用于机械和结构中。

这个规格表可以帮助人们选择适合他们需要的螺纹。

修正后的表格清晰地显示了不同公称直径和螺距的基本尺寸。

这些尺寸可以帮助人们选择正确的螺纹,以确保它们能够正确地连接和承受所需的负载。

使用这个规格表时,人们需要了解他们需要连接的材料和所需的负载。

然后,他们可以查找适合他们需要的螺纹规格。

螺纹规格的选择非常重要,因为错误的规格可能会导致连接的松动或破坏,从而导致机械或结构的故障。

因此,使用这个规格表可以帮助人们选择正确的螺纹规格,以确保他们的连接是牢固和可靠的。

螺纹是指在圆柱或圆锥表面上,沿着螺旋线所形成的具有规定牙型的连续凸起。

根据不同的特征,螺纹可以分为圆柱螺纹和圆锥螺纹,同时也可以按照不同的标准进行分类。

圆柱螺纹分为普通螺纹、美标统一螺纹、非螺纹密封的管螺纹、梯形螺纹和其他螺纹。

普通螺纹是指代号为M,牙形角为60°,基本牙形为平顶的螺纹,其精度等级为内螺纹4~8级,外螺纹3~9级。

美标统一螺纹的代号为UNC、UNF、UNEF、UN、UNS,牙形角也为60°,基本牙形为平顶,精度等级为内螺纹1B~3B,外螺纹1A~3A。

普通螺纹标准规格表螺纹基本知识一、螺纹的名词术语螺纹:在圆柱或圆锥表面上,沿着螺旋线所形成的具有规定牙型的连续凸起。

圆柱螺纹/圆锥螺纹;外螺纹/内螺纹;右旋螺纹/左旋螺纹。

右旋螺纹:顺时针旋转时选入的螺纹。

左旋螺纹:逆时针旋转时选入的螺纹。

完整螺纹:牙顶和牙底具有完整形状的螺纹。

不完整螺纹:牙底完整而牙顶不完整的螺纹。

螺尾:向光滑表面过渡的牙底不完整的螺纹。

有效螺纹:由完整螺纹和不完整螺纹组成的螺纹,不包括螺尾。

公称直径:代表螺纹尺寸的直径。

大径:外螺纹的顶径、内螺纹的底径。

小径:外螺纹的底径、内螺纹的顶径。

中径:一个假想圆柱或圆锥的直径,该圆柱或圆锥的母线通过牙型上沟槽和凸起宽度相等的地方。

单一中径:牙型上沟槽宽度等于1/2基本螺距的地方。

作用中径:在规定的旋合长度内,恰好包容实际螺纹的一个假想螺纹的中径,这个假想螺纹具有理想的螺距、螺纹半角、及牙型高度,并在牙顶和牙底留有间隙,不与实际螺纹大、小径发生干涉。

牙型角:在螺纹牙型上,两相邻牙侧间的夹角。

螺距:相邻两牙在中径线上对应两点间的轴向距离。

螺纹精度:由螺纹公差带和旋合长度共同组成的衡量螺纹质量的综合指标。

二、.螺纹概述一般将螺纹分为圆柱螺纹和圆锥螺纹。

(一)圆柱螺纹1. 普通螺纹(又称米制或公制螺纹)螺纹代号M,牙形角60°,基本牙形为平顶。

精度等级:内螺纹4~8级,外螺纹3~9级。

2. 美标统一螺纹(又称60°英制螺纹)螺纹代号UNC、UNF、UNEF、UN、UNS,牙形角60°,基本牙形为平顶。

精度等级:内螺纹1B~3B,外螺纹1A~3A。

3. 非螺纹密封的管螺纹(又称圆柱管螺纹)螺纹代号G,牙形角55°,基本牙形为圆顶圆底。

精度等级:内螺纹标准级和D级,外螺纹A、B级。

4. 梯形螺纹螺纹代号Tr,牙形角30°(美标为29°),基本牙形为平顶平底。

精度等级:7~9级,(美标为2G~6G)。

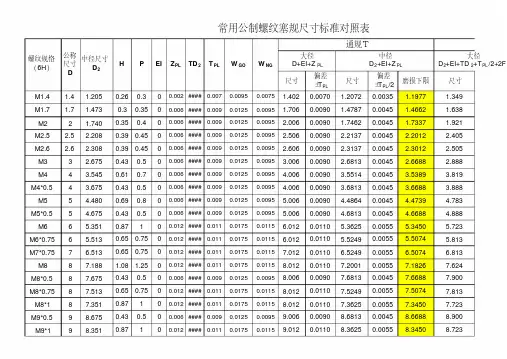

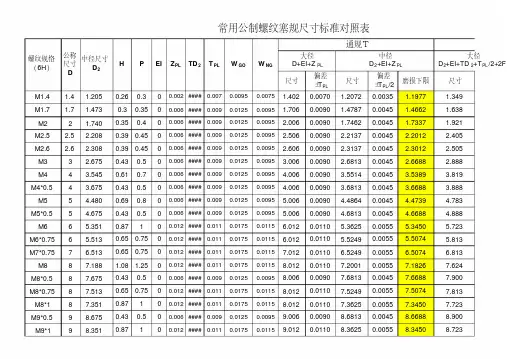

尺寸偏差±T PL 尺寸偏差±T PL /2磨损下限尺寸M1.4 1.4 1.2050.260.300.002####0.0070.00950.0075 1.4020.0070 1.20720.0035 1.1977 1.349M1.7 1.7 1.4730.30.3500.006####0.0090.01250.0095 1.7060.0090 1.47870.0045 1.4662 1.638M22 1.7400.350.400.006####0.0090.01250.0095 2.0060.0090 1.74620.0045 1.7337 1.921M2.5 2.5 2.2080.390.4500.006####0.0090.01250.0095 2.5060.0090 2.21370.0045 2.2012 2.405M2.6 2.6 2.3080.390.4500.006####0.0090.01250.0095 2.6060.0090 2.31370.0045 2.3012 2.505M33 2.6750.430.500.006####0.0090.01250.0095 3.0060.0090 2.68130.0045 2.6688 2.888M44 3.5450.610.700.006####0.0090.01250.0095 4.0060.0090 3.55140.0045 3.5389 3.819M4*0.54 3.6750.430.500.006####0.0090.01250.0095 4.0060.0090 3.68130.0045 3.6688 3.888M55 4.4800.690.800.006####0.0090.01250.0095 5.0060.0090 4.48640.0045 4.4739 4.783M5*0.55 4.6750.430.500.006####0.0090.01250.0095 5.0060.0090 4.68130.0045 4.6688 4.888M66 5.3510.87100.012####0.0110.01750.0115 6.0120.0110 5.36250.0055 5.3450 5.723M6*0.756 5.5130.650.7500.012####0.0110.01750.0115 6.0120.0110 5.52490.0055 5.5074 5.813M7*0.757 6.5130.650.7500.012####0.0110.01750.01157.0120.0110 6.52490.0055 6.5074 6.813M887.188 1.08 1.2500.012####0.0110.01750.01158.0120.01107.20010.00557.18267.624M8*0.587.6750.430.500.006####0.0090.01250.00958.0060.00907.68130.00457.66887.900M8*0.7587.5130.650.7500.012####0.0110.01750.01158.0120.01107.52490.00557.50747.813M8*187.3510.87100.012####0.0110.01750.01158.0120.01107.36250.00557.34507.723M9*0.598.6750.430.500.006####0.0090.01250.00959.0060.00908.68130.00458.66888.900W GOW NGHPEIZ PLTD 2T PL通规T大径D+EI+Z PL 中径D 2+EI+Z PL大径D 2+EI+TD 2+T PL /2+2F 1螺纹规格(6H )公称尺寸D 中径尺寸D 2尺寸偏差±T PL尺寸偏差±T PL/2磨损下限尺寸W GO W NG H P EI Z PL TD2T PL通规T大径D+EI+Z PL中径D2+EI+Z PL大径D2+EI+TD2+T PL/2+2F1螺纹规格(6H)公称尺寸D中径尺寸D2M10109.026 1.3 1.500.012####0.0110.01750.011510.0120.01109.03780.00559.02039.536 M10*0.5109.6750.430.500.006####0.0090.01250.009510.0060.00909.68130.00459.66889.900 M10*0.75109.5130.650.7500.012####0.0110.01750.011510.0120.01109.52490.00559.50749.813 M10*1109.3510.87100.012####0.0110.01750.011510.0120.01109.36250.00559.34509.723 M10*1.25109.188 1.08 1.2500.012####0.0110.01750.011510.0120.01109.20010.00559.18269.624 M121210.863 1.52 1.7500.012####0.0110.01750.011512.0120.011010.87540.005510.857911.448 M12*0.51211.6750.430.500.006####0.0090.01250.009512.0060.009011.68130.004511.668811.906 M12*11211.3510.87100.012####0.0110.01750.011512.0120.011011.36250.005511.345011.733 M12*1.51211.026 1.3 1.500.012####0.0110.01750.011512.0120.011011.03780.005511.020311.546 M141412.701 1.73200.016####0.0140.01750.011514.0160.014012.71700.007012.699513.353 M14*11413.3510.87100.012####0.0110.01750.011514.0120.011013.36250.005513.345013.733 M14*1.251413.188 1.08 1.2500.012####0.0110.01750.011514.0120.011013.20010.005513.182613.644 M14*1.51413.026 1.3 1.500.012####0.0110.01750.011514.0120.011013.03780.005513.020313.546 M14*21412.701 1.73200.016####0.0140.0210.01514.0160.014012.71700.007012.696013.353 M15*0.51514.6750.430.500.006####0.0090.01250.009515.0060.009014.68130.004514.668814.906 M15*11514.3510.87100.012####0.0110.01750.011515.0120.011014.36250.005514.345014.733 M161614.701 1.73200.016####0.0140.0210.01516.0160.014014.71700.007014.696015.353 M16*0.51615.6750.430.500.006####0.0090.01250.009516.0060.009015.68130.004515.668815.906尺寸偏差±T PL尺寸偏差±T PL/2磨损下限尺寸W GO W NG H P EI Z PL TD2T PL通规T大径D+EI+Z PL中径D2+EI+Z PL大径D2+EI+TD2+T PL/2+2F1螺纹规格(6H)公称尺寸D中径尺寸D2M16*1.51615.026 1.3 1.500.012####0.0110.01750.011516.0120.011015.03780.005515.020315.546 M18*0.51817.6750.430.500.006####0.0090.01250.009518.0060.009017.68130.004517.668817.906 M18*11817.3510.87100.012####0.0110.01750.011518.0120.011017.36250.005517.345017.733 M18*21816.701 1.73200.016####0.0140.0210.01518.0160.014016.71700.007016.696017.353 M20*0.52019.6750.430.500.006####0.0090.01250.009520.0060.009019.68130.004519.668819.906 M20*12019.3510.87100.012####0.0110.01750.011520.0120.011019.36250.005519.345019.733 M20*1.52019.026 1.3 1.500.012####0.0110.01750.011520.0120.011019.03780.005519.020319.546 M22*0.52221.6750.430.500.006####0.0090.01250.009522.0060.009021.68130.004521.668821.906 M22*12221.3510.87100.012####0.0110.01750.011522.0120.011021.36250.005521.345021.733 M22*1.52221.026 1.3 1.500.012####0.0110.01750.011522.0120.011021.03780.005521.020321.546 M24*12423.3510.87100.012####0.0110.01750.011524.0120.011023.36250.005523.345023.743 M24*1.52423.026 1.3 1.500.012####0.0110.01750.011524.0120.011023.03780.005523.020323.556 M25*1.52524.026 1.3 1.500.012####0.0110.01750.011525.0120.011024.03780.005524.020324.556 M26*1.52625.026 1.3 1.500.012####0.0110.01750.011526.0120.011025.03780.005525.020325.556 M30*0.753029.5130.650.7500.012####0.0110.01750.011530.0120.011029.52490.005529.507429.831 M30*13029.3510.87100.012####0.0110.01750.011530.0120.011029.36250.005529.345029.743 M30*1.53029.026 1.3 1.500.012####0.0110.01750.011530.0120.011029.03780.005529.020329.556 M30*23028.701 1.73200.016####0.0140.0210.01530.0160.014028.71700.007028.696029.365尺寸偏差±T PL尺寸偏差±T PL/2磨损下限尺寸W GO W NG H P EI Z PL TD2T PL通规T大径D+EI+Z PL中径D2+EI+Z PL大径D2+EI+TD2+T PL/2+2F1螺纹规格(6H)公称尺寸D中径尺寸D2M33*1.53332.026 1.3 1.500.012####0.0110.01750.011533.0120.011032.03780.005532.020332.556 M35*1.53534.026 1.3 1.500.012####0.0110.01750.011535.0120.011034.03780.005534.020334.556 M36*1.53635.026 1.3 1.500.012####0.0110.01750.011536.0120.011035.03780.005535.020335.556 M42*24240.701 1.73200.016####0.0140.0210.01542.0160.014040.71700.007040.696041.365 M45*1.54544.026 1.3 1.500.012####0.0110.01750.011545.0120.011044.03780.005544.020344.556 M50*1.55049.026 1.3 1.500.016####0.0140.0210.01550.0160.014049.04180.007049.020849.570 M52*35250.052 2.6300.016####0.0140.0210.01552.0160.014050.06750.007050.046550.988 M58*1.55857.026 1.3 1.500.016####0.0140.0210.01558.0160.014057.04180.007057.020857.570 M64*16463.3510.87100.012####0.0110.01750.011564.0120.011063.36250.005563.345063.753偏差±T PL 尺寸偏差±T PL /2磨损下限0.0070 1.28370.0035 1.27620.0090 1.56220.0045 1.55270.0090 1.83470.0045 1.82520.0090 2.30720.0045 2.29770.0090 2.40720.0045 2.39770.0090 2.77980.0045 2.77030.0090 3.66790.0045 3.65840.0090 3.77980.0045 3.77030.0090 4.60990.0045 4.60040.0090 4.77980.0045 4.77030.0110 5.50600.0055 5.49450.0110 5.65040.0055 5.63890.0110 6.65040.0055 6.63890.01107.35360.00557.34210.00907.79180.00457.78230.01107.65040.00557.63890.01107.50600.00557.49450.00908.79180.00458.7823止规Z大径EI+TD 2+T PL /2+2F 1中径D 2+EI+TD 2+T PL /2偏差±T PL尺寸偏差±T PL/2磨损下限止规Z大径EI+TD2+T PL/2+2F1中径D2+EI+TD2+T PL/20.01109.21130.00559.1998 0.00909.79180.00459.7823 0.01109.65040.00559.6389 0.01109.50600.00559.4945 0.01109.35360.00559.3421 0.011011.06890.005511.0574 0.009011.79780.004511.7883 0.011011.51600.005511.5045 0.011011.22130.005511.2098 0.014012.92000.007012.9085 0.011013.51600.005513.5045 0.011013.37360.005513.3621 0.011013.22130.005513.2098 0.014012.92000.007012.9050 0.009014.79780.004514.7883 0.011014.51600.005514.5045 0.014014.92000.007014.9050 0.009015.79780.004515.7883偏差±T PL尺寸偏差±T PL/2磨损下限止规Z大径EI+TD2+T PL/2+2F1中径D2+EI+TD2+T PL/20.011015.22130.005515.2098 0.009017.79780.004517.7883 0.011017.51600.005517.5045 0.014016.92000.007016.9050 0.009019.79780.004519.7883 0.011019.51600.005519.5045 0.011019.22130.005519.2098 0.009021.79780.004521.7883 0.011021.51600.005521.5045 0.011021.22130.005521.2098 0.011023.52600.005523.5145 0.011023.23130.005523.2198 0.011024.23130.005524.2198 0.011025.23130.005525.2198 0.011029.66840.005529.6569 0.011029.52600.005529.5145 0.011029.23130.005529.2198 0.014028.93200.007028.9170偏差±T PL尺寸偏差±T PL/2磨损下限止规Z大径EI+TD2+T PL/2+2F1中径D2+EI+TD2+T PL/20.011032.23130.005532.2198 0.011034.23130.005534.2198 0.011035.23130.005535.2198 0.014040.93200.007040.9170 0.011044.23130.005544.2198 0.014049.24480.007049.2298 0.014050.33850.007050.3235 0.014057.24480.007057.2298 0.011063.53600.005563.5245。

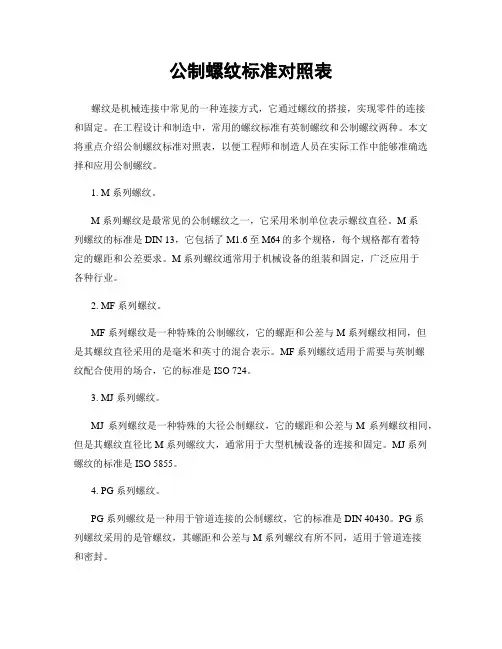

公制螺纹标准对照表螺纹是机械连接中常见的一种连接方式,它通过螺纹的搭接,实现零件的连接和固定。

在工程设计和制造中,常用的螺纹标准有英制螺纹和公制螺纹两种。

本文将重点介绍公制螺纹标准对照表,以便工程师和制造人员在实际工作中能够准确选择和应用公制螺纹。

1. M 系列螺纹。

M 系列螺纹是最常见的公制螺纹之一,它采用米制单位表示螺纹直径。

M 系列螺纹的标准是 DIN 13,它包括了M1.6至M64的多个规格,每个规格都有着特定的螺距和公差要求。

M 系列螺纹通常用于机械设备的组装和固定,广泛应用于各种行业。

2. MF 系列螺纹。

MF 系列螺纹是一种特殊的公制螺纹,它的螺距和公差与M 系列螺纹相同,但是其螺纹直径采用的是毫米和英寸的混合表示。

MF 系列螺纹适用于需要与英制螺纹配合使用的场合,它的标准是 ISO 724。

3. MJ 系列螺纹。

MJ 系列螺纹是一种特殊的大径公制螺纹,它的螺距和公差与M 系列螺纹相同,但是其螺纹直径比M 系列螺纹大,通常用于大型机械设备的连接和固定。

MJ 系列螺纹的标准是 ISO 5855。

4. PG 系列螺纹。

PG 系列螺纹是一种用于管道连接的公制螺纹,它的标准是 DIN 40430。

PG 系列螺纹采用的是管螺纹,其螺距和公差与M 系列螺纹有所不同,适用于管道连接和密封。

5. TR 系列螺纹。

TR 系列螺纹是一种特殊的公制螺纹,它的标准是 DIN 103。

TR 系列螺纹采用的是圆锥螺纹,其螺距和公差与M 系列螺纹有所不同,适用于需要良好密封性能的场合。

6. 其他特殊螺纹。

除了上述常见的公制螺纹系列外,还有一些特殊的公制螺纹,如圆锥管螺纹、汽车管螺纹等,它们都有着特定的标准和应用范围,需要根据实际情况进行选择和应用。

总结。

公制螺纹标准对照表是工程设计和制造中的重要参考资料,它能够帮助工程师和制造人员准确选择和应用合适的公制螺纹,确保零件的连接和固定符合要求。

在实际工作中,我们需要根据具体的需求和要求,选择合适的公制螺纹标准,合理设计和制造螺纹连接,确保其可靠性和稳定性。

常用公制螺纹环规尺寸对照表格.doc螺纹规格公称中径尺寸Z PL TD 2 T PLW GOW NG尺寸(6H ) HP EIDD 2M1.4 1.4 1.205 0.26 0.3 0 0.002 #### 0.007 0.0095 0.0075 M1.7 1.7 1.4730.30.35 0 0.006 #### 0.009 0.0125 0.0095 M2 2 1.740 0.35 0.4 0 0.006 #### 0.009 0.0125 0.0095 M2.5 2.5 2.208 0.39 0.45 0 0.006 #### 0.009 0.0125 0.0095 M2.6 2.6 2.308 0.39 0.45 0 0.006 #### 0.009 0.0125 0.0095 M3 3 2.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M4 4 3.545 0.61 0.7 0 0.006 #### 0.009 0.0125 0.0095 M4*0.5 4 3.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M5 5 4.480 0.69 0.8 0 0.006 #### 0.009 0.0125 0.0095 M5*0.5 5 4.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M6 6 5.351 0.87 1 0 0.012 #### 0.011 0.0175 0.0115 M6*0.75 6 5.513 0.65 0.75 0 0.012 #### 0.011 0.0175 0.0115 M7*0.75 7 6.513 0.65 0.75 0 0.012 #### 0.011 0.0175 0.0115 M8 8 7.188 1.08 1.25 0 0.012 #### 0.011 0.0175 0.0115 M8*0.5 8 7.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M8*0.75 8 7.513 0.65 0.75 0 0.012 #### 0.011 0.0175 0.0115 M8*1 8 7.351 0.87 1 0 0.012 #### 0.011 0.0175 0.0115 M9*0.5 9 8.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M9*198.351 0.8710 0.012 #### 0.011 0.0175 0.0115 通规T大径中径大径D+EI+Z PLD 2 +EI+Z PLD 2+EI+TD 2+T PL /2+2F尺寸偏差尺寸偏差磨损下限尺寸±T PL ±T PL /21.402 0.0070 1.2072 0.0035 1.1977 1.349 1.706 0.0090 1.4787 0.0045 1.4662 1.6382.006 0.0090 1.7462 0.0045 1.7337 1.921 2.506 0.0090 2.2137 0.0045 2.2012 2.405 2.606 0.0090 2.3137 0.0045 2.3012 2.5053.006 0.0090 2.6813 0.0045 2.6688 2.8884.006 0.0090 3.5514 0.0045 3.5389 3.819 4.006 0.0090 3.6813 0.0045 3.6688 3.8885.006 0.0090 4.4864 0.0045 4.4739 4.783 5.006 0.0090 4.6813 0.0045 4.6688 4.8886.012 0.0110 5.3625 0.0055 5.3450 5.723 6.012 0.0110 5.5249 0.0055 5.5074 5.8137.012 0.0110 6.5249 0.0055 6.5074 6.8138.012 0.0110 7.2001 0.0055 7.1826 7.624 8.006 0.0090 7.6813 0.0045 7.6688 7.900 8.012 0.0110 7.5249 0.0055 7.5074 7.8138.012 0.0110 7.3625 0.0055 7.3450 7.7239.006 0.0090 8.6813 0.0045 8.6688 8.900 9.012 0.01108.36250.00558.34508.723螺纹规格公称中径尺寸尺寸(6H )D2DM10109.026 M10*0.5109.675 M10*0.75109.513 M10*1109.351 M10*1.25 109.188 M121210.863 M12*0.51211.675 M12*11211.351 M12*1.51211.026M141412.701 M14*11413.351 M14*1.251413.188 M14*1.51413.026 M14*21412.701 M15*0.51514.675 M15*11514.351M161614.701 M16*0.51615.675 M16*11615.351H P EI Z PL TD 2T PL W GO W NG1.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.65 0.75 0 0.012 #### 0.011 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.08 1.25 0 0.012 #### 0.011 0.0175 0.01151.52 1.75 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.08 1.25 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.0115通规T大径中径大径D+EI+Z PL D2 +EI+Z PL D2+EI+TD 2+T PL /2+2F 尺寸偏差尺寸偏差磨损下限尺寸±T PL ±T PL /210.012 0.0110 9.0378 0.0055 9.0203 9.53610.006 0.0090 9.6813 0.0045 9.6688 9.90010.012 0.0110 9.5249 0.0055 9.5074 9.81310.012 0.0110 9.3625 0.0055 9.3450 9.72310.012 0.0110 9.2001 0.0055 9.1826 9.62412.012 0.0110 10.8754 0.0055 10.8579 11.448 12.006 0.0090 11.6813 0.0045 11.6688 11.906 12.012 0.0110 11.3625 0.0055 11.3450 11.733 12.012 0.0110 11.0378 0.0055 11.0203 11.546 14.016 0.0140 12.7170 0.0070 12.6995 13.353 14.012 0.0110 13.3625 0.0055 13.3450 13.733 14.012 0.0110 13.2001 0.0055 13.1826 13.644 14.012 0.0110 13.0378 0.0055 13.0203 13.54614.016 0.0140 12.7170 0.0070 12.6960 13.35315.006 0.0090 14.6813 0.0045 14.6688 14.90615.012 0.0110 14.3625 0.0055 14.3450 14.73316.016 0.0140 14.7170 0.0070 14.6960 15.35316.006 0.0090 15.6813 0.0045 15.6688 15.90616.012 0.0110 15.3625 0.0055 15.3450 15.733螺纹规格公称中径尺寸尺寸(6H )D2DM16*1.51615.026 M18*0.51817.675 M18*11817.351 M18*21816.701 M20*0.52019.675 M20*12019.351 M20*1.52019.026 M22*0.52221.675 M22*12221.351 M22*1.52221.026 M24*12423.351 M24*1.52423.026 M25*1.52524.026 M26*1.52625.026 M30*0.753029.513 M30*13029.351 M30*1.53029.026 M30*23028.701M333330.727H P EI Z PL TD 2T PL W GO W NG1.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.65 0.75 0 0.012 #### 0.011 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0153.03 3.5 0 0.016 #### 0.014 0.021 0.015通规T大径中径大径D+EI+Z PL D2 +EI+Z PL D2+EI+TD 2+T PL /2+2F 尺寸偏差尺寸偏差磨损下限尺寸±T PL ±T PL /216.012 0.0110 15.0378 0.0055 15.0203 15.546 18.006 0.0090 17.6813 0.0045 17.6688 17.906 18.012 0.0110 17.3625 0.0055 17.3450 17.733 18.016 0.0140 16.7170 0.0070 16.6960 17.353 20.006 0.0090 19.6813 0.0045 19.6688 19.906 20.012 0.0110 19.3625 0.0055 19.3450 19.733 20.012 0.0110 19.0378 0.0055 19.0203 19.546 22.006 0.0090 21.6813 0.0045 21.6688 21.906 22.012 0.0110 21.3625 0.0055 21.3450 21.733 22.012 0.0110 21.0378 0.0055 21.0203 21.546 24.012 0.0110 23.3625 0.0055 23.3450 23.74324.012 0.0110 23.0378 0.0055 23.0203 23.55625.012 0.0110 24.0378 0.0055 24.0203 24.55626.012 0.0110 25.0378 0.0055 25.0203 25.556 30.012 0.0110 29.5249 0.0055 29.5074 29.831 30.012 0.0110 29.3625 0.0055 29.3450 29.743 30.012 0.0110 29.0378 0.0055 29.0203 29.556 30.016 0.0140 28.7170 0.0070 28.6960 29.36533.016 0.0140 30.7428 0.0070 30.7218 31.772螺纹规格公称中径尺寸尺寸(6H )D2DM33*1.53332.026 M35*1.53534.026 M36*1.53635.026 M42*24240.701 M45*1.54544.026 M50*1.55049.026 M52*35250.052 M58*1.55857.026 M64*16463.351常用公制螺纹塞规尺寸标准对照表通规TZ PL TD 2 T PL W GO W NG大径中径大径H P EI D+EI+Z PL D2 +EI+Z PL D2+EI+TD 2+T PL /2+2F尺寸偏差尺寸偏差磨损下限尺寸±T PL ±T PL /21.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 33.012 0.0110 32.0378 0.0055 32.0203 32.5561.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 35.012 0.0110 34.0378 0.0055 34.0203 34.5561.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 36.012 0.0110 35.0378 0.0055 35.0203 35.5561.73 2 0 0.016 #### 0.014 0.021 0.015 42.016 0.0140 40.7170 0.0070 40.6960 41.3651.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 45.012 0.0110 44.0378 0.0055 44.0203 44.5561.3 1.5 0 0.016 #### 0.014 0.021 0.015 50.016 0.0140 49.04180.0070 49.0208 49.5702.6 3 0 0.016 #### 0.014 0.021 0.015 52.016 0.0140 50.06750.0070 50.0465 50.9881.3 1.5 0 0.016 #### 0.014 0.021 0.015 58.016 0.0140 57.0418 0.0070 57.0208 57.5700.87 1 0 0.012 #### 0.011 0.0175 0.0115 64.012 0.0110 63.3625 0.0055 63.3450 63.753止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0070 1.2837 0.0035 1.2762 0.0090 1.5622 0.0045 1.5527 0.0090 1.8347 0.0045 1.8252 0.0090 2.3072 0.0045 2.2977 0.0090 2.4072 0.0045 2.3977 0.0090 2.7798 0.0045 2.7703 0.0090 3.6679 0.0045 3.6584 0.0090 3.7798 0.0045 3.7703 0.0090 4.6099 0.0045 4.6004 0.0090 4.7798 0.0045 4.7703 0.0110 5.5060 0.0055 5.4945 0.0110 5.6504 0.0055 5.6389 0.0110 6.6504 0.0055 6.6389 0.0110 7.3536 0.0055 7.3421 0.0090 7.7918 0.0045 7.7823 0.0110 7.6504 0.0055 7.6389 0.0110 7.5060 0.0055 7.4945 0.0090 8.7918 0.0045 8.7823止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0110 9.2113 0.0055 9.1998 0.0090 9.7918 0.0045 9.7823 0.0110 9.6504 0.0055 9.6389 0.0110 9.5060 0.0055 9.4945 0.0110 9.3536 0.0055 9.3421 0.0110 11.0689 0.0055 11.0574 0.0090 11.7978 0.0045 11.7883 0.0110 11.5160 0.0055 11.5045 0.0110 11.2213 0.0055 11.2098 0.0140 12.9200 0.0070 12.9085 0.0110 13.5160 0.0055 13.5045 0.0110 13.3736 0.0055 13.3621 0.011013.2213 0.0055 13.2098 0.0140 12.9200 0.0070 12.9050 0.009014.7978 0.0045 14.7883 0.0110 14.5160 0.0055 14.5045 0.0140 14.9200 0.0070 14.9050 0.0090 15.7978 0.0045 15.7883止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0110 15.2213 0.0055 15.2098 0.0090 17.7978 0.0045 17.7883 0.0110 17.5160 0.0055 17.5045 0.0140 16.9200 0.0070 16.9050 0.0090 19.7978 0.0045 19.7883 0.0110 19.5160 0.0055 19.5045 0.0110 19.2213 0.0055 19.2098 0.0090 21.7978 0.0045 21.7883 0.0110 21.5160 0.0055 21.5045 0.0110 21.2213 0.0055 21.2098 0.0110 23.5260 0.0055 23.5145 0.0110 23.2313 0.0055 23.2198 0.0110 24.2313 0.0055 24.2198 0.0110 25.2313 0.0055 25.2198 0.0110 29.6684 0.0055 29.6569 0.0110 29.5260 0.0055 29.5145 0.0110 29.2313 0.0055 29.2198 0.0140 28.9320 0.0070 28.9170止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0110 32.2313 0.0055 32.2198 0.0110 34.2313 0.0055 34.2198 0.0110 35.2313 0.0055 35.2198 0.0140 40.9320 0.0070 40.9170 0.0110 44.2313 0.0055 44.2198 0.0140 49.2448 0.0070 49.2298 0.0140 50.3385 0.0070 50.3235 0.0140 57.2448 0.0070 57.2298 0.0110 63.5360 0.0055 63.5245。

公制螺纹尺寸表-资料类关键信息项:1、公制螺纹规格2、螺纹大径3、螺纹中径4、螺纹小径5、螺距6、牙型高度11 协议范围本协议旨在明确和规范公制螺纹的尺寸标准,为公制螺纹的设计、制造、检验和使用提供准确的参考依据。

111 适用对象本协议适用于涉及公制螺纹的各类机械、设备、零部件的生产制造以及相关的技术研究和质量控制等领域。

12 公制螺纹规格定义公制螺纹规格以螺纹的大径和螺距来表示,例如 M10×15 表示大径为 10 毫米,螺距为 15 毫米的公制螺纹。

121 常见公制螺纹规格常见的公制螺纹规格包括 M2、M25、M3、M4、M5、M6、M8、M10、M12 等。

13 螺纹大径螺纹大径是指与外螺纹牙顶或内螺纹牙底相切的假想圆柱的直径。

131 大径的公差范围公制螺纹大径的公差范围根据不同的精度等级而有所不同,一般分为精密级、中等精度级和粗糙级。

132 大径的测量方法测量螺纹大径可使用游标卡尺、千分尺等测量工具,在螺纹的牙顶或牙底处进行测量。

14 螺纹中径螺纹中径是一个假想圆柱的直径,该圆柱的母线通过牙型上沟槽和凸起宽度相等的地方。

141 中径的计算方法中径的计算公式为:中径=大径 06495×螺距142 中径的重要性螺纹中径是决定螺纹配合性质的主要参数,对螺纹的连接强度和密封性有着重要影响。

15 螺纹小径螺纹小径是指与外螺纹牙底或内螺纹牙顶相切的假想圆柱的直径。

151 小径的计算方法小径的计算公式为:小径=大径 10825×螺距152 小径的作用螺纹小径主要用于保证螺纹的强度和防止螺纹根部断裂。

16 螺距螺距是指相邻两牙在中径线上对应两点间的轴向距离。

161 标准螺距系列公制螺纹的标准螺距系列按照一定的规律排列,以满足不同的使用需求。

162 螺距的选择原则螺距的选择应根据螺纹的使用场合、承载能力、装配要求等因素综合考虑。

17 牙型高度牙型高度是指在螺纹牙型上,牙顶到牙底之间的垂直距离。

尺寸偏差±T PL 尺寸偏差±T PL /2磨损下限尺寸M1.4 1.4 1.2050.260.300.002####0.0070.00950.0075 1.4020.0070 1.20720.0035 1.1977 1.349M1.7 1.7 1.4730.30.3500.006####0.0090.01250.0095 1.7060.0090 1.47870.0045 1.4662 1.638M22 1.7400.350.400.006####0.0090.01250.0095 2.0060.0090 1.74620.0045 1.7337 1.921M2.5 2.5 2.2080.390.4500.006####0.0090.01250.0095 2.5060.0090 2.21370.0045 2.2012 2.405M2.6 2.6 2.3080.390.4500.006####0.0090.01250.0095 2.6060.0090 2.31370.0045 2.3012 2.505M33 2.6750.430.500.006####0.0090.01250.0095 3.0060.0090 2.68130.0045 2.6688 2.888M44 3.5450.610.700.006####0.0090.01250.0095 4.0060.0090 3.55140.0045 3.5389 3.819M4*0.54 3.6750.430.500.006####0.0090.01250.0095 4.0060.0090 3.68130.0045 3.6688 3.888M55 4.4800.690.800.006####0.0090.01250.0095 5.0060.0090 4.48640.0045 4.4739 4.783M5*0.55 4.6750.430.500.006####0.0090.01250.0095 5.0060.0090 4.68130.0045 4.6688 4.888M66 5.3510.87100.012####0.0110.01750.0115 6.0120.0110 5.36250.0055 5.3450 5.723M6*0.756 5.5130.650.7500.012####0.0110.01750.0115 6.0120.0110 5.52490.0055 5.5074 5.813M7*0.757 6.5130.650.7500.012####0.0110.01750.01157.0120.0110 6.52490.0055 6.5074 6.813M887.188 1.08 1.2500.012####0.0110.01750.01158.0120.01107.20010.00557.18267.624M8*0.587.6750.430.500.006####0.0090.01250.00958.0060.00907.68130.00457.66887.900M8*0.7587.5130.650.7500.012####0.0110.01750.01158.0120.01107.52490.00557.50747.813M8*187.3510.87100.012####0.0110.01750.01158.0120.01107.36250.00557.34507.723M9*0.598.6750.430.500.006####0.0090.01250.00959.0060.00908.68130.00458.66888.900W GOW NGHPEIZ PLTD 2T PL通规T大径D+EI+Z PL 中径D 2+EI+Z PL大径D 2+EI+TD 2+T PL /2+2F 1螺纹规格(6H )公称尺寸D 中径尺寸D 2尺寸偏差±T PL尺寸偏差±T PL/2磨损下限尺寸W GO W NG H P EI Z PL TD2T PL通规T大径D+EI+Z PL中径D2+EI+Z PL大径D2+EI+TD2+T PL/2+2F1螺纹规格(6H)公称尺寸D中径尺寸D2M10109.026 1.3 1.500.012####0.0110.01750.011510.0120.01109.03780.00559.02039.536 M10*0.5109.6750.430.500.006####0.0090.01250.009510.0060.00909.68130.00459.66889.900 M10*0.75109.5130.650.7500.012####0.0110.01750.011510.0120.01109.52490.00559.50749.813 M10*1109.3510.87100.012####0.0110.01750.011510.0120.01109.36250.00559.34509.723 M10*1.25109.188 1.08 1.2500.012####0.0110.01750.011510.0120.01109.20010.00559.18269.624 M121210.863 1.52 1.7500.012####0.0110.01750.011512.0120.011010.87540.005510.857911.448 M12*0.51211.6750.430.500.006####0.0090.01250.009512.0060.009011.68130.004511.668811.906 M12*11211.3510.87100.012####0.0110.01750.011512.0120.011011.36250.005511.345011.733 M12*1.51211.026 1.3 1.500.012####0.0110.01750.011512.0120.011011.03780.005511.020311.546 M141412.701 1.73200.016####0.0140.01750.011514.0160.014012.71700.007012.699513.353 M14*11413.3510.87100.012####0.0110.01750.011514.0120.011013.36250.005513.345013.733 M14*1.251413.188 1.08 1.2500.012####0.0110.01750.011514.0120.011013.20010.005513.182613.644 M14*1.51413.026 1.3 1.500.012####0.0110.01750.011514.0120.011013.03780.005513.020313.546 M14*21412.701 1.73200.016####0.0140.0210.01514.0160.014012.71700.007012.696013.353 M15*0.51514.6750.430.500.006####0.0090.01250.009515.0060.009014.68130.004514.668814.906 M15*11514.3510.87100.012####0.0110.01750.011515.0120.011014.36250.005514.345014.733 M161614.701 1.73200.016####0.0140.0210.01516.0160.014014.71700.007014.696015.353 M16*0.51615.6750.430.500.006####0.0090.01250.009516.0060.009015.68130.004515.668815.906尺寸偏差±T PL尺寸偏差±T PL/2磨损下限尺寸W GO W NG H P EI Z PL TD2T PL通规T大径D+EI+Z PL中径D2+EI+Z PL大径D2+EI+TD2+T PL/2+2F1螺纹规格(6H)公称尺寸D中径尺寸D2M16*1.51615.026 1.3 1.500.012####0.0110.01750.011516.0120.011015.03780.005515.020315.546 M18*0.51817.6750.430.500.006####0.0090.01250.009518.0060.009017.68130.004517.668817.906 M18*11817.3510.87100.012####0.0110.01750.011518.0120.011017.36250.005517.345017.733 M18*21816.701 1.73200.016####0.0140.0210.01518.0160.014016.71700.007016.696017.353 M20*0.52019.6750.430.500.006####0.0090.01250.009520.0060.009019.68130.004519.668819.906 M20*12019.3510.87100.012####0.0110.01750.011520.0120.011019.36250.005519.345019.733 M20*1.52019.026 1.3 1.500.012####0.0110.01750.011520.0120.011019.03780.005519.020319.546 M22*0.52221.6750.430.500.006####0.0090.01250.009522.0060.009021.68130.004521.668821.906 M22*12221.3510.87100.012####0.0110.01750.011522.0120.011021.36250.005521.345021.733 M22*1.52221.026 1.3 1.500.012####0.0110.01750.011522.0120.011021.03780.005521.020321.546 M24*12423.3510.87100.012####0.0110.01750.011524.0120.011023.36250.005523.345023.743 M24*1.52423.026 1.3 1.500.012####0.0110.01750.011524.0120.011023.03780.005523.020323.556 M25*1.52524.026 1.3 1.500.012####0.0110.01750.011525.0120.011024.03780.005524.020324.556 M26*1.52625.026 1.3 1.500.012####0.0110.01750.011526.0120.011025.03780.005525.020325.556 M30*0.753029.5130.650.7500.012####0.0110.01750.011530.0120.011029.52490.005529.507429.831 M30*13029.3510.87100.012####0.0110.01750.011530.0120.011029.36250.005529.345029.743 M30*1.53029.026 1.3 1.500.012####0.0110.01750.011530.0120.011029.03780.005529.020329.556 M30*23028.701 1.73200.016####0.0140.0210.01530.0160.014028.71700.007028.696029.365尺寸偏差±T PL尺寸偏差±T PL/2磨损下限尺寸W GO W NG H P EI Z PL TD2T PL通规T大径D+EI+Z PL中径D2+EI+Z PL大径D2+EI+TD2+T PL/2+2F1螺纹规格(6H)公称尺寸D中径尺寸D2M33*1.53332.026 1.3 1.500.012####0.0110.01750.011533.0120.011032.03780.005532.020332.556 M35*1.53534.026 1.3 1.500.012####0.0110.01750.011535.0120.011034.03780.005534.020334.556 M36*1.53635.026 1.3 1.500.012####0.0110.01750.011536.0120.011035.03780.005535.020335.556 M42*24240.701 1.73200.016####0.0140.0210.01542.0160.014040.71700.007040.696041.365 M45*1.54544.026 1.3 1.500.012####0.0110.01750.011545.0120.011044.03780.005544.020344.556 M50*1.55049.026 1.3 1.500.016####0.0140.0210.01550.0160.014049.04180.007049.020849.570 M52*35250.052 2.6300.016####0.0140.0210.01552.0160.014050.06750.007050.046550.988 M58*1.55857.026 1.3 1.500.016####0.0140.0210.01558.0160.014057.04180.007057.020857.570 M64*16463.3510.87100.012####0.0110.01750.011564.0120.011063.36250.005563.345063.753偏差±T PL 尺寸偏差±T PL /2磨损下限0.0070 1.28370.0035 1.27620.0090 1.56220.0045 1.55270.0090 1.83470.0045 1.82520.0090 2.30720.0045 2.29770.0090 2.40720.0045 2.39770.0090 2.77980.0045 2.77030.0090 3.66790.0045 3.65840.0090 3.77980.0045 3.77030.0090 4.60990.0045 4.60040.0090 4.77980.0045 4.77030.0110 5.50600.0055 5.49450.0110 5.65040.0055 5.63890.0110 6.65040.0055 6.63890.01107.35360.00557.34210.00907.79180.00457.78230.01107.65040.00557.63890.01107.50600.00557.49450.00908.79180.00458.7823止规Z大径EI+TD 2+T PL /2+2F 1中径D 2+EI+TD 2+T PL /2偏差±T PL尺寸偏差±T PL/2磨损下限止规Z大径EI+TD2+T PL/2+2F1中径D2+EI+TD2+T PL/20.01109.21130.00559.1998 0.00909.79180.00459.7823 0.01109.65040.00559.6389 0.01109.50600.00559.4945 0.01109.35360.00559.3421 0.011011.06890.005511.0574 0.009011.79780.004511.7883 0.011011.51600.005511.5045 0.011011.22130.005511.2098 0.014012.92000.007012.9085 0.011013.51600.005513.5045 0.011013.37360.005513.3621 0.011013.22130.005513.2098 0.014012.92000.007012.9050 0.009014.79780.004514.7883 0.011014.51600.005514.5045 0.014014.92000.007014.9050 0.009015.79780.004515.7883偏差±T PL尺寸偏差±T PL/2磨损下限止规Z大径EI+TD2+T PL/2+2F1中径D2+EI+TD2+T PL/20.011015.22130.005515.2098 0.009017.79780.004517.7883 0.011017.51600.005517.5045 0.014016.92000.007016.9050 0.009019.79780.004519.7883 0.011019.51600.005519.5045 0.011019.22130.005519.2098 0.009021.79780.004521.7883 0.011021.51600.005521.5045 0.011021.22130.005521.2098 0.011023.52600.005523.5145 0.011023.23130.005523.2198 0.011024.23130.005524.2198 0.011025.23130.005525.2198 0.011029.66840.005529.6569 0.011029.52600.005529.5145 0.011029.23130.005529.2198 0.014028.93200.007028.9170偏差±T PL尺寸偏差±T PL/2磨损下限止规Z大径EI+TD2+T PL/2+2F1中径D2+EI+TD2+T PL/20.011032.23130.005532.2198 0.011034.23130.005534.2198 0.011035.23130.005535.2198 0.014040.93200.007040.9170 0.011044.23130.005544.2198 0.014049.24480.007049.2298 0.014050.33850.007050.3235 0.014057.24480.007057.2298 0.011063.53600.005563.5245。

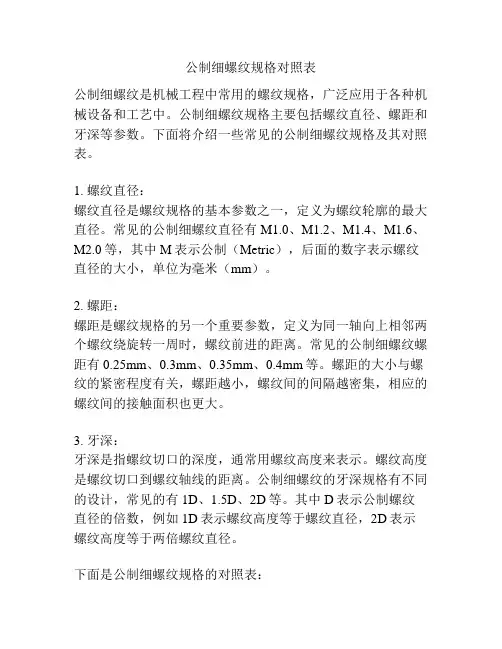

公制细螺纹规格对照表公制细螺纹是机械工程中常用的螺纹规格,广泛应用于各种机械设备和工艺中。

公制细螺纹规格主要包括螺纹直径、螺距和牙深等参数。

下面将介绍一些常见的公制细螺纹规格及其对照表。

1. 螺纹直径:螺纹直径是螺纹规格的基本参数之一,定义为螺纹轮廓的最大直径。

常见的公制细螺纹直径有M1.0、M1.2、M1.4、M1.6、M2.0等,其中M表示公制(Metric),后面的数字表示螺纹直径的大小,单位为毫米(mm)。

2. 螺距:螺距是螺纹规格的另一个重要参数,定义为同一轴向上相邻两个螺纹绕旋转一周时,螺纹前进的距离。

常见的公制细螺纹螺距有0.25mm、0.3mm、0.35mm、0.4mm等。

螺距的大小与螺纹的紧密程度有关,螺距越小,螺纹间的间隔越密集,相应的螺纹间的接触面积也更大。

3. 牙深:牙深是指螺纹切口的深度,通常用螺纹高度来表示。

螺纹高度是螺纹切口到螺纹轴线的距离。

公制细螺纹的牙深规格有不同的设计,常见的有1D、1.5D、2D等。

其中D表示公制螺纹直径的倍数,例如1D表示螺纹高度等于螺纹直径,2D表示螺纹高度等于两倍螺纹直径。

下面是公制细螺纹规格的对照表:螺纹规格直径(mm)螺距(mm)牙深(D)M1.0 1.0 0.25 1DM1.2 1.2 0.25 1DM1.4 1.4 0.3 1DM1.6 1.6 0.35 1DM2.0 2.0 0.4 1DM2.5 2.5 0.45 1.5DM3.0 3.0 0.5 2DM4.0 4.0 0.7 2DM5.0 5.0 0.8 2DM6.0 6.0 1.0 2D以上仅为常见的公制细螺纹规格,实际使用中还有更多规格可以选择。

公制细螺纹由于具有易于制造、安装方便、拧紧力矩小等优点,被广泛应用于机械工程领域。

正确选择合适的螺纹规格,对于机械设备的装配和使用十分重要。

螺纹规格 公称 中径尺寸Z PL TD 2 T PLW GOW NG尺寸 (6H ) HP EIDD 2M1.4 1.4 1.205 0.26 0.3 0 0.002 #### 0.007 0.0095 0.0075 M1.7 1.7 1.4730.30.35 0 0.006 #### 0.009 0.0125 0.0095 M2 2 1.740 0.35 0.4 0 0.006 #### 0.009 0.0125 0.0095 M2.5 2.5 2.208 0.39 0.45 0 0.006 #### 0.009 0.0125 0.0095 M2.6 2.6 2.308 0.39 0.45 0 0.006 #### 0.009 0.0125 0.0095 M3 3 2.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M4 4 3.545 0.61 0.7 0 0.006 #### 0.009 0.0125 0.0095 M4*0.5 4 3.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M5 5 4.480 0.69 0.8 0 0.006 #### 0.009 0.0125 0.0095 M5*0.5 5 4.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M6 6 5.351 0.87 1 0 0.012 #### 0.011 0.0175 0.0115 M6*0.75 6 5.513 0.65 0.75 0 0.012 #### 0.011 0.0175 0.0115 M7*0.75 7 6.513 0.65 0.75 0 0.012 #### 0.011 0.0175 0.0115 M8 8 7.188 1.08 1.25 0 0.012 #### 0.011 0.0175 0.0115 M8*0.5 8 7.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M8*0.75 8 7.513 0.65 0.75 0 0.012 #### 0.011 0.0175 0.0115 M8*1 8 7.351 0.87 1 0 0.012 #### 0.011 0.0175 0.0115 M9*0.5 9 8.675 0.43 0.5 0 0.006 #### 0.009 0.0125 0.0095 M9*198.351 0.8710 0.012 #### 0.011 0.0175 0.0115 通规T大径中径大径D+EI+Z PLD 2 +EI+Z PLD 2+EI+TD 2+T PL /2+2F尺寸偏差尺寸偏差 磨损下限尺寸 ±T PL ±T PL /21.402 0.0070 1.2072 0.0035 1.1977 1.349 1.706 0.0090 1.4787 0.0045 1.4662 1.6382.006 0.0090 1.7462 0.0045 1.7337 1.921 2.506 0.0090 2.2137 0.0045 2.2012 2.405 2.606 0.0090 2.3137 0.0045 2.3012 2.5053.006 0.0090 2.6813 0.0045 2.6688 2.8884.006 0.0090 3.5514 0.0045 3.5389 3.819 4.006 0.0090 3.6813 0.0045 3.6688 3.8885.006 0.0090 4.4864 0.0045 4.4739 4.783 5.006 0.0090 4.6813 0.0045 4.6688 4.8886.012 0.0110 5.3625 0.0055 5.3450 5.723 6.012 0.0110 5.5249 0.0055 5.5074 5.8137.012 0.0110 6.5249 0.0055 6.5074 6.8138.012 0.0110 7.2001 0.0055 7.1826 7.624 8.006 0.0090 7.6813 0.0045 7.6688 7.900 8.012 0.0110 7.5249 0.0055 7.5074 7.813 8.012 0.0110 7.3625 0.0055 7.3450 7.7239.006 0.0090 8.6813 0.0045 8.6688 8.900 9.012 0.01108.36250.00558.34508.723螺纹规格公称中径尺寸尺寸(6H )D2DM10109.026 M10*0.5109.675 M10*0.75109.513 M10*1109.351 M10*1.25 109.188 M121210.863 M12*0.51211.675 M12*11211.351 M12*1.51211.026M141412.701 M14*11413.351 M14*1.251413.188 M14*1.51413.026 M14*21412.701 M15*0.51514.675 M15*11514.351M161614.701 M16*0.51615.675 M16*11615.351H P EI Z PL TD 2T PL W GO W NG1.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.65 0.75 0 0.012 #### 0.011 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.08 1.25 0 0.012 #### 0.011 0.0175 0.01151.52 1.75 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.08 1.25 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.0115通规T大径中径大径D+EI+Z PL D2 +EI+Z PL D2+EI+TD 2+T PL /2+2F尺寸偏差尺寸偏差磨损下限尺寸±T PL ±T PL /210.012 0.0110 9.0378 0.0055 9.0203 9.53610.006 0.0090 9.6813 0.0045 9.6688 9.90010.012 0.0110 9.5249 0.0055 9.5074 9.81310.012 0.0110 9.3625 0.0055 9.3450 9.72310.012 0.0110 9.2001 0.0055 9.1826 9.62412.012 0.0110 10.8754 0.0055 10.8579 11.44812.006 0.0090 11.6813 0.0045 11.6688 11.90612.012 0.0110 11.3625 0.0055 11.3450 11.73312.012 0.0110 11.0378 0.0055 11.0203 11.54614.016 0.0140 12.7170 0.0070 12.6995 13.35314.012 0.0110 13.3625 0.0055 13.3450 13.73314.012 0.0110 13.2001 0.0055 13.1826 13.64414.012 0.0110 13.0378 0.0055 13.0203 13.54614.016 0.0140 12.7170 0.0070 12.6960 13.35315.006 0.0090 14.6813 0.0045 14.6688 14.90615.012 0.0110 14.3625 0.0055 14.3450 14.73316.016 0.0140 14.7170 0.0070 14.6960 15.35316.006 0.0090 15.6813 0.0045 15.6688 15.90616.012 0.0110 15.3625 0.0055 15.3450 15.733螺纹规格公称中径尺寸尺寸(6H )D2DM16*1.51615.026 M18*0.51817.675 M18*11817.351 M18*21816.701 M20*0.52019.675 M20*12019.351 M20*1.52019.026 M22*0.52221.675 M22*12221.351 M22*1.52221.026 M24*12423.351 M24*1.52423.026 M25*1.52524.026 M26*1.52625.026 M30*0.753029.513 M30*13029.351 M30*1.53029.026 M30*23028.701M333330.727H P EI Z PL TD 2T PL W GO W NG1.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.43 0.5 0 0.006 #### 0.009 0.0125 0.00950.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01150.65 0.75 0 0.012 #### 0.011 0.0175 0.01150.87 1 0 0.012 #### 0.011 0.0175 0.01151.3 1.5 0 0.012 #### 0.011 0.0175 0.01151.73 2 0 0.016 #### 0.014 0.021 0.0153.03 3.5 0 0.016 #### 0.014 0.021 0.015通规T大径中径大径D+EI+Z PL D2 +EI+Z PL D2+EI+TD 2+T PL /2+2F尺寸偏差尺寸偏差磨损下限尺寸±T PL ±T PL /216.012 0.0110 15.0378 0.0055 15.0203 15.54618.006 0.0090 17.6813 0.0045 17.6688 17.90618.012 0.0110 17.3625 0.0055 17.3450 17.73318.016 0.0140 16.7170 0.0070 16.6960 17.35320.006 0.0090 19.6813 0.0045 19.6688 19.90620.012 0.0110 19.3625 0.0055 19.3450 19.73320.012 0.0110 19.0378 0.0055 19.0203 19.54622.006 0.0090 21.6813 0.0045 21.6688 21.90622.012 0.0110 21.3625 0.0055 21.3450 21.73322.012 0.0110 21.0378 0.0055 21.0203 21.54624.012 0.0110 23.3625 0.0055 23.3450 23.74324.012 0.0110 23.0378 0.0055 23.0203 23.55625.012 0.0110 24.0378 0.0055 24.0203 24.55626.012 0.0110 25.0378 0.0055 25.0203 25.55630.012 0.0110 29.5249 0.0055 29.5074 29.83130.012 0.0110 29.3625 0.0055 29.3450 29.74330.012 0.0110 29.0378 0.0055 29.0203 29.55630.016 0.0140 28.7170 0.0070 28.6960 29.36533.016 0.0140 30.7428 0.0070 30.7218 31.772螺纹规格公称中径尺寸尺寸(6H )D2DM33*1.53332.026 M35*1.53534.026 M36*1.53635.026 M42*24240.701 M45*1.54544.026 M50*1.55049.026 M52*35250.052 M58*1.55857.026 M64*16463.351常用公制螺纹塞规尺寸标准对照表通规TZ PL TD 2 T PL W GO W NG大径中径大径H P EI D+EI+Z PL D2 +EI+Z PL D2+EI+TD 2+T PL /2+2F尺寸偏差尺寸偏差磨损下限尺寸±T PL ±T PL /21.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 33.012 0.0110 32.0378 0.0055 32.0203 32.5561.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 35.012 0.0110 34.0378 0.0055 34.0203 34.5561.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 36.012 0.0110 35.0378 0.0055 35.0203 35.5561.73 2 0 0.016 #### 0.014 0.021 0.015 42.016 0.0140 40.7170 0.0070 40.6960 41.3651.3 1.5 0 0.012 #### 0.011 0.0175 0.0115 45.012 0.0110 44.0378 0.0055 44.0203 44.5561.3 1.5 0 0.016 #### 0.014 0.021 0.015 50.016 0.0140 49.0418 0.0070 49.0208 49.5702.6 3 0 0.016 #### 0.014 0.021 0.015 52.016 0.0140 50.0675 0.0070 50.0465 50.9881.3 1.5 0 0.016 #### 0.014 0.021 0.015 58.016 0.0140 57.0418 0.0070 57.0208 57.5700.87 1 0 0.012 #### 0.011 0.0175 0.0115 64.012 0.0110 63.3625 0.0055 63.3450 63.753止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0070 1.2837 0.0035 1.2762 0.0090 1.5622 0.0045 1.5527 0.0090 1.8347 0.0045 1.8252 0.0090 2.3072 0.0045 2.2977 0.0090 2.4072 0.0045 2.3977 0.0090 2.7798 0.0045 2.7703 0.0090 3.6679 0.0045 3.6584 0.0090 3.7798 0.0045 3.7703 0.0090 4.6099 0.0045 4.6004 0.0090 4.7798 0.0045 4.7703 0.0110 5.5060 0.0055 5.4945 0.0110 5.6504 0.0055 5.6389 0.0110 6.6504 0.0055 6.6389 0.0110 7.3536 0.0055 7.3421 0.0090 7.7918 0.0045 7.7823 0.0110 7.6504 0.0055 7.6389 0.0110 7.5060 0.0055 7.4945 0.0090 8.7918 0.0045 8.7823止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0110 9.2113 0.0055 9.1998 0.0090 9.7918 0.0045 9.7823 0.0110 9.6504 0.0055 9.6389 0.0110 9.5060 0.0055 9.4945 0.0110 9.3536 0.0055 9.3421 0.0110 11.0689 0.0055 11.0574 0.0090 11.7978 0.0045 11.7883 0.0110 11.5160 0.0055 11.5045 0.0110 11.2213 0.0055 11.2098 0.0140 12.9200 0.0070 12.9085 0.0110 13.5160 0.0055 13.5045 0.0110 13.3736 0.0055 13.3621 0.0110 13.2213 0.0055 13.2098 0.0140 12.9200 0.0070 12.9050 0.0090 14.7978 0.0045 14.7883 0.0110 14.5160 0.0055 14.5045 0.0140 14.9200 0.0070 14.9050 0.0090 15.7978 0.0045 15.7883止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0110 15.2213 0.0055 15.2098 0.0090 17.7978 0.0045 17.7883 0.0110 17.5160 0.0055 17.5045 0.0140 16.9200 0.0070 16.9050 0.0090 19.7978 0.0045 19.7883 0.0110 19.5160 0.0055 19.5045 0.0110 19.2213 0.0055 19.2098 0.0090 21.7978 0.0045 21.7883 0.0110 21.5160 0.0055 21.5045 0.0110 21.2213 0.0055 21.2098 0.0110 23.5260 0.0055 23.5145 0.0110 23.2313 0.0055 23.2198 0.0110 24.2313 0.0055 24.2198 0.0110 25.2313 0.0055 25.2198 0.0110 29.6684 0.0055 29.6569 0.0110 29.5260 0.0055 29.5145 0.0110 29.2313 0.0055 29.2198 0.0140 28.9320 0.0070 28.9170止规Z大径中径EI+TD2+T PL /2+2F 1 D2 +EI+TD 2 +T PL /2偏差尺寸偏差磨损下限±T PL ±T PL /20.0110 32.2313 0.0055 32.2198 0.0110 34.2313 0.0055 34.2198 0.0110 35.2313 0.0055 35.2198 0.0140 40.9320 0.0070 40.9170 0.0110 44.2313 0.0055 44.2198 0.0140 49.2448 0.0070 49.2298 0.0140 50.3385 0.0070 50.3235 0.0140 57.2448 0.0070 57.2298 0.0110 63.5360 0.0055 63.5245。

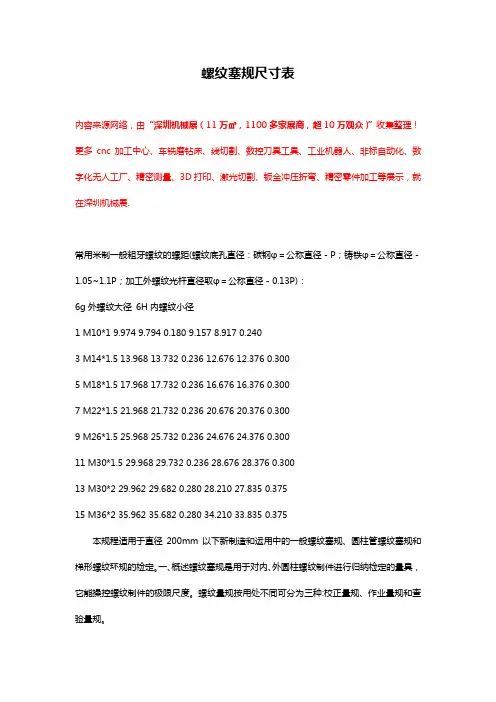

螺纹塞规尺寸表内容来源网络,由“深圳机械展(11万㎡,1100多家展商,超10万观众)”收集整理!更多cnc加工中心、车铣磨钻床、线切割、数控刀具工具、工业机器人、非标自动化、数字化无人工厂、精密测量、3D打印、激光切割、钣金冲压折弯、精密零件加工等展示,就在深圳机械展.常用米制一般粗牙螺纹的螺距(螺纹底孔直径:碳钢φ=公称直径-P;铸铁φ=公称直径-1.05~1.1P;加工外螺纹光杆直径取φ=公称直径-0.13P):6g外螺纹大径6H内螺纹小径1 M10*1 9.974 9.794 0.180 9.157 8.917 0.2403 M14*1.5 13.968 13.732 0.236 12.676 12.376 0.3005 M18*1.5 17.968 17.732 0.236 16.676 16.376 0.3007 M22*1.5 21.968 21.732 0.236 20.676 20.376 0.3009 M26*1.5 25.968 25.732 0.236 24.676 24.376 0.30011 M30*1.5 29.968 29.732 0.236 28.676 28.376 0.30013 M30*2 29.962 29.682 0.280 28.210 27.835 0.37515 M36*2 35.962 35.682 0.280 34.210 33.835 0.375本规程适用于直径200mm以下新制造和运用中的一般螺纹塞规、圆柱管螺纹塞规和梯形螺纹环规的检定。

一、概述螺纹塞规是用于对内、外圆柱螺纹制件进行归纳检定的量具,它能操控螺纹制件的极限尺度。

螺纹量规按用处不同可分为三种:校正量规、作业量规和查验量规。

一般螺纹塞规一般每个公称尺度都是两个为一组。

一个是止规,一个是通规,别离约束了螺纹的尺度上限与下限.假如被测螺纹可以与螺纹通规旋合经过,且与螺纹止规不完全旋合经过(螺纹止规只允许与被测螺纹两段旋合,旋合量不得超越两个螺距),就标明被测螺纹的作用中径没有超越其最大实体牙型的中径,且单一中径没有超出其最小实体牙型的中径,那么就可以确保旋合性和衔接强度,则被测螺纹中径合格。

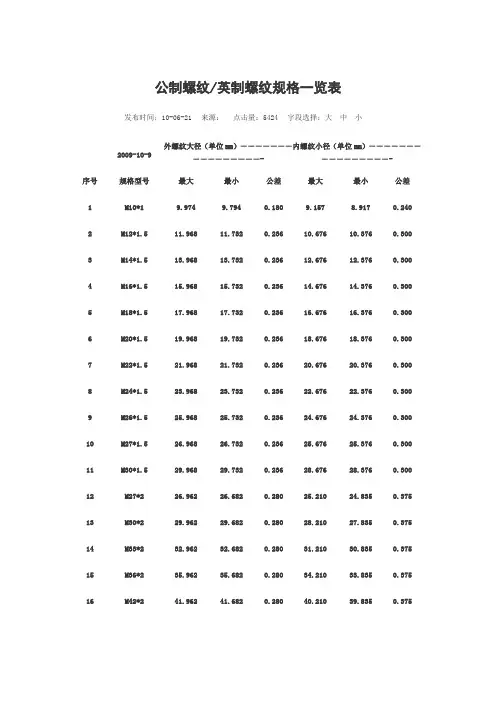

公制螺纹/英制螺纹规格一览表发布时间:10-06-21 来源:点击量:5424 字段选择:大中小2009-10-9外螺纹大径(单位mm)-----------------内螺纹小径(单位mm)-----------------序号规格型号最大最小公差最大最小公差1M10*19.9749.7940.1809.1578.9170.240 2M12*1.511.96811.7320.23610.67610.3760.300 3M14*1.513.96813.7320.23612.67612.3760.300 4M16*1.515.96815.7320.23614.67614.3760.300 5M18*1.517.96817.7320.23616.67616.3760.300 6M20*1.519.96819.7320.23618.67618.3760.300 7M22*1.521.96821.7320.23620.67620.3760.300 8M24*1.523.96823.7320.23622.67622.3760.300 9M26*1.525.96825.7320.23624.67624.3760.300 10M27*1.526.96826.7320.23625.67625.3760.300 11M30*1.529.96829.7320.23628.67628.3760.300 12M27*226.96226.6820.28025.21024.8350.375 13M30*229.96229.6820.28028.21027.8350.375 14M33*232.96232.6820.28031.21030.8350.375 15M36*235.96235.6820.28034.21033.8350.375 16M42*241.96241.6820.28040.21039.8350.375英制螺纹规格一览表外螺纹大径(单位mm)内螺纹小径(单位mm)序号规格型号最大最小公差最大最小公差1G1/8-289.7289.5140.2148.8488.5660.282 2G1/4-1913.15712.9070.25011.89011.4450.445 3G3/8-1916.66216.4120.25015.39514.9500.445 4G1/2-1420.95520.6710.28419.17218.6310.541 5G3/4-1426.44126.1570.28424.65824.1170.541 6G1-1133.24932.8890.36030.93130.2910.640 7G11/4-1141.91041.5500.36039.59238.9520.640 8G11/2-1147.80347.4430.36045.48544.8450.640类别标准名称标准号普通螺纹普通螺纹基本牙型GB/T192 —1981普通螺纹直径与螺距系列GB/T193 —1981普通螺纹基本尺寸GB/T196 —1981普通螺纹公差与配合GB/T197 —1981普通螺纹偏差表GB/T2516 —1981商品紧固件的普通螺纹选用系列JB/T7912 —1999商品紧固件的中等精度普通螺纹极限尺寸GB/T9145 —1988光学螺纹光学仪器特种细牙螺纹ZBN30006—1988光学仪器用目镜螺纹JB/T8204—1995光学仪器用短牙螺纹JB/T5450-1991紧配合螺纹过渡配合螺纹GB/T1167—1996过盈配合螺纹GB/T1181—1998小螺纹小螺纹牙型GB/T1505 4.1—1994 小螺纹直径与螺距系列GB/T1505 4.2—1994小螺纹基本尺寸GB/T1505 4.3—1994小螺纹公差GB/T15054.4-1994小螺纹极限尺寸GB/T15054.5-1994MJ螺纹MJ螺纹基本牙型GJB/T3.1 —1982 MJ螺纹螺栓与螺母螺纹的尺寸与公差GJB/T3.2 —1982MJ螺纹管路件螺纹的尺寸与公差GJB/T3.3 —1985MJ螺纹结构件的尺寸与公差GJB/T3.4 —1985MJ螺纹计算公式GJB/T3.5 —1985MJ螺纹首尾GJB52-1985梯形螺纹梯形螺纹牙型GB/T5796 .1—1986 梯形螺纹直径与螺距系列GB/T5796 .2—1986梯形螺纹基本尺寸GB/T5796 .3—1986梯形螺纹公差GB/T5796 .4—1986梯形螺纹极限尺寸GB/T12359—1990机床梯形螺纹丝杠、螺母技术条件JB/T2886—1992锻钢阀门用短牙梯形螺纹JB/TQ374—1985锯齿形螺纹锯齿形(3 °、30°)螺纹牙型GB/T13576.1—1992锯齿形(3 °、30°)螺纹直径与螺距系列GB/T13576.2—1992锯齿形(3 °、30°)螺纹基本尺寸GB/T13576.3—1992锯齿形(3 °、30°)螺纹公差GB/T13576.4—1992水压机45 °锯齿形螺纹牙型与基本尺寸JB2076—1984管螺纹用螺纹密封的管螺纹GB/T7306 —1987 非螺纹密封的管螺纹GB/T7307 —198760°圆锥管螺纹GB/T12716—1991米制锥螺纹GB/T1415—1992管路旋入端用普通螺纹尺寸系列GB/T1414—1978气瓶专用螺纹GB/T8335-1998通用基准螺纹术语GB/T1479 1—1993公制粗螺纹标准公制细螺纹标准规格标准径最大最小规格标准径最大最小规格标准径最大最小M1.0*0.25 0.75 0.785 0.729 M1.0*0.2 0.8 0.821 0.783 M15*1.0 14 14.353 13.917 M1.1*0.25 0.85 0.885 0.829 M1.1*0.2 0.9 0.921 0.883 M16*1.5 14.5 14.676 14.376 M1.2*0.25 0.95 0.985 0.929 M1.2*0.2 1 1.021 0.983 M16*1.0 15 15.153 14.917 M1.4*0.3 1.1 1.142 1.075 M1.4*0.2 1.2 1.221 1.183 M17*1.5 15.5 15.676 15.376 M1.6*0.35 1.25 1.321 1.221 M1.6*0.2 1.4 1.421 1.383 M17*1.0 16 16.153 15.917 M1.7*0.35 1.35 1.421 1.321 M1.7*0.2 1.45 1.5 1.46 M18*2.0 16 16.21 15.835 M1.8*0.35 1.45 1.521 1.421 M1.8*0.2 1.6 1.621 1.583 M18*1.5 16.5 16.676 16.376 M2.0*0.4 1.6 1.679 1.567 M2.0*0.25 1.75 1.785 1.729 M18*1.0 17 17.153 16.917 M2.2*0.45 1.75 1.888 1.713 M2.2*0.25 1.95 1.985 1.929 M20*2.0 18 18.21 17.835 M2.3*0.4 1.9 1.979 1.867 M2.3*0.25 2.05 2.061 2.001 M20*1.5 18.5 18.676 18.376 M2.5*0.45 2.1 2.138 2.013 M2.5*0.35 2.2 2.221 2.121 M20*1.0 19 19.153 18.917 M2.6*0.45 2.2 2.238 2.113 M2.5*0.35 2.2 2.246 2.186 M22*2.0 20 20.21 19.835 M3.0*0.5 2.5 2.599 2.459 M3.0*0.35 2.7 2.721 2.621 M22*1.5 20.5 20.676 20.376 M3.0*0.6 2.4 2.44 2.28 M3.5*0.35 3.2 3.221 3.121 22*1.0 21 21.153 20.917 M3.5*0.6 2.9 3.01 2.85 M4.0*0.5 3.5 3.599 3.459 M24*2.0 22 22.21 21.835 M4.0*0.7 3.8 3.422 3.242 M4.5*0.5 4 4.099 3.959 M24*1.5 22.5 22.676 22.376M4.0*0.75 3.25 3.326 3.106 M5.0*0.5 4.5 4.599 4.459 M24*1.0 23 23.153 22.917 M4.5*0.7 3.8 3.878 3.688 M5.5*0.5 5 5.099 4.959 M25*2.0 23 23.21 22.835 M5*0.8 4.2 4.334 4.134 M6.0*0.75 5.3 5.378 5.188 M25*1.5 23.5 23.676 23.376 M5*0.9 4.1 4.17 3.98 M6.0*0.5 5.5 5.55 5.4 M25*1.0 24 24.153 23.917 M6*1.0 5 5.153 4.917 M7.0*0.75 6.3 6.378 6.188 M26*1.5 24.5 24.676 24.876 M7*1.0 6 6.153 5.917 M7.0*0.5 6.5 6.55 6.4 M27*2.0 25 25.21 24.735 M8*1.25 6.8 6.912 6.647 M8.0*1 7 7.153 6.917 M27*1.5 25.5 25.676 25.376 M9*1.25 7.8 7.912 7.647 M8.0*0.75 7.3 7.378 7.188 M27*1.0 26 26.153 25.735 M10*1.5 8.5 8.676 8.376 M8.0*0.5 7.5 7.52 7.4 M28*2.0 26 26.21 25.835 M11*1.5 9.5 9.676 9.376 M9.0*1 8 8.153 7.917 M28*1.5 26 26.676 26.376 M12*1.75 10.3 10.24 10.11 M9.0*0.75 8.3 8.378 8.188 M28*1.0 27 27.153 26.917 M14*2.0 12 12.21 11.84 M10*1.25 8.8 8.912 8.647 M30*3.0 27 27.252 26.752 M16*2.0 14 14.21 13.84 M10*1.0 9 9.153 8.917 M30*2.0 28 28.21 27.835 M18*2.5 15.5 15.744 15.29 M10*0.75 9.3 9.378 9.188 M30*1.0 28 28.676 28.376 M20*2.5 17.5 17.744 17.29 M10*0.5 9.5 9.52 9.4 M32*2.0 30 29.153 28.917 M22*2.5 19.5 19.744 19.29 M11*1.0 10 10.15 9.917 M32*1.5 30 30.21 29.835 M24*3.0 21 21.252 20.75 M11*0.75 10.3 10.38 10.19 M33*3.0 30 30.676 30.376 M27*3.0 24 24.252 23.75 M12*1.5 10.5 10.68 10.38 M33*2.0 31 30.252 29.752 M30*3.5 26.5 26.771 26.21 M12*1.25 10.8 10.91 10.65 M33*1.5 31.5 31.21 30.835M12*1 11 11.15 10.92 M35*1.5 33.5 33.676 31.376M12*0.5 11.5 11.52 11.4 M36*3.0 33 33.252 32.752M14*0.5 12.5 12.68 12.38 M36*2.0 34 34.21 33.835M14*1.0 13 13.15 12.92 M36*1.5 34 34.676 34.376M15*1.50 13.5 13.68 13.38美制细螺纹标准公制迫牙丝攻钻孔径规格(丝牙外径)标准径最大最小规格精度等级7-G8 1.25 1.305 1.182 G4-G6 G7-G8 G9 NO.1-72(1.854) 1.55 1.612 1.474 M1.0*0.25 0.86 0.88 NO.2-64(2.134) 1.85 1.912 1.756 M1.1*0.25 0.96 0.98 NO.3-56(2.515) 2.1 2.197 2.025 M1.2*0.25 1.06 1.08 NO.4-48(2.345) 2.4 2.456 2.271 M1.4*0.3 1.24 1.25 NO.5-44(3.175) 2.7 2.74 2.551 M1.6*0.35 1.41 1.43 NO.6-40(3.505) 2.9 3.022 2.82 M1.7*0.35 1.51 1.53 NO.8-36(4.166) 3.5 3.606 3.404 M1.8*0.35 1.61 1.63NO.10-32(4.326) 4.1 4.165 3.963 M2.0*0.4 1.78 1.8NO.12-28(5.846) 4.6 4.724 4.496 M2.2*0.45 1.95 1.981\4-28 5.5 5.588 5.36 M2.3*0.4 2.08 2.15\16-24 6.9 7.035 6.782 M2.5*0.45 2.25 2.283\8-24 8.5 8.636 8.382 M2.6*0.45 2.35 2.387\16-20 9.9 10.033 9.729 M3.0*0.5 2.73 2.751\2-20 11.5 11.607 11.329 M3.5*0.6 3.17 3.29\16-18 12.9 13.081 12.751 M4.0*0.7 3.62 3.65 3.69 5\8-18 14.5 14.681 14.351 M5.0*0.8 4.56 4.6 4.64 3\4-16 17.5 17.678 17.323 M6.0*1.0 5.45 5.5 5.55 7\8-14 20.5 20.675 20.27 M7.0*1.0 6.45 6.5 6.55 1\8-12 23.2 23.571 23.114 M8.0*1.25 7.31 7.38 7.44 1-1\8-12 26.5 26.746 26.289 M10*1.5 9.18 9.25 9.32 1-1\4-12 29.5 29.921 29.464 M10*1.25 9.31 9.38 9.44 1-3\8-12 32 33.096 32.639 M12*1.75 11.04 11.12 11.21 1-1\2-12 36 36.271 35.814 M12*1.25 11.31 11.38 11.44英美联合螺纹标准英美联细螺纹标准规格钻头径2B螺纹径规格钻头径下孔径上限下限上限下限NO.1-64UNC 1.55 1.582 1.425 no.0-80unf 1.25 1.305 1.182 NO.2-56UNC 1.8 1.871 1.695 no.1-72unf 1.55 1.612 1.474 NO.3-48UNC 2.1 2.146 1.941 no.2-64-unf 1.85 1.912 1.756 NO.4-40UNC 2.3 2.385 2.157 no.3-565unf 2.1 2.197 2.025 NO.5-40UNC 2.6 2.679 2.487 no.4-48unf 2.4 2.458 2.271 NO.6-32UNC 2.8 2.895 2.642 no.5-44unf 2.7 2.74 2.551 NO.832UNC 3.4 3.53 3.302 no.6-40unf 2.9 3.022 2.82 NO.10-24UNC 3.9 3.926 3.683 no.8-36unf 3.5 3.606 3.404 NO.12-24UNC 4.5 4.597 4.344 no.10-32unf 4.1 4.165 3.963 1\4-20UNC 5.1 5.257 4..979 no.12-28unf 4.6 4.724 4.496 5\16-18unc 6.6 6.731 6.401 1\4-28unf 5.5 5.588 5.363\8-16UNC 8 8.153 7.798 5\16-24unf 6.9 7.035 6.782 7\16-14UNC 9.4 9.55 9.144 3\8-24unf 8.5 8.636 8.382 1\2-13UNC 10.8 11.023 10.599 7\16-20unf 9.9 10.033 9.729 9\16-12UNC 12.2 12.446 11.989 1\2-unf 11.5 11.607 11.3295\8-11UNC 13.6 13.868 13.386 9\16-unf 12.9 13.081 12.75 3\4-10UNC 16.5 16.84 16.307 5\8-18unf 14.5 14.681 14.35 7\8-9UNC 19.5 19.761 19.177 3\4-16unf 17.5 17.678 17.32 1--8UNC 22.2 22.606 21.971 7\8-14unf 20.5 20.675 20.27 11\8-7UNC 25 25.349 24.813 1--12unf 23.2 23.571 23.11 11\4-7UNC 28.2 28.524 27.813 11\8-12unf 26.5 26.746 26.28 13\8-6UNC 30.8 31.115 30.353 11\4-12unf 29.5 29.921 29.46 11\2-6UNC 34 34.29 33.528 13\8-12unf 32.8 33.096 32.63 13\4-5UNC 39.5 39.827 38.964 11\2-12unf 36 36.271 35.81 2-41\2UNC 45.2 45.593 44.679惠式螺纹标准(旧英制牙)山数节距换算表规格钻头径A例B例山数(25.4) 节数*W1\8-40 2.65 2.6 100 0.254*W5\32-32 3.25 3.2 880 0.317 5*w3\16-24 3..75 3.7 772 0.351 8W1\4-20 5.1 5 64 0.396 9W5\16-18 6.6 5 60 0.423 3W3\8-16 8 6.5 56 0.453 6W7\16-14 9.4 7.9 48 0.529 2W1\2-12 10.7 9.310.5 44 0.577 3W9\16-12 12.3 12 40 0.635W5\8-11 13.7 13.5 36 0.705 6W3\4-10 16.7 16.5 32 0.793 8W7\8-9 19.5 19.3 28 0.907 1W1-8 22.4 22 24 1.058 3W1\8-7 25 24.8 20 1.27W11\4 28.3 28 18 1.411 1W13\8-6 30.5 30.3 16 1.587 5W11\2-6 33.8 33.5 14 1.814 3W15\8-5 36 35.7 13 1.953 8W13\4-5 39.2 39 12 2.116 7W11\8-5 41.8 41.5 11 2.309 1W2-41\2 45 44.7 10 2.54牙套螺纹攻用标准9 2.8222规格钻头径下孔径8 3.175上限下限7 3.6286M3*0.5 3.1 3.2 3.12 6 4.2333M4*0.7 4.2 4.3 4.17 5 5.08M5*0.8 5.2 5.33 5.16 41\2 5.6444M6*1 6.3 6.42 6.25 4 6.35M8*1.25 8.4 8.52 8.31 31\2 7.2571M10*1.5 10.5 10.62 10.37 31\2 7.8154M10*1.25 10.4 10.52 10.31 3 8.4667M10*1 10.3 10.42 10.25 27\8 8.8348M12*1.75 12.5 12.73 12.43 23\4 9.2364M12*1.5 12.5 12.62 12.37 25\8 9.6762M12*1.25 12.5 12.52 12.31 21\2 10.16M14*2 14.5 14.83 14349M14*1.5 14.5 14.62 14.37M16*2 16.5 16.83 16.49M16*1.5 16.5 16.62 16.37M18*2.5 19 19.04 18.58M18*1.5 18.5 18.62 18.37M20*2.5 21 21.04 20.58M20*1.5 20.5 20.62 20.37公制、美制和英制螺纹标准NPT,PT,G 都是管螺纹.NPT 是National (American) Pipe Thread 的缩写,属於美国标准的60 度锥管螺纹,用於北美地区.国家标准可查阅GB/T12716-1991 PT 是Pipe Thread 的缩写,是5 5 度密封圆锥管螺纹,属惠氏螺纹家族,多用於欧洲及英联邦国家.常用於水及煤气管行业,锥度规定为1:16.国家标准可查阅GB/T7306-2000 G 是55 度非螺纹密封管螺纹,属惠氏螺纹家族.标记为G 代表圆柱螺纹.国家标准可查阅GB/T7307-2001 另外螺纹中的1/4、1/2、1/8 标记是指螺纹尺寸的直径,单位是英吋.行内人通常用分来称呼螺纹尺寸,一吋等於8分,1/4 吋就是2分,如此类推.G 好像就是管螺纹的统称(Guan),55,60度的划分属于功能性的,俗称管圆。