最新负性光刻胶显影液(正庚烷)MSDS[整理]

- 格式:docx

- 大小:16.80 KB

- 文档页数:5

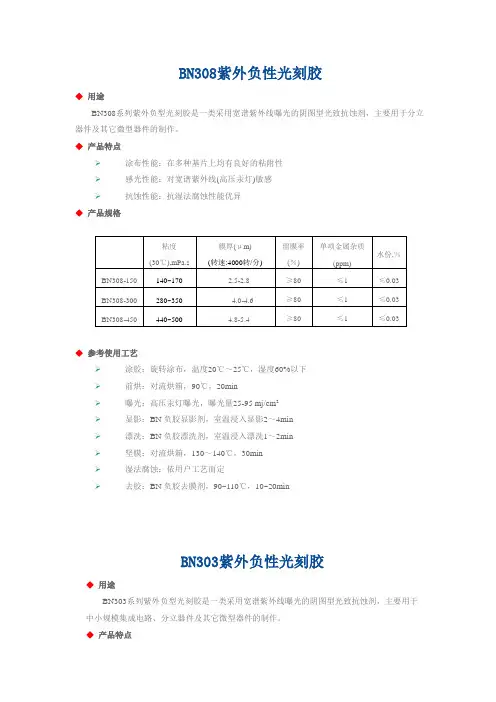

BN308紫外负性光刻胶◆用途BN308系列紫外负型光刻胶是一类采用宽谱紫外线曝光的阴图型光致抗蚀剂,主要用于分立器件及其它微型器件的制作。

◆产品特点涂布性能:在多种基片上均有良好的粘附性感光性能:对宽谱紫外线(高压汞灯)敏感抗蚀性能:抗湿法腐蚀性能优异◆产品规格粘度(30℃),mPa.s膜厚(μm)(转速:4000转/分)留膜率(%)单项金属杂质(ppm)水份,%BN308-150140~170 2.5-2.8≥80≤1≤0.03BN308-300280~350 4.0-4.6≥80≤1≤0.03BN308-450440~500 4.8-5.4≥80≤1≤0.03◆参考使用工艺涂胶:旋转涂布,温度20℃~25℃,湿度60%以下前烘:对流烘箱,90℃,20min曝光:高压汞灯曝光,曝光量25-95 mj/cm2显影:BN负胶显影剂,室温浸入显影2~4min漂洗:BN负胶漂洗剂,室温浸入漂洗1~2min坚膜:对流烘箱,130~140℃,30min湿法腐蚀:依用户工艺而定去胶:BN负胶去膜剂,90~110℃,10~20minBN303紫外负性光刻胶◆用途BN303系列紫外负型光刻胶是一类采用宽谱紫外线曝光的阴图型光致抗蚀剂,主要用于中小规模集成电路、分立器件及其它微型器件的制作。

◆产品特点涂布性能:在多种基片上均有良好的粘附性 感光性能:对宽谱紫外线(高压汞灯)敏感分辨率:实用分辨率可达5μm抗蚀性能:抗湿法腐蚀性能良好◆产品规格粘度(30℃),mPa.s膜厚(μm)(转速:4000转/分)留膜率(%)单项金属杂质(ppm)水份,%BN303-3029.0±1.50.85~0.95≥60≤1≤0.02 BN303-4542.0±2.00.95~1.15≥60≤1≤0.02 BN303-6060.0±2.0 1.05~1.15≥65≤1≤0.02 BN303-60H60.0±2.0 1.3-1.5≥65≤1≤0.02 BN303-100100.0±10.0 2.0~2.3≥75≤1≤0.02 BN-303-100TS100.0±10.0 1.9~2.1≥75≤1≤0.02◆参考使用工艺涂胶:旋转涂布,温度20℃~25℃,湿度60%以下前烘:对流烘箱,80℃,20min曝光:高压汞灯曝光,曝光量15-35 mj/cm2显影:BN负胶显影剂,室温浸入显影1~2min漂洗:BN负胶漂洗剂,室温浸入漂洗1min坚膜:对流烘箱,130~140℃,30min湿法腐蚀:依用户工艺而定去胶:BN负胶去膜剂,90~110℃,10~20min。

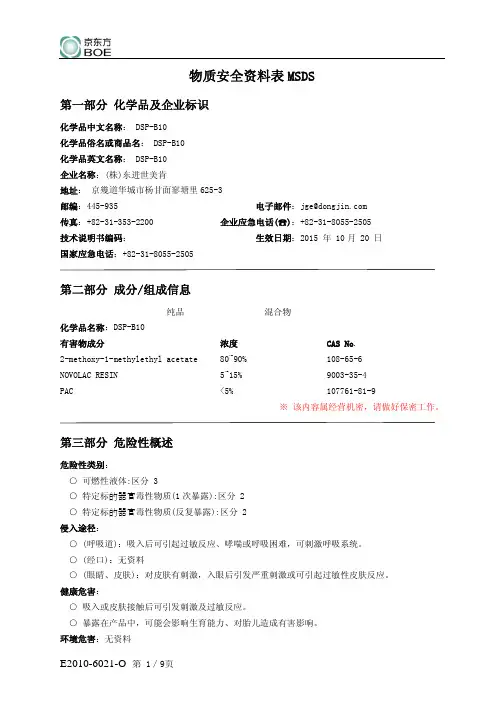

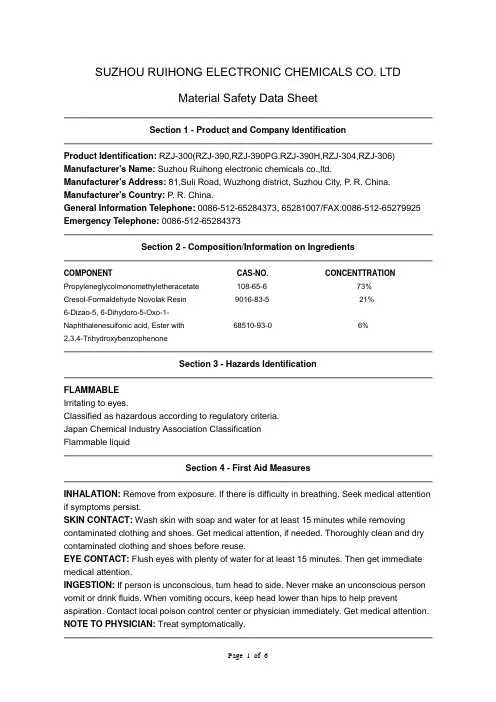

SUZHOU RUIHONG ELECTRONIC CHEMICALS CO. LTDMaterial Safety Data SheetSection 1 - Product and Company IdentificationProduct Identification: RZJ-300(RZJ-390,RZJ-390PG.RZJ-390H,RZJ-304,RZJ-306) Manufacturer's Name: Suzhou Ruihong electronic chemicals co.,ltd.Manufacturer's Address: 81,Suli Road, Wuzhong district, Suzhou City, P. R. China. Manufacturer's Country: P. R. China.General Information Telephone: 0086-512-65284373, 65281007/FAX:0086-512-65279925 Emergency Telephone: 0086-512-65284373Section 2 - Composition/Information on IngredientsCOMPONENT CAS-NO. CONCENTTRATION Propyleneglycolmonomethyletheracetate 108-65-6 73%Cresol-Formaldehyde Novolak Resin 9016-83-5 21%6-Dizao-5, 6-Dihydoro-5-Oxo-1-Naphthalenesulfonic acid, Ester with 68510-93-0 6%2,3,4-TrihydroxybenzophenoneSection 3 - Hazards IdentificationFLAMMABLEIrritating to eyes.Classified as hazardous according to regulatory criteria.Japan Chemical Industry Association ClassificationFlammable liquidSection 4 - First Aid MeasuresINHALATION: Remove from exposure. If there is difficulty in breathing. Seek medical attention if symptoms persist.SKIN CONTACT: Wash skin with soap and water for at least 15 minutes while removing contaminated clothing and shoes. Get medical attention, if needed. Thoroughly clean and dry contaminated clothing and shoes before reuse.EYE CONTACT: Flush eyes with plenty of water for at least 15 minutes. Then get immediate medical attention.INGESTION: If person is unconscious, turn head to side. Never make an unconscious person vomit or drink fluids. When vomiting occurs, keep head lower than hips to help prevent aspiration. Contact local poison control center or physician immediately. Get medical attention. NOTE TO PHYSICIAN: Treat symptomatically.Section 5 - Fire Fighting MeasuresSUITABLE EXTINGUISHING MEDLA: Use water spray, foam, dry chemical or carbon dioxide . Keep containers and surroundings cool with spray.SPECIFIC HAZARDS DURING FIRE FLGHTING: This product may give rise to hazardous vapors in a fire. Vapors can travel a considerable distance to a source of ignition and result in flashback.SPECIAL PROTECTIVE EQUIPMENT FOR FIRE-FIGHTERS: Wear full protective clothing and self-contained breathing apparatus.FURTHER INFORMATION: Pressure may build up in closed containers with possible liberation of combustible vapors.Section 6 - Accidental Release MeasuresPERSONAL PRECAUTIONS:Wear suitable protective clothing.Wear respiratory protection.Eliminate all ignition sources.ENVIRONMENTAL PRECAUTIONS:Prevent the material from entering drains or water courses.Do not discharge directly to a water source.Advise Authorities if spillage has entered watercourse or sewer or has contaminated soil or vegetation .METHODS FOR CLEARING UP:Cover with absorbent or contain. Collect and dispose.Section 7 - Handling and StorageHANDLINGUse local exhaust ventilation. Avoid contact with eyes, skin and clothing. Keep container tightly Closed. Further information on storage conditions; Proprietary photo resist film contains approximately 2-4% of 2.3.4-trihydroxybenzophenone (THBP).Which may sublime duringsoft-bake or hard-bake processing. THBP has low acute toxicity (LD50>5g/kg). Contact with eyes. Skin or mucous membranes cause irritation. To prevent accumulation of THBP on equipment surfaces and ventilation ducts, preventative maintenance program including regular cleaning should be implemented. Wipe surfaces using an appropriate cleaning solvent when possible. Provide adequate general or local exhaust ventilation during the cleaning process. In situations where this is not possible or where solvent or dust concentrations become excessive. Use an air purifying respirator with an organic vapor/toxic particulate cartridge. When cleaning residual THBP, wear protective gloves and adequate protective clothing to prevent skin contact. Practice good personal hygiene to prevent accidental exposure. Clean all protective clothing and equipment thoroughly after each use.STORAGEStorage conditions; Store in original container. Keep away from heat and sources of ignition,Storage area should be cool dry well ventilated out of direct sunlightSection 8 - Exposure Controls & Personal ProtectionEXPOSURE LIMITS:Exposure limits are listed below, if they exist.Component Regulation Type of listing Value2-methoxy-1-methylethyl Rohm and Haas TWA 30ppm AcetateRohm and Haas STEL 90ppmRohm and Haas Absorbed via SkinOEL (EU) TWA 275mg/m3 50ppmOEL (EU) STEL 550mg/m3100ppmOEL (EU) SkinEXPOSURE CONTROLSEYE PROTACTION: gogglesHAND PROTECTION: Butyl rubber gloves. Other chemical resistant gloves may be recommended by your safety professional.SKIN AND BODY PROTECTION: Normal work wear.RESPIRATORY PROTOCTION: Respiratory protection if there is a risk of exposure to high vapor concentrations. The specific respirator selected must be based on the airborne concentration found in the workplace and must not exceed the working limits respirator. ENGINEERING MEASURES: Engineering methods to prevent or control exposure are preferred. Methods include process or personnel enclosure, mechanical ventilation (local exhaust), and control of process conditions.Section 9 - Physical & Chemical PropertiesPHYSICAL STATE: liquidCOLOR: Red AmberODOUR: Ester-likeBOILING POINT: ca.146℃FLASH POINT: 40-46℃VAPOR PRESSURE: 3.7 mmHg at 20℃RETATIVE DENSITY: 0.80-1.00WATER SOLUBILITY: InsolublePH: neutralEVAPORATION RATE: Slower than etherVOC’S:727-950 g/lNOTE: The Physical date presented above are typical values and should not be construed as a specification.Section 10 - Stability & Reactivity DataMATERLALS TO AVOID: Oxidizing agents.CONDITIONS TO AVOID: High temperatures Static discharge.HAZARDOUS: Combustion will generate; carbon monoxide, phenols.HAZARDOUS REACTIONS: Stable under normal conditions.POLYMERIZATION: Will not occur.DECOMPOSITION PRODUCTS: Nitrogen oxides (NOX), aldehydes, acrid smoke and irritating fumes.Section 11 - Toxicological InformationToxicological information on this product or its components appears in this section when such data is available.COMPONENT: 2-methoxy-1-methylethyl acetateAcute oral toxicity LD50 rat 8,532mg/kgCOMPONENT: 2-methoxy-1-methylethyl acetateAcute inhalation toxicity LC50 rat 6h 23.49mg/lCOMPONENT: 2-methoxy-1-methylethyl acetateAcute dermal toxicity LD50 rabbit >5,000 mg/kgCOMPONEN T: CresolAcute dermal toxicity LD50 rabbit >5,000 mg/kgCOMPONENT: 2-methoxy-1-methylethyl acetateTOXICITY TO REPRODUCTIONDermal teratology testing of this solvent (with less than 3% beta isomer) revealed no maternally toxic, teratogenic or fetotoxic responses in rats or rabbits exposed to concentrations of 1,000 and 2,000 mg/kg per day.COMPONENT: 2-methoxy-1-methylethyl acetateMUTAGENLELTYNo significant mutagenic response was observed and the carcinogenic potential of the material is therefore considered to be low.Section 12 - Ecological InformationEcotoxicologioal information on this product or its components appear in this section when such date is available.2-methoxy-1-methylethyl acetateEcotoxicity effectsToxicity to fish LC50 Fathead minnow (Pimephales promelas) 86h 161 mg/l Toxicity aquatic EC50 Daphnia magna 48hInvertebrates >500mg/lSection 13 - Disposal ConsiderationsENVIRONMENTAL PRECAUTIONS: Prevent the material from entering drains or water courses.Do not discharge directly to a water source.Advise Authorities if spillage has entered watercourse or sewer or has contaminated sell or vegetation.DISPOSALDispose in accordance with all local, state (provincial), and federal regulation.Do not remove label until container is thoroughly cleaned. Empty containers may contain hazardous residues. This material and its container must be disposed of in a safe way.Section 14 - MSDS Transport InformationTransport In Accordance With Fire Service Law etc.CLASSIFICATION FOR ROAD ANG RAIL TRANSPORT:Proper shipping name RESIN SOLUTIONUN-No. UN 1866Class 3Packing group ⅢCLASSIFICATION FOR SEA TRANSPORT (IMO-IMDG):Proper shipping name RESIN SOLUTIONUN-No. UN 1866Class 3Packing group ⅢCLASSIFICATION FOR TRANSPORT (IATA/ICAO):Consult current IATA regulations prior to shipping by air. Transportation classifications may vary by container volume and may be influenced by regional or county variations in regulationsSection 15 - Regulatory InformationLabelClassification and labeling have been performed according to regulations.Hazard symbol and indication of dangerXi IrritantContains: 2-methoxy-1-methylethyl acetateR-phrase(s)R10 FlammableR36 Irritating to eyesS-phrase(s)S26 Incase of contact with eyes, rinse immediately with plenty of water and seek Medical advice.S43 Incase of fire. Use sand, dry chemical or alcohol-resistant foam.S63 This material and its container must be disposed of as hazardous waste. JAPAN. KASHIN-HOU LAW LIST (ENCS): All intentional components are listed on the inventory, are exempt, or are supplier certified.US. TOXIC SUBSTANCES CONTROL ACT (TSCA): All components of this product are incompliance with the inventory listing requirements of the U.S. Toxic Substances Control Act (TSCA) Chemical Substance Inventory.JAPAN FIRE SERVICE LAWArticle 2, Dangerous Substance, Class 4 Second oil type, risk gradeⅢNo FireJAPAN WASTE DISPOSAL AND PUBLIC CLEANING LAWJapan Specific Controlled Industrial wasteSection 16 - Other InformationSuzhou Ruihong makes no express or implied warranties, guarantees or representations regarding the product or the information herein, including but not limited to any implied warranty of merchantability or fitness for use. Suzhou Ruihong shall not be liable for any personal injury, property or other damages of any nature, whether compensatory, consequential, exemplary, or otherwise, resulting from any publication, use or reliance upon the information herein.正性光刻胶组成成分: 6 Dizao - 5,6 - Dihydoro - 5 -氧- 1 -萘磺酸,与2,3,4酯,羟基二苯甲酮(6%);甲酚甲醛酚醛树脂(21%);2-甲基丙醇乙酸酯(73%)四甲基氢氧化胺显影液: CH13NO4负胶漂洗液:C6H12O2。

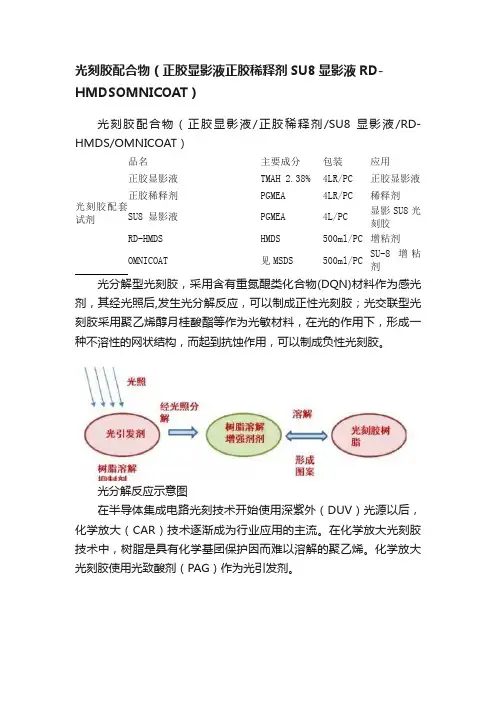

光刻胶配合物(正胶显影液正胶稀释剂SU8显影液RD-HMDSOMNICOAT)光刻胶配合物(正胶显影液/正胶稀释剂/SU8 显影液/RD-HMDS/OMNICOAT)光刻胶配套试剂品名主要成分包装应用正胶显影液TMAH 2.38% 4LR/PC 正胶显影液正胶稀释剂PGMEA 4LR/PC 稀释剂SU8 显影液PGMEA 4L/PC显影SU8光刻胶RD-HMDS HMDS 500ml/PC 增粘剂OMNICOAT 见MSDS 500ml/PCSU-8增粘剂光分解型光刻胶,采用含有重氮醌类化合物(DQN)材料作为感光剂,其经光照后,发生光分解反应,可以制成正性光刻胶;光交联型光刻胶采用聚乙烯醇月桂酸酯等作为光敏材料,在光的作用下,形成一种不溶性的网状结构,而起到抗蚀作用,可以制成负性光刻胶。

光分解反应示意图在半导体集成电路光刻技术开始使用深紫外(DUV)光源以后,化学放大(CAR)技术逐渐成为行业应用的主流。

在化学放大光刻胶技术中,树脂是具有化学基团保护因而难以溶解的聚乙烯。

化学放大光刻胶使用光致酸剂(PAG)作为光引发剂。

光交联反应示意图当光刻胶曝光后,曝光区域的光致酸剂(PAG)将会产生一种酸。

这种酸在后热烘培工序期间作为催化剂,将会移除树脂的保护基团从而使得树脂变得易于溶解。

化学放大光刻胶曝光速递是DQN光刻胶的10倍,对深紫外光源具有良好的光学敏感性,同时具有高对比度,对高分辨率等优点。

化学放大光反应示意图按照曝光波长分类;光刻胶可分为紫外光刻胶(300~450nm)、深紫外光刻胶(160~280nm)、极紫外光刻胶(EUV,13.5nm)、电子束光刻胶、离子束光刻胶、X射线光刻胶等。

不同曝光波长的光刻胶,其适用的光刻极限分辨率不同。

通常来说,在使用工艺方法一致的情况下,波长越短,加工分辨率越佳。

(10-苯基蒽-9-基)硼酸334658-75-2[10-(1-萘基)-9-蒽]硼酸400607-46-7B-(10-[1,1'-联苯]-4-基-9-蒽基)硼酸400607-47-89,9-二甲基芴-2-硼酸333432-28-39,10-双(2-萘基)蒽-2-硼酸867044-28-810-(2-萘基)蒽-9-硼酸597554-03-59,9-二甲基-2,7-芴二硼酸866100-14-3B-9,9'-螺二芴-2'-基硼酸236389-21-2B-[3-(4-二苯并噻吩基)苯基]硼酸1307859-67-1B,B'-2,8-二苯并呋喃二基二硼酸1222008-13-0吡啶-3-硼酸1692-25-7喹啉-3-硼酸191162-39-7喹啉-8-硼酸86-58-89H-咔唑-1-基硼酸869642-36-4二苯并噻吩-2,8-二硼酸761405-37-29-苯基咔唑-2-硼酸1001911-63-2(9-苯基-9H-咔唑-3-基)硼酸854952-58-24-(9H-咔唑-9-基)苯硼酸419536-33-73-(9H-咔唑-9-基)苯硼酸864377-33-3B-[2-(9H-咔唑-9-基)苯基]硼酸1189047-28-6二苯并呋喃-4-硼酸100124-06-9B-2-二苯并噻吩基硼酸668983-97-9联硼酸新戊二醇酯201733-56-4联硼酸频那醇酯73183-34-3二苯并噻吩-2,8-二硼酸761405-37-24-溴苯硼酸5467-74-34-氯苯硼酸1679-18-1硼酸三异丙酯5419-55-63-(2-三亚苯基苯硼酸)频哪醇酯1115639-92-33-甲氧基-2-萘硼酸104115-76-6Benzofuran-2-boronic acidCAS 98437-24-22,4-Dichlorophenylboronic acidCAS 68716-47-2[3-(3-Pyridinyl)phenyl]boronic acidCAS 351422-72-59-(3-bromophenyl)-9-phenyl-9H-fluorene1257251-75-4B-[4-(1-苯基-1H-苯并咪唑-2-基)苯基]-硼酸952514-79-3 [4-(2-苯基-1H-苯并咪唑-1-基)苯基]硼酸867044-33-5四氟硼酸银14104-20-2三亚苯-2-基)硼酸频哪醇酯890042-13-49,9-螺二芴-2-硼酸频哪醇酯884336-44-13-氟-2-甲酰基苯硼酸871126-15-75-氯-2-甲酰基苯硼酸870238-36-1B-(10-[1,1'-联苯]-2-基-9-蒽基)硼酸400607-48-94-(3-吡啶基)苯硼酸170230-28-12-氯-4-(联苯-3-基)-6-苯基-1,3,5-三嗪1689576-03-14-硼酸三苯胺201802-67-79-菲硼酸新戊二醇酯1416371-19-13,5-二甲基苯硼酸172975-69-8二苯并[b,d]呋喃-3-硼酸395087-89-52-溴螺[9H-芴-9,9'-[9H]氧杂蒽]899422-06-19,9-二苯基-3-溴芴1547491-70-24-溴芴酮4269-17-42,7-二溴-9,9-二苯基芴186259-63-25,9-二溴-7,7-二苯基-7H-苯并[c]芴854952-90-22-溴-9,9-二氟-7-碘-9H-芴1499193-60-09,9-二甲基-2-溴芴28320-31-29-溴-7,7-二甲基-7H-苯并[c]芴1198396-46-12,2,7,7-四溴-9,9-螺二芴128055-74-34-溴-9,9-二苯基芴713125-22-52-氨基-9,9-二甲基芴108714-73-42-溴-9,9-二苯基芴474918-32-69-(4-溴苯基)-9-苯基芴937082-81-09,9-二苯基-2-氨基芴1268519-74-92,7-二溴-9,9-二甲基芴28320-32-32-溴-9-芴酮3096-56-8wyf 01.26。

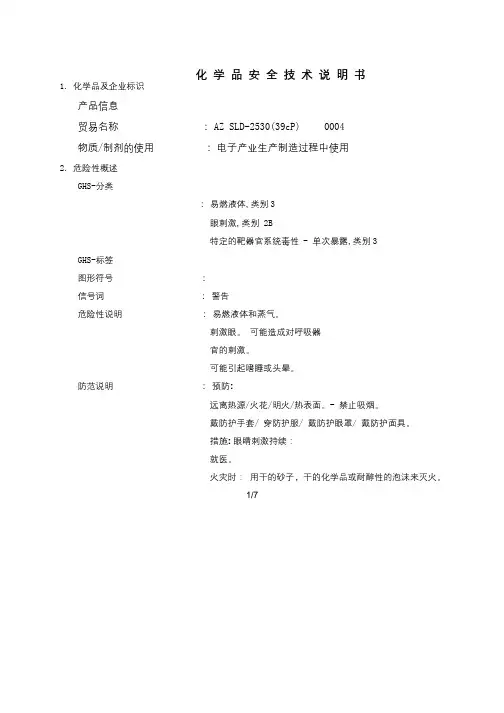

化学品安全技术说明书1. 化学品及企业标识产品信息贸易名称: AZ SLD-2530(39cP) 0004物质/制剂的使用: 电子产业生产制造过程中使用2. 危险性概述GHS-分类: 易燃液体, 类别3眼刺激, 类别2B特定的靶器官系统毒性- 单次暴露, 类别3 GHS-标签图形符号:信号词: 警告危险性说明: 易燃液体和蒸气。

刺激眼。

可能造成对呼吸器官的刺激。

可能引起嗜睡或头晕。

防范说明: 预防:远离热源/火花/明火/热表面。

- 禁止吸烟。

戴防护手套/ 穿防护服/ 戴防护眼罩/ 戴防护面具。

措施: 眼睛刺激持续:就医。

火灾时:用干的砂子,干的化学品或耐醇性的泡沫来灭火。

1/7储存:在通风良好处储存。

保持容器密闭。

处置: 将本品及其容器交由经批准的废物处理厂处置。

3. 成分/组成资料危险组分化学品名称化学文摘登记号(CAS No.) 浓度或浓度范围丙二醇甲醚醋酸酯108-65-6 >= 70%4. 急救措施一般的建议: 如果接触产品后感觉不适,立即就医吸入: 将受伤者移到新鲜空气处并保持其平静如果呼吸微弱、不规则或者停止,迅速解开领子,松开皮带,进行人工呼吸尽快将患者送往最近的医疗中心接受医生的检查和治疗。

请迅速就医并提供给医生相应物质安全资料表皮肤接触: 如果接触皮肤,立即用肥皂水清洗接触部位尽快脱下沾有化学品的衣服、鞋子和袜子,如有必要可用刀除去衣物如有持续刺激,请尽快送往最近的医疗中心接受医生的检查和治疗眼睛接触: 使用大量清水冲洗眼睛至少15分钟,并将眼皮保持张开状态。

迅速就医如化学品不慎溅入眼睛,立即用大量清水冲洗眼睛至少15分钟食入: 如果病人有意识,可以饮用水或者牛奶稀释胃中的物质禁止催吐。

让病人休息并立刻寻求医疗救助。

请迅速就医并提供给医生相应物质安全资料表对医生的特别提示处理: 无适用资料。

5. 消防措施灭火方法及灭火剂: 二氧化碳,水雾,干粉的,抗酒精泡沫2/7。

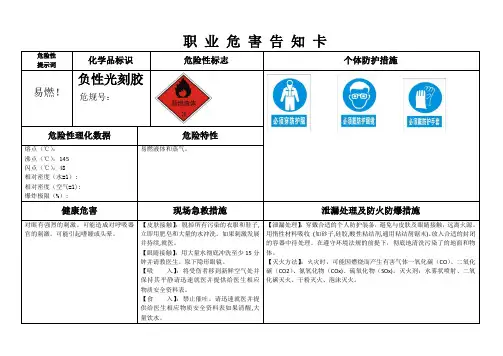

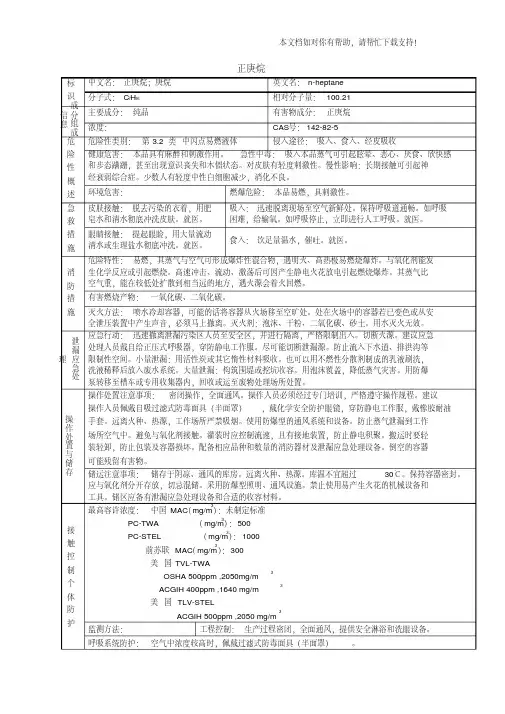

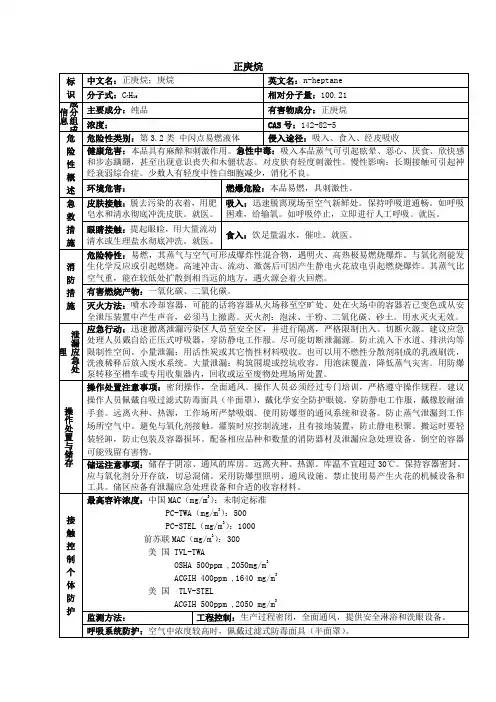

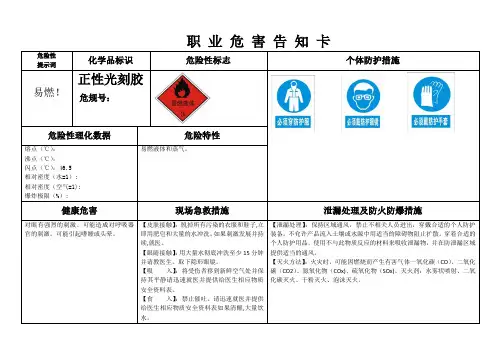

正庚烷化学品安全技术说明书第一部分:化学品名称化学品中文名称:正庚烷化学品英文名称:n-heptane中文名称2:庚烷技术说明书编码:444CAS No.:142-82-5分子式:C7H16分子量:100.21第二部分:成分/组成信息有害物成分含量 CAS No.正庚烷 142-82-5第三部分:危险性概述健康危害:本品有麻醉作用和刺激性。

急性中毒:吸入本品蒸气可引起眩晕、恶心、厌食、欣快感和步态蹒跚,甚至出现意识丧失和木僵状态。

对皮肤有轻度刺激性。

慢性影响:长期接触可引起神经衰弱综合征。

少数人有轻度中性白细胞减少,消化不良。

燃爆危险:本品易燃,具刺激性。

第四部分:急救措施皮肤接触:脱去污染的衣着,用肥皂水和清水彻底冲洗皮肤。

眼睛接触:提起眼睑,用流动清水或生理盐水冲洗。

就医。

吸入:迅速脱离现场至空气新鲜处。

保持呼吸道通畅。

如呼吸困难,给输氧。

如呼吸停止,立即进行人工呼吸。

就医。

食入:饮足量温水,催吐。

就医。

第五部分:消防措施危险特性:易燃,其蒸气与空气可形成爆炸性混合物,遇热源和明火有燃烧爆炸的危险。

与氧化剂接触发生化学反应或引起燃烧。

高速冲击、流动、激荡后可因产生静电火花放电引起燃烧爆炸。

其蒸气比空气重,能在较低处扩散到相当远的地方,遇火源会着火回燃。

有害燃烧产物:一氧化碳、二氧化碳。

灭火方法:喷水冷却容器,可能的话将容器从火场移至空旷处。

处在火场中的容器若已变色或从安全泄压装置中产生声音,必须马上撤离。

灭火剂:泡沫、二氧化碳、干粉、砂土。

用水灭火无效。

第六部分:泄漏应急处理应急处理:迅速撤离泄漏污染区人员至安全区,并进行隔离,严格限制出入。

切断火源。

建议应急处理人员戴自给正压式呼吸器,穿防静电工作服。

尽可能切断泄漏源。

防止流入下水道、排洪沟等限制性空间。

小量泄漏:用活性炭或其它惰性材料吸收。

也可以用不燃性分散剂制成的乳液刷洗,洗液稀释后放入废水系统。

大量泄漏:构筑围堤或挖坑收容。

用泡沫覆盖,降低蒸气灾害。

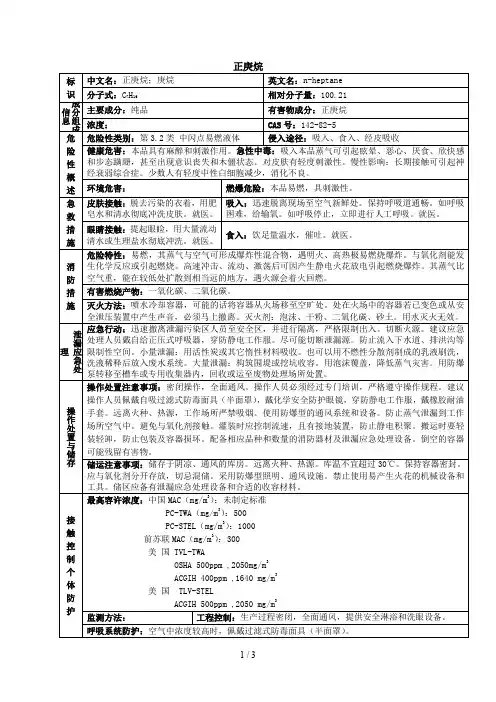

化学品安全技术说明书修订日期: SDS编号:产品名称: 版本:正庚烷第一部分化学品及企业标识化学品中文名:正庚烷化学品英文名:n-heptane;heptane供应商名称:xxxxxxx化工有限公司供应商地址:xxxxxxx开发区供应商电话:0566-xxxxxxx邮编:247260供应商传真:0566-xxxxxxx电子邮件地址:**************供应商应急咨询电话:0566-xxxxxxx化学事故应急咨询专线:0566-xxxxxxx产品推荐及限制用途:用作辛烷值测定的标准、溶剂,以及用于有机合成,实验试剂的制备。

第二部分危险性概述紧急情况概述:高度易燃液体和蒸气,可能引起昏昏欲睡或眩晕,吞咽及进入呼吸道可能致命。

GHS危险性类别:易燃液体-类别2;皮肤腐蚀/刺激-类别2;特异性靶器官毒性-一次接触-类别3(麻醉效应);吸入危害-类别1;危害水生环境-急性危害-类别1;危害水生环境-长期危害-类别1标签要素:象形图:警示词:危险危险信息:H225:高度易燃液体和蒸气H315:造成皮肤刺激H336:可能引起昏昏欲睡或眩晕H304:吞咽及进入呼吸道可能致命H410:对水生生物毒性极大并具有长期持续影响防范说明:预防措施:P210:远离热源/火花/明火/热表面。

禁止吸烟。

P233:保持容器密闭。

P240:容器和接收设备接地/等势联接。

P241:使用防爆的电气/通风/照明/……/设备。

P242:只能使用不产生火花的工具。

P243:采取防止静电放电的措施。

P280:戴防护手套/穿防护服/戴防护眼罩/戴防护面具。

P264:作业后彻底清洗……。

P260:不要吸入粉尘/烟/气体/烟雾/蒸气/喷雾。

P271:只能在室外或通风良好之处使用。

P273:避免释放到环境中。

应急响应:P303+P361+P353:如皮肤(或头发)沾染:立即脱掉所有沾染的衣服。

用水清洗皮肤/淋浴。

P370+P378:火灾时,使用……灭火。

光刻胶光致抗蚀剂含感光树脂、增感剂和溶剂光刻胶是光刻成像的承载介质,其作用是利用光化学反应的原理将光刻系统中经过衍射、滤波后的光信息转化为化学能量,进而完成掩模图形的复制。

目前,集成电路生产中使用的光刻胶一般由聚合物骨架、光致酸产生剂或光敏化合物、溶剂,以及显影保护基团、刻蚀保护基团等其他辅助成分组成。

光刻胶是微电子技术中微细图形加工的关键材料之一,特别是近年来大规模和超大规模集成电路的发展,更是大大促进了光刻胶的研究开发和应用。

印刷工业是光刻胶应用的另一重要领域。

1954 年由明斯克等人首先研究成功的聚乙烯醇肉桂酸酯就是用于印刷工业的,以后才用于电子工业。

光刻胶是一种有机化合物,它被紫外光曝光后,在显影溶液中的溶解度会发生变化。

硅片制造中所用的光刻胶以液态涂在硅片表面,而后被干燥成胶膜。

中文名:光刻胶外文名:photoresist别名:光致抗蚀剂成分:感光树脂、增感剂和溶剂分类:负性胶和正性胶硅片制造中,光刻胶的目的主要有两个:光刻胶原理,小孔成像;技术源头,古老的相机;(1)将掩模版图形转移到硅片表面顶层的光刻胶中;(2)在后续工艺中,保护下面的材料(例如刻蚀或离子注入阻挡层)。

分类:光刻胶的技术复杂,品种较多。

根据其化学反应机理和显影原理,可分负性胶和正性胶两类。

光照后形成不可溶物质的是负性胶;反之,对某些溶剂是不可溶的,经光照后变成可溶物质的即为正性胶。

图1 正性胶的显影工艺与负性胶显影工艺对比1-丙烯酸金刚烷酯121601-93-21-金刚烷基甲基丙烯酸酯16887-36-8丙烯酸三环[5.2.1.02,6]癸-8-基酯7398-56-34-乙酰氧基苯乙烯2628-16-21,3-金刚烷二醇单丙烯酸酯216581-76-92-甲基-2-金刚烷醇丙烯酸酯249562-06-92-乙基-2-金刚烷基丙烯酸酯303186-14-31,3-金刚烷二醇二丙烯酸酯81665-82-92-氧代六氢-2H-3,5-亚甲基环戊二烯并[b]呋喃-6-基甲基丙烯酸酯254900-07-7甲基丙烯酸三环[5.2.1.02,6]癸-8-基酯[34759-34-72-异丙基-2-金刚烷丙烯酸甲酯297156-50-42-异丙基-2-金刚烷醇丙烯酸酯251564-67-7gamma-丁内酯-3-基异丁烯酸酯130224-95-2N-异丙基甲基丙烯酰胺13749-61-6(9H-芴-9,9-二基)双(亚甲基)二丙烯酸酯583036-99-1(5-氧代四氢呋喃-2-基)甲基丙烯酸甲酯156938-09-91-乙基环戊基甲基丙烯酸酯266308-58-11-异丙基-1-环己醇甲基丙烯酸酯811440-77-42-甲基-2-丙烯酸4-羟基苯基酯31480-93-0n-butyl2-(bromomethyl)prop-2-enoate170216-64-52-(溴甲基)丙烯酸甲酯4224-69-5甲基丙烯酸-9-蒽甲酯31645-35-92-oxo-2-((2-oxohexahydro-2H-3,5-methanocyclopenta[b]furan-6-yl)oxy)ethylmethacrylate[347886-81-12-乙烯基萘827-54-32-环己基丙烷-2-基甲基丙烯酸酯186585-56-82-甲基-丙烯酸2-氧代-四氢-呋喃-3-基酯195000-66-9丙烯酸甲基环戊酯178889-49-1丙烯酸1-乙基环戊酯326925-69-32-氧代四氢呋喃-3-基丙烯酸酯328249-37-24-叔丁氧基苯乙烯95418-58-94-(4-(丙烯酰氧基)丁氧基)苯甲酸69260-42-0甲基丙烯酸-2,2,3,3,4,4,4-七氟代-丁酯13695-31-33-(4-vinylphenyloxy)-1-propene16215-47-7acetic acid,4-ethenylbenzene-1,2-diol57142-64-01-(1-乙氧基乙氧基)-4-乙烯基苯157057-20-01-甲基环己基甲基丙烯酸酯76392-14-82-氧代-2-(2,2,3,3,3-五氟丙氧基)乙基甲基丙烯酸酯1176273-16-72,5-二甲基己烷-2,5-二基双(2-甲基丙烯酸酯)131787-39-81-甲基环戊基甲基丙烯酸酯178889-45-71-乙基环己基甲基丙烯酸酯274248-09-84-异丙基苯酚4286-23-1(2-oxo-1,3-dioxolan-4-yl)methyl 2-methylprop-2-enoate13818-44-5乙酸-2-乙烯基苯基酯63600-35-12-(金刚烷-1-基)丁-2-基甲基丙烯酸酯325991-26-21-ethoxyethyl 2-methylprop-2-enoate51920-52-6甲基丙烯酸四氢呋喃-2-基酯15895-80-4oxan-2-yl 2-methylprop-2-enoate52858-59-06-methacryloyl-6-azabicyclo[3.2.0]heptan-7-one1267624-16-73-叔丁氧基苯乙烯105612-79-12-丙烯酸3-(二乙氧基甲基甲硅烷基)丙基酯13732-00-82,3-二羟基丙烯酸丙酯10095-20-22-[(4-乙烯基苯氧基)甲基]环氧乙烷2653-39-63,5-二乙酰氧基苯乙烯155222-48-32-(2,2-二氟乙烯基)双环[2.2.1]庚烷123455-94-7二苯基碘酰氯1483-72-3双[4-(1,1-二甲基乙基)苯基]碘鎓与三氟甲磺酸的盐84563-54-2全氟丁基磺酸三苯基锍盐144317-44-2双(4-叔丁基苯基)氯化碘鎓5421-53-4TBPDPS-PFBS258872-05-81二(4-叔丁基苯基)碘鎓全氟代丁烷磺酸盐194999-85-4(4-苯基硫代苯基)二苯基锍三氟甲磺酸111281-12-0N-羟基萘酰亚胺三氟甲磺酸85342-62-7六氟二酐(6FDA)1107-00-29,9-双(3-氟-4-氨基苯基)芴 (FFDA)127926-65-29,9-双(4-氨基苯基)芴(FDA)15499-84-04,4’-二氨基-2,2’-二甲基联苯 (M-T olidine)84-67-32,2-双(3-氨基-4-羟基苯基) 六氟丙烷83558-87-61,3-双(3-氨基苯氧基)苯 (APB)10526-07-54,4'-双(4-氨苯氧基)联苯(BAPB)13080-85-81,3-双(4-氨苯氧基)苯2479-46-14,4-二氨基联苯-2,2-二羧酸17557-76-52,2'-双(三氟甲基)-4,4'-二氨基苯基醚344-48-9ODA 4,4'-二氨基二苯醚101-80-4BAPP 2,2'-双[4-(4-氨基苯氧基苯基)]丙烷13080-86-9TPE-Q 1,4-双(4-氨基苯氧基)苯3491/12/1BPADA 双酚A型二醚二酐38103-06-9BTDA 3,3',4,4'-二苯甲酮四甲酸二酐2421-28-5BPDA 3,3',4,4'-联苯四羧酸二酐2420-87-3CBDA 环丁烷四甲酸二酐4415-87-6DABA 3,5-二氨基苯甲酸535-87-5TFMB 2,2'-双(三氟甲基)二氨基联苯341-58-2A-BPDA 2,3,3',4'-联苯四甲酸二酐36978-41-3BOAFL 9,9-二[(2,3-环氧丙氧基)苯基]芴47758-37-2TCA 四氢-1H-5,9-甲烷吡喃并[3,4-d]噁英-1,3,6,8(4H)-四酮6053-46-9ODPA 4,4'-氧双邻苯二甲酸酐1823-59-2A-ODPA 3,4'-氧双邻苯二甲酸酐50662-95-8HFBAPP 2,2-双[4-(4-氨基苯氧基)苯基]-1,1,1,3,3,3-六氟丙烷69563-88-84-溴-N-苯基咔唑1097884-37-13,6-二溴-9-(2-乙基己基)-9h-咔唑173063-52-0N-(2-萘基)-3-溴咔唑934545-80-91-溴-N-苯基咔唑1333002-37-13,6-二叔丁基咔唑37500-95-13,6-二溴咔唑6825-20-31-溴咔唑16807-11-72-溴咔唑3652-90-22-氯咔唑10537-08-32-羟基咔唑86-79-33-溴咔唑1592-95-63,6-二苯基-9H-咔唑56525-79-24-溴-9H-咔唑3652-89-93-苯基-9H-咔唑103012-26-611,12-二氢-12,12-二甲基茚并[1,2-a]咔唑1329054-41-29-(4-溴苯基)咔唑57102-42-810-溴-7H-苯并[c]咔唑1698-16-49-(3-溴苯基)-9H-咔唑185112-61-29-(2-溴苯基)-9H-咔唑902518-11-03-溴-N-苯基咔唑1153-85-13,6-二溴-9-苯基咔唑57103-20-5 3-碘-9-苯基咔唑502161-03-79-(1-萘基)-3-溴咔唑934545-83-2 wyf 01.22。

光刻胶产品前程无量(半导体技巧寰宇)1 媒介光刻胶(别名光致抗蚀剂)是指经由过程紫外光.电子束.准分子激光束.X射线.离子束等曝光源的照耀或辐射,使消融度产生变更的耐蚀苛刻膜材料,重要用于集成电路和半导体分立器件的细微图形加工,近年来也慢慢运用于光电子范畴平板显示器(FPD)的制造.因为光刻胶具有光化学迟钝性,可运用其进行光化学反响,经曝光.显影等进程,将所须要的微细图形从掩模版转移至待加工的衬底上,然落后行刻蚀.集中.离子注入等工艺加工,是以是电子信息财产中微电子行业和光电子行业微细加工技巧的症结性基本加工材料.作为经曝光和显影而使消融度增长的正型光刻胶多用于制造IC,经曝光或显影使消融度减小的负型光刻胶多用于制造分立器件.2 国外情形跟着电子器件不竭向高集成化和高速化偏向成长,对微细图形加工技巧的请求越来越高,为了顺应亚微米微细图形加工的请求,国外先后开辟了g线(436nm).i线(365nm).深紫外.准分子激光.化学增幅.电子束.X射线.离子束抗蚀剂等一系列新型光刻胶.这些品种较有代表性的负性胶如美国柯达(Kodak)公司的KPR.KMER.KLER.KMR.KMPR等;结合碳化学(UCC)公司的KTI系列;日本东京应化(Tok)公司的TPR.SVR.OSR.OMR;合成橡胶(JSR)公司的CIR.CBR系列;瑞翁(Zeon)公司的ZPN系列;德国依默克(E.Merk)公司的Solect等.正性胶如:美国西帕来(Shipely)公司的AZ系列.DuPont公司的Waycot系列.日本合成橡胶公司的PFR等等. 2000~2001年世界市场光刻胶临盆商的收益及市场份额公司2001年收益2001年市场份额(%) 2000年收益 2000年市场份额(%)总计Source: Gartner Dataquest今朝,国际上主流的光刻胶产品是分辩率在0.25µm~0.18µm的深紫外正型光刻胶,重要的厂商包含美国Shipley.日本东京应化和瑞士的克莱恩等公司.中国专利CN1272637A2000年公开了国际贸易机械公司创造的193nm光刻胶组合物,在无需相传递掩膜的情形下可以或许分辩尺寸小于150nm,更优选尺寸小于约115nm.2003年美国专利US2003/0082480又公开了Christian Eschbaumer等创造的157nm光刻胶.估计2004年全球光刻胶和助剂的市场范围约37亿美元.3 国内近况国内重要产品有聚乙烯醇肉桂酸酯(相当于美KPR胶).聚肉桂叉丙二酸乙二醇酯聚酯胶.环化橡胶型购胶(相当于OMR-83胶)和重氮萘醌磺酰氯为感光剂主体的紫外正型光刻胶(相当于AZ-1350).个中紫外线负胶已国产化,紫外线正胶可知足2µm工艺请求,深紫外正负胶(聚甲基异丙烯基酮.氯甲基聚苯乙烯,分辩率0.5~0.3µm).电子束正负胶(聚甲基丙烯酸甲酯一甲基丙烯酸缩水甘油酯一丙烯酸乙酯共聚)(分辩率0.25~0.1µm).X射线正胶(聚丁烯砜聚1,2一二氯丙烯酸,分辩率0.2µm),可供给少量产品,用于IC制造的高等次正型胶仍全体依附进口.光刻胶今朝国产才能约为100多吨.据国度有关部分猜测,到2005年微电子用光刻胶将超出200吨. 国内光刻胶重要研制临盆单位有北京化学试剂所.北京化工场.上海试剂一厂.姑苏瑞红电子化学品公司.黄岩有机化工场.无锡化工研讨设计院.北师大.上海交大等.近年来,北京化学试剂所和姑苏瑞红电子化学品公司等单位在平板显示器(FPD)用光刻胶方面进行了大量工作,已研制成功并范围临盆出液晶显示器(LCD)专用正型光刻胶,如北京化学试剂所的BP218系列正型光刻胶实用于TN/STNLCD的光刻制造.北京化学试剂研讨所一向是国度重点科技攻关课题——光刻胶研讨的组长单位.“十五”时代,科技部为了尽快缩小光刻技巧配套用材料与国际先辈程度的差距,将新型高机能光刻胶列入了“863”重大专项筹划之中,并且跨过艺用i线正型光刻胶和248nm深紫外光刻胶两个台阶,直接开展艺用193nm光刻胶的研讨.姑苏瑞红则是微电子化学操行业中惟一一家中外合伙临盆企业,曾作为国度“八五”科研攻关“南边基地”的组长单位,其光刻胶产品以用于LCD的正胶为主,负胶为辅.为加速成长光刻胶财产的程序,北京化学试剂研讨所的上级单位——北京化工团体有限义务公司正在做相干筹划,争夺在“十五”时代,在大兴区兴建的化工基地实现年产光刻胶80吨至100吨的范围.在此筹划中,化工基地前期以临盆紫外负型光刻胶及术用紫外正胶为主,之后还要接踵临盆i 线正胶.术用的193nm高机能光刻胶.而姑苏瑞红也正积极地与国外有名的光刻胶厂商合作,进行248nm深紫外光刻胶的财产化工作,争夺使其产品打入国内合伙或独资的集成电路临盆企业.4 前程无量近年来,光刻胶在微电子行业中不竭开辟出新的用处,如采取光敏性介质材料制造多芯片组件(MCM).MCM技巧可大幅度缩小电子体系体积,减轻其质量,并进步其靠得住性.近年来国外在高等军事电子和宇航电子设备中,已普遍地运用MCM技巧. 可以预感,成长微电子信息财产及光电财产中不成缺乏的基本工艺材料——光刻胶产品在21世纪的运用将更普遍.更深刻.光刻胶的界说及重要感化光刻胶是一种有机化合物,它受紫外光曝光后,在显影液中的消融度会产生变更.一般光刻胶以液态涂覆在硅片概况上,曝光后烘烤成固态. 光刻胶的感化:a.将掩膜板上的图形转移到硅片概况的氧化层中;b.在后续工序中,呵护下面的材料(刻蚀或离子注入).光刻胶来源光刻开端于一种称作光刻胶的感光性液体的运用.图形能被映射到光刻胶上,然后用一个developer就能做出须要的模板图案.光刻胶溶液平日被扭转式滴入wafer.如图wafer被装到一个每分钟能转几千转的转盘上.几滴光刻胶溶液就被滴到扭转中的wafer的中间,离心利巴溶液甩到概况的所有地方.光刻胶溶液黏着在wafer上形成一层平均的薄膜.过剩的溶液从扭转中的wafer上被甩失落.薄膜在几秒钟之内就缩到它最终的厚度,溶剂很快就蒸发失落了,wafer上就留下了一薄层光刻胶.最后经由过程烘焙去失落最后剩下的溶剂并使光刻胶变硬以便后续处理.镀过膜的wafer对特定波成的光线很迟钝,特别是紫外(UV)线.相对来说他们仍然对其他波长的,包含红,橙和黄光不太迟钝.所以大多半光刻车间有特别的黄光体系.光刻胶的重要技巧参数a.分辩率(resolution).差别硅片概况相邻图形特点的才能.一般用症结尺寸(CD,Critical Dimension)来权衡分辩率.形成的症结尺寸越小,光刻胶的分辩率越好.b.比较度(Contrast).指光刻胶从曝光区到非曝光区过渡的陡度.比较度越好,形成图形的侧壁越峻峭,分辩率越好.c.迟钝度(Sensitivity).光刻胶上产生一个优越的图形所需必定波长光的最小能量值(或最小曝光量).单位:毫焦/平方厘米或mJ/cm2.光刻胶的迟钝性对于波长更短的深紫外光(DUV).极深紫外光(EUV)等尤为重要.d.粘滞性/黏度(Viscosity).权衡光刻胶流淌特点的参数.粘滞性跟着光刻胶中的溶剂的削减而增长;高的粘滞性会产生厚的光刻胶;越小的粘滞性,就有越平均的光刻胶厚度.光刻胶的比重(SG,Specific Gravity)是权衡光刻胶的密度的指标.它与光刻胶中的固体含量有关.较大的比重意味着光刻胶中含有更多的固体,粘滞性更高.流淌性更差.粘度的单位:泊(poise),光刻胶一般用厘泊(cps,厘泊为1%泊)来器量.百分泊即厘泊为绝对粘滞率;活动粘滞率界说为:活动粘滞率=绝对粘滞率/比重. 单位:百分斯托克斯(cs)=cps/SG.e.粘附性(Adherence).表征光刻胶粘着于衬底的强度.光刻胶的粘附性缺乏会导致硅片概况的图形变形.光刻胶的粘附性必须经受住后续工艺(刻蚀.离子注入等).f.抗蚀性(Anti-etching).光刻胶必须保持它的粘附性,在后续的刻蚀工序中呵护衬底概况.耐热稳固性.抗刻蚀才能和抗离子轰击才能.g.概况张力(Surface Tension).液体中将概况分子拉向液体主体内的分子间吸引力.光刻胶应当具有比较小的概况张力,使光刻胶具有优越的流淌性和笼罩.h.存储和传送(Storage and Transmission).能量(光和热)可以激活光刻胶.应当存储在密闭.低温.不透光的盒中.同时必须划定光刻胶的闲置刻日和存贮温度情形.一旦超出存储时光或较高的温度范围,负胶会产生交联,正胶会产生感光延迟.光刻胶的分类a.依据光刻胶按照若何响应紫外光的特点可以分为两类:负性光刻胶和正性光刻胶.负性光刻胶(Negative Photo Resist).最早运用,一向到20世纪70年月.曝光区域产生交联,难溶于显影液.特点:优越的粘附才能.优越的阻拦感化.感光速度快;显影时产生变形和膨胀.所以只能用于2μm的分辩率.正性光刻胶(Positive Photo Resist).20世纪70年月,有负性转用正性.正性光刻胶的曝光区域加倍轻易消融于显影液.特点:分辩率高.台阶笼罩好.比较度好;粘附性差.抗刻蚀才能差.高成本.b.依据光刻胶能形成图形的最小光刻尺寸来分:传统光刻胶和化学放大光刻胶.传统光刻胶.实用于I线(365nm).H线(405nm)和G线(436nm),症结尺寸在μm及其以上.化学放大光刻胶(CAR,Chemical Amplified Resist).实用于深紫外线(DUV)波长的光刻胶.KrF(248nm)和ArF(193nm). 光刻胶的化学性质a.传统光刻胶:正胶和负胶. 光刻胶的构成:树脂(resin/polymer),光刻胶中不合伙料的粘合剂,授与光刻胶的机械与化学性质(如粘附性.胶膜厚度.热稳固性等);感光剂,感光剂对光能产生光化学反响;溶剂(Solvent),保持光刻胶的液体状况,使之具有优越的流淌性;添加剂(Additive),用以改变光刻胶的某些特点,如改良光刻胶产生反射而添加染色剂等.负性光刻胶.树脂是聚异戊二烯,一种自然的橡胶;溶剂是二甲苯;感光剂是一种经由曝光后释放出氮气的光敏剂,产生的自由基在橡胶分子间形成交联.从而变得不溶于显影液.负性光刻胶在曝光区由溶剂引起泡涨;曝光时光刻胶轻易与氮气反响而克制交联.正性光刻胶.树脂是一种叫做线性酚醛树脂的酚醛甲醛,供给光刻胶的粘附性.化学抗蚀性,当没有消融克制剂消失时,线性酚醛树脂会消融在显影液中;感光剂是光敏化合物(PAC,Photo Active Compound),最罕有的是重氮萘醌(DNQ),在曝光前,DNQ是一种强烈的消融克制剂,下降树脂的消融速度.在紫外曝光后,DNQ在光刻胶中化学分化,成为消融度加强剂,大幅进步显影液中的消融度因子至100或者更高.这种曝光反响会在DNQ中产生羧酸,它在显影液中消融度很高.正性光刻胶具有很好的比较度,所以生成的图形具有优越的分辩率.b.化学放大光刻胶(CAR,Chemical Amplified Resist). 树脂是具有化学基团呵护(t-BOC)的聚乙烯(PHS).有呵护团的树脂不溶于水;感光剂是光酸产生剂(PAG,Photo Acid Generator),光刻胶曝光后,在曝光区的PAG产生光化学反响会产生一种酸.该酸在曝光后热烘(PEB,Post Exposure Baking)时,作为化学催化剂将树脂上的呵护基团移走,从而使曝光区域的光刻胶由本来不溶于水改变成高度溶于以水为重要成分的显影液.化学放大光刻胶曝光速度异常快,大约是DNQ线性酚醛树脂光刻胶的10倍;对短波长光源具有很好的光学迟钝性;供给陡直侧墙,具有高的比较度;具有μm及其以下尺寸的高分辩率.光刻胶的重要运用范畴模仿半导体(Analog Semiconductors)发光二极管(Light-Emitting Diodes LEDs)微机电体系(MEMS)太阳能光伏(Solar PV)微流道和生物芯片(Microfluidics & Biochips)光电子器件/光子器件(Optoelectronics/Photonics)封装(Packaging)光刻胶的成长趋向中国的微电子和平板显示财产成长敏捷,带动了光刻胶材料与高纯试剂供给商等财产链中的相干配套企业的树立和成长.特别是2009年LED(发光二极管)的缓慢成长,加倍有力地推进了光刻胶财产的成长.中国的光刻胶财产市场在原有分立器件.IC.LCD(液晶显示器)的基本上,又参加了LED,再加上光伏的潜在市场,到2010年中国的光刻胶市场将超出20亿元,将占国际光刻胶市场比例的10%以上. 从国内相干财产对光刻胶的需求量来看,今朝重要照样以紫外光刻胶的用量为主,个中的中小范围(5μm以上技巧)及大范围集成电路(5μm.2~3μμm技巧)企业.分立器件临盆企业对于紫外负型光刻胶的需求总量将分离达到100吨/年~150吨/年;用于集成电路.液晶显示的紫外正性光刻胶及用于LED的紫外正负性光刻胶的需求总量在700吨/年~800吨/年之间.但是超大范围集成电路深紫外术)与193nm(90nm.65nm及45nm的技巧)光刻胶跟着Intel大连等数条大尺寸线的树立,需求量也一日千里.。

正庚烷化学品安全技术说明书

第一部分:化学品名称

化学品中文名称:正庚烷

化学品英文名称:n-heptane

中文名称 2:庚烷

技术说明书编码:444

CAS No.:142-82-5

分子式: C 7H 16

分子量:100.21

第二部分:成分/组成信息

有害物成分

含量 CAS No.

正庚烷

142-82-5

第三部分:危险性概述

健康危害:本品有麻醉作用和刺激性。

急性中毒:吸入本品蒸气可引起眩晕、恶心、厌食、欣快感和步态蹒跚,甚至出现意识丧失

和木僵状态。

对皮肤有轻度刺激性。

慢性影响:长期接触可引起神经衰弱综合征。

少数人有

轻度中性白细胞减少,消化不良。

燃爆危险:本品易燃,具刺激性。

第四部分:急救措施

皮肤接触:脱去污染的衣着,用肥皂水和清水彻底冲洗皮肤。

眼睛接触:提起眼睑,用流动清水或生理盐水冲洗。

就医。

吸入:迅速脱离现场至空气新鲜处。

保持呼吸道通畅。

如呼吸困难,给输氧。

如呼吸停止,

立即进行人工呼吸。

就医。

食入:饮足量温水,催吐。

就医。

也

第五部分:消防措施

危险特性:易燃,其蒸气与空气可形成爆炸性混合物,遇热源和明火有燃烧爆炸的危险。

与

氧化剂接触发生化学反应或引起燃烧。

高速冲击、流动、激荡后可因产生静电火花放电引起

燃烧爆炸。

其蒸气比空气重,能在较低处扩散到相当远的地方,遇火源会着火回燃。

有害燃烧产物:一氧化碳、二氧化碳。

灭火方法:喷水冷却容器,可能的话将容器从火场移至空旷处。

处在火场中的容器若已变色

或从安全泄压装置中产生声音,必须马上撤离。

灭火剂:泡沫、二氧化碳、干粉、砂土。

用

水灭火无效。

第六部分:泄漏应急处理

应急处理:迅速撤离泄漏污染区人员至安全区,并进行隔离,严格限制出入。

切断火源。

建

议应急处理人员戴自给正压式呼吸器,穿防静电工作服。

尽可能切断泄漏源。

防止流入下水

道、排洪沟等限制性空间。

小量泄漏:用活性炭或其它惰性材料吸收。

可以用不燃性分散

剂制成的乳液刷洗,洗液稀释后放入废水系统。

大量泄漏:构筑围堤或挖坑收容。

用泡沫覆

盖,降低蒸气灾害。

用防爆泵转移至槽车或专用收集器内,回收或运至废物处理场所处置。

第七部分:操作处置与储存

操作注意事项:密闭操作,全面通风。

操作人员必须经过专门培训,严格遵守操作规程。

建

议操作人员佩戴过滤式防毒面具(半面罩),戴安全防护眼镜,穿防静电工作服,戴橡胶耐

油手套。

远离火种、热源,工作场所严禁吸烟。

使用防爆型的通风系统和设备。

防止蒸气泄

漏到工作场所空气中。

避免与氧化剂接触。

灌装时应控制流速,且有接地装置,防止静电积

聚。

配备相应品种和数量的消防器材及泄漏应急处理设备。

倒空的容器可能残留有害物。

储存注意事项:储存于阴凉、通风的库房。

远离火种、热源。

库温不宜超过 30℃。

保持容

器密封。

应与氧化剂分开存放,切忌混储。

采用防爆型照明、通风设施。

禁止使用易产生火

花的机械设备和工具。

储区应备有泄漏应急处理设备和合适的收容材料。

第八部分:接触控制/个体防护

前苏联MAC(mg/m3):300

TLVTN:OSHA500ppm,2050mg/m3;ACGIH400ppm,1640mg/m3

TLVWN:ACGIH500ppm,2050mg/m3

工程控制:生产过程密闭,全面通风。

提供安全淋浴和洗眼设备。

呼吸系统防护:空气中浓度较高时,佩戴过滤式防毒面具(半面罩)。

眼睛防护:戴安全防护眼镜。

身体防护:穿防静电工作服。

手防护:戴橡胶耐油手套。

其他防护:工作现场严禁吸烟。

避免长期反复接触。

第九部分:理化特性

主要成分:纯品

外观与性状:无色易挥发液体。

熔点(℃):-90.5

沸点(℃):98.5

相对密度(水=1):0.68

相对蒸气密度(空气=1):3.45

饱和蒸气压(kPa):5.33(22.3℃)

燃烧热(kJ/mol):4806.6

临界温度(℃):201.7

临界压力(MPa):1.62

闪点(℃):-4

引燃温度(℃):204

爆炸上限%(V/V):6.7

爆炸下限%(V/V):1.1

溶解性:不溶于水,溶于醇,可混溶于乙醚、氯仿。

主要用途:用作辛烷值测定的标准、溶剂,以及用于有机合成,实验试剂的制备。

第十部分:稳定性和反应活性

禁配物:强氧化剂。

第十一部分:毒理学资料

急性毒性:LD50:222mg/kg(小鼠静脉)

LC50:75000mg/m3,2小时(小鼠吸入)

第十二部分:生态学资料

其它有害作用:该物质对环境可能有危害,对水体和大气可造成污染,在对人类重要食物链中,特别是在鱼类体内发生生物蓄积。

第十三部分:废弃处置

废弃处置方法:处置前应参阅国家和地方有关法规。

建议用焚烧法处置。

第十四部分:运输信息

危险货物编号:32006

UN编号:1206

包装类别:O52

包装方法:小开口钢桶;安瓿瓶外普通木箱;螺纹口玻璃瓶、铁盖压口玻璃瓶、塑料瓶或金属桶(罐)外普通木箱。

运输注意事项:运输时运输车辆应配备相应品种和数量的消防器材及泄漏应急处理设备。

夏

季最好早晚运输。

运输时所用的槽(罐)车应有接地链,槽内可设孔隔板以减少震荡产生静电。

严禁与氧化剂、食用化学品等混装混运。

运输途中应防曝晒、雨淋,防高温。

中途停留时应远离火种、热源、高温区。

装运该物品的车辆排气管必须配备阻火装置,禁止使用易产生火花的机械设备和工具装卸。

公路运输时要按规定路线行驶,勿在居民区和人口稠密区停留。

铁路运输时要禁止溜放。

严禁用木船、水泥船散装运输。

第十五部分:法规信息

法规信息;化学危险物品安全管理条例(1987年2月17日国务院发布),化学危险物品安全管理条例实施细则(化劳发[1992]677号),工作场所安全使用化学品规定([1996]劳部

发423号)等法规,针对化学危险品的安全使用、生产、储存、运输、装卸等方面均作了相

应规定;常用危险化学品的分类及标志(GB13690-92)将该物质划为第3.2类中闪点易燃液体。

第十六部分:其他信息

参考文献:

填表部门:

数据审核单位:

修改说明:

其他信息:。