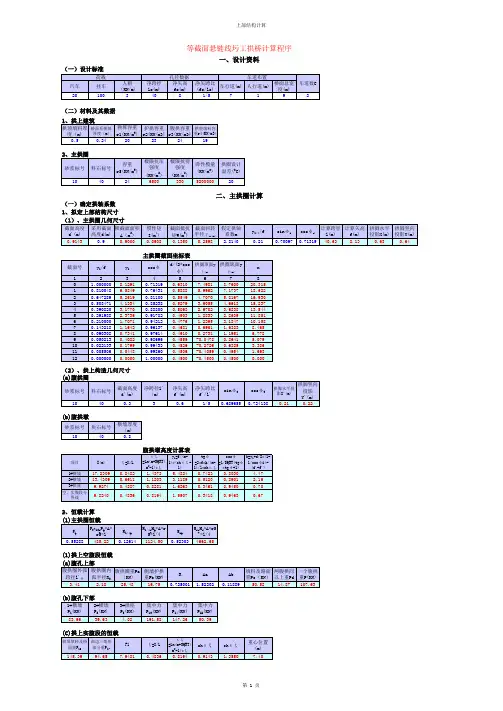

拱桥计算EXCEL

- 格式:xls

- 大小:24.00 KB

- 文档页数:16

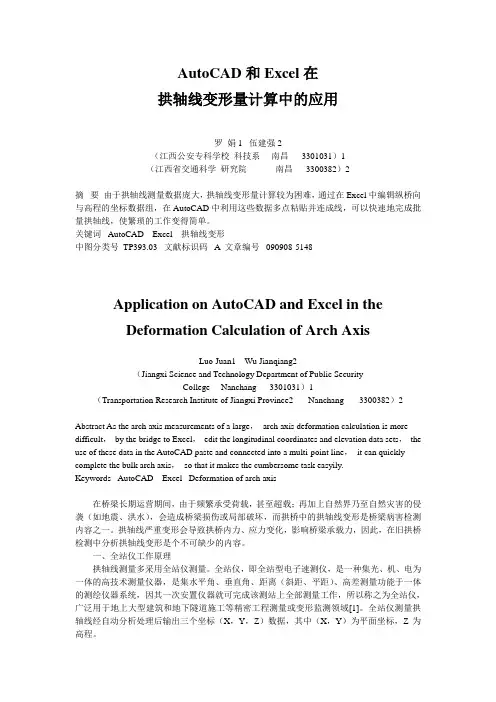

AutoCAD和Excel在拱轴线变形量计算中的应用罗娟1 伍建强2(江西公安专科学校科技系南昌3301031)1(江西省交通科学研究院南昌3300382)2摘要由于拱轴线测量数据庞大,拱轴线变形量计算较为困难,通过在Excel中编辑纵桥向与高程的坐标数据组,在AutoCAD中利用这些数据多点粘贴并连成线,可以快速地完成批量拱轴线,使繁琐的工作变得简单。

关键词AutoCAD Excel 拱轴线变形中图分类号TP393.03 文献标识码A文章编号090908-5148Application on AutoCAD and Excel in theDeformation Calculation of Arch AxisLuo Juan1 Wu Jianqiang2(Jiangxi Science and Technology Department of Public SecurityCollege Nanchang 3301031)1(Transportation Research Institute of Jiangxi Province2 Nanchang 3300382)2Abstract As the arch axis measurements of a large,arch axis deformation calculation is more difficult,by the bridge to Excel,edit the longitudinal coordinates and elevation data sets,the use of these data in the AutoCAD paste and connected into a multi-point line,it can quickly complete the bulk arch axis,so that it makes the cumbersome task easyily.Keywords AutoCAD Excel Deformation of arch axis在桥梁长期运营期间,由于频繁承受荷载,甚至超载;再加上自然界乃至自然灾害的侵袭(如地震、洪水),会造成桥梁损伤或局部破坏,而拱桥中的拱轴线变形是桥梁病害检测内容之一。

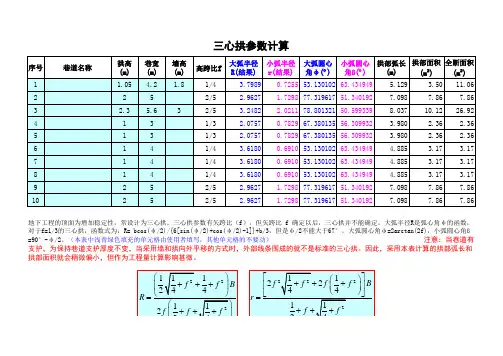

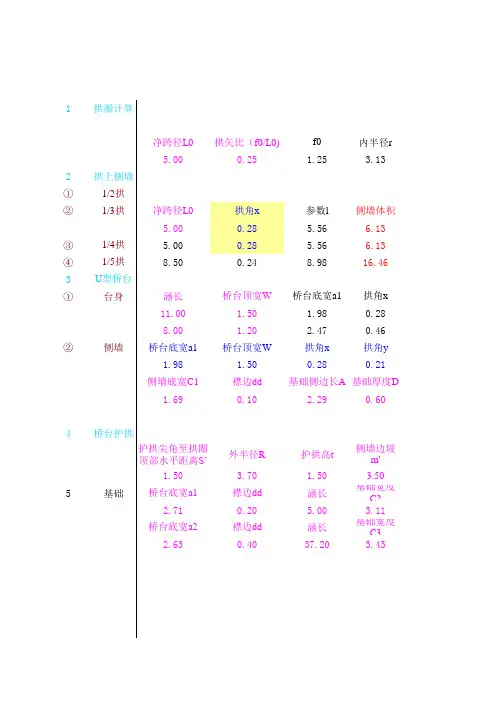

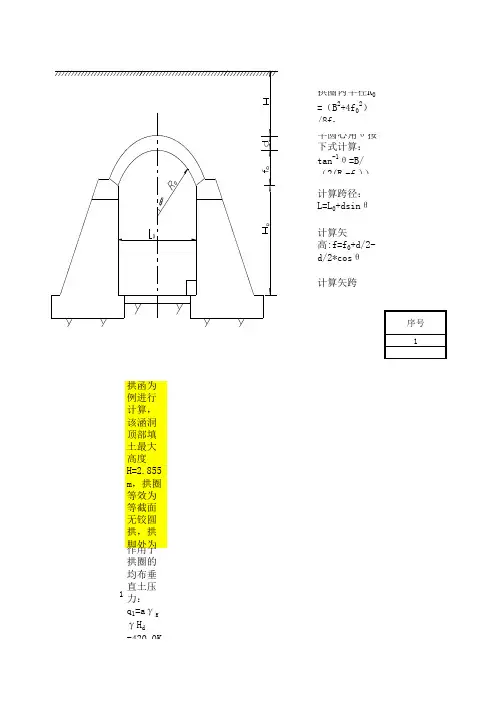

拱圈内半径R 0 =(B 2+4f 02)/8f 0半圆心角θ按下式计算:tan -1θ=B/(2(R 计算跨径:L=L 0+dsin θ计算矢高:f=f 0+d/2-d/2*cos θ计算矢跨比:f/L1拱函为例进行计算,该涵洞顶部填土最大高度H=2.855m,拱圈等效为等1作用于拱圈的均布垂直土压力:q 1=a γg γH d =420.0KN/m2作用于拱圈的水平均布荷载:q 2=a γt γH d tan 2(45-φ/2)=160.0KN/m3作用于拱圈的水平三角形荷载最大强度:q 3=a γt γh tan 2(45-φ/2)=11.718 KN/m 4作用于拱背的填充料重力:W 1=0.03γg γ1L 2=17.86 KN 5拱圈自重:W 2=0.57γg γdL=32.85 KN 6汽车荷载其中,重力系数查截面无铰圆拱内力系数表得到。

荷载类型及数值内力名称系数VA(KN)0.5垂直均布荷载HA、NC(KN)0.63782(KN/m)MA(KN/m)0.00414162.5608MC(KN/m)0.00158VA(KN)1拱背填料土重HA、NC(KN)0.55637(KN)MA(KN/m)-0.0220693.80269939MC(KN/m)-0.01033VA(KN)0均布水平荷载HA(KN)-0.56746(KN/m)MA(KN/m)-0.0223724.05333333NC(KN)MC(KN/m)-0.01317VA(KN)0均布三角形荷载HA(KN)-0.75857(KN/m)MA(KN/m)-0.03795序号27.06NC(KN)MC(KN/m)-0.01038VA(KN)1自重力HA、NC(KN) 1.20645(KN)MA(KN/m)0.00582457.7937546MC(KN/m)0.0019822拱脚截面轴力N A=H A cosθ+V A sinθ=1435.9偏心距e0=∑M A/∑N A= 0.037 m塑性影响系数K=1+1.5e0/y=弯曲压应力σa=∑N/A+∑M/W= 4140.763 KN/m2允许弯曲压应力K[σa]= 14528.795 KN/m2σa< K[σa],截面受压满足要求。

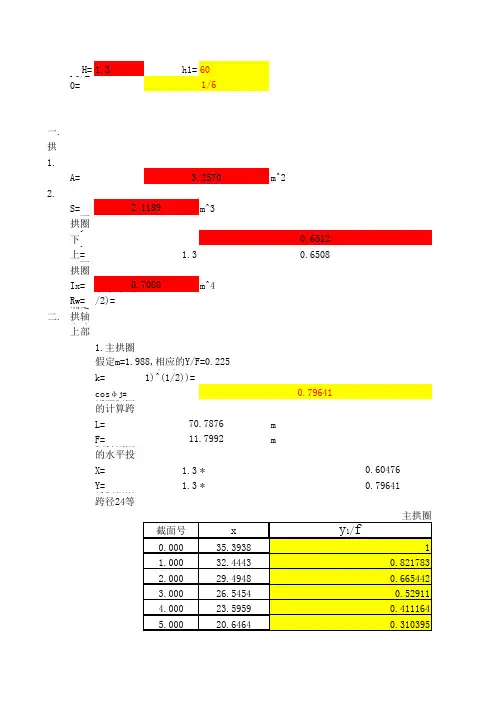

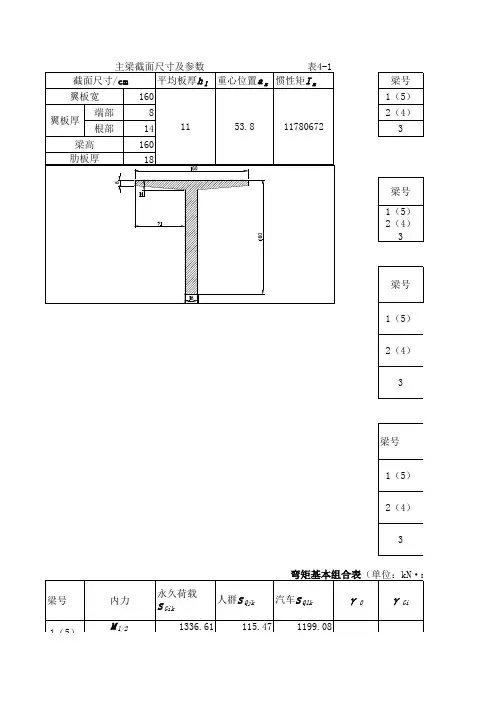

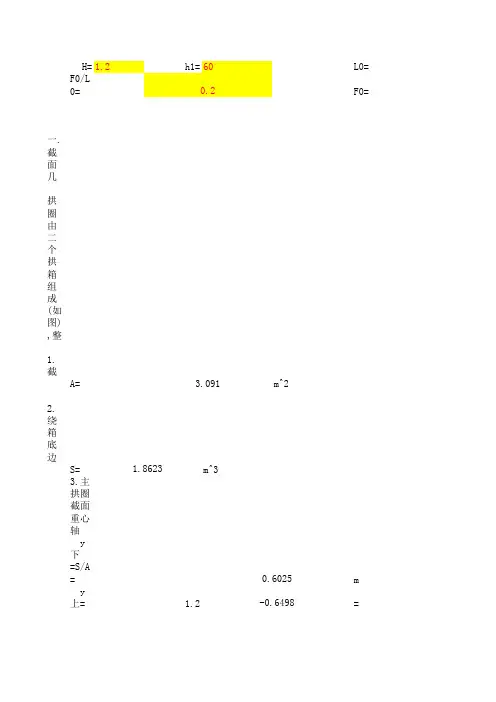

H=1.2h1=60L0=F0/L0=F0=一.截面几何特性计算拱圈由二个拱箱组成(如图),整个设计按全宽进行 1.截面积m^2 2.绕箱底边缘的静面矩S=m^33.主拱圈截面重心轴 y下=S/A=m y上= 1.2=4.主拱圈截面绕重心轴的惯性矩Ix=m^4Rw=(Ix/A)^(1/2)= 二.确定拱轴系数(一)上部结构构造布置1.主拱圈k=ln(m+(m^2-1)^(1/2))=cos φj=则主拱圈的计算跨径和计算矢高:L=m F=m 拱脚截面的水平投影和竖向投影:X= 1.2*Y= 1.2*将拱轴沿跨径24等分,每等分长△L=L/24=截面号xy 1/fy 10.00025.411 1.00010.1841.00023.2940.8188.3302.00023.2940.659 6.7163.00019.0590.522 5.3194.00016.9410.404 4.1195.00014.8230.304 3.0976.00012.7060.220 2.2407.00010.5880.151 1.5358.0008.4700.0950.9729.000 6.3530.0530.54210.000 4.2350.0240.24011.000 2.1180.0060.06012.0000.0000.0000.0002.拱上腹孔布置 从主拱两端起拱线向外延伸2.15m后向跨中对称布置四对圆弧小拱50.8228110.183980.59310.438假定m=2.24,相应的Y/F=0.220.730570.20.60251.8623A= 3.091-0.6498主拱圈几何特性0.730570.68284排架式腹拱墩支承的宽为0.6m的钢筋混凝土盖梁上。

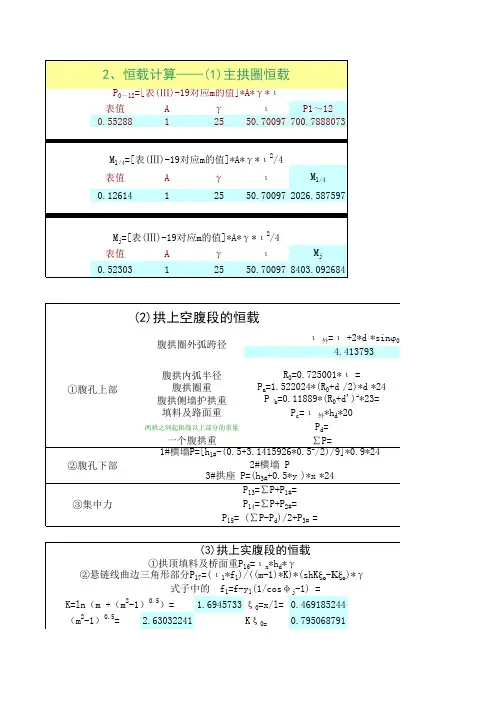

腹拱拱顶的拱背和主拱拱顶的拱背在同一拱线的高度h=y 1+y 上*(1-1/cos φ)-(d'+f 0'),分别计算如下表:项目Lx ξ=2*Lx/L k ξ1号立柱21.5000.846 1.2232号立柱16.9000.6650.9613号立柱12.3000.4840.7004号腹拱座7.9680.3140.453空实腹段分界线7.8850.3100.449由F 0'/L 0'=sin φ0=腹拱拱脚的水平投影和竖向投影:x'=d'sin φ0=y'=d'cos φ0=(二)上部结构恒载计算恒载计算,首先把桥面系换算成填料厚度,然后按主拱圈、横隔板、拱上实腹段、拱上空腹段1.桥面系拱顶填料及沥青表处面层重力1/2*(0.56+.63)*2*7/2*23=则换算容重γ=23KN/m^3的计算平均填料厚度为24h d =(9.4+95.795)/9.8/23=2.主拱圈P 0-12=M l/4=M J =*3.横隔板横隔板的设置受箱肋接头位置的控制,必须先确定接头位置后载按箱肋轴线等弧长(1)箱肋有关几何要素1)箱肋截面积A′=3.02*0.1+3.16*0.1+4*1/2*2)箱肋截面静矩J′=3.02*0.1*(+=3)截面重心距箱底的距离y F ′=J′/A′=4)箱肋计算跨径L′=L 0+2*y F ′*sin φj =5)箱肋轴线弧长S′=(2)确定箱肋接头、设置横隔板1)确定接头位置箱肋分三段吊装合拢,接头宜选在箱肋自重作用O.O870.5240.126腹拱0.1250.552S x ′=2)布置横隔板横隔板沿箱肋中轴线均匀设置,取板间间距△L′S 11/2=1/2*(则接头位置刚好在ε= 端段箱肋弧长S 1=1/2*( 端段箱肋设(3)横隔板与接头加强部分的重力横隔板厚均为0.06m。

1-100m钢筋混凝土拱桥0#台桩基计算一、桥台及承台自重的作用力(顺时为+,反之为-)桥台形式见附图一:二、计算主拱圈作用于拱座的力对承台重心O的力1.根据有关标准图知,作用于拱座上的控制力为:垂直力:V=17450KN水平力:H=23740KN(往河岸)弯矩:M=10480KN*M2.对承台重心O产生的弯矩:M V=4.95*17450=86377.5(KN*M)M H=-9.58*23740=-227429.2(KN*M)3.对承台重心O产生作用合力:垂直力=17450KN水平力=23740KN(往河岸)弯矩=86377.5+10480-227429.2=-130571.7(KN*M)三、计算桥台后静土压力及土抗力1.静土压力计算E j=0.5*ξ*γ*H2*B其中:ξ=0.50(自然土体)γ=20kn/m3h1=13m;h2=10.24mB=5.5m所以:E1=0.5*0.5*20*132*5.5=4647.5(KN)E2=0.5*0.5*20*10.242*5.5=2883.6(KN)平均静土压力=(4647.5*2+2883.6)*0.5=6089.3(KN) 作用力到承台底距离:h=(4647.5*10.24*0.5*10.24+2883.6*0.5*10.24*10.24/3)/((4647. 5*2+2883.6)*0.5*10.24)=294057.41/62354.43=4.72(m) M静=6089.3*4.72=28741.5(KN*M)2.土抗力计算(1)计算土抗力根据桥梁工程(公路与城市道路工程专用)P404知,p k=Mc/(B*h2/3*(h2+f)+K0/K*I0/h2)其中:h2=9.58(m)f=0(偏安全、可不考虑)K0/K =1.25I0=6.8*11.83/12=931.1D=B*h2/3*(h2+f)+K0/K*I0/h2=5.5*9.582/3+1.25*931.1/9.58=289.75Mc=-227429.2+25553.4+86377.5+10480+28741.5=-76276.8(KN*M)台口处的抗力强度p k=76276.8/289.75=263.3(KN*M2)土抗力Pk=0.5*B*p k* h2=0.5*5.5*263.3*9.58=6936.6(KN)(2)对桥台变位的限制a.水平位移:Δ=p k/k=263.3/(120*9.81*103)=0.22mm<6mm,满足要求b.台后填土稳定性的保证Kc=P b/(P j+P k)其中:P b=20*13*tg2(45+35/2)=959.4(KN*M2)P j=0.5*20*13=130(KN*M2)所以Kc=959.4/(263.3+130)=2.44>1.4,满足要求四、作用于承台重心O处的合力垂直力∑Ni=28112.8+17450=45562.8KN水平力∑Hi =23740-6089.3-6936.6=10714.1KN(往河岸)弯矩Mo =Mc-Mp k=-76276.8+1/3*5.5*263.3*9.582=-31974.8KN*M五、桩基计算1.系数计算(1)自由长度:Lo=0m(2)E*I=0.67*E h*I h=3.0*104*3.14*1.84/64=10357530(kn*m2)(3)桩的计算宽度:b1=0.9*(d+1)*K其中:h1=3*(d+1)=3*(1.8+1)=8.4(m)L1=4.5-1.8=2.7<0.6*h1=5.04(m)K=b’+(1-b’)/0.6* L1/ h1=0.5+(1-0.5)/0.6*2.7/8.4=0.768 所以b1=0.9*2.8*0.768=1.935(m)(4)m=(m1*h12+m2*(2*h1+h2)*h2)/h m2=50000(KN/M4)其中:h m=2*(d+1)=5.4(m)(5)变形系数α:α=(m*b1/EI)0.2=(50000*1.935/10357530)0.2=0.3927h’=α*h=0.3927*30=11.78>2.5,可按弹性桩计算(6)EA=3.0*107*1.82/(4*3.14)=7734930(7)单桩面积Ao=4.52/4*3.14=15.904(m2)备注:0.25*35°=8.75°,2*25*tg8.75°=7.70>4.5,取4.5m计算(8)Kc=0.5(摩擦桩)(9)地基系数:Co=mo*b=50000*30=1500000(KN/M4)2.钻孔灌注桩基的计算采用桥梁博士2.9和桥梁大师计算,结果另见。