光耦型号文档

- 格式:docx

- 大小:13.32 KB

- 文档页数:5

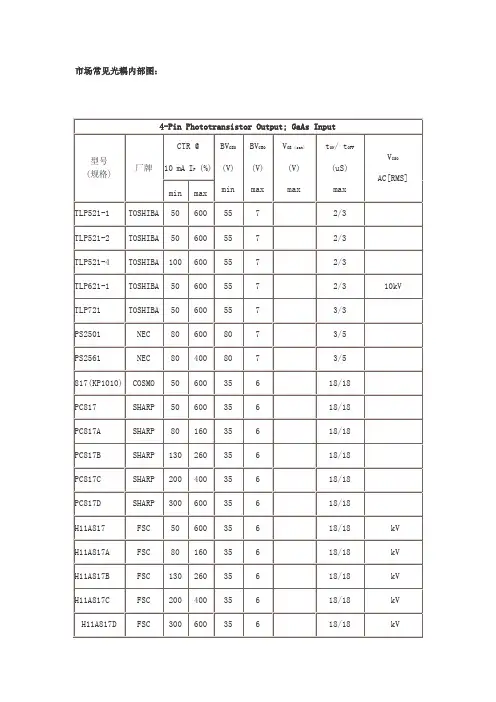

市场常见光耦内部图:光电耦合器(简称光耦)是开关电源电路中常用的器件。

光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

常用的4N系列光耦属于非线性光耦常用的线性光耦是PC817A—C系列。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于弄开关信号的传输,不适合于传输模拟量。

线性光耦的电流传输手特性曲线接进直线,并且小信号时性能较好,能以线性特性进行隔离控制。

开关电源中常用的光耦是线性光耦。

如果使用非线性光耦,有可能使振荡波形变坏,严重时出现寄生振荡,使数千赫的振荡频率被数十到数百赫的低频振荡依次为号调制。

由此产生的后果是对彩电,彩显,VCD,DCD等等,将在图像画面上产生干扰。

同时电源带负载能力下降。

在彩电,显示器等开关电源维修中如果光耦损坏,一定要用线性光耦代换。

常用的4脚线性光耦有PC817A----C。

PC111 TLP521等常用的六脚线性光耦有:TLP632 TLP532 PC614 PC714 PS2031等。

常用的4N25 4N26 4N35 4N36是不适合用于开关电源中的,因为这4种光耦均属于非线性光耦。

以下是目前市场上常见的高速光藕型号:100K bit/S:6N138、6N139、PS87031M bit/S:6N135、6N136、CNW135、CNW136、PS8601、PS8602、PS8701、PS9613、PS9713、CNW4502、HCPL-2503、HCPL-4502、HCPL-2530(双路)、HCPL-2531(双路)10M bit/S:6N137、PS9614、PS9714、PS9611、PS9715、HCPL-2601、HCPL-2611、HCPL-2630(双路)、HCPL-2631(双路)光耦合器的增益被称为晶体管输出器件的电流传输比 (CTR),其定义是光电晶体管集电极电流与LED正向电流的比率(ICE/IF)。

光电晶体管集电极电流与VCE有关,即集电极和发射极之间的电压。

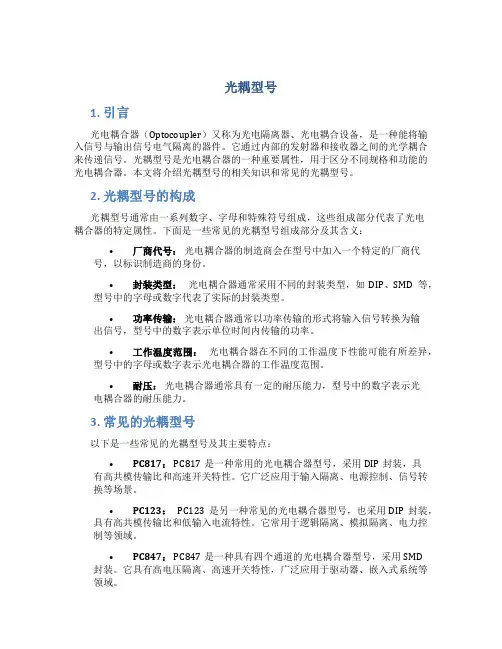

光耦型号1. 引言光电耦合器(Optocoupler)又称为光电隔离器、光电耦合设备,是一种能将输入信号与输出信号电气隔离的器件。

它通过内部的发射器和接收器之间的光学耦合来传递信号。

光耦型号是光电耦合器的一种重要属性,用于区分不同规格和功能的光电耦合器。

本文将介绍光耦型号的相关知识和常见的光耦型号。

2. 光耦型号的构成光耦型号通常由一系列数字、字母和特殊符号组成,这些组成部分代表了光电耦合器的特定属性。

下面是一些常见的光耦型号组成部分及其含义:•厂商代号:光电耦合器的制造商会在型号中加入一个特定的厂商代号,以标识制造商的身份。

•封装类型:光电耦合器通常采用不同的封装类型,如DIP、SMD等,型号中的字母或数字代表了实际的封装类型。

•功率传输:光电耦合器通常以功率传输的形式将输入信号转换为输出信号,型号中的数字表示单位时间内传输的功率。

•工作温度范围:光电耦合器在不同的工作温度下性能可能有所差异,型号中的字母或数字表示光电耦合器的工作温度范围。

•耐压:光电耦合器通常具有一定的耐压能力,型号中的数字表示光电耦合器的耐压能力。

3. 常见的光耦型号以下是一些常见的光耦型号及其主要特点:•PC817: PC817是一种常用的光电耦合器型号,采用DIP封装,具有高共模传输比和高速开关特性。

它广泛应用于输入隔离、电源控制、信号转换等场景。

•PC123:PC123是另一种常见的光电耦合器型号,也采用DIP封装,具有高共模传输比和低输入电流特性。

它常用于逻辑隔离、模拟隔离、电力控制等领域。

•PC847: PC847是一种具有四个通道的光电耦合器型号,采用SMD 封装。

它具有高电压隔离、高速开关特性,广泛应用于驱动器、嵌入式系统等领域。

4. 如何选择适合的光耦型号选择适合的光耦型号需要根据具体的应用需求和性能要求进行评估。

以下是一些选择光耦型号的要点:1.工作条件:确定光电耦合器需要在什么样的工作条件下运行,包括工作温度范围、耐压能力等。

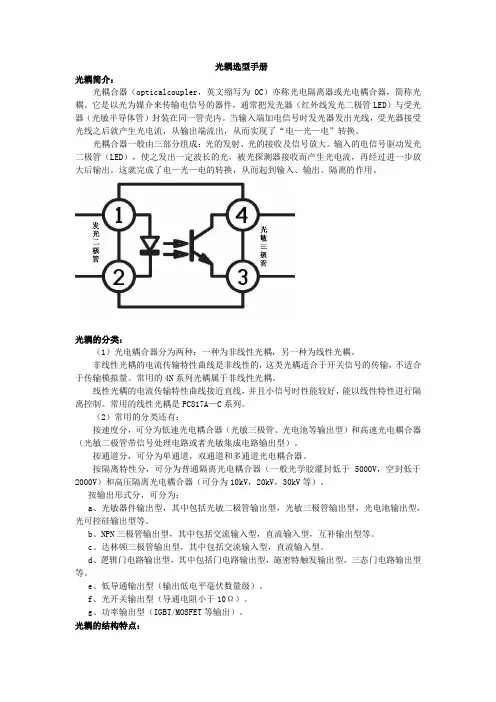

光耦选型手册光耦简介:光耦合器(opticalcoupler,英文缩写为OC)亦称光电隔离器或光电耦合器,简称光耦。

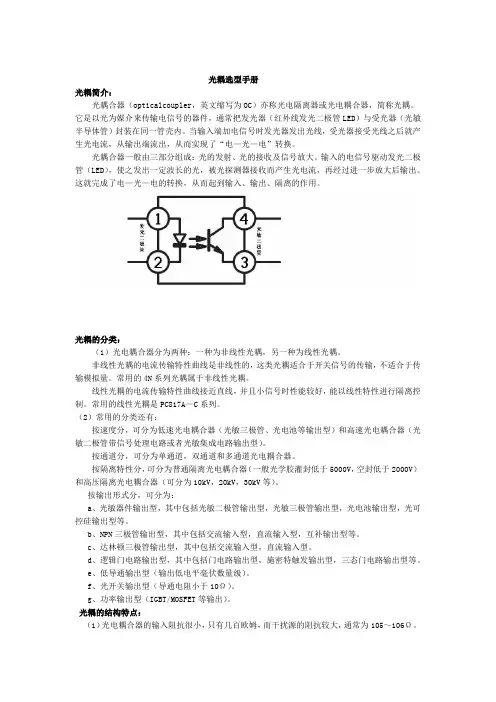

它是以光为媒介来传输电信号的器件,通常把发光器(红外线发光二极管LED)与受光器(光敏半导体管)封装在同一管壳内。

当输入端加电信号时发光器发出光线,受光器接受光线之后就产生光电流,从输出端流出,从而实现了“电—光—电”转换。

光耦合器一般由三部分组成:光的发射、光的接收及信号放大。

输入的电信号驱动发光二极管(LED),使之发出一定波长的光,被光探测器接收而产生光电流,再经过进一步放大后输出。

这就完成了电—光—电的转换,从而起到输入、输出、隔离的作用。

光耦的分类:(1)光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于开关信号的传输,不适合于传输模拟量。

常用的4N系列光耦属于非线性光耦。

线性光耦的电流传输特性曲线接近直线,并且小信号时性能较好,能以线性特性进行隔离控制。

常用的线性光耦是PC817A—C系列。

(2)常用的分类还有:按速度分,可分为低速光电耦合器(光敏三极管、光电池等输出型)和高速光电耦合器(光敏二极管带信号处理电路或者光敏集成电路输出型)。

按通道分,可分为单通道,双通道和多通道光电耦合器。

按隔离特性分,可分为普通隔离光电耦合器(一般光学胶灌封低于5000V,空封低于2000V)和高压隔离光电耦合器(可分为10kV,20kV,30kV等)。

按输出形式分,可分为:a、光敏器件输出型,其中包括光敏二极管输出型,光敏三极管输出型,光电池输出型,光可控硅输出型等。

b、NPN三极管输出型,其中包括交流输入型,直流输入型,互补输出型等。

c、达林顿三极管输出型,其中包括交流输入型,直流输入型。

d、逻辑门电路输出型,其中包括门电路输出型,施密特触发输出型,三态门电路输出型等。

e、低导通输出型(输出低电平毫伏数量级)。

f、光开关输出型(导通电阻小于10Ω)。

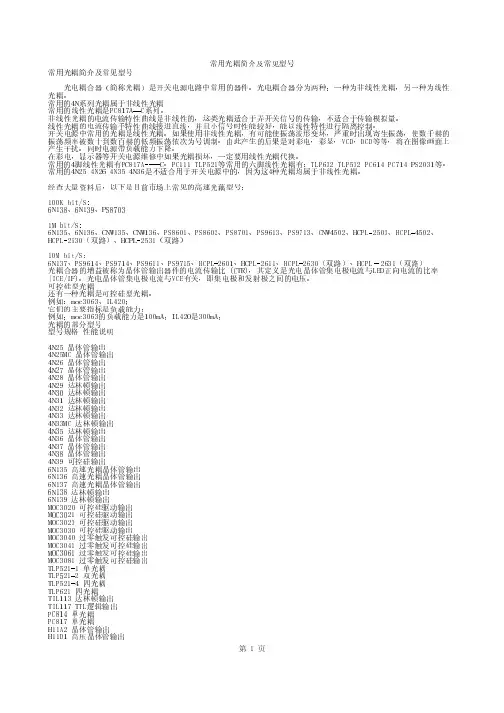

常用光耦简介及常见型号常用光耦简介及常见型号光电耦合器(简称光耦)是开关电源电路中常用的器件。

光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

常用的4N系列光耦属于非线性光耦常用的线性光耦是PC817A—C系列。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于弄开关信号的传输,不适合于传输模拟量。

线性光耦的电流传输手特性曲线接进直线,并且小信号时性能较好,能以线性特性进行隔离控制。

开关电源中常用的光耦是线性光耦。

如果使用非线性光耦,有可能使振荡波形变坏,严重时出现寄生振荡,使数千赫的振荡频率被数十到数百赫的低频振荡依次为号调制。

由此产生的后果是对彩电,彩显,VCD,DCD等等,将在图像画面上产生干扰。

同时电源带负载能力下降。

在彩电,显示器等开关电源维修中如果光耦损坏,一定要用线性光耦代换。

常用的4脚线性光耦有PC817A----C。

PC111 TLP521等常用的六脚线性光耦有:TLP632 TLP532 PC614 PC714 PS2031等。

常用的4N25 4N26 4N35 4N36是不适合用于开关电源中的,因为这4种光耦均属于非线性光耦。

经查大量资料后,以下是目前市场上常见的高速光藕型号:100K bit/S:6N138、6N139、PS87031M bit/S:6N135、6N136、CNW135、CNW136、PS8601、PS8602、PS8701、PS9613、PS9713、CNW4502、HCPL-2503、HCPL-4502、HCPL-2530(双路)、HCPL-2531(双路)10M bit/S:6N137、PS9614、PS9714、PS9611、PS9715、HCPL-2601、HCPL-2611、HCPL-2630(双路)、HCPL-2631(双路)光耦合器的增益被称为晶体管输出器件的电流传输比 (CTR),其定义是光电晶体管集电极电流与LED正向电流的比率(ICE/IF)。

光耦选型手册光耦简介:光耦合器(opticalcoupler,英文缩写为OC)亦称光电隔离器或光电耦合器,简称光耦。

它是以光为媒介来传输电信号的器件,通常把发光器(红外线发光二极管LED)与受光器(光敏半导体管)封装在同一管壳内。

当输入端加电信号时发光器发出光线,受光器接受光线之后就产生光电流,从输出端流出,从而实现了“电—光—电”转换。

光耦合器一般由三部分组成:光的发射、光的接收及信号放大。

输入的电信号驱动发光二极管(LED),使之发出一定波长的光,被光探测器接收而产生光电流,再经过进一步放大后输出。

这就完成了电—光—电的转换,从而起到输入、输出、隔离的作用。

光耦的分类:(1)光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于开关信号的传输,不适合于传输模拟量。

常用的4N系列光耦属于非线性光耦。

线性光耦的电流传输特性曲线接近直线,并且小信号时性能较好,能以线性特性进行隔离控制。

常用的线性光耦是PC817A—C系列。

(2)常用的分类还有:按速度分,可分为低速光电耦合器(光敏三极管、光电池等输出型)和高速光电耦合器(光敏二极管带信号处理电路或者光敏集成电路输出型)。

按通道分,可分为单通道,双通道和多通道光电耦合器。

按隔离特性分,可分为普通隔离光电耦合器(一般光学胶灌封低于5000V,空封低于2000V)和高压隔离光电耦合器(可分为10kV,20kV,30kV等)。

按输出形式分,可分为:a、光敏器件输出型,其中包括光敏二极管输出型,光敏三极管输出型,光电池输出型,光可控硅输出型等。

b、NPN三极管输出型,其中包括交流输入型,直流输入型,互补输出型等。

c、达林顿三极管输出型,其中包括交流输入型,直流输入型。

d、逻辑门电路输出型,其中包括门电路输出型,施密特触发输出型,三态门电路输出型等。

e、低导通输出型(输出低电平毫伏数量级)。

f、光开关输出型(导通电阻小于10Ω)。

TLP521是可控制的光电藕合器件,光电耦合器广泛作用在电脑终端机,可控硅系统设备,测量仪器,影印机,自动售票,家用电器,如风扇,加热器等电路之间的信号传输,使之前端与负载完全隔离,目的在于增加安全性,减小电路干扰,减化电路设计。

东芝TLP521-1,-2和-4组成的砷化镓红外发光二极管耦合到光三极管。

该TLP521-2提供了两个孤立的光耦8引脚塑料封装,而TLP521-4提供了4个孤立的光耦中16引脚塑料DIP封装集电极-发射极电压:55V(最小值)经常转移的比例:50 %(最小)隔离电压:2500 Vrms (最小)图1 TLP521 TLP521-2 TLP521-4 光藕内部结构图及引脚图图2 TLP521-2 光电耦合器引脚排列图Absolute Maximum Ratings 绝对最大额定值(Ta = 25℃)Characteristic 参数Symbol符号Rating 数值TLP521−1TLP521−2TLP521−4注:使用连续负载很重的情况下(如高温/电流/温度/电压和重大变化等),可能会导致本产品的可靠性下降明显甚至损坏。

*1: Ex. rank GB: TLP521−1 (GB)(Note): Application type name for certification test, please use standard product type name, i.e.TLP521−1 (GB): TLP521−1, TLP521−2 (GB): TLP521−2Individual Electrical Characteristic 单独的电气特性参数(Ta = 25℃)Coupled Electrical Characteristic 耦合电气特性参数s (Ta = 25℃)图3 TLP521-1 封装图图4 TLP521-2 封装图图5 TLP521-4 封装图图6 开关时间测试电路特性曲线图:应用电路:图7 打开或关闭12V直流电动机的TTL控制信号输入电路图。

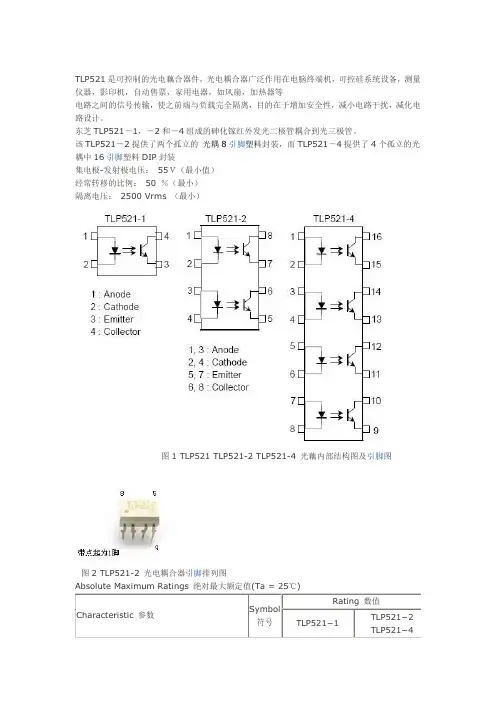

产品规格书Specification Sheet品名(P/N):光电耦合器Photocoupler客户名称(Customer):本厂型号(Mfg P/N):OR-10XX日期(Date):深圳市奥伦德科技股份有限公司(股票代码:832016)Shenzhen Orient Tech Ltd.Co(Ticker Symbol:832016)Web:地址:广东深圳龙岗区黄阁路天安数码城4栋3楼A座518172Add:Block A3rd Floor No.4Building Tian'an Cyber Park Huangge Rd,LongGang Dist,Shenzhen,GD,518172版本版次:A/3●特点(Features)1.电流转换比(CTR:MIN.50%at IF=5mA,VCE=5V,Ta=25℃)2.绝缘电压:(VISO=5,000Vrms)3.高集电极发射极电压(VCEO=70V)4.温度范围:-55℃to110℃5.长爬电距离:>8mm,无铅,符合RoHS标准。

6.CQC approved(No.15801-CQC001041-201800042)7.VDE approved(No.40029733)●说明描述该OR-10XX系列器件包含一个红外发光二极管,光电晶体管探测器。

不含卤素和Sb2O3.它们封装在一个4引脚SOP里面。

●应用范围(Application Range)•可编程控制器•系统设备,测量仪器•电信设备•家用电器,如风扇加热器等。

•不同的电势和阻抗的电路之间的信号传输●最大绝对额定值(常温T=25℃)Max Absolute rated Value(Normal Temperature=25℃)参数Parameter符号Symbol额定值Rated Value单位Unit输入Input 正向电流(Forward Current)I F60mA 结区温度(Junction Temperature)T J125℃逆向电压(Reverse Voltage)V R6V 耗散功率(Consume Power)P100mW输出Output 集极与射极电压(Collector and emitter Voltage)V CEO70V 射极与集极电压(Emitter and collector Voltage)V ECO7集极电流(Collector Current)I C50mA 消耗功率(Consume Power)P C150mW总功率消耗(Total Consume Power)P tot250mW *1绝缘电压(Insulation Voltage)V iso5000Vrms 工作温度(Working Temperature)Topr-55to+110℃存贮温度(Deposit Temperature)T stg-55to+125*2焊锡温度(Soldering Temperature)T sol260*1.交流测试,时间1分钟,湿度.=40~60%AC Test,1minute,humidity=40~60%如下是绝缘测试的方法.Insulation test method as below:(1)将产品的两端短路。

高速光耦型号大全(转贴)默认分类 2009-03-30 11:04 阅读2507 评论5 字号:大大中中小小光电耦合器(简称光耦)是开关电源电路中常用的器件。

光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

常用的4N系列光耦属于非线性光耦常用的线性光耦是PC817A—C系列。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于弄开关信号的传输,不适合于传输模拟量。

线性光耦的电流传输手特性曲线接进直线,并且小信号时性能较好,能以线性特性进行隔离控制。

开关电源中常用的光耦是线性光耦。

如果使用非线性光耦,有可能使振荡波形变坏,严重时出现寄生振荡,使数千赫的振荡频率被数十到数百赫的低频振荡依次为号调制。

由此产生的后果是对彩电,彩显,VCD,DCD等等,将在图像画面上产生干扰。

同时电源带负载能力下降。

在彩电,显示器等开关电源维修中如果光耦损坏,一定要用线性光耦代换。

常用的4脚线性光耦有PC817A----C。

PC111 TLP521等常用的六脚线性光耦有:TLP632 TLP532 PC614 PC714 PS2031等。

常用的4N25 4N26 4N35 4N36是不适合用于开关电源中的,因为这4种光耦均属于非线性光耦。

以下是目前市场上常见的高速光藕型号:100K bit/S:6N138、6N139、PS87031M bit/S:6N135、6N136、CNW135、CNW136、PS8601、PS8602、PS8701、PS9613、PS9713、CNW4502、HCPL-2503、HCPL-4502、HCPL-2530(双路)、HCPL-2531(双路)10M bit/S:6N137、PS9614、PS9714、PS9611、PS9715、HCPL-2601、HCPL-2611、HCPL-2630(双路)、HCPL-2631(双路)光耦合器的增益被称为晶体管输出器件的电流传输比 (CTR),其定义是光电晶体管集电极电流与LED正向电流的比率(ICE/IF)。

14 光耦(HS816、HS816S)数据手册1.41. 引言本文档是关于HS816和HS816S光耦的数据手册。

光耦是一种用于在电路中隔离信号和控制电路的器件。

本手册将介绍光耦的特性、规格和应用示例。

2. 光耦特性2.1 光耦工作原理光耦是由光发射器和光接收器组成的。

光发射器将电信号转换成光信号,光接收器将光信号转换成电信号。

光发射器和光接收器之间通过光学隔离实现电气隔离。

2.2 HS816特性•高速传输:HS816支持高达10 Mbps的传输速率,适用于高速数据传输应用。

•低功耗:HS816的工作电流仅为10 mA,能够节省能源并降低电路发热。

•宽工作温度范围:HS816适用于-40℃至85℃的工作环境,能够适应各种温度条件。

•多通道选择:HS816提供多个通道选择,可满足不同应用的需求。

•高精度:HS816S采用高精度的光学隔离技术,保证信号的准确传输。

•高稳定性:HS816S具有较高的抗干扰能力和稳定性,可以保证信号的可靠传输。

•小封装:HS816S采用紧凑的封装,适合在空间有限的电路板上使用。

3. 光耦规格3.1 HS816规格参数值传输速率10 Mbps工作电流10 mA工作温度范围-40℃至85℃通道选择多个通道参数值传输速率10 Mbps工作电流12 mA工作温度范围-40℃至85℃封装小封装4. 光耦应用示例4.1 隔离电路光耦可用于隔离电路,将高压和低压电路进行隔离,保证安全性和稳定性。

光耦可以将输入信号隔离开,减少干扰和噪音。

4.2 数据传输光耦是一种常用的数据传输工具,可以将数字信号进行光传输,提供高速、稳定的数据传输性能。

例如,在工业控制系统中,光耦可以用于将控制信号从主控制器传输到执行器。

4.3 电力系统监测光耦可以用于电力系统监测,将高压电网和低压电路进行隔离。

通过光耦,可以实现电力系统状态的监测和保护。

5. 结论本文档介绍了HS816和HS816S光耦的特性、规格和应用示例。

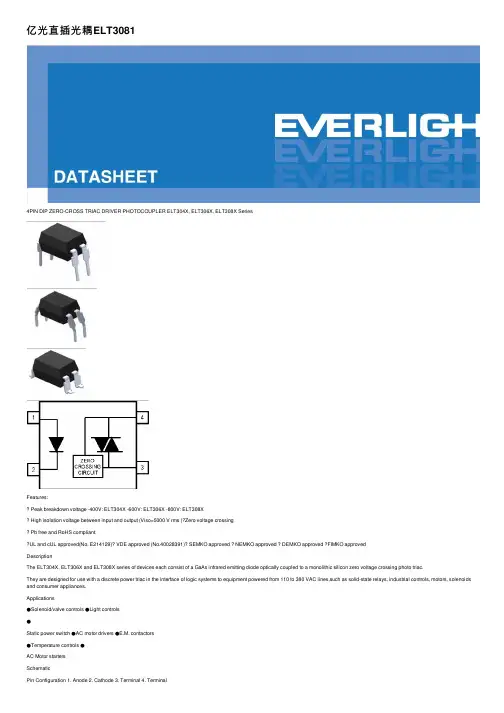

亿光直插光耦ELT30814PIN DIP ZERO-CROSS TRIAC DRIVER PHOTOCOUPLER ELT304X, ELT306X, ELT308X SeriesFeatures:Peak breakdown voltage -400V: ELT304X -600V: ELT306X -800V: ELT308XHigh isolation voltage between input and output (Viso=5000 V rms )Zero voltage crossingPb free and RoHS compliant.UL and cUL approved(No. E214129) VDE approved (No.40028391) SEMKO approved NEMKO approved DEMKO approved FIMKO approvedDescriptionThe ELT304X, ELT306X and ELT308X series of devices each consist of a GaAs infrared emitting diode optically coupled to a monolithic silicon zero voltage crossing photo triac.They are designed for use with a discrete power triac in the interface of logic systems to equipment powered from 110 to 380 VAC lines,such as solid-state relays, industrial controls, motors, solenoids and consumer appliances.Applications●Solenoid/valve controls ●Light controls●Static power switch ●AC motor drivers ●E.M. contactors●Temperature controls ●AC Motor startersSchematicPin Configuration 1. Anode 2. Cathode 3. Terminal 4. TerminalAbsolute Maximum Ratings (Ta=25 )Parameter Symbol Rating Unit Input Forward current I F60mA Reverse voltage V R6VPower dissipation P D100mWOutputOff-state OutputTerminal Voltage ELT304XV DRM400V ELT306X600ELT308X800Peak Repetitive Surge Current I TSM1APower dissipation P C300mW Total power dissipation P TOT330mW Isolation voltage*1V ISO5000Vrms Operating temperature T OPR-55 to 100 Storage temperature T STG-55 to 125 Soldering Temperature*2T SOL260 Notes:*1AC for 1 minute, R.H.= 40 ~ 60% R.H. In this test, pins 1& 2 are shorted together, and pins3 & 4are shorted together. *2 For 10 secondsElectro-Optical Characteristics (Ta=25 unless specified otherwise)InputParameter Symbol Min.Typ.*Max.Unit Condition Forward Voltage V F-- 1.5V I F=30mA Reverse Leakage current I R--10µA V R=6V OutputParameter Symbol Min.Typ.*Max.Unit ConditionPeak Blocking Current ELT304XI DRM--100nA V DRM = Rated V DRMI F=0mAELT306XELT308X500Peak On-state Voltage V TM--3V I TM=100mA peak, I F=Rated I FTCritical Rate of Rise off-state Voltage ELT304XELT306Xdv/dt1000--V/µsV PEAK=Rated V DRM,I F=0 (Fig. 10)ELT308X600--Inhibit Voltage (MT1-MT2voltage above which devicewill not trigger)V INH--20V I F= Rated I FTLeakage in lnhibited State I DRM2--500µA I F= Rated I FT,V DRM=Rated V DRM, off stateTransfer CharacteristicsParameter Symbol Min.Typ.*Max.Unit ConditionLED Trigger Current ELT3041ELT3061ELT3081I FT--15mA Main terminal Voltage=3V ELT3042ELT3062ELT3082--10ELT3043ELT3063ELT3083--5Holding Current I H-280-µA * Typical values at T a= 25°CTypical Electro-Optical Characteristics CurvesFigure 10. Static dv/dt Test Circuit & WaveformMeasurement MethodThe high voltage pulse is set to the required V PEAK value and applied to the D.U.T. output side through the RC circuit above. LED current is not applied. The waveform V T is monitored using a x100 scope probe. By varying R TEST , the dv/dt (slope) is increased, until the D.U.T. is observed to trigger (waveform collapses). The dv/dt is then decreased until the D.U.T. stops triggering. At this point,τRC is recorded and the dv/dt calculated.For example, V PEAK = 600V for ELT306X series. The dv/dt value is calculated as follows:V PEAKApplied V T WaveformτRC0.632 x V PEAK0.63 x 600τRCdv/dt = = 378τRC0.632 x V PEAK τRCdv/dt =50 ?10 k ?D.U.T.R TESTHigh Voltage Pulse SourceC TEST V TA KT1T2Zero Crossing CircuitOrder InformationPart NumberELT304X(Y)(Z)-Vor ELT306X(Y)(Z)-Vor ELT308X(Y)(Z)-VNoteNoteX = Part No. (1, 2, or 3)Y = Lead form option (S, S1, M or none)Z = Tape and reel option (TA, TB, TU,TD or none).V=VDE safety approved optionOption Description Packing quantity None Standard DIP-4100units per tube M Wide lead bend(0.4 inch spacing)100units per tube S(TA)Surface mount lead form+ TA tape & reel option1000units per reel S(TB)Surface mount lead form+ TB tape & reel option1000units per reel S1(TA)Surface mount lead form (low profile) + TA tape & reel option1000 units per reel S1(TB)Surface mount lead form (low profile) + TB tape & reel option1000 units per reel S (TU)Surface mount lead form + TU tape & reel option1500units per reel S(TD)Surface mount lead form + TD tape & reel option1500units per reelS1(TU)Surface mount lead form (low profile) + TU tape & reel option1500units per reel S1(TD)Surface mount lead form (low profile) + TD tape & reel option1500 units per reelPackage Dimension(Dimensions in mm) Standard DIP TypeOption M TypeOption S TypeOption S1 TypeRecommended pad layout for surface mount leadformDevice MarkingNotes EL denotes EverlightT3083denotes Device Number Y denotes 1 digit Year code WWdenotes 2 digit Week code Vdenotes VDE optionT3083EL YWW VTape dimensionsDimension No.Po P1P2t W K Dimension(mm) 4.0±0.112.0±0.1 2.0±0.10.35±0.116.0±0.3 4.75±0.1Tape dimensionsDimension No.A B C D EF Dimension(mm)16.00±0.37.5±0.1 1.75±0.18.0±0.1 2.0±0.1 4.0±0.1Dimension No.G H I J K L Dimension(mm)1.55±0.0510.4±0.10.4±0.054.60±0.15.1±0.11.55±0.05Precautions for Use1. Soldering Condition1.1 (A) Maximum Body Case Temperature Profile for evaluation of Reflow ProfileNote: Reference: IPC/JEDEC J-STD-020DPreheatTemperature min (T smin) 150 °CTemperature max (T smax)200°CTime (T smin to T smax) (t s)60-120 secondsAverage ramp-up rate (T smax to T p) 3 °C/second maxOtherLiquidus Temperature (T L)217 °CTime above Liquidus Temperature (t L)60-100 secPeak Temperature (T P) 260°CTime within 5 °C of Actual Peak Temperature: T P-5°C 30 sRamp-Down Rate from Peak Temperature 6°C /second max.Time 25°C to peak temperature8 minutes max.Reflow times 3 times.DISCLAIMER1.Above specification may be changed without notice. EVERLIGHT will reserve authority on material change for abovespecification.2.When using this product, please observe the absolute maximum ratings and the instructions for using outlined in thesespecification sheets. EVERLIGHT assumes no responsibility for any damage resulting from use of the product which does not comply with the absolute maximum ratings and the instructions included in these specification sheets.3.These specification sheets include materials protected under copyright of EVERLIGHT corporation. Please don’treproduce or cause anyone to reproduce them without EVERLIGHT’s consent.。

光藕型号、电路大全型号-引脚功能说明 脚位 内部结构电路图AQY2104引脚位,单组AQY214 4引脚位,单组 AQY210S 4引脚位,单组 AQY214Sx 4引脚位,单组 AQV210 6引脚位,单组器件AQV212 6引脚位,单组器件 AQV215 6引脚位,单组器件 AQV217 6引脚位,单组器件 AQV214 6引脚位,单组器件 AQV216 6引脚位,单组器件 AQV4146引脚位,单组器件 HCPL2530 高速光耦 8引脚位HCPL2531 高速光耦 8引脚位 HCPL4502 高速光耦8引脚位HCPL2503 高速光耦HCPL2533 高速光耦 8引脚位HCPL2601 高速光耦 8引脚位HCPL2611 高速光耦 8引脚位8引脚位 HCPL2630 高速光耦8引脚位HCPL2631 高速光耦 8引脚位HCPL2731 高速光耦8引脚位K1010 三极管输出4N25 三极管输出6引脚位,单组器件4N26 三极管输出6引脚位,单组器件4N27 三极管输出6引脚位,单组器件4N28 三极管输出6引脚位,单组器件4N29 达林顿管输出6引脚位,单组器件4N30 达林顿管输出6引脚位,单组器件4N31 达林顿管输出6引脚位,单组器件4N32 达林顿管输出6引脚位,单组器件4N33 达林顿管输出6引脚位,单组器件4N35 三极管输出6引脚位,单组器件4N36 三极管输出6引脚位,单组器件4N37 三极管输出6引脚位,单组器件4N38 三极管输出6引脚位,单组器件4N38A 三极管输出6引脚位,单组器件4N39 单向晶闸管输出6引脚位,单组器件4N40 单向晶闸管输出6引脚位,单组器件6N137 逻辑高速输出TTL兼容6N138 高增益高速光耦6N139 高增益高速光耦CNX62A 三极管输出6引脚位,单组器件CNX72A 三极管输出6引脚位,单组器件CNX82A 三极管输出6引脚位,单组器件CNX83A 三极管输出6引脚位,单组器件CNY17-1 三极管输出6引脚位,单组器件CNY17-2 三极管输出6引脚位,单组器件CNY17-3 三极管输出6引脚位,单组器件CNY17-4 三极管输出6引脚位,单组器件CNY17-5 三极管输出6引脚位,单组器件CNY17F-3 三极管输出6引脚位,单组器件CNY17F-4 三极管输出6引脚位,单组器件6 CNY30 单向晶闸管输出CNY34 单向晶闸管输出CNY35 交流输入型光耦三极管输出6引脚位,单组器件CNY75A 三极管输出6引脚位,单组器件CNY75B 三极管输出6引脚位,单组器件CNY75C 三极管输出6引脚位,单组器件CQY80 三极管输出6引脚位,单组器件H11A1 三极管输出6引脚位,单组器件H11A2 三极管输出6引脚位,单组器件H11A3 三极管输出6引脚位,单组器件H11A4 三极管输出6引脚位,单组器件H11A5 三极管输出6引脚位,单组器件H11AA1 交流输入型光耦三极管输出6引脚位,单组器件H11AA2 交流输入型光耦三极管输出6引脚位,单组器件H11AA3 交流输入型光耦三极管输出6引脚位,单组器件H11AA4 交流输入型光耦三极管输出6引脚位,单组器件H11AV1 三极管输出6引脚位,单组器件H11AV2 三极管输出6引脚位,单组器件H11AV3 三极管输出6引脚位,单组器件H11B1 达林顿管输出6引脚位,单组器件H11B2 达林顿管输出6引脚位,单组器件H11B3 达林顿管输出6引脚位,单组器件H11C5 单向晶闸管输出6引脚位,单组器件H11C6 单向晶闸管输出6引脚位,单组器件H11D1 高耐压三极管输出6引脚位,单组器件H11D2 高耐压三极管输出6引脚位,单组器件H11D3 高耐压三极管输出6引脚位,单组器件H11D4 高耐压三极管输出6引脚位,单组器件H11F1 场效应管对称输出6引脚位,单组器件H11F2 场效应管对称输出6引脚位,单组器件H11F3 场效应管对称输出6引脚位,单组器件H11G1 达林顿管输出6引脚位,单组器件H11G2 达林顿管输出6引脚位,单组器件H11G3 达林顿管输出6引脚位,单组器件H11J1 双向可控硅非过零型光藕6引脚位,单组器件H11J2 双向可控硅非过零型光藕6引脚位,单组器件H11J3 双向可控硅非过零型光藕6引脚位,单组器件H11J4 双向可控硅非过零型光藕6引脚位,单组器件H11J5 双向可控硅非过零型光藕6引脚位,单组器件H11L1 施密特触发器输出H11L2 施密特触发器输出H11L3 施密特触发器输出H11L4 施密特触发器输出IL1 三极管输出6引脚位,单组器件IL2 三极管输出 6引脚位,单组器件 IL5 三极管输出型 6引脚位,单组器件 IL74 三极管输出型 6引脚位,单组器件 ILD1 三极管输出 8引脚位 ILD2 三极管输出 8引脚位 ILD5 三极管输出8引脚位ILD74 三极管输出6,8,16引脚位,4组器件ILQ1 三极管输出 16引脚位,4组器件ILQ2 三极管输出16引脚位,4组器件ILQ5 三极管输出 16引脚位,4组器件ILQ74 三极管输出 6引脚位,单组器件IS201 三极管输出型 6引脚位,单组器件 IS202 三极管输出型 6引脚位,单组器件 IS203 三极管输出型 6引脚位,单组器件 IS204 三极管输出型 6引脚位,单组器件 IS205 三极管输出6引脚位,单组器件IS205-1 三极管输出型光电藕合器件 6引脚位,单组器件 IS205-2 三极管输出型光电藕合器件 6引脚位,单组器件 IS206 三极管输出IS357 三极管输出IS4N46 高压达林顿管输出光电藕合器件IS6003 双向可控硅非过零型光藕6引脚位,单组器件IS6005 双向可控硅非过零型光藕6引脚位,单组器件IS6010 双向可控硅非过零型光藕6引脚位,单组器件IS6015 双向可控硅非过零型光藕6引脚位,单组器件IS6030 双向可控硅非过零型光藕6引脚位,单组器件IS604 交流信号输入三极管输出6引脚位,单组器件IS6051IS607 双向可控硅非过零型光藕6引脚位,单组器件IS608 双向可控硅非过零型光藕6引脚位,单组器件IS609 施密特触发器输出IS610 场效应管对称输出6引脚位,单组器件IS611 场效应管对称输出6引脚位,单组器件ISD201 三极管输出 8引脚位ISD202 三极管输出 ISD203 三极管输出 ISD204 三极管输出 ISD5 三极管输出 8引脚位 ISD74 三极管输出光偶8引脚位ISP321-1 三极管输出形式 4引脚位,单组ISP321-2 三极管输出 8引脚位ISP321-4 三极管输出 16引脚位,4组器件ISP521-1 三极管输出形式 4引脚位,单组ISP521-4 三极管输出16引脚位,4组器件ISP620-1 交流信号输入三极管输出4引脚位,单组ISP620-2 交流信号输入三极管输出8引脚位ISP620-4 交流输入型光耦三极管输16引脚位,4组器件出ISP621-2 三极管输出8引脚位ISP621-4 三极管输出16引脚位,4组器件ISP624-1 三极管输出形式4引脚位,单组ISP624-2 三极管输出8引脚位ISP624-4 三极管输出16引脚位,4组器件ISP814-2 交流信号输入三极管输出4引脚位,单组ISP815 达林顿管输出4引脚位,单组ISP815-1 达林顿管输出4引脚位,单组ISP815-2 达林顿管输出4引脚位,单组ISP815-3 达林顿管输出4引脚位,单组ISP817 三极管输出形式4引脚位,单组ISP817-1 三极管输出4引脚位,单组ISP817-2 三极管输出 4 Pin4 Pin ISP817-3 三极管输出4引脚位,单组ISP824 交流信号输入三极管输出8引脚位ISP824-1 交流信号输入三极管输出8引脚位ISP824-2 交流信号输入三极管输出8引脚位ISP824-3 交流信号输入三极管输出8引脚位ISP825 达林顿管输出8引脚位ISP825-1 达林顿管输出8引脚位ISP825-2 达林顿管输出8引脚位ISP825-3 达林顿管输出8引脚位ISP844 交流输入型光耦三极管输出16引脚位,4组器件ISP845 达林顿管输出16引脚位,4组器件ISP847 三极管输出16引脚位,4组器件ISPD64 达林顿管输出6引脚位,单组器件ISPD65 达林顿管输出6引脚位,单组器件ISQ1 三极管输出6引脚位,单组器件ISQ201 三极管输出16引脚位,4组器件ISQ202 三极管输出16引脚位,4组器件ISQ203 三极管输出16引脚位,4组器件ISQ204 三极管输出16引脚位,4组器件ISQ5 三极管输出16引脚位,4组器件ISQ74 三极管输出16引脚位,4组器件MCA2230 达林顿管输出6引脚位,单组器件MCA2231 达林顿管输出6引脚位,单组器件MCA2255 达林顿管输出6引脚位,单组器件MCA230 达林顿管输出6引脚位,单组器件MCA231 达林顿管输出6引脚位,单组器件MCA255 达林顿管输出6引脚位,单组器件MCS2400 单向晶闸管输出6引脚位,单组器件MCT277 三极管输出型6引脚位,单组器件MCT2E 三极管输出型6引脚位,单组器件MCT6 三极管输出8引脚位MCT6 三极管输出8引脚位MCT61 三极管输出光电藕合器件8引脚位MCT62 三极管输出8引脚位MCT66 三极管输出8引脚位MOC3009 双向可控硅非过零型光藕6引脚位,单组器件MOC3010 双向可控硅非过零型光藕6引脚位,单组器件MOC3011 双向可控硅非过零型光藕6引脚位,单组器件MOC3012 双向可控硅非过零型光藕6引脚位,单组器件MOC3020 双向可控硅非过零型光藕6引脚位,单组器件MOC3021 双向可控硅非过零型光藕6引脚位,单组器件MOC3022 双向可控硅非过零型光藕6引脚位,单组器件MOC3023 双向可控硅非过零型光藕6引脚位,单组器件MOC5007 施密特触发器输出MOC5008 施密特触发器输出MOC5009 施密特触发器输出MOC8020 达林顿管输出6引脚位,单组器件MOC8021 达林顿管输出6引脚位,单组器件MOC8030 达林顿管输出6引脚位,单组器件MOC8050 达林顿管输出6引脚位,单组器件MOC8080 达林顿管输出6引脚位,单组器件MOC8100 三极管输出型6引脚位,单组器件MOC8101 三极管输出6引脚位,单组器件MOC8102 三极管输出6引脚位,单组器件MOC8103 三极管输出6引脚位,单组器件MOC8104 三极管输出6引脚位,单组器件MOC8105 三极管输出6引脚位,单组器件MOC8106 三极管输出6引脚位,单组器件MOC8107 三极管输出6引脚位,单组器件MOC8108 三极管输出6引脚位,单组器件MOC8111 三极管输出6引脚位,单组器件MOC8112 三极管输出6引脚位,单组器件MOC8113 三极管输出6引脚位,单组器件PS2501-2 三极管输出8引脚位PS2501-4 三极管输出16引脚位,4组器件PS2502-1 达林顿管输出4引脚位,单组PS2502-2 达林顿管输出8引脚位PS2505-1 交流信号输入三极管输出4引脚位,单组PS2505-2 交流信号输入三极管输出8引脚位PS2505-4 交流输入型光耦三极管输出16引脚位,4组器件SFH609-3 三极管输出型6引脚位,单组器件SFH610-2 三极管输出形式4引脚位,单组SFH610-3 三极管输出形式4引脚位,单组SFH610-4 三极管输出形式4引脚位,单组SFH615A-1 三极管输出形式4引脚位,单组SFH615A-2 三极管输出形式4引脚位,单组SFH615A-3 三极管输出形式4引脚位,单组SFH615A-4 三极管输出形式4引脚位,单组SFH617A-1 三极管输出形式4引脚位,单组SFH617A-2 三极管输出形式4引脚位,单组SFH617A-3 三极管输出形式4引脚位,单组SFH617A-4 三极管输出形式4引脚位,单组SFH617G-1 三极管输出形式4引脚位,单组SFH617G-2 三极管输出形式4引脚位,单组SFH617G-3 三极管输出形式4引脚位,单组SFH617G-4 三极管输出形式4引脚位,单组SFH618-2 三极管输出形式4引脚位,单组SFH618-3 三极管输出形式4引脚位,单组SFH618-4 三极管输出形式4引脚位,单组SFH618A-2 三极管输出形式4引脚位,单组SFH618A-3 三极管输出形式4引脚位,单组SFH618A-4 三极管输出形式4引脚位,单组SFH620A-1 交流信号输入三极管输出4引脚位,单组SFH628-3 交流信号输入 三极管输出4引脚位,单组SFH628-4 交流信号输入 三极管输出4引脚位,单组SFH6286-3 AC Input , Single6引脚位,单组器件TIL111 三极管输出型6引脚位,单组器件TIL113 达林顿管输出6引脚位,单组器件TIL114 三极管输出型 6引脚位,单组器件TIL116 三极管输出型 6引脚位,单组器件 TIL117 三极管输出型6引脚位,单组器件TIL119 达林顿管输出6引脚位,单组器件TIL191 三极管输出形式 4引脚位,单组TIL191A 三极管输出形式4引脚位,单组TIL191B 三极管输出形式4引脚位,单组 TIL192 三极管输出 8引脚位TIL192A 三极管输出8引脚位TIL192B 三极管输出 8引脚位TIL193A 三极管输出 16引脚位,4组器件 TIL193B 三极管输出 16引脚位,4组器件TIL194 交流信号输入 三极管输出TIL194A 交流信号输入 三极管输出 4引脚位,单组 TIL194B 交流信号输入 三极管输出 4引脚位,单组 TIL195 交流信号输入 三极管输出TIL195A 交流信号输入 三极管输出8引脚位TIL195B 交流信号输入 三极管输出8引脚位TIL196 交流信号输入 三极管输出TIL196A 交流信号输入 三极管输出 16引脚位,4组器件TIL196B 交流信号输入 三极管输出 16引脚位,4组器件TIL197 达林顿管输出 4引脚位,单组TIL197A 达林顿管输出 4引脚位,单组TIL197B 达林顿管输出 4引脚位,单组TIL198A 达林顿管输出8引脚位TIL198B 达林顿管输出8引脚位TIL199 达林顿管输出16引脚位,4组器件TIL199A 达林顿管输出16引脚位,4组器件TIL199B 达林顿管输出16引脚位,4组器件TLP321 三极管输出形式4引脚位,单组TLP321-2 三极管输出8引脚位TLP321-4 三极管输出16引脚位,4组器件TLP521 三极管输出形式4引脚位,单组TLP521-2 三极管输出8引脚位TLP521-4 三极管输出16引脚位,4组器件TLP620 交流信号输入三极管输出4引脚位,单组TLP620-4 交流输入型光耦三极管输出16引脚位,4组器件TLP621 三极管输出形式4引脚位,单组TLP621-2 三极管输出8引脚位TLP621-4 三极管输出16引脚位,4组器件TLP624-2 三极管输出8引脚位TLP624-4 三极管输出16引脚位,4组器件TLP721LTV702VA 三极管输出形式6引脚位,单组器件LTV702VB 三极管输出形式6引脚位,单组器件LTV702VC 三极管输出形式6引脚位,单组器件LTV702VD 三极管输出形式6引脚位,单组器件PC354 三极管输出4引脚位,单组PC355NT 三极管输出4引脚位,单组PC357 三极管输出 4 Pin4 PC817PC1138PC829 三极管输出8引脚位PC849 三极管输出光电藕合器件16引脚位,4组器件PS2701-1 三极管输出4引脚位,单组PS2702-2 三极管输出8引脚位PS2702-4 三极管输出16引脚位,4组器件PS2705-1 三极管输出4引脚位,单组PC817 三极管输出光电藕合器件4引脚位,单组TLP121 三极管输出4引脚位,单组TLP126 三极管输出4引脚位,单组LAA110 8引脚位LBA110LCA1106引脚位,单组器件LBB110 8引脚位。

光电耦合器(简称光耦)是开关电源电路中常用的器件。

光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

常用的4N系列光耦属于非线性光耦常用的线性光耦是PC817A—C系列。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于弄开关信号的传输,不适合于传输模拟量。

线性光耦的电流传输手特性曲线接进直线,并且小信号时性能较好,能以线性特性进行隔离控制。

开关电源中常用的光耦是线性光耦。

如果使用非线性光耦,有可能使振荡波形变坏,严重时出现寄生振荡,使数千赫的振荡频率被数十到数百赫的低频振荡依次为号调制。

由此产生的后果是对彩电,彩显,VCD,DCD等等,将在图像画面上产生干扰。

同时电源带负载能力下降。

在彩电,显示器等开关电源维修中如果光耦损坏,一定要用线性光耦代换。

常用的4脚线性光耦有PC817A----C。

PC111 TLP521等常用的六脚线性光耦有:TLP632 TLP532 PC614 PC714 PS2031等。

常用的4N25 4N26 4N35 4N36是不适合用于开关电源中的,因为这4种光耦均属于非线性光耦。

经查大量资料后,以下是目前市场上常见的高速光藕型号:100K bit/S:6N138、6N139、PS87031M bit/S:6N135、6N136、CNW135、CNW136、PS8601、PS8602、PS8701、PS9613、PS9713、CNW4502、HCPL-2503、HCPL-4502、HCPL-2530(双路)、HCPL-2531(双路)10M bit/S:6N137、PS9614、PS9714、PS9611、PS9715、HCPL-2601、HCPL-2611、HCPL-2630(双路)、HCPL -2631(双路)光耦合器的增益被称为晶体管输出器件的电流传输比 (CTR),其定义是光电晶体管集电极电流与LED正向电流的比率(ICE/IF)。

光电晶体管集电极电流与VCE有关,即集电极和发射极之间的电压。

Intelligent Power Module and Gate Drive Interface Optocouplers Technical DataFeatures• Performance Specified for Common IPM Applications over Industrial Temperature Range: -40°C to 100°C• Fast Maximum Propagation Delayst PHL = 480ns t PLH = 550ns• Minimized Pulse Width Distortion PWD = 450 ns• 15 kV/µs Minimum Common Mode Transient Immunity at V CM = 1500 V• CTR > 44% at I F = 10mA • Safety Approval UL Recognized-3750 V rms / 1 min. for HCPL-4506/0466/J456-5000 V rms / 1 min. for HCPL-4506 Option 020 and HCNW4506CSA ApprovedIEC/EN/DIN EN 60747-5-2Approved-V IORM = 560 Vpeak for HCPL-0466 Option 060-V IORM = 630 Vpeak for HCPL-4506 Option 060-V IORM = 891 Vpeak for HCPL-J456-V IORM = 1414 Vpeak for HCNW4506The connection of a 0.1 µF bypass capacitor between pins 5 and 8 is recommended.Applications• IPM Isolation• Isolated IGBT/MOSFET Gate Drive• AC and Brushless DC Motor Drives• Industrial InvertersHCPL-4506HCPL-J456HCPL-0466HCNW4506CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to prevent damage and/or degradation which may be induced by ESD.Functional Diagram Truth TableLEDV O ON L OFFH87613SHIELD52420 k ΩNC ANODE CATHODE NC V CCV LV OGNDSelection GuideStandard White Mold Package 8-Pin DIP 8-Pin DIP Small OutlineWidebody Type (300 Mil)(300 Mil)SO8(400 Mil)Hermetic*Part HCPL-4506HCPL-J456HCPL-0466HCNW4506HCPL-5300NumberHCPL-5301IEC/EN/DIN V IORM = 630 Vpeak V IORM = 891 Vpeak V IORM = 560 Vpeak V IORM = 1414 Vpeak —EN 60747-(Option 060)(Option 060)5-2Approval*Technical data for these products are on separate Agilent publications.Ordering InformationSpecify Part Number followed by Option Number (if desired).Example:HCPL-4506#XXXX020 = UL 5000 V rms/1 minute Option** for HCPL-4506 Only.060 = IEC/EN/DIN EN 60747-5-2 Option** for HCPL-4506/0466.300 = Gull Wing Lead Option for HCPL-4506/J456, HCNW4506.500 = Tape and Reel Packaging Option XXXE = Lead Free OptionOption data sheets are available. Contact Agilent sales representative or authorized distributor for information.**Combination of Option 020 and Option 060 is not available.Remarks: The notation “#” is used for existing products, while (new) products launched since 15th July 2001 and lead free option will use “-”DescriptionThe HCPL-4506 and HCPL-0466contain a GaAsP LED while the HCPL-J456 and the HCNW4506contain an AlGaAs LED. The LED is optically coupled to an inte-grated high gain photo detector.Minimized propagation delaydifference between devices makes these optocouplers excellent solutions for improving inverter efficiency through reduced switching dead time.An on chip 20 k Ω output pull-up resistor can be enabled byshorting output pins 6 and 7, thus eliminating the need for an external pull-up resistor in common IPM applications.Specifications and performance plots are given for typical IPM applications.Package Outline DrawingsHCPL-4506 Outline DrawingHCPL-4506 Gull Wing Surface Mount Option 300 Outline Drawing0.254+ 0.076 - 0.051(0.010+ 0.003) - 0.002)DIMENSIONS IN MILLIMETERS AND (INCHES).* MARKING CODE LETTER FOR OPTION NUMBERS "L" = OPTION 020 "V" = OPTION 060OPTION NUMBERS 300 AND 500 NOT MARKED.NOTE: FLOATING LEAD PROTRUSION IS 0.25 mm (10 mils) MAX.(0.025 ± 0.005)(0.100)BSCDIMENSIONS IN MILLIMETERS (INCHES).LEAD COPLANARITY = 0.10 mm (0.004 INCHES).+ 0.076 - 0.051+ 0.003) - 0.002)NOTE: FLOATING LEAD PROTRUSION IS 0.25 mm (10 mils) MAX.Package Outline DrawingsHCPL-J456 Outline DrawingHCPL-J456 Gull Wing Surface Mount Option 300 Outline Drawing0.254+ 0.076 - 0.051(0.010+ 0.003) - 0.002)DIMENSIONS IN MILLIMETERS AND (INCHES).* MARKING CODE LETTER FOR OPTION NUMBERS "L" = OPTION 020 "V" = OPTION 060OPTION NUMBERS 300 AND 500 NOT MARKED.NOTE: FLOATING LEAD PROTRUSION IS 0.5 mm (20 mils) MAX.(0.025 ± 0.005)(0.100)BSCDIMENSIONS IN MILLIMETERS (INCHES).LEAD COPLANARITY = 0.10 mm (0.004 INCHES).+ 0.076 - 0.051+ 0.003) - 0.002)NOTE: FLOATING LEAD PROTRUSION IS 0.5 mm (20 mils) MAX.HCPL-0466 Outline Drawing (8-Pin Small Outline Package)HCNW4506 Outline Drawing (8-Pin Widebody Package)(0.012)MIN.5.207 ± 0.254 (0.205 ± 0.010) DIMENSIONS IN MILLIMETERS (INCHES).LEAD COPLANARITY = 0.10 mm (0.004 INCHES) MAX. NOTE: FLOATING LEAD PROTRUSION IS 0.15 mm (6 mils) MAX.*1.78 ± 0.15 NOTE: FLOATING LEAD PROTRUSION IS 0.25 mm (10 mils) MAX.+ 0.076 - 0.0051+ 0.003) - 0.002)HCNW4506 Gull Wing Surface Mount Option 300 Outline Drawing1.78 ± 0.15MAX.BSCDIMENSIONS IN MILLIMETERS (INCHES).LEAD COPLANARITY = 0.10 mm (0.004 INCHES).NOTE: FLOATING LEAD PROTRUSION IS 0.25 mm (10 mils) MAX.Pb-Free IR ProfileSolder Reflow Temperature ProfileTIME (SECONDS)T E M P E R A T U R E (°C )ROOMT T T 25T TIMET E M P E R A T U R NOTES:THE TIME FROM 25 °C to PEAK TEMPERATURE = 8 MINUTES MAX. T smax = 200 °C, T smin = 150 °CInsulation and Safety Related SpecificationsValueParameterSymbol HCPL-4506HCPL-J456HCPL-0466HCNW4506UnitsConditionsMinimum External L(101)7.17.4 4.99.6mmMeasured from input Air Gap (External terminals to output Clearance)terminals, shortest distance through air.Minimum External L(102)7.48.0 4.810.0mmMeasured from input Tracking (External terminals to output Creepage)terminals, shortestdistance path along body.Minimum Internal 0.080.50.08 1.0mmThrough insulation Plastic Gapdistance, conductor to (Internal Clearance)conductor, usually the direct distance between the photoemitter and photodetector inside the optocoupler cavity.Minimum Internal NA NA NA 4.0mmMeasured from input Tracking (Internal terminals to outputCreepage)terminals, along internal cavity.Tracking Resistance CTI≥175≥175≥175≥200VoltsDIN IEC 112/VDE 0303(Comparative Part 1Tracing Index)Isolation GroupIIIa IIIa IIIa IIIaMaterial Group (DINVDE 0110, 1/89, Table 1)Regulatory InformationThe devices contained in this data sheet have been approved by the following agencies:Agency/StandardHCPL-4506HCPL-J456HCPL-0466HCNW4506Underwriters Laboratories (UL) UL 1577 Recognized under UL 1577, ComponentRecognized Program, Category FPQU2, File E55361Canadian Standards Component Association (CSA) Acceptance File CA88324 Notice #5 Verband Deutscher DIN VDE 0884 Electrotechniker (VDE) (June 1992)IEC/EN/DIN EN 60747-5-2 Approved under:IEC 60747-5-2:1997 + A1:2002EN 60747-5-2:2001 + A1:2002DIN EN 60747-5-2 (VDE 0884 Teil 2):2003-01All Agilent data sheets report the creepage and clearance inherent to the optocoupler component itself. Thesedimensions are needed as a starting point for the equipment designer when determining the circuit insulation require-ments. However, once mounted on a printed circuit board, minimum creepage and clearance requirements must be met as specified for individual equipment standards. For creepage, the shortest distance path along the surface of a printed circuit board between the solder fillets of the input and output leads must be considered. There are recom-mended techniques such as grooves and ribs which may be used on a printed circuit board to achieve desired creepage and clearances. Creepage and clearance distances will also change depending on factors such as pollution degree and insulation level.IEC/EN/DIN EN 60747-5-2 Insulation Related CharacteristicsHCPL-0466HCPL-4506Description Symbol Option 060Option 060HCPL-J456HCNW4506Unit Installation classification perDIN VDE 0110/1.89, Table 1for rated mains voltage ≤150 V rms I-IV I-IV I-IV I-IVfor rated mains voltage ≤300 V rms I-III I-IV I-IV I-IVfor rated mains voltage ≤450 V rms I-III I-III I-IVfor rated mains voltage ≤600 V rms I-III I-IVfor rated mains voltage ≤1000 V rms I-IIIClimatic Classification55/100/2155/100/2155/100/2155/100/21 Pollution Degree2222(DIN VDE 0110/1.89)Maximum Working V IORM5606308911414V peak Insulation VoltageInput to Output Test Voltage,Method b* V IORM x 1.875 = V PR,100% Production Test with t m=V PR1050118116702652V peak 1 sec, Partial Discharge < 5pCInput to Output Test Voltage,Method a* V IORM x 1.5 = V PR,Type and Sample Test, t m = 60 sec,V PR84094513362121V peak Partial Discharge < 5pCHighest Allowable Overvoltage*V IOTM4000600060008000V peak (Transient Overvoltage, t ini = 10 sec)Safety Limiting Values – maximumvalues allowed in the event of a fail-ure, also see Thermal Derating curve.Case Temperature T S150175175150°C Input Current I S INPUT150230400400mA Output Power P S OUTPUT600600600700mW Insulation Resistance at T S,R S≥ 109≥109≥109≥109ΩV IO = 500 V*Refer to the optocoupler section of the Designer's Catalog, under regulatory information (IEC/EN/DIN EN 60747-5-2) for a detailed description of Method a and Method b partial discharge test profiles.Note: These optocouplers are suitable for "safe electrical isolation" only within the safety limit data. Maintenance of the safety data shall be ensured by means of protective circuits.Note: Insulation Characteristics are per IEC/EN/DIN EN 60747-5-2.Note: Surface mount classification is Class A in accordance with CECC 00802.Absolute Maximum RatingsRecommended Operating ConditionsParameter Symbol Min.Max.Units Power Supply Voltage V CC 4.530Volts Output Voltage V O030Volts Input Current (ON)I F(on)1020mA Input Voltage (OFF)V F(off)*-50.8V Operating Temperature T A-40100°C*Recommended V F(OFF) = -3 V to 0.8 V for HCPL-J456, HCNW4506.Electrical SpecificationsOver recommended operating conditions unless otherwise specified:T A = -40°C to +100°C, V CC = +4.5 V to 30 V, I F(on) = 10 mA to 20mA, V F(off) = -5 V to 0.8 V† Parameter Symbol Device Min.Typ.*Max.Units Test Conditions Fig.Note Current Transfer Ratio CTR4490%I F = 10 mA,5V O = 0.6 VLow Level Output Current I OL 4.49.0mA I F = 10 mA,1, 2V O = 0.6 VLow Level Output Voltage V OL0.30.6V I O = 2.4 mAInput Threshold Current I TH HCPL-4506 1.55mA V O = 0.8 V,116HCPL-0466I O = 0.75 mAHCNW4506HCPL-J4560.6High Level Output Current I OH550µA V F = 0.8 V3High Level Supply Current I CCH0.6 1.3mA V F = 0.8 V,16V O = OpenLow Level Supply Current I CCL0.6 1.3mA I F = 10 mA,16V O = OpenInput Forward Voltage V F HCPL-4506 1.5 1.8V I F = 10 mA4HCPL-0466HCPL-J456 1.2 1.6 1.955HCNW4506 1.6 1.85Temperature Coefficient∆V F/∆T A HCPL-4506-1.6mV/°C I F = 10 mAof Forward Voltage HCPL-0466HCPL-J456HCNW4506-1.3Input Reverse Breakdown BV R HCPL-45065V I R = 10 µAVoltage HCPL-0466HCPL-J4563I R = 100 µAHCNW4506Input Capacitance C IN HCPL-450660pF f = 1 MHz,HCPL-0466V F = 0 VHCPL-J45672HCNW4506Internal Pull-up Resistor R L142025kΩT A = 25°C12,13 Internal Pull-up Resistor∆R L/∆T A0.014kΩ/°CTemperature Coefficient*All typical values at 25°C, V CC = 15 V.†V F(off) = -3 V to 0.8 V for HCPL-J456, HCNW4506.Switching Specifications (R L= 20 kΩ External)Over recommended operating conditions unless otherwise specified:T A = -40°C to +100°C, V CC = +4.5 V to 30 V, I F(on) = 10 mA to 20mA, V F(off) = -5 V to 0.8 V†Parameter Symbol Min.Typ.*Max. Units Test Conditions Fig.Note Propagation Delay T PHL30200400ns C L = 100 pF I F(on) = 10 mA,6, 8,11, Time to Logic HCPL-J456480V F(off) = 0.8 V,10-14, Low at Output100C L = 10 pF V CC = 15.0 V,1316 Propagation Delay T PLH270400550ns C L = 100 pF V THLH = 2.0 V,Time to High V THHL = 1.5 VOutput Level130C L = 10 pFPulse Width PWD200450ns C L = 100 pF20 DistortionPropagation Delay t PLH-t PHL-150200450ns17 Difference BetweenAny 2 PartsOutput High Level|CM H|1530kV/µs I F = 0 mA,V CC = 15.0 V,718 Common Mode V O > 3.0 V C L = 100 pF,Transient Immunity V CM = 1500 V p-pOutput Low Level|CM L|1530kV/µs I F = 10 mA T A = 25°C19 Common Mode V O < 1.0 VTransient ImmunitySwitching Specifications (R L= Internal Pull-up)Over recommended operating conditions unless otherwise specified:T A = -40°C to +100°C, V CC = +4.5 V to 30 V, I F(on) = 10 mA to 20mA, V F(off) = -5 V to 0.8 V†Parameter Symbol Min.Typ.*Max.Units Test Conditions Fig.Note Propagation Delay t PHL20200400ns I F(on) = 10 mA, V F(off) = 0.8 V,6, 911-14, Time to Logic HCPL-J456485V CC = 15.0 V, C L = 100 pF,16 Low at Output V THLH = 2.0 V, V THHL = 1.5 VPropagation Delay Time t PLH220450650nsto High Output LevelPulse Width PWD250500ns20 DistortionPropagation Delay t PLH-t PHL-150250500ns17 Difference BetweenAny 2 PartsOutput High Level|CM H|30kV/µs I F = 0 mA,V CC = 15.0 V,718 Common Mode V O > 3.0 V C L = 100 pF,Transient Immunity V CM = 1500 V p-p,Output Low Level|CM L|30kV/µs I F = 16 mA,T A = 25°C19 Common Mode V O < 1.0 VTransient ImmunityPower Supply PSR 1.0V p-p Square Wave, t RISE, t FALL16 Rejection> 5 ns, no bypass capacitors*All typical values at 25°C, V CC = 15 V.†V F(off) = -3 V to 0.8 V for HCPL-J456, HCNW4506.Package CharacteristicsOver recommended temperature (T A = -40°C to 100°C) unless otherwise specified.Parameter Sym.Device Min.Typ.*Max.Units Test Conditions Fig.Note Input-Output Momentary V ISO HCPL-45063750V rms RH < 50%6,7,10 Withstand Voltage†HCPL-0466t = 1 min.HCPL-J4563750T A = 25°C6,8,10HCPL-450650006,9,Option02015HCNW450650006,9,10 Resistance R I-O HCPL-45061012V I-O = 500 Vdc6 (Input-Output)HCPL-J456ΩHCPL-0466HCNW450610121013Capacitance C I-O HCPL-45060.6pF f = 1 MHz6 (Input-Output)HCPL-0466HCPL-J4560.8HCNW45060.5Notes:1.Derate linearly above 90°C free-airtemperature at a rate of 0.8 mA/°C.2.Derate linearly above 90°C free-airtemperature at a rate of 1.6 mA/°C.3.Derate linearly above 90°C free-airtemperature at a rate of 3.0 mW/°C.4.Derate linearly above 90°C free-airtemperature at a rate of 4.2 mW/°C.5.CURRENT TRANSFER RATIO inpercent is defined as the ratio ofoutput collector current (I O) to theforward LED input current (I F) times100.6.Device considered a two-terminaldevice: Pins 1, 2, 3, and 4 shortedtogether and Pins 5, 6, 7, and 8shorted together.7.In accordance with UL 1577, eachoptocoupler is proof tested byapplying an insulation test voltage≥4500 V rms for 1 second (leakagedetection current limit, I I-O≤5 µA).8. In accordance with UL 1577, eachoptocoupler is proof tested byapplying an insulation test voltage ≥4500 V rms for 1 second (leakagedetection current limit, I i-o≤ 5 µA). 9. In accordance with UL 1577, eachoptocoupler is proof tested byapplying an insulation test voltage ≥6000 V rms for 1 second (leakagedetection current limit, I I-O≤ 5 µA).10. This test is performed before the100% Production test shown in theIEC/EN/DIN EN 60747-5-2 InsulationRelated Characteristics Table, ifapplicable.11. Pulse: f = 20 kHz, Duty Cycle = 10%.12. The internal 20 kΩ resistor can beused by shorting pins 6 and 7together.13. Due to tolerance of the internalresistor, and since propagation delayis dependent on the load resistorvalue, performance can be improvedby using an external 20 kΩ 1% loadresistor. For more information onhow propagation delay varies withload resistance, see Figure 8.14. The R L = 20 kΩ, C L = 100 pF loadrepresents a typical IPM (IntelligentPower Module) load.15. See Option 020 data sheet for moreinformation.16. Use of a 0.1 µF bypass capacitorconnected between pins 5 and 8 canimprove performance by filteringpower supply line noise.17. The difference between t PLH and t PHLbetween any two devices under thesame test condition. (See IPM DeadTime and Propagation DelaySpecifications section.)18. Common mode transient immunity ina Logic High level is the maximumtolerable dV CM/dt of the commonmode pulse, V CM, to assure that theoutput will remain in a Logic Highstate (i.e., V O > 3.0 V).19. Common mode transient immunity ina Logic Low level is the maximumtolerable dV CM/dt of the commonmode pulse, V CM, to assure that theoutput will remain in a Logic Lowstate (i.e.,V O<1.0V).20. Pulse Width Distortion (PWD) isdefined as |t PHL - t PLH| for any givendevice.*All typical values at 25°C, V CC = 15 V.†The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output continuous voltage rating. For the continuous voltage rating refer to the IEC/EN/DIN EN 60747-5-2 Insulation Related Characteristics Table (if applicable), your equipment level safety specification or Agilent Application Note 1074 entitled “Optocoupler Input-Output Endurance Voltage,” publication number 5963-2203E.Figure 4. HCPL-4506 and HCPL-0466Input Current vs. Forward Voltage.Figure 5. HCPL-J456 and HCNW4506Input Current vs. Forward Voltage.Figure 2. Normalized Output Current vs. Temperature.Figure 1. Typical Transfer Characteristics.Figure 3. High Level Output Current vs. Temperature.Figure 6. Propagation Delay Test Circuit.I O – O U T P U T C U R R E N T – m AI F – FORWARD LED CURRENT – mAN O R M A L I Z E D O U T P U T C U R R EN TT A – TEMPERATURE – °C I O H – H I G H L E V E L O U T P U T C U R R E N T– µAT A – TEMPERATURE – °CI F – F O R W A R D C U R R E N T – m AV F – FORWARD VOLTAGE – VOLTS I F – I N P U T F O RW A R D C U R R E N T – m AV F – INPUT FORWARD VOLTAGE – VHCPL-J456/HCNW4506= 15 VI *TOTAL LOAD CAPACITANCEt P – P R O P A G A T I O N D E L A Y – n sRL – LOAD RESISTANCE – k ΩFigure 8. Propagation Delay with External 20 k Ω RL vs. Temperature.Figure 9. Propagation Delay with Internal 20 k Ω RL vs. Temperature.Figure 10. Propagation Delay vs. Load Resistance.Figure 7. CMR Test Circuit. Typical CMR Waveform.Figure 13. Propagation Delay vs. Input Current.Figure 11. Propagation Delay vs. Load Capacitance.Figure 12. Propagation Delay vs.Supply Voltage.CC = 15 VV FFV OV OSWITCH AT A: I F = 0 mA SWITCH AT B: I F = 10 mAV CCV OLt P – P R O P A G A T I O N D E L A Y – n sT A – TEMPERATURE – °C tP – P R O P A G A T I O N D E L A Y – n sCL – LOAD CAPACITANCE – pFt P – P R O P A G A T I O N D E L A Y – n sV CC – SUPPLY VOLTAGE – Vt P – P R O P A G A T I O N D E L A Y – n sI F – FORWARD LED CURRENT – mAt P – P R O P A G A T I O N D E L A Y – n sT A – TEMPERATURE – °CFigure 16. Optocoupler Input to Output Capacitance Model for Unshielded Optocouplers.Figure 15. Recommended LED Drive Circuit.Figure 14. Thermal Derating Curve, Dependence of Safety Limiting Value with Case Temperature per IEC/EN/DIN EN 60747-5-2.Figure 18. LED Drive Circuit with Resistor Connected to LED Anode (Not Recommended).Figure 17. Optocoupler Input to Output Capacitance Model for Shielded Optocouplers.CC = 15 VCC = 15 VO U T P U T P O W E R – P S , I N P U T C U R R E N T – I S0T S – CASE TEMPERATURE – °C 400600800200100300500700(230)O U T P U T P O W E R – P S , I N P U T C U R R E N T – I ST S – CASE TEMPERATURE – °CFigure 23. Recommended LED Drive Circuit for Ultra High CMR.Figure 20. AC Equivalent Circuit for Figure 15 During Common Mode Transients.Figure 19. AC Equivalent Circuit for Figure 18 During Common Mode Transients.Figure 21. Not Recommended Open Collector LED Drive Circuit.Figure 22. AC Equivalent Circuit for Figure 21 During Common Mode Transients.CMCMCMFigure 24. Typical Application Circuit.Figure 26. Waveforms for Dead Time Calculation.Figure 25. Minimum LED Skew for Zero Dead Time.V V I (t PLH-t PHL ) MAX. = t PLH MAX. - t PHL MIN.I *PDD = PROPAGATION DELAY DIFFERENCENOTE: THE PROPAGATION DELAYS USED TO CALCULATE PDD ARE TAKEN AT EQUAL TEMPERATURES.V V I MAXIMUM DEAD TIME (DUE TO OPTOCOUPLER)= (t PLH MAX. - t PLH MIN.) + (t PHL MAX. - t PHL MIN.) = (t PLH MAX. - t PHL MIN.) - (t PLH MIN. - t PHL MAX.) = PDD* MAX. - PDD* MIN.I *PDD = PROPAGATION DELAY DIFFERENCENOTE: THE PROPAGATION DELAYS USED TO CALCULATE THE MAXIMUM DEAD TIME ARE TAKEN AT EQUAL TEMPERATURES.LED Drive Circuit Considerations for Ultra High CMR Performance Without a detector shield, the dominant cause of optocoupler CMR failure is capacitive coupl-ing from the input side of the optocoupler, through the package, to the detector ICas shown in Figure 16. The HCPL-4506 series improveCMR performance by using a detector IC with an optically transparent Faraday shield, which diverts the capacitively coupled current away from the sensitive IC circuitry. However, this shield does not eliminate the capacitive coupling between the LED and the optocoupler output pins and output ground as shown in Figure 17. This capacitive coupling causes perturbations in the LED current during common mode transients and becomes the major source of CMR failuresfor a shielded optocoupler. The main design objective of a high CMR LED drive circuit becomes keeping the LED in the proper state (on or off) during common mode transients. For example, the recommended application circuit (Figure 15), can achieve 15kV/µs CMR while minimizing component complexity. Note that a CMOS gate is recommendedin Figure 15 to keep the LEDoff when the gate is in the high state.Another cause of CMR failure for a shielded optocoupler is direct coupling to the optocoupler output pins through C LEDO1 and C LEDO2 in Figure 17. Many factors influence the effect and magni-tude of the direct coupling including: the use of an internal or external output pull-up resistor, the position of the LED current setting resistor, the connection of the unused inputpackage pins, and the value of thecapacitor at the optocoupleroutput (C L).Techniques to keep the LED inthe proper state and minimize theeffect of the direct coupling arediscussed in the next twosections.CMR with the LED On(CMR L)A high CMR LED drive circuitmust keep the LED on duringcommon mode transients. This isachieved by overdriving the LEDcurrent beyond the inputthreshold so that it is not pulledbelow the threshold during atransient. The recommendedminimum LED current of 10mAprovides adequate margin overthe maximum I TH of 5.0mA (seeFigure 1) to achieve 15kV/µsCMR. Capacitive coupling ishigher when the internal loadresistor is used (due to C LEDO2)and an I F = 16mA is required toobtain 10kV/µs CMR.The placement of the LED currentsetting resistor effects the abilityof the drive circuit to keep theLED on during transients andinteracts with the direct couplingto the optocoupler output. Forexample, the LED resistor inFigure 18 is connected to theanode. Figure 19 shows the ACequivalent circuit for Figure 18during common mode transients.During a +dVcm/dt in Figure 19,the current available at the LEDanode (Itotal) is limited by theseries resistor. The LED current(I F) is reduced from its DC valueby an amount equal to the currentthat flows through C LEDP andC LEDO1. The situation is madeworse because the currentthrough C LEDO1 has the effect oftrying to pull the output high(toward a CMR failure) at thesame time the LED current isbeing reduced. For this reason,the recommended LED drivecircuit (Figure 15) places thecurrent setting resistor in serieswith the LED cathode. Figure 20is the AC equivalent circuit forFigure 15 during common modetransients. In this case, the LEDcurrent is not reduced during a+dVcm/dt transient because thecurrent flowing through thepackage capacitance is suppliedby the power supply. During a-dVcm/dt transient, however, theLED current is reduced by theamount of current flowingthrough C LEDN. But, better CMRperformance is achieved since thecurrent flowing in C LEDO1 during anegative transient acts to keep theoutput low.Coupling to the LED and outputpins is also affected by the con-nection of pins 1 and 4. If CMR islimited by perturbations in theLED on current, as it is for therecommended drive circuit(Figure 15), pins 1 and 4 shouldbe connected to the input circuitcommon. However, if CMRperformance is limited by directcoupling to the output when theLED is off, pins 1 and 4 should beleft unconnected.CMR with the LED Off(CMR H)A high CMR LED drive circuitmust keep the LED off(V F≤V F(OFF)) during commonmode transients. For example,during a +dVcm/dt transient inFigure 20, the current flowingthrough C LEDN is supplied by theparallel combination of the LEDand series resistor. As long as thevoltage developed across theresistor is less than V F(OFF) theLED will remain off and no common mode failure will occur. Even if the LED momentarily turns on, the 100 pF capacitor from pins 6-5 will keep the output from dipping below the threshold. The recommended LED drive circuit (Figure 15) provides about 10V of margin between the lowest optocoupler output voltage and a 3V IPM threshold duringa 15kV/µs transient withV CM=1500V. Additional margin can be obtained by adding a diode in parallel with the resistor, as shown by the dashed line con-nection in Figure 20, to clamp the voltage across the LED below V F(OFF).Since the open collector drive circuit, shown in Figure 21, cannot keep the LED off duringa +dVcm/dt transient, it isnot desirable for applications requiring ultra high CMR H performance. Figure 22 is the AC equivalent circuit for Figure 21 during common mode transients. Essentially all the current flowing through C LEDN during a +dVcm/dt transient must be supplied bythe LED. CMR H failures can occur at dV/dt rates where the current through the LED and C LEDN exceeds the input threshold. Figure 23 is an alternative drive circuit which does achieve ultra high CMR performance by shunting the LED in the off state.IPM Dead Time andPropagation DelaySpecificationsThe HCPL-4506 series includea Propagation Delay Differencespecification intended to helpdesigners minimize “dead time”in their power inverter designs.Dead time is the time periodduring which both the high andlow side power transistors (Q1and Q2 in Figure 24) are off. Anyoverlap in Q1 and Q2 conductionwill result in large currents flow-ing through the power devicesbetween the high and low voltagemotor rails.To minimize dead time thedesigner must consider the propa-gation delay characteristics of theoptocoupler as well as the charac-teristics of the IPM IGBT gatedrive circuit. Considering only thedelay characteristics of the opto-coupler (the characteristics of theIPM IGBT gate drive circuit canbe analyzed in the same way) it isimportant to know the minimumand maximum turn-on (t PHL) andturn-off (t PLH) propagation delayspecifications, preferably over thedesired operating temperaturerange.The limiting case of zero deadtime occurs when the input to Q1turns off at the same time that theinput to Q2 turns on. This casedetermines the minimum delaybetween LED1 turn-off and LED2turn-on, which is related to theworst case optocoupler propaga-tion delay waveforms, as shown inFigure 25. A minimum dead timeof zero is achieved in Figure 25when the signal to turn on LED2is delayed by (t PLH max - t PHL min)from the LED1 turn off. Note thatthe propagation delays used tocalculate PDD are taken at equaltemperatures since the opto-couplers under considerationare typically mounted in closeproximity to each other.(Specifically, t PLH max and t PHL minin the previous equation are notthe same as the t PLH max andt PHL min, over the full operatingtemperature range, specified inthe data sheet.) This delay is themaximum value for the propaga-tion delay difference specificationwhich is specified at 450ns forthe HCPL-4506 series over anoperating temperature range of-40°C to 100°C.Delaying the LED signal by themaximum propagation delay dif-ference ensures that the minimumdead time is zero, but it does nottell a designer what the maximumdead time will be. The maximumdead time occurs in the highlyunlikely case where one opto-coupler with the fastest t PLH andanother with the slowest t PHLare in the same inverter leg. Themaximum dead time in this casebecomes the sum of the spreadin the t PLH and t PHL propagationdelays as shown in Figure 26.The maximum dead time is alsoequivalent to the differencebetween the maximum and mini-mum propagation delay differencespecifications. The maximumdead time (due to the optocoup-lers) for the HCPL-4506 seriesis 600ns (= 450ns -(-150ns) )over an operating temperaturerange of -40°C to 100°C.。

光耦pc817应用电路pc817是常用的线性光藕,在各种要求比较精密的功能电路中常常被当作耦合器件,具有上下级电路完全隔离的作用,相互不产生影响。

<光耦pc817应用电路图>当输入端加电信号时,发光器发出光线,照射在受光器上,受光器接受光线后导通,产生光电流从输出端输出,从而实现了“电-光-电”的转换。

普通光电耦合器只能传输数字信号(开关信号),不适合传输模拟信号。

线性光电耦合器是一种新型的光电隔离器件,能够传输连续变化的模拟电压或电流信号,这样随着输入信号的强弱变化会产生相应的光信号,从而使光敏晶体管的导通程度也不同,输出的电压或电流也随之不同。

PC817光电耦合器不但可以起到反馈作用还可以起到隔离作用。

\\当输入端加电信号时,发光器发出光线,照射在受光器上,受光器接受光线后导通,产生光电流从输出端输出,从而实现了“电-光-电”的转换。

普通光电耦合器只能传输数字信号(开关信号),不适合传输模拟信号。

线性光电耦合器是一种新型的光电隔离器件,能够传输连续变化的模拟电压或电流信号,这样随着输入信号的强弱变化会产生相应的光信号,从而使光敏晶体管的导通程度也不同,输出的电压或电流也随之不同。

PC817光电耦合器不但可以起到反馈作用还可以起到隔离作用。

光耦的测量:用数字表测二极管的方法分别测试两边的两组引脚,其中仅且仅有一次导通的,红表笔接的为阳极,黑表笔接的为阴极(指针表相反)。

且这两脚为低压端,也就是反馈信号引入端。

在正向测试低压端时,再用另一块万用表测试另外高压端两只脚,接通时,红表笔所接为C极,黑表笔接为E极。

当断开低压端的表笔时,高压端的所接万用表读数应为无穷大。

同理:只要在反馈端加一定的电压,高压端就应能导通,反之,该器件应为损坏。

光耦能否代用,主要看其CTR参数值是否接近。

测量的实质就是:就是分别去测发光二极管和3极管的好坏。

另外一种测量说法:用两个万用表就可以测了。

光电耦合器由发光二极管和受光三极管封装组成。

常用光耦简介及常见型号常用光耦简介及常见型号公司内部编号:(GOOD-TMMT-MMUT-UUPTY-UUYY-DTTI- 常用光耦简介及常见型号常用光耦简介及常见型号光电耦合器(简称光耦)是开关电源电路中常用的器件。

光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

常用的4N系列光耦属于非线性光耦常用的线性光耦是PC817A—C系列。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于弄开关信号的传输,不适合于传输模拟量。

线性光耦的电流传输手特性曲线接进直线,并且小信号时性能较好,能以线性特性进行隔离控制。

开关电源中常用的光耦是线性光耦。

如果使用非线性光耦,有可能使振荡波形变坏,严重时出现寄生振荡,使数千赫的振荡频率被数十到数百赫的低频振荡依次为号调制。

由此产生的后果是对彩电,彩显,VCD,DCD等等,将在图像画面上产生干扰。

同时电源带负载能力下降。

在彩电,显示器等开关电源维修中如果光耦损坏,一定要用线性光耦代换。

常用的4脚线性光耦有PC817A----C。

PC111 TLP521等常用的六脚线性光耦有:TLP632 TLP532 PC614 PC714 PS2031等。

常用的4N25 4N26 4N35 4N36是不适合用于开关电源中的,因为这4种光耦均属于非线性光耦。

经查大量资料后,以下是目前市场上常见的高速光藕型号:100K bit/S:6N138、6N139、PS87031M bit/S:6N135、6N136、CNW135、CNW136、PS8601、PS8602、PS8 701、PS9613、PS9713、CNW4502、HCPL-2503、HCPL-4502、HCPL-2530(双路)、HCPL-2531(双路)10M bit/S:6N137、PS9614、PS9714、PS9611、PS9715、HCPL-2601、H CPL-2611、HCPL-2630(双路)、HCPL-2631(双路)光耦合器的增益被称为晶体管输出器件的电流传输比(CTR),其定义是光电晶体管集电极电流与LED正向电流的比率(ICE/IF)。

光电耦合器(简称光耦)是开关电源电路中常用的器件。

光电耦合器分为两种:一种为非线性光耦,另一种为线性光耦。

常用的4N系列光耦属于非线性光耦常用的线性光耦是PC817A—C系列。

非线性光耦的电流传输特性曲线是非线性的,这类光耦适合于弄开关信号的传输,不适合于传输模拟量。

线性光耦的电流传输手特性曲线接进直线,并且小信号时性能较好,能以线性特性进行隔离控制。

开关电源中常用的光耦是线性光耦。

如果使用非线性光耦,有可能使振荡波形变坏,严重时出现寄生振荡,使数千赫的振荡频率被数十到数百赫的低频振荡依次为号调制。

由此产生的后果是对彩电,彩显,VCD,DCD等等,将在图像画面上产生干扰。

同时电源带负载能力下降。

在彩电,显示器等开关电源维修中如果光耦损坏,一定要用线性光耦代换。

常用的4脚线性光耦有PC817A----C。

PC111 TLP521等常用的六脚线性光耦有:TLP632 TLP532 PC614 PC714 PS2031等。

常用的4N25 4N26 4N35 4N36是不适合用于开关电源中的,因为这4种光耦均属于非线性光耦。

以下是目前市场上常见的高速光藕型号:100K bit/S:6N138、6N139、PS87031M bit/S:6N135、6N136、CNW135、CNW136、PS8601、PS8602、PS8701、PS9613、PS9713、CNW4502、HCPL-2503、HCPL-4502、HCPL-2530(双路)、HCPL-2531(双路)10M bit/S:6N137、PS9614、PS9714、PS9611、PS9715、HCPL-2601、HCPL-2611、HCPL-2630(双路)、HCPL-2631(双路)光耦合器的增益被称为晶体管输出器件的电流传输比(CTR),其定义是光电晶体管集电极电流与LED正向电流的比率(ICE/IF)。

光电晶体管集电极电流与VCE有关,即集电极和发射极之间的电压。

光耦型号

1. 简介

光耦是一种电气隔离器件,常用于将输入和输出电路隔离开来,以便在电路之间传递信号。

光耦由发光二极管(LED)和光敏晶体管(光电二极管)组成,通过光的传递来实现电气隔离。

在许多应用中,光耦通常被用于隔离高压电路和低压电路,以提高系统的安全性和稳定性。

2. 光耦型号及特性

在市场上,有许多不同型号的光耦可供选择。

以下是一些常见的光耦型号及其特性:

2.1 PC817

•输入电流:5 mA

•最大工作电压:80 V

•最大耐受电压:6 V

•典型电阻值:50-600 ohms

•转移比(CTR):50-600% 2.2 MOC3021

•输入电流:10-15 mA

•最大工作电压:400 V

•最大耐受电压:6 V

•典型电阻值:100-600 ohms

•转移比(CTR):100-600% 2.3 TLP521

•输入电流:3-16 mA

•最大工作电压:80 V

•最大耐受电压:5 V

•典型电阻值:200-500 ohms

•转移比(CTR):50-600%

2.4 PC123

•输入电流:10-50 mA

•最大工作电压:160 V

•最大耐受电压:4 V

•典型电阻值:50-1000 ohms

•转移比(CTR):100-200%

3. 使用注意事项

3.1 电气参数

在选择光耦型号时,需要注意光耦的电气参数,如输入电流、最大工作电压和最大耐受电压等。

这些参数直接影响到光耦的使用范围和可靠性。

3.2 环境条件

光耦通常需要在一定的环境条件下工作,如温度范围和湿

度等。

在使用光耦时,需要确保其工作环境符合其规定的条件,以避免不必要的损坏和故障。

3.3 电路设计

在使用光耦时,需要合理设计电路,确保输入和输出电路之间的电气隔离有效。

在设计电路时,需要注意输入和输出电压的匹配,以及输入和输出电流的限制。

4. 应用领域

光耦广泛应用于电力电子、通信、工控、医疗设备和家电等领域。

以下是一些常见的应用领域:

•继电器驱动

•开关电源控制

•光耦隔离开关

•交流电源控制

•电动机控制

•电流检测和测量

5. 总结

光耦是一种常见的电气隔离器件,通过光的传递来实现输入和输出电路之间的隔离。

在选择和使用光耦时,需要注意其电气参数、工作环境和电路设计等方面的问题。

光耦在电力电子、通信、工控、医疗设备和家电等领域有着广泛的应用。

通过合理选择和使用光耦,可以提高系统的安全性和稳定性,满足不同应用场景的需求。