广东工业大学材料模具专业英语-课件总结

- 格式:doc

- 大小:203.50 KB

- 文档页数:20

热处理锻后进行一次或多次重新加热和冷却操作的热循环过程,以便使锻件获得所需的显微组织和机械性能。

几乎没有一类锻件是生产出来而不经过热处理的。

未经过热处理的锻件经常被作为低碳钢而应用在非关键的场合或者是为接下来的进一步的热机械加工和热处理做准备。

钢铁的化学成分、产品的尺寸和形状以及期望得到的属性都是决定产品生产周期的重要因素The object of heat treatment metals is to impart certain desired physical properties to the metal or to eliminate undesirable structural conditions which may occur in the processing or fabrication of the material ,In the application of any heat treatment it is desirable that the “previous history” or structural condition of the material be know n so that a method of treatment can be prescribed to produce the desired result. In the absence of information as to the previous processing, microscopic study of the structure is desirable to determine the correct procedure to be followed金属材料热处理的目的是为了使材料获得某些期望得到的物理性能或者是消除发生在金属成型或者加工过程中所产生的不期望得到的组织状态。

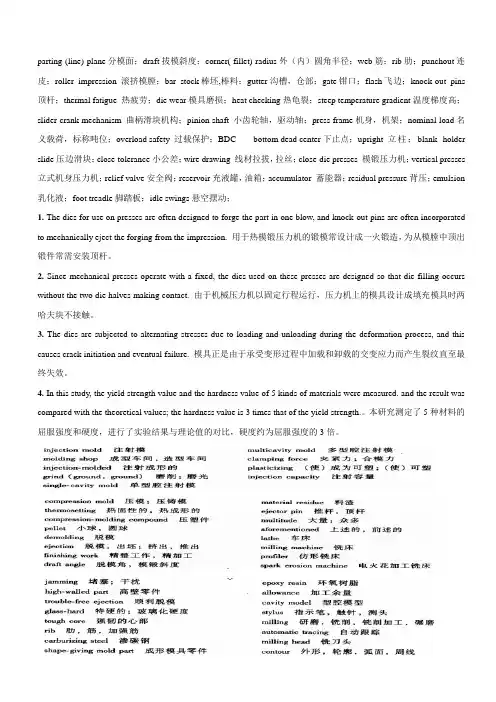

parting (line) plane分模面;draft拔模斜度;corner( fillet) radius外(内)圆角半径;web筋;rib肋;punchout连皮;roller impression 滚挤模膛;bar stock棒坯,棒料;gutter沟槽,仓部;gate钳口;flash飞边;knock-out pins 顶杆;thermal fatigue 热疲劳;die wear模具磨损;heat checking热龟裂;steep temperature gradient温度梯度高;slider-crank mechanism 曲柄滑块机构;pinion shaft 小齿轮轴,驱动轴;press frame机身,机架;nominal load名义载荷,标称吨位;overload safety 过载保护;BDC------bottom dead center下止点;upright 立柱;blank holder slide压边滑块;close-tolerance小公差;wire drawing 线材拉拔,拉丝;close-die presses 模锻压力机;vertical presses 立式机身压力机;relief valve安全阀;reservoir充液罐,油箱;accumulator 蓄能器;residual pressure背压;emulsion 乳化液;foot treadle脚踏板;idle swings悬空摆动;1. The dies for use on presses are often designed to forge the part in one blow, and knock-out pins are often incorporated to mechanically eject the forging from the impression. 用于热模锻压力机的锻模常设计成一火锻造,为从模膛中顶出锻件常需安装顶杆。

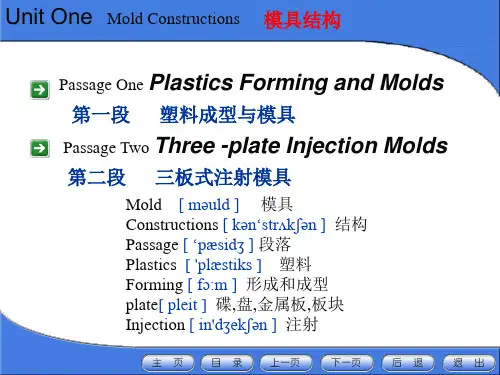

计算机辅助设计computer aided design(CAD)电弧焊 arc welding聚氯乙烯polyvinyl chloride(PVC)吹塑blow moulding计算机辅助制造computer aided manufacturing(CAM)聚乙烯 polyethylene(PE)热固性塑料 thermosetting plastics螺杆预热装置screw preplasticiser unit聚丙烯polypropylene(PP)空回程idle reture stroke成品 finished article溶剂保护电弧焊flux-shielded arc welding模锻 closed-die forging(stamping)临界温度 critical temperature吸塑vacuum forming热塑性塑料thermolplastic生铁 pig iron聚四氟乙烯poly-tetra-fluoro-ethylene (PTFE)(柱塞式)注射成型机(Ram)injection moulding machine模具维护费用dies maintenance costs球化spheroidizing聚合物分子的几何形状 the geometrical form of polymer molecule 模具设计design of die注射模塑infection moulding力学性能mechanical properties分模线parting line铜基合金copper-based alloys金属压力加工metalworking低碳钢low carbon steel抗拉强度tensile strength对焊buttwelding显微组织microstructures碳化钨tungsten carbide(WC)弹性模量modulus of elasticity热处理heat treatment自由锻open-die forging(blacksmith forging)粉末冶金powder metallurgy线状聚合物linear polymers正火和回火normalizing and tempering第一讲1. 1 专业英语阅读材料:Metal Forming Processes in Manufacturing1. 2 阅读课文—— Welding1. 1 专业英语阅读材料: Metal Forming Processes in Manufacturing制造业中的金属成形工艺Metal Forming Processes in ManufacturingMetal forming includes (a) massive forming processes such as forging, extrusion, rolling and drawing and (b) sheet forming processes such as brake forming, deep drawing and stretch forming. Among the group of manufacturing processes discussed earlier, metal forming represents a highly significant group of processes for producing industrial and military components and consumer goods.译文金属成形包括体积成形和板料成形。

聚丙烯polypropylene(PP)聚乙烯 polyethylene(PE)聚四氟乙烯poly-tetra-fluoro-ethylene (PTFE)计算机辅助设计computer aided design(CAD)电弧焊 arc welding聚氯乙烯polyvinyl chloride(PVC)吹塑blow moulding计算机辅助制造computer aided manufacturing(CAM)热固性塑料 thermosetting plastics螺杆预热装置screw preplasticiser unit空回程idle reture stroke成品 finished article溶剂保护电弧焊flux-shielded arc welding模锻 closed-die forging(stamping)临界温度 critical temperature吸塑vacuum forming热塑性塑料thermolplastic生铁 pig iron(柱塞式)注射成型机(Ram)injection moulding machine模具维护费用dies maintenance costs球化spheroidizing聚合物分子的几何形状 the geometrical form of polymer molecule 模具设计design of die注射模塑infection moulding力学性能mechanical properties分模线parting line铜基合金copper-based alloys金属压力加工metalworking低碳钢low carbon steel抗拉强度tensile strength对焊buttwelding显微组织microstructures碳化钨tungsten carbide(WC)弹性模量modulus of elasticity热处理heat treatment自由锻open-die forging(blacksmith forging)粉末冶金powder metallurgy线状聚合物linear polymers正火和回火normalizing and tempering第一讲1. 1 专业英语阅读材料:Metal Forming Processes in Manufacturing1. 2 阅读课文—— Welding1. 1 专业英语阅读材料: Metal Forming Processes in Manufacturing制造业中的金属成形工艺Metal Forming Processes in ManufacturingMetal forming includes (a) massive forming processes such as forging, extrusion, rolling and drawing and (b) sheet forming processes such as brake forming, deep drawing and stretch forming. Among the group of manufacturing processes discussed earlier, metal forming represents a highly significant group of processes for producing industrial and military components and consumer goods.译文金属成形包括体积成形和板料成形。

体积成形有锻造、挤压、轧制和拉拔;板料成形有压弯、深拉深和张拉成形等。

早期对这类制造工艺的讨论认为:金属成形是用于工业,军事及消费品生产的重要工艺。

Metal Forming Processes in ManufacturingA common way of classifying metal forming processes is to consider cold (room temperature) and hot (above the recrystallization temperature) forming. Most materials behave differently under the different temperature conditions. Usually, the yield stress of metal increases with increasing strain (or deformation) duringcold forming and with increasing stain rate (or deformation rate) during hot forming. However, the general principles governing the forming of metals at various temperatures are basically the same; therefore, classification of forming processes based on initial material temperature does not contribute a great deal to the understanding and improvement of theses processes. In fact, tool design, machinery, automation, part handling and lubrication concepts can be best considered by means of a classification based not on temperature but rather on specific input and output geometries and material and production rate conditions. 译文一般将金属成形按温度分为冷成形(室温)和热成形(再结晶温度以上)。

大多数材料在不同的温度有不同的特性。

通常,在冷成形中材料的屈服应力随应变的增加而增加,而在热成形中,材料的屈服应力随应变比(变形率)的增加而增加。

但是,在不同温度下决定金属成形的原理基本是相同的。

因此,成型工艺的分类是以原材料的温度为基础的,而不是根据对这些工艺的了解和改进而进行的。

事实上,模具设计、设备、自动化、零件的操控及润滑概念不是通过温度分类来考虑的,而要考虑材料、输入输出时的零件形状、生产率等因素。

Metal Forming Processes in ManufacturingComplex geometries, in both massive and sheet forming processes, can be obtained equally well by cold or hot forming. Of course, due to the lower yield strength of the deforming material at elevated temperatures, tool stresses and machine loads are, in a relative sense, lower in hot forming than in cold forming.译文在体积成形和板料成形工艺中,用热加工和冷加工都可获得形状复杂的零件。

当然,由于变形材料在高温下屈服强度较低,在热成形时模具压力和设备的吨位要比冷成形时小些。

Lesson13 Welding专业名词及术语:welding 焊接pressurewelding压力焊spotwelding点焊buttwelding对头(缝)焊fusionwelding 熔焊flux-shielded arc welding 溶剂保护电弧焊专业名词及术语:diversity不同,多样性fastening 连接件,紧固件shielding 遮护,屏蔽soldering 软钎焊,(低温)焊料bismuth铋cadmium镉专业名词及术语:rivet铆钉,铆接braze硬钎焊,铜焊oxidation氧化flux 焊接,助熔剂squeeze挤压oxy-acetylene 氧(乙)炔专业名词及术语:torch焊炬electrod电(焊) 极,焊条filler填充剂overlap搭接,重叠strike放电句子分析:1. Not only metals can be welded, so can many of the plastics.不但金属能焊接,许多塑料也能焊接。

2. One of the most important operations in soldering is that of cleaning the surface to be joined, this may be done by some acid cleaner.软钎焊中最重要的操作之一是清除所要焊的金属表面,这可以通过酸性清洁剂来实现。

句子分析:3. The ends of metal are heated to a white heat—for iron, the welding temperature should be about 1300 C –in a flame.用火焰把金属端部加热到白热状态----铁的焊接温度约为1300度。

句子分析:4. Care must be taken to ensure that the surfaces are thoroughly clean first, for dirt will weaken the weld.因为杂质将削弱焊接质量,必须注意要确保金属表面得先清除干净。

句子分析:5. In this important series of welding processes the electric are supplies the heat for fusion while a flux is responsible for the shielding and cleaning functions and often also for the metallurgical control.在这一系列重要的焊接过程中,电弧为熔化金属供热,而焊剂起保护和清理作用,经常用于冶金控制中。