威伏3000超级橡胶修补剂

- 格式:docx

- 大小:321.85 KB

- 文档页数:2

MagicWave 2500 / 3000 TransTig 2500 / 3000TIG & MMA weldingGENERAL REMARKSQuiet, tough, stableTIG welders can raise a heartfelt cheer! Specially for them, Fronius has developed a series of machinesthat make their every wish come true: MagicWave 2500/3000 for DC and AC, and TransTig 2500/3000for DC. Active Wave and digitisation are the key technologies underlying this machine concept.These power sources are up-to-the-minute characters that are a pleasure to work with, in every way: Ever-so discreet, with a super-quiet yet highly stable arc. Extremely straightforward to use - in fact, almostself-explanatory. Tough, powerful and totally digitised. What is more, every single one of them is a member of a complete, totally co-ordinated welding system, all of whose components perfectly complement one another. All in all, the upshot is the sort of welding results which up to now you could only dream of.UTILISATIONFlexible and versatileOne of the many things that make the new MagicWave and TransTig machines such a pleasure to work withis the fact that they are designed for both field and production use. They can cope with the toughest conditions imaginable, putting out up to 250/300 A of power.In terms of materials, these welding systems are very suitable for aluminium and its alloys, but also forlow and high-alloy steels and non-ferrous metals, of course. Thanks to their great versatility, the MagicWave 2500/3000 and TransTig 2500/3000 are used right across the entire spectrum of industry – from the construction of chemical plant, tanks and containersto mechanical and plant engineering, pipeline construction, automotive and railway engineering and aerospace, and taking in all site-erection, maintenance and repair firms. Delivering just as perfect results when used for robot welding as in manual welding.Welding made easyECONOMYA pleasing side-effectThis series of TIG machines is a fine example of just how efficient modern welding systems can be. Their efficiency begins with the high-grade componentrythat is used for all Fronius machines. Special mention should also be made of their high degree of power efficiency, extremely low open-circuit power, automatic cooling-unit cut-out (which has a direct and measurable impact on the current consumption), and of course the automatic cap-shaping function, which reduces the working times needed by the welder. All in all, these features result in outstandingly long operational life,a small number of wearing parts, and lower labour costs. And thus in a welding system that is highly cost-effective in every way.TIG robot welding system with integral cold-wire-feeder unit.WELDING PROPERTIESSimply perfectThe ignition plays a vital rôle in TIG welding. On each of the machines, ignition is possible either with or without touchdown. In non-contact ignition, the arc starts immediately with a high-voltage impulse, ensuring perfect ignition right from the first push of the button – even when you’re using extra-long hosepacks. Touchdown ignition is especially valuable in sensitive areas of application. And the important thing here is to make sure that there are no tungsten inclusions. The digital process control takes good care of this, perfectly controlling the entire sequence.Active Wave ensures peace and quietActive Wave makes TIG AC welding a much quieter business: The integrated digital signal processor always computes – in real time – the waveform that will permit the highest possible arc stability with the lowest possible noise-emission levels. Measurement of these noise levels clearly shows that with Active Wave, even when the machine is delivering 300 A of power, the dbA value is still below 80 dbA.TAC: Spot-by-spot tack weldingBefore you can weld, you have to tack. With TAC, one spot is all it takes – because the pulsed arc sets the two weld-pools in motion, making them “jump together”, in next to no time, to make one single weld-pool. This works fast, and is a lot easier than the old method. The TAC function is also very useful when light-gauge sheets are being welded without filler metal, as here too, the pulsed arc helps the weld-pools to merge more thoroughly.Real skill becomes apparent at the endAt the end of the weld, there are two main things to watch out for: The first of these is the end crater. This has to be filled, at a lower amperage. The power sources take care of this, with the end-crater and downslope functions. The second thing is the gas post-flow, to make sure that the electrode and the weld-pool do not oxidise. In the past, the gas post-flow had to be set manually. On the digital machines, the ideal post-flow time is computed automatically.The way welding ought to be60 120 180 240 300 ANoise volume from conventional inverters Reduced noise volume from Active WaveFor sensitive areas of application: Touchdown ignitiondbA 90807060Simultaneous welding on both sidesWhen joining plates, you normally have to weld a root pass first. This then has to be ground and back-welded –a time-consuming procedure which you can speed up by welding from both sides simultaneously. In “both-sides-simultaneously” TIG-AC welding, both arcs have to be synchronised. This is taken care of by the digital MagicWave power sources.Aluminium is differentAluminium always needs special treatment. So Fronius have made sure that it gets it. For example, in TIG AC welding, aluminium is normally not welded with a pointed electrode tip, but with a shaped cap at the tip of the electrode. On fillet welds, this leads to inadequate root fusion. The MagicWave machines use a pointed electrode with a much smaller shaped cap. This results in perfect root fusion.The cap is shaped automatically, by the way, which means huge time-savings. All you need to do is clamp the pointed electrode into the electrode holder and pre-select the cap diameter, and the arc then immediately forms the shape and size of cap that you want. Another interesting function enables you to make variable adjustments to the AC waveform, giving the welder reliable weld-pool control even at high amperages.SAFETYGreen lights all roundAs anybody at all familiar with Fronius machines will know, their safety features are second to none. This, in itself, is a minimum requirement that every appliance has to fulfil. Every power source comes with the CE mark and with the S mark – permitting welding in confined spaces in conditions of enhanced electrical hazard, also when AC welding, of course. What is more, each of the power sources amply fulfils the requirements of IEC “Degree of protection IP 23”, meaning that it is safely protected from dirt and water, for use in the field. The integral fan is thermostat-controlled and so only runs when it is needed. This reduces dirt collection and prolongs the service life of the power source. At Fronius, though, safety starts even sooner: in the development stage. The MagicWave and TransTig machines were designed from the ground up to be so robust and compact that they can take just about anything in their stride.Cap diameter: 3.2 mm Base metal: AIMg3Sheet thickness: 5 mm Welding amperage: 185 A Welding voltage: 15.6 V AC balance: 0Cap diameter: 1 mm Base metal: AIMg3Sheet thickness: 5 mm Welding amperage: 185 A Welding voltage: 15.6 VAC balance: -5HANDLINGSmall on size, big on quality – the ideal welding torch for this power classOf all the components of the welding system that execute a work function, the welding torch is the most important. You can have the world’s most advanced power source and its very best welder – but if the hosepack is under constant strain, it will still spoil the welding result. Fronius is well aware of this, too. Which is why it is continually developing and improving its welding torches – for instance by adding the water-cooled TIG-welding torch TTW 2500, for the power class up to 250 A.Its ergonomically designed handle-shell is smaller and so fits even better in the welder’s hand - in fact, it can even be held like a pencil. The up/down rockers are easy to actuate while wearing gloves. The handle-shell also integrates a perfect anti-kink feature: The hosepack flexes more quickly, resulting in more precise torch guidance. Importantly for uninterrupted water cooling, the hosepack itself cannot be endlesslyAnything elsewe can do for you?The water-cooled TIG welding torch TTW 2500, with integral up/down rockers.Thanks to its ergonomically shaped handle-shell, the welding torch fits superbly well in the welder’s hand. The perfectly integrated anti-kink device enables the torch to be guided with great precision, even when the hosepack is bent.rotated. A final, economic, argument is that the wearing parts from other Fronius welding torches are all compatible with the TTW 2500.For the power class up to 300 A, other Fronius welding torches can be used as well, of course. Mention should also be made of the TIG welding torch with its integral cold-wire feeder unit for manual and automated cold-wire applications.Perfect interplayFronius is a system supplier. Each member of the system is designed to “fit in” optimally with all the others, in perfect harmony. The system takes in everything from the power source to remote-control units, cooling units, trolleys and a wide range of different robot interfaces, as well as complete welding-data documentation and visualisation.Digital weld-process regulation and controlEnergy-saving inverter technologyGenerator-compatibleThermostat-controlled fan / overtemperature protectionEarth leakage monitoringContinuous welding-current adjustment from torchRemote-controllableSwitchover facility between touchdown and HF ignitionAutomatic gas post-flow (dep. on welding current)Gas-test functionAutomatic cooling-unit cut-outAnti-stick functionFreely selectable parameters on the welding torchJob modeAutomatic cap-shaping functionPolarity reversalRPI ignitionKeylock switchRobot interface, analogue / digitalCold-wire controlOperating modes2-step mode / 4-step modeTAC (programmed tack-welding)AC / DCSpecial 4-step modeTIG pulsed-arcSpot weldingDigital indication ofPlain-text displayRun-statusOperating modeParametersWelding voltage, welding amperage (actual value)Service codesJob numberAdjustable parametersWelding amperageElectrode diameterGas pre-flow time / gas post-flow timeCrater-fill current / start-arcUpslope / downslopeHot-Start / arc-force dynamicAC balance / AC frequency / AC waveformAll plain to seeThe machines in this series are available in threedifferent versions – Standard, Job and Comfort, eachwith differing functions. “Job”, for instance, lets youwork in job mode and allows cold-wire control andautomated applications.The “Comfort” model also includes a number of extraplus-points, such as the plain-text display. This isunique, in terms of both handling guidance and user-friendliness, and ranks at the very forefront of moderntechnology. It functions extremely simply and “tells itlike it is”, in plain text. That means no abbreviations,no numerical codes, just straight-to-the-pointannouncements like “Main current”, “Lowered current”or “Electrode diameter”. The additional parameters canbe set very conveniently using a navigation menu. Theplain-text display is easy to read and absolutely self-explanatory, meaning that anyone can learn to use itstraight away. The “Comfort” control panel lives up tothe usual high Fronius standards, and is easy to operateeven when wearing gloves.Control panel of TT 2500 Standard Control panel of MW 2500 Job Control panel of MW 3000 ComfortThe plain-text display on the “Comfort” models makesthe machines easier to operate by showing wholewords, in a choice of languages, and by visualising thefunctional sequence. Additional parameters can be setvery conveniently, by way of navigable menus.•as standard o optionalCHECKLISTMWMWJobMWComfortTTTTJobTTComfort• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • •• • • •• • •• • •• • •• • • • • •• • • • • •• • •• • • •• • • •• • • •• •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • • • • •• • •o o o o o oo o o oo o o oTECHNICAL DATAPower sourceMW 2500MW 2500 MV MW 3000MW 3000 MV TT 2500TT 2500 MVTT 3000TT 3000 MVMains voltage 50-60 Hz3×400 V3×200-240 V 3×400 V3×200-240 V 3×400 V3×200-240 V 3×400 V3×200-240 V 3×400-460 V 3×400-460 V 3×400-460 V 3×400-460 V 1×200-240 V1×200-240 V1×200-240 V1×200-240 VMains voltage tolerance ± 15 % ± 10 % ± 15 % ± 10 % ± 15 % ± 10 % ± 15 % ± 10 %Mains fuse protection (slow)3×400 (460) V 16 A 16 A 16 A16 A 16 A16 A 16 A16 A 3×230 V 32 A 32 A 32 A 32 A 1×230 V32 A 32 A32 A32 APrimary contin. power (100% d.c)3×400 (460) V 4.5 kVA 4.5 kVA 5.5 kVA 5.5 kVA 4.5 kVA 4.4 kVA 6.1 kVA 6.1 kVA 3×230 V 4.1 kVA 4.7 kVA 4.1 kVA 5.5 kVA 1×230 V4.1 kVA4.7 kVA4.1 kVA5.5 kVACos phi 10.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99Welding current three-phase TIG3-250 A 3-250 A 3-300 A 3-300 A 3-250 A 3-250 A 3-300 A 3-300 A MMA 10-250 A 10-250 A 10-300 A 10-300 A 10-250 A 10-250 A 10-300 A 10-300 A Welding current single-phase TIG 3-220 A 3-220 A 3-220 A 3-220 A 3-220 A 3-220 A 3-220 A 3-220 AMMA 10-180 A10-180 A10-180 A10-180 A10-180 A10-180 A10-180 A10-180 A Welding current at 10min/40 °C (104 °C)3×400 V 40% d.c. 250 A 40% d.c. 250 A 35% d.c. 300 A 35% d.c. 300 A 50% d.c. 250 A 50% d.c. 250 A 50% d.c. 300 A50% d.c. 300 A 3×460 V on MV 100% d.c. 170 A 100% d.c. 170 A 100% d.c. 190 A 100% d.c. 190 A 100% d.c. 190 A 100% d.c. 190 A 100% d.c. 240 A100% d.c. 240 A 3×230 V 35% d.c. 250 A 30% d.c. 300 A 45% d.c. 250 A 45% d.c. 300 A 100% d.c. 160 A 100% d.c. 170 A 100% d.c. 180 A 100% d.c. 220 A 1×230 V45% d.c. 220 A 40% d.c. 220 A 55% d.c. 220 A 55% d.c. 220 A 100% d.c. 150 A100% d.c. 150 A 100% d.c. 170 A 100% d.c. 190 AOpen-circuit voltage89 V 89 V 89 V 89 V 85 V 85 V 85 V 85 V Standardised working voltage TIG 10.1-20.0 V10.1-20.0 V 10.1-22.0 V 10.1-22.0 V 10.1-20.0 V 10.1-20.0 V 10.1-22.0 V 10.1-22.0 V MMA20.4-30.0 V 20.4-30.0 V 20.4-32.0 V 20.4-32.0 V 20.4-30.0 V 20.4-30.0 V 20.4-32.0 V 20.4-32.0 V Ignition voltage (Up)*10 kV 10 kV 10 kV 10 kV 10 kV 10 kV 10 kV 10 kV Type of cooling/insulation class AF/B AF/B AF/BAF/B AF/B AF/B AF/B AF/B Dimensions LxWxH mm560x250x435 560x250x435560x250x435 560x250x435 560x250x435 560x250x435560x250x435 560x250x435Inches22.0x9.8x17.1 22.0x9.8x17.1 22.0x9.8x17.1 22.0x9.8x17.1 22.0x9.8x17.1 22.0x9.8x17.1 22.0x9.8x17.1 22.0x9.8x17.1Weight26.6 kg 28.2 kg 28.1 kg 30.0 kg 24.2 kg 25.9 kg 24.2 kg 25.9 kg 58.64 lb.62.17 lb.61.95 lb.66.14 lb.53.35 lb.57.10 lb.53.35 lb.57.10 lb.Welding torchTTW 2500TTW 3000Welding current AC180 A 250 A DC250 A 300 A Duty cycle 40 % 60 %Electrode diameter 1.0-3.2 mm 1.0-3.2 mm 0.039-0.126 in. 0.039-0.126 in.Weight0.47kg (1.03 lb.)0.75 kg (1.65 lb.)FK 2500 FK 2500 MV Cooling unitFK 2500 FCFK 2500 MV FCMains voltage 50-60 Hz200-240 V 400 V400-460 V Mains voltage tolerance ± 10 % ± 10 % Power consumption 50 Hz/60 Hz0.6/0.7 A0.6-1.4 A Cooling capacity Q=1l/min +25 °C 800 W 800 W Cooling capacity Q=1l/min +40 °C 500 W 500 W Max. delivery rate 3.5 l/min 3.5 l/min Maximum rise 35 m 35 m (114.8 ft.) 35 m (114.8 ft.)Max. pump pressure 4.2 bar (60.9 psi) 4.2 bar (60.9 psi)Coolant volume 4 l (1.1 gal.) 4 l (1.1 gal.)Degree of protection IP 23IP 23Dimensions LxWxH 625x240x225 mm 625x240x225 mm 24.1x9.4x8.9 in. 24.1x9.4x8.9 in.Weight9 kg (20 lb.)11,6 kg (25.6 lb.)IP 23*The arc-ignition feature complies with the Standards governing manual operation.Welding torchTTG 2200TTG 2600Welding current AC180 A 220 A DC220 A 260 A Duty cycle 35 % 35 %Electrode diameter 1.0-4.0 mm 1.0-4.0 mm 0.039-0.157 in. 0.039-0.157 in.Weight0.96 kg(2.11 lb.)0.57 kg (1.25 lb.)w w w .r e k l a m e b u e r o .a t40,0006,2811 (1/07)FRONIUS INTERNATIONAL GMBHBuxbaumstrasse 2, P.O.Box 264,A 4602 Wels, AustriaTel: +43 7242 241-0, Fax: +43 7242 241-3940E-Mail:*****************T e x t a n d i l l u s t r a t i o n s t e c h n i c a l l y c o r r e c t a t t i m e o f g o i n g t o p r i n t . W e r e s e r v e t h e r i g h t t o m a k e m o d i f i c a t i o n s .T h i s d o c u m e n t m a y n o t b e c o p i e d o r o t h e r w i s e r e p r o d u c e d , w h e t h e r i n p a r t o r i n i t s e n t i r e t y , w i t h o u t t h e e x p r e s s p r i o r w r i t t e n c o n s e n t o f F r o n i u s I n t e r n a t i o n a l G m b H . **********************。

VIF3000超级橡胶修补剂产品说明:本品是一种双组分常温快速硫化聚氨酯型橡胶修补剂。

具有良好的填充性和浇注性,修补因磨损、冲击、震动、拉伸等对皮带及橡胶件表面造成的损伤,新型专利便捷式包装,使配比更精确,使用更方便。

应用范围:①输送带接头粘接的无缝处理及破损修补。

②填充密封电缆封头及电缆外套破损修补。

③泵体、叶轮、料槽、导流板、卸料斗等橡胶抗磨涂层及衬里。

④胶辊、轮胎的修补。

产品特点:①高韧性,抗磨损,是普通橡胶的3-5倍。

②耐油,耐老化,耐臭氧及辐射。

③优异的耐水解性,可长期在潮湿工况下使用。

④阻燃,耐高温,适合煤矿井下作业。

⑤专利包装,使配比更准确,混合均匀无气泡。

⑥符合SGS环保要求。

使用方法:①将破损或粘接处切割或打磨出新的界面,除去灰尘、杂屑及油污。

②用橡胶底涂剂MR001处理修补表面,粘接效果会好很多。

③抽出夹在包装袋中间的密封胶条,将袋中的两个组分揉搓2-3分钟至到均匀,这时反应开始,袋中物会有轻微发热感觉。

④剪破包装袋一角,将混匀反应后的胶液涂覆于修补处,用刮板刮平,静置固化2-3小时可轻载运行。

注意事项:①该产品反应活性强,对水汽特别敏感,粘接环境务必保持干燥,否则会有气泡产生,影响粘接质量。

②受环境温度的影响,袋中双组分反应的凝胶时间会有所不同,操作中要注意控制好时间。

VIF 输送带修补胶条产品说明:专为输送带修补而设计制造的强力快粘复合橡胶条,表面为耐磨橡胶,中间嵌加强织物层,底层为半硫化层(CN 层)橡胶,施工时与VIF2002快速冷粘胶配合使用,快速修补输送带划伤,磨损及面层再生。

应用范围:①输送带纵向长距离划伤、划透及皮带边缘磨损的修复,输送带局部橡胶面层损伤、脱落的修复。

②输送带冷硫无缝接头搭接后的封口处理。

③适用于各类输送带的修补,如棉帆布芯输送带,尼龙帆布芯输送带、钢丝绳芯输送带等。

产品特点:①内嵌加强织物层,抗拉强度高,适合于长距离输送带划伤修复。

②表层涂覆耐磨橡胶层,耐温抗磨性能好。

耐3000℃高温的粘合剂

佚名

【期刊名称】《橡胶参考资料》

【年(卷),期】1991(000)012

【摘要】日清纺公司,目前已开发出一种新型的可耐3000℃高温的粘合剂。

这种粘合剂是在碳粉末中通过混入特种添加剂研制而成的。

其主要特点在于:(1)与原来的耐热性(1000℃)粘合剂相比,耐温等级有了大幅度的提高;(2)无腐蚀性;(3)耐药品性优良;(4)具有一定的导电性;(5)对各种碳类材料(石墨 HIP、

【总页数】1页(P56-56)

【正文语种】中文

【中图分类】TQ33

【相关文献】

1.耐高温高绝缘硅橡胶及耐高温硅橡胶粘合剂 [J],

2.耐蒸煮双组份聚氨酯粘合剂的制备与试验 [J], 李昳;董云哲;李明森

3.耐高温粘合剂:更好地满足不同行业的高温应用要求 [J], DELO

4.日研制出耐3000℃高温的粘接剂 [J],

5.耐高温粘合剂Imperon N66和耐湿摩擦固色剂Imperon HWA [J], 邬涛之因版权原因,仅展示原文概要,查看原文内容请购买。

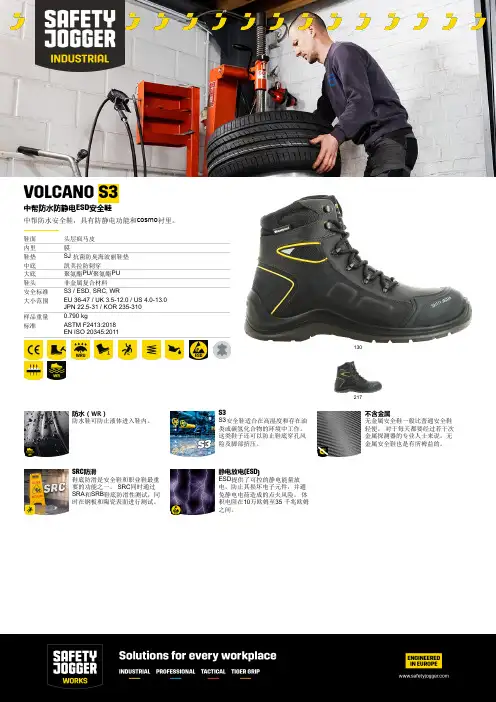

VOLCANO S3中帮防水防静电ESD 安全鞋中帮防水安全鞋,具有防静电功能和cosmo 衬里。

鞋面头层疯马皮内里膜鞋垫SJ 抗菌防臭海波丽鞋垫中底凯芙拉防刺穿大底聚氨酯PU/聚氨酯PU鞋头非金属复合材料安全标准S3 / ESD, SRC, WR大小范围EU 36-47 / UK 3.5-12.0 / US 4.0-13.0JPN 22.5-31 / KOR 235-310样品重量0.790 kg标准ASTM F2413:2018EN ISO 20345:2011130217防水(WR)防水鞋可防止液体进入鞋内。

S3S3安全鞋适合在高湿度和存在油类或碳氢化合物的环境中工作。

这类鞋子还可以防止鞋底穿孔风险及脚部挤压。

不含金属无金属安全鞋一般比普通安全鞋轻便。

对于每天都要经过若干次金属探测器的专业人士来说,无金属安全鞋也是有所裨益的。

SRC 防滑鞋底防滑是安全鞋和职业鞋最重要的功能之一。

SRC 同时通过SRA 和SRB 鞋底防滑性测试,同时在钢板和陶瓷表面进行测试。

静电放电(ESD)ESD 提供了可控的静电能量放电,防止其损坏电子元件,并避免静电电荷造成的点火风险。

体积电阻在10万欧姆至35 千兆欧姆之间。

工业:汽车,化学,清洁,建筑,物流,矿业,油气,工业环境:干燥环境,潮湿环境维护指南:建议定期清洁鞋类,并使用适当的产品保养,旨在延长鞋类寿命。

不得将鞋子摆放至暖气片上烘干,不得在热源附近烘干。

描述测量单位结果EN ISO 20345鞋面头层疯马皮帮面:水蒸气渗透性mg/cm²/h7大于等于 0.8帮面:水蒸气系数mg/cm²45大于等于 15内里膜衬里:水蒸气渗透性。

mg/cm²/h 2.4大于等于 2衬里:水蒸气系数mg/cm²23大于等于 20鞋垫SJ 抗菌防臭海波丽鞋垫Footbed: abrasion resistance (dry/wet) (cycles)转数25600/1280025600/12800大底聚氨酯PU/聚氨酯PU外底耐磨性(体积损耗)mm³outsole_SRB_1小于等于 150Basic Slip resistance - Ceramic + NaLS - Forward heel slip摩擦N/A大于等于 0.31Basic Slip resistance - Ceramic + NaLS - Backward forepart slip摩擦N/A大于等于 0.36SR Slip resistance - Ceramic + glycerin - Forward heel slip摩擦N/A大于等于 0.19SR Slip resistance - Ceramic + glycerin - Backward forepart slip摩擦N/A大于等于 0.220.1 - 1000防静电值MegaOhmtoecap_compression_resistance_1ESD值MegaOhm770.1 - 100后跟吸能J37大于等于 20鞋头非金属复合材料抗冲击鞋包头(冲击后间隙100J)mm N/A N/A抗压鞋包头(压缩后的间隙为10kN)mm N/A N/A抗冲击鞋包头(冲击后间隙200J)mm16大于等于 14抗压鞋包头(压缩后的间隙为15kN)mm19大于等于 14样品大小: 42我们的鞋子在不断发展,所有产品名称和品牌Safety Jogger,均已注册,未经我们的书面同意,不得以任何形式使用或复制。

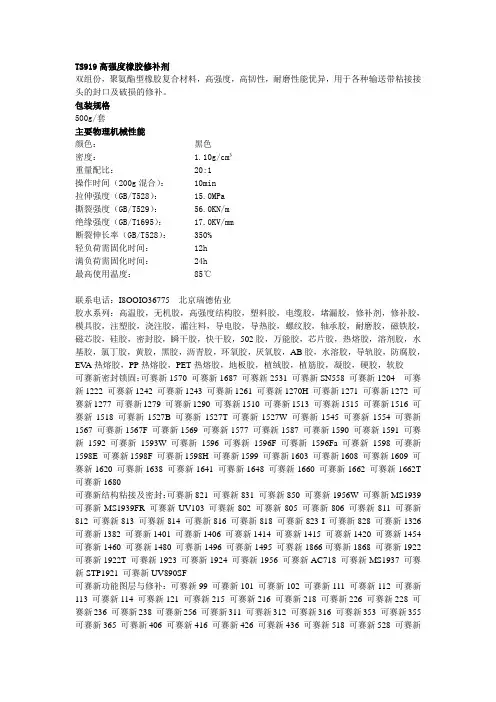

TS919高强度橡胶修补剂双组份,聚氨酯型橡胶复合材料,高强度,高韧性,耐磨性能优异,用于各种输送带粘接接头的封口及破损的修补。

包装规格500g/套联系电话:I8OOIO36775 北京瑞德佑业胶水系列:高温胶,无机胶,高强度结构胶,塑料胶,电缆胶,堵漏胶,修补剂,修补胶,模具胶,注塑胶,浇注胶,灌注料,导电胶,导热胶,螺纹胶,轴承胶,耐磨胶,磁铁胶,磁芯胶,硅胶,密封胶,瞬干胶,快干胶,502胶,万能胶,芯片胶,热熔胶,溶剂胶,水基胶,氯丁胶,黄胶,黑胶,沥青胶,环氧胶,厌氧胶,AB胶,水溶胶,导轨胶,防腐胶,EV A热熔胶,PP热熔胶,PET热熔胶,地板胶,植绒胶,植筋胶,凝胶,硬胶,软胶可赛新密封锁固:可赛新1570 可赛新1687 可赛新2531 可赛新SN558 可赛新1204 可赛新1222 可赛新1242 可赛新1243 可赛新1261 可赛新1270H 可赛新1271 可赛新1272 可赛新1277 可赛新1279 可赛新1290 可赛新1510 可赛新1513 可赛新1515 可赛新1516 可赛新1518 可赛新1527B 可赛新1527T 可赛新1527W 可赛新1545 可赛新1554 可赛新1567 可赛新1567F 可赛新1569 可赛新1577 可赛新1587 可赛新1590 可赛新1591 可赛新1592 可赛新1593W 可赛新1596 可赛新1596F可赛新1596Fa 可赛新1598 可赛新1598E 可赛新1598F 可赛新1598H 可赛新1599 可赛新1603 可赛新1608 可赛新1609 可赛新1620 可赛新1638 可赛新1641 可赛新1648 可赛新1660 可赛新1662 可赛新1662T 可赛新1680可赛新结构粘接及密封:可赛新821 可赛新831 可赛新850 可赛新1956W 可赛新MS1939 可赛新MS1939FR 可赛新UV103 可赛新802 可赛新805 可赛新806 可赛新811 可赛新812 可赛新813 可赛新814 可赛新816 可赛新818 可赛新823-I 可赛新828 可赛新1326 可赛新1382 可赛新1401 可赛新1406 可赛新1414 可赛新1415 可赛新1420 可赛新1454 可赛新1460 可赛新1480 可赛新1496 可赛新1495 可赛新1866可赛新1868 可赛新1922 可赛新1922T 可赛新1923 可赛新1924 可赛新1956 可赛新AC718 可赛新MS1937 可赛新STP1921 可赛新UV890SF可赛新功能图层与修补:可赛新99 可赛新101 可赛新102 可赛新111 可赛新112 可赛新113 可赛新114 可赛新121 可赛新215 可赛新216 可赛新218 可赛新226 可赛新228 可赛新236 可赛新238 可赛新256 可赛新311 可赛新312 可赛新316 可赛新353 可赛新355 可赛新365 可赛新406 可赛新416 可赛新426 可赛新436 可赛新518 可赛新528 可赛新526 可赛新737 可赛新747 可赛新757 可赛新767 可赛新2111可赛新光伏硅胶:可赛新1523 可赛新1526 可赛新1521 可赛新1522 可赛新1527 可赛新1533 可赛新1581 可赛新1588可赛新橡胶粘接与修补:可赛新801 可赛新808 可赛新808FR 可赛新809 可赛新853 可赛新916 可赛新919 可赛新919N 可赛新921 可赛新9191可赛新辅助产品与施胶设备工具:可赛新1749 可赛新1761 可赛新1720 可赛新1731 可赛新1740 可赛新1745 可赛新1748 可赛新1750 可赛新1753 可赛新1755EF低气味可赛新1755EF环保型可赛新1756 可赛新1758 可赛新1762 可赛新1764 可赛新1767 可赛新1768 可赛新1770 可赛新1771 可赛新1790 可赛新PR-90。

3m vetbond 成分

3M Vetbond组织胶是一种被广泛用于动物医疗领域的组织粘合剂,它由3M公司生产。

它的主要成分是2-丙烯酰氧基乙基三甲氧

基硅烷和2-丙烯酸乙酯。

这些成分使得Vetbond具有快速固化、耐

水和耐消毒剂的特性,适用于在动物手术中用于缝合皮肤和组织。

除了主要成分外,Vetbond还可能包含一些辅助成分,用于调节粘

合剂的黏度、流动性和固化时间,以确保其在动物医疗应用中的有

效性和安全性。

总的来说,Vetbond的成分设计旨在提供一种安全、可靠的方法来处理动物的伤口和切口,促进愈合并减少感染的风险。

ORDERING INFORMATIONStock No. 14251 14210 14201 14270 14272Package Size 25ml Dev-tube 70g Twin-tube 500g Tub50ml Cartridge 400ml CartridgeDescription A rapid-curing,general-purpose adhesive/encapsulant.It forms a hard,rigid bond or coating in minutesFeatures∙100%reactive,no solvents∙Good dielectric strength∙Good solvent resistanceIntended Use∙Cures fast for quick metal to metal bonding and repairs∙Pots and encapsulates electronic components and assemblies∙Suitable for bonding metals,fabrics,ceramics,glass,wood and concrete(incombinations)PRODUCT DATAPhysical Properties (Uncured)Colour Light Amber Mixed Viscosity10,000cps Mixed Ratio by Volume&Weight1:1Working time 28 grams @ 23˚C3-6minutes Fixture time10-15minutes Functional cure @ 23˚C 45 - 60 minutes Full Cure12hoursMixed Density 1.10gm/ccPerformance characteristics (cured)7days cured at24˚CAdhesive tensile shear ASTM D100213MPaT Peel4-5N/10mm Service temperature, dry -40 - 93˚C Tensile Elongation1% Specific Volume909cm3/kg %solids by volume100Cured hardness,ASTM D224085D Dielectric strength,ASTM D14919.6KV/mmChemical Resistance 7days room temperature cure(30days immersion)Acetic(dilute)10%Poor Acetone Poor Ammonia Poor Corn Oil Excellent Cutting oil Excellent Ethanol Poor Petrol(unleaded)Excellent Glycols/Antifreeze Fair Hydrochloric10%Poor Isopropanol Poor Kerosene Excellent MEK Poor Mineral Spirits Excellent Motor Oil Excellent Sodium Hydroxide10%Poor Sulphuric10%PoorPlease contact ITW Devcon for other chemicalsUnit3,Shipton Way,Express Business Park,Northampton Road,Rushden,APPLICATION INFORMATIONSurface Preparation 5Minute Epoxy works best on clean surfaces.Surfaces should be free of heavy deposits of grease,oil,dirt or other contaminants,or cleaned with industrial cleaning equipment such as vapour phase degreasers or hot aqueous baths.Abrading or roughing the surfaces of metals will increase the microscopic bond area significantly and optimise the bond strength.Mixing This product is available in cartridge,non-cartridge and28g Devtube form.Cartridge Form:The cartridge should be used with the appropriate manual Applicator Gunand Static Mixer Nozzle.The Static Mixer Nozzle enables the epoxy to be dispensed,metered and directly applied to the surfaces to be bonded.Please note:Once the product cures in the nozzle it has to be thrown away and a newnozzle used.Non-Cartridge Form:Proper homogenous mixing of the two epoxy components of resin andhardener are essential for the curing and development of stated strengths.Always mix thetwo components with clean tools,preferably of a disposable design.For small amounts use Devcon's28g Devtube,which comes with it’s own plunger to extrudethe two components at an equal rate.Application Apply mixed epoxy directly to one surface in an even film or as a bead.Assemble with the mating part within the recommended working time.Obtain firm contact between the parts tominimize any gap and ensure good contact of the epoxy with the mating part.A smallamount of epoxy should flow out the edges to show there is adequate gap filling.For verylarge gaps,apply epoxy to both surfaces and spread to cover the entire area,or make abead pattern,which will allow flow throughout the joint.Let bonded assemblies stand for the recommended functional cure time before handling.They are capable of withstanding processing forces at this point,but should not be dropped,shock loaded or heavily loaded.Storage Shelf Life Devcon Epoxy Adhesives should be stored in a cool,dry place when not used for a long period of time.A shelf life of3years from date of manufacture can be expected when stored at room temperature22ºC in their original containers.Precaution For complete safety and handling information please refer to the appropriate Materials Safety Data Sheets prior to using this product.Warranty Devcon will replace any material found to be defective.Because the storage,handling and application of this material is beyond our control we can accept no liability for the resultsobtained.Disclaimer All information on this data sheet is based on laboratory testing and is not intended for design purposes.ITW Devcon makes no representations or warranties of any kindconcerning this data.For product information visit alternatively for technical assistanceplease call+44(0)8704587388(UK)or+49431718830(Germany)Unit3,Shipton Way,Express Business Park,Northampton Road,Rushden,。

V A L V ESHigh Pressure Valves Series HBulletin H-Tech 03Versa Products Company has been supplying high qualitypneumatic and hydraulic directional control valves and components for over 50 years. We have built a reputation for quality that is unsur-passed in a wide range of markets for high performance solenoids,pneumatic relays and resets and related components.Versa’s H Series is a range of leak-proof high-pressure valves suitable for low viscosity fluids that are ideally suited for the unique needs in the most demanding markets and applications. Low viscosity fluid may be mineral oils, high water based fluids, com-pressed air or natural gas. Standard valves are rated for hydraulic fluids up to 10.5 gpm (40 l/min) in 2-way and 3-way functions.Apply Versa’s optional pneumatic service suffix and many forms of gas can be controlled in various flow configurations. Valves are available with solenoid or pilot actuation and manual overrides are standard. H Series valves are constructed of stainless steel materials, as standard. All valves are manifoldmounted style with a number of standard manifold configurations.Custom manifolding, circuitry and non-standard functions can be easily developed upon request.Major market applications are within the Oil and Gas industry,however H Series valves have been successfully applied in mining,steel, utility, fire-fighting, desalination and more.Corrosion resistant materials.Standard materials are 316 stain-less steel for compatibly with the widest range of medias in almost any service. The use of bar stock raw materials assures leak free operation with no concerns of material consistency or porosity.Ceramic sealing for leak free sealing. Hardened sealing surfaces for long service life. Materials compatible with the widest rangeModular design forstandardized components.This modular design allows for field conversions and the availability of replacement assemblies.Standard override on every valve. Easy setup of equipment. Field-test-ing and equipment trouble shooting are greatly simplified.Pullout design.Internals pullout for easy removal of key parts simplifying service and maintenance.Positive sealing via standard ‘O’ rings. No custom or flat gaskets to leak. Standard ‘O’rings available in every All valves are manifold mounted for easy removal.No need to disturb system piping.Actuator shifting lever.The ASL assures positive shifting through mechanical advantage. The ASL also reduces the force or power requirements to allow for a number of actuators. Many different solenoids are offered with low wattage requirements. A pilot actuator may also be selected, shifting the valve with a low-pressure signal.pressure spikes.The H Series Leak-Proof, High-Pressure ValvesFlowStandard Valve Suffix –HP2 Suffix –AS Suffix –AS1no suffixH020.06 0.3 (0.9) 10,000 (690) N/AN/AN/AH03 0.23 1.2 (5) 6,000 (414) 10,000 (690) 2,320 (160) 3,625 (250) H06 0.79 4.0 (15) 6,000 (414) N/A 2,320 (160) 3,625 (250) H10 1.9 10.5 (40) 5,000 (345) N/A 1,450 (100) N/AValve SizeCvGPM (l/min)PSI (bar)PSI (bar)PSI (bar)PSI (bar)HydraulicPneumaticPressure RatingH Series SpecificationsFunctionThe H Series is a line of stainless or aluminum manifold mounted valves available as 2-way or 3-way, normally open or closed function. Valve function is not field convertible therefore specify function as required. For other functions consult factory.Service MediaHydraulic Service. The standard H Series valve is rated for hydraulic media. Typical hydraulic fluids are considered mineral oil, synthetic oils, water and water glycol. All applications to be confirmed by factory. High-pressure hydraulic service is also available, see pressure chart.Pneumatic Service. H Series valves are rated for pneumatic service, suffix detail option required. See pressure chart. Pneumatic service would be high-pressure air, inert gasses, natural gas and sour gas. All valves, with pneumatic service option are rated for non-lube service, however lubrication is recommended when feasible.Flow/ Pressure RatingsPressures listed above are maximum body pressures. Minimum pressures are based on actuator selection, see actuator section for minimum pressure ratings.All valves are tested prior to shipment.Test pressures are 1.5 times rated pressures for hydraulic service.Pneumatic valves are tested at rated pressures.For higher flows and or pressures contact factory.General SpecificationsFiltrationHydraulic Service: 10 micron (H02 size)20 micron (H03, H06 and H10 size)Pneumatic Service: 20 micron (all sizes)Materials of ConstructionMain Body:316 Stainless steel (standard)304 Stainless steel (optional, add suffix -304)Aluminum, anodized (optional, add suffix -AL)Seals, dynamic:Ceramic seal with stainless steel seat (hydraulic service, standard and suffix -HP2)Ceramic seal with engineered polymer seat (pneumatic service, suffix -AS and -AS1)Seals, Static:BunaFasteners:Stainless SteelManifold:See manifold sectionTemperature rangeTemperature range is based on actuator selection.Please see page 4 for temperature information.Versa exercises diligence to assure that information contained in this catalog is correct, but does not acceptresponsibility for any errors or omissions. Versa also reserves the right to change or delete data or products at any timewithout prior notification. To be sure the data you require is correct, consult factory.Suffix Detail: XBHazardous Location – FlameproofProtection Classification:EEx de II B + H2 T4/T6Area Classification:ZONE 1Ingress Protection:IP44Voltage: 12 to 250 Volts AC or DCPower: H3 13 to 17 Watts, H6 20 WattsElectrical Connection:M20x1.5 w/PG16 cord grip Temperature Rating:T4: -4F to 158F (-20C to 70C)T6: -4F to 104F (-20C to 40C)Suffix Detail: XCHazardous Location – Flameproof Protection Classification:EEx d II C T6Area Classification:ZONE 1Ingress Protection:IP65Voltage: Up to 250 Volts DC Power: 3 WattsElectrical Connection:M20x1.5Temperature Rating:T6 -4F to 140F (-20C to 60C) Suffix Detail: XDHazardous Location – Intrinsic Safe Protection Classification:EEx ia II C T5/T6Area Classification:ZONE 1Ingress Protection:IP54Voltage: 5 to 24 Volts DC Power: up to 2 WattsElectrical Connection:PG7 cord gripTemperature Rating:T6 -4F to 140F (-20C to 60C)T5 -4F to 158F (-20C to 70C)Suffix Detail: XEHazardous Location – Encapsulation Protection Classification:EEx me II T5/T6Area Classification:ZONE 1 Ingress Protection:IP65Voltage: 12 to 125 Volts DC Power: 3 WattsElectrical Connection:M20x1.5Temperature Rating:T6 -4F to 122F (-20C to 50C)T5 -4F to 140F (-20C to 60C) Suffix Detail: XF General PurposeArea Classification:None Ingress Protection: IP54Voltage: 12 to 250 Volts AC or DC Power: H2/H3 13 Watts, H6 36 Watts Electrical Connection:PG9 cord gripTemperature Rating:-4F to 176F (-20C to 80C)Suffix Detail: LP1Latching Manual ResetOperation:Latches in the de-energized position. With loss of solenoid (or pilot)signal, the valve shifts closed and cannotbe re-shifted until manually reset.XBXCXFXDPilots LatchesSolenoidsXESuffix Detail: HP Hydraulic PilotTemperature rating: -4 to 176F (-20 to 80C)Suffix Detail: AP Pneumatic PilotTemperature rating: -4 to 176F (-20 to 80C)H Series Quick Reference Part Number Selector(Part numbers listed below are for standard hydraulic service. For other applications, suffix options are required. Part numbers include valve and actuators only. A manifold is required to completethe assembly part number. See page 6 for manifolds.)Solenoid actuated2-Way and 3-Way normally closed 2-position single solenoid, spring return valvesPressure Ratings:Maximum main body pressure is listed on flow/pressure chart. For higher-pressure hydraulic or pneumatic service select suffix option as required on flow/pressure chart.Minimum pressures are as follows:1.Minimum inlet pressure is 0 psi. Valve is a direct acting design.2.Minimum inlet pressure is 725 psi (50 bar). Valve is a solenoid-pilot design.3.Minimum inlet pressure is 1015 psi (70 bar). Valve is a solenoid-pilot design.All solenoid-operated valves are supplied with manual over-ride. XF solenoid valves are supplied with push button type override. All other valves utilize lever type over-ride. Part numbers reflect normally closed valves. For normally open function change the last digit on the base number from 1 to 2.Pilot actuated2-Way and 3-Way normally closed 2-position single pilot, spring return valvesPressure Rating:Maximum main body pressure is listed on flow/pressure chart. For higher-pressure hydraulic or pneumatic service select suffix option as required on flow/pressure chart. Minimum main body pressure for all pilot valves is 0 psi.Pilot shift pressure, all sizes: 50 psi (3.4 bar)Pilot maximum pressure, all sizes: 3050 psi (210 bar)All pilot operated valves are supplied with manual override. Part numbers reflect normally closed valves. For normally open function change last digit on base number from 1 to 2.H022-Way, NC HSP-20201-HP HSP-20201-AP 3-Way, NC HSP-30201-HP HSP-30201-AP H032-Way, NC HSP-20301-HP HSP-20301-AP 3-Way, NC HSP-30301-HP HSP-30301-AP H062-Way, NC HSP-20601-HP HSP-20601-AP 3-Way, NCHSP-30601-HP HSP-30601-APH10Consult FactoryValve SizeFunctionHydraulic PilotPneumatic PilotXB =Actuator Suffix OptionsAP = Pilot Operated valve,Pneumatic signalHP = Pilot Operated valve,Hydraulic signalSG = Actuator,SG = Solenoid operated, spring return SP = Pilot operated, spring returnGVersa has beensupplying the oiland gas industrywith pneumatic andhydraulic compo-nents for over 50years. We havebuilt a reputationfor quality that isunsurpassed in themarket for highperformance sole-noids, pneumaticrelays and resets,andpilot valves. WARNINGS REGARDING THE DESIGN APPLICATION,INSTALLATION AND SERVICE OF VERSA PRODUCTSThe warnings below must be read and reviewed before designing a system utilizing, installing, servicing, or removing a Versa product. Improper use, installation or servicing of a Versa product could create a hazard to personnel and property.DESIGN APPLICATION WARNINGSVersa products are intended for use where compressed air or industrial hydraulic fluids are present. For use with media other than specified or for non-industrial applications or other applications not within published specifications, consult Versa.Versa products are not inherently dangerous. They are only a component of a larger sys-tem. The system in which a Versa product is used must include adequate safeguards to prevent injury or damage in the event of system or product failure, whether this failure be of switches, regulators, cylinders, valves or any other system component. System design-ers must provide adequate warnings for each system in which a Versa product is utilized. These warnings, including those set forth herein, should be provided by the designer to those who will come in contact with the system.Where questions exist regarding the applicability of a Versa product to a given use, inquiries should be addressed directly to the manufacturer. Confirmation should be obtained direct-ly from the manufacturer regarding any questioned application prior to proceeding. INSTALLATION, OPERATION AND SERVICE WARNINGSDo not install or service any Versa product on a system or machine without first depres-surizing the system and turning off any air, fluid, or electricity to the system or machine. All applicable electrical, mechanical, and safety codes, as well as applicable governmental regulations and laws must be complied with when installing or servicing a Versa product. Versa products should only be installed or serviced by qualified, knowledgeable personnel who understand how these specific products are to be installed and operated. The individ-ual must be familiar with the particular specifications, including specifications for tempera-ture, pressure, lubrication, environment and filtration for the Versa product which is being installed or serviced. Specifications may be obtained upon request directly from Versa. If damages should occur to a Versa product, do not operate the system containing the Versa product. Consult Versa for technical information.LIMITED WARRANTY DISCLAIMER AND LIMITATION OF REMEDIES Versa's H Series products are war-ranted to be free from defective mate-rial and workmanship for a period of three years from the date of manufac-ture, provided said H Series products are used in accordance with Versa specifications. Versa’s liability pur-suant to that warranty is limited to the replacement of the Versa product proved to be defective provided the allegedly defective product is returned to Versa or its authorized distributor. Versa provides no other warranties, expressed or implied, except as stated above. There are no implied warranties of merchantability or fitness for a particular purpose. Versa’s liability for breach of warranty as herein stated is the only and exclu-sive remedy and in no event shall Versa be responsible or liable for inci-dental or consequential damages.Versa Products Company Inc.22 Spring Valley Road Paramus, New Jersey 07652 USA Versa BVPrins Willem Alexanderlaan 1429 7321 GB ApeldoornThe Netherlands。

橡胶老化表面补强方法

橡胶这东西啊,用久了就会老化,表面变得坑坑洼洼或者失去弹性,就像人老了皮肤松弛一样。

那怎么给老化的橡胶表面补强呢?

咱先说说涂抹防护剂这种方法。

就像是给橡胶擦护肤品一样呢。

有专门的橡胶防护剂,涂在老化的橡胶表面,能形成一层保护膜。

这层膜啊,可以阻挡外界的一些东西对橡胶进一步的伤害,像紫外线啦,空气里的那些小坏蛋分子之类的。

而且还能在一定程度上补充橡胶表面流失的一些成分,让它看起来没那么沧桑。

再讲讲硫化补强。

这个听起来有点专业,不过就像给橡胶做个小手术让它重生一样。

通过硫化的方法,可以改变橡胶表面的结构。

在合适的温度、压力和硫化剂的作用下,橡胶表面的分子重新排列组合,变得更加紧密和有力量。

不过这个方法可得小心操作,就像做手术得找个好医生一样,要是硫化的条件没控制好,可能会适得其反呢。

最后呢,还有一种表面涂层处理。

这就像是给橡胶穿上一件新衣服。

可以用一些特殊的涂料,比如含有增强纤维或者特殊聚合物的涂料。

把这些涂料均匀地涂在橡胶老化的表面,等它干了之后,就像给橡胶加了一层铠甲。

这层铠甲不仅能让橡胶表面更结实,还能让它看起来焕然一新,就像给一个旧娃娃重新打扮了一样。

橡胶老化不可怕,只要我们找到合适的表面补强方法,就能让橡胶继续发挥它的作用,继续陪伴我们啦。

威肯WEICON塑料金属填补胶是两种环氧树脂的混和物,能够几乎无收缩的变硬,这种材料可快速、经济有效的用于多种不同的材料的维修,粘接及表面涂层处理,能够进行机械加工,如钻孔和磨平。

塑料金属填补胶按不同的粘性,耐温性和耐磨性分类,主要应用于维修 (例如泄漏的管道,机架,齿轮,铸件、机械零件)、维护(如去除腐蚀破坏和斑痕)工具及模具制造(如浇灌模具)等。

产品性能描述订货号大小单位数量威肯A 钢铁填补胶,适用温度:-35o C到+120o C 10000005 0.5kg 1威肯B 钢铁填补液,适用温度:-35o C到+120o C 10050005 0.5kg 1威肯C 铝填补液,适用温度:-35o C到+220o C 10100005 0.5kg 1威肯F 铝填补胶,适用温度:-35o C到+120o C 10150005 0.5kg 1威肯F2 铝填补胶,适用温度:-35o C到+120o C 10200005 0.5kg 1威肯SF 钢铁填补胶,快速固化,适用温度:-35o C到+90o C 10250005 0.5kg 1威肯WR 矿物填补液,具有耐磨性,适用温度:-35o C到+120o C 10300005 0.5kg 1威肯WR2 矿物填补胶,具有耐磨性,适用温度:-35o C到+120o C 10350005 0.5kg 1威肯陶瓷BL 矿物(碳化硅和锆石)填补液,高耐磨性,适用温度可达180o C 10400005 0.5kg 1威肯陶瓷硬化剂缓慢硬化剂,适用温度:-35o C到+180o C 10405005 0.5kg 1矿物填补胶-超级耐磨,适用温度:-35o C到+150o C,甚至达10460005 0.5kg 1威肯陶瓷W+260o C威肯TI 钛填补胶,适用温度:-35o C到+150o C 10430005 0.5kg 1威肯UW 钛填补胶,可水下固化,适用温度:-35o C到+120o C 10440005 0.5kg 1威肯ST 不锈钢填补胶,适用温度:-35o C到+120o C 10410005 0.5kg 1威肯BR 青铜填补胶,适用温度:-35o C到+120o C 10420005 0.5kg 1威肯HB300 钢铁填补胶,适用温度:-35o C到+200o C,短时达到+280o C 10450005 1.0kg 1威肯铸造树脂反填充液,适用温度:-35o C到+90o C 10520010 1.0kg 1威肯聚氨酯弹性铸造和涂层树脂,具有耐磨性,适用温度:-60o C到+90o C 10510795 0.810kg 1威肯环氧树脂矿物填补胶,适用温度:-35o C到+200o C 10500400 0.4kg 12---------------------------------------------------------------------------------------------------------------------- WEICON HB300型钢铁填补胶-膏状(1.00kg包装)用于具有钢铁填补物的易于使用的填补胶,也可用于垂直的表面,使用简单方便,富有实效。

威伏3000超级橡胶修补剂

威伏超级橡胶修补剂是一常温快速固化聚氨酯橡胶修补剂,威伏3000为双组份反应固化型,适用于橡胶面的修补、填充和冷硫化。

产品性能:

●高耐磨,韧性好,无需底涂亦可与橡胶强力粘接

●阻燃,可用于井下或其他有阻燃要求的场合使用

●填缝自流平,固化速度快

产品应用:

●输送带接头的填缝及破损面的修补

●滚筒冷包胶的接缝填充

●电缆封头或外套破损的修补

●胶辊、轮胎等橡胶制品的修补

●泵阀壳体、叶轮、料槽、导流板、卸料斗等橡胶耐磨层的衬里或修补包装:100g/250g/500g/袋。