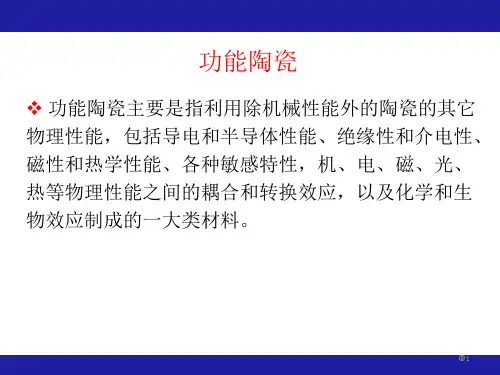

压电陶瓷PPT课件

- 格式:ppt

- 大小:5.48 MB

- 文档页数:69

The enhanced piezoelectric performance of Bi 1/2Na 1/2TiO 3–BaTiO 3ceramics by Ba 0.77Ca 0.23TiO 3substitutionLaihui Luo a ,⇑,Feng Ni a ,Huixin Zhang a ,Hongbing Chen ba Department of Physics,Ningbo University,Ningbo 315211,ChinabInstitute of Materials Science and Engineering,Ningbo University,Ningbo 315211,Chinaa r t i c l e i n f o Article history:Received 30December 2011Received in revised form 2May 2012Accepted 6May 2012Available online 12May 2012Keywords:Lead-free ceramic Piezoelectric Ferroelectric Depolarizationa b s t r a c tIn this study,lead-free (1Àx )Bi 0.47Na 0.47Ba 0.06TiO 3–x Ba 0.77Ca 0.23TiO 3(BNBT–x BCT,x =0–0.12)ceramics were fabricated by ordinary ceramic sintering technique.The results show that Ba 0.77Ca 0.23TiO 3(BCT)has diffused into Bi 0.47Na 0.47Ba 0.06TiO 3(BNBT)lattices to form a new solid solution BNBT–x BCT.Moderate substitution of BCT in BNBT–x BCT (x 60.01)ceramics can enhance the piezoelectric and ferroelectric properties;meanwhile,depolarization temperature of the ceramics does not decrease.BNBT–0.01BCT ceramic exhibits the best piezoelectric properties and strongest ferroelectricity:piezoelectric coefficient d 33=178pC/N;electromechanical coupling factors k t =50%and k p =27%;quality factor Q m =131;rem-nant polarization P r =36l C/cm 2;coercive field E c =24.5kV/cm.The piezoelectric properties,ferroelectric characteristics and depolarization mechanism of the ceramics are investigated and discussed.Published by Elsevier B.V.1.IntroductionLead-based piezoelectric ceramics based on Pb(Zr,Ti)O 3(PZT)are widely used in piezoelectric devices because of their excellent electrical properties near morphotropic phase boundary (MPB)[1].However,the use of lead-based piezoelectric ceramics has caused serious lead pollution due to the high toxicity of lead oxide and its high volatility during sintering.Therefore,much attention has been paid to the search for lead-free piezoelectric ceramics with high piezoelectric properties.Bi 1/2Na 1/2TiO 3(BNT)is considered to be an excellent candidate for lead-free piezoelectric ceramics due to its large remnant polar-ization (P r =38l C/cm 2)at room temperature.However,the piezo-electric performance of the pure BNT is relatively low,and it requires a large driving field during practical application due to its high coercive field (E c =73kV/cm)[2].In order to improve the piezoelectric performance and reduce the driving field of BNT cera-mic,a number of BNT-based solid solutions have been developed,such as BNT–BaTiO 3(BNT–BT)[3,4],BNT–Bi 1/2K 1/2TiO 3[5,6],BNT–KNbO 3[7],BNT–BT–Bi 1/2Li 1/2TiO 3[8],BNT–Ba(Ti,Zr)O 3[9],BNT–BT–KNbO 3[10,11],and BNT–Bi 1/2K 1/2TiO 3–Bi 1/2Li 1/2TiO 3[12].It has been reported that the multi-component piezoelectric ceramics possess better piezoelectric performances than single or binary-component ceramics due to the more complex phase structure in multi-component lead-base piezoelectric ceramics.From the liter-ature mentioned as above,it can also be found that the ternary sys-tems have superior piezoelectric response to the single or binary systems in BNT-based ceramics.Many compounds have been added to BNT–BT to improve its piezoelectric response.However,it seems to be a contradiction between the piezoelectric performances and depolarization tem-perature in BNT-based ceramics.The depolarization temperature reduces sharply with the substitution.It even decreases to ambient temperature,such as BNT–BT–Ag 0.9Li 0.1NbO 3[13],BNT–BT–Bi 1/2Ag 1/2TiO 3[14],BNT–BT–La 1/2Na 1/2TiO 3[15]BNT–BT–K 1/2Na 1/2NbO 3[16,17].Therefore,it is necessary to search a substi-tution to improve the piezoelectric response of BNT–BT ceramics;meanwhile,the depolarization temperature of the ceramics doesn’t reduce.(1Àx )BNT–x BT ceramics with x =0.06–0.07have a large pie-zoelectric response [2,18,19],and 0.94BNT–0.06BT (Bi 0.47Na 0.47Ba 0.06TiO 3)is the optimized composition for a large piezoelectric re-sponse in (1Àx )BNT–x BT solid solution [3,18].Therefore,Bi 0.47Na 0.47Ba 0.06TiO 3(BNBT)is chosen as a basic chemical formula in this work.On the other hand,Ba 0.77Ca 0.23TiO 3(BCT)is tetragonal phase at room temperature.It is also a promising candidate of lead-free piezoelectric material due to its large electrostriction and piezo-electric response [20].BCT combined with Ba(Ti 0.8Zr 0.2)O 3is used to synthesize solid solution Ba(Ti 0.8Zr 0.2)O 3–BCT,and its piezoelec-tric coefficient d 33reaches a ultrahigh value of $620pC/N [21].In this study,the mole ratio of BNT/BT is set as 0.94/0.06,and BCT is chosen as the third component to modify the electrical prop-erties of BNT–BT–Ba 0.77Ca 0.23TiO 3.The chemical formula of ternary system ceramics is written as (1Àx )Bi 0.47Na 0.47Ba 0.06TiO 3–x Ba 0.77-Ca 0.23TiO 3(BNBT–x BCT,x =0–0.12).In the current work,BNBT–x BCT ceramics are prepared by a conventional ceramic technique.0925-8388/$-see front matter Published by Elsevier B.V./10.1016/j.jallcom.2012.05.017Corresponding author.Tel.:+8657487600953;fax:+8657487600744.E-mail address:llhsic@ (L.Luo).The microstructure,ferroelectricity,piezoelectric properties and depolarization mechanism of the ternary system ceramics were investigated and discussed.2.ExperimentalBNBT–x BCT(x=0,0.005,0.01,0.02,0.04,0.06,0.12)prepared by a conventional ceramic fabrication technique.ders:Bi2O3(99.9%),Na2CO3(99.8%),BaCO3(99%),TiOused as starting raw materials.The powders in the stoichiometricin alcohol with agate balls for10h,and then dried andThe calcined powders were reground by ball milling forders were sieved and mixed thoroughly with a PVA binderially pressed into disk samples with a pressure of$100then sintered at1100–1200°C for2h in air to form theSilver paste was pasted on both sides of the disc samplesorder to form electrodes.All specimens were poled underat80°C in silicone oil bath for30min,and then cooledthe polingfield.The crystal structure of the ceramicsfraction(XRD)analyzer(Bruker D8Advance)with Cutric coefficient d33of the samples was measuredmeter(ZJ-3AN,China).Dielectric constant e33and dielectricsamples as a function of temperature at10kHz,100kHzusing a computer-controlled impedance analyzer(Agilent4294A).The polarization vs.electricfield(P–E)hysteresis loop was obtained at1Hz with the RT Premier II ferroelectric workstation.The mechanical quality factor Q m and electromechanical coupling factors k p,k t were calculated using the resonance-antiresonance method with the impedance analyzer(Agilent4294A)according to the IEEE standard on piezoelectricity measurement.Fig.1.XRD patterns of BNBT–x BCT ceramics.Fig.2.P–E hysteresis loops of BNBT–x BCT:(a)x=0.00;(b)x=0.005;(c)x=0.01;(d)x=0.02;(e)x=0.04;(f)x=0.12.3.P r and E c as a function of the BCT content x for the BNBT–x BCT ceramics.3.Results and discussionsX-ray diffraction patterns are shown in Fig.1(a).Thefigure indi-cates that all the BNBT–x BCT ceramics have a pure perovskite structure and no detectable second phase is found,meaning that BCT has diffused into BNBT lattices to form a new solid solution BNBT–x BCT.Many reports in the literature assume the BNT as a rhombohedral phase following the investigation of Jones and Tho-mas[7,22].It is also reported that the symmetry of BNT should be monoclinic phase[23,24].When we come to BNT’s solid solution with BT,the symmetry of the solid solution becomes more com-plex.It is well known that the structure of these solid solutions is nothing but a cubic one at least within the resolution limit of dif-fraction techniques[25–28].A sufficient amount of electricfield can induce the cubic–tetragonal phase transition[29,30].The phase of BNBT can be seen as pseudocubic phase within the sensitivity of XRD at room temperature,meanwhile,BCT is tetrag-onal.It is reasonable to infer that the structure of BNBT–x BCT will transform from pseudocubic phase to tetragonal phase with the increment of BCT content.Fig.1(b)is the XRD patterns in Fig.1(a)with the2h angle ranging from43°to51°.Only one (200)pc peak is observed in the diffraction patterns when the BCT content x is0.00,0.005,and0.01,implying that BNBT–0.00BCT,BNBT–0.005BCT and BNBT–0.01BCT are pseudocubic phase.With the increment of BCT,(200)pc peak splits to(200) and(002)peaks,suggesting that the ceramics transform from pseudocubic phase to tetragonal phase when x P0.02.Fig.2shows the P–E hysteresis loops of BNBT–x BCT ceramics 30°C.It is found that well saturated and square-like loops obtained for ceramics BNBT–0.00BCT,BNBT–0.005BCT and0.01BCT.As shown in Fig.2(a),the remnant polarization coercivefield E c of BNBT–0.00BCT ceramic reach30.5l C/cm28kV/cm,respectively.Remnant polarization P r=36l C/cm coercivefield E c=24.5kV/cm are obtained for BNBT–0.01BCT.Fig.4(a)presents the piezoelectric coefficient d33and electro-mechanical coupling factor k t of BNBT–x BCT ceramics as a function of BCT content x.d33and k t increase sharply as x increases,and then decrease when x P0.02due to the appearance of tetragonal phase.As Fig.4(a)shows,BNBT–0.01BCT ceramic owns a high pie-zoelectric response:d33=178pC/N,k t=50%.The significant enhancement in piezoelectricity of the BNBT–0.01BCT ceramics should be attributed to the appearance of more complex phase structure in the as-prepared ceramics.Fig.4(b)shows the dielectric constant e33and dielectric loss tan d measured at1kHz for BNBT–x BCT ceramics.It can be observed that the behaviors of e33and tan d as a function of BCT content x are analogous to each other, and the maximum values(e33=1121and tan d=0.0330)are obtained at x=0.02and0.06,respectively.Fig.5presents the mechanical quality factor Q m and the planar electromechanical coupling factor k p of BNBT–x BCT ceramics.Both the mechanical quality factor Q m and planar electromechanical coupling factor k p of the ceramics decrease with BCT content.Q m and k p of BNBT–0.01BCT ceramic reach131and27%,respectively.Fig.6shows the temperature dependences of dielectric con-stant e33and dielectric loss tan d for the poled BNBT–x BCT ceramics with x=0,0.01,0.02,0.04,0.06and0.12at10,100and1MHz.As marked in Fig.6(a)-(f),two dielectric anomalies can be observed at T d and T m.T d is corresponding to the depolarization temperature, which can be obtained from the temperature at which thefirst peak of dielectric loss tan d is obtained.When BNBT–x BCT ceramics are heated to the temperature above T d,the piezoelectric response of the samples disappears.Fig.6shows that e33and tan d are dependent on the test frequency near T d.However,T d isPiezoelectric coefficient d33and electromechanical coupling factor k t of BNBT–x BCT ceramics as a function of BCT content x.(b)Dielectric constant e33and of BNBT–x BCT ceramics measured at1kHz.5.Planar electromechanical coupling factor k p and mechanical quality factorof BNBT–x BCT ceramics as a function of BCT content x.independent on the test frequency.T m is corresponding to perature,at which a maximum e 33at 10kHz is obtained.ceramics exhibit a relatively broad dielectric peaks near BNBT–0.00BCT ceramic,a sharp increment of the e 33and tan 107°C is observed,which is attributed to the occurring of ization.At temperature higher than T d ,dielectric constant creases gradually with temperature and reaches the maximum value at temperature T m =270°C.In addition,after a sharp ment of e 33with temperature,an obvious relaxor-like can be observed above T d (Fig.6(a)).As the increment of BCT tent,the phase transition near T d becomes less steep.T d and function of BCT content x is shown in Fig.7.With moderate tution of BCT,both T d and T m of BNBT–x BCT vary a little x .Depolarization temperature T d is critical for piezoelectric vices;a high T d is very significant for the temperature stability piezoelectric devices.T d of BNBT–0.01BCT is 108°C;meanwhile,Temperature dependences of e 33and tan d for the BNBT–x BCT ceramics at 10kHz,100kHz and 1MHz:(a)x =0.00;(b)x =0.01;(c)x =0.02;(d)x =0.04;(e)Fig.7.T d and T m as function of BCT content x .T d of BNBT–0.00BCT is107°C.However,the piezoelectric response of BNBT–0.01BCT is much larger than that of BNBT–0.00BCT.It is highly significant to improve the piezoelectric response without the decrement of the depolarization temperature.The depolariza-tion temperature T d observed here is much higher than the values obtained in BNT–BT–Ag0.9Li0.1NbO3[13],BNT–BT–Bi1/2Ag1/2TiO3and BNT–BT–La1/2Na1/2TiO3[15].In the present study,T d increases sharply with x when x P0.02,and T d of BNBT–0.12BCT reaches164°C.The improvement of T d is related to the develop-temperature,which is consistent with the steep variation of e33 and tan d with temperature near T d,as shown in Fig.6(a).For BNBT–0.06BCT,k p increases little as temperature increases to 120°C.At above120°C,it begins to reduce with temperature.As shown in Fig.8,k p of BNBT–0.06BCT is nearly independent on tem-perature at below120°C.The slope of k p vs.temperature during depolarization for BNBT–0.06BCT is not as steep as that of BNBT–0.00BCT.The results are consistent with the dielectric constant vs.temperature measurement,as shown in Fig.6.The piezoelectric response in ferroelectrics has been attributed to:(1)intrinsic pie-zoelectric response of the ferroelectric lattice;(2)domain move-ment[31,32]:domain moves more easily at higher temperature due to the softening of the Young’s modulus;(3)the phase transi-tion between rhombohedral phase and tetragonal phase,and it is easier to occur at higher temperature near MPB[21,33],which brings a high piezoelectric response.Due to being far away from MPB,there is no contribution to the piezoelectric response from the phase transition between rhombohedral phase and tetragonal phase for BNBT–0.06BCT.In a word,the piezoelectric performances of BNBT–0.06BCT might be mainly from the intrinsic contribution of lattice.However,the phase transition may contribute to the pie-zoelectric response of BNBT–0.00BCT and BNBT–0.01BCT ceramics due to their large dependence of k p on temperature.The P–E hysteresis loops of the BNBT–x BCT ceramics with x=0, 0.01and0.06at different temperature are presented in Fig.9.Allk p as a function of temperature for the BNBT–x BCT ceramics with xand0.06.Fig.9.P–E hysteresis loops of the BNBT–x BCT ceramics at different temperature:(a)x=0.00;(b)x=0.01;(c)x=0.06.Compounds536(2012)113–1181170.01BCT and BNBT–0.06BCT exhibit similar temperature depen-dence of the ferroelectric properties,being similar to the ceramic BNBT–0.00BCT.What occurs near T d?The researchers have different opinions on the depolarization mechanism near T d.Some researchers consider that phase transition from a ferroelectric phase to an antiferroelec-tric phase occurs near T d in BNT-based lead-free piezoelectric ceramics due to the appearance of a constricted hysteresis loop near T d[2,34,35],and a large strain induced by the antiferroelectric-fer-roelectric transition[34,35].However,experiments such as X-ray diffraction,Raman and neutron scattering do not support the exis-tence of anti-ferroelectric phase above T d in BNT-based ceramic [36,37].The appearance of the constricted hysteresis loop is consid-ered as a concrete proof of ferroelectric-antiferroelectric transition. However,constricted hysteresis loop is common in relaxor ferro-electrics even in normal ferroelectrics[38,39].Some researchers consider that macro–micro domain transition occurs near T d in BNT-based ferroelectrics[3,7,40].Some researchers roughly pro-pose that it is polar-nonpolar region transition at T d in BNT-based ceramics[11,13–15].Recently,some scientists[41,42]alleged that long-range ferroelectric phase and ergodic relaxor phase coexist nearly throughout the entire temperature range and reversibly transform into each other with temperature in the relaxor BNT-based ceramics.Sapper et al.think that depolarization during heat-ing occurs before long-range ferroelectric order breaks[43].4.ConclusionIn conclusion,we have successfully prepared lead-free piezo-electric BNBT–x BCT ceramics by a conventional ceramic technique. BNBT–0.01BCT ceramic exhibits excellent piezoelectric properties and strong ferroelectricity:piezoelectric coefficient d33=178pC/ N;electromechanical coupling factors k t=50%and k p=27%;quality factor Q m=131;remnant polarization P r=36l C/cm2;coercivefield E c=24.5kV/cm.Piezoelectric properties and ferroelectricity of BNBT–0.01BCT ceramic are much better than those of BNBT due to its more complex phase structure.The piezoelectric response of BNBT-0.01BCT ceramics increases with temperature before depolarization.Furthermore,depolarization temperature T d of BNBT–0.01BCT ceramic is as high as that of BNBT,achieving 108°C.The P–E loops of the prepared ceramics at different temper-ature are investigated;however,the exact depolarization mechanism is not obtained.The depolarization mechanism of BNT-based ceramics is still open.AcknowledgmentsThis work was supported by the National Natural Science Foun-dation of China(51002082,11004113),Natural Science Foundation of Zhejiang Province(Y4090057),Natural Science Foundation of Ningbo(2009A610016,201201A6105044),the Outstanding(Post-graduate)Dissertation Growth Fundation of Ningbo University (PY20110011)and the K.C.Wong Magna Foundation in Ningbo University(XYL10012,xkz11203).References[1]Y.Saito,H.Takao,T.Tani,T.Nonoyama,K.Takatori,T.Homma,T.Nagaya,M.Nakamura,Nature432(2004)84–87.[2]T.Takenaka,K.Maruyama,K.Sakata,Jpn.J.Appl.Phys.30(1991)2236.[3]B.Chu,D.Chen,G.Li,Q.Yin,J.Eur.Ceram.Soc.22(2002)2115.[4]X.Zhou,H.Gu,Y.Wang,W.Li,T.Zhou,Mater.Lett.59(2005)1649.[5]I.Makoto,Y.Katsuya,S.Muneyasu,N.Yuji,M.Masaru,Appl.Phys.Lett.93(2008)903.[6]A.Sasaki,T.Chiba,Y.Mamiya,E.Otsuki,Jpn.J.Appl.Phys.38(1999)5564.[7]G.Fan,W.Lu,X.Wang,F.Liang,J.Xiao,J.Phys.D:Appl.Phys.41(2008)035403.[8]D.Lin,D.Xiao,J.Zhu,P.Yu,J.Eur.Ceram.Soc.26(2006)3247.[9]H.Ishii,H.Nagata,T.Takenaka,Jpn.J.Appl.Phys.40(2001)5560.[10]H.Ni,L.H.Luo,W.P.Li,Y.J.Zhu,H.S.Luo,J.Alloys Compd.509(2011)3958–3962.[11]J.M.Li,F.F.Wang,X.M.Qin,M.Xu,W.Z.Shi,Appl.Phys.A-Mater.10.1007/s00339-010-6074-5.[12]D.Lin,Q.Zhen,C.Xu,K.W.Kwok,Appl.Phys.A-Mater.93(2008)549–558.[13]L.Wu,N.Liu,F.Zhou,W.Wu,Y.Teng,Y.Li,J.Alloys Compd.507(2010)479–483.[14]L.Wu,D.Xiao,F.Zhou,Y.Teng,Y.Li,J.Alloys Compd.509(2011)466–470.[15]Q.Zheng,C.Xu,D.Lin,D.Gao,K.W.Kwok,J.Phys.D:Appl.Phys.41(2008)125411.[16]S.Zhang,A.B.Kounga,E.Aulbach,H.Ehrenberg,J.Rödel,Appl.Phys.Lett.91(2007)112906.[17]S.Zhang,A.B.Kounga,E.Aulbach,T.Granzow,W.Jo,H.Kleebe,J.Rödel,J.Appl.Phys.103(2008)034107.[18]G.Xu,Z.Duan,X.Wang,D.Yang,J.Cryst.Growth275(2005)113.[19]A.Herabut,A.Safari,J.Am.Ceram.Soc.80(1997)2954.[20]X.Wang,H.Yamada,C.Xu,Appl.Phys.Lett.86(2005)022905.[21]W.Liu,X.B.Ren,Phys.Rev.Lett.103(2009)257602.[22]G.O.Jones,P.A.Thomas,Acta.Cryst.B58(2002)168.[23]S.Gorfman,P.A.Thomas,J.Appl.Cryst.43(2010)1409.[24]E.Aksel,J.S.Forrester,J.L.Jones,et al.,Appl.Phys.Lett.98(2011)152901.[25]R.Ranjan,A.Dviwedi,Solid State Commun.135(2005)394.[26]W.Jo,J.E.Daniels,J.L.Jones,et al.,J.Appl.Phys.109(2011)014110.[27]K.T.P.Seifert,W.Jo,J.Rödel,J.Am.Ceram.Soc.93(2010)1392.[28]J.E.Daniels,W.Jo,J.Rödel,et al.,Acta Mater.58(2010)2103.[29]W.Jo,J.Rödel,et al.,Appl.Phys.Lett.99(2011)042901.[30]J.E.Daniels,W.Jo,J.Rödel,J.L.Jones,Appl.Phys.Lett.95(2009)032904.[31]Q.Zhang,H.Wang,N.Kim,L.E.Cross,J.Appl.Phys.75(1994)454–459.[32]S.-E.Park,T.-R.Shrout,J.Appl.Phys.82(1997)1804.[33]D.Viehland,J.Li,A.Amin,J.Appl.Phys.92(2002)3985.[34]Y.Guo,M.Gu,H.Luo,Y.Liu,R.L.Withers,Phys.Rev.B83(2011)054118.[35]Y.Guo,Y.Liu,R.L.Withers,F.Brink,H.a Chen,Chem.Mater.23(2011)219–228.[36]J.A.Zvirgzds,P.P.Kapostins,J.V.Zvirgde,T.V.Kruzina,Ferroelectrics40(1982)75–77.[37]M.S.Zhang,J.F.Scott,Ferroelectr.Lett.6(1986)147–152.[38]X.Ren,Nat.Mater.3(2004)91–94.[39]Z.Feng,X.Ren,Phys.Rev.B77(2008)134115.[40]Q.Zhang,X.Zhao,R.Sun,H.Luo,Phys.Status Solidi A208(2011)1012–1020.[41]W.Jo,S.Suhaab,E.Sapper,L.Schumitt,H.J.Kleebe,A.Bell,J.Rödel,J.Appl.Phys.110(2011)074106.[42]V.V.Shvartsman,D.C.Lupascu,J.Am.Ceram.Soc.95(2012)1–26.[43]E.Sapper,S.Schaab,W.Jo,T.Granzow,J.Rödel,J.Appl.Phys.111(2012)014105.118L.Luo et al./Journal of Alloys and Compounds536(2012)113–118。