莱富康SW&SRC-W系列螺杆制冷压缩机应用手册(1)

- 格式:doc

- 大小:3.10 MB

- 文档页数:6

佳特意大利莱富康半封闭制冷压缩机意大利莱富康半封闭制冷压缩机武汉佳特制冷设备有限公司是一家专业从事各类制冷设备、制冷配件、电器设备研发、生产、销售、服务为一体的科技型企业。

我司专业销售各型号、各系列的莱富康制冷压缩机,以及压缩的维修、保养及配件销售。

莱富康压缩机适用于空调及中低温工况应用产品简介:莱富康压缩机作为专业生产制冷剂压缩机的企业,坚持以最大限度满足空调和制冷市场的需求为宗旨,不断给市场带来最先进的技术解决方案。

莱富康现拥有意大利和中国两个生产基地,产品现销往全球60多个国家,服务于日趋全球化的市场。

适用冷媒种类:R22, R407C, R404A,R507,R134a;1、莱富康压缩机应用范围广泛:高温、中温及低温应用;同一类型压缩机可使用R22、R404a、R507a、R134a、R407a制冷剂;2、莱富康压缩机选件:曲轴箱加热器、油压开关、能量调节及卸载启动装置、附加缸顶风扇、水冷缸盖、R22低温用CIC喷液装置及船用特殊油槽。

3、莱富康压缩机供货范围(3HP到300HP)。

主要特性:SRC-S 系列压缩机采用滑阀调节,可选择“四级”或“无级”来调节制冷量;SRC-XS 系列压缩机采用旁通调节来调节制冷量,为“三级”冷量调节压缩机冷冻油高效、可替换的油过滤器, SRC-S-785、885、985三款大压缩机无须放油即可更换。

内置可靠的油加热器,多种有效的润滑监控附件可供选择,内置马达保护装置:自带ECO(经济器)接口,可直接连接经济器进一步提高能效比;可连接液喷、外置油冷却器,使压缩机在高排温时应用范围更大SRC-S-785、885、985压缩机可选择不同内容积比(Vi),并可增加内置Vi调节装置,使压缩机具备运行时Vi切换的功能;采用R134a冷媒时,可选用小型电机,多种电机规格可供选择,以应对不同的特殊电压需求。

Jiate Italy Refcomp semi-closed refrigeration compressorItaly Refcomp refrigeration compressorWhan Jiate Refrigeration Equipment Co., Ltd is a scientific and technological enterprise which specializes in producing refrigeration equipment 、refrigeration parts、the electrical equipment which is a coalition of the research and development and manufacturing and marketing and services.Our company sale all models and series of Italian Refcomp refrigeration compressors, and provide compressor maintenance and parts sales service.The introduction of Refcomp compressor (when applied into air-condition and low temperature work condition) Refcomp is a company which specialized in producing refrigeration compressor to maximally meet the market need and persistently bringing the most advanced technology solutions for the air-conditioning and refrigeration industry.Refcomp now has two production bases in Italy and China, the product now export into 60 countries in theworld. The refrigerant type: R22, R407C, R404A,R507,R134a;1. The wide application rage of Refcomp compressor: high, medium, and low temperature application; the same type compressor can use R22、R404a、R507a、R134a、R407 refrigeration2. Refcomp compressor selective parts :Crankcase heater, oil pressure switch, energy regulation and unloading and start device, the additional tank top fan, water-cooled cylinder heads, R22 cryogenic liquid CIC spray device and marine special tank.3. Refcomp compressor supply scope is 3HP to 300HP.Main feature:SRC-S compressor adopt the sliding valve adjustment ("four" or "step less") to control the cooling capacity;SRC-XS compressor adopts bypass adjustment to control the cooling capacity;SRC-S-785、885、985 don’t need to exclude oil when changed.There are built in reliable oil heater, motor protection devices and several kinds of optional efficient Lubrication monitoring parts;ECO (economy) connector for direct connection to further improve the energy efficiency of economic control;。

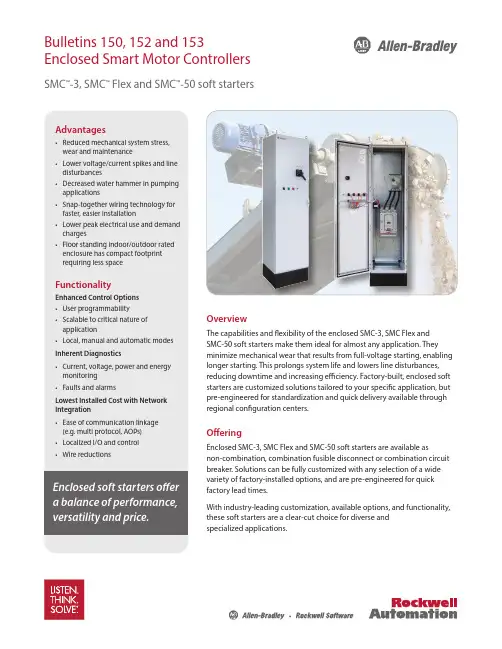

Bulletins 150, 152 and 153Enclosed Smart Motor ControllersSMC ™-3, SMC ™ Flex and SMC ™-50 soft startersOverviewThe capabilities and flexibility of the enclosed SMC-3, SMC Flex and SMC-50 soft starters make them ideal for almost any application. They minimize mechanical wear that results from full-voltage starting, enabling longer starting. This prolongs system life and lowers line disturbances, reducing downtime and increasing efficiency. Factory-built, enclosed soft starters are customized solutions tailored to your specific application, but pre-engineered for standardization and quick delivery available through regional configuration centers.OfferingEnclosed SMC-3, SMC Flex and SMC-50 soft starters are available asnon-combination, combination fusible disconnect or combination circuit breaker. Solutions can be fully customized with any selection of a wide variety of factory-installed options, and are pre-engineered for quick factory lead times.With industry-leading customization, available options, and functionality, these soft starters are a clear-cut choice for diverse and specialized applications.Advantages• Reduced mechanical system stress, wear and maintenance • Lower voltage/current spikes and line disturbances • Decreased water hammer in pumping applications • Snap-together wiring technology for faster, easier installation • Lower peak electrical use and demand charges • Floor standing indoor/outdoor rated enclosure has compact footprint requiring less spaceFunctionalityEnhanced Control Options • User programmability • Scalable to critical nature of application • Local, manual and automatic modes Inherent Diagnostics• Current, voltage, power and energy monitoring • Faults and alarmsLowest Installed Cost with Network Integration• Ease of communication linkage (e.g. multi protocol, AOPs)• Localized I/O and control • Wire reductionsEnclosed soft starters offer a balance of performance, versatility and price.Enclosed SMC-3 soft starterCompact, cost-effective solution for on-machine or pumping applications • Available 3…480 A• Snap-together wiring technology 1Bulletins 150C, 152C, 153CAPPLICATIONS: Conveyors • Fans • Pumps • Chillers • Mixers • LiftsEnclosed Soft Starting SolutionsEnclosed soft starting solutions encompass all the starting, stopping, protection and diagnostics benefits of Allen-Bradley® soft starters, in a customizable, pre-engineered solution. Factory-built enclosed soft starters are shipped ready to install, with quick lead times.Enclosed SMC Flex soft starterModular design with advanced performance and communications flexibility • Available 5…1250 A• Snap-together wiring technology 1• Optional full-numeric keypad, door-mounted HIM Bulletins 150F, 152F, 153FAPPLICATIONS: Compressors • Pumps • Fans • Conveyors • Bandsaws • Chillers • CentrifugesEnclosed SMC-50 soft starterScalable solution, satisfying a wide variety of control needs • Available 90…520 A• Snap-together wiring technology 1• Normal and heavy-duty ratings• Optional start- or run-duty external bypass or integrated bypass • Optional door-mounted HIM with easy-selection arrows andsoft keys for navigation• Optional digital and analog I/O expansion modules and protectionBulletins 150S, 152S, 153SAPPLICATIONS: Pumps • Compressors • Fans • Conveyors • Bandsaws • Mills •Crushers • Grinders • Shredders • Centrifuges1Snap-together wiring available from 90... 520 ASoft Starter Feature ComparisonControl CommandPluggable terminal blockAuxiliary IndicationIndicationSnap-together wiring available from 90...520 APublication 150-PP007C-EN-P – September 2018Copyright © 2018 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.Supersedes 150-PP007B-EN-P - February 2017Allen-Bradley, LISTEN. THINK. SOLVE., Rockwell Software, and SMC are trademarks of Rockwell Automation, Inc. All other trademarks are the property of their respective owners.Find out more aboutModified Industrial Controls:/go/lit/icp-modifiedModified Industrial ControlsThe Modified Industrial Controls business atRockwell Automation can take your panel design needs from conception to completion. We provide a unique engineer-to-engineer relationship that helps to ensure that every aspect of your panel is designed, developed and delivered according to your specifications, schedule and budget.Customizable panels include:• Programmable controllers • Starters• Distributed I/O • Servo drives• Push buttons and pilot lights• Partner products and other third-party devices。

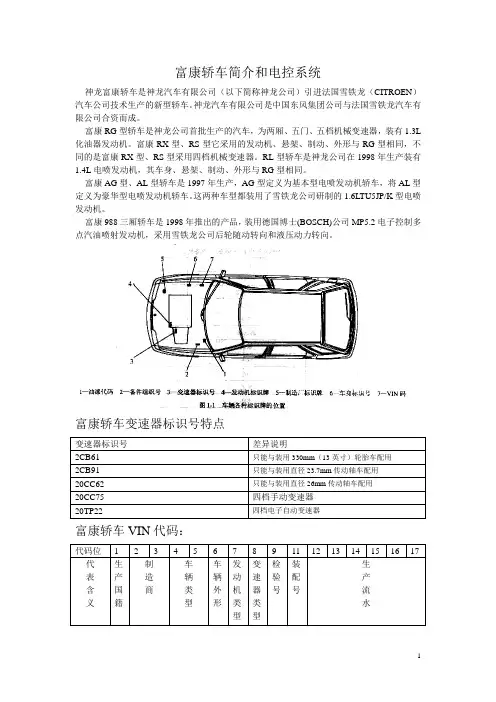

富康轿车简介和电控系统神龙富康轿车是神龙汽车有限公司(以下简称神龙公司)引进法国雪铁龙(CITROEN)汽车公司技术生产的新型轿车。

神龙汽车有限公司是中国东风集团公司与法国雪铁龙汽车有限公司合资而成。

富康RG型轿车是神龙公司首批生产的汽车,为两厢、五门、五档机械变速器,装有1.3L 化油器发动机。

富康RX型、RS型它采用的发动机、悬架、制动、外形与RG型相同,不同的是富康RX型、RS型采用四档机械变速器。

RL型轿车是神龙公司在1998年生产装有1.4L电喷发动机,其车身、悬架、制动、外形与RG型相同。

富康AG型、AL型轿车是1997年生产,AG型定义为基本型电喷发动机轿车,将AL型定义为豪华型电喷发动机轿车。

这两种车型都装用了雪铁龙公司研制的1.6LTU5JP/K型电喷发动机。

富康988三厢轿车是1998年推出的产品,装用德国博士(BOSCH)公司MP5.2电子控制多点汽油喷射发动机,采用雪铁龙公司后轮随动转向和液压动力转向。

富康轿车变速器标识号特点变速器标识号差异说明2CB61 只能与装用330mm(13英寸)轮胎车配用2CB91 只能与装用直径23.7mm传动轴车配用20CC62 只能与装用直径26mm传动轴车配用20CC75 四档手动变速器20TP22 四档电子自动变速器富康轿车VIN代码:代码位 1 2 3 4 5 6 7 8 9 11 12 13 14 15 16 17代表含义生产国籍制造商车辆类型车辆外形发动机类型变速器类型检验号装配号生产流水第4、5位车辆类型两位数字代码的含义车辆外形数字代表的含义发动机字母代码代表含义变速器数字代码表的含义车辆年分字母或数字代码表的含义发动机技术参数项目型号TU3F2/K TU5JP/K 发动机化油器电子控制燃油喷射缸径×行程mm 75×77 78.5×82总排量(L) 1.36 1.587 压缩比8.8 9.6 额定功率(KW)49(5400r/min)65(5600r/min)连杆中心距mm 126.8 133.5夏季适用机油10W40 10W40冬季适用机油15W40 15W40冷机气门间隙(mm)(进/排) 0.20/0.40市区循环油耗(L/100Km)10.5 10.3发动机电子控制系统富康所有装备的1.6L和1.4L电喷发动机都采用德国BOSCH公司开发的MP5.2电子控制多点燃油喷射系统。

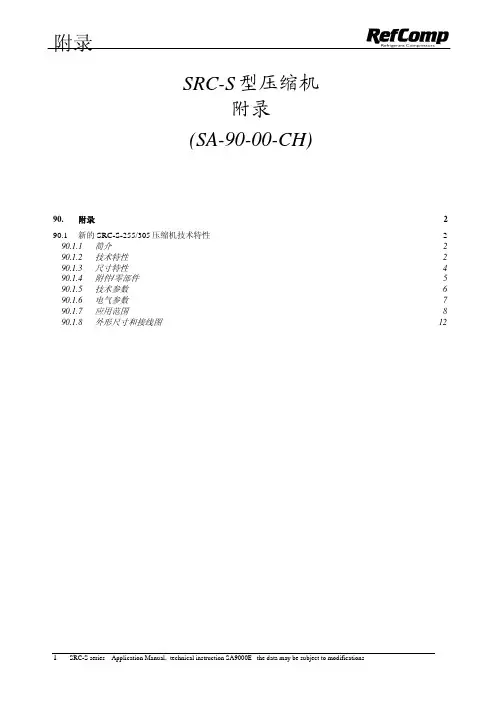

附录(SA-90-00-CH)90.附录 2 90.1新的SRC-S-255/305压缩机技术特性2 90.1.1简介 2 90.1.2技术特性 2 90.1.3尺寸特性 4 90.1.4附件/零部件 5 90.1.5技术参数 6 90.1.6电气参数 7 90.1.7应用范围 890.1.8外形尺寸和接线图 1290. 附录90.1新型 SRC-S-255/305压缩机的技术特性90.1.1 介绍SRC-S 系列中推出了新的型号: 255 和305 取代 了253 和 303。

其技术参数和外形尺寸均有改变。

另外,由于其主要部件和零件组件及代码都有所不同,对此请予以注意。

90.1.2 技术特性与SRC-S-253/303相比,新的SRC-S-255/305 采用本公司最新的SRC-134-S 型压缩机的设计布局,下面对其特性进行详细介绍。

自上而下的压缩过程:能量调节滑阀布置在螺杆的下部。

图 1: 自上而下的压缩过程部分负荷时的控制还是采用三个电磁阀,与原来不同的是只须将电磁阀下面的垫片更换后即可完成制冷量从有级调节到无级调节的转换(见图2)。

因此,就不需要拆装并在14和15号电磁阀下加装扼流螺丝,更无需更换外部的毛细管。

不过,在进行此类转换时,还是需要专用组件(见90.1.4章节)。

Label11416图 2: 全新的制冷量控制装置全新的润滑油进/出接口,在压缩机的机体上直接配有这两个接口,在采用外置油冷却时不需要特殊的组件,见图3,只要将进出口之间的螺栓A 用螺栓B 来替换即可。

螺栓B 在接线盒里可以找到,另外,油进出口的管径没有改变,还是16mm 。

B : T.E.I.F. M14x35螺栓采用外部油冷却器时用,与压缩机一起提供但未安装。

进油口16mm回油口16mmA : T.C.E.I.. M14x16螺栓不用外部油冷却器时安装,供货时已经安装。

图 3:当采用外部油冷却装置时用螺栓B 替换螺栓A机器配有两个油位视镜用于观察油位。

冷冻油的功用、分类以及设备要求冷冻油的功用有哪些在压缩机中,冷冻油主要起润滑、密封、降温以及能量调节四个作用。

(1)润滑冷冻油在压缩机运转中起润滑作用,以减少压缩机运行摩擦和磨损程度,从而延长压缩机的使用寿命。

(2)密封冷冻油在压缩机中起密封作用,使压缩机内活塞与汽缸面之间、各转动的轴承之间达到密封的作用,以防止制冷剂泄漏。

(3)降温冷冻油在压缩机各运动部件间润滑时,可带走工作过程中所产生的热量,使各运动部件保持较低的温度,从而提高压缩机的效率和使用的可靠性。

(4)能量调节对于带有能量调节机构的制冷压缩机,可利用冷冻油的油压作为能量调节机械的动力。

什么是POE和PAG冷冻油为保护臭氧层,国际上对空调设备的制冷剂都做了限制,出现了各种替代制冷剂,其冷冻油也相应发生了变化。

对空调替代制冷剂为R134a、R410a/R407c,其替代分别采用PAG、POE。

POE是Polyol Ester的缩写,又称聚酯油,它是一类合成的多元醇酯类油。

PAG是Polyalkylene Glycol的缩写,是一种合成的聚(乙)二醇类润滑油。

其中,POE油不仅能良好地用于HFC类制冷剂系统中,也能用于烃类制冷。

PAG油则可用HFC类、烃类和氨作为制冷剂的制冷系统中的润滑油。

制冷设备对冷冻油有什么要求由于使用场合和制冷剂的不同,制冷设备对冷冻油的选择也不一样。

对冷冻油的要求有以下几方面:(1)黏度冷冻油黏度油料特性中的一个重要参数,使用不同制冷剂要相应选择不同的冷冻油。

若冷冻油黏度过大,会使机械摩擦功率、摩擦热量和启动力矩增大。

反之,若黏度过小,则会使运动件之间不能形成所需的油膜,从而无法达到应有的润滑和冷却效果。

(2)浊点冷冻油的浊点是指温度降低到某一数值时,冷冻油中开始析出石蜡,使润滑油变得混浊时的温度。

制冷设备所用冷冻油的浊点应低于制冷剂的蒸发温度,否则会引起节流阀堵塞或影响传热性能。

(3)凝固点冷冻油在实验条件下冷却到停止流动的温度称为凝固点。

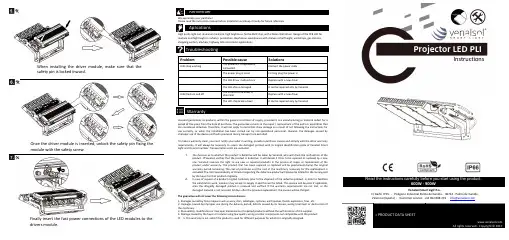

We appreciate your purchase!Please read the instruction manual before installation and keep it handy for future reference.AplicationsHigh purity light cast aluminum heatsink, high brightness, Nichia SMD chip, with a Mean Well driver. Design of the PCB LED for medium and high height in industry: production, diaphanous warehouses with shelves at half height, workshops, gas stations, shopping centers, markets, highway tolls and similar applications.TroubleshootingProblemPossible causeSolutionsLEDs stop working The powerline is improperly connectedConnect the power cable The power plug is loose Firming plug the power in The LED driver malfunctions Replace with a new driverThe LED chip is damaged It can be repaired only by Venalsol. LEDs flash on and off The output of the driver is abnormalReplace with a new driverThe LED chip breaks downIt can be repaired only by Venalsol.WarrantyVenalsol guarantees its products, within the general conditions of supply, provided it is a manufacturing or material defect for a period of five years from the date of purchase. The guarantee consists in the repair / replacement of the parts or assemblies that are considered defective. Therefore, it will not apply to items that show damage as a result of not following the instructions for use correctly, or when the installation has been carried out by non-specialized personnel. Likewise, the damages caused by improper use of the device and faults produced during transport are excluded.To make a warranty claim, you must notify your seller in writing, provide a purchase invoice and comply with the other warranty requirements. It will always be necessary to return the damaged product with its original identification plate of Venalsol Smart Light and its serial number. Transportation costs are excluded.1. The decision as to whether the product is defective will be taken by Venalsol, who will check the malfunction of theproduct. If Venalsol verifies that the product is defective, it will decide if it has to be repaired or replaced by a new one. Venalsol reserves the right to use new or repaired products in the process of repair or replacement of the product under warranty. The product that has been repaired or replaced will be guaranteed during the original warranty period remaining. The cost of personnel and the cost of the machinery necessary for the replacement is excluded. The total responsibility of Venalsol regarding the defective product will always be limited to the money paid by the buyer for that product originally.2. In case of request of a product in good condition, prior to the shipment of the defective product, in order to facilitatethe substitution work, Venalsol may accept to supply it and this will be billed. This invoice will be paid, if applicable, once the allegedly damaged product is received and verified. If the warranty requirements are not met, or the damaged material is not received, 60 days after the previous replacement, the invoice will be charged.The guarantee will not cover the following circumstances:1. Damages caused by force majeure such as wars, riots, sabotages, cyclones, earthquakes, floods, explosions, fires, etc.2. Damages caused by improper use during the delivery period, defects caused by its misuse, wrong treatment or destruction of the machinery.3. Disassembly, modification or improper maintenance of repaired products without the authorization of the supplier.4. Damage caused by the buyer or installer using low quality wiring or other components not compatible with the product. 3.5. This warranty is not valid if the product is used for different purposes for which it is originally designed.Read the instructions carefully before you start using the product.600W - 900WVenalsol Smart Light S.L.C/ Garbí nº15. - Polígono Industrial Palma de Gandía - 46724 - Palma de Gandía Valencia (España) - Customer service: +34 962 808 219 *****************< PRODUCT DATA SHEETAll rights reserved - Copyright © 2017InstructionsWhen installing the driver module, make sure that the safety pin is locked inward.Once the driver module is inserted, unlock the safety pin fixing the module with the safety screw.Finally insert the fast power connections of the LED modules to the drivers module.1. Disconnect the power supply before installation or maintenance of the light.2. It is strictly mandatory to connect the earth cable (Yellow / Green) with the ground connection of the installation.3. Do not touch the power source when the lamp is in operation.4. To avoid damage, electric shock or fire, do not disassemble or replace the lamp (PCB CHIP LED).5. To avoid damage, falls, electric shocks or fires, please do not modify or replace the original accessories with others that are not, without consulting and being authorized by Venalsol beforehand.6. Only qualified personnel can perform the replacement or installation of the luminaire and make sure that it follows the instructions in the manual. If the installation is not carried out properly, it can cause falls, electric shocks, fires or other damages.7. Disconnect the power supply if smoke or odor comes out, as this could result in a fire or electric shock.8. Consult qualified personnel for inspection and maintenance of the lamp9. If the wiring of the luminaire itself is damaged, it can only be replaced by Venalsol..It has passed the tests and verifications necessary to obtain the CE Marking. This product complies with the application standards on Low Voltage (LVD) 2014/35 / EU: EN60598-1: 2015, EN60598-2-24: 2013, EN60598-2-1: 1989, EN62031: 2008, EN62471: 2008, EN62493: 2010 and Electromagnetic Compatibility (EMC) 2014/30 / EU: EN61000-3-2: 2014, EN61000-3-3: 2013, EN61547: 2009, EN55015: 2013This symbol indicates that the product at the end of its useful life should be removed separately from other waste, since it is identified as an appliance for electrical use or domestic appliance according to Royal Decree 208/2005. Therefore, at the end of the use, you must take charge of delivering the product to a selective collection center or to an authorized waste manager. Venalsol is registered in the National Registry of Electrical and Electronic Devices with registration number 3493 and is attached to a Waste Management System for Electrical and Electronic Devices for products with the category of "lighting devices".LED Venalsol luminaires are respectful with the environment. They do not contain mercury and the electronic components used comply with the provisions of the RoHS regulations transposing Royal Decree 208/2005Product specifications 600W900WInput voltage AC100-277V 50/60Hz Clase I (Needs grounding)CRI Ra70 Beam angle 15°, 30°, 60°Classification IP IP66Dimensions598 x 564 x 401mm598 x 792 x 401mmLuminaire net weight 26 ± 0.3kg37 ± 0.3kgPower factor >0.93Useful life≥50000Hrs (LM70&50°C) / ≥100000Hrs (LM80&25°C)Operating temperature -30 ~ +50°C Operating humidity 15% ~ 90%RH Storage temperature-40 ~ +70°CA. Dimensions and installation of the luminaire (mm).600W900WBrownBlueYellow / GreenCeiling mountingWall mountingAll LED modulesIndividual LED moduleMake sure you have inserted the LED module correctly the support fixing ears.Attach the stand base to the mast.Install the support arms on the base of the support. Put the screws ofsecurity. Adjusting the angle of the modules LED。

"冷冻油" 英文对照refrigeration oil;"冷冻油" 在学术文献中的解释1、小型全封闭压缩机中用的润滑油习惯称为冷冻油.近几年我国小型全封闭压缩机生产规模有了较大发展完全依靠进口冷冻油的局面必然要改变.炼油系统为冷冻油国产化作了大量的科研工作并且已有产品大量供应Uniqema(冰熊)冷冻油有利凯玛(Uniqema)是世界领先的合成冷冻润滑油供应商(2007年9月被Lubrizol——CPI的母公司所收购),Uniqema合成冷冻机油Emkarate RL系列产品,是适用于R134a、R404a、R407c、R410a、R502、R507a、R508a、R508B等HFC型不破坏臭氧层的环保制冷剂的合成醇脂类冷冻油(POE),可供选择的粘度指数范围由ISOVG5至VG220。

有利凯玛不断开发新的产品和提高产品质量,使之成为拥有最广泛压缩机厂商认证的冷冻机油品牌,全球已有超过五亿台压缩机成功充装“EMKARATE”牌冷冻机油。

被世界制冷行业公认为制冷压缩机润滑油之最佳选择,已获得世界各主要制冷压缩机生产厂家认证。

ICI冷冻油:英国ICI 有利凯玛Uniqema Emkarate RL 系列合成冷冻机润滑油有利凯玛Uniqema 是ICI 集团重要有成员之一,成立于1999 年,由ICI 表面活性剂、ICI 润滑剂、Solaveil 、Uniqema 国际和Mona 工业5 个公司并购组建的一家工业专用化学品集团公司,1999 年销售额超过10 亿美元。

公司主要业务范围包括表面活性剂,油脂化学品,应用于压缩机、汽车、工业领域合成润滑油,以及其它特种化学品。

公司总部设在荷兰高达,亚太地区的总部设在马来西亚吉隆坡。

有利凯玛在全球设立有十六家生产基地,业务范围涉及全国九十多个国家,现有员工三千多名,产值每年超过十亿美元。

有利凯玛是世界领先的合成冷冻润滑油供应商,ICI Uniqema 合成冷冻机油Emkarate RL 系列产品,是适用于R134a 、R404A 、R407C 、R410A 、R507 、R23 、R508A 、R508B 等HFC 型不破坏臭氧层的环保制冷剂的合成醇脂类冷冻油(POE ),可供选择的粘度指数范围由ISO VG5 至VG 220 。

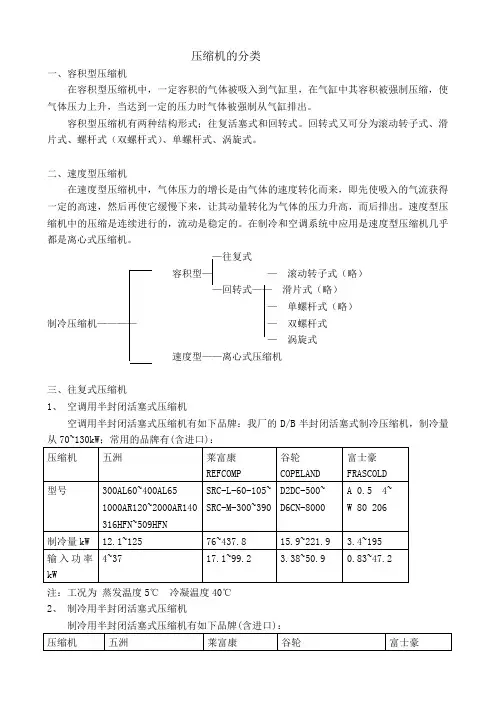

压缩机的分类一、容积型压缩机在容积型压缩机中,一定容积的气体被吸入到气缸里,在气缸中其容积被强制压缩,使气体压力上升,当达到一定的压力时气体被强制从气缸排出。

容积型压缩机有两种结构形式;往复活塞式和回转式。

回转式又可分为滚动转子式、滑片式、螺杆式(双螺杆式)、单螺杆式、涡旋式。

二、速度型压缩机在速度型压缩机中,气体压力的增长是由气体的速度转化而来,即先使吸入的气流获得一定的高速,然后再使它缓慢下来,让其动量转化为气体的压力升高,而后排出。

速度型压缩机中的压缩是连续进行的,流动是稳定的。

在制冷和空调系统中应用是速度型压缩机几乎都是离心式压缩机。

—往复式容积型——滚动转子式(略)—回转式——滑片式(略)—单螺杆式(略)制冷压缩机—————双螺杆式—涡旋式速度型——离心式压缩机三、往复式压缩机1、空调用半封闭活塞式压缩机空调用半封闭活塞式压缩机有如下品牌:我厂的D/B半封闭活塞式制冷压缩机,制冷量注:工况为蒸发温度5℃冷凝温度40℃2、制冷用半封闭活塞式压缩机注:工况为蒸发温度-15℃冷凝温度40℃3、低温用半封闭活塞式压缩机沈阳谷轮3S、4S、6S系列半封闭活塞式压缩机,最低蒸发温度-45℃,其中最大制冷量的6STW-3200在蒸发温度-40℃,冷凝温度40℃时,制冷量11.3kW。

特点:1)可同时适应R22和R404A2)宽广的应用范围:蒸发温度-45℃~ -5℃3)采用DTC喷液技术(排气温度控制阀)4)电子式电机保护器四、涡旋式压缩机1、主要介绍谷轮ZR系列柔性2、特点:1)效率高:能效比比目前市场上最先进的活塞式压缩机还高12%;2)可靠性好:运动部件少,轴向和径向的谷轮专利柔性设计提高了耐液击和容忍杂质的能力;3)内置电机保护:能有效保护电机免受高温和高电流的损坏;4)躁音低:噪音比活塞式压缩机低5分贝以上;5)制热效果好:近100%的容积效率带来良好的制热能力。

3、注意事项:1)新的压缩机吸气口、排气口有橡胶塞子,用时应先拔掉排气口的橡胶塞子,再拔掉吸气口的橡胶塞子。

Solest 220 & Castrol Icematic SW 220 混合没有问题Solest 220 可以用来做以下3个产品的对等替代:Castrol Icematic SW 200 , Icematic SW 220XL 和 Icematic 220HT同一个公司底下的两个品牌系列Solest 170 & Solest 220 也大量使用于 R134a 的螺杆冷冻机以下为多元醇酯 ( POE ) 冷冻油的对照 :POE 10 : CP-2910 , CP-2910A , CP-2910E , CP-2910ASPOE 15 : CP-2915 . CP-2915A , CP-2915AS , CP-2915EPOE 22 : CP-2922 , CP-2922A , CP-2922AS , CP-2922E多元醇酯 POE 合成冷冻油的对照POE 32 : Solest LT-32 , Solest 31-HE , Solest 33 , Solest 35POE 46 : Solest 46POE 68 : Solest 68POE 72 : Solest 72POE 85 : CP-4214-85POE 120 : Solest 120POE 150 : CP-4214-150POE 170 : Solest 170多元醇酯 POE 合成冷冻油的对照POE 170 : Solest 170POE 220 : Solest 220POE 320 : CP-4214-320POE 370 : Solest 370Solest 170 & Solest 220 也大量使用于 R134a 的螺杆冷冻机Toromont (特罗蒙德) 的设计也是 Solest 170RefComp : Solest 170Bitzer : POE 170 : Solest 170Century : Solest 170Roltec : Solest 170Solest 220 & Castrol Icematic SW 220 混合基本上没有问题开利 R134a 螺杆机的设计为 POE 220 , Solest 220 ,比泽尔的设计为 POE 170 , Solest 170Solest 170 & Solest 220 也大量使用于 R134a 的螺杆冷冻机POE 170 ( Solst 170 ) 的设计有:R134a 螺杆冷冻机比泽尔 Bitzer ,莱富康 RefComp世纪 Century罗特 RoltecSolest 170, POE 170 , Solest 170 , POE 170 , Solets 170 , POE 170 Solest 170 & Solest 220 也大量使用于 R134a 的螺杆冷冻机POE 220 的设计有:开利:POE 220 : Solest 220汉钟:POE 220 : Solest 220R134a , R404, R407C , R410螺杆热泵合成冷冻油:POE 220 , Solest 220 , POE 220 , Solest 220 , POE 220 , Solest 220 POE 170, Solest 170 , POE 170 , Solest 170 , POE 170, Solest 170 POE 120, Solest 120 , POE 120 , Solest 120 , POE 120 , Solest 120 Solest 170 & Solest 220 也大量使用于 R134a 的螺杆冷冻机POE 120 为复盛的设计:POE 120 , Solest 120 , POE 120 , Solest 120 , POE 120 , Solest 120 , POE 120 , Solest 120Solest 170 & Solest 220 也大量使用于 R134a 的螺杆冷冻机POE 68 为特灵 Trane 的设计:POE 68 , Solest 68 , POE 68 , Solest 68 , POE 68 , Solest 68 , POE 68 , Solest 68 , POE 68多元醇酯 POE 合成冷冻油的对照Solest 220 : Icematic SW 220Solest 220 : Icematic SW 220XLSolest 220 : Icematic SW 220HTSolest 220 : Icematic SW 220Solest 220 : Icematic SW 220XLSolest 220 : Icematic SW 220HTSolest 220 : Icematic SW 220Solest 220 : Icematic SW 220HT多元醇酯 POE 合成冷冻油的对照Solest 31-HE : Icematic SW 32Solest 31-HE : Icematic SW 32Solest 46 : Icematic SW 46Solest 68 : Icematic SW 68多元醇酯 POE 合成冷冻油的对照Solest 220 : Icematic SW 220Solest 220 : Icematic SW 220XLSolest 220 : Icematic SW 220HTSolest 220 : Icematic SW 220Solest 220 : Icematic SW 220HTSolest 220 : Icematic SW 220XL多元醇酯 POE 合成冷冻油的对照Solest 220 : Emkarate RL 220HSolest 220 : Emkarate RL 220HSolest 220 : Emkarate RL 220HSolest 220 : Emkarate RL 220HSolest 220 : Emkarate RL 220HSolest 220 : Emkarate RL 220HPOE 32 ( 多元醇酯 32 号冷冻油)的相关对照Solest 31-HE : Icematic SW 32 : Emkarate RL 32HSolest 31-HE : Icematic SW 32 : Emkarate RL 32HSolest 31-HE : Icematic SW 32 : Emkarate RL 32H美国CPI中国总代理中国王工:139******** (油王)网址:约克压缩机用油对照表.jpg(40.5 KB, 下载次数: 18)VILTER压缩机油表.jpg(33.51 KB, 下载次数: 4)比泽尔压缩机油对照表.jpg(25.02 KB, 下载次数: 7)丹佛斯压缩机油品对照表.jpg(28.01 KB, 下载次数: 4)汉钟压缩机油对照表.jpg(23.85 KB, 下载次数: 9)开利CARRIER压缩机冷冻油对照表.bmp.jpg(82.06 KB, 下载次数: 3)冷王压缩机油对照表.jpg(32.47 KB, 下载次数: 3)特灵油品对照表.jpg(54.44 KB, 下载次数: 4)约克frick油品对照表.jpg(76.24 KB, 下载次数: 3)BITZER半封闭压缩机冷冻油更换操作规范一、冷冻油更换的条件1、空调机组长时间工作,压缩机已达到保养时限(机组初次运行2000小时、之后运行累计三年或运行时间超过10000~12000小时);2、因电机烧毁而更换压缩机;更换压机后连续运行100小时的氟系统;3、对于现场组装的机组或在接近工况极限下运行的机组,在累计运行100小时后要更换冷冻油;4、根据氟系统清洁度情况酌情处理。

ZH• 104226 - 欧盟机型• 104222 - 日本机型重要物品!切勿毁坏要求所有操作人员和维修人员阅读并理解本手册是客户的责任。

请联系当地 Carlisle Fluid Technologies 代表另外获取本手册副本。

请在使用本 产品之前仔细阅读所有说明。

EV2-30维修手册ZH产品描述 / 声明对象:电动泵 E2、E4, EV2本产品专为以下用途设计:溶剂性和水性材料适用危险区域使用:危险区域 1防护等级:II 2 G X IIB T4 (Pump)II 2 G Exd/Exde IIB T4 IP55 (Motor) CE0722II 2 GD ck T4 (Gearbox)本符合标准/注册成立声明的签发由制造商全权负责:Carlisle Fluid Technologies UK Ltd, Ringwood Road,Bournemouth, BH11 9LH. UK为及代表Carlisle Fluid Technologies UK Ltd 签署:D Smith销售总监 (EMEA)Element Materials Technology (0891)提交技术文件29/6/18Bournemouth,BH11 9LH,UK本符合标准/注册成立声明的签发由制造商全权负责:机械指令 2006/42/EC ATEX 指令 2014/34/EU 电磁兼容指令 2014/30/EU因为我方严格遵守以下法定文件和协调标准:EN ISO 12100:2010 机械安全 — 设计通则EN 12621:+A1:2010 压力下覆层材料的供应和循环用机器 — 安全要求EN 1127-1:2011 爆炸性环境 — 爆炸预防 — 基本概念EN 13463-1: 2009潜在爆炸性环境中使用的非电气设备 — 基本方法和要求EN 13463-5:2011 潜在爆炸性环境用非电气设备 — 结构安全“C”型保护EN 13463-8:2003 潜在爆炸性环境用非电气设备。

产品原理:

莱斯康汽车自动离合器是通过先进的模控技术实现的。

系统传感器迅速将车辆的状态(如:发动机的转速、车速、刹车、挡位)等信息输送给ECU,当车辆驾驶者要起步或换挡时,ECU会根据车辆状态驱动离合执行机构合上或打开离合器,同时执行机构上的位移传感器又将离合器的状态信息反馈给ECU,形成一个闭环的反馈系统,以达到对执行机构动作的精确控制。

与此同时,ECU会根据车辆状态信息(车速、转速等)指导驾驶者做出正确的加减挡动作,从而实现对离合器的智能化控制,以达到离合系统与车辆其他系统的有机配合,大大降低了驾驶者的操控难度,真正实现了手动挡汽车的智能化操控。

系统主体:

汽车自动离合器主要由ECU、传感器、直流伺服电机、执行机构组成,ECU是整个系统的核心,负责检测各个传感器和开关量信号、完成控制算法运算,控制执行机构的动作,指导驾驶员做出正确的换挡动作。

主要技术参数:

工作电压:12-15V;工作电流:0.2-12A;工作温度:-30-85C;响应时间:0.01S。