BPS产品简介

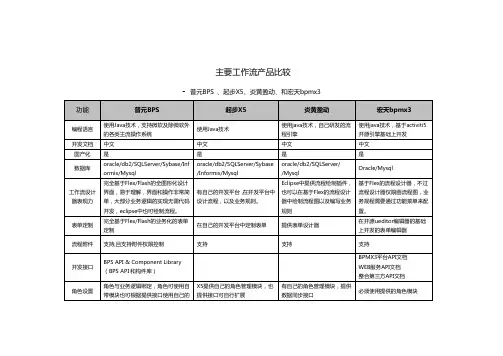

- 格式:docx

- 大小:242.87 KB

- 文档页数:1

BPS方案1. 简介BPS(Business Process Standardization,业务流程标准化)方案是一种将企业内部业务流程进行标准化和优化的方法。

通过制定统一、规范的流程标准,BPS方案旨在提高企业的效率、降低成本,并增加业务的可控性和可复制性。

2. BPS方案的优势BPS方案在企业管理和运营中具有以下优势:2.1 提高效率通过标准化业务流程,BPS方案可以消除冗余的操作和重复的工作,从而提高工作效率。

员工可以更加便捷地完成日常工作任务,减少错误和失误,提高工作质量和效率。

2.2 降低成本BPS方案通过优化业务流程,可以降低企业的运营成本。

标准化的流程可以减少资源和时间的浪费,避免重复购买和使用工具和软件,从而降低企业运营和管理的成本。

2.3 增加可控性将业务流程标准化之后,企业可以更加清晰地了解和掌控每个环节的进展和状态。

通过引入合适的绩效指标和监控机制,企业可以更好地评估业务流程的运行情况,并及时调整和改进。

2.4 提高品质和稳定性BPS方案通过明确规范的流程标准,可以提高产品和服务的品质和稳定性。

标准化的流程可以确保产品和服务的一致性,并帮助企业发现和解决潜在的质量问题。

3. BPS方案的实施步骤3.1 识别关键业务流程首先,企业需要识别出关键的业务流程,即对企业运营和管理具有重要影响的流程。

这些流程可能包括订单处理、项目管理、销售流程等。

3.2 收集相关信息在开始制定流程标准之前,企业需要收集相关信息。

这包括与业务流程相关的文件、记录、员工意见和建议等。

收集到的信息将帮助企业更好地了解现有流程的问题和瓶颈。

3.3 制定流程标准根据收集到的信息,企业可以开始制定流程标准。

流程标准应该包括具体的操作步骤、所需的资源和工具、时间要求等。

标准化的流程应该简化流程,避免冗余操作,并提高效率。

3.4 培训和推广完成流程标准制定之后,企业应该进行培训和推广工作。

培训可以确保员工理解并能够正确执行新的流程标准。

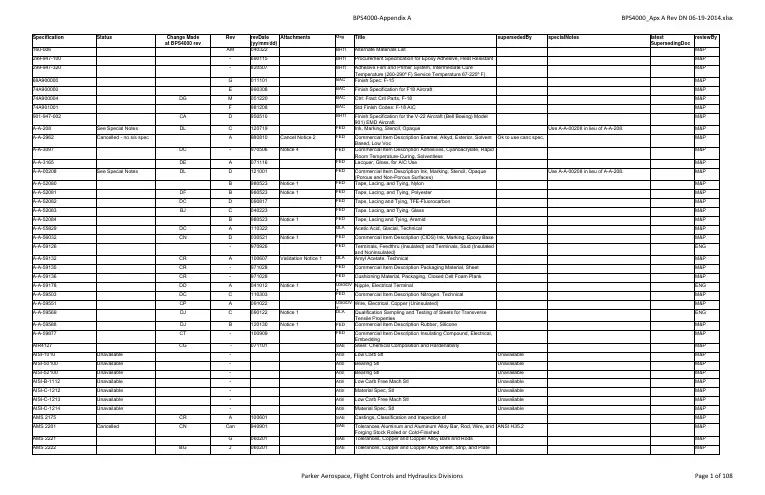

at BPS4000 rev(yy/mm/dd)SupersedingDoc160-006AM040322BHTI Alternate Materials List M&P 299-947-100-690115BHTI Procurement Specification for Epoxy Adhesive, Heat Resistant M&P 299-947-320-820507BHTI Adhesive Film and Primer System, Intermediate CureTemperature (260-290º F) Service Temperature 67-225º F)M&P 68A900000G011101BAC Finish Spec: F-15M&P 74A900000E990308BAC Finish Specification for F18 Aircraft M&P 74A900004DG M051220BAC Ctrl: Fract Crit Parts, F-18M&P 74A901001F981208BAC Std Finish Codes: F-18 A\C M&P 901-947-002CA D950510BHTI Finish Specification for the V-22 Aircraft (Bell Boeing) Model901) EMD AircraftM&P A-A-208See Special Notes DL C120719FED Ink, Marking, Stencil, Opaque Use A-A-00208 in lieu of A-A-208.M&P A-A-2962Cancelled - no s/s spec A980810Cancel Notice 2FED Commercial Item Description Enamel, Alkyd, Exterior, SolventBased, Low VocOk to use canc spec.M&P A-A-3097DC-970506Notice 4FED Commercial Item Description Adhesives, Cyanoacrylate, RapidRoom Temperature-Curing, SolventlessM&P A-A-3165DE A071116FED Lacquer, Gloss, for A/C Use M&P A-A-00208See Special Notes DL D121001FED Commercial Item Description Ink, Marking, Stencil, Opaque(Porous and Non-Porous Surfaces)Use A-A-00208 in lieu of A-A-208.M&P A-A-52080B980523Notice 1FED Tape, Lacing, and Tying, Nylon M&P A-A-52081DF B980523Notice 1FED Tape, Lacing, and Tying, Polyester M&P A-A-52082DC D090817FED Tape, Lacing and Tying, TFE-Fluorocarbon M&P A-A-52083BJ C040223FED Tape, Lacing, and Tying, Glass M&P A-A-52084B980523Notice 1FED Tape, Lacing and Tying, Aramid M&P A-A-55829DC A110322DLA Acetic Acid, Glacial, Technical M&P A-A-56032CN D030521Notice 1FED Commercial Item Description (CIDS) Ink, Marking, Epoxy Base M&P A-A-59126-970926FED Terminals, Feedthru (Insulated) and Terminals, Stud (Insulatedand Noninsulated)ENG A-A-59132CR A100607Validation Notice 1DLA Amyl Acetate, Technical M&P A-A-59135CR-971028FED Commercial Item Description Packaging Material, Sheet M&P A-A-59136CR-971028FED Cushioning Material, Packaging, Closed Cell Foam Plank M&PA-A-59178DD A041012Notice 1USGOVT Nipple, Electrical Terminal ENGA-A-59503DC C110303FED Commercial Item Description Nitrogen, Technical M&PA-A-59551CP A091022USGOVT Wire, Electrical, Copper (Uninsulated) M&PA-A-59569DJ C090122Notice 1DLA Qualification Sampling and Testing of Steels for TransverseTensile PropertiesENG A-A-59588DJ B120130Notice 1FED Commercial Item Description Rubber, Silicone M&P A-A-59877CT-100909FED Commercial Item Description Insulating Compound, Electrical,EmbeddingM&P AIR4127CG - 071101SAE Steel: Chemical Composition and Hardenability M&P AISI-1010Unavailable-AISI Low Carb Stl Unavailable M&P AISI-50100Unavailable-AISI Bearing Stl Unavailable M&P AISI-52100Unavailable-AISI Bearing Stl Unavailable M&P AISI-B-1112Unavailable-AISI Low Carb Free Mach Stl Unavailable M&P AISI-C-1212Unavailable-AISI Material Spec, Stl Unavailable M&P AISI-C-1213Unavailable-AISI Low Carb Free Mach Stl Unavailable M&P AISI-C-1214Unavailable-AISI Material Spec, Stl Unavailable M&P AMS 2175CR A100601SAE Castings, Classification and Inspection of M&P AMS 2201Cancelled CN Can940901SAE Tolerances Aluminum and Aluminum Alloy Bar, Rod, Wire, andForging Stock Rolled or Cold-FinishedANSI H35.2M&P AMS 2221G060201SAE Tolerances, Copper and Copper Alloy Bars and Rods M&P AMS 2222BG J060201SAE Tolerances, Copper and Copper Alloy Sheet, Strip, and Plate M&Pat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2223BF H060201SAE Tolerances Copper and Copper Alloy Seamless Tubing M&P AMS 2224G060201SAE Tolerances Copper and Copper Alloy Wire M&P AMS 2241CN R070701SAE Tolerances, Corrosion and Heat-Resistant Steel, Iron Alloy,M&PTitanium, and Titanium Alloy Bars and WireM&P AMS 2242CC G080604SAE Tolerances Corrosion and Heat Resistant Steel, Iron Alloy,Titanium and Titanium Alloy Sheet, Strip and PlateAMS 2243DH K130601SAE Tolerances Corrosion and Heat-Resistant Steel Tubing M&PM&P AMS 2248DB G110301SAE Chemical Check Analysis Limits Corrosion and Heat-ResistantSteels and Alloys, Maraging and other Highly-Alloyed Steels,and Iron AlloysAMS 2249CN G090701SAE Chemical Check Analysis Limits Titanium and Titanium Alloys M&PM&P AMS 2259CN E071201SAE Chemical Check Analysis Limits Wrought Low-Alloy andCarbon SteelsAMS 2269CN F060501SAE Chemical Check Analysis Limits Nickel, Nickel Alloys, andM&PCobalt AlloysM&P AMS 2300CU L100801SAE Steel Cleanliness, Premium Aircraft-Quality Magnetic ParticleInspection ProcedureM&P AMS 2301CT K100801SAE Steel Cleanliness, Aircraft Quality Magnetic Particle InspectionProcedureAMS 2303CT F100801SAE Steel Cleanliness, Aircraft Quality, Martensitic CorrosionM&PResistant Steels Magnetic Particle Inspection ProcedureM&P AMS 2304CV B100801SAE Steel Cleanliness, Special Aircraft-Quality Magnetic ParticleInspection ProcedureM&P AMS 2310BE F060201SAE Qualification Sampling and Testing of Steels for TransverseTensile PropertiesAMS 2315DF G130201SAE Determination of Delta Ferrite Content M&P AMS 2350Cancelled - no s/s spec CN BA891001SAE Standards and Test Methods Ok to use canc spec.M&PM&P AMS 2355DB K110301SAE Quality Assurance Sampling and Testing Aluminum Alloys andMagnesium Alloy Wrought Products (Except Forging Stock),and Rolled, Forged, or Flash Welding RingsAMS 2360CN D070701SAE Room Temperature Tensile Properties of Castings M&PM&P AMS 2370DB K110601SAE Quality Assurance Sampling and Testing Carbon and Low-AlloySteel Wrought Products and Forging StockAMS 2371DB J110601SAE Quality Assurance Sampling and Testing Corrosion and Heat-M&PResistant Steels and Alloys Wrought Products and ForgingStockM&P AMS 2372DB F110601SAE Quality Assurance Sampling and Testing Carbon and Low-AlloySteel ForgingsAMS 2375CN D070601SAE Control of Forgings Requiring First Article Approval M&P AMS 2380CN F080601SAE Approval and Control of Premium-Quality Titanium Alloys M&P AMS 2400DG X130201SAE Plating, Cadmium M&P AMS 2401DF J130201SAE Plating, Cadmium Low Hydrogen Content Deposit M&P AMS 2403BM L041001SAE Plating, Nickel General Purpose M&P AMS 2404CH F081201SAE Plating, Electroless Nickel M&P AMS 2405DL E131001SAE Electroless Nickel Plate, Low Phosphorous M&P AMS 2406DE M121101SAE Plating, Chromium Hard Deposit M&P AMS 2408DL K130901SAE Plating, Tin M&P AMS 2410CR K100401SAE Plating, Silver Nickel Strike, High Bake M&P AMS 2411DM H131201SAE Plating, Silver for High Temperature Applications M&P AMS 2412CN J091201SAE Plating, Silver Copper Strike, Low Bake M&P AMS 2416CU L101201SAE Plating, Nickel-Cadmium Diffused M&P AMS 2417DL J130901SAE Plating, Zinc-Nickel Alloy M&P AMS 2418CU H110201SAE Plating, Copper M&P AMS 2419BM C030501SAE Plating, Cadmium-Titanium M&PM&P AMS 2420D021201SAE Plating of Aluminum for Solderability Zinc Immersion Pre-Treatment Processat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2423See Special Notes CE D020401SAE Plating, Nickel Hard Deposit Continue to use AMS-QQ-N-290 for Class 2Nickel.M&P AMS 2424CR F100401SAE NI Plate, Low Stressed Deposit M&P AMS 2426DL E130901SAE Coating, Cadmium Vacuum Deposition M&P AMS 2427DD D070701SAE Aluminum Coating Ion Vapor Deposition M&P AMS 2429CY D111001SAE Bronze Plate Masking M&P AMS 2430DB S120701SAE Shot Peening, Automatic M&P AMS 2432DF D130201SAE Shot Peening, Computer Monitored M&P AMS 2433C041001SAE Plating, Nickel-Thallium-Boron or Nickel-Boron M&P AMS 2434CY D110901SAE Plating, Tin-Zinc Alloy M&P AMS 2435Noncurrent CN G070601SAE Coating, Tungsten Carbide-Cobalt Coating, Detonation Process M&P AMS 2437BN C710111SAE Coating, Plasma Spray Deposition M&P AMS 2438CL D090701SAE Plating, Chromium Thin, Hard, Dense Deposit M&P AMS 2444BM A001201SAE Coating, Titanium Nitride Physical Vapor Deposition M&P AMS 2451CW C110701SAE Plating, Brush General Requirements M&PAMS 2460See Special Notes DF A130301SAE Plating, Chromium If dwg requires chrome plate per AMS-QQ-C-320then stress relief and embritlmnt (emb) bake reliefper BPS4620. If dwg req's chrome plate per AMS2460then stress relief and bake relief per AMS M&PAMS 2468Cancelled CN G981001SAE Hard Anodic Coating Treatment of Aluminum Alloys AMS 2469M&P AMS 2469DM J140201SAE Hard Anodic Coating Treatment of Aluminum and AluminumAlloys Processing and Performance RequirementsM&P AMS 2470DH N130701SAE Anodic Treatment of Aluminum Alloys Chromic Acid Process M&P AMS 2471DM H140201SAE Anodic Treatment of Aluminum Alloys Sulfuric Acid Process,Undyed CoatingM&P AMS 2472DD F070801SAE Anodic Treatment of Aluminum Alloys Sulfuric Acid Process,Dyed CoatingM&P AMS 2473DK H130801SAE Chemical Film Treatment for Aluminum Alloys General PurposeCoatingM&P AMS 2474Noncurrent DD D060201SAE Chemical Treatment for Aluminum Alloys Low ElectricalResistance CoatingAMS 2477M&P AMS 2477DD A100401SAE Conversion Coating for Aluminum Alloys Low Electrical Coating M&P AMS 2481CP J100201SAE Phosphate Treatment Antichafing M&P AMS 2482CN D100101SAE Hard Anodic Coating on Aluminum AlloysPolytetrafluoroethylene (PTFE)-Impregnated or CodepositedM&P AMS 2485BY K080101SAE Coating, Black Oxide M&P AMS 2486CR E100501SAE Conversion Coating of Titanium Alloys Fluoride-PhosphateTypeM&P AMS 2487CN A000301SAE Anodic Treatment of Titanium and Titanium Alloys Solution pH12.4 MaximumM&P AMS 2488D000606SAE Anodic Tr: Ti, Ti Alys M&P AMS 2515DE G130101SAE Polytetrafluoroethylene (PTFE) Resin Coating Low Build, 370 to400 °C (698 to 752 °F) FusionM&P AMS 2516DF E130301SAE Polytetrafluoroethylene (PTFE) Resin Coating High Build, 370to 400 °C (698 to 752 °F) FusionM&P AMS 2525DJ D130701SAE Graphite Coating, Thin Lubricating Film Impingement Applied M&P AMS 2526DE D130101SAE Molybdenum Disulfide Coating, Thin Lubricating FilmImpingement AppliedM&P AMS 2590DD-101201SAE Rotary Flap Peening of Metal Parts M&P AMS 2615BM F060901SAE Pressure Testing Hydraulic Pressure as Specified M&P AMS 2630CR C100101SAE Inspection, Ultrasonic Product Over 0.5 Inch (12.7 mm) Thick M&P AMS 2631CW D110701SAE Ultrasonic Inspection Titanium and Titanium Alloy Bar and Billet M&P AMS 2632BN A950301SAE Inspection, Ultrasonic, of Thin Materials 0.50 Inch (12.7 mm)and Under in Cross-Sectional ThicknessM&P AMS 2635Cancelled Can810701SAE Radiographic Insp ASTM E1742M&Pat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2640Cancelled CH Can960401SAE Magnetic Particle Inspection ASTM E1444M&P AMS 2645Cancelled CH Can950201SAE Fluorescent Penetrant Inspection ASTM E1417M&P AMS 2649DM D131201SAE Etch Inspection of High Strength Steel Parts M&P AMS 2658CN C091001SAE Hardness and Conductivity Inspection of Wrought AluminumAlloy PartsM&P AMS 2664CH F950701SAE Brazing, Silver for Use Up to 800 °F (427 °C)M&P AMS 2665DH H130501SAE Brazing, Silver for Use up to 400 °F (204 °C)M&P AMS 2666Cancelled Can840101SAE Ag Braz, High Temp AMS 2664M&P AMS 2670BK J060601SAE Brazing, Copper M&P AMS 2671Cancelled CH Can920101SAE Copper Brazing Corrosion and Heat Resistant Steels andAlloysAMS 2670M&P AMS 2672CY G120101SAE Brazing, Aluminum Torch or Furnace M&P AMS 2673DB E120101SAE Brazing, Aluminum and Aluminum Alloys Molten Flux (Dip)M&P AMS 2675DF H130201SAE Brazing, Nickel Alloy Filler Metal M&P AMS 2680C010601SAE Electron-Beam Welding for Fatigue Critical Applications M&P AMS 2681B000301SAE Electron Beam Welding M&P AMS 2685Noncurrent CP E071001SAE Welding, Tungsten Arc, Inert Gas GTAW Method M&P AMS 2689Noncurrent CH A980201SAE Fusion Welding Titanium and Titanium Alloys M&P AMS 2694DE C130101SAE In-Process Welding of Castings M&P AMS 2700DA E111101SAE Passivation of Corrosion Resistant Steels All acceptance testing shall be per Class 4except for Martensitic CRES alloy 440C,which requires no class testing.M&PAMS 2728DC C120901SAE Heat Treatment of Wrought Copper Beryllium Alloy Parts M&P AMS 2745CJ A071201SAE Induction Hardening of Steel Parts M&P AMS 2750DB E120701SAE Pyrometry M&P AMS 2753CF C080801SAE Liquid Salt Bath Ferritic Nitrocarburizing Non-Cyanide Bath M&P AMS 2755Cancelled CM Can090701SAE Nitriding, Molten Salt Bath Process not available, consider AMS 2753 asreplacement.M&P AMS 2759CE E081001SAE Heat Treatment of Steel Parts General Requirements M&PAMS 2759/1CJ E090201SAE Heat Treatment of Carbon and Low-Alloy Steel Parts MinimumTensile Strength Below 220 ksi (1517 MPa)Supersedes MIL-H-6875 for carbon & low-alloy steels below 220 ksi.M&PAMS 2759/2CR F100501SAE Heat Treatment of Low-Alloy Steel Parts Minimum TensileStrength 220 ksi (1517 MPa) and Higher Supersedes MIL-H-6875 for low-alloy steels,220 ksi & higher.M&PAMS 2759/3CE E080801SAE Heat Treatment Precipitation-Hardening Corrosion-Resistantand Maraging Steel Parts Supersedes MIL-H-6875 for precipitationhardening & maraging steel.M&PAMS 2759/4CA C080301SAE Heat Treatment Austenitic Corrosion-Resistant Steel Parts Supersedes MIL-H-6875 for austentic steels.M&P AMS 2759/5D040601SAE Heat Treatment Martensitic Corrosion Resistant Steel Parts Supersedes MIL-H-6875 for martensiticsteels.M&P AMS 2759/6BM B051101SAE Gas Nitriding and Heat Treatment of Low - Alloy Steel Parts Use Standard Drawing Notes per BDS2240.M&P AMS 2759/7CT B100501SAE Carburizing and Heat Treatment of Carburizing Grade SteelPartsM&PAMS 2759/8CG A070601See Special Notes SAE Ion Nitriding 1. Infrared pyrometry may be used to measuretemperature. 2. The nitriding temperature may beless than 50 degrees below the tempering or agingtemperature provided that the core hardness is notreduced. 3. for small loads, a minimum of twot t ti i b d i li M&PAMS 2759/9CL D090501SAE Hydrogen Embrittlement Relief (Baking of Steel Parts)Supersedes MIL-H-6875 for stress relievingsteels.M&P AMS 2759/10CN A060601SAE Automated Gaseous Nitriding Controlled by Nitriding Potential M&P AMS 2759/11BW-050401SAE Stress Relief of Steel Parts M&P AMS 2762Noncurrent CP B020101SAE Carburizing Carbon and Low-Alloy Steel Parts M&P AMS 2768CR C100701SAE Heat Treatment of Magnesium Alloy Castings M&P AMS 2769DD B091201SAE Heat Treatment of Parts in a Vacuum M&P AMS 2770DM L140501SAE Heat Treatment of Wrought Aluminum Alloy Parts M&Pat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2771DF E130201SAE Heat Treatment of Aluminum Alloy Castings M&P AMS 2772CW F110701SAE Heat Treatment of Aluminum Alloy Raw Materials M&P AMS 2774DC D121001SAE Heat Treatment Wrought Nickel Alloy and Cobalt Alloy Parts M&P AMS 2800CN D060801SAE Identification Finished Parts M&P AMS 2801B030301SAE Heat Treatment of Titanium Alloy Parts M&PM&P AMS 2807CF B080201SAE Identification Carbon and Low-Alloy Steels, Corrosion and Heat-Resistant Steels and Alloys Sheet, Strip, Plate and AircraftTubingAMS 3025CN C090901SAE Polyalkylene Glycol Heat Treat Quenchant M&P AMS 3106Cancelled Can830401SAE Primer, Adhesive, Corr Inhib AMS 3107M&P AMS 3107A910401SAE Primer, Adhesive, Corr-Inhibiting M&P AMS 3195CV F110501SAE Silicone Rubber Sponge, Closed Cell, Medium M&PM&P AMS 3216G050901SAE Fluorocarbon (FKM) Rubber High-Temperature - FluidResistant Low Compression Set 70 to 80AMS 3218C050901SAE Fluorocarbon (FKM) Rubber High-Temperature - FluidM&PResistant Low Compression Set 85 to 95M&P AMS 3276CB E080301SAE Sealing Compound, Integral Fuel Tanks and General Purpose,Intermittent Use to 360 °F (182 °C)AMS 3301DB H110601SAE Silicone Rubber, General Purpose, 40 Durometer M&P AMS 3305H900401SAE Silicone Rubber, Gen Purp, 75-85M&P AMS 3374DL D131101SAE Sealing Compound Aircraft Firewall, Silicone M&P AMS 3410J981001SAE Flux, Ag Braz M&P AMS 3411D981001SAE Flux Silver Brz, High Temp M&PM&P AMS 3644BL G060901SAE Plastic: Polyimide for Molded Rod, Bar, and Tube, Plaque, andformed PartsM&P AMS 3645CY D120101SAE Polychlorotrifluoroethylene (PCTFE), Compression MoldedHeavy Sections, UnplasticizedM&P AMS 3650CY D120101SAE Rods, Sheets, and Molded Shapes, Polychlorotrifluoroethylene(PCTFE) UnplasticizedAMS 3651Cancelled Can870401SAE PTFE AMS 3667M&P AMS 3651Cancelled Can870401PTFE AMS 3652M&P AMS 3651Cancelled Can870401PTFE AMS 3656M&P AMS 3651Cancelled Can870401PTFE AMS 3660M&P AMS 3652C930101SAE PTFE Film, Non-Crit Grade M&P AMS 3656CW H110801SAE PTFE Extrusions, Normal Strength, As Sintered M&P AMS 3657CW F110801SAE PTFE, Extrusions, Premium Strength, As Sintered M&P AMS 3658CW F110801SAE PTFE, Extrusions, Premium M&P AMS 3659CW F110801SAE Polytetrafluoroethylene (PTFE) Extrusions, Premium Strength,M&PSintered and Stress-RelievedAMS 3660CW E110801SAE Polytetrafluoroethylene Moldings M&P AMS 3666DB E120101SAE PTFE Sht, Glass Reinforced M&PM&P AMS 3667CW E110801SAE Polytetrafluoroethylene Sheet, Molded General Purpose Grade,As SinteredAMS 3668CW E110801SAE PTFE, Moldings, Premium Grade, A Sintered M&P AMS 3670/1B950401SAE Unfilled Polyamide-Imide, Bar M&P AMS 3824CN C950901SAE Cloth, Glass Finished for Resin Laminates M&P AMS 4001Cancelled CK Can070701SAE Aluminum Sheet and Plate 0.12Cu (1100-0) Annealed ASTM B209M&P AMS 4013DM G140201SAE Aluminum Sheet, Laminated Surface Bonded M&PM&P AMS 4015CN L070201SAE Aluminum Alloy, Sheet and Plate 2.5Mg - 0.25Cr (5052-0)AnnealedM&P AMS 4016DE M130101SAE Aluminum Alloy, Sheet and Plate 2.5Mg - 0.25Cr (5052-H32)Strain Hardened, Quarter Hard, and Stabilizedat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 4017CN K041201SAE Aluminum Alloy Sheet and Plate 2.5Mg - 0.25Cr (5052-H34)M&PStrain-Hardened, Half Hard, and StabilizedM&P AMS 4023Noncurrent CN E840401SAE Aluminum Alloy Sheet and Plate Alclad 1.0Mg - 0.60Si - 0.28Cu- 0.20Cr (Alclad 6061; -T6 Sheet, -T651 Plate)AMS 4025CE L080701SAE Aluminum Alloy, Sheet and Plate 1.0Mg - 0.60Si-0.28Cu-AMS-QQ-A-250/11A - cancelled - 2008M&P0.20Cr(6061-0) AnnealedAMS-QQ-A-250/11A - cancelled - 2008M&P AMS 4026CE M080701SAE Aluminum Alloy, Sheet and Plate 1.0Mg -0.60Si-0.28Cu-0.20Cr(6061;-T4 Sheet, T-451 Plate) Solution Heat Treated andNaturally AgedAMS-QQ-A-250/11A - cancelled - 2008M&P AMS 4027CE N080701SAE Aluminum Alloy, Sheet and Plate 1.0Mg -0.60Si-0.28Cu-0.20Cr(6061;-T6 Sheet, T-651 Plate) Solution and Precipitation HeatTreatM&P AMS 4037CY P111201SAE Aluminum Alloy, Sheet and Plate 4.4Cu - 1.5Mg - 0.60Mn(2024; - T3 Flat Sheet, T351 Plate) Solution Heat TreatedM&P AMS 4048CW N100801SAE Aluminum Alloy Sheet and Plate, Alclad 5.6Zn - 2.5Mg - 1.6Cu -0.23Cr (Alclad 7075-O) Annealed or When Specified, "Asfabricated" (Alclad 7075-F)AMS 4049CW L101201SAE Aluminum Alloy Sheet and Plate, Alclad 5.6Zn - 2.5Mg - 1.6Cu -M&P0.23Cr (Alclad 7075; -T6 Sheet - T651 Plate) Solution andPrecipitation Heat TreatedAMS 4056DB G101001SAE Aluminum Alloy, Sheet and Plate 4.4Mg - 0.70Mn - 0.15CrM&P(5083-01)M&P AMS 4080CN N091201SAE Aluminum Alloy, Drawn Seamless Tubing 1.0Mg - 0.60Si -0.28Cu - 0.20Cr (6061-O) AnnealedM&P AMS 4081CC J080601SAE Aluminum Alloy Tubing, Hydraulic, Seamless, Drawn, Round1.0Mg - 0.60Si - 0.28Cu - 0.20Cr (6061-T4) Solution HeatTreated and Naturally AgedM&P AMS 4083DE L121101SAE Aluminum Alloy Tubing, Hydraulic, Seamless, Drawn, Round1.0Mg - 0.60Si - 0.28Cu - 0.20Cr- (6061-T6) Solution andPrecipitation Heat TreatedM&P AMS 4086BL N060901SAE Aluminum Alloy, Drawn, Round, Seamless Hydraulic Tubing4.4Cu-1.5Mg-0.60Mn (2024-T3) Solution Heat Treated, ColdWorked, and Naturally AgedAMS 4088BT K070301SAE Aluminum Alloy, Drawn, Seamless Tubing 4.4Cu-1.5Mg-M&P0.60Mn (2024-T3) Solution Heat Treated and Cold WorkedAMS 4107F051101SAE Alum Aly Die Forg, (7050-T14)M&PM&P AMS 4113CH E030701SAE Aluminum Alloy, Extruded Profiles 1.0Mg - 0.60Si - 0.28Cu -0.20Cr (6061-T6) Solution and Precipitation Heat TreatedM&P AMS 4115CU H090701SAE Aluminum Alloy, Rolled or Cold-Finished, Bars, Rods, Wire,and Flash Welded Rings Annealed 1.0Mg - 0.60Si - 0.2Cu -0.20Cr (6061-0)M&P AMS 4116CN H090701SAE Aluminum Alloy, Bars, Rods, and Wire 1.0Mg - 0.60Si - 0.3Cu -0.20Cr (6061-T4) Cold Finished, Solution Heat Treated andNaturally AgedM&P AMS 4117CM J090701SAE Aluminum Alloy, Rolled or Cold Finished Bars, Rods, and Wireand Flash Welded Rings 1.0Mg -0.60Si - 0.28Cu - 0.20Cr(6061; - T6, -T651) Solution and Precipitation Heat TreatedAMS 4120M&P AMS 4119Cancelled CN Can900101SAE Aluminum Alloy Bars, Rolled, Drawn, or Cold Finished 4.4Cu -1.5Mg - 0.60Mn (2024-T351) Stress Relief StretchedAMS 4120R020901SAE Aluminum Alloy, Rolled or Cold Finished Bars, Rods, and WireM&P4.4Cu - 1.5 Mg - 0.60Mn (2024) Solution Heat Treated andNaturally Aged (T4) Solution Heat Treated, Cold Worked, andNaturally Aged (T351)M&P AMS 4121CA H071101SAE Aluminum Alloy Bars, Rods, and Wire, Rolled or Cold Finished4.5Cu - 0.85Si - 0.80Mn - 0.50Mg (2014-T6) Solution andPrecipitation Heat TreatedM&P AMS 4123CN H060101SAE Aluminum Alloy, Rolled or Cold Finished Bars and Rods (7075-T651) Solution and Precipitation Heat TreatedM&P AMS 4124DG E120901SAE Aluminum Alloy, Rolled or Cold Finished Bars, Rods, and Wire5.6Zn-2.5Mg-1.6Cu-0.23Cr (7075-T7351) Solution HeatTreated, Stress Relieved by Stretching and OveragedM&P AMS 4128CN D071001SAE Aluminum Alloy Bars, Rolled or Cold Finished 1.0Mg - 0.60Si -0.30Cu - 0.20Cr (6061-T451) Solution Heat Treated and StressRelieved by Stretchingat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 4132DF G130201SAE Aluminum Alloy, Die and Hand Forgings, Rolled Rings, andM&PForging Stock 2.3Cu-1.6Mg-1.1Fe-1.0Ni-0.18Si-0.07Ti (2618-T61) Solution and Precipitation Heat TreatedM&P AMS 4133CN E090301SAE Aluminum Alloy Forgings and Rolled Rings 4.4Cu -0.85Si -0.80Mn - 0.50Mg (2014-T6) Solution and Precipitation HeatTreatedAMS 4133M&P AMS 4135Cancelled CN Can860401SAE Aluminum Alloy Forgings 4.5Cu - 0.85Si - 0.80Mn - 0.50Mg(2014-T6) Solution and Precipitation Heat TreatedAMS 4141CE F081001SAE Aluminum Alloy Die Forgings 5.6Zn - 2.5Mg - 1.6Cu - 0.23CrM&P(7075-T73) Solution and Precipitation Heat TreatedAMS 4144BN F060501SAE Aluminum Alloy, Hand Forgings and Rolled Rings 6.3Cu -M&P0.30Mn - 0.18Zr - 0.10V - 0.06Ti (2219-T852/T851) SolutionHeat Treated, Mechanically Stress Relieved, and PrecipitationHeat-TreatedM&P AMS 4149D020901SAE Aluminum Alloy, Die and Hand Forgings 5.6n - 2.5Mg - 1.6Cu -0.23Cr (7175-T74) Solution and Precipitation Heat TreatedAMS 4150DG M130401SAE Aluminum Alloy, Extrusions and Rings 1.0Mg - 0.60Si - 0.28Cu -M&P0.20Cr - (6061-T6) Solution and Precipitation Heat TreatedM&P AMS 4162D030701SAE Aluminum Alloy, Extrusions 6.3Cu - 0.30Mn - 0.18Zr - 0.10V -0.06Ti (2219-T8511) Solution Treated, Stress Relief Stretched,Straightened, and Precipitation Heat TreatedM&P AMS 4173DG F130401SAE Aluminum Alloy, Extrusions 1.0Mg - 0.60Si - 0.30Cu - 0.20Cr(6061-T6511) Solution Heat Treated, Stress Relieved byStretching, Straightened, and Precipitation Heat TreatedM&P AMS 4181C030401SAE Aluminum Alloy, Welding Wire 7.0Si - 0.38Mg - 0.10Ti (4008)(UNS A94008)M&P AMS 4182CN G091201SAE Alum Aly Wire, Annealed 5.0Mg - 0.12Mn - 0.12Cr (5056-0)AnnealedAMS 4185DB E120201SAE Fill Mtl, Alum Braz, 12SI, (4047)M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4181M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4233M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4244M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4245M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4246M&PM&P AMS 4210CN K050301SAE Aluminum Alloy, Castings 5.0Si - 1.2Cu - 0.50Mg (355.0-T51)Precipitation Heat TreatedM&P AMS 4212CU K110201SAE Aluminum Alloy Castings 5.0Si - 1.2Cu - 0.50Mg (355.0-T6)Solution and Precipitation Heat TreatedM&P AMS 4214CN J080601SAE Castings, Aluminum Alloy Sand 5.0Si - 1.2Cu - 0.50Mg (355.0T71) Solution Heat Treated and OveragedM&P AMS 4215CN H080301SAE Aluminum Alloy, Castings 5.0Si - 1.2Cu - 0.50Mg (C355.0-T6)Solution and Precipitation Heat TreatedM&P AMS 4217CN H070401SAE Aluminum Alloy, Castings 7.0Si - 0.32Mg (A356.0-T6) (formerlyT6P Temper) Solution and Precipitation Heat TreatedM&P AMS 4218CN J100101SAE Aluminum Alloy Castings 7.0Si-0.35Mg (A356.0-T6) (formerlyT6P Temper) Solution and Precipitation Heat TreatedM&P AMS 4223CN D070401SAE Aluminum Alloy, Castings 4.5Cu - 0.70Ag - 0.30Mn - 0.25Mg -0.25Ti (A201.0-T4) Solution Heat Treated and Naturally AgedOk to use canc spec.M&P AMS 4224Cancelled - no s/s spec CN C100101SAE Aluminum Alloy Castings, Sand 4.0Cu - 2.1Ni - 2.0Mg - 0.30Cr -0.30Mn - 0.13T - 0.13V (243.0) StabilizedM&P AMS 4225CN D070601SAE Aluminum Alloy, Heat Resistant, Castings 5.0Cu - 1.5Ni -0.25Mn - 0.25Sb - 0.25Co - 0.20Ti - 0.20Zr (203.0-T6) SolutionHeat Treated and Precipitation Heat TreatedM&P AMS 4226Noncurrent CN A830101SAE Aluminum Alloy Castings, High Strength 5.0Cu - 0.35Mn -0.18Zr- 0.10V (224.0) Solution and Precipitation Heat Treated(Overaged)AMS 4227Cancelled - no s/s spec CN E050701SAE Aluminum Alloy, Casting, Sand, 8.0Cu 6.0Mg 0.50Mn 0.50Ni,Ok to use canc spec.M&PAs CastAMS 4229DA F120201SAE Aluminum Alloy Castings, High Strength 4.5Cu - 0.7Ag -M&P0.30Mn - 0.25Mg - 0.25Ti (A201.0-T7) Solution Heat Treatedand OveragedM&P AMS 4233C030301SAE Aluminum Alloy, Welding Wire 4.5 Cu - 0.70Ag - 0.30Mn -0.25Mg - 0.25Ti (A201.0-T7) Solution Heat Treated andOveragedat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 4235CN B080301SAE Aluminum Alloy Castings 4.6Cu - 0.35Mn - 0.25Mg - 0.22Ti(A206.0-T71) Solution and Precipitation Heat TreatedM&P AMS 4236DF C130201SAE Aluminum Alloy Castings 4.6Cu - 0.35Mn - 0.25Mg - 0.22Ti(A206.0-T4) Solution Heat Treated and Naturally AgedM&P AMS 4237Cancelled - no s/s spec CN B070401SAE Aluminum Alloy Castings, Sand 4.6Cu - 0.35Mn - 0.25Mg -0.22Ti (206.0 - T71) Solution Heat Treated and Naturally AgedOk to use canc spec.M&P AMS 4241CN D091101SAE Aluminum Alloy Castings 7.0Si - 0.58Mg - 0.15Ti -0.06Be(D357.0 - T6) Solution and Precipitation Heat Treated DendriteArm Spacing (DAS) ControlledM&PAMS 4244CE B080701SAE Aluminum Alloy, Welding Wire 4.6Cu - 0.35Mn - 0.25Mg -0.22Ti for Welding A206.0 Type AlloysM&PAMS 4245CR E100401SAE Aluminum Alloy, Welding Wire 5.0Si - 1.2Cu - 0.50Mg (355)(UNS A03550)M&PAMS 4246Noncurrent CP D080201SAE Aluminum Alloy, Welding Wire 7.0Si - 0.52Mg (357) (UNSA03570)M&PAMS 4260Not Acceptable to Use atParker HannifinAerospace CL G080601SAE Alum Aly Cast, Invest (356.0-T6)BPS4829AMS 4260 rev. G unacceptable for ParkerUse. BPS4829 created as replacement.M&PAMS 4261CN F091201SAE Aluminum Alloy Castings, Investment 7.0Si - 0.32Mg (356.0 -T51) Precipitation Heat TreatedM&P AMS 4280CN J080601SAE Aluminum Alloy Castings, Permanent Mold 5.0Si - 1.2Cu -0.5Mg (355.0-T71) Solution Heat Treated and OveragedM&P AMS 4284DC J110301SAE Aluminum Alloy Castings, Permanent Mold 7.0Si - 0.30Mg(356.0-T6) Solution and Precipitation Heat TreatedM&P AMS 4289CN-011101SAE Aluminum Alloy Castings 7.0Si - 0.55Mg - 0.12Ti (F357.0-T6)Solution and Precipitation Heat TreatedM&P AMS 4291CT H101001SAE Aluminum Alloy, Die Castings 8.5Si - 3.5Cu (A380.0-F) (SeeAS1990) As CastM&P AMS 4315CK-050701SAE Aluminum Alloy Sheet and Plate 5.6Zn - 2.5Mg - 1.6Cu - 0.23Cr7075: (-T76 Sheet, -T7651 Plate) Solution and PrecipitationHeat TreatedM&PAMS 4316CY A111101SAE Aluminum Alloy, Alclad Sheet and Plate 5.6Zn - 2.5Mg M&P AMS 4437DM F140201SAE Magnesium Alloy Castings, Sand 8.7Al - 0.70Zn (AZ91C-T6)Solution Heat Treated and AgedM&P AMS 4507BW H011101SAE Copper Alloy (Brass), Sheet, Strip, and Plate 70Cu - 30Zn HalfHard (H02)M&P AMS 4510CN G010501SAE Phosphor Bronze, Sheet, Strip, and Plate 94.5Cu - 4.0Sn -0.19P Spring Temper (H08)M&P AMS 4511A040701SAE Copper Beryllium Alloy Castings 97Cu-2.1Be-0.52(Co+Ni)-0.28Si Solution and Precipitation Heat Treated (TFOO)M&P AMS 4530CY J110901SAE Copper-Beryllium Alloy Sheet, Strip, and Plate 98Cu - 1.9BeSolution Heat Treated (TB00)M&P AMS 4533DF D130201SAE Copper-Beryllium Alloy, Bars and Rods 98Cu - 1.9Be Solutionand Precipitation Heat Treated (TF00, formerly AT)-UNSC17200M&PAMS 4597CY A111201SAE Copper-Nickel-Tin Alloy, Bars and Rods 77Cu - 15Ni - 8SnSolution Annealed, Cold Finished and Spinodal Hardened (TXTS)M&PAMS 4631Noncurrent CL E880401SAE Aluminum Bronze Rods, Bars, and Forgings 90.5Cu - 7.5Al -1.95: Stress RelievedM&P AMS 4633CL A031201SAE Bronze, Aluminum Silicon, Rods, Bars, and Forgings 90Cu -7.0Al - 1.8Si Drawn and Stress Relieved (HR50)M&P AMS 4634CL B090301SAE Aluminum Bronze Bars, Rods, and Forgings 905Cu - 7.5Al -1.9Si Stress RelievedM&P AMS 4635CL F090701SAE Aluminum Bronze Bars, Rods, and Forgings 87Cu - 9Al - 3FeStress RelievedM&P AMS 4640CV H110501SAE Aluminum Bronze, Bars, Rods, Shapes, Tubes, and Forgings81.5Cu - 10.0Al - 4.8Ni - 3.0Fe Drawn and Stress Relieved(HR50) or Temper Annealed (TQ50)M&PAMS 4650DF M130201SAE Copper-Beryllium Alloy, Bars, Rods, Shapes and Forgings98Cu - 1.9Be Solution Heat Treated TB00 (A)M&P AMS 4651CN C050701SAE Copper-Beryllium Alloy, Bars and Rods 98Cu - 1.9Be (CDA172) Hard Temper (TD04)M&P AMS 4674CN G060901SAE Nickel - Copper Alloy, Corrosion-Resistant, Bars and Forgings67Ni - 30Cu - 0.04S Free MachiningM&P AMS 4701CN G091001SAE Copper Wire, Oxygen-Free 99.95 (Cu+Ag) Annealed M&P。

业务流程服务器用户手册➢目录1 系统概述 (3)1.1 概述 (3)1.2特点及功能 (3)2技术概览 (4)2.1体系结构 (4)2.2基础服务 (6)2.3 管理与监控 (6)3 快速开始 (6)3.1 概述 (6)3.2 基本功能快速入门 (12)4安装指南 (15)4.1 系统配置要求 (15)4.2 产品安装 (15)4.3 安装后的工作 (16)5 管理指南 (16)5.1 系统管理 (16)5.2 系统日志 (22)A.概述BPS成为业务出服务(以下简称BPS)是一套完整的基于WEB界面的工作流管理系统(BPM),用于部署、管理、监控业务流程及其实例。

它是基于WSO2—Carbon平台开发的,以OSGi框架为基础,高度模块化,可根据SOA需要个性化增减系统模块。

B.特点及功能BPS的主要特点:高度模块化:模块间独立性强,可根据功能需求自由定制;安全性高:具备完整的用户权限管理机制,并可对发布的业务流程加密,提高安全可靠性;配置灵活:后台管理系统具有全面丰富的配置详单,可对系统进行全面的监视,并可根据需要自由配置系统监视功能。

BPS的主要功能:B PS主要用于部署、管理和监控业务流程及其流程实例。

A.体系结构a)数据交互结构上图说明WSO2—Business Process Server与其他WSO2产品的交互关系。

在工作流服务器运行时,会与AppServer、DataService、ESB、Governance Registry、Gadget Server等不同类服务器发生数据交互。

前端交互:BPS作为SOA的重要组成部分,是在Portal之后直接支持业务运转的关键服务器。

BPS通过Gadget Server与用户发生交互,接收业务流请求,并将响应和执行结果及时通过Gadget Server将呈现结果;内部运行:BPS执行BPEL流程时,BPS借助Governance Registry扩展对BPEL的解析支持;在监控流程运行情况方面,系统通过事件监听(Event Listener)和消息拦截(Message Exchange Interceptor)对运行情况进行监控,获取数据并显示在WEB端管理后台;底层交互:BPS运行时必然需要数据服务(DS)支持和应用服务(AS)支持,同时也需要其挂载的ESB提供代理服务等支持。

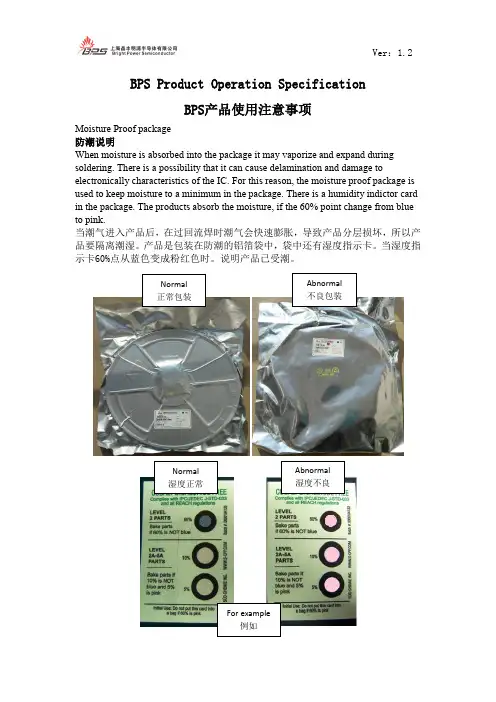

BPS Product Operation SpecificationBPS 产品使用注意事项Moisture Proof package防潮说明When moisture is absorbed into the package it may vaporize and expand during soldering. There is a possibility that it can cause delamination and damage toelectronically characteristics of the IC. For this reason, the moisture proof package is used to keep moisture to a minimum in the package. There is a humidity indictor card in the package. The products absorb the moisture, if the 60% point change from blue to pink.当潮气进入产品后,在过回流焊时潮气会快速膨胀,导致产品分层损坏,所以产品要隔离潮湿。

产品是包装在防潮的铝箔袋中,袋中还有湿度指示卡。

当湿度指示卡60%点从蓝色变成粉红色时。

说明产品已受潮。

Storage Conditions产品储存/仓储条件The IC should be kept at 30℃ or less and 80%RH or less. The IC's shelf life is two year.在打开包装(铝箔袋)前,(仓储,运输时)在打开包装前,产品需存放在≤30℃和≤80%湿度环境中,保质期为2年。

The IC should be kept at 30℃or less and 70%RH or less. The IC should be soldered within 168 hours after opening the package. For the de-pack unused IC, they should be stored in moisture proof packages with desiccant, and record the exposed time. Total exposed time shall within 168 hours.打开包装后,产品要存放在≤30℃和≤70%湿度环境中,并确保168小时内上板过焊接。

数字平调系统产品简介版本:V1.0天津七一二通信广播有限公司移动通信事业部文件目录1.系统介绍 (1)2.产品概况 (1)2.1系统组成 (1)2.2设备指标及功能 (2)2.2.1 机车台 (2)2.2.2 区长台 (4)2.2.3 手持台 (5)2.2.4 中间站 (7)1.系统介绍铁路现有模拟平调系统存在无法实现信令强插、频率资源紧张等问题。

数字化平调系统能有效的解决以上问题,因此平调系统从模拟方式向数字方式转换是必然趋势。

同时,我公司现有多款模拟平调系统的产品,积累了较多经验,产品技术比较成熟。

我公司以自主研发的数字信道机为核心部件,成功研制了新一代的数字平调系统。

2.产品概况2.1 系统组成数字平调系统由机车台、区长台和手持台组成。

机车台还可以配备显示终端,用来显示调车作业单。

图1 系统图2.2 设备指标及功能2.2.1 机车台图2 4011C机车台图3 调车作业单显示终端机车台的主要功能:1)具有接收调车信令的功能,并且能够根据调车信令显示色灯信号和播放提示语音。

2)具有通话功能,且支持信令强插,在通话状态下也可正常接收调车指令。

3)具有呼叫调车区长功能。

4)具有自检功能,开机时检查各设备是否正常工作。

5)具有调车信令、调车作业单和通话录音的存储功能。

6)具有外接监控接口,用于将指令码送往运记。

7)机车台可通过按钮对音量和调车组进行调整和更改,并通过数码管进行显示。

8)信号灯亮度可调节,实现司机的夜间工作需求。

9)具有制动员领车功能。

10)具有调车作业单显示终端接口,支持调车作业单接收功能。

11)可通过U盘转储记录和升级程序。

机车台的主要指标:1)电源要求:DC 110V±20%。

2)工作环境温度:-25℃~+55℃。

3)相对湿度:93+2-3%(40℃)。

4)存储温度:-40℃~+60℃。

5)表5-4 发射机电性能要求及试验方法序号项目技术要求1 载波频率容差 ≤±5ppm2 载波输出功率 2.5~4W3 调制失真 ≤7%4 邻道功率(比值) ≤-60dB6)表5-5 接收机电性能要求及试验方法序号 项 目 技 术 要 求1 最大可用灵敏度 ≤-116dBm2 在高输入值的误码特性误码率:≤0.01%(连续的比特流); 不正确的信息数量:≤1 (丢失或损坏)。

普元bps 子流程-回复普元bps 子流程:从增长到提高,打造企业持续发展的基石在当今高度竞争的商业环境中,企业需要不断地寻求创新和提高效率的方式来保持竞争优势。

普元bps(Business Process Standardization)作为一种流程优化的方法,已经被越来越多的企业所采用。

本文将以普元bps 为主题,一步一步回答什么是普元bps,为什么它在如今的业务环境中如此重要,并探讨如何实施普元bps以提高企业的持续发展。

第一步:了解普元bps是什么普元bps是指在企业中使用标准化流程来优化和改进业务的方法。

它的目标是通过消除冗余、提高效率和质量,从而提高业务运营的整体水平。

普元bps将业务流程划分为一系列的子流程,并通过设计标准化的工作流程和运营模式来统一企业的业务运营。

第二步:理解普元bps在业务环境中的重要性在快速变化的商业环境中,企业需要灵活应对市场需求的变化,并提供高质量、高效率的产品和服务。

普元bps可以帮助企业完成这一目标。

它可以提供以下几个方面的好处:1. 提高效率:普元bps通过标准化流程和规范操作,消除了重复和冗余工作,从而提高了工作效率。

它还可以通过自动化和数字化技术,减少人为错误和延迟,加快业务处理速度。

2. 降低成本:普元bps可以帮助企业降低运营成本。

通过优化流程和资源利用率,企业可以减少不必要的开支,并提高利润率。

3. 提高质量:普元bps通过标准化工作流程和监控机制,有助于提高产品和服务的质量。

它可以确保每个环节都经过严格的质量控制,消除潜在问题和风险,从而提供一致的高质量产品。

4. 加强竞争力:普元bps可以帮助企业提高竞争力。

通过优化业务流程,企业能够更快地适应市场的需求变化,并提供更好的产品和服务。

这使企业能够在市场竞争中脱颖而出,并吸引更多的客户。

第三步:实施普元bps以提高企业的持续发展要实施普元bps,企业需要按照以下步骤进行:1. 分析当前业务流程:企业需要首先对自身的业务流程进行分析,了解当前的问题和瓶颈。

硬件使用说明书—TC1026版本:V1.10|中文文档修订历史:版权信息上海同星智能科技有限公司上海市嘉定区曹安公路4801号6/8层本着为用户提供更好服务的原则,上海同星智能科技有限公司(下称“同星智能”)在本手册中将尽可能地为用户呈现详实、准确的产品信息。

但介于本手册的内容具有一定的时效性,同星智能不能完全保证该文档在任何时段的时效性与适用性。

本用户手册中的信息和数据如有更改,恕不另行通知。

为了得到最新版本的信息,请您访问同星智能官方网站或者与同星智能工作人员联系。

感谢您的包容与支持!未经同星智能书面许可,不得以任何形式或任何方式复制本手册的任何部分。

@版权所有2023,上海同星智能科技有限公司。

保留所有权利。

目录1.产品简介 (1)1.1产品概述 (1)1.2典型应用 (1)1.3功能和参数 (1)1.3.1功能特征 (1)1.3.2技术参数 (2)1.3.3电气参数 (2)1.4发货清单 (3)2.硬件接口说明 (4)2.1硬件接口说明 (4)2.2LED指示灯说明 (5)3.快速使用 (6)3.1下载安装TSMaster上位机 (6)3.2连接设备,配置通道 (8)3.3报文发送 (9)3.4帮助文档及视频教学 (10)3.5TSMaster API二次开发 (11)3.5.1Python调用动态库 (11)3.5.2C调用动态库 (11)3.5.3调用接口示例 (12)3.6示例工程 (14)4.检查和维护 (15)5.常见问题及解答 (16)5.1线路连接正确但无法正常通信: (16)5.2报文观察不便以及信号过滤: (17)5.3如何加载数据库: (18)5.4如何自动记录报文: (18)5.5如何回放报文(离线回放和在线回放): (19)6.附录CAN2.0B协议帧格式 (20)6.1CAN2.0标准帧: (20)6.2CAN2.0扩展帧: (21)7.免责声明 (21)关于同星........................................................................................................................................汽车电子工具链国产领导品牌1.产品简介1.1产品概述TC1026是同星智能推出的一款多通道CANFD和LIN总线接口设备,CANFD总线速率最高支持8M bps,LIN支持速率0~20K bps,产品采用高速USB2.0接口与PC连接,Windows系统免驱设计使得设备具备极佳的系统兼容性。

–使用安装说明书–分体挂壁式冷暖变频空调器型 号:KFR-26GW/BpSJAKFR-35GW/BpSJAKFR-26GW/BpGJAKFR-35GW/BpGJAKFR-26GW/BpDJAKFR-35GW/BpDJAKFR-26GW/BpEJAKFR-35GW/BpEJA机种名:RAK-SJ26PHAPC/RAC-SJ26WHAPC RAK-SJ35PHAPC/RAC-SJ35WHAPCRAK-GJ26PHAPC/RAC-GJ26WHAPCRAK-GJ35PHAPC/RAC-GJ35WHAPCRAK-DJ26PHAPC/RAC-DJ26WHAPCRAK-DJ35PHAPC/RAC-DJ35WHAPCRAK-EJ26PHAPC/RAC-EJ26WHAPCRAK-EJ35PHAPC/RAC-EJ35WHAPC145811136 4 14 15 1622 23 24目 录安全警示产品简介使用说明产品使用条件产品有毒有害物质声明技术参数遥控器介绍Wi -Fi 功能机器的维护保养安装说明安装前注意事项安装简图安装程序及重点清除空气顺序检查运行售后维修敬告客户特别提示使用产品前,请仔细阅读本说明书,并妥善保管。

1.本空调器使用的制冷剂为环保的碳氢物R32,该制冷剂无色无味,属于可燃制冷剂;2.在安装、使用、维修前,请先阅读专业手册;3.安装、移机或维修时,请委托经销商会专门技术人员安装;4.所有作业人员或制冷回路维修人员都应获得行业认可的评估机构颁发的有效证书,以认定其具备行业认可的评估规范所要求的安全处置制冷剂的资质;5.务必按照设备制造商推荐的方法进行设备的维护和修理。

如果需要其他专业人员协助维护和修理设备,则应在具备使用可燃制冷剂资质的人员监督下进行;6.应遵守国家有关气体法规的规定;7.空调器安装、运行和存放时的房间面积必须不小于4m 2;8.空调器的贮存应能防止因事故引起的机械损伤;9.请勿刺破或点燃空调器;10.除厂商特别推荐,不要使用任何方法来加速除霜过程或对结霜部分进行清洁;11.必须采用真空泵进行排空工作,严禁采用机身内制冷剂排空。

----------------------平常说的10M and 100M网是指bit还是byte?100M hub相连各机加起来是100M还是每个是100M?======================(1)、根据进制规定,传送速度可以有两种表示方法bps 和Bps,但是他们是有严格区别。

Bps 中的B 使用的是二进制系统中的Byte字节,bps中的 b 是十进制系统中的位元。

在我们常说的56K拨号,100M局域网都是bps计量,当用于软件下在时,下载工具一般是以Bps计算(2)、“10M and 100M”指的是bit,“100M hub”是指每个100M。

(3)、是指波特尔, 除以8就是字节数了. 如56K的猫, 是指56K波特尔, 换成字节, 也就是常说了B/M/G单位, 是7K字节, 慢吧!网卡也是这样算了, 所以100Mbps网卡, 实际速度不会超过100/8=14M字节.(4)、还有两个检验位, 我记不清是算在这个8位里面还是在外面, 如果是在外面另算的话, 就是除以10, 而不是除以8.(6)、数据传输速率数据传输速率是指数字化仪每秒能输出的坐标的对数。

单位为“对/秒”。

不过数据数量还和传输的波特率有关。

波特率是在网络应用中经常使用到一个技术指标,在这里则是表示数字化仪和计算机系统交换、传输的速度。

它是指每秒钟设备或网络之间能够传输的二进制信息位数,它的单位是bps(bit per second)。

波特率越高,数据传输率自然也就越大。

当然,数字化仪的波特率也不是完全用来进行数据传输,在这其中会有损耗和延时,因此在选购时需要两者结合起来看。

比如同样19200bps波特率的产品,有的产品的数据传输速率为200对/秒,有的则可以达到350对/秒。

===========什么是kbps?常用的表示速率的单位kbps,就是kilo bits per second(千比特每秒),也就是kb/s.正常CD采样率是44.1KHz,每个样本用16bit,立体声是两个声道,那么标准CD是44.1K×16×2=1411.2kbps。

bps博世支持原则博世(Bosch)是一家以技术和服务为核心的全球领先供应商,致力于提供创新的解决方案,以改善人们的生活质量。

作为一家拥有百年历史的公司,博世一直秉持着支持原则(Support Principles),始终将可持续发展和社会责任作为企业发展的重要指导。

博世以质量为本。

作为一家技术驱动型企业,博世始终坚持以卓越的品质为用户提供可靠的产品和服务。

在博世的支持原则中,质量是核心要素之一。

博世注重产品的持久性和可靠性,以确保用户长期受益。

他们通过严格的质量控制和测试流程,确保产品的稳定性和性能。

此外,博世还通过持续的创新和改进,不断提升产品的质量和性能,以满足用户的需求和期望。

博世以安全为重。

作为一家供应全球市场的企业,博世深知安全的重要性。

在博世的支持原则中,安全是至关重要的价值观之一。

博世在产品设计和制造过程中,始终将安全作为首要考虑因素。

他们不仅遵守相关的安全标准和法规,还不断投入资源和精力,研发和生产更安全可靠的产品。

此外,博世还积极参与各种安全教育和宣传活动,提高用户对安全的意识和重视程度。

第三,博世以可持续发展为导向。

作为一家全球企业,博世深知可持续发展的重要性。

在博世的支持原则中,可持续发展被视为企业发展的核心理念。

博世致力于通过可持续的业务模式和创新解决方案,推动经济、环境和社会的协调发展。

他们注重节能减排和资源利用的效率,推动绿色生产和可再生能源的应用,以及提倡员工的健康和福利。

博世还积极参与社区和公益事业,回馈社会,推动社会公平和可持续发展。

第四,博世以合作为基础。

作为一家全球化企业,博世深知合作的重要性。

在博世的支持原则中,合作是企业成功的关键要素之一。

博世与供应商、客户、合作伙伴等各方积极合作,共同推动创新和发展。

他们倡导开放、公平和透明的合作关系,建立互信和共赢的合作伙伴关系。

通过共同努力和合作,博世与各方共同创造价值,实现可持续发展。

在博世的支持原则的指导下,博世不断致力于提供更好的产品和服务,推动社会的进步和发展。

Primeton BPS 典型应用案例1.人民银行。

2010年,基于普元的BPS建设了ACS(Account Central System ) 中央银行会计核算数据集中系统,作为人民银行会计综合业务系统的核心系统,支持各项中央银行业务的处理, 是人民银行重要的基础业务和信息系统。

ACS每日会计核算业务量不少于10万笔,每天需要处理的流程环节上千万。

2.建设银行。

2007年,建立了支撑新一代全流程信贷系统与内部管理流程的统一流程平台,建立了技术规范和标准。

其中引入了普元的流程平台BPS作为其中关键的平台软件。

3.交通银行。

2010年,交行选择普元公司的BPS产品建立了信用卡中心统一流程管理平台,并且基于普元BPS的“业务与技术一体化”设计思想,实现了交行532业务技术一体化流程定制实施模式,很大程度上提升了流程建设与优化的效率。

532是指:50%的流程完全由业务人员配置出来,30%的中等复杂流程由业务人员配置+技术人员支持完成,20%的复杂流程由技术人员技术实现。

系统上线后,仅用一个月即实现了争议管理流程等10多个流程,而且超出60%的大部分流程都是有业务部门的配置员定制完成。

4.中国银行。

依托于BPS改造的信用卡进件管理系统自2009年4月份投产以来,运行顺利。

在高峰期间每天可处理7-8万件任务。

此外,信用卡审批时间也由之前的30天缩短到目前的10天;员工的工作效率随之提高,由之前每人每天处理50件任务提高到80件;由于系统的灵活易用性不断加强,应对新业务的响应速度也大大提升。

5.中国联通。

2010年,中国联通选择普元公司的BPS产品建设了全国大集中的基于SOA的财务报账平台。

系统集中建设分省实施,满足各省个性化的流程需求。

系统已经上线26个省,用户数25万,目前有10个省全面应用,平均每天处理约10万审批单。

6.陕西移动。

2010年1月,基于普元BPS流程产品“高性能和高可用性”解决方案实施的陕西移动服务开通系统正式上线。

at BPS4000 rev(yy/mm/dd)SupersedingDoc160-006AM040322BHTI Alternate Materials List M&P 299-947-100-690115BHTI Procurement Specification for Epoxy Adhesive, Heat Resistant M&P 299-947-320-820507BHTI Adhesive Film and Primer System, Intermediate Cure Temperature (260-290º F) Service Temperature 67-225º F)M&P 68A900000G011101BAC Finish Spec: F-15M&P 74A900000E990308BAC Finish Specification for F18 Aircraft M&P 74A900004DG M051220BAC Ctrl: Fract Crit Parts, F-18M&P 74A901001F981208BAC Std Finish Codes: F-18 A\C M&P 901-947-002CA D950510BHTI Finish Specification for the V-22 Aircraft (Bell Boeing) Model 901) EMDAircraftM&P A-A-208See Special Notes DL C120719FED Ink, Marking, Stencil, Opaque Use A-A-00208 in lieu of A-A-208.M&PA-A-2962Cancelled - no s/s spec A980810Cancel Notice2FED Commercial Item Description Enamel, Alkyd, Exterior, Solvent Based, LowVocOk to use cancspec.M&PA-A-3097DC-970506Notice 4FED Commercial Item Description Adhesives, Cyanoacrylate, Rapid RoomTemperature-Curing, SolventlessM&P A-A-3165DE A071116FED Lacquer, Gloss, for A/C Use M&P A-A-00208See Special Notes DL D121001FED Commercial Item Description Ink, Marking, Stencil, Opaque (Porous andNon-Porous Surfaces)Use A-A-00208 in lieu of A-A-208.M&P A-A-52080B980523Notice 1FED Tape, Lacing, and Tying, Nylon M&P A-A-52081DF B980523Notice 1FED Tape, Lacing, and Tying, Polyester M&P A-A-52082DC D090817FED Tape, Lacing and Tying, TFE-Fluorocarbon M&P A-A-52083BJ C040223FED Tape, Lacing, and Tying, Glass M&P A-A-52084B980523Notice 1FED Tape, Lacing and Tying, Aramid M&P A-A-55829DC A110322DLA Acetic Acid, Glacial, Technical M&P A-A-56032CN D030521Notice 1FED Commercial Item Description (CIDS) Ink, Marking, Epoxy Base M&P A-A-59126-970926FED Terminals, Feedthru (Insulated) and Terminals, Stud (Insulated andNoninsulated)ENG A-A-59132CR A100607ValidationNotice 1DLA Amyl Acetate, Technical M&P A-A-59135CR-971028FED Commercial Item Description Packaging Material, Sheet M&P A-A-59136CR-971028FED Cushioning Material, Packaging, Closed Cell Foam Plank M&PA-A-59178DD A041012Notice 1USGOVT Nipple, Electrical Terminal ENGA-A-59503DC C110303FED Commercial Item Description Nitrogen, Technical M&PA-A-59551CP A091022USGOVT Wire, Electrical, Copper (Uninsulated) M&PA-A-59569DJ C090122Notice 1DLA Qualification Sampling and Testing of Steels for Transverse TensilePropertiesENG A-A-59588DJ B120130Notice 1FED Commercial Item Description Rubber, Silicone M&P A-A-59877CT-100909FED Commercial Item Description Insulating Compound, Electrical, Embedding M&P AIR4127CG - 071101SAE Steel: Chemical Composition and Hardenability M&P AISI-1010Unavailable-AISI Low Carb Stl Unavailable M&P AISI-50100Unavailable-AISI Bearing Stl Unavailable M&P AISI-52100Unavailable-AISI Bearing Stl Unavailable M&P AISI-B-1112Unavailable-AISI Low Carb Free Mach Stl Unavailable M&P AISI-C-1212Unavailable-AISI Material Spec, Stl Unavailable M&P AISI-C-1213Unavailable-AISI Low Carb Free Mach Stl Unavailable M&P AISI-C-1214Unavailable-AISI Material Spec, Stl Unavailable M&P AMS 2175CR A100601SAE Castings, Classification and Inspection of M&P AMS 2201Cancelled CN Can940901SAE Tolerances Aluminum and Aluminum Alloy Bar, Rod, Wire, and ForgingStock Rolled or Cold-FinishedANSI H35.2M&P AMS 2221G060201SAE Tolerances, Copper and Copper Alloy Bars and Rods M&P AMS 2222BG J060201SAE Tolerances, Copper and Copper Alloy Sheet, Strip, and Plate M&Pat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2223BF H060201SAE Tolerances Copper and Copper Alloy Seamless Tubing M&P AMS 2224G060201SAE Tolerances Copper and Copper Alloy Wire M&P AMS 2241CN R070701SAE Tolerances, Corrosion and Heat-Resistant Steel, Iron Alloy, Titanium, andM&PTitanium Alloy Bars and WireM&P AMS 2242CC G080604SAE Tolerances Corrosion and Heat Resistant Steel, Iron Alloy, Titanium andTitanium Alloy Sheet, Strip and PlateAMS 2243DH K130601SAE Tolerances Corrosion and Heat-Resistant Steel Tubing M&PM&P AMS 2248DB G110301SAE Chemical Check Analysis Limits Corrosion and Heat-Resistant Steels andAlloys, Maraging and other Highly-Alloyed Steels, and Iron AlloysAMS 2249CN G090701SAE Chemical Check Analysis Limits Titanium and Titanium Alloys M&P AMS 2259CN E071201SAE Chemical Check Analysis Limits Wrought Low-Alloy and Carbon Steels M&P AMS 2269CN F060501SAE Chemical Check Analysis Limits Nickel, Nickel Alloys, and Cobalt Alloys M&PM&P AMS 2300CU L100801SAE Steel Cleanliness, Premium Aircraft-Quality Magnetic Particle InspectionProcedureAMS 2301CT K100801SAE Steel Cleanliness, Aircraft Quality Magnetic Particle Inspection Procedure M&PM&P AMS 2303CT F100801SAE Steel Cleanliness, Aircraft Quality, Martensitic Corrosion Resistant SteelsMagnetic Particle Inspection ProcedureM&P AMS 2304CV B100801SAE Steel Cleanliness, Special Aircraft-Quality Magnetic Particle InspectionProcedureM&P AMS 2310BE F060201SAE Qualification Sampling and Testing of Steels for Transverse TensilePropertiesAMS 2315DF G130201SAE Determination of Delta Ferrite Content M&PM&P AMS 2350Cancelled - no s/s spec CN BA891001SAE Standards and Test Methods Ok to use cancspec.M&P AMS 2355DB K110301SAE Quality Assurance Sampling and Testing Aluminum Alloys and MagnesiumAlloy Wrought Products (Except Forging Stock), and Rolled, Forged, orFlash Welding RingsAMS 2360CN D070701SAE Room Temperature Tensile Properties of Castings M&PM&P AMS 2370DB K110601SAE Quality Assurance Sampling and Testing Carbon and Low-Alloy SteelWrought Products and Forging StockM&P AMS 2371DB J110601SAE Quality Assurance Sampling and Testing Corrosion and Heat-ResistantSteels and Alloys Wrought Products and Forging StockM&P AMS 2372DP G140601SAE Quality Assurance Sampling and Testing Carbon and Low-Alloy SteelForgingsAMS 2375CN D070601SAE Control of Forgings Requiring First Article Approval M&P AMS 2380CN F080601SAE Approval and Control of Premium-Quality Titanium Alloys M&P AMS 2400DG X130201SAE Plating, Cadmium M&P AMS 2401DF J130201SAE Plating, Cadmium Low Hydrogen Content Deposit M&P AMS 2403BM L041001SAE Plating, Nickel General Purpose M&P AMS 2404DP G131201SAE Plating, Electroless Nickel M&P AMS 2405DL E131001SAE Electroless Nickel Plate, Low Phosphorous M&P AMS 2406DE M121101SAE Plating, Chromium Hard Deposit M&P AMS 2408DL K130901SAE Plating, Tin M&P AMS 2410CR K100401SAE Plating, Silver Nickel Strike, High Bake M&P AMS 2411DM H131201SAE Plating, Silver for High Temperature Applications M&P AMS 2412CN J091201SAE Plating, Silver Copper Strike, Low Bake M&P AMS 2416CU L101201SAE Plating, Nickel-Cadmium Diffused M&P AMS 2417DL J130901SAE Plating, Zinc-Nickel Alloy M&P AMS 2418CU H110201SAE Plating, Copper M&P AMS 2419BM C030501SAE Plating, Cadmium-Titanium M&PM&P AMS 2420D021201SAE Plating of Aluminum for Solderability Zinc Immersion Pre-TreatmentProcessM&P AMS 2423See Special Notes CE D020401SAE Plating, Nickel Hard Deposit Continue to use AMS-QQ-N-290 for Class 2Nickel.AMS 2424CR F100401SAE NI Plate, Low Stressed Deposit M&Pat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2426DL E130901SAE Coating, Cadmium Vacuum Deposition M&P AMS 2427DD D070701SAE Aluminum Coating Ion Vapor Deposition M&P AMS 2429CY D111001SAE Bronze Plate Masking M&P AMS 2430DB S120701SAE Shot Peening, Automatic M&P AMS 2432DF D130201SAE Shot Peening, Computer Monitored M&P AMS 2433C041001SAE Plating, Nickel-Thallium-Boron or Nickel-Boron M&P AMS 2434CY D110901SAE Plating, Tin-Zinc Alloy M&P AMS 2435Noncurrent CN G070601SAE Coating, Tungsten Carbide-Cobalt Coating, Detonation Process M&P AMS 2437BN C710111SAE Coating, Plasma Spray Deposition M&P AMS 2438CL D090701SAE Plating, Chromium Thin, Hard, Dense Deposit M&P AMS 2444BM A001201SAE Coating, Titanium Nitride Physical Vapor Deposition M&P AMS 2451CW C110701SAE Plating, Brush General Requirements M&PAMS 2460See Special Notes DF A130301SAE Plating, Chromium If dwg requires chrome plate per AMS-QQ-C-320then stress relief and embritlmnt (emb) bake reliefper BPS4620. If dwg req's chrome plate per AMS2460then stress relief and bake relief per AMS M&PAMS 2468Cancelled CN G981001SAE Hard Anodic Coating Treatment of Aluminum Alloys AMS 2469M&P AMS 2469DM J140201SAE Hard Anodic Coating Treatment of Aluminum and Aluminum AlloysProcessing and Performance RequirementsM&P AMS 2470DH N130701SAE Anodic Treatment of Aluminum Alloys Chromic Acid Process M&P AMS 2471DM H140201SAE Anodic Treatment of Aluminum Alloys Sulfuric Acid Process, UndyedCoatingM&P AMS 2472DD F070801SAE Anodic Treatment of Aluminum Alloys Sulfuric Acid Process, Dyed Coating M&P AMS 2473DK H130801SAE Chemical Film Treatment for Aluminum Alloys General Purpose Coating M&P AMS 2474Noncurrent DD D060201SAE Chemical Treatment for Aluminum Alloys Low Electrical ResistanceCoatingAMS 2477M&P AMS 2477DD A100401SAE Conversion Coating for Aluminum Alloys Low Electrical Coating M&P AMS 2481CP J100201SAE Phosphate Treatment Antichafing M&P AMS 2482CN D100101SAE Hard Anodic Coating on Aluminum Alloys Polytetrafluoroethylene (PTFE)-Impregnated or CodepositedM&P AMS 2485BY K080101SAE Coating, Black Oxide M&P AMS 2486CR E100501SAE Conversion Coating of Titanium Alloys Fluoride-Phosphate Type M&P AMS 2487CN A000301SAE Anodic Treatment of Titanium and Titanium Alloys Solution pH 12.4MaximumM&P AMS 2488D000606SAE Anodic Tr: Ti, Ti Alys M&P AMS 2515DE G130101SAE Polytetrafluoroethylene (PTFE) Resin Coating Low Build, 370 to 400 °C(698 to 752 °F) FusionM&P AMS 2516DF E130301SAE Polytetrafluoroethylene (PTFE) Resin Coating High Build, 370 to 400 °C(698 to 752 °F) FusionM&P AMS 2525DJ D130701SAE Graphite Coating, Thin Lubricating Film Impingement Applied M&P AMS 2526DE D130101SAE Molybdenum Disulfide Coating, Thin Lubricating Film Impingement Applied M&P AMS 2590DD-101201SAE Rotary Flap Peening of Metal Parts M&P AMS 2615BM F060901SAE Pressure Testing Hydraulic Pressure as Specified M&P AMS 2630CR C100101SAE Inspection, Ultrasonic Product Over 0.5 Inch (12.7 mm) Thick M&P AMS 2631CW D110701SAE Ultrasonic Inspection Titanium and Titanium Alloy Bar and Billet M&P AMS 2632BN A950301SAE Inspection, Ultrasonic, of Thin Materials 0.50 Inch (12.7 mm) and Under inCross-Sectional ThicknessM&P AMS 2635Cancelled Can810701SAE Radiographic Insp ASTM E1742M&P AMS 2640Cancelled CH Can960401SAE Magnetic Particle Inspection ASTM E1444M&P AMS 2645Cancelled CH Can950201SAE Fluorescent Penetrant Inspection ASTM E1417M&P AMS 2649DM D131201SAE Etch Inspection of High Strength Steel Parts M&P AMS 2658CN C091001SAE Hardness and Conductivity Inspection of Wrought Aluminum Alloy Parts M&Pat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2664CH F950701SAE Brazing, Silver for Use Up to 800 °F (427 °C)M&P AMS 2665DH H130501SAE Brazing, Silver for Use up to 400 °F (204 °C)M&P AMS 2666Cancelled Can840101SAE Ag Braz, High Temp AMS 2664M&P AMS 2670BK J060601SAE Brazing, Copper M&P AMS 2671Cancelled CH Can920101SAE Copper Brazing Corrosion and Heat Resistant Steels and Alloys AMS 2670M&P AMS 2672CY G120101SAE Brazing, Aluminum Torch or Furnace M&P AMS 2673DB E120101SAE Brazing, Aluminum and Aluminum Alloys Molten Flux (Dip)M&P AMS 2675DF H130201SAE Brazing, Nickel Alloy Filler Metal M&P AMS 2680C010601SAE Electron-Beam Welding for Fatigue Critical Applications M&P AMS 2681B000301SAE Electron Beam Welding M&P AMS 2685Noncurrent CP E071001SAE Welding, Tungsten Arc, Inert Gas GTAW Method M&P AMS 2689Noncurrent CH A980201SAE Fusion Welding Titanium and Titanium Alloys M&P AMS 2694DE C130101SAE In-Process Welding of Castings M&P AMS 2700DA E111101SAE Passivation of Corrosion Resistant Steels All acceptance testing shall be per Class 4except for Martensitic CRES alloy 440C,which requires no class testing.M&PAMS 2728DC C120901SAE Heat Treatment of Wrought Copper Beryllium Alloy Parts M&P AMS 2745CJ A071201SAE Induction Hardening of Steel Parts M&P AMS 2750DB E120701SAE Pyrometry M&P AMS 2753CF C080801SAE Liquid Salt Bath Ferritic Nitrocarburizing Non-Cyanide Bath M&P AMS 2755Cancelled CM Can090701SAE Nitriding, Molten Salt Bath Process not available, consider AMS 2753as replacement.M&P AMS 2759CE E081001SAE Heat Treatment of Steel Parts General Requirements M&PAMS 2759/1CJ E090201SAE Heat Treatment of Carbon and Low-Alloy Steel Parts Minimum TensileStrength Below 220 ksi (1517 MPa)Supersedes MIL-H-6875 for carbon & low-alloy steels below 220 ksi.M&PAMS 2759/2CR F100501SAE Heat Treatment of Low-Alloy Steel Parts Minimum Tensile Strength 220 ksi(1517 MPa) and Higher Supersedes MIL-H-6875 for low-alloysteels, 220 ksi & higher.M&PAMS 2759/3CE E080801SAE Heat Treatment Precipitation-Hardening Corrosion-Resistant and MaragingSteel Parts Supersedes MIL-H-6875 for precipitationhardening & maraging steel.M&PAMS 2759/4CA C080301SAE Heat Treatment Austenitic Corrosion-Resistant Steel Parts Supersedes MIL-H-6875 for austenticsteels.M&P AMS 2759/5D040601SAE Heat Treatment Martensitic Corrosion Resistant Steel Parts Supersedes MIL-H-6875 for martensiticsteels.M&P AMS 2759/6BM B051101SAE Gas Nitriding and Heat Treatment of Low - Alloy Steel Parts Use Standard Drawing Notes per BDS2240.M&P AMS 2759/7CT B100501SAE Carburizing and Heat Treatment of Carburizing Grade Steel Parts M&PAMS 2759/8CG A070601See SpecialNotes SAE Ion Nitriding 1. Infrared pyrometry may be used to measuretemperature. 2. The nitriding temperature may beless than 50 degrees below the tempering oraging temperature provided that the corehardness is not reduced. 3. for small loads, ai i f t t t ti iM&PAMS 2759/9CL D090501SAE Hydrogen Embrittlement Relief (Baking of Steel Parts)Supersedes MIL-H-6875 for stress relievingsteels.M&P AMS 2759/10CN A060601SAE Automated Gaseous Nitriding Controlled by Nitriding Potential M&P AMS 2759/11BW-050401SAE Stress Relief of Steel Parts M&P AMS 2762Noncurrent CP B020101SAE Carburizing Carbon and Low-Alloy Steel Parts M&P AMS 2768CR C100701SAE Heat Treatment of Magnesium Alloy Castings M&P AMS 2769DD B091201SAE Heat Treatment of Parts in a Vacuum M&P AMS 2770DM L140501SAE Heat Treatment of Wrought Aluminum Alloy Parts M&P AMS 2771DF E130201SAE Heat Treatment of Aluminum Alloy Castings M&P AMS 2772CW F110701SAE Heat Treatment of Aluminum Alloy Raw Materials M&P AMS 2774DC D121001SAE Heat Treatment Wrought Nickel Alloy and Cobalt Alloy Parts M&P AMS 2800CN D060801SAE Identification Finished Parts M&Pat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 2801B030301SAE Heat Treatment of Titanium Alloy Parts M&PM&P AMS 2807CF B080201SAE Identification Carbon and Low-Alloy Steels, Corrosion and Heat-ResistantSteels and Alloys Sheet, Strip, Plate and Aircraft TubingAMS 3025CN C090901SAE Polyalkylene Glycol Heat Treat Quenchant M&P AMS 3106Cancelled Can830401SAE Primer, Adhesive, Corr Inhib AMS 3107M&P AMS 3107A910401SAE Primer, Adhesive, Corr-Inhibiting M&P AMS 3195DP G140501SAE Silicone Rubber Sponge, Closed Cell, Medium M&PM&P AMS 3216G050901SAE Fluorocarbon (FKM) Rubber High-Temperature - Fluid Resistant LowCompression Set 70 to 80M&P AMS 3218C050901SAE Fluorocarbon (FKM) Rubber High-Temperature - Fluid Resistant LowCompression Set 85 to 95M&P AMS 3276CB E080301SAE Sealing Compound, Integral Fuel Tanks and General Purpose, IntermittentUse to 360 °F (182 °C)AMS 3301DB H110601SAE Silicone Rubber, General Purpose, 40 Durometer M&P AMS 3305H900401SAE Silicone Rubber, Gen Purp, 75-85M&P AMS 3374DL D131101SAE Sealing Compound Aircraft Firewall, Silicone M&P AMS 3384DP-130801SAE RUBBER, FLUOROCARBON ELASTOMER (FKM) 70 TO 80M&PHARDNESS, LOW TEMPERATURE SEALING Tg -22 deg. F (-30 deg. C)FOR ELASTOMERIC SHAPES OR PARTS IN GAS TURBINE ENGINEOIL, FUEL AND HYDRAULIC SYSTEMSAMS 3410J981001SAE Flux, Ag Braz M&P AMS 3411D981001SAE Flux Silver Brz, High Temp M&P AMS 3644BL G060901SAE Plastic: Polyimide for Molded Rod, Bar, and Tube, Plaque, and formedM&PPartsM&P AMS 3645CY D120101SAE Polychlorotrifluoroethylene (PCTFE), Compression Molded HeavySections, UnplasticizedAMS 3650CY D120101SAE Rods, Sheets, and Molded Shapes, Polychlorotrifluoroethylene (PCTFE)M&PUnplasticizedAMS 3651Cancelled Can870401SAE PTFE AMS 3667M&P AMS 3651Cancelled Can870401PTFE AMS 3652M&P AMS 3651Cancelled Can870401PTFE AMS 3656M&P AMS 3651Cancelled Can870401PTFE AMS 3660M&P AMS 3652C930101SAE PTFE Film, Non-Crit Grade M&P AMS 3656CW H110801SAE PTFE Extrusions, Normal Strength, As Sintered M&P AMS 3657CW F110801SAE PTFE, Extrusions, Premium Strength, As Sintered M&P AMS 3658CW F110801SAE PTFE, Extrusions, Premium M&P AMS 3659CW F110801SAE Polytetrafluoroethylene (PTFE) Extrusions, Premium Strength, SinteredM&Pand Stress-RelievedAMS 3660CW E110801SAE Polytetrafluoroethylene Moldings M&P AMS 3666DB E120101SAE PTFE Sht, Glass Reinforced M&P AMS 3667CW E110801SAE Polytetrafluoroethylene Sheet, Molded General Purpose Grade, AsM&PSinteredAMS 3668CW E110801SAE PTFE, Moldings, Premium Grade, A Sintered M&P AMS 3670/1B950401SAE Unfilled Polyamide-Imide, Bar M&P AMS 3824CN C950901SAE Cloth, Glass Finished for Resin Laminates M&P AMS 4001Cancelled CK Can070701SAE Aluminum Sheet and Plate 0.12Cu (1100-0) Annealed ASTM B209M&P AMS 4013DM G140201SAE Aluminum Sheet, Laminated Surface Bonded M&P AMS 4015CN L070201SAE Aluminum Alloy, Sheet and Plate 2.5Mg - 0.25Cr (5052-0) Annealed M&P AMS 4016DE M130101SAE Aluminum Alloy, Sheet and Plate 2.5Mg - 0.25Cr (5052-H32) StrainM&PHardened, Quarter Hard, and StabilizedAMS 4017CN K041201SAE Aluminum Alloy Sheet and Plate 2.5Mg - 0.25Cr (5052-H34) Strain-M&PHardened, Half Hard, and StabilizedAMS 4023Noncurrent CN E840401SAE Aluminum Alloy Sheet and Plate Alclad 1.0Mg - 0.60Si - 0.28Cu - 0.20CrM&P(Alclad 6061; -T6 Sheet, -T651 Plate)at BPS4000 rev(yy/mm/dd)SupersedingDocAMS 4025CE L080701SAE Aluminum Alloy, Sheet and Plate 1.0Mg - 0.60Si-0.28Cu-0.20Cr(6061-0)AMS-QQ-A-250/11A - cancelled - 2008M&PAnnealedAMS-QQ-A-250/11A - cancelled - 2008M&P AMS 4026CE M080701SAE Aluminum Alloy, Sheet and Plate 1.0Mg -0.60Si-0.28Cu-0.20Cr (6061;-T4Sheet, T-451 Plate) Solution Heat Treated and Naturally AgedAMS 4027CE N080701SAE Aluminum Alloy, Sheet and Plate 1.0Mg -0.60Si-0.28Cu-0.20Cr (6061;-T6AMS-QQ-A-250/11A - cancelled - 2008M&PSheet, T-651 Plate) Solution and Precipitation Heat TreatM&P AMS 4037CY P111201SAE Aluminum Alloy, Sheet and Plate 4.4Cu - 1.5Mg - 0.60Mn (2024; - T3 FlatSheet, T351 Plate) Solution Heat TreatedM&P AMS 4048CW N100801SAE Aluminum Alloy Sheet and Plate, Alclad 5.6Zn - 2.5Mg - 1.6Cu - 0.23Cr(Alclad 7075-O) Annealed or When Specified, "As fabricated" (Alclad 7075-F)M&P AMS 4049CW L101201SAE Aluminum Alloy Sheet and Plate, Alclad 5.6Zn - 2.5Mg - 1.6Cu - 0.23Cr(Alclad 7075; -T6 Sheet - T651 Plate) Solution and Precipitation HeatTreatedAMS 4056DB G101001SAE Aluminum Alloy, Sheet and Plate 4.4Mg - 0.70Mn - 0.15Cr (5083-01)M&P AMS 4080CN N091201SAE Aluminum Alloy, Drawn Seamless Tubing 1.0Mg - 0.60Si - 0.28Cu - 0.20CrM&P(6061-O) AnnealedM&P AMS 4081CC J080601SAE Aluminum Alloy Tubing, Hydraulic, Seamless, Drawn, Round 1.0Mg -0.60Si - 0.28Cu - 0.20Cr (6061-T4) Solution Heat Treated and NaturallyAgedM&P AMS 4083DE L121101SAE Aluminum Alloy Tubing, Hydraulic, Seamless, Drawn, Round 1.0Mg -0.60Si - 0.28Cu - 0.20Cr- (6061-T6) Solution and Precipitation HeatTreatedM&P AMS 4086BL N060901SAE Aluminum Alloy, Drawn, Round, Seamless Hydraulic Tubing 4.4Cu-1.5Mg-0.60Mn (2024-T3) Solution Heat Treated, Cold Worked, and NaturallyAgedM&P AMS 4088BT K070301SAE Aluminum Alloy, Drawn, Seamless Tubing 4.4Cu-1.5Mg-0.60Mn (2024-T3)Solution Heat Treated and Cold WorkedAMS 4107F051101SAE Alum Aly Die Forg, (7050-T14)M&PM&P AMS 4113CH E030701SAE Aluminum Alloy, Extruded Profiles 1.0Mg - 0.60Si - 0.28Cu - 0.20Cr (6061-T6) Solution and Precipitation Heat TreatedM&P AMS 4115CU H090701SAE Aluminum Alloy, Rolled or Cold-Finished, Bars, Rods, Wire, and FlashWelded Rings Annealed 1.0Mg - 0.60Si - 0.2Cu - 0.20Cr (6061-0)M&P AMS 4116CN H090701SAE Aluminum Alloy, Bars, Rods, and Wire 1.0Mg - 0.60Si - 0.3Cu - 0.20Cr(6061-T4) Cold Finished, Solution Heat Treated and Naturally AgedM&P AMS 4117CM J090701SAE Aluminum Alloy, Rolled or Cold Finished Bars, Rods, and Wire and FlashWelded Rings 1.0Mg -0.60Si - 0.28Cu - 0.20Cr (6061; - T6, -T651)Solution and Precipitation Heat TreatedAMS 4120M&P AMS 4119Cancelled CN Can900101SAE Aluminum Alloy Bars, Rolled, Drawn, or Cold Finished 4.4Cu - 1.5Mg -0.60Mn (2024-T351) Stress Relief StretchedAMS 4120R020901SAE Aluminum Alloy, Rolled or Cold Finished Bars, Rods, and Wire 4.4Cu - 1.5M&PMg - 0.60Mn (2024) Solution Heat Treated and Naturally Aged (T4)Solution Heat Treated, Cold Worked, and Naturally Aged (T351)M&P AMS 4121CA H071101SAE Aluminum Alloy Bars, Rods, and Wire, Rolled or Cold Finished 4.5Cu -0.85Si - 0.80Mn - 0.50Mg (2014-T6) Solution and Precipitation HeatTreatedM&P AMS 4123CN H060101SAE Aluminum Alloy, Rolled or Cold Finished Bars and Rods (7075-T651)Solution and Precipitation Heat TreatedM&P AMS 4124DG E120901SAE Aluminum Alloy, Rolled or Cold Finished Bars, Rods, and Wire 5.6Zn-2.5Mg-1.6Cu-0.23Cr (7075-T7351) Solution Heat Treated, Stress Relievedby Stretching and OveragedM&P AMS 4128CN D071001SAE Aluminum Alloy Bars, Rolled or Cold Finished 1.0Mg - 0.60Si - 0.30Cu -0.20Cr (6061-T451) Solution Heat Treated and Stress Relieved byStretchingAMS 4132DF G130201SAE Aluminum Alloy, Die and Hand Forgings, Rolled Rings, and Forging StockM&P2.3Cu-1.6Mg-1.1Fe-1.0Ni-0.18Si-0.07Ti (2618-T61) Solution andPrecipitation Heat TreatedM&P AMS 4133CN E090301SAE Aluminum Alloy Forgings and Rolled Rings 4.4Cu -0.85Si -0.80Mn -0.50Mg (2014-T6) Solution and Precipitation Heat TreatedAMS 4135Cancelled CN Can860401SAE Aluminum Alloy Forgings 4.5Cu - 0.85Si - 0.80Mn - 0.50Mg (2014-T6)AMS 4133M&PSolution and Precipitation Heat TreatedAMS 4141CE F081001SAE Aluminum Alloy Die Forgings 5.6Zn - 2.5Mg - 1.6Cu - 0.23Cr (7075-T73)M&PSolution and Precipitation Heat TreatedAMS 4144BN F060501SAE Aluminum Alloy, Hand Forgings and Rolled Rings 6.3Cu - 0.30Mn - 0.18Zr -M&P0.10V - 0.06Ti (2219-T852/T851) Solution Heat Treated, MechanicallyStress Relieved, and Precipitation Heat-Treatedat BPS4000 rev(yy/mm/dd)SupersedingDocAMS 4149D020901SAE Aluminum Alloy, Die and Hand Forgings 5.6n - 2.5Mg - 1.6Cu - 0.23Cr(7175-T74) Solution and Precipitation Heat TreatedM&P AMS 4150DG M130401SAE Aluminum Alloy, Extrusions and Rings 1.0Mg - 0.60Si - 0.28Cu - 0.20Cr -(6061-T6) Solution and Precipitation Heat TreatedM&P AMS 4162D030701SAE Aluminum Alloy, Extrusions 6.3Cu - 0.30Mn - 0.18Zr - 0.10V - 0.06Ti (2219-T8511) Solution Treated, Stress Relief Stretched, Straightened, andPrecipitation Heat TreatedM&PAMS 4173DG F130401SAE Aluminum Alloy, Extrusions 1.0Mg - 0.60Si - 0.30Cu - 0.20Cr (6061-T6511) Solution Heat Treated, Stress Relieved by Stretching,Straightened, and Precipitation Heat TreatedM&PAMS 4181C030401SAE Aluminum Alloy, Welding Wire 7.0Si - 0.38Mg - 0.10Ti (4008) (UNSA94008)M&P AMS 4182CN G091201SAE Alum Aly Wire, Annealed 5.0Mg - 0.12Mn - 0.12Cr (5056-0) Annealed M&P AMS 4185DB E120201SAE Fill Mtl, Alum Braz, 12SI, (4047)M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4181M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4233M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4244M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4245M&P AMS 4188Cancelled Can861001SAE Wldg Wire AMS 4246M&P AMS 4210CN K050301SAE Aluminum Alloy, Castings 5.0Si - 1.2Cu - 0.50Mg (355.0-T51) PrecipitationHeat TreatedM&P AMS 4212CU K110201SAE Aluminum Alloy Castings 5.0Si - 1.2Cu - 0.50Mg (355.0-T6) Solution andPrecipitation Heat TreatedM&P AMS 4214CN J080601SAE Castings, Aluminum Alloy Sand 5.0Si - 1.2Cu - 0.50Mg (355.0 T71)Solution Heat Treated and OveragedM&P AMS 4215CN H080301SAE Aluminum Alloy, Castings 5.0Si - 1.2Cu - 0.50Mg (C355.0-T6) Solution andPrecipitation Heat TreatedM&P AMS 4217CN H070401SAE Aluminum Alloy, Castings 7.0Si - 0.32Mg (A356.0-T6) (formerly T6PTemper) Solution and Precipitation Heat TreatedM&P AMS 4218CN J100101SAE Aluminum Alloy Castings 7.0Si-0.35Mg (A356.0-T6) (formerly T6PTemper) Solution and Precipitation Heat TreatedM&P AMS 4223CN D070401SAE Aluminum Alloy, Castings 4.5Cu - 0.70Ag - 0.30Mn - 0.25Mg - 0.25Ti(A201.0-T4) Solution Heat Treated and Naturally AgedM&PAMS 4224Cancelled - no s/s spec CN C100101SAE Aluminum Alloy Castings, Sand 4.0Cu - 2.1Ni - 2.0Mg - 0.30Cr - 0.30Mn -0.13T - 0.13V (243.0) Stabilized Ok to use cancspec.M&PAMS 4225CN D070601SAE Aluminum Alloy, Heat Resistant, Castings 5.0Cu - 1.5Ni - 0.25Mn - 0.25Sb- 0.25Co - 0.20Ti - 0.20Zr (203.0-T6) Solution Heat Treated andPrecipitation Heat TreatedM&PAMS 4226Noncurrent CN A830101SAE Aluminum Alloy Castings, High Strength 5.0Cu - 0.35Mn - 0.18Zr- 0.10V(224.0) Solution and Precipitation Heat Treated (Overaged)M&PAMS 4227Cancelled - no s/s spec CN E050701SAE Aluminum Alloy, Casting, Sand, 8.0Cu 6.0Mg 0.50Mn 0.50Ni, As Cast Ok to use cancspec.M&PAMS 4229DA F120201SAE Aluminum Alloy Castings, High Strength 4.5Cu - 0.7Ag - 0.30Mn - 0.25Mg -0.25Ti (A201.0-T7) Solution Heat Treated and OveragedM&PAMS 4233C030301SAE Aluminum Alloy, Welding Wire 4.5 Cu - 0.70Ag - 0.30Mn - 0.25Mg - 0.25Ti(A201.0-T7) Solution Heat Treated and OveragedM&PAMS 4235CN B080301SAE Aluminum Alloy Castings 4.6Cu - 0.35Mn - 0.25Mg - 0.22Ti (A206.0-T71)Solution and Precipitation Heat TreatedM&PAMS 4236DF C130201SAE Aluminum Alloy Castings 4.6Cu - 0.35Mn - 0.25Mg - 0.22Ti (A206.0-T4)Solution Heat Treated and Naturally AgedM&PAMS 4237Cancelled - no s/s spec CN B070401SAE Aluminum Alloy Castings, Sand 4.6Cu - 0.35Mn - 0.25Mg - 0.22Ti (206.0 -T71) Solution Heat Treated and Naturally Aged Ok to use cancspec.M&PAMS 4241CN D091101SAE Aluminum Alloy Castings 7.0Si - 0.58Mg - 0.15Ti -0.06Be (D357.0 - T6)Solution and Precipitation Heat Treated Dendrite Arm Spacing (DAS)ControlledM&PAMS 4244CE B080701SAE Aluminum Alloy, Welding Wire 4.6Cu - 0.35Mn - 0.25Mg - 0.22Ti forWelding A206.0 Type AlloysM&PAMS 4245CR E100401SAE Aluminum Alloy, Welding Wire 5.0Si - 1.2Cu - 0.50Mg (355) (UNS A03550)M&PAMS 4246Noncurrent CP D080201SAE Aluminum Alloy, Welding Wire 7.0Si - 0.52Mg (357) (UNS A03570)M&PAMS 4260Not Acceptable to Use atParker HannifinAerospace CL G080601SAE Alum Aly Cast, Invest (356.0-T6)BPS4829AMS 4260 rev. G unacceptable for ParkerUse. BPS4829 created as replacement.M&P。

h j h x .r c e e s .a c .c n第37卷㊀第2期2018年㊀㊀2月环㊀境㊀化㊀学ENVIRONMENTALCHEMISTRYVol.37,No.2February2018㊀2017年6月26日收稿(Received:June26,2017).㊀∗国家自然科学基金(41473008)资助.SupportedbytheNationalNaturalScienceFoundationofChina(41473008).㊀∗∗通讯联系人,Tel:0316⁃2267728,E⁃mail:mashengming@igge.cnCorrespondingauthor,Tel:0316⁃2267728,E⁃mail:mashengming@igge.cnDOI:10.7524/j.issn.0254⁃6108.2017062604宋淑玲,马生明.双酚S毒理学㊁人体暴露水平与健康效应研究进展[J].环境化学,2018,37(2):200⁃208.SONGShuling,MAShengming.Toxicology,humanexposureandhealtheffectsofbisphenolS[J].EnvironmentalChemistry,2018,37(2):200⁃208.双酚S毒理学、人体暴露水平与健康效应研究进展∗宋淑玲1㊀马生明2∗∗(1.国家地质实验测试中心,北京,100037;㊀2.中国地质科学院地球物理地球化学勘查研究所,廊坊,065000)摘㊀要㊀双酚S(BPS)是类雌激素干扰物双酚A(BPA)的主要替代品.尽管BPS已被广泛用于塑料等产品中,但其生态安全性和对人体暴露产生的毒性作用却不明了.随着BPS分子和细胞水平毒理学研究的深入,特别是其对动物体繁殖和神经内分泌系统表现出的毒性,使BPS人体暴露的安全性遭到了质疑.本文以BPS毒理学和人体暴露水平研究为聚焦点,阐述了近年来BPS不同水平毒理学研究进展和结论.在此基础上介绍当前人体BPS暴露研究的相关内容,包括人体BPS暴露途径㊁暴露水平和健康效应最新的调查结果.基于当前研究中存在的争论和有待解决的科学问题,未来的热点将集中在暴露的潜在毒性和风险评价方面.应该加快人体BPS暴露水平及暴露毒性研究,而BPS暴露形态㊁浓度及时间是人体BPS暴露毒性㊁特别是BPS早期暴露毒性深入研究不可忽略的重要因素.关键词㊀双酚S,毒理学,人体暴露毒性,暴露水平.Toxicology,humanexposureandhealtheffectsofbisphenolSSONGShuling1㊀㊀MAShengming2∗∗(1.NationalResearchCenterforGeoanalysis(NRCGA),Beijing,100037,China;2.InstitutesofGeophysicalandGeochemicalExploration,ChineseAcademyofGeologicalScience(CAGS),Langfang,065000,China)Abstract:BisphenolS(BPS)isamajorsubstitutefortheestrogendisruptor,bisphenolA(BPA).AlthoughBPShasbeenwidelyusedinplasticsproducts,theecologicalsafetyandtoxiceffectsofBPSonhumanareunknown.WiththeintensivetoxicologicalstudyofBPSatmolecularandcellularlevels,especiallytoxicityontheanimalreproductiveandneuroendocrinesystems,safetyofhumanexposurehasbeenquestioned.ThispaperfocusedonBPStoxicologyandhumanexposureresearch.ToxicologyresearchprogressandtheresultsinrecentyearsweredescribedatdifferentlevelsofBPS,andtherelatedcontentsoftoxicitystudiesforcurrenthumanBPSexposurewereintroduced,includinghumanexposurepathways,exposurelevelandthelatestsurveyresultsofhealtheffects.Basedonthecurrentresearchargumentsandscientificproblemstobesolved,thefuturestudiesofhumanexposuretoBPSshouldbefocusedonpotentialtoxicityandriskassessment.ThestudiesonhumanBPSexposurelevelandexposuretoxicityshouldbespeededup,andexposureforms,concentrationsandtimeswouldbeimportantfactorsforstudiesonhumanexposuretoxicity,especiallyonearlyexposuretoxicityinthefutureresearch.Keywords:biphenolS,toxicology,humanexposuretoxicity,exposurelevel.h j h x .r c e e s .a c .c n ㊀2期宋淑玲等:双酚S毒理学㊁人体暴露水平与健康效应研究进展201㊀双酚A(4,4ᶄ⁃异亚丙基双酚,BisphenolA,缩写成BPA)是碳酸酯类塑料产品的主要原料,也广泛用于塑料产品的着色剂.大量的研究已经表明,BPA对动物体具有雌激素干扰作用.因此,随着BPA暴露风险[1⁃4]㊁环境和生物毒性[5⁃6]的发现,2011年欧盟委员会按照预防原则禁止在婴幼儿奶瓶中使用BPA.此后,全球许多国家掀起了BPA的禁用热潮[7⁃8],我国也于2011年限制了BPA在儿童用品中的使用,并规定和颁布了一些产品中BPA的使用限量标准.伴随着BPA的限用和禁用,BPA的多种替代产品被快速研发和投入使用.这些替代品包括:四溴双酚A㊁六氟双酚A和双酚S等.而双酚S(4,4ᶄ⁃二羟基二苯砜,BisphenolS,缩写成BPS)是主要的替代品,并被广泛应用.随着BPS的广泛使用,研究人员加紧了BPS环境行为和动物毒理学研究,这些毒理学研究结果包括分子水平㊁体外细胞水平和活体动物暴露毒性试验.但是,这些毒理学研究结果却令人堪忧:BPS不仅具有一定的分子和体外细胞毒性,同时动物的体外暴露毒性也非常明显[9-15].与此同时,基于已有的BPS毒理学研究所取得的认识,研究人员积极推进人体BPS暴露水平㊁暴露途径和暴露毒性的调查研究.这些研究结果对BPS的安全使用㊁人体BPS暴露量控制,以及BPS暴露毒性及流行病学的防治必将发挥重要作用,具有重要意义.本文将重点从BPS毒理学以及人体BPS暴露水平研究两方面,介绍BPS毒理学在分子水平㊁细胞水平和活体动物水平的研究进展.同时,通过当前人体BPS暴露途径㊁暴露水平和暴露量,已有的人体暴露毒性调查结果,总结近年来BPS毒理学研究的最新成果,以及不同国家和地区BPS暴露水平及差异.并在此基础上提出BPS毒理学和人体暴露毒性研究的新问题,以及发展的新方向.1㊀BPS暴露毒理学研究及其进展(ResearchprogressonexposuretoxicityofBPS)BPA被禁用或限用后,BPS作为替代品被快速投入使用,然而其在环境中的行为,特别是生物安全性的相关研究不够深入,尤其缺少其对生物体环境暴露风险㊁安全性及毒理学研究的数据与结果.因此,BPS投入使用后其生物安全性及其毒理学研究非常活跃.至今,研究人员已经从分子水平㊁细胞水平和活体动物水平3个层次开展了BPS毒理学研究,并取得了一些进展.1.1㊀BPS分子和细胞水平的暴露毒理学研究事实上,BPS作为BPA的替代品被投入使用时,BPS的毒理学和生物安全性的相关研究还非常有限,仅少数的研究表明BPS具有与BPA相似的急性毒性[9]和雌激素活性[10]外,主要是关于BPS与BPA及其他替代品理化性质及简单的环境行为研究.这些研究包括BPS在不同环境中的稳定性,有氧㊁厌氧和不同水环境条件下BPS的降解规律㊁速度以及持久性.研究结果表明BPS比BPA在环境中更加稳定㊁难降解㊁持久性更强[11⁃13].BPS被投入使用后,研究表明其与BPA有极其相似的暴露途径,即经口和经皮暴露.因此,基于BPS及BPA已有的毒理学研究结果,研究人员针对BPS的特征性暴露途径,从多个方面展开了分子水平的BPS暴露毒理学研究,并取得了许多研究进展.例如有人研究了BPS对胰蛋白酶和胃蛋白酶的生物活性,结果表明,BPS可与胰蛋白酶和胃蛋白酶发生键合或绑定,从而改变两种酶的骨架结构,进而对两种酶产生活性抑制作用[14].该研究结果同时表明,随着BPS暴露浓度增加(0 0.0002mol㊃L-1),胃蛋白酶比胰蛋白酶的活性降低更为明显;而Mathew等[15]采用了稳态㊁同步㊁时间分辨和圆二色光谱分析技术和手段,在分子水平开展了BPS和BPA与血清蛋白两者结合作用的研究,结果表明BPS和BPA的荧光猝灭途径不相同,即BPS在低浓度时发生静态猝灭,在高浓度时发生动态猝灭;并且研究结果表明BPS比BPA对血清蛋白的结合能力更强,且这种结合是一种不可逆的结合,当BPS在10-5mol㊃L-1时可以对α-螺旋结构产生扰动,在更高浓度可以使其完全失去物理结构功能.除了分子水平的毒性和毒理研究,一些新的研究结果还证实了细胞水平下,BPS的毒性和毒理学特性.较早引起研究者兴趣的是BPS的雌激素活性,如2012年Grignard等[16]就已经通过细胞水平的毒理实验证明,BPS与BPA具有相似的雌激素活性(即对17β⁃雌二醇具有干扰作用)和结构活性.此后,许多研究者还发现,BPS的细胞水平毒性不仅仅表现在雌激素活性方面.例如Boucher等[17]的研究表明,当BPS的暴露浓度达到25μmol㊃L-1时,BPS可以影响人体前脂肪细胞的活性,诱导脂肪细胞的分化和形成.Zhang[18]等首先将BPS与过氧化氢酶(Catalase,CAT)直接作用,通过多光谱法和分子对接调查测定h j h x .r c e e s .a c .c n 202㊀环㊀㊀境㊀㊀化㊀㊀学37卷了分子水平BPS对CAT结构和活性的改变作用,结果表明BPS在CAT酶的底物通道上,可以通过氢键和疏水力两种作用结合甘氨酸117残基㊁改变CAT的结构和活性.其次,该研究者以老鼠肝细胞和肾细胞为实验对象,比较了BPS暴露浓度对肝细胞和肾细胞的损害与细胞凋亡作用.这个研究结果表明当BPS暴露浓度在1 0.1mmol㊃L-1范围时,12h内肝细胞和肾细胞凋亡数没有显著增加,而当BPS暴露浓度达到一定水平时(0.1 1.0mmol㊃L-1),肝细胞和肾细胞的凋亡数量与BPS暴露浓度具有正相关性[18].这表明一定浓度的BPS可诱导动物肝细胞和肾细胞的氧化应激作用.2015年,Fol等[19]利用体外细胞模型开展BPS等对人和斑马鱼的细胞特性生物转化,评价BPS在0.1 100μmol㊃L-1浓度范围内的毒性和雌激素活性筛查.此项研究结果证实,尽管通常用于评价雌激素活性测试的细胞生物转化率较低(整个浓度范围内),且有差异,但BPS在人体和斑马鱼肝细胞内的代谢模式非常相似.通过对近年来BPS分子水平和细胞水平毒理学研究的总结,基本可以确定BPS生物毒性的具体分子机制主要是对生物体特殊的酶进行干扰,即BPS其特殊的结构可以与多种酶结合,破坏酶的物理结构,从而导致酶物理结构功能的丧失,最终产生生物毒性.尽管研究人员开展了BPS在分子水平和细胞水平毒理学和毒性研究,也取得了一些结果,但最受关注的仍然是BPS对动物体㊁特别是高等动物的雌激素干扰作用.下文将介绍动物早期BPS暴露产生的繁殖和神经内分泌系统发育毒性[20⁃21]的研究进展.1.2㊀BPS活体动物水平的暴露毒理学研究由于斑马鱼的基因与人类基因有近80%的相似性,当前,研究者主要以斑马鱼为研究对象,开展BPS活体动物水平的暴露毒理学研究.研究内容主要围绕BPS的暴露毒性,以及产生毒性的浓度水平或暴露剂量.例如多个研究者[20,22]开展了不同暴露浓度或暴露水平的BPS对活体斑马鱼雌激素内分泌功能和繁殖能力的影响.2013年,Ji等[20]将雌体和雄体斑马鱼同时暴露在3个不同浓度水平的BPS水体中(0.5㊁5.0㊁50μg㊃L-1),持续21d监测考察,暴露浓度对繁殖能力㊁性类固醇激素和下丘脑⁃垂体⁃性腺(HPG)轴基因转录的影响.研究结果表明当暴露浓度大于0.5μg㊃L-1时,鱼卵数量㊁雌体的性腺指数和雄体的睾丸素都明显降低,同时雌体和雄体血浆β-17雌二醇(雌激素化合物,是雌激素水平高低的主要指标)浓度均显著升高.最终导致母代斑马鱼孵化时间推迟㊁孵化速度降低,而这种副作用即使在后期将母体转移到无BPS的水体时也不会消失.此外,研究结果还证实,与对照组相比,子代斑马鱼如果继续暴露在低水平BPS环境,将会损坏胎盘的孵化能力㊁增加鱼幼崽畸形的几率.总之,该研究结果表明,即使母体经受低水平的BPS暴露,也会造成后代HPG轴的反馈循环调节,并影响后代的发育.根据BPS以上分子水平㊁细胞水平和动物水平的毒性研究结果,不难看出BPS作为BPA的替代产品,其与BPA具有相似的毒性,特别是对高等动物都具有雌激素受体干扰作用.鉴于以上研究结果,研究人员开始质疑BPS替代BPA是否真正安全,它对人体的暴露毒性是否低于BPA,BPS和BPA谁更安全[21,23]?针对这种质疑,2016年Qiu等[21]继Ji等[20]的研究结果进一步详细比较了BPS和BPA对斑马鱼早期发育过程中神经内分泌系统的毒性,并揭示了BPS和BPA造成这种暴露毒性的多个细胞介导途径.结果表明母体BPS和BPA的低暴露浓度(1 100μg㊃L-1)均会导致繁殖和后代神经内分泌系统受损.因此,研究者指出,BPS与BPA对动物体早期发育能够造成相似的暴露毒性,BPS作为BPA的替代品并不具有更好的生态安全性,采用BPS替代BPA并不是明智得选择.以上研究已经证明,动物体遭受BPS早期暴露(特别是胎儿时期的暴露),甚至是μg㊃L-1级低浓度的暴露剂量也会对胎儿幼体发育和母体繁殖能力产生毒副作用.由于针对人体开展相似的早期暴露毒性研究尚存在多种困难,研究者只能以人体暴露水平㊁暴露源和暴露途径为研究手段,积极通过不同介质中BPS浓度的调查和监测,开展了不同人群BPS暴露途径和暴露水平的调查研究,为人体BPS暴露毒性研究提供重要的基础数据,并取得了一些进展.2㊀BPS暴露途径与暴露量的研究及进展(TheprogressonexposurepathanddoseofBPS)BPS作为一种潜在毒性物质,研究其暴露途径具有重要意义.通过暴露途径的研究,可以掌握BPS暴露来源㊁暴露形态㊁以及BPS在人体内的代谢途径与特征,估算和评价暴露量,也可以控制主要暴露h j h x.r c e e s .a c .c n ㊀2期宋淑玲等:双酚S毒理学㊁人体暴露水平与健康效应研究进展203㊀途径,控制和降低暴露量,从而降低暴露风险.BPS暴露途径和暴露量的研究主要分为成人和人体早期BPS暴露途径及暴露量研究.2.1㊀成人BPS的暴露途径㊁暴露源㊁暴露量及研究进展研究已经证实,BPS与BPA相似,在多种食物(材)中都有BPS的检出[24],其以经口和皮肤暴露为主,而暴露途径与暴露源密切相关.当前关于成人BPS暴露途径和暴露源的研究主要是集中在各种环境或含有BPS材料(暴露源)中BPS浓度的检测,以及人体每日不同暴露途径暴露量的估算和评价方面.例如,一些食品㊁特别是罐装蔬菜㊁饮料和肉食品的包装材料中含有BPS,从而使经口暴露成为BPS的一个主要暴露途径.已有研究者报道了罐装食品中BPS的含量,结果表明罐装食品与含有BPS的包装材料接触后,BPS会转移到食品中,其含量可以到μg㊃kg-1的水平[25],主要原因是一些食品包装材料中含有BPS,而BPS污染的食物及含有BPS的包装材料则是主要的暴露源.这一研究结果也被Ce㊅sen等[26]的研究结果证实.Ce㊅sen研究分析了36个产自欧洲和非洲国家蜂蜜中BPS及其它双酚类(Biphenols,BPs)化合物浓度,结果表明蜂蜜中BPS的浓度最高可以达到320ng㊃g-1,但作者也指出BPS及其他BPs化合物浓度的高低主要取决于蜂蜜的产地或来源,而非包装材料.除了包装材料及食品中存在的BPS可造成人体的经口暴露外,一些研究也表明室内灰尘也是造成BPS呼吸或经口暴露的一个主要途径[27⁃28].例如Liao等[27]对不同国家室内(办公室㊁居所和实验室)灰尘中包括BPS在内的BPA及多种替代品的浓度进行了检测,结果表明BPS是灰尘中检出率和检出浓度最高的3种BPs化合物之一,并估算了美国㊁中国㊁日本和韩国成年人和幼儿通过灰尘遭受BPs化合物的总暴露水平.总体上幼儿暴露水平高于成年人,而中国人暴露水平依次低于美国㊁日本和韩国,幼儿和成人的每日暴露水平分别为4.61ng㊃kg-1bw㊃d-1和0.78ng㊃kg-1bw㊃d-1.尽管研究者普遍认为室内灰尘中BPS是人体BPS的主要暴露源和途径,但不同国家㊁甚至相同国家室内灰尘中BPS的浓度差异很大,表1中列举了不同国家或同一国家灰尘中BPS的浓度[27⁃29].表1㊀不同国家灰尘中BPS浓度及成人暴露量估算值Table1㊀BPSconcentrationsinindoordustandtheestimateddailyintake(EDI)ofhumansindifferentcounties国家CountryBPS浓度均值AverageconcentrationofBPS/(ng㊃g-1)每日暴露水平估算值aDailyexposurelevel/(ng㊃kg-1bw㊃d-1)年份Year参考文献Reference中国1700.78(0.12)2010[27]<2.00.0012012 2014[28]美国6301.72(0.42)2006,2010[27]<2.00.0012012 2014[28]日本8102.65(0.56)2012[27]1600.082012 2014[28]韩国3603.13(0.25)2012[27]3.60.0022012 2014[28]越南<2.00.0012012 2014[28]希腊8600.342012 2014[28]印度4.20.0022012 2014[28]科威特200.012012 2014[28]哥伦比亚2.40.0012012 2014[28]巴基斯坦1.80.0012012 2014[28]罗马尼亚820.032012 2014[28]沙特阿拉伯280.012012 2014[28]㊀㊀注:a.BPs的EDI,括号中为依据原文献灰尘中BPS浓度计算的BPS的EDI值.a.EDIforBPs,andthevalueinbracketwastheestimatedEDIaccordingtothereference.相比于经口暴露,BPS的经皮暴露或接触性暴露主要来源于一些生活用品中的BPS.例如BPS是多种纸制品的添加剂.这些纸制品包括日常生活中容易接触的打印纸和热敏纸.而热敏纸经回收利用后主要用于广告纸㊁信封㊁包装纸㊁车票和报纸等的生产[30].因此接触纸制品也是人体BPS暴露的一个重要h j h x .r c e e s .a c .c n 204㊀环㊀㊀境㊀㊀化㊀㊀学37卷途径,而纸产品中的BPS是人体的一个重要暴露源.2012年Liao[30]等对16种纸和纸产品进行BPS含量分析.结果表明,所有类型的纸制品中均有BPS的检出,但不同类型纸产品中BPS的浓度不同,其中热敏纸中BPS的检出率为100%,浓度范围为1.38ˑ10-5mg㊃g-1至22.0mg㊃g-1,几何均值最大,可以达到0.181mg㊃g-1.因此,热敏纸是人体BPS的主要暴露源或途径.根据这些研究结果,研究者估算了普通人群和职业人群通过纸制产品接触,造成的BPS平均每日暴露量(EDI)分别为4.18ng㊃kg-1bw㊃d-1和312ng㊃kg-1bw㊃d-1.㊀2.2㊀人体早期BPS暴露途径㊁暴露量及研究进展BPS对活体动物早期暴露后产生的繁殖和神经内分泌系统发育毒性[20⁃21],即其具有的雌激素干扰作用,使人体早期BPS暴露途径及其毒理学相关性评价成为近年来研究的焦点和热点.受斑马鱼活体暴露毒性研究的影响,人体早期BPS暴露途径的研究主要集中在母体内胎儿的暴露途径㊁暴露量和暴露毒性的研究.当前,研究者一致认为,孕期女性经口或经皮暴露BPS后,母体内的BPS会通过脐带血对胎儿造成BPS或其代谢物暴露.如前所述,BPS和BPA通过各种暴露途径进入人体后,主要通过血液或尿液进行代谢.而为了防止采血器具可能引入的BPS等同类化合物的干扰,研究者多通过调查和测试孕期女性尿液中BPs化合物浓度,评价和估算胎儿在母体内BPS的暴露水平㊁并进一步开展早期BPs化合物暴露量及毒性的相关性研究.例如已有研究者调查和报道了孕期女性尿液中BPA的浓度,并研究了BPA暴露量或暴露水平与儿童早期发育障碍(如儿童好动㊁焦虑和压抑等心理内化问题)的相关性.但与BPA相比,至今尚无以母体尿液中BPS浓度评价胎儿在母体内BPS早期暴露量或水平的报道,更没有关于人体BPS早期暴露毒性的研究报道.仅有Liu等(2017年)刚发表的关于母体血液和脐带血中BPS的研究[31].该研究首次同时分析了孕妇血液和脐带血中的BPS的浓度.该研究结果表明,尽管母体血液和脐带血中BPS浓度较低,但研究区域脐带血中BPS的检出率比母体血液中BPS的检出率高.这一研究结果也证实了,母体血液中的BPS可以越过胎盘的保护,造成胎儿BPS暴露,脐带血是胎儿BPS潜在暴露途径[31].遗憾的是由于脐带血中BPS检出率和检出浓度较低,研究者只测试了BPS总量(BPS自由体和其它代谢物浓度总和),无法从统计学上估算和评价研究区域胎儿早期BPS暴露水平和暴露量,更无法明确血液等样品中BPS的主要存在形态和暴露形式.除了采用脐带血开展人体胎儿期BPS暴露研究,也有人尝试使用母乳为介质,通过测试其BPS的浓度评价婴幼儿母乳喂养阶段BPS的暴露量.例如,Deceuninck等[32]建立了母乳中BPS总量和其他BPS等的分析测试方法,并对30个母乳样品中BPS进行了分析.尽管仅有一个样品中有BPS检出,但BPS的检出浓度达到了μg㊃kg-1水平.由于检出率太低,研究者无法对研究区域婴幼儿BPS暴露量和BPS主要暴露形态进行评价.近期,Xue等[33]报道了77种婴幼儿纺织品和服装中BPS等BPS化合物的含量,并估算了婴幼儿BPS的皮肤接触性暴露水平.结果表明:BPS的检出率和检出浓度均仅次于BPA,检出率为53%,检出浓度均值为15ng㊃g-1;婴幼儿年龄越小BPS的暴露量越大:即1 3个月,3 6个月和6 12月大的婴幼儿BPS的皮肤接触每日暴露量分别是9.38㊁8.61㊁8.20pg㊃kg-1bw㊃d-1.2.3㊀不同国家人体BPS暴露量及差异如上所述,BPS的暴露途径和暴露源很多,也比较复杂,许多研究者已经估算和评价了不同暴露源或暴露途径造成的人体暴露量.研究者也通过BPS进入一些动物和人体后的代谢特征表明,BPS经口等暴露后主要通过尿液和血液代谢,并通过尿液排出体外.因此关于人体BPS的暴露总量的研究主要是通过尿液和血液中BPS浓度进行评价.当前,人体BPS暴露总量的研究主要集中在美国和亚洲,以及少量的欧洲和中东国家[29].例如Liao等[27]研究调查和报道了美国和7个亚洲国家成人尿液中BPS等BPS化合物的浓度,估算和比较了不同国家人体BPS的暴露量和水平.该研究结果表明,日本和美国人尿液中BPS的检出率和暴露量显著高于中国和其它亚洲国家,其主要原因是日本和美国比中国较早地使用BPS.如图1依据Liao的研究结果[27]给出了日本㊁美国和中国使用BPS(或BPS替代BPA)的时间,以及人体尿液中BPS的检出率和浓度水平,并表明了两者之间的负相关性.此外,该研究还分析了年龄和性别对尿液中BPS浓度的影响,并通过对同一国家的样本分析结果证实性别与尿液中BPS浓度不具有普遍相关性,但年龄与尿液中BPSh j h x .r c e e s .a c .c n㊀2期宋淑玲等:双酚S毒理学㊁人体暴露水平与健康效应研究进展205㊀的浓度有一定的相关性.例如,低年龄段人群,特别是青少年和年轻人其饮食和生活习惯造成BPS的多种途径和高暴露量,所以其尿液中BPS偏高.此外,也有研究人员长期监测和调查了一个国家人体尿液中BPS浓度,评价该国人体BPS暴露水平及发展趋势.例如Ye等[34]报道了2004 2014年内美国人尿液中BPS和BPA等BPS浓度及其变化趋势.结果表明:尽管美国人尿液中BPA在研究期间检出率和检出浓度最高,但随着时间的推移,成人尿液中BPS的浓度具有明显的上升趋势.作者的研究结果证实了Liao[27]等的结论,并推断,伴随着BPA的禁用,BPS将逐渐取代BPA成为检出率最高的BPS化合物,并且其浓度会进一步升高.图1㊀不同国家BPA限用时间及人体尿液中BPS检出浓度负相关性图Fig.1㊀NegativecorrelationbetweentheBPSconcentrationinhumanurineandthebannedtimeofBPAindifferentcounties3㊀BPS毒理学研究的新需求和发展方向(TheresearchneedandfuturedevelopmentonBPStoxicology)3.1㊀选择良好的评价介质,推进人体BPS早期暴露水平和暴露毒性研究研究表明,BPS暴露影响斑马鱼内分泌㊁繁殖和早期神经内分泌系统发育[20⁃21].那么,人体早期BPS的暴露是否对儿童发育也有相同的毒害作用?因此,妊娠期胎儿BPS暴露水平已经引起研究者的关注,而选择良好的生物介质是胎儿BPS早期暴露水平㊁暴露毒性及毒理学研究的关键.如前所述,BPS与BPA经口暴露后,自由态和结合态代谢产物可快速进入血液和尿液[35⁃36].但为了防止血液取样器具等引起的BPA污染[37],许多研究以孕期女性尿液为评价介质[38-41],开展了胎儿BPA暴露量(水平)的调查,并延伸研究了这种暴露水平与儿童早期发育的暴露毒性,研究结果表明胎儿时期BPA的暴露总量与儿童焦虑症㊁多动症和抑郁问题具有典型相关性,且这种暴露毒性可能存在性别选择性.相比BPA,BPS此类的研究才刚刚起步,目前处于BPS早期暴露水平的调查阶段,尚未进入BPS早期暴露毒性的研究阶段.例如只有极少数的研究采用脐带血为介质开展了胎儿BPS的暴露途径和潜在暴露风险的研究[31],鲜有以母体孕期尿液中BPS浓度,评价胎儿BPS暴露量,尤其是儿童后期行为和控制能力与早期暴露相关性的研究.我们认为其主要原因是当前尿液和血液中BPS浓度和检出率偏低,以尿液和血液(或脐带血)为介质开展胎儿BPS暴露量和暴露毒性研究存在一定困难.在当前这种情况下,需要选择良好的评价介质,尽快推进胎儿BPS暴露量和水平的调查,为进一步开展BPS早期暴露毒性评价提供技术手段和基础数据.因此,一方面,研究者可尝试以灰尘这种BPS检出率高的介质,或孕期母体BPS饮食暴露量,采用母体间接暴露量来评价胎儿的BPS暴露水平;另一方面,随着BPS使用时间增长㊁使用量不断增大,研究者会加快以尿液为介质开展胎儿BPS暴露量和暴露毒性的研究.3.2㊀加强生物介质中不同形态BPS分析技术研究和标准品的研制研究表明,BPS与BPA相同,通过各种途径进入人体后主要以自由态和结合态存在.BPA代谢后主要产物有BPA-葡糖苷酸(BPA结合态的降解物,缩写成BPAG)和BPA-硫酸盐(BPA结合态的降解物,缩写成BPAS).目前,研究不同生物介质中BPA及降解产物时,大多数研究者可以通过标准品实现自由态BPA㊁BPAG和BPAS的准确定性和定量.但对于BPS,研究者可以肯定的是BPS进入人体后也主要以自由态h j h x .r c e e s .a c .c n 206㊀环㊀㊀境㊀㊀化㊀㊀学37卷和各种结合态存在,但具体的结合态存在形式还未明确.因此,BPS的代谢物或各种结合态的标准品也未有研究报道.由于缺少BPS降解物的标准品,以及介质中自由态BPS浓度低㊁超出方法检出限[31,42]等原因,以往尿液㊁血液㊁母乳㊁食品和灰尘等各种介质中只报道BPS总量,没有自由态BPS和不同结合态BPS浓度的研究结果.表2给出已有文献报道的不同介质中BPS和BPA分析技术及检出限(Limitofdetection,LOD).表2㊀不同基质中BPS及BPA检出限及检出浓度(ng㊃mL-1)Table2㊀LimitofdetectionanddetectedconcentrationforBPSandBPAindifferentmatrix(ng㊃mL-1)化合物Coumpound尿液或血液Urineorserum母乳Breastmilk检出限LOD/(ng㊃mL-1)检出浓度Concentration/(ng㊃mL-1)检出限LOD/(ng㊃mL-1)检出浓度Concentration/(ng㊃mL-1)BPA0.101.100.301.02(均值)aBPS0.020.230.0010.20 0.30b㊀㊀注:a.依据文献数据计算的均值;b.推测值.a.averagevalueofreference;b.anestimatedvalue.由此可见,未来BPS毒理学和人体暴露水平及毒性研究中一个重要内容是揭示BPS进入人体后,不同代谢途径中BPS代谢产物的结构,开展不同结合态BPS标准品的研制,以及不同形态BPS高灵敏度分析方法的研究.3.3㊀积极开展不同形态BPS的暴露量㊁暴露时间及人体暴露毒性调查和评价研究已有关于BPS分子水平㊁细胞水平和动物水平的毒理学研究,均是以自由态BPS暴露浓度评价BPS的暴露毒性,研究结果也表明自由态的BPS毒性或内激素破坏活性最高.但当前BPS暴露量的评价均是以BPS总量为依据.因此,笔者认为BPS的暴露形态和暴露时间将是人体早期暴露评价中不容忽视的要素.Gauderat等[43]最新关于动物BPA胎期暴露研究结果也强调了这一点.近期Gauderat等[43]在胎羊BPA早期暴露毒性研究中发现,一些研究普遍认为没有毒性作用的BPA⁃葡糖苷酸(BPA结合态的降解物,缩写成BPAG)[42]与自由态BPA可发生循环转化,早期解离成自由态BPA,并保持长期的低剂量水平,从而造成胎羊低剂量自由态BPA的长期暴露.因此,研究者认为BPAG浓度是胎儿BPA暴露量或毒性的决定因素,同时指出应该关注低剂量自由态BPA暴露的时间效应.而当前人体BPS的暴露水平[27⁃28,42]或暴露毒性[44]的研究均是以BPS总浓度为评价指标,鲜有关于人体不同形态BPS暴露量(水平)㊁暴露时间及相关毒理学的研究及结论.那么,BPS是否与BPA具有相似的毒性表现特征,即自由态BPS及其代谢物在人体中如何相互转换,这种转换对暴露量和暴露毒性有怎样的影响,BPS的哪种存在形式是暴露量或暴露毒性的决定因素,这些将是未来BPS暴露毒性研究必须要回答和解决的问题.因此,基于目前人体BPA早期暴露毒性评价的认识现状,以及自由态BPS在动物[20⁃21]和细胞等水平[12,15,18⁃19,45]表现出的雌激素和神经内分泌系统干扰作用,我们相信,识别评价介质中的BPS暴露形态㊁暴露量和暴露时间,在人体早期BPS暴露水平及下一步的毒性评价中都具有重要意义,而某种存在形态的BPS可能正是毒性评价中的决定因素.4㊀结论与展望(Conclusionandperspectives)综上所述,随着BPA对动物体雌激素干扰作用的发现和证实,BPS作为BPA的主要替代品在全球广泛应用,而研究者也针对BPS开展了多种暴露毒性㊁暴露水平和暴露途径的调查或研究.本文总结了近年来研究者对BPS在分子水平㊁细胞水平和活体动物暴露毒性的研究进展,已有的研究普遍表明BPS与BPA相似,在动物早期暴露后会产生雌激素干扰作用和神经内分泌系统发育毒性,但就人体早期的暴露毒性尚无明确的结论.进而介绍了人体BPS暴露的主要途径,以及研究者通过各种评价介质开展不同国家人体BPS暴露量的调查和研究结果.这些结果证明当前人体BPS暴露水平普遍较低,但有逐渐增强的趋势.基于目前BPS暴露毒性㊁人体暴露途径和暴露量的研究结果,认为未来BPS毒理学和人体暴露毒性研究有3个新发展方向:选择良好的评价介质,开展不同人群BPS,特别是胎儿和婴幼儿BPS暴露量的评价研究;加强不同形态BPS标准品和分析方法研究,实现自由态BPS及主要代谢物的准确定性和。

关键价值

Primeton BPS®是业界第一个完全基于业务化思想实现的流程平台产品,不仅提供了高性能、高可用和可扩展的流程引擎,以

支撑各种复杂的流程模式及人工活动的处理,而且具有卓越的面向业务的流程建模能力和流程即时调整能力,支撑业务分析人员

基于Web的方式以完全业务化、零编码的手段进行流程的建模与调整,从而快捷实现业务流程并敏捷响应业务流程变化。

Primeton BPS ®经过了大量电信、银行等大型客户的案例验证。

高性能和高扩展性

流程业务化配置与调整

富有中国流程管理特色的流程平台

很强的环境融合与系统集成能力

业务流程敏捷响应

– 更好支持中国特色流程模式与业务场景。

– 基于SOA和S-EDA构建的核心引擎,提供超高并发、高可用的支撑能力。

– 以“业务与技术一体化”的方式实现业务流程建模、流程表单及规则业务化调整,缩短流程新建和变化的周期。

– 基于BPS内置的复杂流程模式和业务场景的支持能力、Web服务集成能力,降低应用开发工作量。

– 安徽电信服务保障项目中,最高同时在线人数达3000人,按照统计,流程调整的速度大幅提升,从原来1~3个月上线一个流程到现在的一周左右,

并且绝大部分是用户自己就可以调整和增加。

– 实现业务流程、业务活动的可视化监控和审计,持续评估与优化流程。

本地化专业服务

– 普元作为本地厂商,通过专业化的服务团队和服务保障体系,可以提供应用开发与实施全程的本地化快捷服务支持,保障客户项目成功实施。

– 经过同行案例的证明,可以支持金融、电信、大型企业等核心系统的流程实现。

高性能的企业应用

– 陕西移动服务开通项目中,每分钟处理6500笔完整开通业务同时,响应时间平均仅为0.010秒,每天完成近200万笔业务流程。

– 中国联通全国大集中的财务报账平台,系统集中建设分省实施,满足各省个性化的流程需求,系统已经上线26个省,用户数25万,目前有10个省全

面应用,平均每天处理约10万审批单。

– 广东移动EOMS项目中,用户数3000~4000人,最高同时在线人数达1300人,日均流程处理量达1万笔以上,99%的流程响应时间不超过2秒。

国内部分金融客户

中国人民银行 中国建设银行 中国银行 中国交通银行 中国农业银行 中国邮政储蓄银行 宁波银行

上海银行 中国银联 厦门银行 长沙银行 中国证券登记结算公司上海分公司/深圳分公司