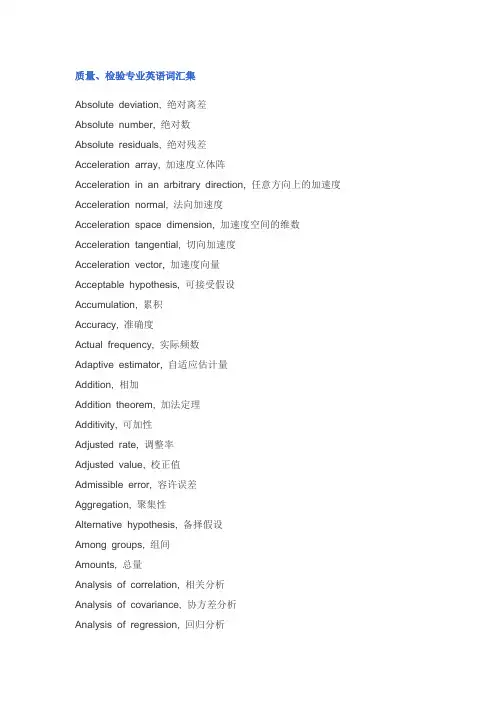

质量专业英语大全

- 格式:doc

- 大小:91.00 KB

- 文档页数:19

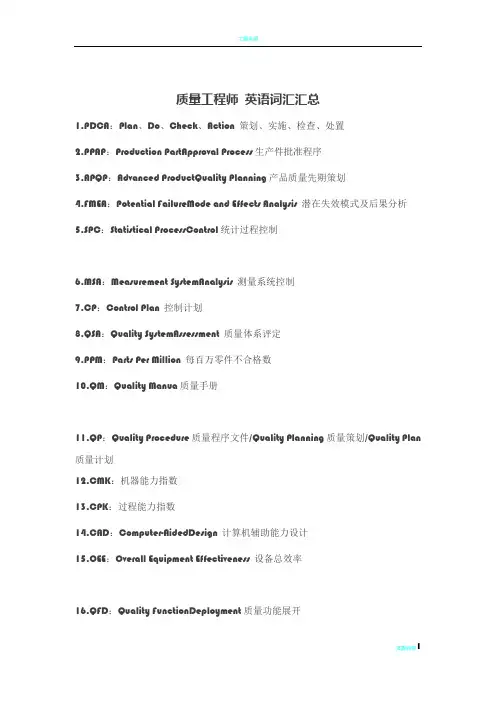

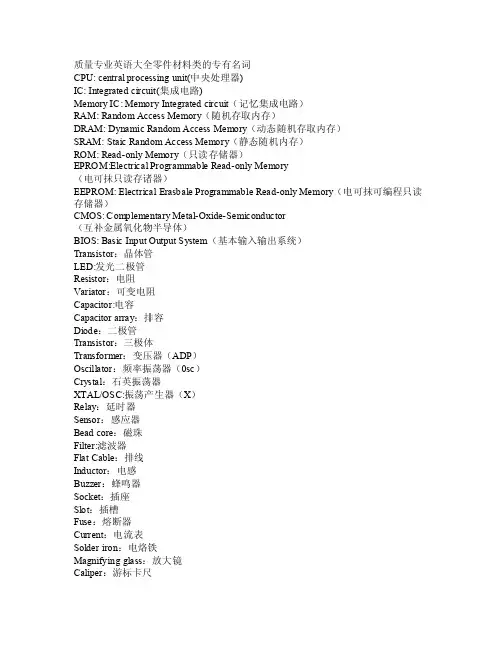

质量工程师-英语词汇汇总质量工程师英语词汇汇总1.PDCA:Plan、Do、Check、Action 策划、实施、检查、处置2.PPAP:Production PartApproval Process生产件批准程序3.APQP:Advanced ProductQuality Planning产品质量先期策划4.FMEA:Potential FailureMode and Effects Analysis 潜在失效模式及后果分析5.SPC:Statistical ProcessControl统计过程控制6.MSA:Measurement SystemAnalysis 测量系统控制7.CP:Control Plan 控制计划8.QSA:Quality SystemAssessment 质量体系评定9.PPM:Parts Per Million 每百万零件不合格数10.QM:Quality Manua质量手册11.QP:Quality Procedure质量程序文件/Quality Planning质量策划/Quality Plan 质量计划12.CMK:机器能力指数13.CPK:过程能力指数14.CAD:Computer-AidedDesign 计算机辅助能力设计15.OEE:Overall Equipment Effectiveness 设备总效率16.QFD:Quality FunctionDeployment质量功能展开17.FIFO:First in, First out先进先出18.COPS:Customer OrientedProcesses顾客导向过程19.TCQ:Time、Cost、Quality时间、成本、质量20.MPS:Management Processes管理性过程21.SPS:Support Processes支持性过程22.TQM:Total QualityManagement全面质量管理23.PQA:Product QualityAssurance产品质量保证(免检)24.QP-QC-QI:质量三步曲,质量计划-质量控制-质量改进25.QAF:Quality AssuranceFile质量保证文件26.QAP:Quality AssurancePlan质量保证计划27.PFC:Process Flow Chart过程流程图28.QMS:Quality ManagementSystems质量管理体系29.JIT:Just In Time准时(交货)30.ERP:EnterpriseRequirement Planning企业需求计划31.QC:Quality Control 质量控制32.QA:Quality Audit 质量审核/QalityAssurance 质量保证33.IQC:In Come QualityControl 进货质量控制34.IPQC:In Process QualityControl 过程质量控制35.FQC:Final QualityControl 成品质量控制36.OQC:Out Quality Control 出货质量控制37.4M1E:Man、Machine、Material、Method、Environment人、机、料、法、环38.5W1H:Why、What、Who、When、Where、How 为何/做什么/谁做/时间/地点/如何做39.6S:Seiri、Seiton、Seiso、Seiketsu、Shitsuke、Safety 整理、整顿、清扫、清洁、素养、安全40.TRI值:Total Record Injury(三种)可记录工伤值41.SMART:精明原则,SpecificMeasurable Achievable Result Oriented Timed(具体的描述、可以测量的、可以通过努力实现的、有结果导向性的、有时间性的)——————企业常用英文缩写——————1.5S:5S管理2.ABC:作业制成本制度(Activity-BasedCosting)3.ABB:实施作业制预算制度(Activity-BasedBudgeting)4.ABM:作业制成本管理(Activity-BaseManagement)5.APS:先进规画与排程系统(AdvancedPlanning and Scheduling)6.ASP:应用程序服务供货商(ApplicationService Provider)7.ATP:可承诺量(Available ToPromise)8.AVL:认可的供货商清单(ApprovedVendor List)9.BOM:物料清单(Bill OfMaterial)10.BPR:企业流程再造(BusinessProcess Reengineering)11.BSC:平衡记分卡(BalancedScoreCard)12.BTF:计划生产(Build ToForecast)13.BTO:订单生产(Build To Order)14.CPM:要径法(Critical PathMethod)15.CPM:每一百万个使用者会有几次抱怨(Complaintper Million)16.CRM:客户关系管理(CustomerRelationship Management)17.CRP:产能需求规划(CapacityRequirements Planning)18.CTO:客制化生产(ConfigurationTo Order)19.DBR:限制驱导式排程法(Drum-Buffer-Rope)20.DMT:成熟度验证(DesignMaturing Testing)21.DVT:设计验证(DesignVerification Testing)22.DRP:运销资源计划(DistributionResource Planning)23.DSS:决策支持系统(DecisionSupport System)24.EC:设计变更/工程变更(EngineerChange)25.EC:电子商务(ElectronicCommerce)26.ECRN:原件规格更改通知(EngineerChange Request Notice)27.EDI:电子数据交换(ElectronicData Interchange)28.EIS:主管决策系统(ExecutiveInformation System)29.EMC:电磁相容(ElectricMagnetic Capability)30.EOQ:基本经济订购量(EconomicOrder Quantity)31.ERP:企业资源规划(EnterpriseResource Planning)32.FAE:应用工程师(FieldApplication Engineer)33.FCST:预估(Forecast)34.FMS:弹性制造系统(FlexibleManufacture System)35.FQC:成品质量管理(Finish orFinal Quality Control)36.IPQC: 制程质量管理(In-ProcessQuality Control)37.IQC:进料质量管理(IncomingQuality Control)38.ISO:国际标准组织(InternationalOrganization for Standardization)39.ISAR:首批样品认可(InitialSample Approval Request)40.JIT:实时管理(Just In Time)41.KM:知识管理(KnowledgeManagement)42.L4L:逐批订购法(Lot-for-Lot)43.LTC:最小总成本法(Least TotalCost)44.LUC:最小单位成本(Least UnitCost)45.MES:制造执行系统(ManufacturingExecution System)46.MO:制令(Manufacture Order)47.MPS:主生产排程(MasterProduction Schedule)48.MRO:请修(购)单(MaintenanceRepair Operation)49.MRP:物料需求规划(MaterialRequirement Planning)50.MRPII:制造资源计划(ManufacturingResource Planning)51.NFCF:更改预估量的通知Notice forChanging Forecast52.OEM:委托代工(OriginalEquipment Manufacture)53.ODM:委托设计与制造(OriginalDesign & Manufacture)54.OLAP:在线分析处理(On-LineAnalytical Processing)55.OLTP:在线交易处理(On-LineTransaction Processing)56.OPT:最佳生产技术(OptimizedProduction Technology)57.OQC:出货质量管理(Out-goingQuality Control)58.PDCA:PDCA管理循环(Plan-Do-Check-Action)59.PDM:产品数据管理系统(ProductData Management)60.PERT:计划评核术(ProgramEvaluation and Review Technique)61.PO:订单(Purchase Order)62.POH:预估在手量(Product onHand)63.PR:采购申请(PurchaseRequest)64.QA:品质保证(QualityAssurance)65.QC:质量管理(Quality Control)66.QCC:品管圈(Quality ControlCircle)67.QE:品质工程(QualityEngineering)68.RCCP:粗略产能规划(Rough CutCapacity Planning)69.RMA:退货验收(ReturnedMaterial Approval)70.ROP:再订购点(Re-Order Point)71.SCM:供应链管理(Supply ChainManagement)72.SFC:现场控制(Shop FloorControl)73.SIS:策略信息系统(StrategicInformation System)74.SO:订单(Sales Order)75.SOR:特殊订单需求(Special OrderRequest)76.SPC:统计制程管制(StatisticProcess Control)77.TOC:限制理论(Theory ofConstraints)78.TPM:全面生产管理(TotalProduction Management)79.TQC:全面质量管理(Total QualityControl)80.TQM:全面品质管理(Total QualityManagement)81.WIP:在制品(Work In Process)——————部门名称的专有名词——————QS:Quality system品质系统CS:Coutomer Sevice 客户服务QC:Quality control品质管理IQC:Incoming quality control 进料检验LQC:Line Quality Control 生产线品质控制IPQC:In process quality control 制程检验FQC:Final quality control 最终检验OQC:Outgoing quality control 出货检验QA:Quality assurance 品质保证SQA:Source(supplier) Quality Assurance 供应商品质保证(VQA) CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance 制程品质保证QE:Quality engineer 品质工程CE:component engineering零件工程EE:equipment engineering设备工程ME:manufacturing engineering制造工程TE:testing engineering测试工程PPE roduct Engineer 产品工程IE:Industrial engineer 工业工程ADM: Administration Department行政部RMA:客户退回维修CSDI:检修PC:producing control生管MC:mater control物管GAD: General Affairs Dept总务部A/D: Accountant /Finance Dept会计LAB: Laboratory实验室DOE:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD: Product Department生产部PA:采购(PUR: Purchaing Dept)SMT:Surface mount technology 表面粘着技术MFG:Manufacturing 制造MIS:Management information system 资迅管理系统DCC:document control center 文件管制中心——————场内作业中的专有名词——————QT:Quality target品质目标QP:Quality policy目标方针QI:Quality improvement品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX:Maximum最大值MIN:Minimum最小值DIA iameter直径DIM imension尺寸LCL:Lower control limit管制下限UCL:Upper control limit管制上限EMI:电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement 连续工序改善Compatibility:兼容性Marking:标记DWG rawing图面Standardization:标准化Consensus:一致Code:代码ZD:Zero defect零缺点Tolerance:公差Subject matter:主要事项Auditor:审核员BOM:Bill of material物料清单Rework:重工ID:identification识别,鉴别,证明PILOT RUN: (试投产)FAI:首件检查FPIR:First Piece Inspection Report首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index(准确度)CPK: capability index of process(制程能力) PMP:制程管理计划(生产管制计划)MPI:制程分析DAS efects Analysis System 缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number批号Version:版本Quantity:数量Valid date:有效日期MIL-STD:Military-Standard军用标准ICT: In Circuit Test (线路测试)ATE:Automatic Test Equipment自动测试设备MO: Manafacture Order生产单T/U: Touch Up (锡面修补)I/N:手插件P/T:初测F/T: Function Test (功能测试-终测)AS 组立P/K:包装TQM:Total quality control全面品质管理MDA:manufacturing defect analysis制程不良分析(ICT) RUN-IN:老化实验HI-pot:高压测试FMI:Frequency Modulation Inspect高频测试DPPM: Defect Part Per Million(不良率的一种表达方式:百万分之一) 1000PPM即为0.1% Corrective Action: (CAR改善对策)ACC:允收REJ:拒收S/S:Sample size抽样检验样本大小SI-SIV:Special I-Special IV特殊抽样水平等级CON:Concession / Waive特采ISO:国际标准化组织ISA:Industry Standard Architecture工业标准体制结构OBA:开箱稽核FIFO:先进先出PDCA:管理循环Plan do check action计划,执行,检查,总结WIP:在制品(半成品)S/O: Sales Order (业务订单)P/O: Purchase Order (采购订单)P/R: Purchase Request (请购单)AQL:acceptable quality level允收品质水准LQL;Limiting quality level最低品质水准QVL:qualified vendor list合格供应商名册AVL :认可的供货商清单(Approved Vendor List) QCD: Quality cost delivery(品质,交期,成本)MPM:Manufacturing project management制造专案管理KPI:Key performance indicate重要绩效指标MVT:Manufacturing Verification Test制造验证试产Q/R/S:Quality/Reliability/Service质量/可靠度/服务STL:ship to line(料到上线)NTF:No trouble found误判CIP:capacity improvement plan(产能改善计划)MRB:material review board(物料审核小组)MRB:Material reject bill退货单JIT:just in time(即时管理)5S:seiri seiton seiso seiketsu shitsuke(整理,整顿,清扫,清洁,修养)SOP:standard operation process(标准作业程序)SIP:Specification inspection process制程检验规格TOP: Test Operation Process (测试作业流程)WI: working instruction(作业指导书)SMD:surface mounting device(表面粘着原件)FAR:failure aualysis report故障分析报告CAR:Corrective action report改善报告BPR:企业流程再造(Business Process Reengineering)ISAR :首批样品认可(Initial Sample Approval Request)-JIT:实时管理(Just In Time)QCC :品管圈(Quality Control Circle)Engineering Department (工程部)TQEM: Total Quality Environment Management(全面品质环境管理)PD: Production Department (制造)LOG: Logistics (后勤支持)Shipping: (进出口)AOQ:Average Output Quality平均出货质量AOQL:Average Output Quality Level平均出货质量水平FMEA:failure model effectiveness analysis失效模式分析CRB: Change Review Board (工程变更会议)CSA:Customer Simulate Analysis客户模拟分析SQMS:Supplier Quality Management System供应商品质管理系统QIT: Quality Improvement Team 品质改善小组QIP:Quality Improvement Plan品质改善计划CIP:Continual Improvement Plan持续改善计划M.Q.F.S: Material Quality Feedback Sheet (来料品质回馈单) SCAR: Supplier Corrective Action Report (供货商改善对策报告)8D Sheet: 8 Disciplines sheet ( 8D单)PDCA:PDCA (Plan-Do-Check-Action) (管理循环)MPQ: Material Packing Quantity (物料最小包装量) DSCN: Delivery Schedule Change Notice (交期变更通知) QAPS: Quality Assurance Process Sheet (品质工程表) DRP :运销资源计划(Distribution Resource Planning) DSS:决策支持系统(Decision Support System)EC :电子商务(Electronic Commerce)EDI :电子资料交换(Electronic Data Interchange)EIS :主管决策系统(Excutive Information System)ERP:企业资源规划(Enterprise Resource Planning) FMS :弹性制造系统(Flexible Manufacture System)KM :知识管理(Knowledge Management)4L :逐批订购法(Lot-for-Lot)LTC :最小总成本法(Least Total Cost)LUC :最小单位成本(Least Unit Cost)MES :制造执行系统(Manufacturing Execution System) MPS :主生产排程(Master Production Schedule)MRP :物料需求规划(Material Requirement Planning) MRPⅡ:制造资源计划(Manufacturing Resource Planning) OEM :委托代工(Original Equipment Manufacture) ODM :委托设计与制造(Original Design & Manufacture) OLAP:线上分析处理(On-Line Analytical Processing) OLTP:线上交易处理(On-Line Transaction Processing)OPT :最佳生产技术(Optimized Production Technology) PDCA:PDCA管理循环(Plan-Do-Check-Action) PDM:产品数据管理系统(Product Data Management)) RCCP:粗略产能规划(Rough Cut Capacity Planning) SCM :供应链管理(Supply Chain Management)SFC :现场控制(Shop Floor Control)TOC:限制理论(Theory of Constraints)TQC :全面品质管制(Total Quality Control)FYI/R:for your information/reference仅供参考ASAP:尽快S/T:Standard time标准时间TPM:total production maintenance:全面生产保养ESD Wrist strap:静电环IT:information technology信息技术,资讯科学CEO:Chief Executive Officer执行总裁COO:Chief Operaring Officer首席业务总裁SWOT:Strength,Weakness,Opportunity,Threat优势﹐弱点﹐机会﹐威胁Competence:专业能力Communication:有效沟通Cooperation:统御融合Vibration Testing:振动测试IDP:Individual Development Plan个人发展计划MRP:Material Requirement Planning物料需求计划MAT'S:Material材料LRR:Lot Rejeet Rate批退率ATIN:Attention知会3C:Computer ,Communication , Consumer electronic消费性电子5W1H:When , Where , Who , What , Why , Ho5M: Man , Machine , Material , Method , Measurement人,机器,材料,方法,测量4MIE: Man,Material,Machine,Method,Environment人力,物力,财务,技术,时间(资源)7M1I: Manpower , Machine , Material , Method, Market , Management , Money , Information人力,机器,材料,方法, 市场,管理,资金,资讯Accuracy 准确度Action 行动Activity 活动Analysis Covariance 协方差分析Analysis of Variance 方差分析Approved 承认Attribute 计数值Average 平均数Balance sheet 资产负债对照表Binomial 二项分配Brainstorming Techniques 脑力风暴法Cause and Effect Matrix 因果图(鱼骨图)CL:Center Line 中心线Check Sheets 检查表Complaint 投诉Conformity 合格(符合)Control 控制Control chart 控制(管制)图Correction 纠正Correlation Methods 相关分析法CPI: continuouse Process Improvement 连续工序改善 Cross Tabulation Tables 交叉表CS: Customer Sevice 客(户)服(务)中心DSA: Defects Analysis System 缺陷分析系统Data 数据Description:品名DCC: Document Control Center 文控中心Decision 决策、判定Defects per unit 单位缺点数Description 描述Device 装置Do 执行DOE: Design of Experiments 实验设计Element 元素Engineering recbnology 工程技Environmental 环境Equipment 设备Estimated accumulative frequency 计算估计累计数E Equipment Variation 设备变异External Failure 外部失效,外部缺陷FA: Failure Analysis 失效分析Fact control 事实管理Fatigue 疲劳FMEA: Failure Mode and Effect Analysis失效模式与效果分析 FP First-Pass Yield (第一次通过)合格率FQA: Final Quality Assurance 最终品质保证FQC: Final Quality control 最终品质控制Gauge system 测量系统Grade 等级Histogram 直方图Improvement 改善Initial review 先期审查Inspection 检验Internal Failure 内部失效、内部缺陷IPQC: In Process Quality Control 制程品质控制IQC: Incomming Quality Control 来料品质控制IS International Organization for Standardization 国际标准化组织 LCL: Lower Control limit 管制下限LQC: Line Quality Control 生产线品质控制LSL: Lower Size Limit 规格下限Machine 机械Manage 管理Materials 物料Measurement 测量Median 中位数MSA: Measurement System Analysis 测量系统分析Occurrence 发生率Operation Instruction 作业指导书Organization 组织Parto 柏拉图PPM arts per Million (百万分之)不良率Plan 计划Policy 方针Population 群体PQA: Process Quality Assurance 制程品质保证Practice 实务(践)Prevention 预防Probability 机率Probability density function 机率密度函数Procedure 流程Process 过程Process capability analysis 制程能力分析(图)Process control and Process capability制程管制与制程能力 Product 产品Production 生产Projects 项目QA: Quality Assurance 品质保证QC: Quality Control 品质控制QE: Quality Engineering 品质工程QFD: Quality Function Desgin 品质机能展开(法)Quality 质量Quality manual 品质手册Quality policy 品质政策(质量方针)Random experiment 随机试验Random numbers 随机数R:Range 全距(极差)Reject 拒收Repair 返修Repeatusility 再现性Reproducibility 再生性Requirement 要求Responsibilities 职责Review 评审Reword 返工Rolled yield 直通率RPN: Risk Priority Number 风险系数Sample 抽样,样本Sample space 样本空间Sampling with replacement 放回抽样Sampling without replacement 不放回抽样Scatter diagram 散布图分析Scrap 报废Simple random sampling 简单随机取样Size 规格SL: Size Line 规格中心线Stratified random sampling 分层随机抽样SOP: Standard Operation Procedure 标准作业书SPC: Statistical Process Control 统计制程管制Specification 规范SQA: Source(Supplier) Quality Assurance 供货商品质保证Stage sampling 分段随机抽样Standard Deviation 标准差Sum of squares 平方和Taguchi-method 田口(试验)方法Theory 原理TQC: Total Quality Control 全面品质控制TQM: Total Quality Management 全面品质管理Traceablity 追溯Training 培训UCL: Upper Control Limit 管制(控制)上限USL: Upper Size Limit 规格上限Validation 确认Variable 计量值Verification 验证Version 版本VOC: Voice of Customer 客户需求VOE: Voice of Engineer 工程需求Inventory stock report:庫存清单报告Sales order report:出货报告。

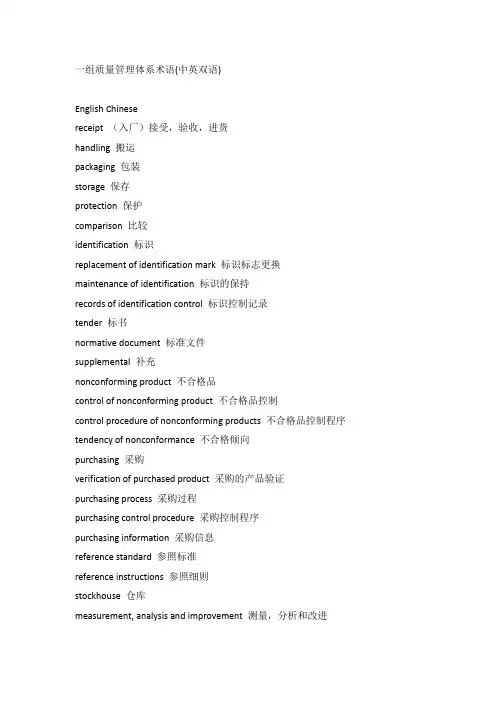

一组质量管理体系术语(中英双语English Chinesereceipt (入厂接受,验收,进货handling 搬运packaging 包装storage 保存protection 保护comparison 比较identification 标识replacement of identification mark 标识标志更换maintenance of identification 标识的保持records of identification control 标识控制记录tender 标书normative document 标准文件supplemental 补充nonconforming product 不合格品control of nonconforming product 不合格品控制control procedure of nonconforming products 不合格品控制程序tendency of nonconformance 不合格倾向purchasing 采购verification of purchased product 采购的产品验证purchasing process 采购过程purchasing control procedure 采购控制程序purchasing information 采购信息reference standard 参照标准reference instructions 参照细则stockhouse 仓库measurement, analysis and improvement 测量,分析和改进measurement result 测量结果control procedure of monitoring and measuring devices 测量设备控制程序planning 策划preservation of product 产品保护control procedure for maintenance, replacement and records of product identification 产品标识的保持,更换及记录控制程序procedure for product identification and traceability 产品标识和可追溯性程序conformity of product 产品的符合性monitoring and measurement of product 产品的监督和测量product plan 产品方案control procedure for product preservation 产品防护控制程序method of product release 产品放行方法conformity of product,product conformity 产品符合性product realization 产品实现planning of product realization 产品实现策划product characteristics 产品特性input to product requirements 产品要求的输入product status 产品状态final acceptance of product 产品最后验收procedure 程序program documents 程序文件continual improvement 持续改进procedure for continual improvement of quality management system 持续改进质量体系程序adequacy 充分性storage location 存放地点agency personnel 代理人员submission of tenders 递交标书adjustment 调整,调节statutory and regulatory requirements 法律法规要求rework, vt 返工repair, vt 返修subcontractor 分承包方annex 附录improvement 改进improvement actions 改进措施on-the—job training 岗位技能培训responsibility of individual department and post 各部门,各岗位职责change identification 更改标记change order number 更改单编号process sheets 工艺单process specification 工艺规程procedure(process card 工艺规程(工艺卡process characteristics 工艺特性Job Description Format 工种描述单work environment 工作环境impartiality 公正性functional requirements 功能要求supplier 供方supplier evaluation procedure 供方评价程序supplier provided special processes 供方提供的特殊过程verification at supplier's premises 供方现场验证supply chain 供应链criteria for supplier selection, evaluation and re—evaluation 供应商选择、评估和再评估准则communication 沟通customer 顾客customer property 顾客财产control procedure for customer property 顾客财产控制程序customer feedback 顾客反馈Customer Service Contact Form 顾客服务联系表customer cummunications 顾客沟通customer satisfaction 顾客满意statistical analysis of customer satisfaction 顾客满意度统计分析customer complaint 顾客投诉identificaion of customer requirements 顾客要求的识别management review 管理评审records from management review 管理评审记录management review control procedure 管理评审控制程序management representative 管理者代表management responsibility 管理职责specified limits of acceptability 规定的可接受界限specified use 规定的用途process 过程complexity of processes 过程的复杂性monitoring and measurement of processes 过程的监视和测量operation of process 过程的运行status of processes 过程的状态process approach 过程方法process controls 过程控制process control documents 过程控制文件process performance 过程业绩appropriateness 合适性changes to contractor 合同的更改contract review control procedure 合同评审控制程序internet sales 互联网销售environmental conditions 环境条件monogram pragram requirements 会标纲要要求type of activities 活动类型infrastructure 基础建设infrastructure 基础设施fundamentals and vocabulary 基础与词汇control of records 记录控制technical specificaion 技术规范process trace sheet 加工跟踪单monitoring and measurement 监视和测量monitoring and measuring device 监视和测量装置control of monitoring and measuring devices 监视和测量装置控制check method 检查方法frequency of checks 检查频次calibration status 检定状态inspection and test control procedure 检验和试验控制程序identification procedure for inspection and test status 检验和试验状态标识程序inspection witness point 检验见证点inspection hold point 检验停止点buildings 建筑物delivery 交付post-delivery activities 交付后的活动delivery activities 交付活动interface 接口acceptance of contract or orders 接受合同或定单type of medium 介质类型experience 经验correction action 纠正措施Corrective action response time 纠正措施答复时间,纠正措施响应时间management procedure for corrective actions 纠正措施管理程序corrective action response times 纠正措施响应时间development activity 开发活动traceability mark 可追溯性标志objectivity 客观性Customer Service Log 客户服务记录簿control feature 控制特性,控制细节control features 控制细则periodic assessment of stock 库存定期评估justification 理由routine 例程,惯例,常规质量职能分配表论证范围internal communication 内部沟通internal audit 内部审核internal audit procedure 内部审核程序internally controlled standard 内控标准internal audit 内审results of internal and external audits 内外部审核结果competence 能力training 培训training needs 培训需要evaluate 评价records of the results of the review 评审结果的记录review output 评审输出review input 评审输入Purchase Requisition 请购单authority 权限validation 确认concession 让步human resources 人力资源job training of personnel 人员岗位培训qualification of personnel 人员资格equipment control procedure 设备控制程序device type 设备类型order of design changes 设计更改通知单design and development control procedure 设计和开发控制程序design and development 设计开发design and development planning 设计开发策划control of design and development changes 设计开发更改控制design and development review 设计开发评审design and development validation 设计开发确认design and development outputs 设计开发输出design and development inputs 设计开发输入design and development verification 设计开发验证design validation 设计确认design documentation 设计文件编制design acceptance criteria 设计验收准则design verification 设计验证audit program 审核大纲conduct of audits 审核行为audit criteria 审核准则production process control 生产过程控制production process control procedure 生产过程控制程序production and service provision 生产和服务提供control of production and service provision 生产和服务提供的控制validation of processes for production and service provision 生产和服务提供过程的确认production order 生产令identification and traceability 识别和可追溯性identification and traceability maintenance and replacement 识别和可追溯性维护与替换invalidate 使失效market survey 市场调研suitability 适宜性scope 适用范围controlled condition 受控状态terms and definitions 术语与定义analysis of data 数据分析sequence 顺序transfer of ownership 所有权转移system document 体系文件statistical technique 统计方法outsource(vt a process 外包过程external source 外部来源documents of external origin 外来文件outsource, vt 外协unique identification 唯一的标识maintenance 维护Document Change Control 文件更改控制Request For Document Change (RDC 文件更改需求单control of documents 文件控制documentation requirements 文件要求enquiry 问询,询价field nonconformity analysis 现场不符合分析relevance 相关性interaction 相互作用detail design 详细设计,详图设计,零件设计,施工设计sales department 销售部sales contract 销售合同checklist 校验表,一览表,检查一览表calibration 校准submission of action plans 行动计划的递交documented procedures 形成文件的程序documented statement 形成文件的声明performance requirements 性能要求licensee responsibilities 许可证持有者责任acceptance criteria 验收准则verification arrangement 验证安排verification results 验证结果customer focus 以客户为关注点,以客户为焦点awareness 意识introduction 引言,概述,介绍normative references 引用标准application 应用visit to user 用户访问review of requirements related to the product 有关产品的要求评审competent 有能力的effectiveness 有效性determination of requirements related to the product 与产品有关的要求的确定customer-related processes 与顾客有关的过程preventive action 预防措施management procedure for preventive actions 预防措施管理程序planned results 预期的结果intended use 预期的用途procedure for competence, knowledge and training of personnel 员工能力, 知识和培训程序personnel training procedure 员工培训程序supporting services 支持性服务functions 职能部门responsibility 职责assignment of responsibility 职责分工workmanship 制造工艺manufacturing acceptance criteria 制造验收准则quality policy 质量方针quality programs 质量纲领quality management system 质量管理体系quality management system planning 质量管理体系策划performance of the quality management system 质量管理体系业绩quality plan 质量计划quality records 质量记录quality objectives 质量目标quality audit 质量审核quality manual 质量手册quality problem handling form 质量问题处理单quality requirements 质量要求allocation table of quality responsibilities 质量职能分配表availability of resources 资源的可获得性resource management 资源管理allocation of resources 资源配置provision of resources 资源提供general requirements 总要求,一般要求constituent part 组成部件organization 组织continual improvement of the organization 组织的持续改进size of organization 组织的规模Organizational Diagram 组织机构图final acceptance 最终验收 work instructions 作业指导书。

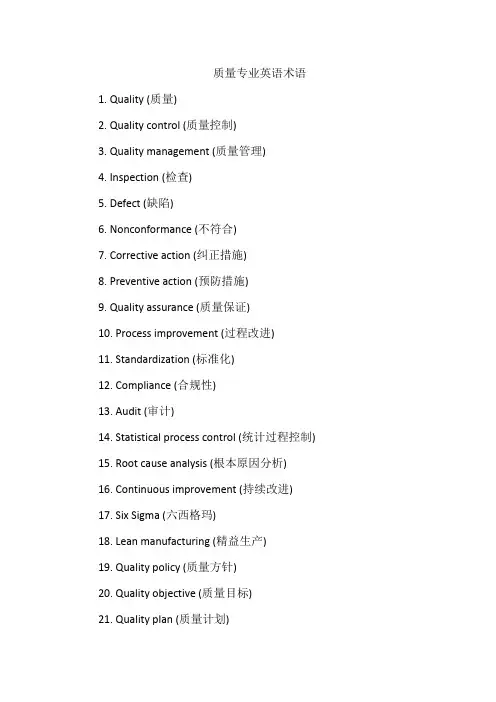

质量部英文专业术语

以下是质量部常用的英文专业术语:

1. Quality Assurance (QA) -量保证

2. Quality Control (QC) 质量控制

3. Defect -缺陷

4. Nonconformance -不合格

5. Inspection -检查、验收

6. Audit -审计

7. Corrective Action -纠正措施

8. Preventive Action -预防措施

9. Root Cause Analysis -根本原因分析

10. Continuous Improvement -持续改进

11. Six Sigma -六西格玛(一种追求减少变异和提高质量的管理方法)

12. Lean Manufacturing -精益生产(通过消除浪费和提高价值流来提高效率和质量)

13. Statistical Process Control (SPC) -统计过程控制

14. Failure Mode and Effects Analysis (FMEA) -失效模式与影响分析

15. Quality Management System (QMS) -质量管理体系

这些术语是质量管理和质量控制领域中常见的英文专业术语,用于描述和讨论质量相关的概念、方法和工作流程。

一组质量管理体系术语(中英双语)English Chinesereceipt (入厂)接受,验收,进货handling 搬运packaging 包装storage 保存protection 保护comparison 比较identification 标识replacement of identification mark 标识标志更换maintenance of identification 标识的保持records of identification control 标识控制记录tender 标书normative document 标准文件supplemental 补充nonconforming product 不合格品control of nonconforming product 不合格品控制control procedure of nonconforming products 不合格品控制程序tendency of nonconformance 不合格倾向purchasing 采购verification of purchased product 采购的产品验证purchasing process 采购过程purchasing control procedure 采购控制程序purchasing information 采购信息reference standard 参照标准reference instructions 参照细则stockhouse 仓库measurement, analysis and improvement 测量,分析和改进measurement result 测量结果control procedure of monitoring and measuring devices 测量设备控制程序planning 策划preservation of product 产品保护control procedure for maintenance, replacement and records of product identification 产品标识的保持, 更换及记录控制程序procedure for product identification and traceability 产品标识和可追溯性程序conformity of product 产品的符合性monitoring and measurement of product 产品的监督和测量product plan 产品方案control procedure for product preservation 产品防护控制程序method of product release 产品放行方法conformity of product,product conformity 产品符合性product realization 产品实现planning of product realization 产品实现策划product characteristics 产品特性input to product requirements 产品要求的输入product status 产品状态final acceptance of product 产品最后验收procedure 程序program documents 程序文件continual improvement 持续改进procedure for continual improvement of quality management system 持续改进质量体系程序adequacy 充分性storage location 存放地点agency personnel 代理人员submission of tenders 递交标书adjustment 调整,调节statutory and regulatory requirements 法律法规要求rework, vt 返工repair, vt 返修subcontractor 分承包方annex 附录improvement 改进improvement actions 改进措施on-the-job training 岗位技能培训responsibility of individual department and post 各部门, 各岗位职责change identification 更改标记change order number 更改单编号process sheets 工艺单process specification 工艺规程procedure(process card) 工艺规程(工艺卡)process characteristics 工艺特性Job Description Format 工种描述单work environment 工作环境impartiality 公正性functional requirements 功能要求supplier 供方supplier evaluation procedure 供方评价程序supplier provided special processes 供方提供的特殊过程verification at supplier's premises 供方现场验证supply chain 供应链criteria for supplier selection, evaluation and re-evaluation 供应商选择、评估和再评估准则communication 沟通customer 顾客customer property 顾客财产control procedure for customer property 顾客财产控制程序customer feedback 顾客反馈Customer Service Contact Form 顾客服务联系表customer cummunications 顾客沟通customer satisfaction 顾客满意statistical analysis of customer satisfaction 顾客满意度统计分析customer complaint 顾客投诉identificaion of customer requirements 顾客要求的识别management review 管理评审records from management review 管理评审记录management review control procedure 管理评审控制程序management representative 管理者代表management responsibility 管理职责specified limits of acceptability 规定的可接受界限specified use 规定的用途process 过程complexity of processes 过程的复杂性monitoring and measurement of processes 过程的监视和测量operation of process 过程的运行status of processes 过程的状态process approach 过程方法process controls 过程控制process control documents 过程控制文件process performance 过程业绩appropriateness 合适性changes to contractor 合同的更改contract review control procedure 合同评审控制程序internet sales 互联网销售environmental conditions 环境条件monogram pragram requirements 会标纲要要求type of activities 活动类型infrastructure 基础建设infrastructure 基础设施fundamentals and vocabulary 基础与词汇control of records 记录控制technical specificaion 技术规范process trace sheet 加工跟踪单monitoring and measurement 监视和测量monitoring and measuring device 监视和测量装置control of monitoring and measuring devices 监视和测量装置控制check method 检查方法frequency of checks 检查频次calibration status 检定状态inspection and test control procedure 检验和试验控制程序identification procedure for inspection and test status 检验和试验状态标识程序inspection witness point 检验见证点inspection hold point 检验停止点buildings 建筑物delivery 交付post-delivery activities 交付后的活动delivery activities 交付活动interface 接口acceptance of contract or orders 接受合同或定单type of medium 介质类型experience 经验correction action 纠正措施Corrective action response time 纠正措施答复时间,纠正措施响应时间management procedure for corrective actions 纠正措施管理程序corrective action response times 纠正措施响应时间development activity 开发活动traceability mark 可追溯性标志objectivity 客观性Customer Service Log 客户服务记录簿control feature 控制特性,控制细节control features 控制细则periodic assessment of stock 库存定期评估justification 理由routine 例程,惯例,常规质量职能分配表论证范围internal communication 内部沟通internal audit 内部审核internal audit procedure 内部审核程序internally controlled standard 内控标准internal audit 内审results of internal and external audits 内外部审核结果competence 能力training 培训training needs 培训需要evaluate 评价records of the results of the review 评审结果的记录review output 评审输出review input 评审输入Purchase Requisition 请购单authority 权限validation 确认concession 让步human resources 人力资源job training of personnel 人员岗位培训qualification of personnel 人员资格equipment control procedure 设备控制程序device type 设备类型order of design changes 设计更改通知单design and development control procedure 设计和开发控制程序design and development 设计开发design and development planning 设计开发策划control of design and development changes 设计开发更改控制design and development review 设计开发评审design and development validation 设计开发确认design and development outputs 设计开发输出design and development inputs 设计开发输入design and development verification 设计开发验证design validation 设计确认design documentation 设计文件编制design acceptance criteria 设计验收准则design verification 设计验证audit program 审核大纲conduct of audits 审核行为audit criteria 审核准则production process control 生产过程控制production process control procedure 生产过程控制程序production and service provision 生产和服务提供control of production and service provision 生产和服务提供的控制validation of processes for production and service provision 生产和服务提供过程的确认production order 生产令identification and traceability 识别和可追溯性identification and traceability maintenance and replacement 识别和可追溯性维护与替换invalidate 使失效market survey 市场调研suitability 适宜性scope 适用范围controlled condition 受控状态terms and definitions 术语与定义analysis of data 数据分析sequence 顺序transfer of ownership 所有权转移system document 体系文件statistical technique 统计方法outsource(vt) a process 外包过程external source 外部来源documents of external origin 外来文件outsource, vt 外协unique identification 唯一的标识maintenance 维护Document Change Control 文件更改控制Request For Document Change (RDC) 文件更改需求单control of documents 文件控制documentation requirements 文件要求enquiry 问询,询价field nonconformity analysis 现场不符合分析relevance 相关性interaction 相互作用detail design 详细设计,详图设计,零件设计,施工设计sales department 销售部sales contract 销售合同checklist 校验表,一览表,检查一览表calibration 校准submission of action plans 行动计划的递交documented procedures 形成文件的程序documented statement 形成文件的声明performance requirements 性能要求licensee responsibilities 许可证持有者责任acceptance criteria 验收准则verification arrangement 验证安排verification results 验证结果customer focus 以客户为关注点,以客户为焦点awareness 意识introduction 引言,概述,介绍normative references 引用标准application 应用visit to user 用户访问review of requirements related to the product 有关产品的要求评审competent 有能力的effectiveness 有效性determination of requirements related to the product 与产品有关的要求的确定customer-related processes 与顾客有关的过程preventive action 预防措施management procedure for preventive actions 预防措施管理程序planned results 预期的结果intended use 预期的用途procedure for competence, knowledge and training of personnel 员工能力, 知识和培训程序personnel training procedure 员工培训程序supporting services 支持性服务functions 职能部门responsibility 职责assignment of responsibility 职责分工workmanship 制造工艺manufacturing acceptance criteria 制造验收准则quality policy 质量方针quality programs 质量纲领quality management system 质量管理体系quality management system planning 质量管理体系策划performance of the quality management system 质量管理体系业绩quality plan 质量计划quality records 质量记录quality objectives 质量目标quality audit 质量审核quality manual 质量手册quality problem handling form 质量问题处理单quality requirements 质量要求allocation table of quality responsibilities 质量职能分配表availability of resources 资源的可获得性resource management 资源管理allocation of resources 资源配置provision of resources 资源提供general requirements 总要求,一般要求GHTFconstituent part 组成部件organization 组织continual improvement of the organization 组织的持续改进size of organization 组织的规模Organizational Diagram 组织机构图final acceptance 最终验收work instructions 作业指导书页脚内容11。

品质名词(中英对照)AABC analysis ABC 分析Abnormality 不正常性Abscissa 横坐标Absolute deviation 绝对离差Absolute dispersion 绝对离势Absolute error 绝对误差Absolute frequency 绝对次数Absolute number 绝对数Absolute reliability 绝对可靠度Absolute term 绝对项Absolute value 绝对值Absolute variation 绝对变异Abstract number 抽象数Abstract unit 抽象单位Accelerated factor 加速系数,加速因子Accelerated life test 加速寿命试验Accelerated test 加速试验Acceleration 加速度Acceptable limit 允收界限Acceptable process 允收制程水平Acceptable quality 允收品质Acceptable quality level (AQL) 允收质量水平Acceptable reliability level (ARL) 允收可靠度水平Acceptability 允收性Acceptability criterion 允收标准Acceptance 允收,验收Acceptance, probability of 允收机率Acceptance, region of 允收区域Acceptance and rejection criteria 允收与拒收准则Acceptance boundary 允收界限Acceptance coefficient 允收系数Acceptance control chart 验收管制图Acceptance cost 验收费用Acceptance criteria 允收准则Acceptance error 允收误差Acceptance inspection 验收检验Acceptance limit 允收界限Acceptance line 允收线Acceptance number 允收(不良品)数Acceptance plan 验收计划Acceptance procedure 验收程序Acceptance/rectification scheme 允收/精选方案Acceptance sampling, attribute 计数值验收抽样Acceptance sampling, variable 计量值验收抽样Acceptance sampling plan 验收抽样计划Acceptance sampling scheme 验收抽样方案Acceptance test 验收试验Acceptance value 允收值Acceptance zone 允收区域Acceptance product 允收品Accepting lot 允收批Access time 接近时间,故障诊断时间Accessibility 可接近性Accident rate 意外率Accidental error 偶误,偶然误差Accidental fluctuation 偶然波动Accidental movement 意外移动Accounting test 验算(决算)试验Accumulated operating time 累积操作时间Accuracy 准确度Accuracy of data 数据准确度Accuracy of estimation 估计准确度Accuracy of the mean 平均数准确度Achieved availability 实际可用度Action 行动,措施Action, corrective 矫正行动(措施)Action control chart 行动管制图Action limit 行动界限Active line 行动线Active maintenance time 实际维护时间Active parallel redundancy 主动并复联(置)Active preventive maintenance 现行预防维护时间Active redundancy 主动复联(置)Active repair time 实际修复时间Active standby 主动备用Active time 运用时间Actual frequency 实际次数Actual limit 实际界限Actual range 实际全距Actual value 实际值Adaptability 可适应性Adaptive control 修改管制Addition theorem 加法定理Additivity 加法性,可加性Adjusted average 修正平均数Adjusted value 修正值Adjustment factor 调整系数Administration time for a repair 修复之管理时间Administrative time 管理时间Adopted value 采用值Advisory Group on Reliability of Electronic Equipment (AGREE) 电子装备可靠度顾问团Aeronautical Radio, Incorporated (ARINC) 航空无线电公司After-sales service 售后服务Age 年限Age at death 死亡年限Age at failure 失效年限Age-based maintenance 年限基准维护Aggregative method 综合法Aging 老化Agreement of quality assurance 质量保证之协议Agreement on verification method 验(查)证方法之协议Alarm signals 警告(报)讯号Alert time 待命时间Algebraic sum 代数和Algorism (Algorithm) 阿拉伯数字计数法Alias 假名Alienation 余相关Alignment chart 列线图Allocation 配当Allocation of reliability 可靠度配当Allowable percent defective (Acceptable quality level, AQL) 允收不良率(允收质量水平)Allowance 允差,裕度Alternative hypothesis 对立假设American Management Association (AMA) 美国管理协会American National Standards Institute (ANSI) 美国标准协会American Society for Quality Control (ASQC) 美国质量管理学会American Society for Mechanical Engineers (ASME) 美国机械工程师学会American Society for Testing and Materials (ASTM) 美国材料试验学会American Standard Association (ASA) 美国标准协会American Statistical Association (ASA) 美国统计协会American War Standards (AWS) 美国战时标准Ambient condition 周遭条件Analysis, sequential 逐次分析Analysis by accumulated frequency 累积法,累积次数分析Analysis by non-accumulated frequency 次数法,非累积次数分析Analysis of correlation 相关分析Analysis of covariance 共变异数分析Analysis of means (AVON) 平均数分析Analysis of problem 问题之分析Analysis of variance (ANOVA) 变异数分析Analysis sample 分析样本Analytical error 分析误差Angular transformation 角度转(变)换Anti-logarithm 逆对数Anti-mode 逆众数AOQL Sampling Table 平均出厂质量界限抽样数Applicability 应用性Applied statistics 应用统计学Apportionment of reliability 可靠度配当Apportionment techniques 配当技术Appraisal cost 鉴定成本,评估成本Appraisal system 评估制度Appraisal of quality 质量评估Approach to sequential testing 逐次试验法Approval of processes and equipment 核准制程与设备Approximate mode 近似众数Approximate number 近似数值Approximation 近似法,概算AQL (Acceptable quality level) 允收(质量)水平Arbitrary average (Assumed average,Arbitrary mean) 假定平均数Arbitrary origin 假定原点Arbitrary scale 假定标度Area bar chart 面积条图Area chart (diagram, graph) 面积图Area sampling 地区抽样Arithmetic average 算术平均数Arithmetic cross 算术交叉Arithmetic graph 算术图Arithmetic line chart 算术线图Arithmetic mean 算术平均数Arithmetic paper 算术纸Arithmetic probability paper 算术机率纸Arithmetic progression (Arithmetic series) 算术级数,等差级数Arithmetic scale 算术标度,等差标度Arithmetic series 算术级数,等差级数Army Ordnance Table 陆军兵工署(抽样)表Army Service Forces Table 陆军(抽样)表序列Array 序列Array distribution 序列分配(布)Array of data 数据序列Assemble 装配(组立)Assembled product 装配品Assembly 装配件Assembly inspection 装配检验Assembly quality analysis report 装配质量分析报告Assessed failure rate 评估失效率Assessed mean active -maintenance time 评估时间现行维护时间Assessed mean life 评估平均寿命Assessed mean time between failures 评估平均失效间格时间Assessed mean time to failure 评估平均失效前时间Assessed reliability 评估可靠度Assessed value 评估值Assessment of subcontractor 分包商之评鉴Assignable cause (Special cause) 非机遇原因(特殊原因)Assignable variation 非机遇变异Associated dependent variable 相联因变数Associated variate 相联变量Association coefficient 相联系数Association of attribute 品性相联Association table 相联表,联合表Assumed mean (Assumed average,Arbitrary average) 假定平均数Assumed median 假定中位数Assumed origin 假定原点Assurance quality 保证质量Assurance function 保证功能Asymmetrical distribution 不对称分配(布)Asymmetry 不对称Asymptotic distribution 趋近分配(布)At random 随机Attribute 计数值,属性Attribute classification 品性分类Attribute data 计数数据Attribute inspection 计数值检验Attribute sampling 计数值抽样Attribute sampling plan 计数值抽样计划Attribute testing (Go no-go testing) 计数值试验(通过与不通过试验)Attribute value 计数值Audit 稽核Audit for reliability 可靠度稽核Audit of decision 稽核决策Audit plan 稽核计划Audit report 稽核报告Auditing report 稽核报告Auto-correlation 自动相关Automatic switch-over redundancy 自动切换复联(置)Automatic test equipment (Am) 自动试验装备Auto-regression 自动回归Availability 可用性,可用度Average (Mean) 平均数,平均值Average, grand 总平均Average, moving 移动平均数Average, sample 样本平均数Average, standard error of 标准误平均数Average, universe 群体平均数Average, weighted 加权平均数Average amount of inspection 平均检验数Average and range chart 平均数及全距(管制)图Average availability 平均可用度Average deviation (A.D.) (Mean deviation) 平均差Average error (Mean error) 平均误差Average number of defects 平均缺点数Average of ratios 比例平均数Average outgoing quality (AOQ) 平均出厂质量Average outgoing quality curve 平均出厂质量曲线Average outgoing quality level 平均出厂质量水平Average outgoing quality limit (AOQL) 平均出厂水平Average quality level 平均出厂质量界限Average quality level line 质量平均线Average quality protection 平均质量保护Average range 平均全距Average run length (ARL) 平均连串长度Average sample number (ASN) 平均样品数Average range 平均全距Average run length (ARL) 平均连串长度Average sample number(ASN) 平均样本数Average sample number curve 平均样本曲线Average sample size (ASS) 平均样本大小Average sample size curve 平均样本大小曲线Average sample 平均抽样Average total inspection (ATI) 平均总检验(件)数Average total inspection curve 平均总检验数曲线Average value 平均值Avoidable cause 可避免之原因Avoidable quality cost 可避免之质量成本Axiom 公理Axis 轴Axis of abscissa 横轴Axis of ordinate 纵轴BBad lot 坏批Balance frequency 平衡次数Balanced complete type 平衡完备型Balanced design 平衡设计Balanced experiment 平衡实验Balanced incomplete type 平衡不完备型Balanced sample 平衡样本Band chart 带形图Band curve chart 带形曲线图Bank of reliability data 可靠度数据库Bar chart (diagram) 条(形)图Bartlett's test 巴特莱特试验Base line 基线Base number 基数Base period 基期Base point 基点Basic reliability 基本可靠度Batch (Lot) 批Batch of material 材料批Batch process 分批制造方法Batch size 批量Batch testing 批试验Bathtub curve 浴缸曲线Bathtub failure curve 浴缸失效曲线Bayes' estimator 贝式估计式Bayes' theorem 贝式定理Bayesian approach 贝式法Bayesian approcah to design 贝式设计法Bayesian estimation 贝式估计Bead map 标珠图Bell-shaped curve 钟形曲线Bell-shaped distribution 钟形分配(布)Bell-shaped failure pattern 钟形失效型态Bell System 贝尔系统Bell Telephone Laboratories 贝尔电话实验室Bell Telephone Laboratories Sampling Table 贝尔(电话实验室)抽样表Benign failure 无危险的失效Bernoulli distribution 白努利分配(布)Best fit 最适配合Best fitting line 最适线Best fitting curve 最适曲线Best linear invariant estimator 最佳线型不变估计式Best linear unbiased estimator 最佳线型不偏估计式Beta coefficient β系数Beta distribution β分配(布)Beta function β函数Between-class variance 组间变异数Between-column variance 组间变异Between-column variation 行间变异Between-row variation 列间变异Between sample variation 样本间变异Bias 偏差Bias, downward 向下偏差Bias, downward type 向下型偏差Bias, upward 向上偏差Bias, upward type 向上型偏差Biased error 偏误Biased estimate 偏差估计Biased sample 偏差样本Biased test 偏差试验Bilateral 双边Bill of material (BOM) 物料清单Bimodal 双峰Bimodal curve 双峰曲线Bimodal distribution 双峰分配(布)Bimodal redundancy 双峰型复联(置)Bimodality 双峰性Binary system 二元制Binomial, skewed 偏态二项Binomial coefficient 二项系数Binomial curve 二项曲线Binomial distribution 二项分配(布)Binomial equation 二项方程式Binomial expansion 二项展开式Binomial population 二项群体Binomial probability distribution 二项机率分配(布)Binomial probability paper(BIPP) 二项机率纸Binomial series 二项级数Binomial theorem 二项定理Bi-serial 双数列Biserial correlation 双数列相关Biserial coefficient of correlation 双数列相关系数Biserial ratio of correlation 双数列相关比Bivariate 双变量Bivariate distribution 双变量分配(布)Bivariate frequency distribution 双变量次数分配(布)Bivariate normal distribution 双变量常态分配(布)Blend 混,混合Block 量块,(实验)区,方块Block design 实验区设计Block diagram 方块图Block factor 地区因素Block in series 串联方块Boundary 界Boundary, cell 组界Bowker-Goode variables plan Bowker-Goode 记量值(抽样)计划Bowl drawing 碗珠抽样Bowl experiment 碗珠实验Bowl test 碗珠试验Bowley's coefficient of skewness Bowley偏态系数Bowley's formula Bowley公式Bureau of Ordnance, U.S. Navy 美国海军兵工署Break-even chart 损益平衡图Break-even point (BEP) 损益平衡点Breakthrough 突破British Standards Institution 英国标准协会Broken curve 中断曲线Broken series 中断数列Broken trend 中断趋势Built-in test (BIT) 内含测试,自测Bureau of Commodity Inspection and Quarantine (BCIQ) 商品检验局Bulk sampling Burn-in 大宗抽样Business Process Management (BPM) 业务流程管理Buyer 买方,客户CC chart C(管制)图Calculated value (Computed value) 计算值Calculation chart 计算图Calendar time 日历时间Calibration 校正Calibration record 校正记录Camp-Meidell inequality Camp-Meidell不等式Capability 能力Capability, machine 机器能力Capability, process 制程能力Capability ratio 能力比Capacity 能量,容量Caption 纵标目Carrying out the audit 实施稽核Cartogram 统计图Case method 个案法Catastrophic failure 突然故障,崩坏失效,致命失效Category 类别Cauchy distribution Cauchy 分配(布)Causality 因果律Cause 原因Cause, assignable 非机遇原因Cause, avoidable 可避免原因Cause, chance 机遇原因Cause, common 共同原因Cause, findable 可寻找原因Cause, random 随机原因Cause, special 特殊原因Cause, substantial 本质原因Cause, unavoidable 不可避免原因Cause and effect 因果Cause and effect diagram 特性要因图Cell 组Cell boundary 组界Cell deviation (d) 组离差Cell frequency (f) 组次数Cell interval (i,h) 组距Cell limit 组限Cell method 分组法Cell mid-point (Xm) 组中点Cell value 组值Censored sample 检剔样本Censored test 检剔试验Censorship 检剔Census 普查Center line 中线Central inspection station 中央检验站Central limit theory 趋中理论,中央极限理论Central limit theorem 趋中理论,中央极限理论Central line (CL.) 中心线Central moment 中心动差Central ordinate 中纵坐标Central tendency 集中趋势Central value 中值,中心值Certainty 确定性Certified chart 验证图Certified equipment 合格设备Certified quality engineer (CQE) 合格质量工程师Certified quality technician (CQT) 合格质量技术师Certified reliability engineer (CRE) 合格可靠度工程师Certification 验证Chain model 炼结模型Chain reliability 炼结可靠度Chain sampling plan (CHSP) 炼结抽样计划Chance 机遇Chance cause 机遇原因Chance error (Probable error) 机遇误差,机误Chance factor 机遇因素Chance failure 机遇故障,机遇失效Chance failure period 机遇失效期Chance fluctuation 机遇波动Chance variable 机遇变数Chance variation 机遇变异Change control 改变(变更)管理Chaotic variation 混乱变异Characteristic (质量)特性Characteristic, qualitative 质的特性Characteristic, quantitative 量的特性Characteristic curve, operating (OC curve) 操作特性曲线,OC曲线Characteristic diagram 特性要因图Characteristic function 特性函数Characteristic life 特性寿命Characteristic operating curve (OC curve) 特性操作曲线(OC曲线)Characteristic value 特性值Chargeable failure 可计列失效,故障Charlier check Charlier 覆检法Chart 图,(管制)图Chart, acceptance control 验收管制图Chart, average and range 平均数及全距(管制)图Chart, average number of defects 平均缺点数(管制)图Chart, control 管制图Chart, cumulative sum 累积和(管制)图Chart, defects per unit 每单位内缺点数(管制)图Chart, fraction defective 不良率(管制)图Chart, group 多项(管制)图Chart, individual 个别值(管制)图Chart, median 中位数(管制)图Chart, moving and range 移动平均数及全距(管制)图Chart, moving range 移动全距(管制)图Chart, modified control limits 修正管制界限(管制)图Chart, multi-variation 变异值(管制)图Chart, multiple 复式(管制)图Chart, number defectives 不良(品)数(管制)图Chart, number of defects 缺点数(管制)图Chart, percent defective 不良率管制图Chart, range 全距(管制)图Chart, run 操作(记录)图Chart, shop 工厂(管制)图Chart, Shewhart control Shewhart 管制图Chart, two-way control 双向管制图Chebyshev's inequality Chebyshev 不等式Check inspection 复核检验Check sampling 复核检验员Check inspector 复核抽样Chi-square ,卡方Chi-square distribution 分配(布),卡方分配(布)Chi-square test 检定,卡方检定Chi-squared distribution 分配(布),卡方分配(布)Chip 小圆片Chronic defect 慢性缺点Chronological chart 时序图Chronological series 时序数列Class 组Class boundaries (True class limits)组界(真实组限)Class form 组形Class frequency (f) 组次数Class interval (i,h) 组距Class limit 组限Class mark 组标,中值Class mean 组平均数Class mid-point(Xm) 组中点Class mid-value 组中值Class of median 组中位数Class value 组值Classes, number of 组数Classification chart 分组,分类Classification frequency 分组次数Classification frequency series 分组次数数列Classification of defectives 不良品分类Classification of defects 缺点分类Classfication of failure 失效分类,故障分类Classification process 分组(方)法Clearance 间隙,余隙Cluster 集团Cluster sampling 集团抽样Cochran's test Cochran 检定Code 简化,代号Code letter 代字Coded unit 简化单位Coded value 简化值Coding 简化Coding rule 简化规则Coefficient 系数Coefficient, correlation 相关系数Coefficient of alienation 余相关系数Coefficient of association 相关系数Coefficient of binomial distribution 二项分配(布)系数Coefficient of colligation 束联系数Coefficient of contingency 列联系数Coefficient of correlation 相关系数Coefficient of determination (r2) 定限系数Coefficient of dispersion 离势系数Coefficient of kurtosis 峰度系数Coefficient of multiple correlation 复相关系数Coefficient of net correlation 净相关系数Coefficient of net regression 净回归系数Coefficient of non-determination 不定限系数Coefficient of part correlation 部份相关系数Coefficient of partial correlation 部份相关系数Coefficient of rank correlation 等级相关系数Coefficient of reliability 可靠度系数Coefficient of regression 回归系数Coefficient of skewness 偏态系数,偏斜系数Coefficient of variation (CV) 变异系数Cold standby 冷置系数Collective quality 集体品质Columbia sampling table Columbia 抽样计划Column (Column/Row) 行,纵行(行/列)Column head 标目Column diagram 直行图Combination 组合Combinational model 复合模型Combined environmental reliability test (CERT) 复合环境可靠度试验Combined failure 复合失效,复合故障Combined stress life test 复合应力寿命试验Commissioning 委制Commodity 商品Common cause (Chance cause) 共同原因(机遇原因)Company standard 公司标准Companys need 公司需要Company-wide quality control (CWQC) 全公司质量管理Comparability 可比性Comparable measure 可比量数Compensating error 补偿误差Compensating fluctuation 补偿波动Competing product 竞争产品Complete association 全相联Complete block design 完全区集法Complete confounding 完全交络Complete dissociation 全不相联Complete failure 完全故障,完全失效Completely randomized design 完全随机法Complaint 抱怨Complaint index 抱怨指标Completed product verification 成品验证Component 组件,组件Component bar chart 成份条图Component distiibution 组成份分配(布)Component part diagram 成份图Component ratio 成份比Component reliability 组件可靠度Component variance 成份变异数Components of variance 变异数成份Composite curve 复合曲线Composite design 复合法Composite hypothesis 复合假设,组合假设Composite unit 复合单位Compound distribution 复合分配(布)Compound event 复合事件Compound probability 复合机率Compounding technique 复合法Compressed limit 压缩界限Compressed limit gauging 压缩界限规则Computed value 计算值Concentric circle diagram 同心圆图Conception of limit 极限概念Conceptual design 概念设计Conceptual design review 概念设计审查Concession 特采,特认Concomitant factor 共变因素Concomitant variable 共变数Concomitant variation 共变异Concurrency 并行Condition maintenance 状态维护Condition monitoring 状态监督Condition-based maintenance 状态基准维护Conditional probability 条件机率Conditions of use 使用条件Confidence 信任,信赖Confidence coefficient 信任系数,信赖系数Confidence interval 信任区间,信赖区间Confidence in test results 试验结果的信赖度Confidence level 信任水平,信赖水平Confidence limit 信任界限,信赖界限Confidence range 信任全距,信赖全距Configuration control 型态管制Configuration items 型态件Configuration management 型态管理Confirmation 确认Conformance to the requirement 符合要求Conformation 一致Conforming article 合格品Conformity 符合Confounding 交络Confounding, complete 完全交络Confounding, partial 部份交络Connector 连接器Consignment 委托,寄售Consistency 一致性Constancy 恒久性Constancy of great numbers 大数恒久性Constant 常数Constant cause system 恒常原因系统Constant error 恒常误差Constant failure period 恒常失效期Constant failure rate dustribution 恒常失效率分配(布)Constant weight (Fixed weight) 固定权数Constraint 束缚Consultant 管理顾问师Consumer 消费者Consumer acceptance specification 消费者允收规格Consumerism 消费者主义Consumer's risk (CR) 消费者冒险率Consumer test panel 消费者试验小组Consumer preference 消费者偏好Consumer sensitivity test 消费者感官试验Contingency 列联Contingency coefficient 列联系数Contingency table 列联表Contingency theorem 列联理论Continuity correction 连续校正Continuous change 连续变更Continuous data 连续数据Continuous distribution 连续分配(布)Continuous production 连续生产Continuous sampling 连续抽样Continuous sampling plan (CSP) 连续抽样计划Continuous series 连续数列Continuous variable 连续变量Contract 合约Contract preparation 拟定合约Contract review 合约检讨Contract requirements 合约需求Contract requirements analysis 合约需求分析Contractors 合约商Contrast analysis 对照分析Control, in 在管制(状态)下Control, lack of 缺乏管制Control, out of 超出管制Control, state of 管制状态Control, under 在管制(状态)下Control chart 管制图Control chart, cumulative sum 累积和管制图Control chart, defects per unit 每单位内缺点数管制图Control chart, two-way 双向管制图Control chart factor 管制图系数Control chart for attribute 计数值管制图Control chart for variable (measurement) 计量值管制图Control chart method 管制图法Control chart pattern 管制图类型Control factor 管制因素Control gaging (gauging) 管制规测Control level 管制水平Control limit 管制界限Control limit, lower 管制下限Control limit, modified 修正管制界限Control limit, upper 管制上限Control limit factor 管制界限因子Control line 管制线Control of measuring and test equipment 量测与试验设备之管制Control of nonconforming material 不合格物料之管制Control of nonconforming product 不合格产品之管制Control of production 生产管制Control of reliability 可靠度管制Control of verification status 验证状况之管制Control plan 管制计划Control point 管制点Control station 管制站Control system 管制系统Controllability 可管制性Controlled process 管制制程Controlled state 管制状态Controlled variability 管制变异性Controlled variable 管制变数Controlling item 管制项目Convenience lot 合宜的批Convergence 收敛Cooked distribution 中断分配(布)Coordinate 坐标Coordinate axis 坐标轴Coordinate line 坐标线Coordination 协调Coordination for reliability 可靠度协调Correction 校正,修正Correction, Sheppard Sheppard 校正数Correction factor 修正因子Correction for continuity 连续校正Correction for mean 平均数校正Correction term 校正项Corrective action 矫正行动,改正措施Corrective maintenance 矫正维护,改正维护Corrective maintenance time 矫正维护时间,改正维护时间Corrective sorting 修正选别Correlated measure 相关量数Correlated samples 相关样本Correlation 相关Correlation, coefficient of 相关系数Correlation, direct 直接相关Correlation, index of 相关指数Correlation, inverse 反相关Correlation, multiple 复相关Correlation, negative 负相关Correlation, net 净相关Correlation, nonlinear 非线性相关Correlation, nonsense 无意义相关Correlation, part 部份相关,偏相关Correlation, partial 部份相关,偏相关Correlation, perfect 完全相关Correlation, rank 等级相关Correlation, serial 数序相关Correlation, simple 简相关Correlation, zero 零相关Correlation analysis 相关分析Correlation chart 相关图Correlation, coefficient 相关系数Correlation coefficient, rank 等级相关系数Correlation matrix 相关矩阵Correlation of attributes 品性相关Correlation ratio 相关比Correlation of x on y x与y的相关比Correlation ratio of y on x y与x的相关比Correlation scatter chart 相关散布图Correlation surface 相关面Correlation table 相关表Correlation theory 相关理论Correlogram 相关图Corrosive atmosphere 腐蚀性空气Cost 成本,费用Cost, acquisition 取得成本Cost, appraisal 评估(鉴定)成本Cost, external failure 外部失败成本Cost, internal failure 内部失败成本Cost, life cycle 寿命周期成本Cost, logistic 后续成本Cost, prevention 预防成本Cost, quality 质量成本Cost, quality control 质量管理成本Cost, rework 重加工成本Cost effectiveness 成本效益Cost function 成本机能Cost model for reliability optimization 可靠度最佳化成本模式Cost reduction 成本减低Count (Countable) data 点计数据Counter variation 反行变异Co-variation 共变异Covariance 共变异数,共变数Covariance analysis 共变异数分析Covariance matrix 共变异矩阵Craps, game of 掷骰游戏Credibility 信用Creep failure 潜变失效,潜变故障Crest 峰Criteria for workmanship 工作技艺准则Criterion 准则,规范Criterion, acceptance 验收准则(规范)Critical component control 重要组件管制Critical defect 严重缺点Critical defective 严重不良品Critical design review 关键设计审查Critical failure 关键故障,严重失效Critical items 关键品目,重要件Critical path 要径Critical path analysis 要径分析法Critical region 临界区域,弃却区域,判定区Critical value 临界值,判定值Criticality 严重性,关键性Cross 交叉Cross check 互校Cross classification 交叉分类Cross correlation 交叉相关Cross formula 交互公式Cross-hatch 交叉线Cross-hatched map 交叉图Cross-over design 交叉计划Crossed design 交叉法Crude mode 概括众数Crude moment 概括动差Cubic chart (diagram) 立方图Culled 检选Cumulant 累积数Cumulation, downward 向下累积Cumulation, total 全部累积Cumulation, upward 向上累积Cumulation average chart 累积平均数(管制)图Cumulative curve 累积曲线Cumulative curve chart 累积曲线图Cumulative damage 累积损坏Cumulative distribution (Ogive) 累积分配(布)Cumulative distribution function 累积分配(布)函数Cumulative error 累积误差Cumulative failure frequency 累积故障次数,累积失效次数Cumulative frequency 累积次数Cumulative frequency arrangement 累积次数排列Cumulative frequency curve 累积次数曲线Cumulative frequency 累积次数曲线图Cumulative frequency distribution 累积次数分配(布)Cumulative frequency polygon 累积(次数)多边形Cumulative frequency (probability) function 累积次数(机率)函数Cumulative frequency table 累积次数表Cumulative function 累积函数Cumulative graph 累积图Cumulative hazard function 累积冒险函数Cumulative mean 累积平均数Cumulative normal distribution 累积常态分配Cumulative number of failures 累积失效数,累积故障数Cumulative percentage of failures 累积失效百分率,累积故障百分率Cumulative probability distribution 累积机率分配(布)Cumulative sum 累积和Cumulative sum chart 累积和(管制)图Cumulative sum control chart 累积和管制图Cumulative terms 累积项Curtailed (Truncated) inspection 截略检验Curtailed (Truncated) sample inspection截略样品检验Curtailed sampling 截略抽样Curtailed sampling inspection 截略抽样检验Curtaijed sampling plan 截略抽样计划Curtailment of sampling plan 抽样计划之截略Curve 曲线Curve, frequency 次数曲线Curve, normal 常态曲线Curve chart (diagram) 曲线图Curve fitting 曲线配合Curve of error 误差曲线Curve of means 平均数曲线Curve of probability 机率曲线Curve type criterion 曲线型准则Curve shape 曲线形状Curvilinear correlation 曲线相关Curvilinear regression 曲线回归Curvilinear trend 曲线趋势Curvilinearity 曲线性Customer 客户,顾客Customer complaint 顾客抱怨Customer feedback information 顾客回馈信息Customer incurred cost 顾客引发成本Customer operation cost 顾客作业成本Customer repair cost 顾客修理成本Customer requirement 顾客要求Customer satisfaction 顾客满意度Customer's need 顾客需要Cusum chart 累积和(管制)图Cycles 周期Cycles between failures 失效间隔周期,故障间隔周期Cycle of operation 操作周期Cyclic curve 周期(循环)曲线Cyclic damage 周期性损坏Cyclic load 周期性负荷Cyclical deviation 周期(循环)离差Cyclical fluctuation 周期波动Cyclical trend 周期趋势Cyclical movement 周期移动Cyclical variation 周期变异Cycling failure rate 周期性失效率,周期性故障率DD chart d管制图Data 数据Data analysis 数据分析Data bank 资料室(库)Data exchange program 数据交换计划Data, inspection 检验数据Data item 数据项,文件项目Data processing 数据处理Death rate 死亡率Debug (debugging) 除错Decile 十分位数Decimal fraction 小数Decision function 决策函数Decision line 决定线Decision making 决策Decision variable 决策变数Decreasing failure rate distribution 递减失效率分配(布)Decrement 减量Decrement rate 减率Defect 疵病,缺点Defect, chronic 慢性缺点Defect, critical 严重缺点Defect, incidental 偶发缺点Defect, major 主要缺点Defect, minor 次要缺点Defect, sporadic 突发缺点Defect and failure analysis 缺点与失效分析Defect chart 缺点数(管制)图Defect Free 零缺点Defect prevention 缺点预防Defects, number of 缺点数Defects classification 缺点分类Defects per hundred units (dphu) 百件缺点数Defects per unit chart 每单位(内)缺点数(管制)图Defects per unit plan 每单位(内)缺点数(管制)计划Defective 不良品Defective, fraction 不良率Defective chart 不良品数(管制)图Defective material 不良材料Defective number 不良品数Defective part 不良零件Defective parts, percentage of 不良零件百分率Defective prevention 不良品预防Defective unit 不良品(单位)Defectives, number of 不良(品)数Defectives classification 不良品分类Definition(s) 定义Deflated series 调节数列Deflated value 调节值Deflating index 调节指数Degradation 劣化Degradation failure 劣化故障,劣化失效Degree of accuracy 准确度Degree of approximation 近似度Degree of association 相联度Degree of confidence 信任(赖)度Degree of contribution 贡献度Degree of freedom (DF) 自由度Degree of reliability 可靠度Delivery 交货,出厂Delivery inspection 出厂检验Delivery qulaity 出厂品质Delivery time 运送时间Demerit 减点Demerit chart 减点(数)(管制)图Demerit rating 减点评比Demerits per unit 每单位(内)减点数Demonstration 示范,验证,展现Demonstration test 验证试验,展现试验Density function 密度函数Dependability 可恃性,相依性,依赖性Dependent factor 因变因子Dependent failure 相依失效,相依故障Dependent variable 因变数Derating 降等,额降,减额定Derivation 导出Derived table 导出表Descriptive item 说明项Descriptive statistics 记述统计(学)Design 设计Design baseline 设计准则Design change 设计变更Design considerations 设计考虑Design control 设计管制Design change control 设计变更管制Design control, new 新设计管制Design criterion 设计准则Design disclosure package 设计启导文件Design effect cost 设计效应成本Design freeze 设计冻结Design in 设计进去Design input 设计输入Design matrix 设计矩阵Design output 设计输出Design of experiment 实验计划Design planning 设计规画Design profile 设计轮廓Design proving 设计认可Design qualification 设计之合格性Design release 设计发布Design requalification 设计合格之再认定Design review 设计审查Design specification 设计规格Design validation 设计确认Design verification 设计验证,查证Design verification test 设计验证试验Designation 名称Designed experiment 实验计划Destructive inspection (test) 破坏性检验(试验)Detailed design 细部设计Detailed design review 细部设计审查Detailed inspection (100% inspection) 全数检验(百分之百检验)Detect 侦测Detection of a failure unit 失效单位之检测,故障单位之检测Detection time 检测时间Deterioration 衰变,劣化Determination, coefficient of 定限系数Development 发展Development test 发展试验Deviation 离差Deviation, average 平均差Deviation, mean 平均差Deviation, root-mean-square 均方根差Deviation, sample standard 样本标准差Deviation, standard 标准差Deviation, universe standard 群体标准差。

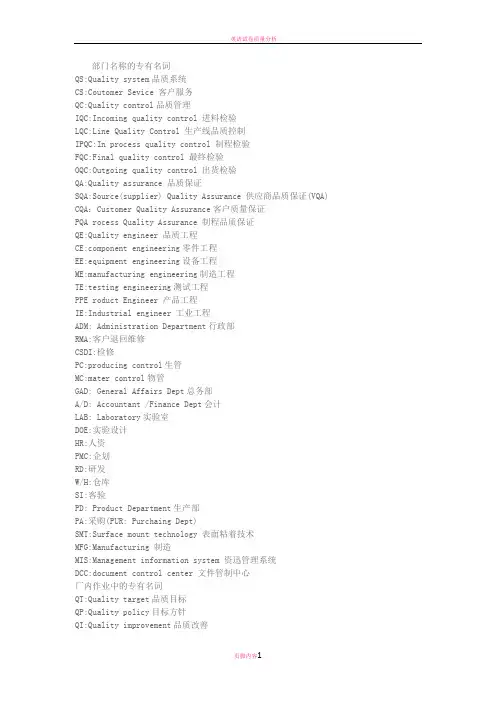

部门名称的专有名词QS:Quality system品质系统CS:Coutomer Sevice 客户服务QC:Quality control品质管理IQC:Incoming quality control 进料检验LQC:Line Quality Control 生产线品质控制IPQC:In process quality control 制程检验FQC:Final quality control 最终检验OQC:Outgoing quality control 出货检验QA:Quality assurance 品质保证SQA:Source(supplier) Quality Assurance 供应商品质保证(VQA) CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance 制程品质保证QE:Quality engineer 品质工程CE:component engineering零件工程EE:equipment engineering设备工程ME:manufacturing engineering制造工程TE:testing engineering测试工程PPE roduct Engineer 产品工程IE:Industrial engineer 工业工程ADM: Administration Department行政部RMA:客户退回维修CSDI:检修PC:producing control生管MC:mater control物管GAD: General Affairs Dept总务部A/D: Accountant /Finance Dept会计LAB: Laboratory实验室DOE:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD: Product Department生产部PA:采购(PUR: Purchaing Dept)SMT:Surface mount technology 表面粘着技术MFG:Manufacturing 制造MIS:Management information system 资迅管理系统DCC:document control center 文件管制中心厂内作业中的专有名词QT:Quality target品质目标QP:Quality policy目标方针QI:Quality improvement品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX:Maximum最大值MIN:Minimum最小值DIA iameter直径DIM imension尺寸LCL:Lower control limit管制下限UCL:Upper control limit管制上限EMI:电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement 连续工序改善Compatibility:兼容性Marking:标记DWG rawing图面Standardization:标准化Consensus:一致Code:代码ZD:Zero defect零缺点Tolerance:公差Subject matter:主要事项Auditor:审核员BOM:Bill of material物料清单Rework:重工ID:identification识别,鉴别,证明PILOT RUN: (试投产)FAI:首件检查FPIR:First Piece Inspection Report首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index(准确度)CPK: capability index of process(制程能力) PMP:制程管理计划(生产管制计划)MPI:制程分析DAS efects Analysis System 缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number批号Version:版本Quantity:数量Valid date:有效日期MIL-STD:Military-Standard军用标准ICT: In Circuit Test (线路测试)ATE:Automatic Test Equipment自动测试设备MO: Manafacture Order生产单T/U: Touch Up (锡面修补)I/N:手插件P/T:初测F/T: Function Test (功能测试-终测)AS 组立P/K:包装TQM:Total quality control全面品质管理MDA:manufacturing defect analysis制程不良分析(ICT) RUN-IN:老化实验HI-pot:高压测试FMI:Frequency Modulation Inspect高频测试DPPM: Defect Part Per Million(不良率的一种表达方式:百万分之一) 1000PPM即为0.1% Corrective Action: (CAR改善对策)ACC:允收REJ:拒收S/S:Sample size抽样检验样本大小SI-SIV:Special I-Special IV特殊抽样水平等级CON:Concession / Waive特采ISO:国际标准化组织ISA:Industry Standard Architecture工业标准体制结构OBA:开箱稽核FIFO:先进先出PDCA:管理循环Plan do check action计划,执行,检查,总结WIP:在制品(半成品)S/O: Sales Order (业务订单)P/O: Purchase Order (采购订单)P/R: Purchase Request (请购单)AQL:acceptable quality level允收品质水准LQL;Limiting quality level最低品质水准QVL:qualified vendor list合格供应商名册AVL :认可的供货商清单(Approved Vendor List) QCD: Quality cost delivery(品质,交期,成本)MPM:Manufacturing project management制造专案管理KPI:Key performance indicate重要绩效指标MVT:Manufacturing Verification Test制造验证试产Q/R/S:Quality/Reliability/Service质量/可靠度/服务STL:ship to line(料到上线)NTF:No trouble found误判CIP:capacity improvement plan(产能改善计划)MRB:material review board(物料审核小组)MRB:Material reject bill退货单JIT:just in time(即时管理)5S:seiri seiton seiso seiketsu shitsuke(整理,整顿,清扫,清洁,修养)SOP:standard operation process(标准作业程序)SIP:Specification inspection process制程检验规格TOP: Test Operation Process (测试作业流程)WI: working instruction(作业指导书)SMD:surface mounting device(表面粘着原件)FAR:failure aualysis report故障分析报告CAR:Corrective action report改善报告BPR:企业流程再造 (Business Process Reengineering)ISAR :首批样品认可(Initial Sample Approval Request)-JIT:实时管理 (Just In Time)QCC :品管圈 (Quality Control Circle)Engineering Department (工程部)TQEM: Total Quality Environment Management(全面品质环境管理)PD: Production Department (制造)LOG: Logistics (后勤支持)Shipping: (进出口)AOQ:Average Output Quality平均出货质量AOQL:Average Output Quality Level平均出货质量水平FMEA:failure model effectiveness analysis失效模式分析CRB: Change Review Board (工程变更会议)CSA:Customer Simulate Analysis客户模拟分析SQMS:Supplier Quality Management System供应商品质管理系统QIT: Quality Improvement Team 品质改善小组QIP:Quality Improvement Plan品质改善计划CIP:Continual Improvement Plan持续改善计划M.Q.F.S: Material Quality Feedback Sheet (来料品质回馈单) SCAR: Supplier Corrective Action Report (供货商改善对策报告) 8D Sheet: 8 Disciplines sheet ( 8D单)PDCA:PDCA (Plan-Do-Check-Action) (管理循环)MPQ: Material Packing Quantity (物料最小包装量)DSCN: Delivery Schedule Change Notice (交期变更通知) QAPS: Quality Assurance Process Sheet (品质工程表)DRP :运销资源计划 (Distribution Resource Planning)DSS:决策支持系统 (Decision Support System)EC :电子商务 (Electronic Commerce)EDI :电子资料交换 (Electronic Data Interchange)EIS :主管决策系统 (Excutive Information System)ERP:企业资源规划 (Enterprise Resource Planning) FMS :弹性制造系统 (Flexible Manufacture System)KM :知识管理 (Knowledge Management)4L :逐批订购法 (Lot-for-Lot)LTC :最小总成本法 (Least Total Cost)LUC :最小单位成本 (Least Unit Cost)MES :制造执行系统 (Manufacturing Execution System) MPS :主生产排程 (Master Production Schedule)MRP :物料需求规划 (Material Requirement Planning) MRPⅡ:制造资源计划 (Manufacturing Resource Planning) OEM :委托代工 (Original Equipment Manufacture)ODM :委托设计与制造 (Original Design & Manufacture) OLAP:线上分析处理 (On-Line Analytical Processing) OLTP:线上交易处理 (On-Line Transaction Processing) OPT :最佳生产技术 (Optimized Production Technology) PDCA:PDCA管理循环 (Plan-Do-Check-Action)PDM:产品数据管理系统 (Product Data Management)) RCCP:粗略产能规划 (Rough Cut Capacity Planning) SCM :供应链管理 (Supply Chain Management)SFC :现场控制 (Shop Floor Control)TOC:限制理论 (Theory of Constraints)TQC :全面品质管制 (Total Quality Control)FYI/R:for your information/reference仅供参考ASAP:尽快S/T:Standard time标准时间TPM:total production maintenance:全面生产保养ESD Wrist strap:静电环IT:information technology信息技术,资讯科学CEO:Chief Executive Officer执行总裁COO:Chief Operaring Officer首席业务总裁SWOT:Strength,Weakness,Opportunity,Threat优势﹐弱点﹐机会﹐威胁Competence:专业能力Communication:有效沟通Cooperation:统御融合Vibration Testing:振动测试IDP:Individual Development Plan个人发展计划MRP:Material Requirement Planning物料需求计划MAT'S:Material材料LRR:Lot Rejeet Rate批退率ATIN:Attention知会3C:Computer ,Communication , Consumer electronic消费性电子5W1H:When , Where , Who , What , Why , Ho5M: Man , Machine , Material , Method , Measurement人,机器,材料,方法,测量4MIE: Man,Material,Machine,Method,Environment人力,物力,财务,技术,时间(资源)7M1I: Manpower , Machine , Material , Method, Market , Management , Money , Information人力,机器,材料,方法, 市场,管理,资金,资讯1 Accuracy 准确度2 Action 行动3 Activity 活动4 Analysis Covariance 协方差分析5 Analysis of Variance 方差分析6 Approved 承认7 Attribute 计数值8 Average 平均数9 Balance sheet 资产负债对照表10 Binomial 二项分配11 Brainstorming Techniques 脑力风暴法12 Cause and Effect Matrix 因果图(鱼骨图)13 CL:Center Line 中心线14 Check Sheets 检查表15 Complaint 投诉16 Conformity 合格(符合)17 Control 控制18 Control chart 控制(管制)图19 Correction 纠正20 Correlation Methods 相关分析法21 CPI: continuouse Process Improvement 连续工序改善22 Cross Tabulation Tables 交叉表23 CS: Customer Sevice 客(户)服(务)中心24 DSA: Defects Analysis System 缺陷分析系统25 Data 数据 Description:品名26 DCC: Document Control Center 文控中心27 Decision 决策、判定28 Defects per unit 单位缺点数29 Description 描述30 Device 装置31 Do 执行32 DOE: Design of Experiments 实验设计33 Element 元素34 Engineering recbnology 工程技35 Environmental 环境36 Equipment 设备37 Estimated accumulative frequency 计算估计累计数38 E Equipment Variation 设备变异39 External Failure 外部失效,外部缺陷40 FA: Failure Analysis 失效分析41 Fact control 事实管理42 Fatigue 疲劳43 FMEA: Failure Mode and Effect Analysis失效模式与效果分析44 FP First-Pass Yield (第一次通过)合格率45 FQA: Final Quality Assurance 最终品质保证46 FQC: Final Quality control 最终品质控制47 Gauge system 测量系统48 Grade 等级49 Histogram 直方图50 Improvement 改善51 Initial review 先期审查52 Inspection 检验53 Internal Failure 内部失效、内部缺陷54 IPQC: In Process Quality Control 制程品质控制55 IQC: Incomming Quality Control 来料品质控制56 IS International Organization for Standardization 国际标准化组织57 LCL: Lower Control limit 管制下限58 LQC: Line Quality Control 生产线品质控制59 LSL: Lower Size Limit 规格下限60 Machine 机械61 Manage 管理62 Materials 物料63 Measurement 测量64 Median 中位数65 MSA: Measurement System Analysis 测量系统分析66 Occurrence 发生率67 Operation Instruction 作业指导书68 Organization 组织69 Parto 柏拉图70 PPM arts per Million (百万分之)不良率71 Plan 计划72 Policy 方针73 Population 群体74 PQA: Process Quality Assurance 制程品质保证75 Practice 实务(践)76 Prevention 预防77 Probability 机率78 Probability density function 机率密度函数79 Procedure 流程80 Process 过程81 Process capability analysis 制程能力分析(图)82 Process control and Process capability制程管制与制程能力83 Product 产品84 Production 生产85 Projects 项目86 QA: Quality Assurance 品质保证87 QC: Quality Control 品质控制88 QE: Quality Engineering 品质工程89 QFD: Quality Function Desgin 品质机能展开(法)90 Quality 质量91 Quality manual 品质手册92 Quality policy 品质政策(质量方针)93 Random experiment 随机试验94 Random numbers 随机数95 R:Range 全距(极差)96 Reject 拒收97 Repair 返修98 Repeatusility 再现性99 Reproducibility 再生性100 Requirement 要求101 Responsibilities 职责102 Review 评审103 Reword 返工104 Rolled yield 直通率105 RPN: Risk Priority Number 风险系数106 Sample 抽样,样本107 Sample space 样本空间108 Sampling with replacement 放回抽样109 Sampling without replacement 不放回抽样110 Scatter diagram 散布图分析111 Scrap 报废112 Simple random sampling 简单随机取样113 Size 规格114 SL: Size Line 规格中心线115 Stratified random sampling 分层随机抽样116 SOP: Standard Operation Procedure 标准作业书117 SPC: Statistical Process Control 统计制程管制118 Specification 规范119 SQA: Source(Supplier) Quality Assurance 供货商品质保证120 Stage sampling 分段随机抽样121 Standard Deviation 标准差122 Sum of squares 平方和123 Taguchi-method 田口(试验)方法124 Theory 原理125 TQC: Total Quality Control 全面品质控制126 TQM: Total Quality Management 全面品质管理127 Traceablity 追溯128 Training 培训129 UCL: Upper Control Limit 管制(控制)上限130 USL: Upper Size Limit 规格上限131 Validation 确认132 Variable 计量值133 Verification 验证134 Version 版本135 VOC: Voice of Customer 客户需求136 VOE: Voice of Engineer 工程需求137 Inventory stock report:庫存清单报告138 Sales order report:出货报告质量人员名称类QC quality control 品质管理人员FQC final quality control 终点质量管理人员IPQC in process quality control 制程中的质量管理人员OQC output quality control 最终出货质量管理人员IQC incoming quality control 进料质量管理人员TQC total quality control 全面质量管理POC passage quality control 段检人员QA quality assurance 质量保证人员OQA output quality assurance 出货质量保证人员QE quality engineering 质量工程人员质量保证类FAI first article inspection 新品首件检查FAA first article assurance 首件确认CP capability index 能力指数CPK capability process index 模具制程能力参数SSQA standardized supplier quality audit 合格供货商质量评估FMEA failure model effectiveness analysis 失效模式分析FQC运作类AQL Acceptable Quality Level 运作类允收质量水平S/S Sample size 抽样检验样本大小ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的Q/R/S Quality/Reliability/Service 质量/可靠度/服务P/N Part Number 料号L/N Lot Number 批号AOD Accept On Deviation 特采UAI Use As It 特采FPIR First Piece Inspection Report 首件检查报告PPM Percent Per Million 百万分之一制程统计品管专类SPC Statistical Process Control 统计制程管制SQC Statistical Quality Control 统计质量管理GRR Gauge Reproductiveness & Repeatability 量具之再制性及重测性判断量可靠与否DIM Dimension 尺寸DIA Diameter 直径N Number 样品数其它质量术语类QIT Quality Improvement Team 质量改善小组ZD Zero Defect 零缺点QI Quality Improvement 质量改善QP Quality Policy 目标方针TQM Total Quality Management 全面质量管理RMA Return Material Audit 退料认可7QCTools 7 Quality Control Tools 品管七大手法通用之件类ECN Engineering Change Notice 工程变更通知(供货商)ECO Engineering Change Order 工程改动要求(客户)PCN Process Change Notice 工序改动通知PMP Product Management Plan 生产管制计划SIP Standard Inspection Procedure 制程检验标准程序SOP Standard Operation Procedure 制造作业规范IS Inspection Specification 成品检验规范BOM Bill Of Material 物料清单PS Package Specification 包装规范SPEC Specification 规格DWG Drawing 图面系统文件类ES Engineering Standard 工程标准CGOO China General PCE龙华厂文件IWS International Workman Standard 工艺标准ISO International Standard Organization 国际标准化组织GS General Specification 一般规格部类PMC Production & Material Control 生产和物料控制PCC Product control center 生产管制中心PPC Production Plan Control 生产计划控制MC Material Control 物料控制DC Document Center 资料中心QE Quality Engineering 质量工程(部)QA Quality Assurance 质量保证(处)QC Quality Control 质量管理(课)PD Product Department 生产部LAB Laboratory 实验室IE Industrial Engineering 工业工程R&D Research & Design 设计开发部生产类PCs Pieces 个(根,块等)PRS Pairs 双(对等)CTN Carton 卡通箱PAL Pallet/skid 栈板PO Purchasing Order 采购订单MO Manufacture Order 生产单D/C Date Code 生产日期码ID/C Identification Code (供货商)识别码SWR Special Work Request 特殊工作需求L/N Lot Number 批号P/N Part Number 料号OEM Original Equipment Manufacture 原设备制造PC Personal Computer 个人计算机CPU Central Processing Unit 中央处理器A.S.A.P As Soon As Possible 尽可能快的E-MAIL Electrical-Mail 电子邮件N/A Not Applicable 不适用QTY Quantity 数量I/O input/output 输入/输出NG Not Good 不行,不合格C=0 Critical=0 极严重不允许APP Approve 核准,认可,承认CHK Check 确认ASS'Y Assembly 装配,组装T/P True Position 真位度5WIH When, Where, Who, What, Why, How to6M Man, Machine, Material, Method, Measurement, Message4MTH Man, Material, Money, Method, Time, How 人力,物力,财务,技术,时间(资源)SQA Strategy Quality Assurance 策略质量保证DQA Design Quality Assurance 设计质量保证MQA Manufacture Quality Assurance 制造质量保证SSQA Sales and service Quality Assurance 销售及服务质量保证LRR Lot Reject Rate 批退率SPS Switching power supply 电源箱DT Desk Top 卧式(机箱)MT Mini-Tower 立式(机箱)DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringPCB Printed Circuit Board 印刷电路板CAR Correction Action Report 改善报告NG Not Good 不良WDR Weekly Delivery Requirement 周出货要求PPM Percent Per Million 百万分之一TPM Total Production Maintenance 全面生产保养MRP Material Requirement Planning 物料需计划OS Operation System 操作系统TBA To Be Assured 待定,定缺D/C Drawing ChangeP/P Plans & ProcedureEMI Electrical-Music Industry 电子音乐工业Electrical Magnetic Interference 电子干扰RFI Read Frequency Input 读频输入MMC Maximum Material ConditionMMS Maximum Material SizeLMC Least Material ConditionLMS Least Material SizeLED lighting-emitting diode 发光二极管QBR Quarter Business RecordCIP Continuous improvement processFGI Forecasted Goal InventoryCNC Computerized numeral controllerB2C Business to customerB2B Business to businessAVL Approved vendor listPOP Procedure of packagingEOL End of lifeVDCS Vender defect correcting sheetPDCS Process defect correcting sheet GRN Goods receiving noteA/R Accounting receivableA/P Accounting payable。