传动系统离合器论文中英文对照资料外文翻译文献

- 格式:doc

- 大小:60.00 KB

- 文档页数:11

CLUTCHThe engine produces the power to drive the vehicle. The drive line or drive train transfers the power of the engine to the wheels. The drive train consists of the parts from the back of the flywh eel to the wheels. These parts include the clutch, th e transmission, the drive shaft, and the final drive assembly (Figure 8-1).The clutch which includes the flywheel, clutch disc, pressure plate, springs, pressure plate cover and the linkage necessary to operate the clutch is a rotating mechanism between t he engine and the transmission (Figure 8-2). It operates through friction which comes from contact between the parts. That is the reason why the clutch is called a friction mechanism. After engagement, the clutch must continue to transmit all the engine torque to the transmission depending on the friction without slippage. The clutch is also used to disengage the engine from the drive train whenever the gears in the transmission are being shifted from one gear ratio to another.To start the engine or shift the gears, the driver has to depress the clutch pedal with the purpose of disengagement the transmission from the engine. At that time, the driven members connected to the transmission input shaft are either stationary or rotating at a speed that is slower or faster than the driving members connected to the engine crankshaft. There is no spring pressure on the clutch assembly parts. So there is no friction between the driving members and driven members. As the driver lets loose the clutch pedal, spring pre ssure increases on the clutch parts. Friction between the parts also increases. The pressure exerted by the springs on the driven members is controlled by the driver through the clutch pedal and linkage. The positive engagement of the driving and driven members is made possible by the friction between the surfaces of the members. When full spring pressure is applied, the speed of the driving and driven members should be the same. At themoment, the clutch must act as a solid coupling device and transmit al l engine power to the transmission, without slipping.However, the transmission should be engaged to the engine gradually in order to operate the car smoothly and minimize torsional shock on the drive train because an engine at idle just develops little power. Otherwise, the driving members are connected with the driven members too quickly and the engine would be stalled.The flywheel is a major part of the clutch. The flywheel mounts to the engine’s crankshaft and transmits engine torque to the clutch assembly. The flywheel, when coupled with the clutch disc and pressure plate makes and breaks the flow of power from the engine to the transmission.The flywheel provides a mounting location for the clutch assembly as well. When the clutch is applied, the flyw heel transfers engine torque to the clutch disc. Because of its weight, the flywheel helps to smooth engine operation. The flywheel also has a large ring gear at its outer edge, which engages with a pinion gear on the starter motor during engine cranking.The clutch disc fits between the flywheel and the pressure plate. The clutch disc has a splined hub that fits over splines on the transmission input shaft. A splined hub has grooves that match splines on the shaft. These splines fit in the grooves. Thus, t he two parts are held together. However, back-and-forth movement of the disc on the shaft is possible. Attached to the input shaft, At disc turns at the speed of the shaft.The clutch pressure plate is generally made of cast iron. It is round and about the same diameter as the clutch disc. One side of the pressure plate is machined smooth. This side will press th e clutch disc facing are against the flywheel. The outer side has various shapes to facilitate attachment of spring and release mechanisms. The two primary types of pressure plate assemblies are coil spri ng assembly and diaphragmspring (Figure 8-3).In a coil spring clutch the pressure plate is backed by a number of coil springs and housed with them in a pressed-steel cover bolted to the flywheel. The springs push against the cover. Neither the driven plate nor the pressure plate is connected rigidly to the flywheel and both can move either towards it or away. When the clutch pedal is depressed a thrust pad riding on a carbon or ball thrust bearing i s forced towards the flywheel. Levers pivoted so that they engage with the thrust pad at one end and the pressure plate at the other end pull the pressure plate back against its springs. This releases pressure on the driven plate disconnecting the gearbox from the engine (Figure 8-4).Diaphragm spring pressure plate assemblies are widely used in most modern cars. The diaphragm spring is a single thin sheet of metal which yields when pressure is applied to it. When pressure is removed the metal springs back to its original shape. The centre portion of the diaphragm spring is slit into numerous fingers that act as release levers. When the clutch assembly rotates with the engine these weights are flung outwards by centrifugal forces and cause the levers to pre ss against the pressure plate. During disengagement of the clutch the fingers are moved forward by the release bearing. The spring pivots over the fulcrum ring and its outer rim moves away from the flywheel. The retracting spring pulls the pressure plate a way from the clutch plate thus disengaging the clutch (Figure 8-5).When engaged the release bearing and the fingers of the diaphragm spring move towards the transmission. As the diaphragm pivots over the pivot ring its outer rim forces the pressure plate against the clutch disc so that the clutch plate is engaged to the flywheel.The advantages of a diaphragm type pres sure plate assembly are its compactness, lower weight, fewer moving parts, less effort to en gage, reduces rotational imbalance by providin g a balanced force around the pressure plate and less chances of clutch slippage.The clutch pedal is connected to the disengagement mechanism either by a cable or, more com monly, by a hydraulic system. Either way, pushing the pedal down operates the dise ngagement mechanism which puts pressure on the fingers of the clutch diaphragm via a release bearing and causes the diaphragm to release the clutch plate. With a hydraulic mechanism, the clutch pedal arm operates a piston in the clutch master cylinder. Thi s forces hydraulic fluid through a pipe to the clutch release cylinder where another piston operates the clutch disengagement mechanism. The alternative is to link the clutch pedal to the disengagement mechanism by a cable.The other parts including the cl utch fork, release bearing, bell-housing, bell housing cover, and pilot bushing are needed to couple and uncouple the transmission. The clutch fork, which connects to the linkage, actually operates the clutch. The release bearing fits between the clutch fork and the pressure plate assembly. The bell housing covers the clutch assembly. The bell housing c over fastens to the bottom of the bell housing. This removable cover allows a mechanic to inspect the clutch without removing the transmission and bell housing. A pilot bushing fits into the back of th e crankshaft and holds the transmission input shaft.Torque ConverterThe BasicsJust like manual transmission cars, cars with automatic transmissions need a way to let the en gine turn while the wheels and gears in the transmission come to a stop. Manual transmission cars use a clutch, which completely disconnects the engine from the transmission. Automatic transmis sion cars use a torque converter.A torque converter is a type of fluid coupling, which allows the engine to spin somewhat independently of the transmission. If the engine is turning slowly, such as when the car is idling at a stoplight,the amount of torque passed through the torque converter is very small, so keeping the car still requires only a li ght pressure on the brake pedal.If you were to step on the gas pedal while the car is stopped, you would have to press harder on the brake to keep the car from moving. This is because when you step on the gas, the engine speeds up and pumps more fluid into the torque converter, causing more torque to be transmitted to the wheels.Inside a Torque ConverterThere are four components inside the very strong housing of the torque converter:1. Pump;2. Turbine;3. Stator;4. Transmission fluid.The housing of the torque converter is bolted to the flywheel of the engine, so it turns at what ever speed the engine is running at. The fins that make up the pump of the torque converter are at tached to the housing, so they also turn at the same speed as the engine. The cutaway below shows how everything is connected inside the torque converter (Figure 8-6).The pump inside a torque converter is a type of centrifugal pump. As it spins, fluid is flung to the outside, much as the spin cycle of a washing machine flings water and clothes to the outside of the wash tub. As fluid is flung to the outside, a vacuum is created that draws more fluid in at the center.The fluid then enters the blades of the turbine, which is connected to the transmission. The turbine causes the transmission to spin, which basically moves the car. The blades of the turbine are curved. This means that the fluid, which enters the turbine from the outside, has to change direction before it exits the center of the turbine. It is this directional change that causes the turbine to spin.The fluid exits the turbine at the center, moving in a different direction than when it entered. The fluid exits the turbine moving opposite the direction that the pump (and engine) is turning. If the fluid were allowed to hit the pump, it would slow the engine down, wasting power. This is why a torque converter has a stator.The stator resides in the very center of the torque converter. Its job is to redirect the fluid returning from the turbine before it hits the pump again. This dramatically increases the efficiency of the torque converter.The stator has a very aggressive blade design that almost completely reverses the direction of the fluid. A one-way clutch (inside the stator) connects the stator to a fixed shaft i n the transmission. Because of this arrangement, the stator cannot spin with the fluid - i tc a n s p i n o n l y i n t h e o p p o s i t ed i re c t i o n,f o r c i ng th e f l ui d t oc h a n g ed i re c t i o n a s i t h i t s t h e s t a t o r b l a d e s.Something a little bit tricky happens when the car gets moving. There is a point, around 40 mph (64 kph), at which both the pump and the turbine are spinning at almost the same speed (the pump always spins slightly faster). At this point, the fluid returns from the turbine, entering the pump already moving in the same direction as the pump, so the stator is not needed.Even though the turbine changes the direction of the fluid and flings it out the back, the fluid still ends up moving in the direction that the turbine is spinning because the turbine is spinning faster in one direction than the fluid is being pumped in the other direction. If you were standing in the back of a pickup moving at 60 mph, and you threw a ball out the back of that pickup at 40 mph, the ball would still be going forward at 20 mph. This is similar to what happens in the tur bine: The fluid is being flung out the back in one direction, but not as fast as it was going to start with in the other direction.At these speeds, the fluid actually strikes the back sides of the stator blades, causing the stator to freewheel on its one-way clutch so it doesn’t hinder the fluid moving through it.Benefits and Weak PointsIn addition to the very important job of allowing a car come to a complete stop without stalling the engine; the torque converter a ctually gives the car more torque when you accelerate out of a Stop. Modern torque converters can multiply the torque of the engine by two to three times. This effect only happens when the engine is turning much faster than the transmission.At higher speeds, the transmission catches up to the engine, eventually moving at almost the same speed. Ideally, though, the transmission would move at exactly the same speed as the engine, because this difference in speed wastes power. This is part of the reason why cars with automatic transmissions get worse gas mileage than cars with manual transmissions.To counter this effect, some cars have a torque converter with a lockup clutch. When the two halves of the torque converter get up to speed, this clutch locks them together, eliminating the slip page and improving efficiency.离合器发动机产生动力用以驱动车辆。

Clutch technology development historyIn the 100 years of the history of the development of automobile, almost all of the components in terms of technology development have experienced great changes: reliability, production cost, convenient maintenance, energy saving and emission reduction and so on, have been and will always be the automotive industry in the pursuit of goals, these goals for Automotive engineers continue to develop solutions newer and better.Technically, it was not until 1910 that the reciprocating piston internal combustion engine was significantly more efficient than cars and electric vehicles. In 1902, a gasoline engine car first broke the record of the highest speed, and before that, the highest speed record has been created by steam cars and electric cars. Supporters of the three different drivers of the car have been racing and racing for the first ten years of twentieth Century to break the record.Liquid fuel to drive the car to "steam and electric vehicles" (steam and electric vehicle supporters habit called) has a very prominent advantage is its nearly ideal torque characteristics, they do not need a clutch, does not need the transmission, so it is easy to operate, less failure, easier to maintain. Since the reciprocating piston internal combustion engine can only output torque when it reaches a certain speed, it is necessary to have a separate joint between the engine and the transmission. Gasoline engines need to use the clutch engagement function to start the car, because only when the engine reaches a certain speed, the output torque. In addition to the engagement of the clutch, the clutch's separation function is also important because it is free to move in the vehicle. In view of the complexity of the related problems, there is no clutch engagement function in many small car design structures in the early stage.Origin of clutchThe working principle of first generation clutch from the early use of mechanical equipment factory industrial society. Through the analogy of belt transmission, a kind of flat belt is introduced into the car. By means of the tension of the belt pulley, the belt transfers the output torque of the engine to the driving gear, and when the belt is relaxed by adjusting the roller, the belt slipping is equivalent to the separation of the clutch. Because this process causes the abrasion of the belt is too fast, people will adopt a new method: install a drive pulley with the same size of the idler wheel, by pulling the lever, the drive belt from the idler wheel to drive wheel.This belt drive is a disadvantage, low efficiency, easy to wear, especially the transfer of power shortage in rainy days; on the other hand is the requirement of transmission gear to increase engine torque to constantly improve, this has prompted engineers to explore better to replace the clutch.The result is clutch invented a variety of people, including modern clutch pioneer -- Based on the principle of friction clutch. This is a disc located at the end of the crankshaft and connected to another stationary disk. When the two disks are in contact, the friction is produced, and the stationary disk begins to rotate. With the increase of the clamping force, the driving disc drives the driven disc to make thespeed of the driven disk continuously improve until the transmission is working normally, and the two disks rotate at the same speed. Before the two disks are fully engaged, they are in contact with one side and slip, and most of the kinetic energy from the engine is converted into heat. This structure can meet the following two requirements: on the one hand gently gently engage in when starting a car engine will stall, it will not cause the transmission jitter; on the other hand, the clutch can be nondestructively torque to the transmission.Clutch pedal to work through. Press the clutch pedal, pull the conical seat ring through the separation fork, release the spring, so as to separate the clutch.Early clutchIn 1889, Daimler's steel wheel car had used the basic form of this design principle: equipped with a tapered / bevel friction clutch. The freely movable conical disc is located on the transmission shaft, and the flywheel with a tapered groove on the crankshaft can be firmly engaged. The coil spring presses the conical disc into the tapered groove of the flywheel and the clutch is engaged; the foot pedal can be stepped down, and the conical disc can be pulled back by separating the sleeve and the spring, thereby separating the clutch and interrupting the power transmission. Originally used as a conical disc friction surface material, but was quickly replaced the leather. The latter is soaked in castor oil, can prevent moisture, oil / fat. The utility model has the advantages that the utility model can be automatically adjusted, and the input shaft of the transmission is not stressed. On the one hand, the wear of friction plate is too fast, the replacement is too complex, after the friction in the design of the friction plate spring pin or drive to improve. On the other hand, the flywheel and clutch cone is too large, so that the inertia torque is larger and the clutch is much slower than the required separation process.To solve the above problems, around 1910s, with another clutch brake or brake transmission, it through a second foot pedal to play a role, usually the second pedal and the clutch pedal are connected together, and are located in the rear of the pedal shaft.When changing the speed, many drivers are used to make the clutch slipping and not shift, then the flywheel heating degree is more serious than only by the tapered disc friction cone disc by friction layer of leather to heat. After a long period of long-distance driving, due to the thermal expansion of the flywheel, the cone may be more engaging with the flywheel, but when the flywheel temperature drops, it is difficult to separate the cone from the flywheel.Until the first World War period, metal friction began to spread up. Previously, people also experimented with other different materials, such as NAG company designed a camelhair cone disc thin steel sheet pressing, and fitted with a fanlike blade used for cooling, it engages in the two part, bolted to the flywheel on the leather ring line. The two part of the structure allows the free movement of the leather wire ring, thereby simplifying the clutch maintenance and reducing the number of times the clutch is stuck.Daimler motor company has developed an open friction clutch with an aluminum cone. In order to separate the soft, the oil on the friction layer.Because of the simple structure, the cone disc clutch has been the dominant position in the whole 1920s. Cylindrical friction surfaces are not accepted because of their poor operating performance. Only cylindrical clutch spring clutch with the evolution version, due to its creative design, only by Daimler in late nineteenth Century early twentieth Century with the Mercedes Benz car, and continued until the first world war.The traditional single disc dry clutchIn spring clutch, a wearable spiral spring, and the input shaft of the transmission drum end, mounted in the recess of the flywheel. One end of the spiral spring plate is connected with the flywheel, and the other end is fastened on the spring cover. The clutch pedal presses the spring plate, the leaf spring is more and more tight around the drum shape (automatic enhancement), and drives the transmission input shaft. Only a small force can compress the spring and make the clutch soft.About the development of spring clutch in the Daimler company at the same time, Professor Hele-Shaw from the UK also completed the test of multi disc clutch, which is also considered a precursor to the current traditional single disc dry clutch. One of the key advantages of the "Weston" clutch, which can be produced on a large scale, is that it has a large area of friction and can be continuously engaged in a smaller mounting space.In multi disc clutch, flywheel connected to the drum cover, and according to the outer shape of the coil inside the slot, and allow the disc to rotate with the crankshaft and flywheel, and longitudinal movement. The same number of concave disks are positioned in the center of the hub, and the hub is connected to the clutch shaft. These disks can be moved longitudinally along the clutch shaft on the hub. During the installation, the internal and external driven plates of the clutch are alternately connected to form a set of disks, such as the active and driven disks are always connected with each other.The driven disc work like this: start the bronze plate is always facing the steel wheel, and the spiral spring under the pressure plate is pressed together. In this way, all disks are continuously engaged. The gradual increase in the friction force allows the clutch to engage very softly. With the decrease of the spring pressure, the driven plate is separated, and the supporting part of the driving plate starts to bend from the plane of the driven plate. By changing the number of driven disc pairs, the clutch can be adjusted to fit the output power of each engine.Multi disc clutch for oil / gasoline, can also be dry. The dry type is special, and the friction layer is riveted by rivets. Multi disc clutch, especially the oil bath type multi disc clutch, its biggest drawback is a certain degree of hysteresis, which can only be part of the separation, resulting in difficult shift.After several years, single disc clutch has eliminated the cone disc and multi disc clutch. De Dion and Bouton are the first to realize that a single disc clutch is the future direction of the clutch. With the appearance of Ferodo asbestos friction sheet, clutch technology has made great progress. Asbestos friction sheet has been used since 1920s, until it is replaced by non asbestos friction sheet. The advantage of a single disc dry clutch is obvious: the lower drive disc mass allows it to stop fasterafter separation, thus making it easier to shift gears - a complete farewell to the transmission brake structure.The original structure single disc dry relatively complex. The clutch housing is bolted to the flywheel and the clutch cover is bolted to the clutch housing. The clutch cover with the spring to the inner side of the compression lever is transferred from the intermediate plate through the friction disc, and the torque from the flywheel is transmitted to the transmission. The friction disc is connected to the connection or transmission input shaft by the driver. The clutch is separated and joined by means of a sliding ring plate that allows the tapered disc to move forward and backward. Each side of the cone disc acts on the separating lever correspondingly, and the separating lever is operated by a spiral spring, and is pressed or separated. Due to the fact that the cone is rotating and the sliding ring is stationary, it needs to be lubricated periodically.The spiral spring clutch pressing force provided by the spring, won the people's recognition. At first, the coil spring is placed in the middle of the test, but only a few smaller spiral or spiral spring along the outer ring of the clutch housing arrangement of the structure to be mass production. The release lever compresses the coil spring by a separate bearing which can move freely on the transmission input shaft to separate the clutch. The pressing force can be due to the use of different spring and change, but there is a fatal disadvantage, namely with the increase of engine speed, a spiral spring located in the outer ring of the pressure plate, due to the centrifugal force to the spring cover direction to the outward pressure, the friction between the spring and the cover, the pressing force performance curve change.As the engine speed increases, the clutch becomes heavier and heavier. In addition, the separation bearing used to separate the lever has been in a state of pressure, so that it and the clutch cover is easy to wear, especially in the high speed of the engine gear shift, will soon wear.The birth of diaphragm clutchIn order to solve the problems of these systems, we developed a diaphragm spring clutch diaphragm spring clutch, the research laboratory was born in 1936 of general motors, and mass production in late 1930s in the United states. In Europe, after the Second World War, people began to be familiar with the diaphragm spring clutch through the American General Company military truck, and in the middle of 1950s in a number of single European models. Porsche 356, BMW Goggomobil 700 and DKW Munga is the first batch of the diaphragm spring clutch is equipped with German cars. Diaphragm spring clutch mass production began in 1965 with the Opel Rekord models.Because of the diaphragm spring clutch can be balanced and symmetrical rotation, so it is not affected by the engine speed. The diaphragm spring clutch was a success in 1960s, when the camshaft top mounted high speed engine (Glas, BMW, Alpha Romeo) was widely used to replace the camshaft engine. By the end of the 1960s, almost all car manufacturers have adopted diaphragm spring clutch.Here need to emphasize is: let LuK in diaphragm spring clutch mass production, played a crucial role. Replace all the separate lever helical spring system withdiaphragm spring, brings a lot of advantages: simple structure, constant pressing force, installation space is relatively high pressing force only needs a relatively small (very important for transverse engine) and is not affected by the impact of engine speed. Because of these characteristics, almost all of the modern use of diaphragm spring clutch, and its application in the multi-function car is also more and more - has been the use of spiral spring clutch.With the development of correspondingly, clutch disc has been optimized. Reciprocating piston internal combustion engine changes in the speed and torque generated by the vibration of the crankshaft, clutch, transmission input shaft to the transmission, resulting in noise and severe gear wear. In the modern automobile, the weight of the flywheel and the vehicle is increasing, so the clutch driven disc with the torque damper and the wave spring is developed.Long time operated clutch needs a strong thigh, because the pedal force must be transferred through the connecting rod or shaft / cable. With the application of the clutch and the hydraulic separation mechanism in 1950s in 1930s, the driving comfort has been improved.To try different clutch automatic clutch to make operation more simple: in 1918, Wolseley first proposed the concept of electromagnetic clutch. In the early 1930s, the French Cotal company produced a luxury car with a magnetic clutch, a pre selector transmission. The most famous is the centrifugal clutch to adjust the clamping force by centrifugal force and automatic clutch, such as Saxomat (Fichtel & Sax company), LuKomat (LuK), Manumatik (Borg & Beck) and Ferlec (Ferodo).离合器技术发展史在100多年的汽车发展史中,几乎所有的零部件在技术方面都经历过巨大的发展变化:可靠性、生产成本、维护便利性、节能减排性等,都已经且将一直成为汽车行业的追求目标,这些发展目标要求汽车工程师们不断地开发出更新更好的解决方案。

附录附录A外文文献原文7-Speed Dual Clutch Transmission System for Sporty Application ABSTRACT:With its 7-speed dual clutch transmission, ZF has introduced an innovative transmission for sporty applications. The close ratios combined with extremely spontaneous drive behavior makes it an ideal transmission for sporty applications. This article describes the compact gear set with lubrication by injection for improving the level of efficiency and increasing the engine-speed-strength, the dual clutch unit as well as the hydraulic control unit, which is based on the pre-control principle, are also described in detail. The hy-draulic control principle provides the option of a hydraulic cruise mode in the event of an electronics failure. In addition to the transmission design, functional features that also highlight the sporty character of the transmission are described in detail.Key words: Automatic transmission; Dual clutch; Vehicle connection; Efficiency1 IntroductionWhen it comes to the field of automatic transmissions, dual clutch systems currently represent the benchmark in terms of spontaneity and sportiness. In this type of transmission, which is based on a countershaft transmission, these advantages are combined with a very direct "vehicle connection", high rpm performance, and excellent transmission efficiency.The 7-speed dual clutch transmission for the standard driveline presented here is designed for a torque capacity of up to 520 Nm and rotational speeds of up to 9250 rpms. In order to be able to achieve these performance data in the existing installation space, a concept was developed in which an oil chamber as well as lubrication by injection are used. Before introducing the transmission′s several unique features in more detail below, an overview of the basic transmission design will be presented, Fig. 1.The engine torque is introduced to the dual clutch via a torsion damper (not shown in Fig. 1). The multidisk clutches in the dual clutch are radially nested in one another and transfer the torque to both input shafts in the countershaft transmission gear set. In this case, due to the installation space, the countershaft is not located under the main shaft, but is tilted laterally. This becomes possible because the concept is based on lubrication by injection with a dry sump. On the one hand, lubrication by injection improves heat removal, on the other, there are nonoticeable losses due to the gears splashing in the oil pan. The oil is supplied to the transmission via an internal gear pump which is driven by a spur gear train behind the dual clutch. With the help of a spur gear train, the drive unit has the advantage that, via different gear ratio phases and depending on the intended use, the flow rate and the max. speed of the pump can be adapted. An additional advantage is that based on theresulting I proved installation space, an optimal ratio between the pump width and the pump diameter can be achieved for the pump′s level of efficiency. The hydraulic control unit is arranged under the gear set. The hydraulic unit supplies the clutch, based on need, with pressure and cooling oil as well as shift actuators. The latter are arranged laterally to the gear set and work with double-acting cylinders. The sensor for detecting the position of the gearshifts is attached directly onto the four gearshifts. The transmission has an external control unit.Fig.1Overview dual clutch transmission (DCT)2 Seven speeds with sophisticated stepping-a concept for extrme sporti- nessThe gear set concept of the dual clutch transmission introduced here was developed in house taking into consideration the following requirements:High power densityHigh speed endurance strength up to 9250 rpm Variability and modular designRepresentation of transmission-ratio spreads of about 4.7 and 6.8 with 7 speedsUse of existing synergies for manual transmissionsAfter extensive systematic development of the gear set in which many thousands of variants were produced and compared, the gear set concept that is illustrated in Fig. 2 is the final variant and the ideal concept for achieving the goals specified.The gear set selected is based on the constant drive concept and consists of two concentric drive shafts each of which are driven by one of the two multidisk clutches in theFig.2Gear set scheme of 7D variantdual clutch, two countershafts also concentric to one another, a main shaft and an output shaft. The gear ratios are engaged by the four synchronizer units A/B, C/D, E/F, and G/H, which are arranged on the main shaft and on the hollow countershaft and these are connected to the loose wheels or the adjacent shafts. An important feature in the gear set is the connectability of both countershafts through the C/D synchronizer unit. In the D shift position, the gear ratios selected in this way can be doubly used which reduces construction costs compared to conventional dual clutch gear sets. Similarly, this feature is used in first gear because then the vehicle is started up using the more powerful K1 clutch. Because of this dual use of the last gear level in the transmission for the first and second gear, the desired ratio step 1-2 is achieved through the transmission ratios of both constant drive phases.The use of the K1 clutch for starting up in first gear results inevitably in the direct gear also being assigned to the odd subsection. In this case, the fifth and seventh gears can be selected as a direct drive. With this feature, it was possible to develop a modular gear set which, on just a few changes,contains two different transmission gear ratio variants with fundamentally different characters.For the first version, with an overall spread of about 4 . 7 , the seventh gear is selected as a direct gear (called the 7D variant). Fig. 2 shows the relevant gear set diagram with the performance flows in all speeds. Due to its sophisticated gear steps, this transmission is highly suitable for very sporty vehicles that need only a "little" transmission stepping due to the high rotating engine. Optimal tractive power can be provided at any time duringvehicle operation.The second version is based on the 7D variant, however, fifth gear was selected as the direct drive. When maintaining the torque multiplication ratio and in adapting the transmission ratio of several lower gear levels, you get the 5D variant with a considerably higher transmission-ratio spread for vehicles with increased comfort demands and simultaneously reduced consumption.Fig. 3 illustrates the design of the 7D variant. The main similarity with existing manual transmissions for standard transmissions is noticeable. Due to the compact gear set design, the sufficient shaft dimensioning and the favorable arrangement in proximity of the bearing of the high transmitting ratios, central bearing glasses were not necessary despite the proportionally large bearing clearance.Overall, only two housing bearing levels are necessary where the front level is located behind both constant gears. In addition, a very compact and inexpensive transmission design could be implemented based on the bearing concept selected, especially in the area of the hollow shaft.Fig.3Sectional Drawing of 7D variant3 The dual clutchThe central module of this highly topical transmission concept is the wet dual clutch. With a broad spectrum of technical features, it implements the functional provisions of the transmission control unit and thus distinguishes the special character of this transmission concept.Very fast delay times, low inertia and good, comfortable friction value progressions facilitate, very sporty handling with highly dynamic gear shifting and comfortable cruising at a high level of efficiency. The dual clutch placed directly on the transmission input accepts the engine torque from thtorsion damper and feeds it to one of the two subsections, depending on the situation.Safety considerations have led to a "normall open" design.The radial arrangement of the multidisk pack age represents the best combination of performanc and installation space need, Fig. 4.Fig.4Dual clutchCareful lining and oil selection as well as intensive enhancement of this tribological system are the requirements for comfort and performance of this clutch throughout its service life.Through intense testing and detailed calculations, it was possible to achieve a very high therma loading capacity. As part of the process, the lining type, dimensioning, and grooving as well as equal distribution of thermal load and oil flow in the multidisk package are decisive design features.Low torque drag even with low temperatures as well as high speed endurance strength support comfort and a high level of sportiness, but are also important safety requirements.Rotating, centrifugal force-compensating clutch cylinders with hysteresis optimized gaskets make the clutches easy to control. Integrated plate springs reliably accept rapid piston resetting even at high speeds.In the case of an open clutch, only transmission input shafts with very low additional mass inertia are used. This supports rapid synchronizing sequences and a long service life of the synchronizer units.4 The hydraulic control unitIn the present dual clutch transmission, the hydraulic control unit fulfills the following tasks:Actuating the dual clutchShifting the gearshifts, i. e. engaging/synchronizing the gearCooling the dual clutchGear lubricationEmergency stop function in case of complete failure of transmission electronicsSeveral features in the hydraulic control unit as well as criteria for the selection of the control concept are going to be described in more detail below.4.1 PerformanceThe use of the dual clutch transmission in sporty vehicles demands high performance from the hydraulic control unit, especially with regard to the first two tasks because the timely "handling" of these tasks come into play in gear shifting and gear shifting times.That is why particular value is placed on the selection of the right control unit concept as part of the system design. During the decision process, the choice was made, in principle, between two concepts, Fig. 5.Fig.5Control concept direct control / precontrolPrecontrol of the valvesDirect control of the valves (so-called cartridge valves)In case of direct control, the valve that is used for pressure control, e.g. a clutch, is directly connected to the power-generating proportional solenoids and provides the main pressure to the corresponding clutch pressure.The precontrol uses the pressure that is supplied by a pressure controller, for example, to actuate an additional valve that supplies the clutch pressure from the main pressure.To assess the performance of both concepts, a larger number of compared measurements were performed with different systems, of which two systems shall be considered here:ZF hydraulic control unit with precontrol for DCT standard driveComparative hydraulic control unit with direct controlA reference clutch was used as the clutch to engage. Criteria for assessing the performance were (see also Fig. 6):Fig.6Delay, increase/rise, and fall times. Red curve: Power /Electric current. Green curve: ClutchpressureDelay time, 1 to 4Time of step response until clutch inflation pressure, 1 to 2Time of the step response up to 90% of the main pressure 1 to 3Time of pressure drop (emptying times), 5 to 6Fig. 6 shows, as an example, the times for a transmission oil temperature of + 20°C to be reached. One notices that the direct control first in dicates a lower delay time (14.3 ms) compared to the precontrol (30.1 ms), see also time of brand 1to 4.For increase to clutch inflation pressure or to 90% of the main pressure shows, however, the advantage of the precontrolled system (see also summarizing tab 1).Emptying times, also present a disadvantage for direct control. Trans-mission oil temperature of -20°C also show comparable results for step responses and fall times.All of the tests support the statement that direct control has an advantageous effect with small oil volumes. However, if large oil volumes have to be transported, precontrol valves are to be preferred due to larger opening cross-sections.4.2 Operational safetyOperational safety is determined essentially due to the soiling tendency because the so-called silting can lead to the valves getting jammed. Provocation tests with transmission-specific environmental conditions (dirty oil) demonstrated the influences of soiling on the characteristic curves. Technical, trouble-free characteristic curve progressions could be illustrated only with a high dither amplitude in valve actuation, which leads, in turn, to increased valve wear-and-tear due to the micro movements that it causes. The increased tendency toward soiling can result needing a fine filter.4.3 CostsIn addition to the delay time comparison as well as assessing the operational safety, the costs were relevant for a final evaluation. The compari son with regard to the hydraulic and electro-mag netic components shows that a precontrol system has cost benefits compared to a direct control system. Added to this are the higher flows with the actuation of direct control valves, which, in turn, result in a more expensive TCU. Furthermore, in opting for precontrol, ZF is able to "pool" together pressure controllers in large quantities because these, too, are used in the automatic ZF planetary gear set.4.4 Emergency stop functionIn case there is a complete outage in the transmission electronics, a hydraulic emergency stop function is actuated in the transmission. The clutch that is pressurized with a larger amount of pressure in the event of a system outage will continue to be pressurized. This condition is maintained until an adjustable engine speed threshold is achieved, then the clutch opens in order to prevent the engine from being choked. It is not possible to re-start this system.5 Sporty functionsFor function developers, the dual clutch transmission offers the opportunity to combine the comfort of a stepped automatic transmission with the dynamics and sportiness of a countershaft transmission. Connected, therefore, are typical " catalog values," such as time from zero to 100 kilometers per hour or the time from 80 to 120 kilometers per hour with correspondingly fast kick-down shifting, but also subjective acceleration sensitivity during a shifting sequence where the purist among the manual transmission drivers still wants to feel that jolt of acceleration.One function especially designed for the dual clutch transmission in sports cars is the "race start"function. The race start is a function used to achieve optimal acceleration from astandstill, i.e. in the shortest time from 0 to 100 km/h. The sequence progresses as follows: The engine is brought to a suitably high rpm with the clutch engaged in first gear. The driver simultaneously actuates the brakes with the lef foot so that the clutch can already be lightly engaged and the gas pedal (full throttle) in order to bring the vehicle up to the target speed. By simultaneously pressing and holding an operating element, such as the selector lever or a push button on the steering wheel, the race start intention is conveyed to the system, the engine speed adjusted and the start up prevented until the driver releases the brake. During the race start, the clutch is closed under the control of the wheel slip with which the optimal acceleration is achieved and by exploiting the dynamic engine torque (inertia torque). The entire procedure progresses automatically once the driver releases so that even an inexperienced drivercan achieve the best possible drive performance figures. Obviously, the driver can cancel the procedure by removing his/her foot from the gas pedal or touching the brakes. Also, the system recognizes when the street conditions do not permit a race start, such as wet roads, for example. Due to the optimal start-up and a shifting sequence into second gear free of traction interruption (see also sports shifting), the race start function enables the acceleration time of 0 to 100 km/h to be improved by an average of 0.2 sec compared to a car with a manual transmission. At the same time, this functionality helps avoid improper use and resulting clutch overload.The top chart in Fig. 7 illustrates the engine and transmission input shaft speed, the lower chart shows the vehicle′s longitudinal acceleration. Starting with a cranking speed of 6,800 rpm, the clutch begins to close, which leads to an engine pressure up to about 4,000 rpm. The dynamic engine torque used to achieve this results in an acceleration of 0.7-0.9 g. In the process, noticeable vibrations in the transmission input shaft speed signal develop due to the wheel slip regulation. After about 1.2 sec, the vehicle is accelerated only by the engine torque with approx. 0.5 g. It must be mentioned here that this test was performed using a vehicle with very high traction. In most cases, a starting speed of only up to about 4,000 rpm is reasonable.A further function developed for the dual clutch transmission is so-called sports shifting. This is described in more detail below.In general, a gear-shift change by the driver is only perceived acoustically by the change in the engine speed. The transition from the acceleration level of the original gear toFig.7Measurement of a race starthe new gear should be made smoothly and continuously. This also corresponds to the standard shifting sequences in auto-matic and dual clutch transmissions. However, many drivers of sporty cars wish that they had the option of both distinctive comfort shifting sequences as well as sporty shifting sequences, which, besides the haptic response (acceleration jolt), also have an acceleration advantage as a result. To this end, the dynamic engine torque can also be used again. The requirement for this is the torque capacity of the dual clutch which has to be able to transmit this torque increase. As the possible torque increase depends on the gradients of the engine speed, this can be used particularly effectively in shifting gears with a large speed difference with the target gear (large ratio spread/ratio step), which is why the gear changes 1-2, 2-3, and 3-4 are offered. In the process, sports shifting from the frst to second gear can serve as a supplement to the ace start for improving the acceleration time from to 100 km/h. As the use of the dynamic torque is pure application topic, we distinguish, as a rule,between three shifting systems. Fig. 8 illustrates he stylized differences and features between the hifting systems, Fig. 9 shows an original measurement from a prototype vehicle.The top chart shows the respective engine and ransmission speed, the bottom chart shows the orques from both clutches. The bottom line in the hart represents the clutch from the target gear that is used to achieve the torque increase during engine sp eed adjustment and thereby acceleration gains.Fig.8Simplified depiction of acceleration procedures with Fig.9Measurement of sports shift 2-3 in the vehicle附录B外文文献翻译运动型7速双离合器变速器系统摘要:ZF公司的7速双离合器变速器是一款创新型的、适用于运动型车辆的变速器。

附录How Does the Clutch WorkThe clutch is a device to engage and disengage power from the engine, allowing the vehicle to stop and start.A pressure plate or “driving member” is bolted to the engine flywheel, and a clutch plate or “driven member” is loc ated between the flywheel and the pressure plate. The clutch plate is spline to the shaft extending from the transmission to the flywheel, commonly called a clutch shaft or input shaft. When the clutch and pressure plates are locked together by friction, the clutch shaft rotates with the engine crankshaft. Power is transferred from the engine to the transmission, where it is routed through different gear rations to obtain the best speed and power to start and keep the vehicle moving.The flywheel is located at the rear of the engine and is bolted to the crankshaft. It helps absorb power impulses, resulting in a smoothly-idling engine and provides momentum to carry the engine through its operating cycle. The rear surface of the flywheel is machined flat and the clutch components are attached to it. The driving member is commonly called the pressure plate. It is bolted to the engine flywheel and its main purpose is to exert pressure against the clutch plate, holding the plate tight against the flywheel and allowing the power to flow from the engine to the transmission. It must also be capable of interrupting the power flow by releasing the pressure on the clutch plate. This allows the clutch plate to stop rotating while the flywheel and pressure plate continues to rotate.The pressure plate consist of a heavy metal plate, coil springs or diaphragm spring, release levers (fingers), and a cover. When coil springs are used, they are evenly spaced around the metal plate and located between the plate and the metal cover. This places an even pressure against the plate, which in turn presses the clutch plate tight against the flywheel. The cover is bolted tightly to the flywheel and the metal pate is movable, due to internal linkages. The coil springs are arranged to exert direct or indirect tension on the metal plate, depending upon the manufacturer’s design. Three release levers (fingers), evenly spaced around the cover, are used on most pressure plates to release the holding pressure of the springs on the clutch plate, allowing it to disengage the power flow.When a diaphragm spring is used instead of coil springs, the internal linkage is necessarily different to provide an “over-center” action to release the clutch plate from the flywheel. Its operation can be compared to the operation of an oilcan. When depressing the slightly curved metal on the bottom of the oilcan, it goes over-center and gives out a loud “clicking” noise; when released, the noise is again heard as the metal returns to its originalposition. A click is not heard in the clutch operation, but the action of the diaphragm spring is the same as the oilcan.The clutch plate or driven member consists of a round metal plate attached to a splined hub. The outer portion of the round plate is covered with a friction material of molded or woven asbestos and is riveted or bonded to the plate. The thickness of the clutch plate and /or facings may be warped to give a softer clutch engagement. Coil springs are often installed in the hub to help provide a cushion against the twisting force of engagement. The splined hub is mated to (and turns) a splined transmission shaft when the clutch is engaged.The release (throw out) bearing is usually a ball bearing unit, mounted on a sleeve, and attached to the release or throw out lever. Its purpose is to apply pressure to the diaphragm spring or release levers in the pressure plate. When the clutch pedal is depressed, the pressure of the release bearing or lever actuates the internal linkages of the pressure plate, releasing the clutch plate and interrupting the power flow. The release bearing is not in constant contract with the pressure plate. A linkage adjustment clearance should be maintained.The clutch pedal provides mechanical means for the driver to control the engagement and disengagement of the clutch. The pedal is connected mechanically to either a cable or rods, which are directly connected to the release bearing lever.When the clutch pedal is depressed, the linkage moves the release bearing lever. The release lever is attached at the opposite end to a release bearing which straddles the transmission clutch shaft, and presses inward on the pressure plate gingers or the diaphragm spring. This inward pressure acts upon the fingers and internal linkage of the pressure plate and allows the clutch plate to move away from the flywheel, interrupting the flow of power.While the clutch pedal is depressed and the power flow interrupted, the transmission can be shifted in to any gear. The clutch pedal is slowly released to gradually move the clutch pate toward the flywheels under pressure of the pressure plate springs. The friction between the clutch plate and flywheel becomes greater as the pedal is released and the engine speed increased. Once the vehicle is moving, the need for clutch slippage is lessened, and the clutch pedal can be fully released.Coordination between the clutch pedal and accelerator is important to avoid engine stalling, shock to the driveline components and excessive clutch slippage and overheating.离合器如何工作离合器是传递和分离发动机动力的装置,实现车辆的停车和启动。

附录 AClutch between engine and transmission installed in the car to travel from the start the whole process, often need to use the clutch. Its role is to make the engine and transmission can be gradually between the joint, thus ensuring a smooth start car; temporarily cut off the link between the engine and transmission to shift at the time of shift and reduce the impact; When the car when emergency braking from Separate role in preventing the transmission and other drive system overload, play a protective role.Clutch similar to the switch, splice or break away from the power transmission and, accordingly, have any form of auto clutch, but the form is different.By the friction plate clutch, springs, pressure plate and the power output shaft composed, arranged between the engine and gearbox, the engine flywheel to the torque is passed to the stored transmission, to ensure that vehicles in different driving conditions passed to the driver Wheel driving force and the right amount of torque, is the scope of the powertrain. In the half-time of linkage, clutch and power input power output allowed speed difference, that is, the speed error to achieve through its transfer an appropriate amount of power. Clutch is divided into three work status, ie the clutch all connections, some of the half clutch linkage and the clutch is not linked.When a vehicle in normal driving, the pressure plate is jammed against the friction plate on the flywheel, pressure plate and friction plate at this time the friction between the largest between the input shaft and output shaft remained relatively static friction, both the same speed . When the vehicle is started, the driver depresses the clutch, clutch pedal movement by pulling back pressure plate, which is the separation of the pressure plate and friction disc, pressure plate and flywheel at this time no contact, but also the relative friction does not exist. Last one, that is, half of the clutch linkage status. At this point, the pressure plate and friction disc friction less than the full-linked state. Clutch pressure plate and flywheel friction plate on the sliding friction between the state. Flywheel speed is greater than the output shaft speed, transmission out of the power from the flywheel to the transmission part of the pass. Between the engine and driving wheels at this time is equivalent to a soft connection status.In general, the clutch and the shift in the vehicle when starting to play a role, this time a transmission shaft and the speed difference between the two shafts, engine power must be cut with a shaft after the synchronizer can be very good a shaft speed will be kept synchronized with the second axis, gear hanging up after, and then through the clutch shaft and the engine power will be a combination of the power continue to be transmitted. In the clutch, there is an essential buffer device, which consists of two similar to the flywheel with the disc, the disc hit a rectangular groove, the groove arrangement of the spring, in the face of fierce shock between the two disc springs between the elastic effect, buffer external stimuli. Effective protection of the engine and clutch. Various parts of the clutch, pressure plate spring strength, friction coefficient of friction plate, clutch diameter, location, and the clutch friction disc clutch performance is to determine the number of key factors, the greater the stiffness of the spring, the higher the friction coefficient of friction plates, the larger the diameter of the clutch, clutch performance, the better.附录 B离合器安装在发动机与变速器之间,汽车从启动到行驶的整个过程中,经常需要使用离合器。

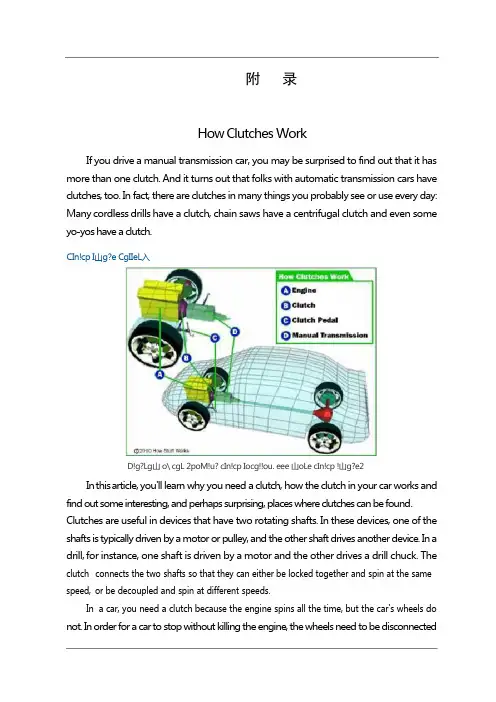

附录How Clutches WorkIf you drive a manual transmission car, you may be surprised to find out that it has more than one clutch. And it turns out that folks with automatic transmission cars have clutches, too. In fact, there are clutches in many things you probably see or use every day: Many cordless drills have a clutch, chain saws have a centrifugal clutch and even some yo-yos have a clutch.CIn!cp I山g?e CgIIeL入D!g?Lg山 o\ cgL 2poM!u? cIn!cp Iocg!!ou. eee 山oLe cIn!cp !山g?e2In this article, you'll learn why you need a clutch, how the clutch in your car works and find out some interesting, and perhaps surprising, places where clutches can be found. Clutches are useful in devices that have two rotating shafts. In these devices, one of the shafts is typically driven by a motor or pulley, and the other shaft drives another device. In a drill, for instance, one shaft is driven by a motor and the other drives a drill chuck. The clutch connects the two shafts so that they can either be locked together and spin at the same speed,or be decoupled and spin at different speeds.In a car,you need a clutch because the engine spins all the time,but the car's wheels do not. In order for a car to stop without killing the engine, the wheels need to be disconnectedf rom the engine somehow. The clutch allows us to smoothly engage a spinning engine to a non-spinning transmission by controlling the slippage between them.To understand how a clutch works, it helps to know a little bit about friction, which is a measure of how hard it is to slide one object over another. Friction is caused by the peaks and valleys that are part of every surface -- even very smooth surfaces still have microscopic peaks and valleys. The larger these peaks and valleys are, the harder it is to slide the object. You can learn more about friction in How Brakes Work.A clutch works because of friction between a clutch plate and a flywheel. We'll look at how these parts work together in the next section.Fly Wheels,Clutch Plates and FrictionIn a car’s clutch, a flywheel connects to the engine, and a clutch plate connects to the transmission. You can see what this looks like in the figure below.When your foot is off the pedal, the springs push the pressure plate against the clutch disc, which in turn presses against the flywheel. This locks the engine to the transmission input shaft, causing them to spin at the same speed.Pressure plateThe amount of force the clutch can hold depends on the friction between the clutch plate and the flywheel, and how much force the spring puts on the pressure plate. The friction force in the clutch works just like the blocks described in the friction section of How Brakes Work, except that the spring presses on the clutch plate instead of weight pressing the block into the ground.W h en the clutch pedal is pressed, a cable or hydraulic piston pushes on the release fork, which presses the throw-out bearing against the middle of the diaphragm spring. As the middle of the diaphragm spring is pushed in, a series of pins near the outside of the spring causes the spring to pull the pressure plate away from the clutch disc (see below). This r eleases the clutch from the spinning engine.Common ProblemsFrom the 1950s to the 1970s, you could count on getting between 50,000 and 70,000 miles from your car's clutch. Clutches can now last for more than 80,000 miles if you use them gently and maintain them well. If not cared for, clutches can start to break down at 35,000 miles. Trucks that are consistently overloaded or that frequently tow heavy loads can also have problems with relatively new clutches.Photo courtesy Carolina MustangClutch plateThe clutch only wears while the clutch disc and the flywheel are spinning at different speeds. When they are locked together, the friction material is held tightly against the flywheel, and they spin in sync. It's only when the clutch disc is slipping against the flywheel that wearing occurs. So, if you are the type of driver who slips the clutch a lot, you'll wear out your clutch a lot faster.Sometimes the problem is not with slipping, but with sticking. If your clutch won't release properly, it will continue to turn the input shaft. This can cause grinding, or completely p revent your car from going into gear. Some common reasons a clutch may stick are: Broken or stretched clutch cable - The cable needs the right amount of tension to push and pull effectively.Leaky or defective slave and/or master clutch cylinders - Leaks keep the cylinders from building the necessary amount of pressure.Air in the hydraulic line - Air affects the hydraulics by taking up space the fluid needs to build pressure.Misadjusted linkage - When your foot hits the pedal, the linkage transmits the wrong amount of force.Mismatched clutch components - Not all aftermarket parts work with your clutch.depress fully. If you have to press hard on the pedal, there may be something wrong. Sticking or binding in the pedal linkage, cable, cross shaft, or pivot ball are common causes. S o metimes a blockage or worn seals in the hydraulic system can also cause a hard clutch. Another problem associated with clutches is a worn throw-out bearing, sometimes called a clutch release bearing. This bearing applies force to the fingers of the spinning pressure plate to release the clutch.If you hear a rumbling sound when the clutch engages,you might have a problem with the throw-out.Types of ClutchesThere are many other types of clutches in your car and in your garage.An automatic transmission contains several clutches. These clutches engage and disengage various sets of planetary gears. Each clutch is put into motion using pressurized hydraulic fluid. When the pressure drops, springs cause the clutch to release. Evenly spacedridges, called splines, line the inside and outside of the clutch to lock into the gears and the clutch housing. You can read more about these clutches in How Automatic Transmissions Work.An air conditioning, compressor in a car has an electromagnetic clutch. This allows the compressor to shut off even while the engine is running. When current flows through a magnetic coil in the clutch, the clutch engages. As soon as the current stops, such as when you turn off your air conditioning, the clutch disengages.Most cars that have an engine-driven cooling fan have a thermostatically controlled viscous clutch -- the temperature of the fluid actually drives the clutch. This clutch is positioned at the hub of the fan, in the airflow coming through the radiator. This type of clutch is a lot like the viscous coupling sometimes found in all-wheel drive cars. The fluid in the clutch gets thicker as it heats up, causing the fan to spin faster to catch up with the engine rotation. When the car is cold, the fluid in the clutch remains cold and the fan spins s lowly, allowing the engine to quickly warm up to its proper operating temperature.Many cars have limited slip differentials or viscous couplings, both of which use clutches to help increase traction. When your car turns, one wheel spins faster than the other, which makes the car hard to handle. The slip differential makes up for that with the help of its clutch. When one wheel spins faster than the others, the clutch engages to slow it down and match the other three. Driving over puddles of water or patches of ice can also spin your wheels. You can learn more about differentials and viscous couplings in How Differentials Work.Gas-powered chain saws and weed eaters have centrifugal clutches, so that the chains or strings can stop spinning without you having to turn off the engine. These clutches work automatically through the use of centrifugal force. The input is connected to the engine crankshaft. The output can drive a chain, belt or shaft. As the rotations per minute increase, w eighted arms swing out and force the clutch to engage. Centrifugal clutches are also often found in lawn mowers, go-karts, mopeds and mini-bikes. Even some yo-yos are m anufactured with centrifugal clutches.C lu tches are valuable and necessary to a number of applications. For more information on clutches and related topics, check out the links on the following page.离合器工作原理如果您驾驶手动变速箱的汽车,您可能会惊讶地发现,它有一个以上的离合器。

附 录录1Clutch of new developments in technologyAbstract: in recent years car design and manufacturing technology progress for all to see. In order to further improve product performance, prolong service life, common mechanical clutch technology is also produced a remarkable change. No matter from structural characteristics, product process performance, or control technology, mechanical clutch of technological progress in some extent reflects the development of design concepts, and possible technology trends in the future.Keywords: clutch; Technology development1, introductionIn car technology rapid development today, especially with the electronic technology in cars, the extensive application of vehicle drivetrain is had great progress, as an important part of the transmission of the clutch assembly force transmission, the burden of reducing vibration and prevent system overload very important role. To make sure that the power transmission and reliable, separate thoroughly, combined with soft, damping good, small volume, light weight, easy, long service life, making the clutch product either cash from the performance, structure, or manufacturing mode and control, in the occurrence of a lot of change. They greatly optimized clutch all aspects of performance, to some extent look, these changes are also reflected the development direction of the clutch.2, engine flywheel new structureAs one of the flywheel storage components engine, is also part of the clutch initiative. As the car transmission belong to multi-freedom torsional vibration system, whether the incentive and transmission system, or the associated force vibration type and the coupling vibration with other statements are very complex. In order to adapt to car driving conditions of vibration and noise reduction of reducing the need, making cars, ride comfort the role of torsional shock absorber is extremely important. It should be able to adjust the system inherent frequency, the system mainly low-order resonance critical speed remove common, also need to use speed range, still need to decrease amplitude damping of transmission system can reduce idle noise, ease the impact of the special case load. Previous clutch platen set on by a twist of shock absorber, decorate a space place is restricted, shock absorber work reverse Angle small, torsion stiffness big, capacity small, springs, and therefore not guarantee the intensity of vibration reduction is limited.In recent years, the emergence of a reverse damping characteristics and performance to price are ideal double quality flywheel structure. The flywheel by primary flywheel, reverse shock absorber and subprime flywheel composition, among them, the primary flywheel on one hand we should provide for the shock absorber and clutch installation space, on theother hand also with appropriate rotational inertia insure a car, and reduce passed back starting the amplitude. Generally, double quality flywheel adopts with circular arc shape along the spiral spring primary flywheel outer periphery decorate way, in limited circumstances decorate a space, the arrangement to obtain larger primary flywheel rotational inertia. The inertia and the clutch after brief increase engine speed fluctuation of related parts, shorten their service life. To avoid the above phenomenon, often need additional Settings special damping, such, can increase the difficulty and cost of product development. Because the engine of the car front front drive type of transmission installation space is limited, so this kind of structure in FF type cars to the promotion. Meanwhile, this kind of decorate spring along the circumference, due to high speed double quality flywheel centrifugal role, spring wear when, or even produces broken.Using radial layout springs can improve the double quality flywheel of the above mentioned products defect. It consists of primary flywheel, 3 ~ 4 springs box, damping dish and subprime flywheel composition. Because the suspension spring box of radial layout, the primary flywheel rely on four posts the muscles of rib takes form enough flywheel stiffness and produced similar with traditional flywheel inertia.This kind is decorated in a small space to with smaller quality to gain the maximum rotation inertia, help reduce the assembly structure, the axial dimensions for subprime flywheel and clutch decorate a space make more. Its damping device by a wear-resisting plastic gasket, a belt of steel plate and a slot disc spring washers constitute, they set in damping plate, rely on damping disc hole flanging positioning and compaction, the damping disk with primary flywheel riveted by the subprime, plastic gasket flywheel slot drive. Practice proves that the double quality than ever, this structure can be the flywheel in a limited space get quite good vibration reduction.Engine for the job, usually by the flywheel, inertia and the clutch clutch disc provides together. The ideal flywheel structure should be to offer the same, and ensure enough inertia structure stiffness premise to minimize the flywheel quality, stamping steel way to replace traditional casting can obtain the flywheel ways to produce the effect. Change the pressure by casting lron yuntechtc ring, start toothed ring and steel blunt system drivers disk of three parts. In the ring gear driving plate welding, pressure rings and drivers disk riveting, pressure ring of moment of inertia of the subject constitutes a flywheel, and provide for the clutch friction surface and heat conduction. Drivers disk improve enough flywheel stiffness, and using laser welding and clutch cover, this is connected to this structure forms of changescan be compared to traditional iron flywheel reduce quality 5% ~ 10%. USES the steel plate stamping type flywheel, and clutch cover and flywheel connections between after replacing bolt connection with welding, reducing the number and machinery manufactured parts, which reduces the production cost. The foregoing radial layout springs double quality can use this stamping yuntechtc for structure form, reducing axial dimensions []17. 3, clutch discClutch platen design of the main contradiction is facing, on one hand, hope to have as played platen diameter, in order to obtain the good preach torsional characteristic, reducing friction slices wear quantity and improve the service life, on the other hand, hope the decrease of the platen as possible, so as to shorten the rotational inertia of the variable transmission shift, ensure the synchronization time of smooth, transmission clutch platen ontology conscious drops, and therefore made wavy often difficult to coordinate the contradiction. When using triangle groove platen ontology structure, while keeping the original way wavy platen ontology has the axial elastic properties at the same time, because of its large on the plane can be formed, enough to make its and friction slices adhesive is used to connect the replacement of traditional riveting, so that in friction chip will not need the thickness of the steel back to reserve rivet, so clutch friction slices thickness, which can reduce the platen axial dimensions, and can be reduced by 10% of inertia can reduce nearly 25%. In other words, keep the premise of inertia unchanged, possible will platen diameter increases, so can the arrangement for torsional shock absorber, let a space when damper spring job increase, the rigidity of the shock absorber in diameter can be reduced greatly, increasing the space for setting also provides an ideal damping components fundamental conditions. On the other hand, because platen diameter increases, the optimization of diaphragm spring separation means it can obviously reduce leverage than the load bearing separation.Using triangle groove platen ontology and friction piece of adhesive technology, still can make clutch friction slices surface pressure distribution, and more uniform can improve the service life of friction slices.4, clutch diaphragm springUsing the diaphragm spring of a nonlinear elastic properties, can increase the ability of clutch abrasion resistance. Usually, can pass the clutch when installation, adjustment diaphragm spring axial position, to keep the spring of compaction force, but due to the manufacturing process of previous position error is quite large, so often wasted spring this portion of elastic energy, enables the abrasion resistance ability get full play. When the clutch cover and flywheel connection with the above welding way to finish, the clutch assembly may allow such position when the adjustment, thus, the corresponding clutchscratch-resistant ability can improve the 4% ~ 30%.To improve the ability to change its antiwear properties, but also can the diaphragm spring is reinforced by controlling method of separation means and the rib disc supporting ring approach to getting.[]175, clutch control systemAutomatic transmission in cars growing popularity of today, due to its lack of transmission efficiency of cars, and motorists feel lost control, makes mechanical clutch still has wide market. Along with the computer technology and the rapid development of modern control technology has to clutch may reality automatic control, automatic clutch management system (CMC) is the product of this idea. The driver speaking, clutch automatic control system is that it is the most obvious advantage of cancelled the clutch pedal, thus improve the driving comfort, whether in the city the frequent change of traffic environment, or in the ramp, its advantages are started is quite clear. Meanwhile, in order to reduce the transmission low noise and vibration, CMC is likely to clutch real-time control of sliding, all these can improve automobile driving safety. Although the automatic transmission can also play the same role in price, but the CMC, fuel efficiency, engine braking and rapid response, etc but again the obvious advantage. In addition, it has no peristalsis phenomenon, and can make control shift timing. Drivers On the other hand, for car itself, because the CMC reduced because the actual driving quite frequent false operation produces drivetrain stress, therefore, can reduce the transmission and its transmission parts design dimensions, in general driving conditions, electronic control ensures the accuracy and speed than artificially operation circumstance clutch of wear small, long service life.CMC consists of three parts: namely is used to identify the driver intention and the clutch, the transmission working state of sensors,Clutch actuators and electronic control unit, drivers shift HuanDangGan movements and intention through the release of the accelerator pedal to identify, this requires signal judge strategy and control must be very quick, to avoid the feeling of driver produce shift block, when pilots inadvertently tinkering with the transmission system when rod may not false action. In addition, the CMC through the engine speed, the transmission input shaft speed and throttle position signal to clutch slip for mind control, which can eliminate the car driving common vibration and noise. Such as a limit control to prevent slip in 1 and 2, block small throttle low-speed driving, the car slightly tilted forward, generating about 1Hz very uncomfortable zitterbewegung, through in the clutch of transient torsional direction change quickly, to eliminate the separation clutch in clutch under the condition of incomplete combinations, when pilots alternate relaxation and trample accelerator pedal, because thetransmission torque change to the sharp produced recoiling sickening crash; or depressing Through the precise relative slip between 50 ~ 100rpm control, can eliminate in high-grade, high and low speed conditions when the engine driving torque values in the passenger cabin can smell the low-frequency resonance produced, and when the transmission in 2 ~ 3 block,engine speed 12 ~ 2500rpm and high load, the transmission possible beats noise; Through the separation clutch, convenient when the elimination of the idle will clutch and neutral transmission combine, engine torque peak in the transmission of idle speed noise produced. The key is to prevent vibration noise sensitivity and accuracy, this system requirements system has high control ability, rely on modern computer and hydraulic control technology has been possible this some.[]186, closingBy adopting a new design concept, can make clutch axial dimensions is much shorter, platen diameter increases, power transmission more reliable, clutch capacity increases, separation bearing load is reduced, torsion vibration reduction improve, processing manufacturing easier, lower cost, service life can be extended 50% and than before can be expected, along with the automatic control technology mature gradually perfect, clutch control mode will also continue to rapid development.附 录录 2汽车离合器技术的新发展摘要:近年来汽车设计和制造技术的进步有目共睹。