品保常用专业术语

- 格式:doc

- 大小:31.50 KB

- 文档页数:4

DOA(dead on arrival) 一到就死的那些产品,MRB:Material Review Board 原意是“材料审查委员会”(一)QC:品质控制(Quality Control)(1)、QE:品质工程(Quality Engineering)(2)、QA:品质保证(Quality Assurance)(3)、IQC:进料检验(In Coming Quality Control))(4)、FQC:最终品质检验(Final Quality contro)(5)、OQC:出货检验(Outgoing Quality Control)(6)、IPQC:制程检验(In process Quality Control)(7)、QCC:品管圈(Quality Control Circle)(8)、TQM:全面品质经营(Total Quality Manage)或者TQC(Total Quality Control)(9)、SPC:统计制程管制(Statistics Process Control)(10)、COQ:品质成本(Cost Of Quality)(11)、AQL:允收品质水准(Accept Quality Control)二、spc:统计制程控制FMEA:失效模式与效果分析msa:测量系统分析doe:试验设计本标准首先对现有的质量标准和有关出版物作了筛选,确定了本标准应包含的质量术语,然后给出了定义。

在上述出版物中使用的许多术语有专门的含义和用途,而不是在词典中能查到的一般性定义。

因此,希望通过使用本标准的定义,有助于沟通和理解。

对某些通用术语加以定义,以澄清它们有质量领域中的用法也是必要的。

下列有关质量体系的系列标准,直接采用本标准定义的术语:GB/T19000-ISO9000 质量管理和质量保证标准──选择和使用指南GB/T19001-ISO9001 质量体系──设计/开发、生产、安装和服务的质量保证模式GB/T19002-ISO9002 质量体系──生产和安装的质量保证模式GB/T19003-ISO9003 质量体系──最终检验和试验的质量保证模式GB/T19004-ISO9004 质量管理和质量体系要素──指南1 范围和适用领域本标准对产品和服务与质量概念相关的、基本和主要术语给出了定义,以便于质量标准的制定和应用以及在国际交流中的相互理解。

成为质量部一名合格的品管员应具备的条件------QA版1、首先应掌握品管员应具备的最基本的品质基础知识(1)现目前智迪公司所使用的抽样方案为:GB/T 2828.1-2003单次Ⅱ级抽样方案,等同于美国军用标准MIL-STD-105D。

(2)常见英文字母的含义AQL:接收质量限 QC:品质控制IQC:来料品质控制 IPQC:制程品质控制QA:品质保证 OQC:出货品质控制QST:品质体系小组 AC/RE:允收数/拒收数LCL:下控制限 UCL:上控制限BOM:物料清单 QFD:质量功能展开PMC:生产材料控制(即物控部) Quality:品质CR:严重不合格(致命缺陷) N:批量MAJ:主要不合格 n:样本量MIN:次要不合格(轻微不合格)(3)常见包装英文字母/单词含义NET Weight(N.W):净重 MEAS:尺寸 Order NO.:订单号Gross Weight(G.W):毛重 Customer:顾客/消费者 Carton NO.:卡通箱号Quantity(QTY):数量 Model NO.:型号 Color:颜色Made in china:中国制造 Wireless:无线的 PO NO.:客户单号Football mouse:足球鼠标 Keyboard:键盘 Receiver:接收器Black:黑色的 Red:红色的 Yellow:黄色的 Total:总数Supplier:供方 Phone:电话号码 Remark:备注(4)包装外箱图案含义产品中不含有毒有害物质或元素垃圾筒环保标识轻拿轻放可再生循环堆码层数堆码层数怕雨怕雨怕雨小心轻放向上向上不可脚踩不可脚踩易碎易碎不可使用小刀可循环利用2、名词解释(1)严重不合格:指在产品使用过程中、有明显存在不安全因素(对使用者构成电击或大灾害、意外伤害、危险或抵触行销国家的标准与法令等)、或不能符合客户特殊要求,以及产品完全无功能,有病毒之缺点。

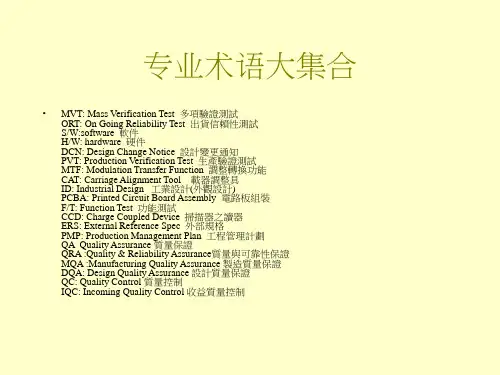

•品保常用专业术语LCL: Lower Control limit 管制下限AQL Acceptable Quality Level 可接受质量水平Control plan 管制计划Correction 纠正Cost down 降低成本CS: customer Sevice 客户中心Data 数据Data Collection 资料收集Description 描述Device 装置Digital 数字Do 执行DOE: Design of Experiments 实验设计Environmental 环境Equipment 设备FMEA: Failure Mode and Effect analysis 失效模式与效果分析FA: Failure Analysis 坏品分析FQA: Final Quality Assurance 最终质量保证FQC: Final Quality control 最终质量控制Gauge system 量测系统Grade 等级Inductance 电感Improvement 改善Inspection 检验IPQC: In Process Quality Control 制程质量控制IQC: Incoming Quality Control 来料质量控制ISO: International Organization for Standardization 国际标准组织LQC: Line Quality Control 生产线质量控制LSL: Lower Size Limit 规格下限LCL: Lower Control limit 管制下限MS A:Measurement System Analysis测量系统分析它使用数理统计和图表的方法对测量系统的误差进行分析,以评估测量系统对于被测量的参数来说是否合适,并确定测量系统误差的主要成份。

Materials 物料Measurement 量测Occurrence 发生率Operation Instruction 作业指导书Organization 组织Parameter 参数Parts 零件Pulse 脉冲Policy 方针Procedure 流程Process 过程Product 产品Production 生产Program 方案Projects 项目QA: Quality Assurance 质量保证QC: Quality Control 质量控制QE: Quality Engineering 质量工程QFD: Quality Function Design 质量机能展开Quality 品质Quality manual 品质手册Quality policy 质量政策Range 全距Record 记录Reflow 回流Reject 拒收Repair 返修Repeatability 再现性Reproducibility 再生性Requirement 要求Residual 误差Response 回应Responsibilities 职责Review 评审Rework 返工Rolled yield 直通率sample 抽样,样本Scrap 报废SOP: Standard Operation Procedure 标准作业书SPC: Statistical Process Control 统计制程管制Specification 规格SQA: Source(Supplier) Quality Assurance 供货商质量保证Taguchi-method 田口方法TQC: Total Quality Control 全面质量控制TQM: Total Quality Management 全面质量管理Traceability 追溯UCL: Upper Control Limit 管制上限USL: Upper Size Limit 规格上限Validation 确认Variable 计量值Verification 验证Version 版本QCC Quality Control Circle 质量圈/QC小组PDCA Plan Do Check Action 计划执行检查总结Consumer electronics 消费性电子产品Communication 通讯类产品Core value (核心价值)Love 爱心Confidence 信心Decision 决心Corporate culture (公司文化)Integration 融合Responsibility 责任Progress 进步QC quality control 品质管理人员FQC final quality control 终点质量管理人员IPQC in process quality control 制程中的质量管理人员OQC output quality control 最终出货质量管理人员IQC incoming quality control 进料质量管理人员TQC total quality control 全面质量管理POC passage quality control 段检人员QA quality assurance 质量保证人员OQA output quality assurance 出货质量保证人员QE quality engineering 质量工程人员FAI first article inspection 新品首件检查FAA first article assurance 首件确认CP capability index 能力指数SSQA standardized supplier quality audit 合格供货商质量评估FMEA failure model effectiveness analysis 失效模式分析AQL Acceptable Quality Level 运作类允收质量水平S/S Sample size 抽样检验样本大小ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的Q/R/S Quality/Reliability/Service 质量/可靠度/服务P/N Part Number 料号L/N Lot Number 批号AOD Accept On Deviation 特采UAI Use As It 特采FPIR First Piece Inspection Report 首件检查报告PPM Percent Per Million 百万分之一SPC Statistical Process Control 统计制程管制SQC Statistical Quality Control 统计质量管理GR&R Gauge Reproducibility & Repeatability 量具之再制性及重测性判断量可靠与否DIM Dimension 尺寸DIA Diameter 直径QIT Quality Improvement Team 质量改善小组ZD Zero Defect 零缺点QI Quality Improvement 质量改善QP Quality Policy 目标方针TQM Total Quality Management 全面质量管理RMA Return Material Audit 退料认可7QCTools 7 Quality Control Tools 品管七大手法通用之件类ECN Engineering Change Notice 工程变更通知(供货商)ECO Engineering Change Order 工程改动要求(客户)PCN Process Change Notice 工序改动通知PMP Product Management Plan 生产管制计划SIP Standard Inspection Procedure 制程检验标准程序SOP Standard Operation Procedure 制造作业规范IS Inspection Specification 成品检验规范BOM Bill Of Material 物料清单PS Package Specification 包装规范SPEC Specification 规格DWG Drawing 图面系统文件类ES Engineering Standard 工程标准IWS International Workman Standard 工艺标准ISO International Standardization Organization 国际标准化组织GS General Specification 一般规格部类PMC Production & Material Control 生产和物料控制PCC Product control center 生产管制中心PPC Production Plan Control 生产计划控制MC Material Control 物料控制DCC Document Control Center 文件控制中心QE Quality Engineering 质量工程(部)QA Quality Assurance 质量保证处QC Quality Control 质量管理(课)PD Product Department 生产部LAB Laboratory 实验室IE Industrial Engineering 工业工程R&D Research & Design 设计开发部。

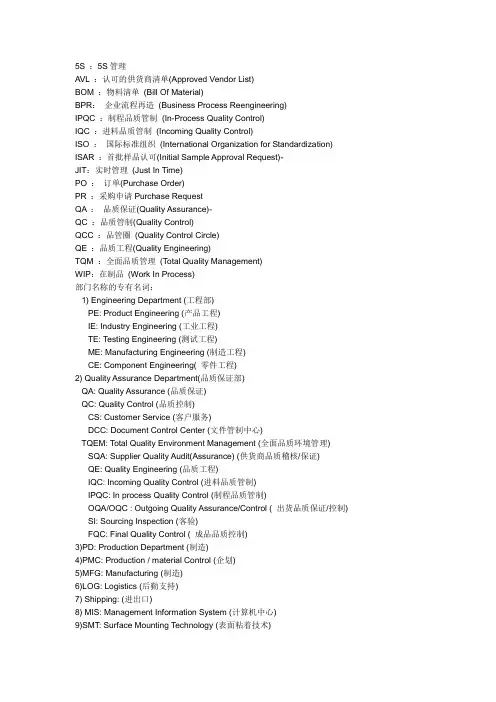

5S :5S管理AVL :认可的供货商清单(Approved Vendor List)BOM :物料清单(Bill Of Material)BPR:企业流程再造(Business Process Reengineering)IPQC :制程品质管制(In-Process Quality Control)IQC :进料品质管制(Incoming Quality Control)ISO :国际标准组织(International Organization for Standardization) ISAR :首批样品认可(Initial Sample Approval Request)-JIT:实时管理(Just In Time)PO :订单(Purchase Order)PR :采购申请Purchase RequestQA :品质保证(Quality Assurance)-QC :品质管制(Quality Control)QCC :品管圈(Quality Control Circle)QE :品质工程(Quality Engineering)TQM :全面品质管理(Total Quality Management)WIP:在制品(Work In Process)部门名称的专有名词:1) Engineering Department (工程部)PE: Product Engineering (产品工程)IE: Industry Engineering (工业工程)TE: Testing Engineering (测试工程)ME: Manufacturing Engineering (制造工程)CE: Component Engineering( 零件工程)2) Quality Assurance Department(品质保证部)QA: Quality Assurance (品质保证)QC: Quality Control (品质控制)CS: Customer Service (客户服务)DCC: Document Control Center (文件管制中心)TQEM: Total Quality Environment Management (全面品质环境管理)SQA: Supplier Quality Audit(Assurance) (供货商品质稽核/保证)QE: Quality Engineering (品质工程)IQC: Incoming Quality Control (进料品质管制)IPQC: In process Quality Control (制程品质管制)OQA/OQC : Outgoing Quality Assurance/Control ( 出货品质保证/控制) SI: Sourcing Inspection (客验)FQC: Final Quality Control ( 成品品质控制)3)PD: Production Department (制造)4)PMC: Production / material Control (企划)5)MFG: Manufacturing (制造)6)LOG: Logistics (后勤支持)7) Shipping: (进出口)8) MIS: Management Information System (计算机中心)9)SMT: Surface Mounting Technology (表面粘着技术)10) M/I: Manual In Process (手插件)EC/CP/ECN:1)Engineering Change/Change Process/Engineering Change Notice (工程变更)2) CRB: Change Review Board (工程变更会议)3) QIT: Quality Improvement Team 品质改善小组4) M.Q.F.S: Material Quality Feedback Sheet (来料品质回馈单)5) SCAR: Supplier Corrective Action Report (供货商改善对策报告)6) 8D Sheet: 8 Disciplines sheet ( 8D单)12) 5S: SEIRI、SEITON、SEISO、SEIKETSU、SHITSUKE (整理,整顿,清扫,清洁,素养)13) BOM/LOM: Bill Of Material/ List Of Material (物料清单)14) OBA: Out of Box Audit (开箱稽核)15) FIFO: First In First Out (先进先出)'16) CAR: Corrective Action Report (改善措施报告)17) MRB: Material Review Board (物料审核小组)18) JIT: Just in time 实时管理19) SPC: Statistic Process Control (预计制程管制)20) PDCA:PDCA (Plan-Do-Check-Action) (管理循环)21) WIP: Work in Process (在制品)22) MPQ: Material Packing Quantity (物料最小包装量)23) S/O: Sales Order (业务订单)24) P/O: Purchase Order (采购订单)25) P/R: Purchase Request (请购单)26) DSCN: Delivery Schedule Change Notice (交期变更通知)27) PILOT RUN: (试投产)28) ICT: In Circuit Test (线路测试)29) F/T: Function Test (功能测试)30) T/U: Touch Up (锡面修补)31) DPPM: Defect Part Per Million (不良率的一种表达方式(百万分之)32) Corrective Action: (改善对策)33)Rework: (返工)34) SOP: Standard Operation Process (标准作业流程)35)TOP: Test Operation Process (测试作业流程)36) SMD: Surface Mounting Device (表面粘着装置)37) QAPS: Quality Assurance Process Sheet (品质工程表)。

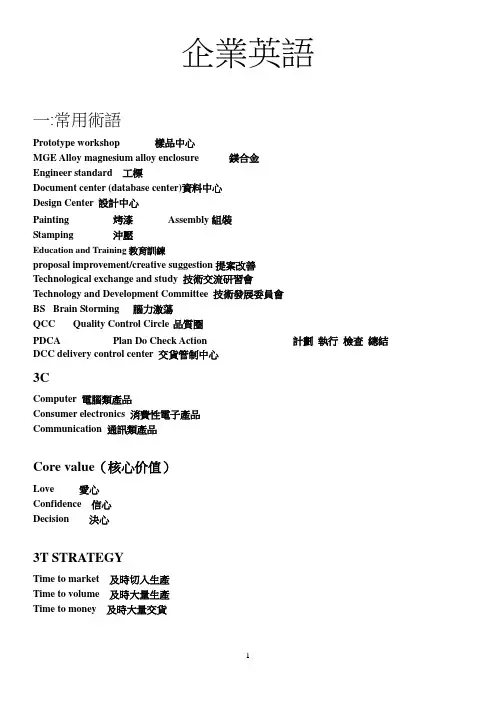

企業英語一:常用術語Prototype workshop 樣品中心MGE Alloy magnesium alloy enclosure 鎂合金Engineer standard 工標Document center (database center)資料中心Design Center 設計中心Painting 烤漆Assembly組裝Stamping 沖壓Education and Training教育訓練proposal improvement/creative suggestion提案改善Technological exchange and study 技術交流研習會Technology and Development Committee 技術發展委員會BS Brain Storming 腦力激蕩QCC Quality Control Circle 品質圈PDCA Plan Do Check Action 計劃執行檢查總結DCC delivery control center 交貨管制中心3CComputer 電腦類產品Consumer electronics 消費性電子產品Communication 通訊類產品Core value(核心价值)Love 愛心Confidence 信心Decision 決心3T STRATEGYTime to market 及時切入生產Time to volume 及時大量生產Time to money 及時大量交貨FOUR CONTROL YSTEM 四大管制系統Engineering control system 工程管制系統Quality control system品質管制系統Manufacturing control system生產管制系統Management control system經營管制系統7SClassification整理(sorting, organization)-seiriRegulation整頓(arrangement, tidiness)-seitonCleanliness清掃(sweeping, purity)-seisoConservation清洁(cleaning, cleanliness)-seiktsuCulture教養(discipline)-shitsukeSave 節約Safety安全二:英文縮寫品質人員名稱類QC quality control 品質管理人員FQC final quality control 終點品質管制人員IPQC in process quality control 制程中的品質管制人員OQC output quality control 最終出貨品質管制人員IQC incoming quality control 進料品質管制人員TQC total quality control 全面質量管理POC passage quality control 段檢人員QA quality assurance 質量保證人員OQA output quality assurance 出貨質量保證人員QE quality engineering 品質工程人員品質保證類FAI first article inspection 新品首件檢查FAA first article assurance 首件確認CP capability index 能力指數CPK capability process index 模具製程能力參數SSQA standardized supplier quality audit 合格供應商品質評估FMEA failure model effectiveness analysis 失效模式分析FQC運作類AQL Acceptable Quality Level 運作類允收品質水準S/S Sample size 抽樣檢驗樣本大小ACC Accept 允收REE Reject 拒收CR Critical 極嚴重的MAJ Major 主要的MIN Minor 輕微的Q/R/S Quality/Reliability/Service 品質/可靠度/服務P/N Part Number 料號L/N Lot Number 批號AOD Accept On Deviation 特采UAI Use As It 特采FPIR First Piece Inspection Report 首件檢查報告PPM Percent Per Million 百萬分之一制程統計品管專類SPC Statistical Process Control 統計製程管制SQC Statistical Quality Control 統計品質管制GRR Gauge Reproductiveness & Repeatability 量具之再制性及重測性判斷量可靠與否DIM Dimension 尺寸DIA Diameter 直徑N Number 樣品數其它品質術語類QIT Quality Improvement Team 品質改善小組ZD Zero Defect 零缺點QI Quality Improvement 品質改善QP Quality Policy 目標方針TQM Total Quality Management 全面品質管理RMA Return Material Audit 退料認可7QCTools 7 Quality Control Tools 品管七大手法通用之件類ECN Engineering Change Notice 工程變更通知(供應商)ECO Engineering Change Order 工程改動要求(客戶)PCN Process Change Notice 工序改動通知PMP Product Management Plan 生產管制計劃SIP Standard Inspection Procedure 製程檢驗標準程序SOP Standard Operation Procedure 製造作業規範IS Inspection Specification 成品檢驗規範BOM Bill Of Material 物料清單PS Package Specification 包裝規範SPEC Specification 規格DWG Drawing 圖面系統文件類ES Engineering Standard 工程標準CGOO China General PCE龍華廠文件IWS International Workman Standard 工藝標準ISO International Standard Organization 國際標準化組織GS General Specification 一般規格部類PMC Production & Material Control 生產和物料控制PCC Product control center 生產管制中心PPC Production Plan Control 生產計劃控制MC Material Control 物料控制DC Document Center 資料中心QE Quality Engineering 品質工程QA Quality Assurance 品質保證QC Quality Control 品質管制)PD Product Department 生產部LAB Laboratory 實驗室IE Industrial Engineering 工業工程R&D Research & Design 設計開發部生產類PCs Pieces 個(根,塊等) PRS Pairs 雙(對等)CTN Carton 卡通箱PAL Pallet/skid 棧板PO Purchasing Order 采購訂單MO Manufacture Order 生產單D/C Date Code 生產日期碼ID/C Identification Code (供應商)識別碼SWR Special Work Request 特殊工作需求L/N Lot Number 批號P/N Part Number 料號OEM Original Equipment Manufacture 原設備製造PC Personal Computer 個人電腦CPU Central Processing Unit 中央處理器A.S.A.P As Soon As Possible 盡可能快的E-MAIL Electrical-Mail 電子郵件N/A Not Applicable 不適用QTY Quantity 數量I/O input/output 輸入/輸出NG Not Good 不行,不合格C=0 Critical=0 極嚴重不允許APP Approve 核準,認可,承認CHK Check 確認ASS'Y Assembly 裝配,組裝T/P True Position 真位度5WIH When, Where, Who, What, Why, How to6M Man, Machine, Material, Method, Measurement, Message4MTH Man, Material, Money, Method, Time, How 人力,物力,財務,技術,時間(資源) SQA Strategy Quality Assurance 策略品質保證DQA Design Quality Assurance 設計品質保證MQA Manufacture Quality Assurance 製造品質保證SSQA Sales and service Quality Assurance 銷售及服務品質保證LRR Lot Reject Rate 批退率SPS Switching power supply 電源箱DT Desk Top 臥式(機箱)MT Mini-Tower 立式(機箱)DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringPCB Printed Circuit Board 印刷電路板CAR Correction Action Report 改善報告NG Not Good 不良WDR Weekly Delivery Requirement 周出貨要求PPM Percent Per Million 百萬分之一TPM Total Production Maintenance 全面生產保養MRP Material Requirement Planning 物料需計劃OS Operation System 作業系統TBA To Be Assured 待定,定缺D/C Drawing ChangeP/P Plans & ProcedureEMI Electrical-Music Industry 電子音樂工業Electrical Magnetic Interference 電子干扰RFI Read Frequency Input 讀頻輸入MMC Maximum Material ConditionMMS Maximum Material SizeLMC Least Material ConditionLMS Least Material SizeLED lighting-emitting diode 發光二极管QBR Quarter Business RecordCIP Continuous improvement process FGI Forecasted Goal InventoryCNC Computerized numeral controller B2C Business to customerB2B Business to businessA VL Approved vendor listPOP Procedure of packagingEOL End of lifeVDCS Vender defect correcting sheet PDCS Process defect correcting sheet GRN Goods receiving noteA/R Accounting receivableA/P Accounting payable三:專業詞匯通用類president董事長operator作業員position職務general manager總經理special assistant 特助deputy manager |'depjuti|=vice manager副理deputy supervisor =vice supervisor副課長group leader組長line leader線長supervisor 課長responsible department負責單位Human Resources Department 人力資源部Head count 人頭數production department生產部門planning department企劃部QC Section品管課stamping factory沖壓廠painting factory烤漆廠molding factory成型廠administration/general affairsdept./總務部production unit生產單位meeting minutes會議記錄distribution department分發單位subject主題conclusion結論decision items決議事項pre-fixed finishing date預定完成日Color management 顏色管理Visual management 目視管理production capacity生產力first count初盤first check初盤復櫂second count 復盤second check復盤復核quantity of physical inventorysecond count 復盤點數量physical inventory盤點數量physical count quantity帳面數量difference quantity差異量spare parts physical inventorylist備品盤點清單cause analysis原因分析waste materials廢料description品名specification 規格model機種work order工令revision版次remark備注registration登記registration card登記卡to control管制application form for purchase請購單consume, consumption消耗to notify通知to fill in填寫to collect, to gather收集statistics統計cosmetic inspection standard外觀檢驗規範computer case 電腦外殼(組件) personal computer enclosure電腦機箱產品front plate前板rear plate后板chassis |'∫æsi| 基座bezel panel面板Hood 上蓋base pan 基座bezel 面板riser card 擴充卡flat cable 排線TOP driver cage 上磁架bottom driver cage 下磁架resin film 樹脂膜raw materials原料materials物料steel plate鋼板roll/coil material捲料spare parts =buffer備品plastic parts塑膠件sheet metal parts/stamping parts 沖件material check list物料檢查表finished product成品semi-finished product半成品good product/accepted goods/accepted parts/good parts良品defective product/non-goodparts不良品disposed goods處理品warehouse/hub倉庫packing material包材basket蝴蝶竺plastic basket膠筐flow chart流程表單production tempo生產進度現狀lots of production生產批量manufacture procedure制程to revise, modify修訂to switch over to, switch—to,switching over切換engineering bottleneck, projectdifficulty工程瓶頸glove(s)手套glove(s) with exposed fingers割手套Band-Aid創可貼Industrial alcohol工業酒精broom掃把mop拖把vacuum cleaner吸塵器rag 抹布garbage container灰箕garbage can垃圾箱garbage bag垃圾袋liaison聯絡單rags抹布lamp holder燈架to mop the floor拖地to clean a table擦桌子air pipe 氣管delivery deadline交貨期die worker模工production, to produce生產equipment設備resistance電阻beacon警示燈coolant冷卻液crusher破碎機club car高爾夫球車plate電鍍power button電源按鍵reset button重置鍵forklift叉車Workshop traveler 天車trailer =long vehicle拖板車Hydraulic trolley手壓車hydraulic hand jack油壓板車casing = containerization裝箱velocity速度patent專利coordinate座標supply and demand供求career card履歷卡barricade隔板carton box紙箱to pull and stretch拉深work cell/work shop工作間sub-line支線bottleneck 瓶頸模具工程類plain die簡易模pierce die沖孔模forming die成型模progressive die連續模stage die工程模compound die復合模shearing die剪邊模riveting die鉚合模feature die公母模male die公模female die母模cavity型控母模core模心公模die change 換模to fix a die裝模to repair a die修模punch set上模座punch pad上墊板punch holder上夾板stripper pad脫料背板up stripper上脫料板upper plate上模板lower plate下模板die pad下墊板die holder下夾板die set下模座bottom block下墊腳bottom plate下托板(底板) upper supporting blank上承板upper padding plate blank上墊板top plate上托板(頂板)top block上墊腳stripping plate內外打(脫料板) outer stripper外脫料板inner stripper內脫料板lower stripper下脫料板punch 沖頭insert入塊(嵌入件) deburring punch壓毛邊沖子groove punch壓線沖子stamped punch字模沖子round punch圓沖子special shape punch異形沖子bending block折刀roller滾軸baffle plate擋塊located block定位塊supporting block for location定位支承塊air cushion plate氣墊板air-cushion eject-rod氣墊頂桿trimming punch切邊沖子stiffening rib punch = stinger加強筋衝子ribbon punch壓筋沖子reel-stretch punch卷圓壓平沖子guide plate定位板sliding block滑塊sliding dowel block滑塊固定塊die locker鎖模器pressure plate =plate pinch壓板thickness gauge厚薄規cutting die, blanking die沖裁模die block模塊folded block折彎塊sliding block滑塊location pin定位銷lifting pin頂料銷die plate, front board模板padding block墊塊stepping bar墊條panel board鑲塊to load a die裝上模具to unload a die 御模具active plate活動板lower sliding plate下滑塊板upper holder block上壓塊upper mid plate上中間板spring box彈簧箱spring-box eject-rod彈簧箱頂桿spring-box eject-plate彈簧箱頂板bushing block襯套cover plate蓋板guide pad導料塊pilot導正筒trim剪外邊pierce剪內邊pocket for the punch head挂鉤槽slug hole廢料孔radius半徑shim/wedge/heel/pad/spacer/gasket楔子torch-flame cut火焰切割set screw止付螺絲form block折刀round pierce punch =die button圓沖子shape punch =die insert異形子stock located block定位塊metal plate鈑金miller銑床grinder磨床tolerance公差score =groove壓線sliding block滑塊lathe車active plate活動板baffle plate擋塊cover plate蓋板groove punch壓線沖子air-cushion eject-rod氣墊頂桿spring-box eject-plate彈簧箱頂板capability能力parameter參數factor系數driller鉆床set up die架模height of die setting up架模高度analog-mode device類模器inner guiding post內導柱inner hexagon screw內六角螺釘dowel pin固定銷coil spring彈簧lifter pin頂料銷eq-height sleeves =spool等高套筒pin銷lifter guide pin浮升導料銷guide pin導正銷wire spring圓線彈簧outer guiding post外導柱stop screw止付螺絲located pin定位銷outer bush外導套press specification沖床規格die height閉模高度flow mark流痕welding mark溶合痕post screw insert螺紋套筒埋值self tapping screw自攻螺絲stripper plate脫料板piston活塞handle mold手持式模具flash mold溢流式模具positive mold擠壓式模具split mold分割式模具die lifter舉模器top stop上死點bottom stop下死點one stroke一行程to continue, cont.連動to grip(material)吸料location lump, locating piece, location block定位塊reset復位to file burr 銼毛刺embedded lump |in'bed| |l mp|鑲塊stamping-missing漏沖to tight a bolt擰緊螺栓to loosen a bolt擰鬆螺栓punched hole沖孔to cut edge =side cut =side scrap切邊to bending折彎to pull, to stretch拉伸engraving, to engrave刻印stamping 油印to stake鉚合designing, to design設計design modification設計脩改成gauge(or jig)治具pedal踩踏板stopper阻擋器flow board流水板torque扭矩spline =the multiple keys花鍵quenching淬火tempering回火annealing退火carbonization碳化alloy合金tungsten high speed steel鎢高速的moly high speed steel鉬高速的forming成型(抽击,沖击)draw hole抽孔bending折彎emboss击點dome击圓semi-shearing半剪stamp mark沖記號deburr or coin壓毛邊punch riveting沖壓鉚合side stretch側沖壓平reel stretch卷圓壓平groove壓線stamp letter沖字(料號)tick-mark nearside正面壓印tick-mark farside反面壓印extension DWG展開圖procedure DWG工程圖die structure DWG模具結構圖沖壓類punch, press沖punching machine 沖床hydraulic machine油壓機jack升降機decoiler整平機manufacture management製造管理stamping, press沖壓feeder送料機rack, shelf, stack料架taker取料機to reverse material 翻料to load material上料to unload material卸料to return material/stock to退料scraped |'skræpid|報廢scrape ..v.刮;削robot機械手production line流水線packaging tool打包機packaging打包成型類well type蓄料井insulated runner絕緣澆道方式hot runner熱澆道runner plat澆道模塊valve gate閥門澆口band heater環帶狀的電熱器spindle閥針spear head鉋尖頭slag well冷料井cold slag冷料渣air vent排氣道welding line熔合痕eject pin頂出針knock pin頂出銷return pin回位銷反頂針sleeve套筒stripper plate脫料板insert core放置入子runner stripper plate澆道脫料板guide pin導銷eject rod (bar)(成型機)頂業捧subzero深冷處理three plate三極式模具runner system澆道系統stress crack應力電裂orientation定向sprue gate射料澆口,直澆口nozzle射嘴sprue lock pin料頭鉤銷(拉料杆) slag well冷料井side gate側澆口edge gate側緣澆口tab gate搭接澆口film gate薄膜澆口flash gate閘門澆口slit gate縫隙澆口fan gate扇形澆口dish gate因盤形澆口diaphragm gate隔膜澆口ring gate環形澆口submarine gate潛入式澆口tunnel gate隧道式澆口pin gate針點澆口runner less無澆道sprue less 無射料管方式long nozzle延長噴嘴方式spur澆口;溶waste廢料board看板sliding rack滑料架to impose lines壓線to compress, compressing壓縮character die字模to feed, feeding送料material change, stock change材料變更feature change 特性變更prepare for, make preparations for準備rotating speed, revolution轉速abnormal handling異常處理組裝類Assembly line組裝線Layout布置圖Conveyer流水線運輸帶Rivet machine拉釘機Rivet gun拉釘槍Screw driver起子Electric screw driver電動起子Hydraulic machine 液壓機Pneumatic screw driver氣動起子automation自動化to stake, staking, riveting鉚合add lubricant oil加潤滑油argon welding氬焊cylinder油缸robot機械手conveying belt輸送帶transmission rack輸送架to draw holes抽孔bolt螺栓nut 螺母screw 螺絲identification tag標示單screwdriver plug起子插座automatic screwdriver電動啟子to move, to carry, to handle搬運be put in storage入庫packing包裝staker = riveting machine鉚合機fit together組裝在一起fasten鎖緊(螺絲)fixture 夾具(治具)pallet/skid棧板barcode條碼barcode scanner條碼掃描器fuse together熔合fuse machine/heat stake熱熔機processing, to process加工delivery, to deliver 交貨to return delivery to. to senddelivery back to return of goods退貨easily damaged parts易損件standard parts標準件to lubricate潤滑spring 彈簧spare tools location/buffer手工備品倉spare molds location模具備品倉tox machine自鉚機噴漆類phosphate皮膜化成viscosity涂料粘度alkalidipping脫脂main manifold主集流脈organic solvent有機溶劑demagnetization去磁;消磁high-speed transmission高速傳遞heat dissipation熱傳rack上料volatile揮發性degrease脫脂rinse水洗alkaline etch齡咬desmot剝黑膜D.I. rinse純水次Chromate鉻酸處理Anodize陽性處理seal封孔scraped products報放品disposed products處理品dismantle the die折模auxiliary function輔助功能heater band 加熱片thermocouple熱電偶derusting machine除銹機degate打澆口dryer烘干機induction感應induction light感應光response =reaction =interaction感應ram連杆edge finder巡邊器concave击convex凹cold slug冷塊blush 導色gouge溝槽;鑿槽satin texture段面咬花witness line證示線grit沙礫granule =pellet =grain細粒sand blasting噴沙grit maker抽粒機cushion緩沖fillet鑲;嵌邊roller pin formality滾針形式cam driver鍘楔shank摸柄crank shaft曲柄軸品質類qualified products, up-to-grade products良品defective products, notup-to-grade products不良品defective product box不良品箱poor processing 制程不良poor incoming part來件不良exposed metal/bare metal金屬裸露excessive defect過多的缺陷critical defect極嚴重缺陷major defect主要缺陷minor defect次要缺陷not up to standard不合規格cosmetic defect外觀不良lack of painting烤漆不到位slipped screw head/slippery slipped thread滑絲missing part漏件wrong part錯件oxidation氧化defective threading抽芽不良poor staking鉚合不良deficient purchase來料不良deficient manufacturing procedure制程不良cosmetic inspection外觀檢查inner parts inspection內部檢查blister 氣泡angular offset 角度偏差dent 壓痕scratch 刮傷deformation 變形filings 鐵削defective label 不良標簽abrasion 磨損Breaking. (be)broken,(be)cracked斷裂short射料不足nick缺口speck瑕疪shine亮班splay 銀紋gas mark焦痕delaminating起鱗speckle斑點mildewed =moldy = mouldy發霉deformation變形burr(金屬)flash(塑件)毛邊poor staking鉚合不良excessive gap間隙過大grease/oil stains油污inclusion雜質shrinking/shrinkage縮水mixed color雜色fold of packaging belt打包帶折皺painting make-up補漆discoloration羿色water spots水漬impurity 雜質Mismatch 錯位failure, trouble 故障deformation 變形rust 生銹peel 脫漆Shrink 縮水Contamination 臟污water spots 水漬Gap 間隙label error 標簽錯誤Missing label 漏貼rejection criteria 拒收標准Suspected rejects 可疑庇abrasion 損傷、磨損Texture surface 印花紋表面Streak 條紋stains 污點Blotch 斑點discoloration 脫色Inclusion 雜質slug mark 壓痕dirt grime 灰塵blush 毛邊薄膜sink 下凹Hickey 漏漆labels and logos 貼紙與商標Configuration labels 組合貼紙corrugated container 瓦擺紙箱Delaminating 脫層splattering 散點Gouge 銼孔puckering 折痕。

DOA(dead on arrival) 一到就死的那些产品,MRB:Material Review Board 原意是“材料审查委员会”(一)QC:品质控制(Quality Control)(1)、QE:品质工程(Quality Engineering)(2)、QA:品质保证(Quality Assurance)(3)、IQC:进料检验(In Coming Quality Control))(4)、FQC:最终品质检验(Final Quality contro)(5)、OQC:出货检验(Outgoing Quality Control)(6)、IPQC:制程检验(In process Quality Control)(7)、QCC:品管圈(Quality Control Circle)(8)、TQM:全面品质经营(Total Quality Manage)或者TQC(Total Quality Control)(9)、SPC:统计制程管制(Statistics Process Control)(10)、COQ:品质成本(Cost Of Quality)(11)、AQL:允收品质水准(Accept Quality Control)二、spc:统计制程控制FMEA:失效模式与效果分析msa:测量系统分析doe:试验设计本标准首先对现有的质量标准和有关出版物作了筛选,确定了本标准应包含的质量术语,然后给出了定义。

在上述出版物中使用的许多术语有专门的含义和用途,而不是在词典中能查到的一般性定义。

因此,希望通过使用本标准的定义,有助于沟通和理解。

对某些通用术语加以定义,以澄清它们有质量领域中的用法也是必要的。

下列有关质量体系的系列标准,直接采用本标准定义的术语:GB/T19000-ISO9000 质量管理和质量保证标准──选择和使用指南GB/T19001-ISO9001 质量体系──设计/开发、生产、安装和服务的质量保证模式GB/T19002-ISO9002 质量体系──生产和安装的质量保证模式GB/T19003-ISO9003 质量体系──最终检验和试验的质量保证模式GB/T19004-ISO9004 质量管理和质量体系要素──指南1 范围和适用领域本标准对产品和服务与质量概念相关的、基本和主要术语给出了定义,以便于质量标准的制定和应用以及在国际交流中的相互理解。

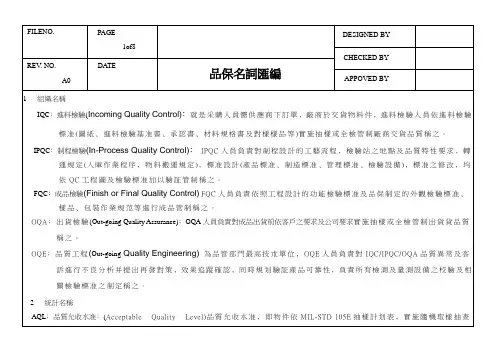

品保名词解释

SQE——供应质量工程师

OQC——出厂检验六西格玛品质论坛"Q.x9r1s k

IQE——原材料质量工程师

IPQE——过程质量工程师

FQE——最终品质工程师

QSE——质量体系工程%} ^ P ` ]

QAE——品质保证工程-质量-SPC ,six sigma,TS16949,MSA,FMEA P&A+R O R

S

VQE——vendor Quality Engineer厂商品质工程师

QE ——品质工程师3T h a9K S K7]0m

IQC——品质检验控制

QA——品质分析师

JQE——Joint Quality Engineer是接口品质工程师(Joint Quality Engineer,Dell系供应商特有)

DQA——是设计品保工程师

IPQC——In-process Quality control过程质量控制

FQC——Final Quality control最终品质控制

QST——Quality system team品质体系小组

IQC——来料品质控制-六西格玛品质论坛sgO'b1e Q K"l

OQC——出货品质控制

FQC——入库品质控制

IPQC——过程品质控制QC——quality control质量控制。

1.4P:產品(Product)、價格(Price)、促銷(Promotion)、通路(Place)。

2.4R:拒絕使用有害環境物質、減量使用有害環境物質、重複使用有害環境物質、回收再利用使用有害環境物質3.5S:是由日本企業研究出來的一種環境塑造方案,其目的在藉由整理(SEIRI)、整頓(SEITON)、清掃(SEISO)、清潔(SEIKETSU)及身美(SHITSUKE)五種行為來創造清潔、明朗、活潑化之環境,以提高效率、品質及顧客滿意度。

在原文中(日文),這五項皆是以"S"為其發音開頭故稱此種方案為「5S」。

5S活動的對象原本是針對現場的環境,它對生產現場環境全局進行綜合考慮,並制訂切實可行的計劃與措施,從而達到規範化管理,有許多公司擴展到辦公室的管理以增進辦公效率,常見的手法為紅牌作戰,看板及衍生的目視管理。

4.ABB(Activity-Based Budgeting) 實施作業制預算制度5.ABC(Activity-Based Costing)作業制成本制度:ABC及ABM(Activity-Base Management)作業制成本管理,以作業別作為分攤成本的基礎,在企業管理上可運用在定價決策、生產及產能決策、產品管理、顧客管理及企業策略上,同時具有提供決策者即時且有效、精確資訊的特性,對企業在創造競爭優勢上,是具有相當大的功能,其做法常為最古老的簿記再加上電腦分類系統,由於會計資料數量龐大,在電腦尚未普及前必須採行種種簡化如訂定分攤比例,但簡化可能會導致失真。

6.ABM(Activity-Base Management) 作業制成本管理7.ACD(Automatic Call Distributor)自動話務分配。

8.AOQ(Average Outgoing Quality) :平均出廠品質(指一連串貨批在選別檢驗後之平均不合格率。

9.AOQL(Average Outgoing Quality Limit):平均出廠品質界限(在各種品質水準下,貨批在選別檢驗後最高不合格率。

品质常用术语

1. “靠谱”!就像你找了个特别靠谱的朋友,不管啥时候都能靠得住。

比如说你让靠谱的同事帮忙处理个紧急任务,他绝对能办得妥妥当当。

2. “精细”呀!就像一位能工巧匠精心雕琢一件艺术品,每一个细节都处理得那么完美。

比如那精细制作的糕点,看着就诱人。

3. “耐用”呗!好比一双质量超好的鞋子,能陪你走过很长的路。

像我家那台耐用的老冰箱,用了好多年还好好的呢。

4. “优质”啊!就如同品尝一杯顶级的美酒,那滋味简直无与伦比。

像那个优质的服务,真的让人感觉超棒。

5. “可靠”啦!类似有一个永远在你背后支持你的伙伴。

比如那可靠的汽车,从来不会在关键时刻掉链子。

6. “精益求精”哟!就像一个不断追求完美的艺术家,永不满足。

比如那些精益求精的工匠们,打造出了多少令人惊叹的作品。

7. “扎实”呀!仿佛是一栋根基牢固的大楼,稳稳地矗立着。

像扎实的学习基础,会让以后的路更好走。

8. “上乘”啊!好比穿着一套用上乘面料制作的衣服,那质感就是不一样。

比如那用上乘食材做出来的美食,味道肯定特别好。

9. “一流”喽!就像世界一流的运动员,在赛场上闪闪发光。

像一

流的技术团队,能解决各种难题。

10. “卓越”啦!类似站在山峰之巅的强者,让人敬仰。

比如追求卓越的企业,总能引领行业发展。

我觉得这些品质常用术语都非常重要,它们代表着高标准、高质量,无论是在生活还是工作中,都能让我们感受到价值和意义。

LCL: Lower Control limit 管制下限AQL Acceptable Quality Level 可接受质量水平Control plan 管制计划Correction 纠正Cost down 降低成本CS: customer Sevice 客户中心Data 数据Data Collection 资料收集Description 描述Device 装置Digital 数字Do 执行DOE: Design of Experiments 实验设计Environmental 环境Equipment 设备FMEA: Failure Mode and Effect analysis 失效模式与效果分析FA: Failure Analysis 坏品分析FQA: Final Quality Assurance 最终质量保证FQC: Final Quality control 最终质量控制Gauge system 量测系统Grade 等级Inductance 电感Improvement 改善Inspection 检验IPQC: In Process Quality Control 制程质量控制IQC: Incoming Quality Control 来料质量控制ISO: International Organization for Standardization 国际标准组织LQC: Line Quality Control 生产线质量控制LSL: Lower Size Limit 规格下限LCL: Lower Control limit 管制下限MS A:Measurement System Analysis测量系统分析它使用数理统计和图表的方法对测量系统的误差进行分析,以评估测量系统对于被测量的参数来说是否合适,并确定测量系统误差的主要成份。

Materials 物料Measurement 量测Occurrence 发生率Operation Instruction 作业指导书Organization 组织Parameter 参数Parts 零件Pulse 脉冲Policy 方针Procedure 流程Process 过程Product 产品Production 生产Program 方案Projects 项目QA: Quality Assurance 质量保证QC: Quality Control 质量控制QE: Quality Engineering 质量工程QFD: Quality Function Design 质量机能展开Quality 品质Quality manual 品质手册Quality policy 质量政策Range 全距Record 记录Reflow 回流Reject 拒收Repair 返修Repeatability 再现性Reproducibility 再生性Requirement 要求Residual 误差Response 回应Responsibilities 职责Review 评审Rework 返工Rolled yield 直通率sample 抽样,样本Scrap 报废SOP: Standard Operation Procedure 标准作业书SPC: Statistical Process Control 统计制程管制Specification 规格SQA: Source(Supplier) Quality Assurance 供货商质量保证Taguchi-method 田口方法TQC: Total Quality Control 全面质量控制TQM: Total Quality Management 全面质量管理Traceability 追溯UCL: Upper Control Limit 管制上限USL: Upper Size Limit 规格上限Validation 确认Variable 计量值Verification 验证Version 版本QCC Quality Control Circle 质量圈/QC小组PDCA Plan Do Check Action 计划执行检查总结Consumer electronics 消费性电子产品Communication 通讯类产品Core value (核心价值)Love 爱心Confidence 信心Decision 决心Corporate culture (公司文化)Integration 融合Responsibility 责任Progress 进步QC quality control 品质管理人员FQC final quality control 终点质量管理人员IPQC in process quality control 制程中的质量管理人员OQC output quality control 最终出货质量管理人员IQC incoming quality control 进料质量管理人员TQC total quality control 全面质量管理POC passage quality control 段检人员QA quality assurance 质量保证人员OQA output quality assurance 出货质量保证人员QE quality engineering 质量工程人员FAI first article inspection 新品首件检查FAA first article assurance 首件确认CP capability index 能力指数SSQA standardized supplier quality audit 合格供货商质量评估FMEA failure model effectiveness analysis 失效模式分析AQL Acceptable Quality Level 运作类允收质量水平S/S Sample size 抽样检验样本大小ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的Q/R/S Quality/Reliability/Service 质量/可靠度/服务P/N Part Number 料号L/N Lot Number 批号AOD Accept On Deviation 特采UAI Use As It 特采FPIR First Piece Inspection Report 首件检查报告PPM Percent Per Million 百万分之一SPC Statistical Process Control 统计制程管制SQC Statistical Quality Control 统计质量管理GR&R Gauge Reproducibility & Repeatability 量具之再制性及重测性判断量可靠与否DIM Dimension 尺寸DIA Diameter 直径QIT Quality Improvement Team 质量改善小组ZD Zero Defect 零缺点QI Quality Improvement 质量改善QP Quality Policy 目标方针TQM Total Quality Management 全面质量管理RMA Return Material Audit 退料认可7QCTools 7 Quality Control Tools 品管七大手法通用之件类ECN Engineering Change Notice 工程变更通知(供货商)ECO Engineering Change Order 工程改动要求(客户)PCN Process Change Notice 工序改动通知PMP Product Management Plan 生产管制计划SIP Standard Inspection Procedure 制程检验标准程序SOP Standard Operation Procedure 制造作业规范IS Inspection Specification 成品检验规范BOM Bill Of Material 物料清单PS Package Specification 包装规范SPEC Specification 规格DWG Drawing 图面系统文件类ES Engineering Standard 工程标准IWS International Workman Standard 工艺标准ISO International Standardization Organization 国际标准化组织GS General Specification 一般规格部类PMC Production & Material Control 生产和物料控制PCC Product control center 生产管制中心PPC Production Plan Control 生产计划控制MC Material Control 物料控制DCC Document Control Center 文件控制中心QE Quality Engineering 质量工程(部)QA Quality Assurance 质量保证处QC Quality Control 质量管理(课)PD Product Department 生产部LAB Laboratory 实验室IE Industrial Engineering 工业工程R&D Research & Design 设计开发部。