GWSP系列无油涡旋真空泵介绍(中英文)

- 格式:pdf

- 大小:285.16 KB

- 文档页数:4

真空系统常用词语及解释中英对照0001.1标准环境条件standardambientcondition:温度为20℃,相对湿度为65%,大气压力为:101325Pa=1013.25mbar=760Torr。

1.2气体的标准状态standardreferenceconditionsforgases:温度为0℃,压力为:101325Pa。

1.3压力(压强)ppressur e:气体分子从某一假想平面通过时,沿该平面的正法线方向的动量改变率,除以该平面面积或气体分子作用于其容器壁表面上的力的法向分量,除以该表面面积。

注:"压力"这一术语只适用于气体处于静止状态的压力或稳定流动时的静态压力。

1.4帕斯卡Papascal:国际单位制压力单位,1Pa=1N/m2。

1.5托Torrtorr:压力单位,1Torr=1/760atm。

1.6标准大气压atmstandardatmospher e:压力单位,1atm=101325Pa。

1.7毫巴mbarmillibar:压力单位,1mbar=102Pa。

1.8分压力partialpressur e:混合气体中某一组分的压力。

1.9全压力totalpressur e:混合气体中所有组分压力的总和。

1.10真空vacuum:在指定空间内,低于环境大气压力的气体状态。

1.11真空度degreeofvacuum:表示真空状态下气体的稀薄程度,通常用压力值来表示。

1.12真空区域rangesofvacuum:真空区域大致划分如下:真空区域压力PaTorr低真空105~102760~1中真空102~10-11~10-3高真空10-1~10-510-3~10-7超高真空〈10-5〈10-71.13气体gas:不受分子间相互作用力的约束且能自由地占据任意空间的物质。

汪:在真空技术中,"气体"一词不严格地应用于非可凝气体和蒸汽。

1.14非可凝气体non-condensablegas:在临界温度以上的气体,即单纯增加压力不能使其液化的气体。

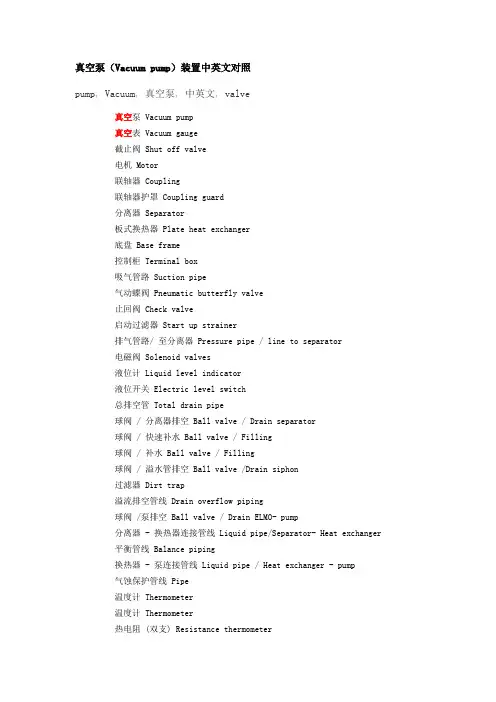

真空泵(Vacuum pump)装置中英文对照pump, Vacuum, 真空泵, 中英文, valve真空泵 Vacuum pump真空表 Vacuum gauge截止阀 Shut off valve电机 Motor联轴器 Coupling联轴器护罩 Coupling guard分离器 Separator板式换热器 Plate heat exchanger底盘 Base frame控制柜 Terminal box吸气管路 Suction pipe气动蝶阀 Pneumatic butterfly valve止回阀 Check valve启动过滤器 Start up strainer排气管路/ 至分离器 Pressure pipe / line to separator电磁阀 Solenoid valves液位计 Liquid level indicator液位开关 Electric level switch总排空管 Total drain pipe球阀 / 分离器排空 Ball valve / Drain separator球阀 / 快速补水 Ball valve / Filling球阀 / 补水 Ball valve / Filling球阀 / 溢水管排空 Ball valve /Drain siphon过滤器 Dirt trap溢流排空管线 Drain overflow piping球阀 /泵排空 Ball valve / Drain ELMO- pump分离器 - 换热器连接管线 Liquid pipe/Separator- Heat exchanger平衡管线 Balance piping换热器 - 泵连接管线 Liquid pipe / Heat exchanger - pump气蚀保护管线 Pipe温度计 Thermometer温度计 Thermometer热电阻 (双支) Resistance thermometer压力开关 Pressure switch压力开关 Pressure switch压力表 Pressure gauge气动控制件 Pneumatic control set地脚螺栓 Foudation boltList of equipment 设备清单Overall dimension drawing 外形尺寸图Flow diagram 系统流程图Foundation plan 基础载荷图Pump section view 零件装配剖面图Pump overall dimension drawing 泵外形尺寸图Circuit diagram 接线端子图Pneumatic control system diagram 气动系统原理图Pump operating instruction 泵使用说明书System operating instruction 系统使用说明书。

同方泵业TongFang HI-TECH PUMP CO.L TD2BW4-OBK4成套装置2BW4-OBK4 Complete sets of equipment安装使用说明书Installation Manual湖北同方高科泵业有限公司HUBEI TongFang HI-TECH PUMP CO.L TD概述SummaryI. 湖北同方高科泵业有限公司是生产水环真空泵的专业厂家,2BW4型水环真空泵成套装置(机组)是我公司在引进德国西门子公司技术的基础上进一步改良而来,用于25MW、50MW、100MW、135 MW、200MW、300MW、600MW 和1000MW发电机组配套以及化工、卷烟等行业。

抽吸容器中的气体以形成一定真空度,达到提高发电出力,增加蒸发效果以及干燥、吸附的目的。

工作介质一般为不含固体颗粒的常温清水,其规格主要有2BW4 203、2BW4 253、2BW4 303、2BW4 353、2BW4 403几种类型的机组,机组制造及管路连接法兰采用德国DIN标准,以2BW4 203-0BK4为例说明型号及意义:I. HUBEI TongFang HI-TECH PUMP CO.LTD is a corporation specializes in producing water cycle vacuum pump. The 2BW4 type water cycle vacuum pump complete set equipment is designed based on Germany Siemens technology with optimization. It is used in 25MW, 50MW, 100MW, 135 MW, 200MW, 300MW, 600MW and 1000MW generators power plant, and chemistry, tobacco industries. It can suck the air in the vessel and form the vacuum of a certain level in order to increase the generated power, improve the evaporation effect, drying and adsorption. The working mediator is usually normal temperature clean water and the types are 2BW4 203、2BW4 253、2BW4 303、2BW4 353、2BW4 403. The manufacture of the unit and the flange for connecting the pipes adopts the German DIN standard, here take the 2BW4 203-0BK4 for example to paraphrase the meaning:2BW 4 203-0 B K 4填料内供水密封water supply padding seal带电动机成套(不带大气喷射器)Complete set with motor (without air ejector)材质为碳钢(E时材质为不锈钢)The material quality is the carbon steel (when the letter is E, material quality isstainless steel)泵型号Pump model第4次改进后的真空泵成套装置The 4th improvement vacuum pump complete equipment set改进后的水环真空泵成套型号Improved water cycle vacuum pump complete model二、2BW4-0BK(0EK4)机组结构及原理II. 2BW4-0BK (0EK4) unit structure and principle2.1机械部分2.1 Mechanical part(1)结构(1)Structure(a)2BW4-0BK(0EK4)机组结构见图VI采用闭式循环主要由以下几个部分组成:(a)2BW4-0BK (0EK4) the unit structure sees Figure VI. Use the closed cycle and it is mainly composed of the following several parts:1、水环真空泵2、底座3、电机4、控制箱5、汽水分离器6、排水管7、液位计8、联轴器(转速与电机不一致时带减速机)9、热交换器16、进气管17、泵排气管18、成套排气管(与分离器一体)28、泵供水管28a、喷射支管(电厂用)16b、环形断流阀18c、止回阀22a、补水电磁阀22b、输出调节器24b、手动球阀(旁边管路输)47、压力开关47b、压差开关1、water cycle vacuum pump2、pedestal3、electrical motor4、control box5、air and water separator6、discharge pipes7、Liquid meter8、the shaft coupling (when the rotational speed is inconsistent with electrical motor a speed reducer will be adopted)9、heat exchanger 16、air feeder pipe 17、pump exhaust pipe 18、complete set exhaust pipes (together with the separator) 28、pump water supply pipe 28a、the spraying branch pipe (power plant uses) 16b、ring-shape water stopping valve 18c、the check valve 22a、water sypply magnet valve 22b、output adjustor 24b、the manual ball valve (side pipeline supply) 47、pressure switches 47b、differential pressure switch(b)、2BW4型成套接口及尺寸表(b)、2BW4 complete set connection and size table序号Serial number代号Codenumber名称Name公称直径Nominal diameter法兰标准号Flange standardnumber2BW4203 2BW4253 2BW4303 2BW4353 2BW4403法兰标准号Flange standardnumber1 N1.2 汽体吸入口Air/waterinduction port125 150 200 250 300 DIN25762 N2.2 汽体排出口Air/wateroutput125 150 200 250 300 DIN25763 N3.3进水口Water inletRp1 Rp1 Rp1 Rp1 Rp1 Rp165 4 N4.6总排水口General wateroutput40 40 40 40 40 DIN25665 N5.0 热交换器进水口Heatexchangerwater inlet50 80 100 100 100 DIN26336 N6.0 热交换器进水口Heatexchangerwater inlet50 80 100 100 100 DIN26337 N8.泵压缩空气口The pumpcompressedair portRp1/4 Rp1/4 Rp1/4 Rp1/4 Rp1接口说明:Connection explanation:1、汽体吸入口接汽轮机、凝汽背压出口处。

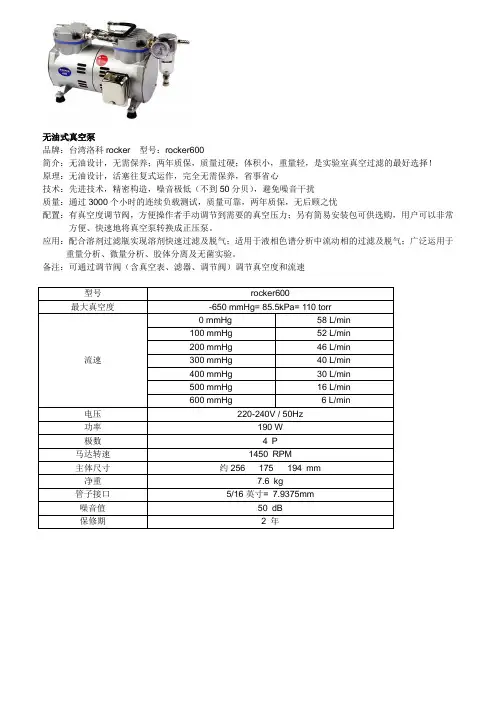

无油式真空泵

品牌:台湾洛科rocker 型号:rocker600

简介:无油设计,无需保养;两年质保,质量过硬;体积小,重量轻,是实验室真空过滤的最好选择!

原理:无油设计,活塞往复式运作,完全无需保养,省事省心

技术:先进技术,精密构造,噪音极低(不到50分贝),避免噪音干扰

质量:通过3000个小时的连续负载测试,质量可靠,两年质保,无后顾之忧

配置:有真空度调节阀,方便操作者手动调节到需要的真空压力;另有简易安装包可供选购,用户可以非常方便、快速地将真空泵转换成正压泵。

应用:配合溶剂过滤瓶实现溶剂快速过滤及脱气;适用于液相色谱分析中流动相的过滤及脱气;广泛运用于重量分析、微量分析、胶体分离及无菌实验。

备注:可通过调节阀(含真空表、滤器、调节阀)调节真空度和流速

型号rocker600

最大真空度-650 mmHg= 85.5kPa= 110 torr

流速

0 mmHg 58 L/min 100 mmHg 52 L/min 200 mmHg 46 L/min 300 mmHg 40 L/min 400 mmHg 30 L/min 500 mmHg 16 L/min 600 mmHg 6 L/min

电压220-240V / 50Hz

功率190 W

极数 4 P

马达转速1450 RPM

主体尺寸约256 ×175 ×194 mm 净重7.6 kg

管子接口5/16英寸= 7.9375mm 噪音值50 dB

保修期 2 年。

无油涡旋真空泵的结构—原理无油涡旋真空泵的主要结构包括泵头、驱动装置和配套设备。

泵头是真空泵的核心部分,由驱动装置提供动力来驱动泵头的工作,而配套设备则包括电机、变速器、风扇、水冷器等。

此外,还有一个控制系统来控制泵头的启动、关闭和运行状态。

泵头是无油涡旋真空泵最重要的部分,通常由泵体、叶轮和驱动装置组成。

泵体是泵头的主体部分,它通常由铸铝合金或不锈钢制成,具有高强度和耐腐蚀性。

泵体内部有一个旋转的叶轮,叶轮上有凹槽,这些凹槽和泵体之间的空间形成了泵的工作腔。

泵体的顶部有一个进气口,可以将气体引入泵内。

在泵体的底部有一个排气口,通过排气口将抽出的气体排出。

驱动装置通常由电动机和传动装置组成。

电动机通过传动装置将动力传递给泵体,驱动叶轮旋转。

电动机通常采用交流电机或直流电机,具有高效、低噪音和可靠性的特点。

传动装置通常由机械齿轮和传动带组成,将电动机的旋转力矩传递给泵体,使其产生旋转运动。

无油涡旋真空泵的工作原理如下:当泵头启动时,电动机带动叶轮旋转,通过离心力将气体推入凹槽中。

在叶轮旋转的过程中,凹槽不断地与进气口和排气口交替相连。

当叶轮旋转的一侧与进气口相连时,气体被吸入泵体,形成一个密封的工作腔。

随着叶轮的继续旋转,这个工作腔不断向排气口推进,气体因叶轮的作用逐渐被压缩,并被排出泵体。

同时,在叶轮的旋转过程中,泵体内部不断形成新的工作腔。

这个过程是连续进行的,形成了一个无油涡旋真空泵的工作循环。

通过连续的旋转运动和排气过程,泵头将气体从真空室中抽出,从而形成真空。

根据不同的需要,泵的工作速度可以通过控制驱动装置的转速来调整。

无油真空泵用途无油真空泵是一种特殊类型的真空泵,其工作原理是通过机械运动将气体抽出,而不需要使用润滑油来降低摩擦和密封。

无油真空泵具有广泛的用途,下面将介绍几个典型的应用领域。

无油真空泵在实验室中的应用非常广泛。

实验室通常需要在一定的真空环境下进行各种物理、化学实验。

无油真空泵可以提供所需的真空度,并能够快速、稳定地排出气体,保证实验过程的准确性和稳定性。

无油真空泵还可以用于实验室设备的真空干燥、真空冷冻、真空脱气等操作。

无油真空泵在半导体制造业中也发挥着重要作用。

半导体制造过程需要在高度洁净的环境中进行,以确保半导体产品的质量和性能。

无油真空泵可以提供高度稳定的真空环境,避免油污染对产品造成的影响。

同时,无油真空泵的运行更加可靠、安全,并且不会产生有害物质,符合半导体制造的严格要求。

无油真空泵还广泛应用于医疗设备中。

例如,在放射治疗过程中,需要将患者的体内空气抽出,以确保放射线的准确定位和治疗效果。

无油真空泵可以提供所需的真空度,并且运行安静、平稳,不会对患者造成不适。

此外,无油真空泵还可用于医疗设备的清洗、干燥、灭菌等工序。

无油真空泵还常用于电子设备制造、食品加工、制药工业等领域。

在电子设备制造中,无油真空泵可以用于真空封装、真空干燥等操作。

在食品加工过程中,无油真空泵可以用于真空包装、真空脱气等工序,以延长食品的保质期。

在制药工业中,无油真空泵可以用于药品的真空干燥、真空浓缩等工艺。

无油真空泵是一种应用广泛的设备,其无油运行原理使其具有许多优点,例如高度稳定的真空度、可靠安全的运行、无污染等。

无油真空泵在实验室、半导体制造、医疗设备以及电子设备制造、食品加工、制药工业等领域都有重要的应用。

随着技术的不断进步,无油真空泵的性能将进一步提高,应用领域也将不断拓展。

美容仪无油真空泵工作原理(一)美容仪无油真空泵工作原理详解1. 美容仪简介美容仪是一种应用于面部和身体护理的电子设备,通过科技手段提供各种美容和护肤效果。

其中,无油真空泵是美容仪中的一个核心组件,接下来我们将详细介绍其工作原理。

2. 什么是无油真空泵无油真空泵是一种不需要使用润滑油的泵,其通过特殊的设计和材料选择,实现了在工作过程中不产生润滑剂、不沾染粉尘的特点。

这种泵常用于对空气或气体进行抽取、压缩和循环,在美容仪中主要扮演抽取功能的角色。

3. 真空泵的基本原理真空泵工作时,通过不同的方式降低一定区域内气体的压力,从而使周围的气体以较高压力自动流入被抽空的区域,形成真空状态。

简单来说,真空泵就是利用压力差实现气体流动的装置。

4. 无油真空泵的工作原理旋片式真空泵无油真空泵中的一种常见类型是旋片式真空泵,其由一个固定的外壳和随着转子旋转的内部旋片组成。

工作时,电机将转子通过传动装置带动旋转,从而产生离心力。

离心力使旋片与外壳内壁密封紧密,形成泵腔。

转子的形状决定了泵腔容积的变化。

工作原理1.吸气过程:当旋片开始旋转时,泵腔容积逐渐增大,造成一定的负压。

随着泵腔内压力降低,周围空气会通过进气孔流入泵腔。

2.排气过程:旋片继续旋转,泵腔容积逐渐减小,压力升高。

泵腔内的气体经过出气口排出。

5. 美容仪中的应用美容仪中的无油真空泵在美容护肤方面有着广泛的应用。

它的主要作用包括: - 深层清洁:通过产生负压,将毛孔中的污垢和皮脂吸出,有效清洁堵塞的毛孔。

- 毛孔收缩:通过排除毛孔中的污垢和皮脂,帮助毛孔收缩,改善皮肤质地。

- 营养渗透:美容仪配合化妆水、精华液等护肤品,可以利用负压原理实现渗透、吸收和输送,提高护肤品的效果。

6. 结论无油真空泵是美容仪中重要的组成部分,通过负压原理实现了深层清洁、毛孔收缩和营养渗透等功效。

对于美容仪的选购和使用,了解其工作原理是非常重要的。

Agilent TwisTorr FSTurbo Pump FamilyThe new generation Turbo Pumpswith TwisTorr drag technology and Agilent Floating SuspensionAgilent Quality and ReliabilityYour Benefit–Reduced cost of ownership and system down-timeEasy System IntegrationYour Benefit–Compact design –P lug and play –E asy pump driving and monitoring –O peration in any position–O il-free solutionTwisTorr FS Family Features–Ceramic ball bearings withpermanent lubrication–PCB, onboard, rack control units with Serial and Profibus communication–Retrofitable to any pumpIndustrial and SemiconductorsThe TwisTorr FS turbo pumps offer dry, clean vacuum for demanding in d ustrial and semiconductor applica t ions.Agilent TwisTorr FS Pump ApplicationsThe new TwisTorr FS technology represents a unique blend of performance and features that is perfectly suited for a wide range of applicationsAcademia, Government and ResearchUnmatched vacuum performance in its class, with TwisTorr stages op t imized for H2 compression, make it the ideal solution for demanding ac a demic and research applications.Surface AnalysisThanks to low vibration, low noise and high stability, the TwisTorr FS turbo pumps meet the specific needs of electron microscopes.Analytical InstrumentationHigh throughput and optimized per f ormance for light gases in routine applications are suited perfectly for use in analytical instruments.2Now FeaturingYour solution for high performance, quality, and reliability* The new TwisTorr 704 FS – CutawayQuiet and Low-VibrationYour Benefit–Excellent vibration level (damping effect) –Quiet pump during operationTwisTorr FS Family Features– A gilent Floating SuspensionSuperior PerformanceYour Benefit–Low ultimate pressure –Fast pumpdown–Smaller/less expensive backing pump –Suitable for high gas load applications–Lower power consumptionTwisTorr FS Family FeaturesTwisTorr Drag Stages allow for: –Superior compression ratio–High foreline pressure tolerance –Best-in-class pumping speedTwisTorr FS Family Features– A gilent Floating Suspension – B earings and rotor stable/constant positioning over timeNew 3D Software for Pump Control✓ Optimized Performance, Maximum Flexibility and Extended Reliability ✓ Dynamic speed and power tuning according to inlet pressure, gas load, and temperature✓ Always the best performance in every working point Learn more, see pages 8-93704 FS, 804 FSAgilent Warranty:and ReliabilityVibration test - TwisTorr 404 FS, 704 FS, 804 FS*The compatibility with vibrations generated by external sources was proven through a set of tests on a batch of pumps, both in operative and inoperative conditions.Each pump was exposed to energy levels from 0.5 to 2 g during 105 minutes’ vibration cycles in vertical, horizontal, upside-down orientation at full rotational speed and not operative.The test confirmed pump robustness and fullcompatibility to vibrations as No rotor mechanical contacts or change to pumps’ operation werehighlighted and the pump unbalance remained well below acceptance threshold.Lifetest - TwisTorr 404 FS, 704 FS, 804 FS*Pump reliability proven through an accelerated life test on a significant number of pumps, exposed for extended time to accelerating factors.The test provided confidence in pump’s hassle-freeoperation for an average period longer than five years.Shock test - TwisTorr 404 FS, 704 FS, 804 FS*Pump resistance to shocks proven by a set of tests on a batch of pumps both in operative and inoperative conditions.Every pump exposed to a 30 to 120 g acceleration (equivalent to a drop from 82 cm / 32” - not operative pump, and 15 cm / 6” - operative pump).Pumps shock-tested six times in vertical, horizontal, upside-down orientation.No issue occurred to the tested pumps after the full batch of 24 drops (No rotor mechanical contacts, No change to pumps operation).The pump unbalance verified after every drop highlighted minor variations,remaining well below acceptance threshold : the shock test confirmed the pumprobustness and reliability.Agilent TwisTorr FS Turbo PumpsTwisTorr FS: Design Process, Quality, and Reliability Test ElementsThe «Product Life Cycle» method drives and tracks the design process through the six steps of proposal, investigation, lab prototype, production prototype, pilot run, and ramp to volume. Reiterated controls and tracking ensure full confidence in performance, quality, and the regulatory data published for users.4Quiet and Low-VibrationStability OverTimeThermal test - TwisTorr 404 FS, 704 FS, 804 FS*Pumps were exposed for 86 h to temperatures ranging from -40 °C to +70 °C (not operative) and from 0° C to 40 °C (operative).The pump unbalance and correct operation was verified 11 times on everypump finding only minor variations, well below acceptance threshold. The thermal test confirmed the pump’s robustness and full compatibility to every operative and not operative temperature condition of applications or during storage and transport.Fourier analysisTwisTorr 404 FS, 704 FS, 804 FS*The pump vibration spectrum is verified on every pump during the manufacturing process and before the pump shipment as a final test of pump’s correct operation.Average maximum vibration level at full speed: 0.4 m/s 2.Noise testTwisTorr 404 FS, 704 FS, 804 FS*Pump noise was verified through a set of tests on a batch of pumps in 12 different operative statuses and orientationsincluding: vertical, horizontal, and upside-down positions; with and without gasload; high temperature and low temperature; full speed and low speed.The average pump noise resulting from the 168 measurements was 43 dB(A) +/-3σ in normal operation.Packaging test - TwisTorr 404 FS, 704 FS, 804 FS*The packaging functionality verified with test session on packed pumps, subjected to a test of 18 drops from 96 cm (37.8 inch) height.The test confirmed that packaging can limit the acceleration provided to the pump during a typical transportation to the 30 g.From the shock test, we know that 30 g is a level ofacceleration fully compatible with TwisTorr pump design.*NOTE: Test data provided arereferred to TwisTorr 404 FS, 704 FS, 804 FS – similar data are available on request even for 84 FS and 304 FS.FFT Analysis - TwisTorr 404 FS, 704 FS, 804 FSNoise distribution cart - TwisTorr 404, 704, 804 FS5Space Saving Design–Our rotor is based on the proven Agilent monolithic rotor design, which positions the TwisTorr stator between two smooth spinning disks and therefore exploits the pumping action by both disk surfaces in series. –The double-sided spiral groove design on theTwisTorr stators combines centripetal and centrifugal pumping action in series, greatly reducing the size of the drag section.Agilent TwisTorr Technology*–Pumping effect is created by a spinning rotor disk, which transfers momentum to gas molecules. –Gas molecules are forced to follow spiral groove design on the stator. The specific design of the channel ensures constant local pumping speed and avoids reverse pressure gradients, minimizing power consumption.(*) US Patents applications 12/343961 and 12/343980, 24 Dec. 2008.Compression ratio–Compression ratio for N 2 of a single TwisTorr stage can increase up to a factor of 100 with respect to a MacroTorr stage of the same space and rotor speed, without reducing foreline tolerance and pumping speed.Leading Edge Performance–The TwisTorr pumps offer the highest pumping speed in their category for all gases. –The state of the art TwisTorr technology also achieves the highest compression ratios for light gases in a commercially available turbomolecular pump. –While offering the highest performance, average power consumption by the new drag section design is reduced by a factor of four, compared to previous designs.Spiral groove design on the upper section of the TwisTorr stator causes a centripetal pumping action).Gas flow in centripetal and centrifugal direction throughTwisTorr channelsThe pumping effect is repeated for each of the pump’s TwisTorr stagesSpiral groove design on the lower section of the TwisTorr stator causes a centrifugal pumping action.What is TwisTorr?The new molecular-drag technology, applied to the entire family from 84 FS to 804 FSCentripetal pumping action Lower surface area of rotating disk transfers momentum to gas molecules.Centrifugal pumping action Upper surface area of rotating disk transfers momentum to gas molecules.6What is Agilent Floating Suspension?Innovative solutions for low vibration and stability over timePerfect bearing alignmentVibration damping–AFS geometrical precision guarantees perfect bearing alignment –Designed radial and axial stiffness,optimized rotor dynamic behaviour, and acoustic noise –Lower AFS acts as an axial springproviding bearing preload and axial rotor positioning –Thermal stabilityRadial press fitting to maintain the best working condition for bearings over timeHigh performance elastomer for vibration dampingTo ensure–Low vibration and acoustical noise –Optimal working conditions for the bearings, extended operating life –Exceptional stability for the very demanding SEM applicationLower AFSUpper AFSThermal stabilityOptimized rotor dynamic BehaviourTwisTorrrotor, floating suspension, and electrical motor7Maximum flexibility, speed, and simplicity, thanks to a unique smart vacuum system:Dynamic speed and power tuning according to inlet pressure, gas load, and temperature.Always the best performance in every working point.Steering towards flexibility, speed of execution, and simplicity, TwisTorr 404 FS, 704 FS, and 804 FS are now introducing a new Agilent innovative footstep - 3D pump control software.The innovative pump driving function provides maximum flexibility, speed, and simplicity: Always the best possible throughput performance according to the pump operative conditions.A unique vacuum system is able to quickly and automatically ensure the entire spectrum of customers’ application needs, from UHV to high gas-load, on a single turbo pump.An automatic routine manages the pump’s rotational frequency and power according to the required inlet pressure and gas-load, at the specific application’s temperature point.The new TwisTorr medium TMP Controllers.Rack or onboard, available for 404 FS, 704 FS, 804 FS pumps with 3D firmware for performance optimizationAgilent TwisTorr FS Turbo Pumps8«3D» software drives the pumpHigh Gas Flow High VacuumPump parameters dynamic setting/tuning––Power –TemperatureApplication requirements auto detection High Throughput High CompressionTwisTorr Technology Output/Performance 9Quality RepairWhen uncompromised quality at the right price is of essence You need a trusted partner to deliver it. Specialized Repair Centers around the globe bring Agilent quality standards closer to you.When your TwisTorr turbo pump needs attention, we have the right know how and the experience to deal with it. Your trusted solution:–Certified process andworkmanship–Genuine Agilent partsYour work is important to us. Our technology refresh programs and tailored service plans are designed to protect and secure your investment. Customized service contracts and a comprehensive upgrade program are designed around your business needs and make us the natural choice as your vacuum service partner. Your advantage:–Stay up to date with the technology–Close to your business –Personalized coverageDedicated Solutions 10Technical SpecificationsPumping SpeedCompression RatioTechnical SpecificationsPumping Speed12Technical SpecificationsArMax GasThroughput (*)N 2He Ar(*) Backing pump 11.6 m Compression ratio and foreline tolerance (**) N 2He H 2Ar(**) Foreline Tolerance defined as the pressure at which the turbopump still produce a compression of 100 and estimated in water cooling modeBase pressure with recomm.Pumping SpeedCompression RatioTechnical SpecificationsPumping SpeedP u m p i n g S p e e d (l /s )Compression Ratio C o m p r e s s i o n r a t i oRecommended forepumpAgilent DS102 Rotary Vane Pump Agilent IDP-7 Dry Scroll PumpAgilent TwisTorr FS Turbo Pumps14Pumping SpeedCompression Ratio1,E-08 1,E-07 1,E-06 1,E-05 1,E-04 1,E-03 1,E-02Inlet Pressure [mbar]1,E-2 1,E-1 1,E+0/chem/TwisTorrFSfamily15Agilent TwisTorr FS Turbo Pump FamilyThe new generation Turbo Pumps with TwisTorr drag technology and Agilent Floating SuspensionAgilent TechnologiesUnited StatesAgilent Technologies 121 Hartwell Avenue,Lexington MA 02421, USA Tel: +1 781 861 7200Fax: +1 781 860 5437Toll free: +1 800 882 7426*******************************ChinaBeijing OfficeAgilent Technologies (China) Co. Ltd No.3, Wang Jing Bei Lu, Chao Yang District,Beijing, 100102, China Tel: +86 (0)10 6439 7888Fax: +86 (0)10 6439 2765Toll free: 800 820 3278*************************************************************Shanghai OfficeAgilent Technologies16F Shanghai Litong Plaza, No.1350 North Si Chuan Road, Hongkou District,Shanghai, 200080, China Tel: +86 (0)21 3612 7688Fax: +86 (0)21 6628 5169Toll free: 800 820 3278*************************************************************Guangzhou Office Agilent Technologies Unit 08, 66/F, Citic Plaza, 233 Tian He Bei RdGuangzhou, 510613, China Tel: +86 (0)20 38113988Fax: +86 (0)20 86695861Toll free: 800 820 3278Shenzhen Office Agilent Technologies3/F Dutyfree Business Bldg.,No.6, 1st Fu Hua Road, Futian CBD Shenzhen, 518048Tel: +86 (0)755 8307 9589Fax: +86 (0)755 8276 3182Toll free: 800 820 3278BrazilAgilent Technologies BrasilAvenida Marcos Penteado de Ulhoa Rodrigues, 939 - 6° andar Castelo Branco Office Park Torre Jacarandá - TamboréBarueri, Sao Paulo CEP: 06460-040Tollfree************BeneluxAgilent Technologies Netherlands BV Groenelaan 5, 1186 AA Amstelveen The NetherlandsTel: +31 20 547 2000Fax: +31 20 547 2093Toll free: 00 800 234 234 00*******************************FranceAgilent TechnologiesParc Technopolis - Z.A. de Courtaboeuf 3, avenue du Canada - CS 9026391978 Les Ulis cedex, France Tel: : +33 1 64 53 60 13Fax: +33 (0) 1 64 53 50 01Toll free: 00 800 234 234 00*********************Germany and Austria Agilent TechnologiesSales & Services GmbH & Co. KG Lyoner Str. 2060 528 Frankfurt am Main, Germany Tel: +49 69 6773 43 2230Fax: +49 69 6773 43 2250Toll free: 00 800 234 234 00*******************************IndiaAgilent Technologies India Pvt Ltd Unit Nos 105-116First Floor, Splendor Forum,Plot No.-3 , District Centre, Jasola New Delhi-110025Ph: +91 11 4623 7100Fax: +91 4623 7105TollFree:180****1517*********************ItalyAgilent Technologies Italia SpA via F.lli Varian 5410040 Leinì (Torino), Italy Tel: +39 011 9979 111Fax: +39 011 9979 350Toll free: 00 800 234 234 00*******************************JapanAgilent Technologies Japan, Ltd.Vacuum Products Division Hachioji Site9-1, Takakura-machi, Hachioji-shi,Tokyo, 192-8510 Japan Toll-Free: 0120-477-111TEL: 042-656-7884FAX: 0120-880-598, 042-656-7880************************KoreaAgilent Technologies Korea Ltd.Shinsa 2nd Bldg. 1F, 966-5 Daechi-dong Kangnam-gu, Seoul, Korea 135-280Tel: +82 (0)2 2194 9449Fax: +82 (0)2 3452 3947Toll free: 080 222 2452*******************************MexicoAgilent TechnologiesConcepcion Beistegui No 109Col Del Valle, C.P . 03100, Mexico, D.F.Tel: +52 5 523 9465Fax: +52 5 523 9472SingaporeAgilent Technologies Singapore Pte Ltd.No.1 Yishun Avenue 7, Singapore 768923Tel: +65 6215 8045Fax: +65 6754 0574Tollfree:180****2622*******************************Southeast AsiaAgilent Technologies Sales Sdn Bhd Unit 201, Level 2 uptown 2,2 Jalan SS21/37, Damansara Uptown 47400 Petaling Jaya, Selangor, Malaysia Tel: +603 7712 6106Fax: +60 3 6733 8121Toll free: 1 800 880 805*******************************TaiwanAgilent Technologies Taiwan Limited 20 Kao-Shuang Road Ping-Chen City Tao-Yuan Hsien,32450 Taiwan, R.O.C.Tel: +886 3 4959004Fax: +886 3 4924628Toll free: 0800 018 768*******************************UK and IrelandAgilent Technologies LDA UK Limited LakesideCheadle Royal Business Park Stockport, Cheshire SK8 3GR, UK Tel: +44 (0) 1865 291570Fax: +44 (0) 1865 291571Toll free: 00 800 234 234 00*******************************This information is subject to change without notice.© Agilent Technologies, Inc. 2018Published April 2018VPD-0418EN。

漩涡气泵相关知识的说明与介绍漩涡气泵详细介绍--旋涡气泵具有结构简单、体积小、运行可靠、流量稳定、保养较少、低噪声、寿命长、气源纯净和耗能少等特点。

目前,在国外己得到广泛的应用,特别是在一定流量、压力范围内可取代空气压缩机、水环泵、滑片泵,并可大大减少设备的投资,尤其是随着石油化工、轻工、食品、纺织和环保等行业的迅速发展,国内外对旋涡气泵的研究与开发将不断深入,其产品规格、数量与日俱增,应用前景十分看好。

漩涡气泵的特点:1.采用的是无油运转,能使鼓风机输出的空气更加的干净纯净。

2.压力高、风量大、噪音低、机器重量轻。

环形高压鼓风机转子与转子、转子与机体之间的间隙小。

大大加强了风的压力。

3.采用特殊叶片设计,其叶片制造度高、耐磨损、风力大、使用寿命长。

4.质量可靠、能在海拔5000以上的环境下正常工作,耐高温,耐严寒。

5.免维护使用,在质保期之内,基本上不需要任何维护。

漩涡气泵的用途:食品机械设备,污水处理设备,鱼塘增氧设备,吸尘除尘设备,上料供料设备,塑料机械设备,包装机械设备,木工机械设备,清洗机械设备,印刷机械设备,锅炉燃烧设备,冷却机械设备,养殖企业设备,废气排放设备,激光切割设备,温泉泳池设备,环境机械设备,真空脱水设备,吹膜机械设备,灌装机械设备,纺织机械设备,切纸机械设备,吸料吹料设备,烘干吹干设备,雕刻机械设备,卫生巾机械设备,尿不湿机械设备,风刀干燥机设备,PCB线路板设备,饮料生产线设备,风刀除水设备,豆类制品设备,热风干燥设备,环保行业等等。

漩涡气泵维护工作制度1.风机必须专人使用,专人维修。

2.风机不许带病运行。

3.定期清除风机内部的灰尘,特别是叶轮上的灰尘、污垢等杂质,以防止锈蚀和失衡。

4.风机维修必须强调首先断电停车。

5.对温度计及油标的灵敏性定期检查。

6.除每次拆修后应更换润滑油外,正常情况下3-6月更换一次润滑油。

普旭BUSCH真空泵Busch是世界上最大的真空泵、鼓风机和压缩机的供应商之一。

拥有超过40年的专业经验以及众多优秀员工,并一直以"前瞻性"的眼光努力地改善我们的产品和自身。

我们始终坚持不懈地进行创新性的工作以开创未来的真空世界。

拥有最现代化的生产工艺、机械、设备,所有的质量控制都远远超出了DIN EN ISO 9001 的要求。

到2007年为止,Busch 真空泵及真空系统在全球范围内拥有1800名雇员,成为全球工业用真空泵的最大供应商。

广泛的真空泵系列、专业的真空知识、在真空系统建造方面的丰富经验以及广泛的服务网络,使得Busch完全有能力为客户提供理想并完善的真空解决方案。

我们的目标是为客户提供最高的投资回报。

个性化的专业咨询,最优产品的选择,迅捷的现场服务,是我们实现这个目标的关键因素。

我们在各种专业应用领域的丰富经验、知识和产品设计也为实现这个目标提供了基础。

Busch总部位于德国马尔堡。

除了Busch控股公司以外,还有德国的制造厂,Busch产品公司,销售组织,Dr.-Ing. K. Busch 有限公司和服务公司。

除此之外,Busch还有位于瑞士、英国、丹麦、美国的5家制造厂。

Ateliers Busch S.A., Chevenez, 瑞士Composites BuschS.A., Porrentruy, 瑞士Busch GVT, Congleton, 英国Busch Manufacturing, Virginia Beach, 美国油润滑旋片真空泵广泛应用于真空包装及其他众多工业领域的真空泵,提供强劲动力、久经考验、运行可靠。

∙强劲动力∙可靠,并可连续运作∙风冷,无需水冷良好的耐水汽性维护简便针对特殊需求的专用产品:湿气较高的工作环境处理氧气获得ATEX 认证3 - 1600 m³/h (50 Hz)3,6 - 1920 m³/h (60 Hz)0,1 - 2 hPa (mbar)Huckepack双级设计、一次油润滑旋片真空泵适用于化工和其他行业的众多工艺流程。