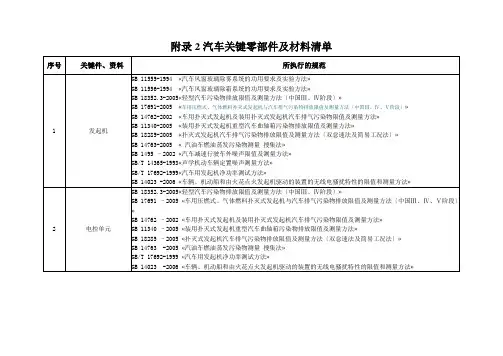

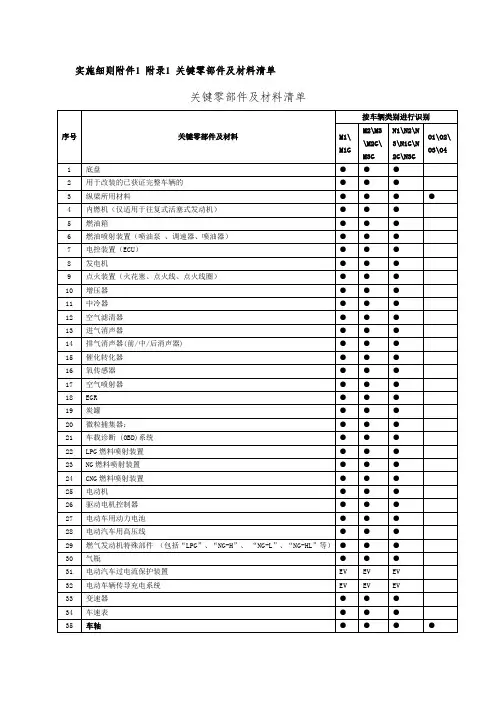

附录2汽车关键零部件与材料清单(M、N类)

- 格式:doc

- 大小:111.00 KB

- 文档页数:11

3C认证实际上是英文名称“China Compulsory Certification”(中国强制性产品认证制度)的英文缩写,也是国家对强制性产品认证使用的统一标志。

作为国家安全认证(CCEE)、进口安全质量许可制度(CCIB)、中国电磁兼容认证(EMC)三合一的“CCC"权威认证,是中国质检总局和国家认监委与国际接轨的一个先进标志,有着不可替代的重要性.它是我国政府按照世贸组织有关协议和国际通行规则,为保护广大消费者人身和动植物生命安全,保护环境、保护国家安全,依照法律法规实施的一种产品合格评定制度。

其主要特点是:国家公布统一的目录,确定统一适用的国家标准、技术规则和实施程序,制定统一的标志标识,规定统一的收费标准。

凡列入强制性产品认证目录内的产品,必须经国家指定的认证机构认证合格,取得相关证书并加施认证标志后,方能出厂、进口、销售和在经营服务场所使用。

目前,中国公布的首批必须通过强制性认证的产品共有十九大类一百三十二种。

主要包括电线电缆、低压电器、信息技术设备、安全玻璃、消防产品、机动车辆轮胎、乳胶制品等。

作用

3C标志一般贴在产品表面,或通过模压压在产品上,仔细看会发现多个小菱形的“CCC"暗记。

每个3C标志后面都有一个随机码,每个随机码都有对应的厂家及产品.认证标志发放管理中心在发放强制性产品认证标志时,已将该编码对应的产品输入计算机数据库中,消费者可通过国家认监委强制性产品认证标志防伪查询系统对编码进行查询。

汽车零部件名称及应用材料类型Automotive components are essential parts that make up a vehicle, contributing to its overall functionality and performance. These components are made from various materials, each carefully chosen for its specific application. In this article, we will explore the different types of automotive components and the materials commonly used in their manufacturing.One of the most crucial automotive components is the engine, which powers the vehicle. Engines are typically made of cast iron or aluminum alloys. Cast iron, known for its durability and heat resistance, is commonly used for engine blocks. On the other hand, aluminum alloys are preferred for their lightweight nature, which helps improve fuel efficiency. The engine's pistons, crankshafts, and cylinder heads are also made from aluminum alloys to reduce weight and enhance performance.Moving on to the braking system, components such asbrake discs and drums are typically made from cast iron due to its excellent heat dissipation properties. Cast iron can withstand high temperatures generated during braking, ensuring reliable and consistent performance. Brake pads,on the other hand, are composed of friction materials such as ceramic, semi-metallic, or organic compounds. These materials are chosen for their ability to provide optimal braking performance, durability, and noise reduction.Suspension systems play a crucial role in providing a comfortable and stable ride. Components like control arms, springs, and shock absorbers are commonly made from steel alloys. Steel offers excellent strength and durability, allowing these components to withstand the constant stress and impact encountered on the road. Additionally, somehigh-performance vehicles may incorporate lightweight materials such as carbon fiber or aluminum alloys in their suspension systems to further enhance performance.The body of a vehicle is composed of various components, including panels, frames, and doors. Traditionally, these components were made from steel due to its strength andaffordability. However, advancements in technology have led to the use of alternative materials such as aluminum,carbon fiber, and high-strength steel. Aluminum offers weight reduction benefits, while carbon fiber provides exceptional strength-to-weight ratio. High-strength steel, on the other hand, combines strength and formability, making it ideal for structural components.Interior components of a vehicle, such as seats, dashboard, and trim, are made from a wide range ofmaterials to provide comfort, aesthetics, and durability. Seats are typically upholstered with materials like leather, fabric, or synthetic fibers, offering a balance between comfort and luxury. Dashboard and trim components are often made from plastic materials due to their versatility, easeof molding, and cost-effectiveness. However, premiumvehicles may incorporate wood, aluminum, or carbon fiber trims to enhance the interior's aesthetics and perceived quality.Lastly, electrical and electronic components areintegral to modern vehicles. Wiring harnesses, connectors,and circuit boards are commonly made from copper and various types of plastics. Copper is an excellent conductor of electricity, ensuring efficient transmission ofelectrical signals. Plastics are used for their insulating properties and ability to withstand high temperatures. Additionally, electronic components such as sensors and control modules are made from semiconductor materials like silicon or gallium arsenide.In conclusion, automotive components are made from a wide variety of materials, each carefully selected based on its specific application. From the engine to the braking system, suspension, body, interior, and electronics, different materials are used to ensure optimal performance, durability, and safety. The constant advancements in material science and manufacturing techniques continue to push the boundaries of automotive component design, leading to more efficient, lightweight, and technologically advanced vehicles.。

汽车零件清单---1. 背景介绍在汽车制造和维修领域,了解汽车的零件清单对于顺利进行相关工作起着至关重要的作用。

汽车零件清单是一份详细列出汽车所需零部件的清单,它可以帮助汽车制造商、汽车修理店和汽车爱好者更好地管理和安排他们的工作。

本文档将提供一份完整的汽车零件清单,包括常见的汽车零部件、其功能以及相关注意事项。

2. 汽车零件清单以下是常见的汽车零部件以及对应的功能和注意事项:2.1 发动机- 功能:发动机是汽车的动力源,通过燃烧汽油或柴油产生的能量驱动车辆运行。

- 注意事项:定期更换机油和滤清器,定期检查发动机冷却液和维护正常的发动机温度。

2.2 传动系统- 功能:传动系统将发动机产生的动力传输到车辆的车轮上,使车辆运行。

- 注意事项:定期检查传动系统液体的水平和质量,以确保传动系统正常工作。

2.3 刹车系统- 功能:刹车系统用于停车或减速车辆,保证行车安全。

- 注意事项:定期检查刹车片和刹车盘的磨损情况,及时更换以保证刹车效果。

2.4 悬挂系统- 功能:悬挂系统帮助保持车辆的稳定性和乘坐舒适度。

- 注意事项:定期检查悬挂系统的减震器和弹簧的工作状态,及时更换磨损的部件。

2.5 电气系统- 功能:电气系统提供车辆的电力支持,包括照明、起动和充电等。

- 注意事项:定期检查电池的电量和线路的连接情况,确保电气系统正常运行。

2.6 空调系统- 功能:空调系统用于调节车辆内部的温度和湿度,提供舒适的驾驶环境。

- 注意事项:定期检查空调系统的制冷剂压力和滤清器的清洁度,确保空调系统的正常运行。

2.7 轮胎- 功能:轮胎是车辆与地面接触的唯一部分,对车辆的行驶稳定性和操控性起着至关重要的作用。

- 注意事项:定期检查轮胎的胎纹深度和气压,及时更换磨损的轮胎。

3. 总结本文档提供了一份详细的汽车零件清单,介绍了常见汽车零部件的功能和注意事项。

通过了解和掌握这些零件的信息,汽车制造商、汽车修理店和汽车爱好者可以更好地管理和维护汽车,确保汽车的正常运行和行车安全。

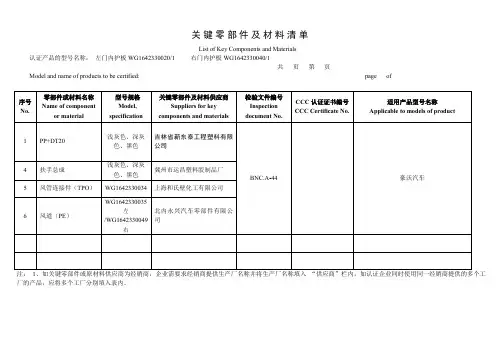

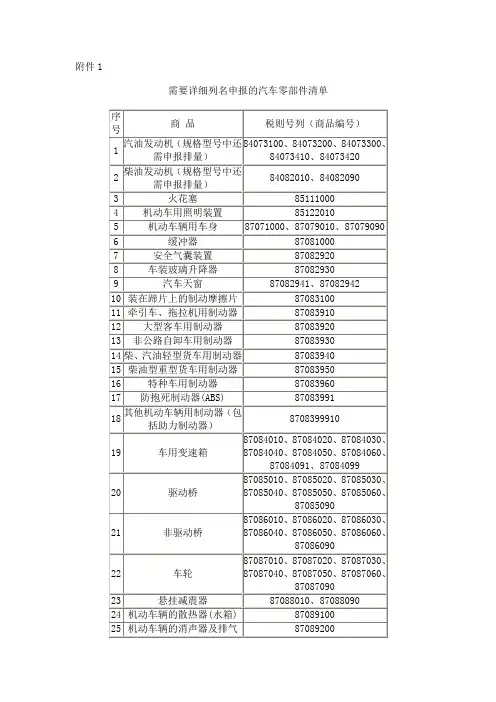

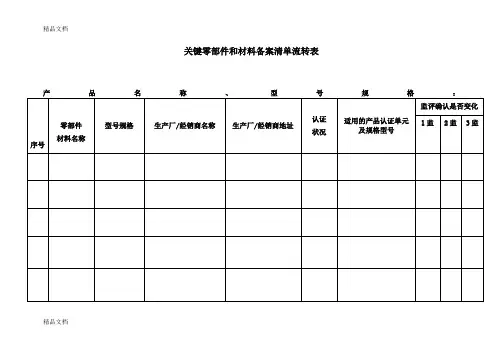

附件1

需要详细列名申报的汽车零部件清单

附件2

汽车零部件规范申报报关单参考样本(仅供参考)表一:生产件的规范申报报关单参考样本

中华人民共和国海关进口货物报关单(样本)预录入编号: xx海关编号: xx

表二:以成套散件形式进口生产件的规范申报报关单参考样本

中华人民共和国海关进口货物报关单(样本)预录入编号: xx海关编号: xx

表三:通用零部件(生产件)的规范申报报关单参考样本

中华人民共和国海关进口货物报关单(样本)预录入编号: xx海关编号: xx

表四:实际成交计量单位与法定计量单位不同的生产件规范申报报关单参考样本

中华人民共和国海关进口货物报关单(样本)

预录入编号: xx海关编号: xx

表五:维修件的规范申报报关单参考样本

中华人民共和国海关进口货物报关单(样本)预录入编号: xx海关编号: xx

表六:品牌与适用的整车厂牌不一致的维修件规范申报报关单参考样本

中华人民共和国海关进口货物报关单(样本)

预录入编号: xx海关编号: xx。

一、发动机配件与易损件一)发动机是汽车的动力装置,以往复活塞式发动机为例,其主要配件如下:1、曲柄连杆机构2、配气机构3、润滑系4、冷却系5、燃料系6、离合装置7、排气装置8、其它二)常耗易损件气缸体、汽缸套、汽缸盖、气缸盖罩、汽缸盖衬垫、活塞、活塞环、活塞销、活塞销衬套、连杆、曲轴、连杆轴承与曲轴轴承、飞轮总成、气门、气门导管、气门弹簧、气门座圈、凸轮轴、气门挺杆、气门推杆、气门摇臂、凸轮轴正时齿、轮、正时链条(齿形皮带)、进排气歧管总成、机油泵、机油集滤器、油底壳、汽油泵、化油器、汽油滤清器、空气滤清器、散热器、节温器、水泵、风扇皮带。

二、底盘配件与易损件一)汽车底盘主要配件汽车底盘由传动系、行驶系、转向系、制动系四部分组成,其主要配件如下:1、传动系2、行驶系3、转向系4、制动系二)汽车底盘常耗易损件离合器总成、离合器从动盘总成、离合器传动操纵机构、离合器液压主缸和轮缸、变速器、传动轴及万向节、主、从动锥齿轮、半轴、转向节、轮毂、轮毂螺栓及螺母、钢板弹簧、螺旋弹簧、钢板弹簧衬套、减震器、转向盘、转向器、动力转向装置、纵拉杆与横拉杆、空压机、液压制动主缸和轮缸、液压制动软管,气压制动软管、前、后制动片、离合器拉锁、滚动轴承、汽车轮胎。

三、车身配件与易损件一)车身主要配件1、车身外配件2、驾驶室内配件3、车身其它配件二)车身常见易损件纵梁、蒸发器、蒸发器壳体、驾驶室、翼子板和挡泥板、保险杠、牌照板、车外后视镜、装饰条、车门槛嵌条、杂物盒、烟灰缸、杂物箱、立柱饰护板四、汽车常用工作液一)汽油牌号及使用原则汽油的牌号是指汽油的辛烷值指标,其直接反映汽油的抗爆性能。

常见的汽油主要有90#、93#和97#这几种,其选用应根据发动机的压缩比匹配,一般应遵循以下原则:1、压缩比在8.5-9.5之间的中档轿车,压缩比大于9.5的轿车,应使用97#汽油。

2、使用牌号相近的汽油代替时,应对发动机进行调整。

3、安装有三元催化剂或氧传感器的汽车也应该选择含铅量低的汽车。

单元二汽车常见易损件和常用材料学习目标完成本单元学习后,你应能:1.掌握汽车发动机、底盘、电气设备和车身的易损件。

2.了解车用燃料的种类与质量要求。

3.了解车用汽油、车用轻柴油、发动机润滑油的作用与质量要求。

4.了解车辆齿轮油和润滑脂的作用与质量要求。

5.了解汽车制动液的作用与质量要求。

6.了解发动机冷却液的作用与质量要求。

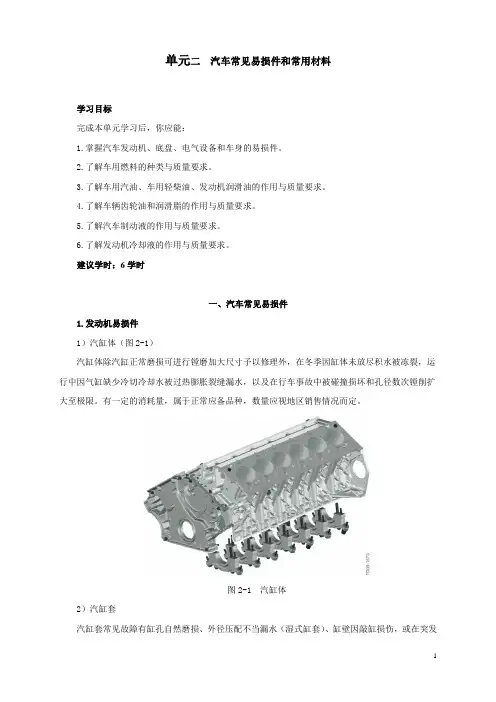

建议学时:6学时一、汽车常见易损件1.发动机易损件1)汽缸体(图2-1)汽缸体除汽缸正常磨损可进行镗磨加大尺寸予以修理外,在冬季因缸体未放尽积水被冻裂,运行中因气缸缺少冷切冷却水被过热膨胀裂缝漏水,以及在行车事故中被碰撞损坏和孔径数次镗削扩大至极限。

有一定的消耗量,属于正常应备品种,数量应视地区销售情况而定。

图2-1 汽缸体2)汽缸套汽缸套常见故障有缸孔自然磨损、外径压配不当漏水(湿式缸套)、缸壁因敲缸损伤,或在突发情况下如连杆螺栓松脱被连杆击穿等,必备品,耗量较大,应有一定的备量。

3)汽缸盖(图2-2)除未发现的制造缺陷如隐藏裂纹、排气门座压配松弛等引起的漏水现象外,主要是使用不当和自然疲劳损坏。

常备品,应有一定的备量。

图2-2 汽缸盖4)汽缸盖衬垫(图2-3)常见故障有缸盖紧固螺栓或螺栓拧紧力失准或松弛,制造上的缺陷,漏水造成热化学腐蚀等,结果封闭汽缸孔边缘部位烧蚀泄漏、水孔边缘部分热腐蚀缺损使封闭失效。

一次性使用配件,消耗量很大,通常有作为随车主要维修备用品,应有较多库存备量。

图2-3 汽缸盖衬垫5)活塞活塞的常见故障有自然磨损,在发动机过热时会造成部分铝合金属熔蚀发生拉缸或咬死,磨损后配合间隙过大、积碳早燃时会击伤、裂缝等。

主要易损件,消耗量大、规格多,是营销必备品种。

6)活塞环(图2-4)常见故障有因活塞拉缸被折断,自然磨损,弹性衰减等。

主要易损件,消耗量大、规格多,是营销必备品种。

图2-4 活塞环7)活塞销常见故障有外径自然磨损,在特殊工况下或制造上未检出的隐藏裂缝造成的折断。

附录A(资料性附录)汽车工业产品类别、主要产品和零部件清单及其工序组成表A.1汽车产品类别、主要产品及零部件清单产品类别主要产品及零部件汽车整车乘用车、汽车底盘、载货汽车、客车、电车汽车用发动机汽、柴油车用发动机、新能源汽车用发动机专用汽车及挂车a 专用汽车(即改装汽车)厢式汽车、罐式汽车、自卸汽车、仓栅式汽车、起重举升汽车、特殊结构汽车等挂车厢式挂车、罐式挂车、自卸挂车、仓栅式挂车、起重举升挂车、特殊结构挂车等零部件及配件(以主要生产工艺分类)总成类部件变速器(箱)、车桥、离合器、水泵、机油泵、涡轮增压器、风扇、燃油泵等铆焊类部件车身、车架、底架、车厢或货箱、储气筒、轮毂等壳芯类部件消声器、催化转换器、滤清器等钎焊类部件散热器、中冷器、机油冷却器等树脂类零部件保险杠、翼子板、仪表盘、内饰件、水箱、燃油箱、通风管、软垫和安全带等粉末冶金类零件进排气门座、同步器锥环、连杆、齿轮和减震器零件等其他类零件曲轴、凸轮轴、连杆、气缸套、飞轮及齿圈、活塞、发动机齿轮和气门室罩等注:表中内容覆盖《国民经济行业分类》(GB/T4754—2017)中汽车制造业(C36)的全部内容。

a依据GB/T17350的分类。

表A.2汽车产品及零部件的工序组成一览表产品类型工序名称下料锻造铸造冲压机械加工粉末冶金焊接铆接树脂纤维加工粘接热处理电镀预处理转化膜处理涂装装配检测试验乘用车●●●●●●●●●汽车底盘●●〇●〇●●●●●载货汽车●●〇●〇〇●●●●●客车和电车●●〇●〇●●●●●●●汽车用发动机〇〇●●●●●●专用汽车和挂车●●●●●〇●●●●●●零部件及配件总成类部件●〇〇●●●●〇●●●铆焊类部件●●●●●●●●●●壳芯类部件●●●●●●钎焊类部件●●●●●●树脂类零部件●●●〇●粉末冶金类零件●●〇●●其他类零件〇〇〇●〇〇注:●为必需的工艺,〇为可能包括的工艺。

一、汽车大全: (一)车型微型车 小型车 紧凑型车 中型车 中大型车 豪华车 MPV SUV 跑车 微面 皮卡 新能源 客车(二)卡车分类微型卡车、轻型卡车、中型卡车、重型卡车、超重型卡车(三)主要品牌 1、微型车2、小型车新奥拓北斗星比亚迪F0smart 双座乐驰奔奔mini哈弗M1QQ3熊猫海马王子悦悦精灵3、紧凑型车4、中型车甲壳虫 雨燕 Polo 晶锐悦翔 同悦 羚羊 雅力士奥迪A1嘉年华晶锐中华速锐速腾550朗逸新宝来中华高尔夫K3长城C30世嘉骐达东风标致4085、中大型车歌诗图大众CC宝马3系君威K5蒙迪欧致胜马自达6雅阁迈锐宝君越锐志奔驰C 级奥迪A6L宝马5系奔驰E 级新皇冠捷豹XF宝马5系沃尔沃S80L林荫大道6、豪华车7、MPV奥迪A6帕萨特R36红旗H 系列克莱斯勒300C宝马7系奔驰S 级奥迪A8L辉腾雅致幻影迈巴赫62捷豹XJ总裁慕尚红旗卓越GE长安欧诺途安宏光别克GL88、SUV9、跑车菱智瑞风逸致奥德赛马自达8和悦RS夏朗马自达5途观 W5翼虎昂科拉Encore奥迪Q5哈弗H6比亚迪S6B40哈弗M4北汽B90纳智捷大7 SUV斯巴鲁XV10、微面11、皮卡MurcielagoCaymanCarrera GT458Italia欧陆劳恩斯-酷派野马奔驰SLGallardo捷豹XK宝马6系奥迪R8众泰永源一汽 五菱威旺 铃木 开瑞 金杯海马哈飞东南长安商用昌河12、新能源13、客车北汽福田 东风商用车 江淮汽车 陕汽重卡一汽解放中国重汽比亚迪F3 DM 混合动力版奔驰B 级NGT 混合动力版凯美瑞混合动力版日产聆风别克君越混合动力版凯美瑞混合动力版波导混合动力客车 路尊大霸王 江淮M209 长安金牛星大海狮比亚迪K9宇通客车金龙客车青年客车黄海客车申龙客车二、专用车辆重型卡车、轻卡、道路清扫车、清障车、警用车、运钞车、消防车、邮政车、牵引车、半挂车、自卸车、厢式车、罐式车、特种车、起重运输车、高空作业车、大型拖车、环卫车、园林作业车辆、桥梁检测车、机场专用车,冷藏保鲜车辆及零配件等。