外文翻译---港口起重机

- 格式:docx

- 大小:29.48 KB

- 文档页数:7

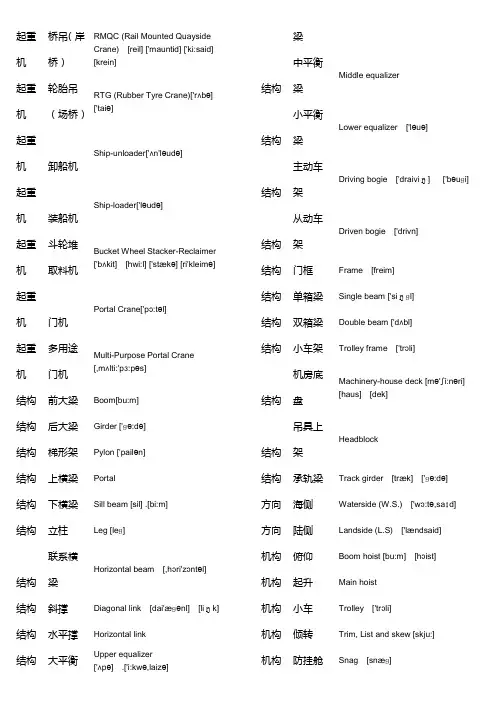

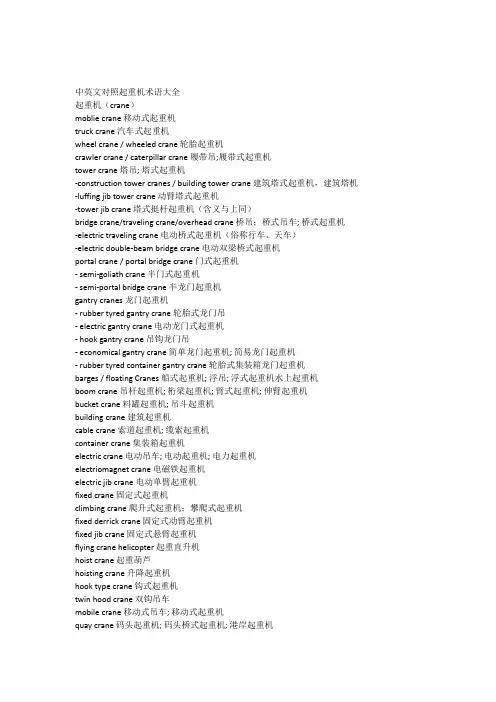

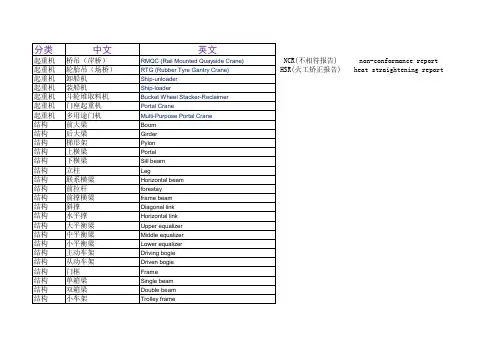

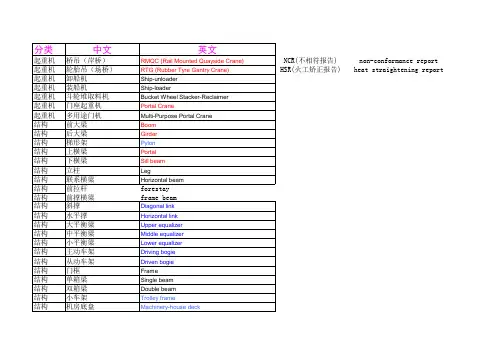

起重机桥吊(岸桥)RMQC (Rail Mounted Quayside Crane) [reil] ['mauntid] ['ki:said] [krein]起重机轮胎吊(场桥)RTG (Rubber Tyre Crane)['rʌbə]['taiə]起重机卸船机Ship-unloader['ʌn'ləudə] 起重机装船机Ship-loader['ləudə]起重机斗轮堆取料机Bucket Wheel Stacker-Reclaimer['bʌkit] [hwi:l] ['stækə] [ri'kleimə]起重机门机Portal Crane['pɔ:təl]起重机多用途门机Multi-Purpose Portal Crane[,mʌlti:'pɜ:pəs]结构前大梁Boom[bu:m]结构后大梁Girder ['ɡə:də]结构梯形架Pylon ['pailən]结构上横梁Portal结构下横梁Sill beam [sil] .[bi:m] 结构立柱Leg [leɡ]结构联系横梁Horizontal beam [,hɔri'zɔntəl]结构斜撑Diagonal link [dai'æɡənl] [liŋk] 结构水平撑Horizontal link结构大平衡梁Upper equalizer['ʌpə] .['i:kwə,laizə]结构中平衡梁Middle equalizer结构小平衡梁Lower equalizer ['ləuə]结构主动车架Driving bogie ['draiviŋ] ['bəuɡi]结构从动车架Driven bogie ['drivn]结构门框Frame [freim]结构单箱梁Single beam ['siŋɡl] 结构双箱梁Double beam ['dʌbl] 结构小车架Trolley frame ['trɔli]结构机房底盘Machinery-house deck [mə'ʃi:nəri][haus] [dek]结构吊具上架Headblock结构承轨梁Track girder [træk] ['ɡə:də] 方向海侧Waterside (W.S.) ['wɔ:tə,saɪd]方向陆侧Landside (L.S) ['lændsaid]机构俯仰Boom hoist [bu:m] [hɔist]机构起升Main hoist机构小车Trolley ['trɔli]机构倾转Trim, List and skew [skju:]机构防挂舱Snag [snæɡ]机构防摇Anti-sway ['ænti] [swei]机构大车Gantry ['ɡæntri]机构吊具Spreader ['spredə]机构双箱吊具Twin-spreader机构维修行车Maintenance crane ['meintinəns] 机构托绳小车Catenary trolley [kə'ti:nəri]机构拖令小车Festoon [fes'tu:n]机构减速箱Reducer [ri:'dju:sə]机构抓斗Grab bucket [ɡræb] ['bʌkit]机构电缆卷筒Cable reel ['keibl] [ri:l]房,室机器房Machinery house [mə'ʃi:nəri]房,室电气房Electric room房,室司机室Operator cabin ['ɔpəreitə]['kæbin]房,室俯仰室Boom hoise cabin [bu:m] [hɔiz] 房,室理货室Check room房,室计算机房Computer room [kəm'pju:tə]房,室动力房Power station ['steiʃən]零件卷筒Drum [drʌm]零件滑轮Pulley ['puli]零件钢丝绳Steel rope [sti:l] [rəup]零件法兰Flange [flændʒ]零件支座Support [sə'pɔ:t]零件轴Shaft [ʃɑ:ft]零件销轴Pin [pin]零件主动轴Driving shaft零件从动轴Driven shaft零件车轮Wheel零件水平轮Horizontal wheel [,hɔri'zɔntəl]零件轨道Rail [reil]零件联轴节Coupling ['kʌpliŋ]零件螺母Nut [nʌt]零件螺栓Bolt [bəult]零件垫片Washer ['wɔʃə]零件转销Twistlock零件托棍Roller ['rəulə]零件齿轮Gear [ɡiə]零件齿条Rack [ræk]零件轴承Bearing ['bɛəriŋ]零件弹簧Spring [spriŋ]零件挡圈Check ring零件活塞Piston零件油标Oil indicater ['indikeit]零件铭牌Name plate [pleit]零件卸克Shackle ['ʃækl]零件凸轮Cam [kæm]零件吊耳Lug [lʌɡ]零件吊钩Hook [huk]零件定位块Location block [ləu'keiʃən] [blɔk] 零件抗剪块Anti-cut block零件抗磨块Anti-attrite block [ə'trait]零件导板Slipper ['slipə]装置清扫装置Cleaning device ['kli:niŋ] [di'vais]装置挡绳装置Ward off rope device [wɔ:d] [rəup]装置张紧装置Tensioning device ['tenʃəniŋ]装置牵引装置Tow device [təu]装置换绳装Rope changer ['tʃeindʒə]置装置联动装置Linkage ['liŋkidʒ]装置温度计Thermometer [θə'mɔmitə]焊接面板Top plate [tɔp]焊接侧板Web [web]焊接底板Bottom plate ['bɔtəm]焊接对接Butt [bʌt]焊接角接Corner ['kɔ:nə]焊接筋板Stiffener ['stifnə]焊接隔板Diaphragm ['daiəfræm]焊接咬边Undercut ['ʌndəkʌt]焊接气孔Pore [pɔ:]焊接裂纹Crack [kræk]焊接飞溅Spatter ['spætə]焊接夹渣Slag-including [slæɡ]油漆底漆Primer coat [praim] [kəut]油漆中层漆Middle coat ['midl]油漆面漆Final coat ['fainəl]油漆漆膜厚度Average film thickness ['ævəridʒ]平均的['θiknis]油漆磷化漆Phosphorized paint ['fɔsfəraiz] 走道走道Walkway ['wɔ:kwei]走道梯子平台Ladder and platform ['lædə]['plætfɔ:m]走道拦杆,扶手Grab rail [ɡræb]走道格栅板Grating plate ['ɡreitiŋ]走道直梯Ladder探伤无损探伤NDT (Non-destructure test)[di:'strʌktʃə]探伤超声波探伤UT (Ultrasonic test) [,ʌltrə'sɔnik] 探伤射线探伤RT (Radial test) ['reidiəl]探伤磁粉探伤MT (Magnetic test) [mæɡ'netik]材料钢板Steel plate材料圆钢Round steel [raund]材料锻件Forged piece [fɔ:dʒ] [pi:s]材料铸件Cast [kɑ:st]材料角钢Angle iron ['æŋɡl] ['aiən]材料工字钢I-shaped steel [ʃeipt]电气电缆槽Cable groove ['keibl] [ɡru:v]电气扎带Bandage ['bændidʒ]电气继电器Relay [ri'lei]电气接触器Contactor ['kɔntæktə]电气变压器Transformer [træns'fɔ:mə]电气空调Air-condition ['ɛəkən,diʃən]电气排风扇Exhausting fan [iɡ'zɔ:st]电气风速仪Anemoscope [ə'neməskəup]电气电梯Elevator ['eliveitə]电气航空灯Aviation light [,eivi'eiʃən]电气投光灯Flood light [flʌd]电气照明灯Illuminating lamp [i'lju:mi,neitiŋ] 电气应急灯Emergency lamp [læmp]电气紧停Emergency stop [i'mə:dʒənsi] 电气限位Limit ['limit]电气重锤限位Hammer limit ['hæmə]电气交流电Alternating current ['ɔ:ltə,neɪtɪŋ] ['kʌrənt]电气直流电Direct current电气调试Commissioning [kə'miʃəniŋ] 热处理淬火Quench [kwentʃ]热处理退火Anneal [ə'ni:l]热处理回火Temper ['tempə]热处理调质Hardening and Tempering ['hɑ:dəniŋ] ['tempəriŋ]热处理正火Normalization [,nɔ:məlai'zeiʃən] 参数同轴度Axiality [,æksi'æliti]参数温度Temperature ['tempəritʃə]参数湿度Humidity [hju:'miditi]参数转速Rotary speed ['rəutəri] [spi:d] 参数速度Speed参数外伸距Outreach [aut'ri:tʃ]参数后伸距Backreach参数轨距Gauge [ɡeidʒ]参数轮压Wheel pressure工作焊接Welding ['weldiŋ]工作打磨Grinding ['ɡraindiŋ]工作油漆Painting ['peintiŋ]工作镗孔Counterboring ['kauntə'bɔ:riŋ] 工作装配Assembling试车静载Static load ['stætik]试车动载Dynamic load [dai'næmik]试车额定载荷Standard load ['stændəd]试车超载Overload [,əuvə'ləud]试车连续试车Endurance test [in'djuərəns] 液压电磁阀Solenoid valve ['səulinɔid]液压溢流阀Relief valve [ri'li:f]液压减压阀Pressure reduce valve液压节流阀Throttle valve ['θrɔtl]液压加热器Immersion heater [i'mə:ʃən]['hi:tə]液压空气滤清器Air filter [ɛə] ['filtə]液压回油滤油器Oil return filter液压单向节流阀Check/throttle valve液压插装阀Cartridge valve液压液压硬管(卡套管)Tube [tju:b]液压液压硬管(焊接管)Pipe [paip]液压油箱Reservoir ['rezəvwɑ:]液压压力继电器Pressure relay [ri'lei]液压温度计Thermometer [θə'mɔmitə]。

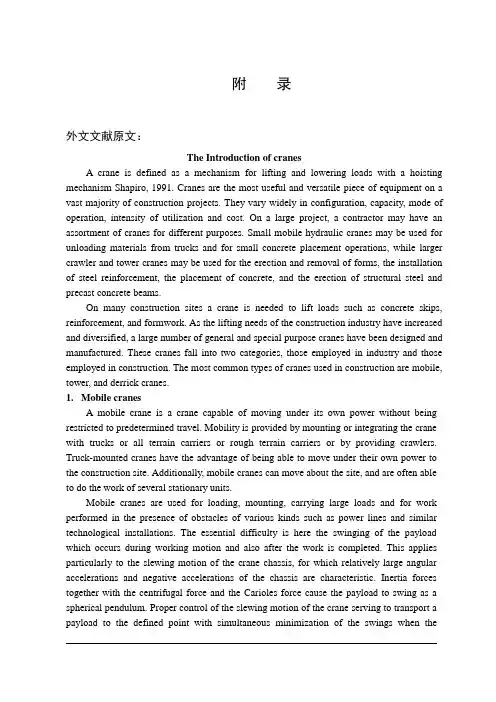

附录外文文献原文:The Introduction of cranesA crane is defined as a mechanism for lifting and lowering loads with a hoisting mechanism Shapiro, 1991. Cranes are the most useful and versatile piece of equipment on a vast majority of construction projects. They vary widely in configuration, capacity, mode of operation, intensity of utilization and cost. On a large project, a contractor may have an assortment of cranes for different purposes. Small mobile hydraulic cranes may be used for unloading materials from trucks and for small concrete placement operations, while larger crawler and tower cranes may be used for the erection and removal of forms, the installation of steel reinforcement, the placement of concrete, and the erection of structural steel and precast concrete beams.On many construction sites a crane is needed to lift loads such as concrete skips, reinforcement, and formwork. As the lifting needs of the construction industry have increased and diversified, a large number of general and special purpose cranes have been designed and manufactured. These cranes fall into two categories, those employed in industry and those employed in construction. The most common types of cranes used in construction are mobile, tower, and derrick cranes.1.Mobile cranesA mobile crane is a crane capable of moving under its own power without being restricted to predetermined travel. Mobility is provided by mounting or integrating the crane with trucks or all terrain carriers or rough terrain carriers or by providing crawlers. Truck-mounted cranes have the advantage of being able to move under their own power to the construction site. Additionally, mobile cranes can move about the site, and are often able to do the work of several stationary units.Mobile cranes are used for loading, mounting, carrying large loads and for work performed in the presence of obstacles of various kinds such as power lines and similar technological installations. The essential difficulty is here the swinging of the payload which occurs during working motion and also after the work is completed. This applies particularly to the slewing motion of the crane chassis, for which relatively large angular accelerations and negative accelerations of the chassis are characteristic. Inertia forces together with the centrifugal force and the Carioles force cause the payload to swing as a spherical pendulum. Proper control of the slewing motion of the crane serving to transport a payload to the defined point with simultaneous minimization of the swings when theworking motion is finished plays an important role in the model.Modern mobile cranes include the drive and the control systems. Control systems send the feedback signals from the mechanical structure to the drive systems. In general, they are closed chain mechanisms with flexible members [1].Rotation, load and boom hoisting are fundamental motions the mobile crane. During transfer of the load as well as at the end of the motion process, the motor drive forces, the structure inertia forces, the wind forces and the load inertia forces can result in substantial, undesired oscillations in crane. The structure inertia forces and the load inertia forces can be evaluated with numerical methods, such as the finite element method. However, the drive forces are difficult to describe. During start-up and breaking the output forces of the drive system significantly fluctuate. To reduce the speed variations during start-up and braking the controlled motor must produce torque other than constant [2,3], which in turn affects the performance of the crane.Modern mobile cranes that have been built till today have oft a maximal lifting capacity of 3000 tons and incorporate long booms. Crane structure and drive system must be safe, functionary and as light as possible. For economic and time reasons it is impossible to build prototypes for great cranes. Therefore, it is desirable to determinate the crane dynamic responses with the theoretical calculation.Several published articles on the dynamic responses of mobile crane are available in the open literature. In the mid-seventies Peeken et al. [4] have studied the dynamic forces of a mobile crane during rotation of the boom, using very few degrees of freedom for the dynamic equations and very simply spring-mass system for the crane structure. Later Maczynski et al. [5] studied the load swing of a mobile crane with a four mass-model for the crane structure. Posiadala et al. [6] have researched the lifted load motion with consideration for the change of rotating, booming and load hoisting. However, only the kinematics were studied. Later the influence of the flexibility of the support system on the load motion was investigated by the same author [7]. Recently, Kilicaslan et al. [1] have studied the characteristics of a mobile crane using a flexible multibody dynamics approach. Towarek [16] has concentrated the influence of flexible soil foundation on the dynamic stability of the boom crane. The drive forces, however, in all of those studies were presented by using so called the metho d of ……kinematics forcing‟‟ [6] with assumed velocities or accelerations. In practice this assumption could not comply with the motion during start-up and braking.A detailed and accurate model of a mobile crane can be achieved with the finite element method. Using non-linear finite element theory Gunthner and Kleeberger [9] studied the dynamic responses of lattice mobile cranes. About 2754 beam elements and 80 truss elements were used for modeling of the lattice-boom structure. On this basis a efficient software for mobile crane calculation––NODYA has been developed. However, the influences of the drive systems must be determined by measuring on hoisting of the load[10], or rotating of the crane [11]. This is neither efficient nor convenient for computer simulation of arbitrary crane motions.Studies on the problem of control for the dynamic response of rotary crane are also available. Sato et al. [14], derived a control law so that the transfer a load to a desired position will take place that at the end of the transfer of the swing of the load decays as soon as possible. Gustafsson [15] described a feedback control system for a rotary crane to move a cargo without oscillations and correctly align the cargo at the final position. However, only rigid bodies and elastic joint between the boom and the jib in those studies were considered. The dynamic response of the crane, for this reason, will be global.To improve this situation, a new method for dynamic calculation of mobile cranes will be presented in this paper. In this method, the flexible multibody model of the steel structure will be coupled with the model of the drive systems. In that way the elastic deformation, the rigid body motion of the structure and the dynamic behavior of the drive system can be determined with one integrated model. In this paper this method will be called ……complete dynamic calculation for driven “mechanism”.On the basis of flexible multibody theory and the Lagrangian equations, the system equations for complete dynamic calculation will be established. The drive- and control system will be described as differential equations. The complete system leads to a non-linear system of differential equations. The calculation method has been realized for a hydraulic mobile crane. In addition to the structural elements, the mathematical modeling of hydraulic drive- and control systems is decried. The simulations of crane rotations for arbitrary working conditions will be carried out. As result, a more exact representation of dynamic behavior not only for the crane structure, but also for the drive system will be achieved. Based on the results of these simulations the influences of the accelerations, velocities during start-up and braking of crane motions will be discussed.2.Tower cranesThe tower crane is a crane with a fixed vertical mast that is topped by a rotating boom and equipped with a winch for hoisting and lowering loads (Dickie, 990). Tower cranes are designed for situations which require operation in congested areas. Congestion may arise from the nature of the site or from the nature of the construction project. There is no limitation to the height of a high-rise building that can be constructed with a tower crane. The very high line speeds, up to 304.8 mrmin, available with some models yield good production rates at any height. They provide a considerable horizontal working radius, yet require a small work space on the ground (Chalabi, 1989). Some machines can also operate in winds of up to 72.4 km/h, which is far above mobile crane wind limits.The tower cranes are more economical only for longer term construction operations and higher lifting frequencies. This is because of the fairly extensive planning needed for installation, together with the transportation, erection and dismantling costs.3. Derrick cranesA derrick is a device for raising, lowering, and/or moving loads laterally. The simplest form of the derrick is called a Chicago boom and is usually installed by being mounted to building columns or frames during or after construction (Shapiro and Shapiro, 1991).This derrick arrangement. (i.e., Chicago boom) becomes a guy derrick when it is mounted to a mast and a stiff leg derrick when it is fixed to a frame.The selection of cranes is a central element of the life cycle of the project. Cranes must be selected to satisfy the requirements of the job. An appropriately selected crane contributes to the efficiency, timeliness, and profitability of the project. If the correct crane selection and configuration is not made, cost and safety implications might be created (Hanna, 1994). Decision to select a particular crane depends on many input parameters such as site conditions, cost, safety, and their variability. Many of these parameters are qualitative, and subjective judgments implicit in these terms cannot be directly incorporated into the classical decision making process. One way of selecting crane is achieved using fuzzy logic approach.Cranes are not merely the largest, the most conspicuous, and the most representative equipment of construction sites but also, at various stages of the project, a real “bottleneck” that slows the pace of the construction process. Although the crane can be found standing idle in many instances, yet once it is involved in a particular task ,it becomes an indispensable link in the activity chain, forcing at least two crews(in the loading and the unloading zones) to wait for the service. As analyzed in previous publications [6-8] it is feasible to automate (or, rather, semi-automate) crane navigation in order to achieve higher productivity, better economy, and safe operation. It is necessary to focus on the technical aspects of the conversion of existing crane into large semi-automatic manipulators. By mainly external devices mounted on the crane, it becomes capable of learning, memorizing, and autonomously navigation to reprogrammed targets or through prêt aught paths.The following sections describe various facets of crane automation:First, the necessary components and their technical characteristics are reviewed, along with some selection criteria. These are followed by installation and integration of the new components into an existing crane. Next, the Man –Machine –Interface (MMI) is presented with the different modes of operation it provides. Finally, the highlights of a set of controlled tests are reported followed by conclusions and recommendations.Manual versus automatic operation: The three major degrees of freedom of common tower cranes are illustrated in the picture. In some cases , the crane is mounted on tracks , which provide a fourth degree of freedom , while in other cases the tower is “telescope” or extendable , and /or the “jib” can be raised to a diagonal position. Since these additional degrees of freedom are not used routinely during normal operation but rather are fixed in a certain position for long periods (days or weeks), they are not included in the routineautomatic mode of operation, although their position must be “known” to the control system.外文文献中文翻译:起重机介绍起重机是用来举升机构、抬起或放下货物的器械。

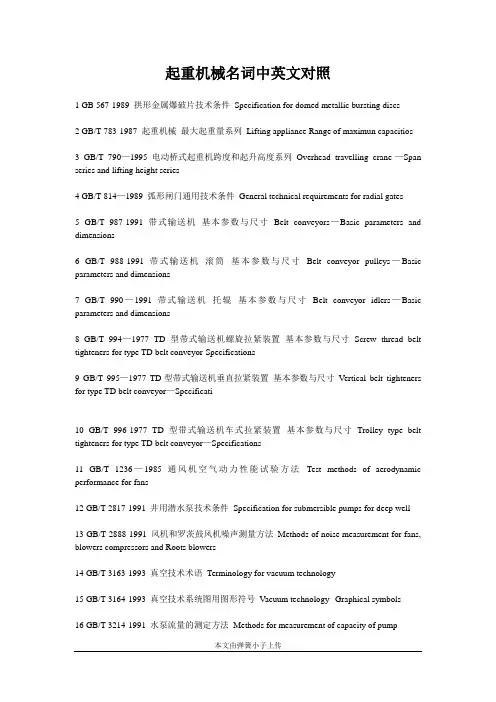

起重机械名词中英文对照1 GB 567-1989 拱形金属爆破片技术条件Specification for domed metallic bursting discs2 GB/T 783-1987 起重机械最大起重量系列Lifting appliance Range of maximun capacitios3 GB/T 790—1995 电动桥式起重机跨度和起升高度系列Overhead travelling crane-—Span series and lifting height series4 GB/T 814—1989 弧形闸门通用技术条件General technical requirements for radial gates5 GB/T 987-1991 带式输送机基本参数与尺寸Belt conveyors—Basic parameters and dimensions6 GB/T 988-1991 带式输送机滚筒基本参数与尺寸Belt conveyor pulleys—Basic parameters and dimensions7 GB/T 990—1991 带式输送机托辊基本参数与尺寸Belt conveyor idlers—Basic parameters and dimensions8 GB/T 994—1977 TD型带式输送机螺旋拉紧装置基本参数与尺寸Screw thread belt tighteners for type TD belt conveyor-Specifications9 GB/T 995—1977 TD型带式输送机垂直拉紧装置基本参数与尺寸Vertical belt tighteners for type TD belt conveyor—Specificati10 GB/T 996-1977 TD型带式输送机车式拉紧装置基本参数与尺寸Trolley type belt tighteners for type TD belt conveyor—Specifications11 GB/T 1236—1985 通风机空气动力性能试验方法Test methods of aerodynamic performance for fans12 GB/T 2817-1991 井用潜水泵技术条件Specification for submersible pumps for deep well13 GB/T 2888-1991 风机和罗茨鼓风机噪声测量方法Methods of noise measurement for fans, blowers compressors and Roots blowers14 GB/T 3163-1993 真空技术术语Terminology for vacuum technology15 GB/T 3164-1993 真空技术系统图用图形符号Vacuum technology--Graphical symbols16 GB/T 3214-1991 水泵流量的测定方法Methods for measurement of capacity of pump17 GB/T 3215-1982 炼厂、化工及石油化工流程用离心泵通用技术条件Centrifugal pumps for refinery,chemical and petrochemical processes——General technical specifications18 GB/T 3216-1989 离心泵、混流泵、轴流泵和旋涡泵试验方法Test methods for centrifugal, mixed flow, axial and regenerative pumps19 GB/T 3235—1982 通风机基本型式、尺寸、参数及性能曲线Basic types,sizes,parameters and characteristics of fans20 GB/T 3264—1989 单张纸平版胶印机技术条件Specification for sheet—fed planographic offset press21 GB/T 3811—1983 起重机设计规范Design rules for cranes22 GB/T 4307-1984 起重吊钩名词术语Lifting hooks——Nomenclature23 GB/T 4652-1984 双臂式装载机试验方法Method for testing the gathering arm loaders24 GB/T 4774—1984 离心机和过滤机名词术语Terminology of centrifuge and filter25 GB/T 4975-1995 容积式压缩机术语总则Displacement compressors vocabulary-—General26 GB/T 4976-1985 压缩机分类Compressors——Classification27 GB/T 4980—1985 容积式压缩机噪声声功率级的测定-—工程法Determination of sound power level for noise emitted by displacement compressors—-Engineering method28 GB/T 4983-1985 拧紧型真空快卸法兰Vacuum technology screwed type quick release flange29 GB 5099—1994 钢质无缝气瓶Seamless steel gas cylinders30 GB 5100-1994 钢质焊接气瓶Welded steel gas cylinders31 GB/T 5140—1985 叉车挂钩型货叉术语Fork lift trucks—-Hook—on type fork arms--V ocabulary32 GB/T 5141—1985 平衡重式叉车稳定性基本试验Counter balanced lift trucks--Stability-—Basic tests33 GB/T 5142-1985 前移式和插腿式叉车稳定性试验Reach and straddle fork lift trucks--Stability tests34 GB 5143-1985 高起升车辆护顶架技术要求和试验方法High-lift rider trucks—-Overhead guards—-Specification and testing35 GB/T 5182-1996 叉车货叉技术要求和试验Fork—lift trucks——Fork arms——Technical characteristics and testing36 GB/T 5183-1985 叉车货叉的尺寸Fork lift trucks—-Fork arms--Dimensions37 GB/T 5184-1996 叉车挂钩型货叉和货叉架安装尺寸Fork-lift trucks-—Hook-on type fork arms and fork arm carriages—-Mounting dimensions38 GB/T 5621—1985 凿岩机械与气动工具性能试验方法Test methods of performance for rock drilling machines and pneumatic tools39 GB/T 5656—1994 离心泵技术条件(II类) Technical specifications for centrifugal pumps-—Class II40 GB/T 5657—1995 离心泵技术条件(I类) Technical specifications for centrifugal pumps-—Class I41 GB/T 5660—1985 轴向吸入离心泵底座尺寸和安装尺寸End-suction centrifugal pumps-—Baseplate and installation dimensions42 GB/T 5661-1985 轴向吸入离心泵机械密封和软填料用的空腔尺寸End-suction centrifugal pumps--Dimensions of cavities for mechanical seals and for soft packing43 GB/T 5662—1985 轴向吸入离心泵(16 bar) 标记、性能和尺寸End-suction centrifugalpumps (rating 16 bar)——Designation,nominal duty point and dimensions44 GB/T 5773-1986 容积式制冷压缩机性能试验方法The methods of performance test for positive displacement refrigerant compressor45 GB 5842-1996 液化石油气钢瓶Liquefied petroleum gas cylinders46 GB/T 5905-1986 起重机试验规范和程序Cranes-—Test code and procedures47 GB/T 5973—1986 钢丝绳用楔形接头Cuneiform conector for use with steel wire ropes48 GB/T 5974。

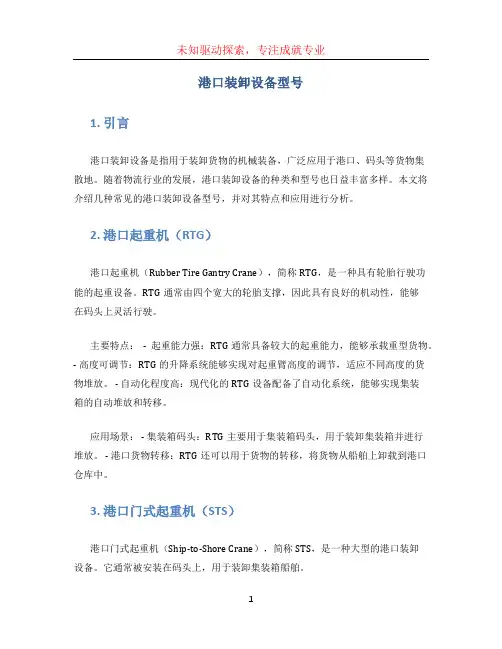

港口装卸设备型号1. 引言港口装卸设备是指用于装卸货物的机械装备,广泛应用于港口、码头等货物集散地。

随着物流行业的发展,港口装卸设备的种类和型号也日益丰富多样。

本文将介绍几种常见的港口装卸设备型号,并对其特点和应用进行分析。

2. 港口起重机(RTG)港口起重机(Rubber Tire Gantry Crane),简称RTG,是一种具有轮胎行驶功能的起重设备。

RTG通常由四个宽大的轮胎支撑,因此具有良好的机动性,能够在码头上灵活行驶。

主要特点:- 起重能力强:RTG通常具备较大的起重能力,能够承载重型货物。

- 高度可调节:RTG的升降系统能够实现对起重臂高度的调节,适应不同高度的货物堆放。

- 自动化程度高:现代化的RTG设备配备了自动化系统,能够实现集装箱的自动堆放和转移。

应用场景: - 集装箱码头:RTG主要用于集装箱码头,用于装卸集装箱并进行堆放。

- 港口货物转移:RTG还可以用于货物的转移,将货物从船舶上卸载到港口仓库中。

3. 港口门式起重机(STS)港口门式起重机(Ship-to-Shore Crane),简称STS,是一种大型的港口装卸设备。

它通常被安装在码头上,用于装卸集装箱船舶。

主要特点: - 大起重能力:STS起重机具备较大的起重能力,能够同时操作多个集装箱。

- 高度可调节:STS起重机的升降系统能够根据集装箱船舶的高度进行自动调节。

- 快速操作:STS起重机采用现代化的控制系统和自动化技术,可以快速进行装卸操作。

应用场景: - 集装箱码头:STS起重机可以用于装卸集装箱船舶,并将集装箱堆放到合适的区域。

4. 港口堆高机(Stacker)港口堆高机(Stacker)是一种用于堆放货物的特种装卸设备。

它通常用于堆放散装货物、木材等非集装箱货物。

主要特点: - 负重能力强:堆高机通常具备较强的负重能力,能够堆放较重的货物。

- 高度可调节:堆高机的叉臂可以根据货物的堆放高度进行调节。

The History of Crane1. OverviewThe first construction cranes were invented by the Ancient Greeks and were powered by men or beasts of burden, such as donkeys. These cranes were used for the construction of tall buildings. Larger cranes were later developed, employing the use of human treadwheels, permitting the lifting of heavier weights. In the High Middle Ages, harbor cranes were introducedto load and unload ships and assist with their construction – some were built into stone towers for extra strength and stability. The earliest cranes were constructed from wood, but cast iron and steel took over with the coming of the Industrial Revolution.For many centuries, power was supplied by the physical exertion of men or animals, although hoists in watermills and windmills could be driven by the harnessed natural power. The first 'mechanical' power was provided by steam engines, the earliest steam crane being introducedin the 18th or 19th century, with many remaining in use well into the late 20th century. Modern cranes usually use internal combustion engines or electric motors and hydraulic systems to provide a much greater lifting capability than was previously possible, although manual cranes are still utilized where the provision of power would be uneconomic.Cranes exist in an enormous variety of forms – each tailored to a specific use. Sizes range from the smallest jib cranes, used inside workshops, to the tallest tower cranes, used for constructing high buildings. For a while, mini - cranes are also used for constructing high buildings, in order to facilitate constructions by reaching tight spaces. Finally, we can find larger floating cranes, generally used to build oil rigs and salvage sunken ships. This article also covers lifting machines that do not strictly fit the above definition of a crane, but are generally known as cranes, such as stacker cranes and loader cranes.2. History(1)Ancient GreeceThe crane for lifting heavy loads was invented by the Ancient Greeks in the late 6th century BC. The archaeological record shows that no later than c.515 BC distinctive cuttings for both lifting tongs and lewis irons begin to appear on stone blocks of Greek temples. Since these holes point at the use of a lifting device, and since they are to be found either above the center of gravity of the block, or in pairs equidistant from a point over the center of gravity, they are regarded by archaeologists as the positive evidence required for the existence of the crane.The introduction of the winch and pulley hoist soon lead to a widespread replacement of ramps as the main means of vertical motion. For the next two hundred years, Greek building sites witnesseda sharp drop in the weights handled, as the new lifting technique made the use of several smaller stones more practical than of fewer larger ones. In contrast to the archaic period with its tendencyto ever-increasing block sizes, Greek temples of the classical age like the Parthenon invariably featured stone blocks weighing less than 15-20 tons. Also, the practice of erecting large monolithic columns was practically abandoned in favor of using several column drums.Although the exact circumstances of the shift from the ramp to the crane technology remain unclear, it has been argued that the volatile social and political conditions of Greece were moresuitable to the employment of small, professional construction teams than of large bodies of unskilled labor, making the crane more preferable to the Greek polis than the more labor-intensive ramp which had been the norm in the autocratic societies of Egypt or Assyria.The first unequivocal literary evidence for the existence of the compound pulley system appears in the Mechanical Problems (Mech. 18, 853a32-853b13) attributed to Aristotle (384-322 BC), but perhaps composed at a slightly later date. Around the same time, block sizes at Greek temples began to match their archaic predecessors again, indicating that the more sophisticated compound pulley must have found its way to Greek construction sites by then.Ancient RomeThe heyday of the crane in ancient times came during the Roman Empire, when construction activity soared and buildings reached enormous dimensions. The Romans adopted the Greek crane and developed it further. We are relatively well informed about their lifting techniques, thanks to rather lengthy accounts by the engineers Vitruvius (De Architectura 10.2, 1-10) and Heron of Alexandria (Mechanica 3.2-5). There are also two surviving reliefs of Roman treadwheel cranes, with the Haterii tombstone from the late first century AD being particularly detailed.The simplest Roman crane, the Trispastos, consisted of a single-beam jib, a winch, a rope, and a block containing three pulleys. Having thus a mechanical advantage of 3:1, it has been calculated that a single man working the winch could raise 150 kg (3 pulleys x 50 kg = 150), assuming that 50 kg represent the maximum effort a man can exert over a longer time period. Heavier crane types featured five pulleys (Pentaspastos) or, in case of the largest one, a set of three by five pulleys (Polyspastos) and came with two, three or four masts, depending on the maximum load. The Polyspastos, when worked by four men at both sides of the winch, could already lift 3000 kg (3 ropes x 5 pulleys x 4 men x 50 kg = 3000 kg). In case the winch was replaced by a treadwheel, the maximum load even doubled to 6000 kg at only half the crew, since the treadwheel possesses a much bigger mechanical advantage due to its larger diameter. This meant that, in comparison to the construction of the Egyptian Pyramids, where about 50 men were needed to move a 2.5 ton stone block up the ramp (50 kg per person), the lifting capability of the Roman Polyspastos proved to be 60 times higher (3000 kg per person).However, numerous extant Roman buildings which feature much heavier stone blocks than those handled by the Polyspastos indicate that the overall lifting capability of the Romans went far beyond that of any single crane. At the temple of Jupiter at Baalbek, for instance, the architrave blocks weigh up to 60 tons each, and one corner cornice block even over 100 tons, all of them raised to a height of about 19 m. In Rome, the capital block of Trajan's Column weighs 53.3 tons, which had to be lifted to a height of about 34 m (see construction of Trajan's Column).It is assumed that Roman engineers lifted these extraordinary weights by two measures (see picture below for comparable Renaissance technique): First, as suggested by Heron, a lifting tower was set up, whose four masts were arranged in the shape of a quadrangle with parallel sides, not unlike a siege tower, but with the column in the middle of the structure (Mechanica 3.5). Second, a multitude of capstans were placed on the ground around the tower, for, although having a lower leverage ratio than treadwheels, capstans could be set up in higher numbers and run by more men (and, moreover, by draught animals). This use of multiple capstans is also described by AmmianusMarcellinus (17.4.15) in connection with the lifting of the Lateranense obelisk in the Circus Maximus (ca. 357 AD). The maximum lifting capability of a single capstan can be established by the number of lewis iron holes bored into the monolith. In case of the Baalbek architrave blocks, which weigh between 55 and 60 tons, eight extant holes suggest an allowance of 7.5 ton per lewis iron, that is per capstan. Lifting such heavy weights in a concerted action required a great amount of coordination between the work groups applying the force to the capstans.Middle AgesDuring the High Middle Ages, the treadwheel crane was reintroduced on a large scale after the technology had fallen into disuse in western Europe with the demise of the Western Roman Empire. The earliest reference to a treadwheel (magna rota) reappears in archival literature in France about 1225, followed by an illuminated depiction in a manuscript of probably also French origin dating to 1240. In navigation, the earliest uses of harbor cranes are documented for Utrecht in 1244, Antwerp in 1263, Brugge in 1288 and Hamburg in 1291, while in England the treadwheel is not recorded before 1331.Generally, vertical transport could be done more safely and inexpensively by cranes than by customary methods. Typical areas of application were harbors, mines, and, in particular, building sites where the treadwheel crane played a pivotal role in the construction of the lofty Gothic cathedrals. Nevertheless, both archival and pictorial sources of the time suggest that newly introduced machines like treadwheels or wheelbarrows did not completely replace more labor-intensive methods like ladders, hods and handbarrows. Rather, old and new machinery continued to coexist on medieval construction sites and harbors.Apart from treadwheels, medieval depictions also show cranes to be powered manually by windlasses with radiating spokes, cranks and by the 15th century also by windlasses shaped like a ship's wheel. To smooth out irregularities of impulse and get over 'dead-spots' in the lifting process flywheels are known to be in use as early as 1123.The exact process by which the treadwheel crane was reintroduced is not recorded, although its return to construction sites has undoubtedly to be viewed in close connection with the simultaneous rise of Gothic architecture. The reappearance of the treadwheel crane may have resulted from a technological development of the windlass from which the treadwheel structurally and mechanically evolved. Alternatively, the medieval treadwheel may represent a deliberate reinvention of its Roman counterpart drawn from Vitruvius' De architectura which was available in many monastic libraries. Its reintroduction may have been inspired, as well, by the observation of the labor-saving qualities of the waterwheel with which early treadwheels shared many structural similarities.Structure and placementThe medieval treadwheel was a large wooden wheel turning around a central shaft with a treadway wide enough for two workers walking side by side. While the earlier 'compass-arm' wheel had spokes directly driven into the central shaft, the more advanced 'clasp-arm' type featured arms arranged as chords to the wheel rim, giving the possibility of using a thinner shaft and providing thus a greater mechanical advantage.Contrary to a popularly held belief, cranes on medieval building sites were neither placed on the extremely lightweight scaffolding used at the time nor on the thin walls of the Gothic churches which were incapable of supporting the weight of both hoisting machine and load. Rather, cranes were placed in the initial stages of construction on the ground, often within the building. When a new floor was completed, and massive tie beams of the roof connected the walls, the crane was dismantled and reassembled on the roof beams from where it was moved from bay to bay during construction of the vaults. Thus, the crane ‘grew’ and ‘wandered’ with the building with the result that today all extant construction cranes in England are found in church towers above the vaulting and below the roof, where they remained after building construction for bringing material for repairs aloft.Less frequently, medieval illuminations also show cranes mounted on the outside of walls with the stand of the machine secured to putlogs.Mechanics and operationIn contrast to modern cranes, medieval cranes and hoists - much like their counterparts in Greece and Rome - were primarily capable of a vertical lift, and not used to move loads for a considerable distance horizontally as well. Accordingly, lifting work was organized at the workplace in a different way than today. In building construction, for example, it is assumed that the crane lifted the stone blocks either from the bottom directly into place, or from a place opposite the centre of the wall from where it could deliver the blocks for two teams working at each end of the wall. Additionally, the crane master who usually gave orders at the treadwheel workers from outside the crane was able to manipulate the movement laterally by a small rope attached to the load. Slewing cranes which allowed a rotation of the load and were thus particularly suited for dockside work appeared as early as 1340. While ashlar blocks were directly lifted by sling, lewis or devil's clamp (German Teufelskralle), other objects were placed before in containers like pallets, baskets, wooden boxes or barrels.It is noteworthy that medieval cranes rarely featured ratchets or brakes to forestall the load from running backward. This curious absence is explained by the high friction force exercised by medieval treadwheels which normally prevented the wheel from accelerating beyond control. Harbor usageAccording to the "present state of knowledge" unknown in antiquity, stationary harbor cranes are considered a new development of the Middle Ages. The typical harbor crane was a pivoting structure equipped with double treadwheels. These cranes were placed docksides for the loading and unloading of cargo where they replaced or complemented older lifting methods like see-saws, winches and yards.Two different types of harbor cranes can be identified with a varying geographical distribution: While gantry cranes which pivoted on a central vertical axle were commonly found at the Flemish and Dutch coastside, German sea and inland harbors typically featured tower cranes where the windlass and treadwheels were situated in a solid tower with only jib arm and roof rotating. Interestingly, dockside cranes were not adopted in the Mediterranean region and the highly developed Italian ports where authorities continued to rely on the more labor-intensive method ofunloading goods by ramps beyond the Middle Ages.Unlike construction cranes where the work speed was determined by the relatively slow progressof the masons, harbor cranes usually featured double treadwheels to speed up loading. The two treadwheels whose diameter is estimated to be 4 m or larger were attached to each side of the axle and rotated together. Today, according to one survey, fifteen treadwheel harbor cranes from pre-industrial times are still extant throughout Europe.[28] Beside these stationary cranes, floating cranes which could be flexibly deployed in the whole port basin came into use by the 14th century.RenaissanceA lifting tower similar to that of the ancient Romans was used to great effect by the Renaissance architect Domenico Fontana in 1586 to relocate the 361 t heavy Vatican obelisk in Rome. From his report, it becomes obvious that the coordination of the lift between the various pulling teams required a considerable amount of concentration and discipline, since, if the force was not applied evenly, the excessive stress on the ropes would make them rupture.Early modern ageCranes were used domestically in the 17th and 18th century. The chimney or fireplace crane was used to swing pots and kettles over the fire and the height was adjusted by a trammel.4. Types of the cranesMobileMain article: Mobile craneThe most basic type of mobile crane consists of a truss or telescopic boom mounted on a mobile platform - be it on road, rail or water.FixedExchanging mobility for the ability to carry greater loads and reach greater heights due to increased stability, these types of cranes are characterized that they, or at least their main structure does not move during the period of use. However, many can still be assembled and disassembled.外文翻译起重机的历史1. 概况第一台具有机械结构的起重机是由古希腊人发明的,并且由人或者是牲畜比如驴,作为动力源。

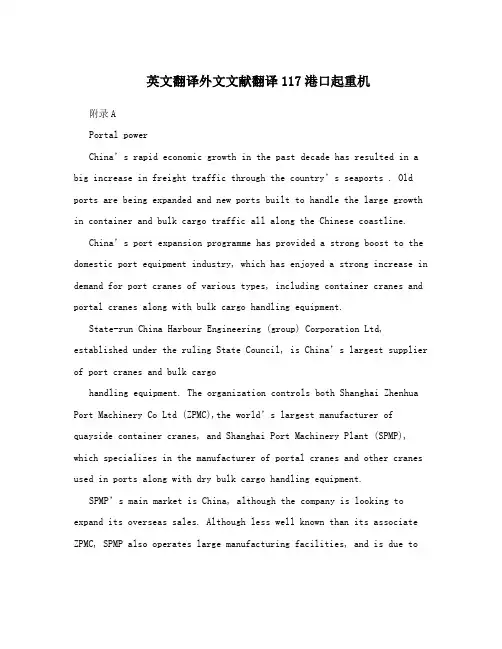

英文翻译外文文献翻译117港口起重机附录APortal powerChina’s rapid economic growth in the past decade has resulted in a big increase in freight traffic through the country’s seaports . Old ports are being expanded and new ports built to handle the large growth in container and bulk cargo traffic all along the Chinese coastline.China’s port expansion programme has provided a strong boost to the domestic port equipment industry, which has enjoyed a strong increase in demand for port cranes of various types, including container cranes and portal cranes along with bulk cargo handling equipment.State-run China Harbour Engineering (group) Corporation Ltd, established under the ruling State Council, is China’s largest supplier of port cranes and bulk cargohandling equipment. The organization controls both Shanghai Zhenhua Port Machinery Co Ltd (ZPMC),the world’s largest manufacturer of quayside container cranes, and Shanghai Port Machinery Plant (SPMP), which specializes in the manufacturer of portal cranes and other cranes used in ports along with dry bulk cargo handling equipment.SPMP’s main market is China, although the company is looking to expand its overseas sales. Although less well known than its associate ZPMC, SPMP also operates large manufacturing facilities, and is due tomove part of its production shortly to Changxing Island near Shanghai where ZPMC already operates a large container crane fabrication plant.Portal and other harbour cranes are SPMP’s major production item. During thepast two years, the corporation has won contracts for 145 portal cranes from port authorities throughout China, both from new ports under construction and ports undergoing expansion.In recent years, SPMP has also supplied portal cranes to the United States, Iraq,and Myanmar.The port Rangoon of Myanmar in has purchased a 47m,40t portalcrane while BIW of the United States has purchased three cranes-15t,150t, and 300t portal cranes. Elsewhere, SPMP has supplied 12 portal cranes to several ports in Iraq since the end of the Saddam regime.In China, SPMP’s recent major orders for portal cranes includeeight 40t, 45m radius cranes for Tianjin Overseas Mineral Terminal, while Yan Tai Port Bureau in Guangdong in southern China has purchased six 40t, 45m radius cranes. Other large orders include seven 10t, 25m radius cranes for Zhenjiang Port Group and an order of 1025t, 33m radius cranes from Fangcheng Port Bureau, while the Yingkou Port Group has ordered 1325t,35m radius cranes along with two 40t, 44m radius port cranes.MANY CRANES BUILT TO ORDERSPMP also supplies other cranes used in ports and harbours, many of which are built to order for clients. Quayside container cranes havebeen supplied to a number of foreign clients including Bangkok Port in Thailand, Kaohsiung Port in Taiwan, and Port of Vancouver in Canada. In China, SPMP has supplied quayside container cranes to Shanghai Port, Tianjin Port, Yin Kou Port, Yan Tai Port and others. The company also supplies rubber-tyred container gantry cranes to domestic and overseas clients. Customers for other cranes used in ports include Guangzhou Port in Guangdong, which purchased a 25t floating crane while Zhonggang Port has bought two double trolley 125/63t gantry cranes, along with a700t overhead crane, In 2003 Zhonggang Port awarded a contract to SPMP for a 2,600t floating crane, whichi is the largest crane the company has made in recent years.Other customers include Zhongyuan Nanytong Shipyard of Jiangsu Province has purchased two 300t goliath cranes for use in its shipyard, while S hanghai Waigaoqiao Shipyard uses two of SPMP’s 600t goliath cranes for its shipbuilding operations. SPMP has two factories. The Shanghai plant employs 2,000 workers while a factory in Jiangsu Province employs 1,500 workers. The combined total of 3,500 workers includes 800 technical and management staff involved in designing, developing, and building portal and other cranes along with dry bulk cargo loading and unloading equipment.Currently, SPMP is preparing to vacate its Shanghai factory site as the comp any’sexisting plot of land is part of a riverside area earmarked by the Shanghai Expo in 2010. SPMP’s Shanghai factory will close at the end of 2006, and move to a new site on nearby Changxing Island.“The new factory will be much bigger than the present plant,” Li said. “Phase 1 will be ready for us when we move at the end of 2006.”In addition to moving the Shanghai factory to a new site, SPMP expects future business operation with ZPMC.Officials at China Harbour Engineering (Group) Corporation are understood to have told SPMP of plants for SPMP and ZPMC to co-operate more in bidding for projects in future. Both companies are expected to retain their individual manufacturing capability, however, with precise details of future co-operation still some way from being finalised.Meanwhile, SPMP associate company ZPMC is strengthening its position as the world’s largest manufacturer of ship-to-shore container cranes, supplying slightlymore than half the annual international container crane market. In addition to operating four crane production complexes for its crane manufacturing and other businesses.ZPMC’s full range of products includes quayside container cranes, rubber-tyredgantry cranes, bulk material ship loaders and unloaders, bucket-wheel stackers and reclaimers, portal cranes, floating cranes, and engineering vessels. The company has also diversified into manufacturing other large steel structures including large steel bridges.ZPMC EXPANDING PRODUCTIONZPMC’s cranes and other products are in use at over 150 shipping terminals in 37 countries and regions worldwide. By the end of December 2005, ZPMC had supplied 705 quayside container cranes, and had orders in hand to deliver another 128 quayside container cranes in 2006. In addition, at the end of 2005 ZPMC had delivered 1,148 rubber-tyred gantry cranes to customers worldwide and had orders in hand to deliver 308 rubber-tyred gantry cranes to customers in 2006.ZPMC is expanding production facilities in expectation that the volume of orders will grow in future. The company owns four crane production complexes in Shanghai and the surrounding area at Jiangyin, Changzhou, Zhangjiang and Changxing Island. The Changxing production site, which was completed in 2001, covers one million sq m, and has a 3.5km coastline. The facility is capable of manufacturing 160 quayside ship-to-shore container cranes each year along with 300 rubber-tyred gantry cranes and 200,000 metric tons of large steel bridge structures. Plans call for a futher 3 million sq m of land to be reclaimed at Changxing, which ZPMC will develop to become its largest production centre.Korea looks inward In a fragmented global port crane industry, Korean manufacturers are being forced to look for more business in their domestic marketsSouth Korea’s container crane and port crane equipment manufacturing industry has become more focused on the domestic market inrecent years as manufacturers have faced tough price competition from ZPMC of China in major foreign markets. The problem is the same as that faced by other port crane manufacturers around the world, none of which account for more than about an 8% share of the world container crane market.As well as ZPMC, competition from European and Japanese equipment suppliers is also strong, both for quayside container cranes and for rubber-tyred gantry crane contracts. While South Korean firms-including Hyundai Heavy Industries, Samsung Heavy Industries, Doosan Heavy Industries, and Hanjin Heavy Industries – continueto bid for international contracts, winning large orders has become increasingly rare.Doosan Heavy Industries & Construction Co Ltd is believed to be the only South Korean port crane maker to have won a large container crane contract during the past few years, with most orders booker by Korean manufacturers being for less than10 crane units.Doosan recently completed delivery of a 42-unit rubber-tyred gantry crane (RTGC) order to the Port of Singapore Authority PSN that was awarded in 2004. Including a recent contract. Doosan has received orders to supply the Port of Singapore with a total of 120 RTGCs since 1997. The recent batch of RTGCs is designed for increased safety. Esch of the RTGCs is fitted with 16 wheels instead of the usual eight.“We have supplied container crane s locally and overseas. Most projects are one or two units, but Singapore has been 120 units,” commented a source in Doosan Heavy Industries’ material handling equipment division. “Container cranes can lift one ortwo containers depending on the client, but the twin spreader design is normal now. Our biggest contract before was with Pusan Port for over 10 container cranes.”BUILDING POWER PLANTSDoosan Heavy Industries’ major activities include the design and construction ofpower plants. Apart from supplying protection equipment, Doosan also manufactures turbines and generator sets. Doosan has a large castings and forging division. Other major activities include the construction of desalination plants in the Middle East.Container port handling equipme nt is produced by Doosan’s material handling equipment division, which supplies coal handling equipment and bulk cargo handling facilities for other industries.Port of Singapore Authority is the largest customer for RTGCs. Other recent clients include Southern Gateway Terminals in Colombo, Sri Lanka, and Korea Express in the Port of Pusan.Doosan also supplies ship to shore container cranes. Recent quayside gantry crane clients include Jakarta Container Terminal in Indonesia, Jawaharlal Nehru Port near Mumbai in India, and Frazer Terminal in Vancouver.“Prospects for our port crane sales are not bright. ZPMC is dominating the world market due to price,” the source commented. “We are looking for projects notinvoving ZPMC as they are not concerned with all projects. We got contracts inSingapore in 2004 and 2005. We had no success anywhere else, but we are still bidding on various tenders.”Doosan is expected to be one of the bidders for container cranes to be installed in South Korea’s planned Kwangyan g Bay Port expansion. The company’s R&D division is involved developing new automated controls that will be required for quayside container cranes installed in the port expansion.“Container cranes are well developed in technical terms. There is nothing e lse to develop except for automation,” the source said. “We are developing more automated controls, but the new features are not commercialized yet.Our government has a plan for Kwangyang Bay 3-2 terminal project, which they announced will be developed as an automated terminal. We have to adapt to this. The tender has been postponed for about six years. We expect the project will be tendered again in 2007 or 2008.”South Korea’s other container crane manufacturers also are expected to bid for the Kwangyang Bay project, which is likely to be awarded to a local supplier. Hyundal Samho Heavy Industries will be among the bidders having recently commissioned five automated rail mounted gantry cranes(RMGCs) also known as automated transfer cranes at Pusan East Container Terminal (PECT) .The terminal has become the first terminal in Korea to install automated cranes, which are in service at new berths four and five .The cranes stack nine-wide between a 28.5m rail gauge, and have dual cantilevers covering two road lanes . Stack height is 1 over 6 by 9ft6in high and operational speeds are 150m/min for the gantry , 120m/min for the trolley and 75-80m/min for the empty hoist .Among other recent orders that Hyundai has won is a contract for four quayside container cranes from Hutchison Port Holdings and one for Uam Port.Competition from ZPMC remains the main challenge in winning overseas contracts according to Hyundai Heavy Industries sales manager Lee Yong Tae : “ We are trying to get more projects , but ZPMC has a very low price . We will try to cut our price but we think it will lead to a bad situation in future . ”“ if customers think that quality is important then we are ok , but if they just think about price we cannot win the project . We have experience of building cranes to liftone or two containers .We buy the main crane controls system from ABB and then use a Korean fabricator .”附录B港口起重机中国经济在过去的高速增长已经大幅增加了本国港口货流量,以至于不断扩大老港口以及不断修建新的港口以应对快速增长的集装箱业务以及大宗货物的流通。

中英文对照起重机术语大全起重机(crane)moblie crane 移动式起重机truck crane 汽车式起重机wheel crane / wheeled crane 轮胎起重机crawler crane / caterpillar crane 履带吊;履带式起重机tower crane 塔吊; 塔式起重机-construction tower cranes / building tower crane 建筑塔式起重机,建筑塔机-luffing jib tower crane 动臂塔式起重机-tower jib crane 塔式挺杆起重机(含义与上同)bridge crane/traveling crane/overhead crane 桥吊;桥式吊车; 桥式起重机-electric traveling crane 电动桥式起重机(俗称行车、天车)-electric double-beam bridge crane 电动双梁桥式起重机portal crane / portal bridge crane门式起重机- semi-goliath crane 半门式起重机- semi-portal bridge crane 半龙门起重机gantry cranes 龙门起重机- rubber tyred gantry crane 轮胎式龙门吊- electric gantry crane 电动龙门式起重机- hook gantry crane 吊钩龙门吊- economical gantry crane 简单龙门起重机; 简易龙门起重机- rubber tyred container gantry crane 轮胎式集装箱龙门起重机barges / floating Cranes 船式起重机; 浮吊; 浮式起重机水上起重机boom crane 吊杆起重机; 桁梁起重机; 臂式起重机; 伸臂起重机bucket crane 料罐起重机; 吊斗起重机building crane 建筑起重机cable crane 索道起重机; 缆索起重机container crane 集装箱起重机electric crane 电动吊车; 电动起重机; 电力起重机electriomagnet crane 电磁铁起重机electric jib crane 电动单臂起重机fixed crane 固定式起重机climbing crane 爬升式起重机;攀爬式起重机fixed derrick crane 固定式动臂起重机fixed jib crane 固定式悬臂起重机flying crane helicopter 起重直升机hoist crane 起重葫芦hoisting crane 升降起重机hook type crane 钩式起重机twin hood crane 双钩吊车mobile crane 移动式吊车; 移动式起重机quay crane 码头起重机; 码头桥式起重机; 港岸起重机revolving track crane 回转式轨道起重机circular crane 旋转式吊车环形吊车roof crane 屋顶起重机transporter crane 桁架式起重机electric crane 电动吊车; 电动起重机gasoline crane 汽油起重机hydraulic crane 液力起重机; 液压起重机derrick crane 人字扒杆人字起重机-travelling derrick crane 移动式人字扒杆jib crane / cantilever crane 悬臂式起重机wall crane 壁式起重机heavy duty crane 重型起重机crane output / carrying capacity of crane / lifting capacity of crane 吊车起重能力crane load 起重机起重量; 起重机起重量crane rating 起重机定额; 起重机载重量crane radius 起重机起吊半径; 起重机伸臂活动半径; 起重机伸距craneage 吊车工时crane beam 行车梁起重机大梁crane stair 起重机楼梯hoist drive mechanism 起重机驱动机构travelling crab 起重机小车hoisting controller 起重控制器吊车控制手柄hoisting facility 起重设施lifting gear 起重装置crane (runway) girder 吊车梁crane support wall 吊车支承墙crane boom 起重机吊架; 起重架; 吊车臂; 吊车起重扒杆; 吊杆crane column 吊车柱crane hook / grab (or lift hook)( or dolly)起重机吊钩crane jib 起重机吊杆crane bridge 起重机桥crane buffer 吊车缓冲器crane rope / crane cable起重钢绳; 起重机吊索; 吊车钢丝绳crane carriage 起重小车; 横行小车crane carrier 起重机载运车crane controller 起重控制器crane fall 起重机索crane motor / crane hoist type motor 起重机电动机crane platform 起重机平台crane rail 吊车轨,起重机轨道crane runner 吊车司机crane runway 起重机走道; 天车滑道crane weigher 吊车秤crane wheel 吊车车轮lifting tackle 起重滑车lever of crane 起重机臂hoisting tools 起重工具吊具lifting rope 吊绳起重钢丝绳起重吊装术语:hoist / load up 起升lower / load down 下降hoist slowly / load up slowly 微微起升lower slowly / load down slowly 微微下降use main hoist/use main line 使用主钩use whip hoist/use whip line 使用小钩raise boom / boom up(臂架类吊车)抬起主臂lower boom / boom down (同上)降下主臂raise boom slowly / boom up slowly(臂架类吊车)微微抬起主臂lower boom slowly / boom down slowly (同上)微微降下主臂swing (根据指挥手势、旗语或)移动摆动stop 停止Emergency stop 紧急停止Extend boom / extend hydranlic boom (汽车吊类)伸长主臂Retract boom / shorten hydranlic boom (汽车吊类)缩回主臂raise the boom and lower the load /boom up and load down (汽车吊类)抬主臂降主钩(俗称顿杆松钩)lower the boom and raise the load /boom dwon and load up (汽车吊类)降主臂起主钩(俗称趴杆起钩)turn left 向左转turn right 向右转crane output / carrying capacity of crane / lifting capacity of crane 吊车起重能力crane load 起重机起重量; 起重机起重量crane rating 起重机定额; 起重机载重量crane radius 起重机起吊半径; 起重机伸臂活动半径; 起重机伸距craneage 吊车工时crane beam 行车梁起重机大梁crane stair 起重机楼梯hoist drive mechanism 起重机驱动机构travelling crab 起重机小车hoisting controller 起重控制器吊车控制手柄hoisting facility 起重设施lifting gear 起重装置crane (runway) girder 吊车梁crane support wall 吊车支承墙crane boom 起重机吊架; 起重架; 吊车臂; 吊车起重扒杆; 吊杆crane column 吊车柱crane hook / grab (or lift hook)( or dolly)起重机吊钩crane bridge 起重机桥crane buffer 吊车缓冲器crane rope / crane cable起重钢绳; 起重机吊索; 吊车钢丝绳crane carriage 起重小车; 横行小车crane carrier 起重机载运车crane controller 起重控制器crane fall 起重机索crane motor / crane hoist type motor 起重机电动机crane platform 起重机平台crane rail 吊车轨,起重机轨道crane runner 吊车司机crane runway 起重机走道; 天车滑道crane weigher 吊车秤crane wheel 吊车车轮crane winch 起重机绞车lifting tackle 起重滑车lever of crane 起重机臂hoisting tools 起重工具吊具lifting rope 吊绳起重钢丝绳。

HSR(火工矫正报告)heat straightening report

edge

angle

below

bottom

camber

oriention

key plan

图纸描述单一mono

图纸描述待定later

图纸描述合适的applicable 图纸描述辅助的auxiliary

图纸描述避免avoid

图纸描述深度depth

图纸描述描述description 图纸描述名称designation 图纸描述详图details

图纸描述直径diameter

图纸描述尺寸dimension

图纸描述正面图elevation

图纸描述膨胀expansion

图纸描述适宜的fitted

图纸描述间距gap

图纸描述缀板guesset

图纸描述增加量increment

图纸描述中间intermediary 图纸描述允许permit

图纸描述相似的similar

图纸描述形状shape

图纸描述表scheudule

图纸描述剖面sections

图纸描述硬/强硬的stiff

图纸描述厚thick

图纸描述薄的thin

图纸描述穿过thru

图纸描述紧固tight

图纸描述桁架truss

图纸描述典型的typical 图纸描述单位unite

图纸描述垂直vertical 图纸描述宽width。

中英文对照外文翻译(文档含英文原文和中文翻译)Control of Tower Cranes WithDouble-Pendulum Payload DynamicsAbstract:The usefulness of cranes is limited because the payload is supported by an overhead suspension cable that allows oscilation to occur during crane motion. Under certain conditions, the payload dynamics may introduce an additional oscillatory mode that creates a double pendulum. This paper presents an analysis of this effect on tower cranes. This paper also reviews a command generation technique to suppress the oscillatory dynamics with robustness to frequency changes. Experimental results are presented to verify that the proposed method can improve the ability of crane operators to drive a double-pendulum tower crane. The performance improvements occurred during both local and teleoperated control.Key words:Crane , input shaping , tower crane oscillation , vibrationI. INTRODUCTIONThe study of crane dynamics and advanced control methods has received significant attention. Cranes can roughly be divided into three categories based upontheir primary dynamic properties and the coordinate system that most naturally describes the location of the suspension cable connection point. The first category, bridge cranes, operate in Cartesian space, as shown in Fig. 1(a). The trolley moves along a bridge, whose motion is perpendicular to that of the trolley. Bridge cranes that can travel on a mobile base are often called gantry cranes. Bridge cranes are common in factories, warehouses, and shipyards.The second major category of cranes is boom cranes, such as the one sketched in Fig. 1(b). Boom cranes are best described in spherical coordinates, where a boom rotates aboutaxes both perpendicular and parallel to the ground. In Fig. 1(b), ψis the rotation aboutthe vertical, Z-axis, and θis the rotation about the horizontal, Y -axis. The payload is supported from a suspension cable at the end of the boom. Boom cranes are often placed on a mobile base that allows them to change their workspace.The third major category of cranes is tower cranes, like the one sketched in Fig. 1(c). These are most naturally described by cylindrical coordinates. A horizontal jib arm rotates around a vertical tower. The payload is supported by a cable from the trolley, which moves radially along the jib arm. Tower cranes are commonly used in the construction of multistory buildings and have the advantage of having a small footprint-to-workspace ratio. Primary disadvantages of tower and boom cranes, from a control design viewpoint, are the nonlinear dynamics due to the rotational nature of the cranes, in addition to the less intuitive natural coordinate systems.A common characteristic among all cranes is that the pay- load is supported via an overhead suspension cable. While this provides the hoisting functionality of the crane, it also presents several challenges, the primary of which is payload oscillation. Motion of the crane will often lead to large payload oscillations. These payload oscillations have many detrimental effects including degrading payload positioning accuracy, increasing task completion time, and decreasing safety. A large research effort has been directed at reducing oscillations. An overview of these efforts in crane control, concentrating mainly on feedback methods, is provided in [1]. Some researchers have proposed smooth commands to reduce excitation of system flexible modes [2]–[5]. Crane control methods based on command shaping are reviewed in [6].Many researchers have focused on feedback methods, which necessitate the addition necessitate the addition of sensors to the crane and can prove difficult to use in conjunction with human operators. For example, some quayside cranes have been equipped with sophisticated feedback control systems to dampen payload sway. However, the motions induced by the computer control annoyed some of the human operators. As a result, the human operators disabled the feedback controllers. Given that the vast majority of cranes are driven by human operators and will never be equipped with computer-based feedback, feedback methods are not considered in this paper.Input shaping [7], [8] is one control method that dramatically reduces payload oscillation by intelligently shaping the commands generated by human operators [9], [10]. Using rough estimates of system natural frequencies and damping ratios, a series of impulses, called the input shaper, is designed. The convolution of the input shaper and the original command is then used to drive the system. This process is demonstrated with atwo-impulse input shaper and a step command in Fig. 2. Note that the rise time of the command is increased by the duration of the input shaper. This small increase in the rise time is normally on the order of 0.5–1 periods of the dominant vibration mode.Fig. 1. Sketches of (a) bridge crane, (b) boom crane, (c) and tower crane.Fig. 2. Input-shaping process.Input shaping has been successfully implemented on many vibratory systems including bridge [11]–[13], tower [14]–[16], and boom [17], [18] cranes, coordinate measurement machines[19]–[21], robotic arms [8], [22], [23], demining robots [24], and micro-milling machines [25].Most input-shaping techniques are based upon linear system theory. However, some research efforts have examined the extension of input shaping to nonlinear systems [26], [14]. Input shapers that are effective despite system nonlinearities have been developed. These include input shapers for nonlinear actuator dynamics, friction, and dynamic nonlinearities [14], [27]–[31]. One method of dealing with nonlinearities is the use of adaptive or learning input shapers [32]–[34].Despite these efforts, the simplest and most common way to address system nonlinearities is to utilize a robust input shaper [35]. An input shaper that is more robust to changes in system parameters will generally be more robust to system nonlinearities that manifest themselves as changes in the linearized frequencies. In addition to designing robust shapers, input shapers can also be designed to suppress multiple modes of vibration [36]–[38].In Section II, the mobile tower crane used during experimental tests for this paper is presented. In Section III, planar and 3-D models of a tower crane are examined to highlight important dynamic effects. Section IV presents a method to design multimode input shapers with specified levels of robustness. InSection V, these methods are implemented on a tower crane with double-pendulum payload dynamics. Finally, in Section VI, the effect of the robust shapers on human operator performance is presented for both local and teleoperated control.II. MOBILE TOWER CRANEThe mobile tower crane, shown in Fig. 3, has teleoperation capabilities that allow it to be operated in real-time from anywhere in the world via the Internet [15]. The tower portion of the crane, shown in Fig. 3(a), is approximately 2 m tall with a 1 m jib arm. It is actuated by Siemens synchronous, AC servomotors. The jib is capable of 340°rotation about the tower. The trolley moves radially along the jib via a lead screw, and a hoisting motor controls the suspension cable length. Motor encoders are used for PD feedback control of trolley motion in the slewing and radial directions. A Siemens digital camera is mounted to the trolley and records the swing deflection of the hook at a sampling rate of 50 Hz [15].The measurement resolution of the camera depends on the suspension cable length. For the cable lengths used in this research, the resolution is approximately 0.08°. This is equivalent to a 1.4 mm hook displacement at a cable length of 1 m. In this work, the camera is not used for feedback control of the payload oscillation. The experimental results presented in this paper utilize encoder data to describe jib and trolley position and camera data to measure the deflection angles of the hook.Base mobility is provided by DC motors with omnidirectional wheels attached to each support leg, as shown in Fig. 3(b). The base is under PD control using two HiBot SH2-based microcontrollers, with feedback from motor-shaft-mounted encoders. The mobile base was kept stationary during all experiments presented in this paper. Therefore, the mobile tower crane operated as a standard tower crane.Table I summarizes the performance characteristics of the tower crane. It should be noted that most of these limits are enforced via software and are not the physical limitations of the system. These limitations are enforced to more closely match theoperational parameters of full-sized tower cranes.Fig. 3. Mobile, portable tower crane, (a) mobile tower crane, (b) mobile crane base.TABLE I MOBILE TOWER CRANE PERFORMANCE LIMITSFig. 4 Sketch of tower crane with a double-pendulum dynamics.III. TOWER CRANE MODELFig.4 shows a sketch of a tower crane with a double-pendulum payload configuration. The jib rotates by an angle around the vertical axis Z parallelto the tower column. The trolley moves radially along the jib; its position along the jib is described by r . The suspension cable length from the trolley to the hook is represented by an inflexible, massless cable of variable length 1l . The payload is connected to the hook via an inflexible, massless cable of length 2l . Both the hook and the payload are represented as point masses having masses h m and p m , respectively.The angles describing the position of the hook are shown in Fig. 5(a). The angle φrepresents a deflection in the radial direction, along the jib. The angle χ represents a tangential deflection, perpendicular to the jib. In Fig. 5(a), φ is in the plane of the page, and χ lies in a plane out of the page. The angles describing the payload position are shown in Fig. 5(b). Notice that these angles are defined relative to a line from the trolley to the hook. If there is no deflection of the hook, then the angle γ describes radial deflections, along the jib, and the angle α represents deflections perpendicular to the jib, in the tangential direction. The equations of motion for this model were derived using a commercial dynamics package, but they are too complex to show in their entirety here, as they are each over a page in length.To give some insight into the double-pendulum model, the position of the hook and payload within the Newtonian frame XYZ are written as —h q and —p q , respectivelyWhere -I , -J and -K are unit vectors in the X , Y , and Z directions. The Lagrangian may then be written asFig. 5. (a) Angles describing hook motion. (b) Angles describing payload motion.Fig. 6. Experimental and simulated responses of radial motion.(a) Hook responses (φ) for m 48.01=l ,(b) Hook responses for m 28.11=lThe motion of the trolley can be represented in terms of the system inputs. The position of the trolley —tr q in the Newtonian frame is described byThis position, or its derivatives, can be used as the input to any number of models of a spherical double-pendulum. More detailed discussion of the dynamics of spherical double pendulums can be found in [39]–[42].The addition of the second mass and resulting double-pendulum dramatically increases the complexity of the equations of motion beyond the more commonly used single-pendulum tower model [1], [16], [43]–[46]. This fact can been seen in the Lagrangian. In (3), the terms in the square brackets represent those that remain for the single-pendulum model; no —p q terms appear. This significantly reduces the complexity of the equations because —p q is a function of the inputs and all four angles shown in Fig. 5.It should be reiterated that such a complex dynamic model is not used to design the input-shaping controllers presented in later sections. The model was developed as a vehicle to evaluate the proposed control method over a variety of operating conditions and demonstrate its effectiveness. The controller is designed using a much simpler, planar model.A. Experimental V erification of the ModelThe full, nonlinear equations of motion were experimentally verified using several test cases. Fig.6 shows two cases involving only radial motion. The trolley was driven at maximum velocity for a distance of 0.30 m, with 2l =0.45m .The payload mass p m for both cases was 0.15 kg and the hook mass h m was approximately 0.105 kg. The two cases shown in Fig. 6 present extremes of suspension cable lengths 1l . In Fig. 6(a), 1l is 0.48 m , close to the minimum length that can be measured by the overhead camera. At this length, the double-pendulum effect is immediately noticeable. One can see that the experimental and simulated responses closely match. In Fig. 6(b), 1l is 1.28 m, the maximum length possible while keeping the payload from hitting the ground. At this length, the second mode of oscillation has much less effect on the response. The model closely matches the experimental response for this case as well. The responses for a linearized, planar model, which will be developed in Section III-B, are also shown in Fig. 6. The responses from this planar model closely match both the experimental results and the responses of the full, nonlinear model for both suspension cable lengths.Fig. 7. Hook responses to 20°jib rotation:(a) φ (radial) response;(b) χ (tangential) response.Fig. 8. Hook responses to 90°jib rotation:φ(radial) response;(b) χ(tangential) response.(a)If the trolley position is held constant and the jib is rotated, then the rotational and centripetal accelerations cause oscillation in both the radial and tangential directions. This can be seen in the simulation responses from the full nonlinear model in Figs. 7 and 8. In Fig. 7, the trolley is held at a fixed position of r = 0.75 m, while the jib is rotated 20°. This relatively small rotation only slightly excites oscillation in the radial direction, as shown in Fig. 7(a). The vibratory dynamics are dominated by oscillations in the tangential direction, χ, as shown in Fig. 7(b). If, however, a large angular displacement of the jib occurs, then significant oscillation will occur in both the radial and tangential directions, as shown in Fig. 8. In this case, the trolley was fixed at r = 0.75 m and the jib was rotated 90°. Figs. 7 and 8 show that the experimental responses closely match those predicted by the model for these rotational motions. Part of the deviation in Fig. 8(b) can be attributed to the unevenness of the floor on which the crane sits. After the 90°jib rotation the hook and payload oscillate about a slightly different equilibrium point, as measured by the overhead camera.Fig.9.Planardouble-pendulummodel.B.Dynamic AnalysisIf the motion of the tower crane is limited to trolley motion, like the responses shown in Fig. 6, then the model may be simplified to that shown in Fig. 9. This model simplifies the analysis of the system dynamics and provides simple estimates of the two natural frequencies of the double pendulum. These estimates will be used to develop input shapers for the double-pendulum tower crane.The crane is moved by applying a force )(t u to the trolley. A cable of length 1l hangs below the trolley and supports a hook, of mass h m , to which the payload is attached using rigging cables. The rigging and payload are modeled as a second cable, of length 2l and point mass p m . Assuming that the cable and rigging lengths do not change during the motion, the linearized equations of motion, assuming zero initial conditions, arewhere φ and γ describe the angles of the two pendulums, R is the ratio of the payload mass to the hook mass, and g is the acceleration due to gravity.The linearized frequencies of the double-pendulum dynamics modeled in (5) are [47]Where Note that the frequencies depend on the two cable lengths and the mass ratio.Fig. 10. Variation of first and second mode frequencies when m l l 8.121=+.Fig. 10 shows the two oscillation frequencies as a function of both the rigging length and the mass ratio when the total length from trolley to payload is held constant at 1.8 m. The total length is set to this value because it corresponds to the maximum length of the tower crane that was shown in Fig. 3. This maximum length corresponds to the largest possible swing amplitudes, so Fig. 10 represents the frequencies that are possible in this worst-case scenario. The low frequency is maximized when the two cable lengths are equal. Note that over the wide range of parameter values shown in Fig. 10, the low frequency varies only ±10% from its median value of 0.42 Hz. In contrast, the second mode deviates ±34% over the same parameter range.Ⅳ. CONCLUSIONA dynamic analysis of a tower crane with a payload exhibiting double-pendulumdynamics was presented. A simplified model was used to estimate the frequency andcontribution to the total response of each of the vibratory modes. An input-shaping control method to limit the residual oscillation, with robustness to errors in frequency, was then developed using the simple model.This input shaper was experimentally tested for various cases, and its robustnessto changes in suspension cable length and nonlinear effects during slewing werepresented. The influence of this input shaper on operator performance was then examined for two different obstacle courses, one simple and one difficult. The human operators negotiated the two obstacle courses both locally and remotely, teleoperating the crane via the Internet. Input shaping was shown to dramatically improve task completion times, while reducing the number of obstacle collisions. An ANOV A analysis showed that this improvement was statistically significant for nearly all tests.运用双摆载荷动力学控制塔式起重机摘要:起重机的作用之所以有限,是因为载荷由架空缆支撑着,而架空缆在起重机运行期间是允许振动的发生。