球阀使用说明书英文版(ball valve)

- 格式:doc

- 大小:102.50 KB

- 文档页数:5

球阀使用说明书 Q41F 浮动式球阀球 阀 (Ball Valve)球阀是由旋塞演变而来的,它的启闭件为一个球体,利用球体绕阀杆的轴线旋转90度实现开启和关闭的目的。

球阀在管道上主要用于切断、分配和改变介质流动方向,设计成V 形开口的球阀还具有良好的流量调节功能。

球阀不仅结构简单,密封性好,而且在一定的公称通径范围内体积较、重量轻、材料耗阀门品种之一。

特别是在美、日、德、法、意、西、英等工业发达国家,球阀的使用非常广泛,使用品种和数量仍在继续扩大,并向高温、高压、大口径、高密封性、长寿命、优良的调节性能以及一阀多功能方向发展,其可靠性及其他性能指标均达到较高水平,并已部分取代闸阀、截止阀、节流阀。

随着球阀的技术进步,在可以预见的短时间内,特别是在石油天然气管线上、炼油裂解装置上以及核工业上将有更广泛的应用。

此外,在其他工业中的大中型口径、中低压力领域,球阀也将会成为主导的阀门类型之一。

球阀结构爆炸图序号名称数量1 阀盖 12 密封垫 13 四氟密封圈 24 螺帽 45 螺栓 46 球 17 阀体 18 内六角螺丝 29 四氟填料 410 压盖 111 阀杆 112 四氟圈(阀杆密封) 1另有定位片、手柄、蜗轮、电动头(视工况而定)球阀的优点是:(1) 具有最低的流阻(实际上为零)。

(2) 因在工作时不会卡住(在无润滑剂时),故能可靠地应用于腐蚀性介质和低沸点液体中。

(3) 在较大的压力和温度范围内,能实现完全密封。

(4) 可实现快速启闭,某些结构的启闭时间仅为0.05~0.1s,以保证能用于试验台的自动化系统中。

快速启闭阀门时,操作无冲击。

(5) 球形关闭件能在边界位置上自动定位。

(6) 工作介质在双面上密封可靠。

(7) 在全开和全闭时,球体和阀座的密封面与介质隔离,因此高速通过阀门的介质不会引起密封面的侵蚀。

(8) 结构紧凑、重量轻,可以认为它是用于低温介质系统的最合理的阀门结构。

(9) 阀体对称,尤其是焊接阀体结构,能很好地承受来自管道的应力。

SUNGO V ALVES GROUP CO.,LTD管线阀门PIPELINE V ALVE浮动球阀使用说明书FLOATING BALL VALVE OPERATING INSTRUCTIONS管线浮动球阀使用说明书 Pipeline Floating Ball Valve OperatingInstruction1、用途和性能规范:Purpose and Specification本产品是我公司按API 6D/API 608设计、制造的钢制管线浮动球阀,适用于液体、气体等介质,在管路上作启闭装置,具有密封结构可靠、先进,流阻小,启闭迅速、灵活,使用寿命长,安全可靠,维修方便等优点,可广泛的用于石油、化工、炼制、钢铁、造纸、医药等行业。

This products is our company according to the API 6D/API 608 designs and manufactures of steel pipeline floating ball valve, It is used for liquid,gas etc tubing line open or main advantages include: Reliable sealing structure、Thechnology advanced、Small liquid resistance、Flexible open and close、Long service life、Safe reliabe、Convienient maintance etc. This kind of ball valve is widely utilized in Petroleum、Chemical industry、refinement、Steel and iron、papermaking, medicine etc.产品性能规范表Performance Specification2、采用的主要标准:The main adoption standard设计制造与结构长度按API 6D/API 608的规定;Design conform to API 6D/API 608法兰型式及尺寸按ASME 的规定;Flange conform to ASME结构长度按ASME 的规定;Face to face conform to ASME阀门的温度-压力额定值按ASME 的规定;Temperature-class conform to ASME检验和试验按API 6D的规定;Test conform to API 6D防火标准按API 607/6FA的规定。

A S P E C I A L I S T I N D E S I G N&M A N U F A C T U R E O F V A L V E S目录目录 (1)Preface 前言 (2)Product Features产品特点 (3)Applicable Standards 设计规范 (4)Installation,Operation and Maintenance Instructions for V-Port Segment Control Valve – JSB Series 安装,操作和维护说明 (6)Storage 保存 (6)Preparation and preservation for storage保存的准备及维护 (6)Handling requirements处理要求 (6)Storage and preservation before installation组装前的保存及维护 (8)Installation 安装 (10)Preparation before installation安装之前的准备工作 (10)Installation Instructions安装操作 (11)Maintaince 维护 (14)Disassembly & Assembly拆卸和组装 (15)Valve disassembly阀的拆御 (16)Valve re-assembly重新组装阀 (17)A S P E C I A L I S T I N D E S I G N&M A N U F A C T U R E O F V A L V E SPreface 前言1. Please read this manual before installation or servicing.请在安装和维修阀门前阅读此操作手册2. Before installing or servicing, please ensure the line pressure has been relieved and anyhazardous fluid has been drained or purged from the system.请在安装和维修前,确保管道压力已经泄放,同时危险的流体已经排放掉。

Ball valves球阀使用说明书Ball Valve Operating Manual)浙江石化阀门有限公司Zhejiang Petrochemical Valve Co., Ltd.二O一一年 Year 2011、一用途Application球阀是一种管线阀门产品,用于接通或截断管路中的介质。

一般是处于全开或全关状态,在微开状态下可作流量的调节使用。

广泛适用于工况条件下水、气、油品等介质的各种管路中。

Ball valve is pipeline valve, used for connecting or cutting off medium in the pipelines. Normally it is at the state of opening or closing. And it couldfunction as regulating the flow when it is at the state of slightly open. It isused on the pipeline such as water, gas, oil etc.二性能规范 Performance Specification压力等级: Class150; Class300; Class600;Pressure: Class150; Class300; Class600;公称尺寸:NPS 2 ~NPS24;Nominal Size: NPS 2 ~NPS24、阀体材料: ASTM A216 WCB; ASTM A351 CF8;Body Material:ASTM A216 WCB;ASTM A351 CF8;产品的设计、制造按API6D的规定;检查试验按API6D的规定;法兰连接尺寸按 ASME 的规定;结构长度按API6D的规定;Designed and manufactured according to API6D; Inspected and tested accordingto API6D;Flange ends according to ASME ; Face to face according to API 6D适用介质:水、蒸汽、油品等。

Swagelok® Alternative Fuel Ser vice (AFS) Ball ValvesFor High-Pressure, High-Flow ApplicationsSwagelok AFS Ball Valves■ Working pressures up to 6000 psig (413 bar)■ Flow coefficients (C v) from 4.0 to 13.8■ Fractional and metric Swagelok tube fittings; ISO and NPT pipe end connections available■ 316 stainless steel body and end connections■ Manual and pneumatic actuation2 Swagelok Alternative Fuel Service (AFS) Ball ValvesCertifications■ ANSI / AGA NGV 3.1 / CGA 12.3-M95,Classification: Manual valve Pressure: 4500 psig (310 bar)Temperature: –40 to 250°F (–40 to 121°C)■ ANSI / IAS NGV 4.6 / CSA 12.56-M99,Classification: Class APressure: 4500 psig (310 bar)Temperature: –40 to 185°F (–40 to 85°C)■ ECE R110 Manual Service Valve Type ApprovalClassification: Class 0Pressure: 3770 psig (260 bar)Temperature: –40 to 248°F (–40 to 120°C)■ Certifications do not include attachments to the valve,such as actuators or a different handle mechanism.Features■ High flow—C v from 4.0 to 13.8■ All wetted components arecompatible with hydrogen andcompressed natural gas (CNG)■ Maximum pressure rating: 6000 psig(413 bar)■ Temperature rating: –40 to 250°F(–40 to 121°C)■ Low operating torque■ No packing adjustment required ■ Field repairable with seal kitSwagelok Alternative Fuel Service (AFS) Ball ValvesImportant InformationAbout Swagelok AFS Ball ValvesSwagelok AFS ball valves are designed to be used inthe fully open or fully closed position.Valves that have not been cycled for a period of timemay have a higher initial actuation torque.Pressure-Temperature RatingsRatings are based on ASME Code for Pressure Piping B31.3, Process Piping. To determine working pressure ratings in accordance with ASME B31.1, Power Piping, for 316 stainless steel, multiply pressure by:■ 0.86 for temperatures from 100 to 200°F (37 to 93°C).■ 0.82 for temperatures up to 250°F (121°C).consistent, low actuation torquechemical compatibilitypressure systemsSwagelok Alternative Fuel Service (AFS) Ball Valves 3USAUSAEUROFlow Data at 70°F (20°C)NitrogenFlow,stdL/minNitrogenFlow,stdft3/minPressure Drop, psiPressure Drop, barInlet Pressure 3600 psig (248 bar)Inlet Pressure 5000 psig (344 bar)NitrogenFlow,stdL/minNitrogenFlow,stdft3/minPressure Drop, psiPressure Drop, barMaterials of ConstructionWetted components listed in italics.412510113131418678919121615174 Swagelok Alternative Fuel Service (AFS) Ball ValvesOrdering Information and DimensionsSelect an ordering number.Dimensions, in inches (millimeters), are for reference only and are subject to change.➀ V alves can be ordered with two different end connections. Contact your authorized Swagelok sales and service representative.➁ N ot available with AGA, IAS, and ECE R110 certifications; not recommended for panel mounting; not available with pneumatic actuator.➂ T hread type ISO/BSP (tapered), based on DIN 3852, Swagelok RT fittings.See specifications ISO 7/1, BS EN ISO 10226-1, and JIS B0203.Options and AccessoriesLocking Brackets■ Designed to lock valve in the openand closed position■ Accommodates shackle diametersup to 0.344 in. (8.7 mm)■ To order the locking bracket factory-assembled on a valve, add -LH to the valve ordering number.Example: SS-AFSS6-LHTo order the locking bracket for fieldassembly, use kit ordering number: SS-51K-AFS-LHHandle OptionsBlack nylon directional handles are standard.■ To order adirectional handle ofanother color,add a handleto the valve ordering number.Example: SS-AFSS6-RD■ To order a nylon ovalhandle, add -K to the valve ordering number.Example: SS-AFSS6-K ■ To order a black aluminumdirectional handle, add -AHD to the valve ordering number.Example: SS-AFSS6-AHDHandle KitsThe replacement handle kit includes a handle with set screw and instructions.■ Black nylon directional handle kitordering number: NY-5K-AFS-BKTo order a nylon directional handle kitin a color other than black, replace -BK in the kit ordering number with a handle color designator.Example: NY-5K-AFS -RD ■ Nylon oval handle kit orderingnumber: NY-5K-AFSK-BK■ Black aluminum directional handle kitordering number: A-5K-AFS-BKStem Seal Material OptionUltralow-temperature fluorocarbon FKM is standard. Ultralow-temperature nitrile (Buna C) is available as an option to enhance valve cycle life. Valves with ultralow-temperature nitrile have atemperature rating of –40 to 200°F (–40 to 93°C) and are not certified to AGA, IAS, or ECE R110.To order, add -BCS to the valve ordering number.Example. SS-AFSS6-BCSSwagelok Alternative Fuel Service (AFS) Ball Valves 5SwagelokPneumatic ActuatorsThe Swagelok rack and pinion pneumatic actuator is compact,lightweight, easily mountable, and can be operated with standard shop air. The actuators are available in spring-return and double-acting modes. For technical data, including materials of construction, air displacement, and weight, see the Swagelok Ball Valve Actuation Options catalog, MS-02-343.DimensionsDimensions, in inches (millimeters), are for reference only and are subject to change.Actuated assemblies mustbe properly aligned andsupported. Improper alignment or inadequate support of the actuated assembly may result in shorter valve life.Actuator Pressure at Maximum System PressureRequired pressures based on valve performance using pressurized air or nitrogen.For dual-mounted assemblies (two valves mounted to one actuator), add DM to the ordering number. Example: SS-AFSS6-33DHT DMActuator Service Ratings➀ M aximum working pressure for valves mounted to low-temperature service actuators is4500 psig (310 bar).Factory-Assembled ActuatorsTypical Ordering NumberD = Double actingC = Normally closed spring return O = Normally open spring returnD H TActuator Service N one = StandardHT = High temperature LT = Low temperature ➀➀ M aximum working pressurefor valves mounted to low-temperature service actuators is 4500 psig (310 bar).Ordering InformationActuators for Field AssemblyOrder one actuator kit and one mounting bracket kit for each valve.Mounting bracket kit ordering number:MS-MB-AFS-133➀ M aximum working pressure for valves mounted to low-temperature service actuators is 4500 psig (310 bar).6 Swagelok Alternative Fuel Service (AFS) Ball ValvesISO 5211-Compliant Pneumatic ActuatorsSwagelok ISO 5211-compliant rack and pinion pneumatic actuators are available in spring-return and double-acting modes.For technical data, including actuator materials of construction and weight, see the Swagelok Ball Valve Actuation Options catalog, MS-02-343.For additional information on selecting and sizing ISO 5211-compliantactuators, see the Actuated Ball Valve Selection Guide—ISO 5211-Compliant Actuator Mounting Bracket Kits, MS-02-136.Factory-Assembled ActuatorsTypical Ordering NumberD = Double actingC4 = Normally closed spring return O4 = Normally open spring returnD H TActuator Service N one = StandardHT = High temperatureActuated assemblies mustbe properly aligned andsupported. Improper alignment or inadequate support of the actuated assembly may result in shorter valve life.Ordering InformationActuators for Field AssemblyOrder one actuator kit and one mounting bracket kit for each valve.Mounting bracket kit ordering number:SS-MB-AFS-F05-14DIN-MActuator Service RatingsDimensionsDimensions, in inches (millimeters), are for reference only and are subject to change.Swagelok Alternative Fuel Service (AFS) Ball Valves 7Maintenance KitsKit components are of the same materials and grades listed in Materials of Construction, page 3.Seat Seal KitsThe seat seal kit contains two seats, seat O-rings, seatbackup rings, seat springs, end screw gaskets, lubricant with Material Safety Data Sheet (MSDS), and instructions.Kit ordering number: SS-9K-AFSStem and Seat Seal KitsThe stem and seat seal kit contains a stem O-ring, two guide rings, stem backup ring, thrust washer, packing bolt gasket, two seats, seat O-rings, seat backup rings, seat springs, end screw gaskets, lubricant with Material Safety Data Sheet (MSDS), and instructions.Kit ordering number: SS-91K-AFSTo order a kit with a stem O-ring of optional ultralow-temperature nitrile (Buna C) material, use kit ordering number: SS-91K-AFS-BCSOptions for ISO 5211-Compliant andSwagelok Pneumatic ActuatorsSwagelok offers a range of accessories to enhance instrumentation and process ball valve performance and control, including solenoid valves, limit switches, and position sensors. Factory assemblies and kits for field assembly are available.For more information, see the Swagelok Ball ValveActuation Options catalog, MS-02-343.Safe Product SelectionWhen selecting a product, the total system design must be considered to ensure safe, trouble-free performance. Function, material compatibility, adequate ratings,proper installation, operation, and maintenance are the responsibilities of the system designer and user.Warranty InformationSwagelok products are backed by The Swagelok Limited Lifetime Warranty. For a copy, visit or contact your authorized Swagelok representative.Swagelok—TM Swagelok Company © 2004–2014 Swagelok Company Printed in U.S.A., AGS November 2014, R11MS-02-303。

NAF-Trunnball ball valves Maintenance and installation instructionsList of spare parts Fi 41.66(2)GB08.09ContentsSAFETYGeneral 1 Lifting 2 Receiving inspection 3 Installation 4 Flange gaskets 5 Starting up 6 Ordering of spare parts 7 Maintenance 8 To remove the valve from the pipework 8.1 To inspect and replace the ball and seatrings 8.2 Valves with seatrings in PTFE 8.3 Valves with chromium-plated ball andseatrings in alloy 6 8.4 Valves with ball and seatring in alloy 6 8.5 To change the stem bearing and packing box type 8.6 PSDCL, i.e type 898_EF-XXXX-BABADATo change the upper stem sealing with o-rings 8.7 i.e. type 898_95-XXXX.To change the stem bearing and sealing i.e. type 8.8 898_95-XXXX.Mounting the actuator to the valve 8.9SAFETY- Assess all the risks to eliminate the risk of personal injury and material damage. Read these instructionsthoroughly!- Always use the necessary protective equipment and comply with applicable safety directives whenworking with hazardous or hot/cold medium.- Never operate a valve without fi rst ensuring that there is no risk of crush injuries. The risk is highest withautomatic valves.- Take necessary safety precautions to prevent unintentional manoeuvre - i.e to atmosphere.- Never dismantle a valve or part of a valve without ensuring that the line is free of pressure and anycontent.- Ball valves must always be dismantled in semi-open position to avoid trapping pressure and medium.- Always check that the valve type and material is suitable for its intended use. This applies especially to highly oxidising and corrosive medium. Observe also the risk of erosion and explosion as well as decaying medium. If in doubt, always request a writtenrecommendation from NAF AB.1. GeneralThis instruction is valid for NAF-Trunnball ball valves in accordance with catalogue sheet Fk 41.66 GB.2. LiftingAll lifting must be made inthe valve itself and not in theactuator. The joint betweenthe valve and the actuatoris designed principally forcarrying the operating torqueand the deadweight of theactuator (see Fig. 1).alve 3. Receiving inspectionAll valves leaving our works are inspected and testedin accordance with the relevant requirements or in accordance with the special conditions specifi ed by the customer. Valves equipped with actuators are subject to functional testing and are adjusted in such a manner that every unit is completely ready for direct installation inthe pipework. However, in view of damage that may have occurred during transport, it is advisable that receiving inspection is performed, if possible.We would suggest the following inspection procedure:- Check that the valve delivered is correct interms of type, size, equipment, etc.- Examine the valve, actuator and valve positioner regarding possible damages.4. InstallationBefore installing the valve, ensure that the pipework is free from impurities, that the pipe ends between which the valve is to be installed are parallel and are correctly aligned, and that the distance between the pipe ends corresponds to the valve length, including gaskets. The valve must not be used for drawing together or aligning incorrectly run pipes as this will cause needless loads on the valve and pipe which may lead to diffi cult damages during operation. See Fig. 2.Wrong installation Correct installation Fig. 2. Ensure that the pipe ends align and have thecorrect distanceNAF-Trunnball valves can be installed in any position and with optional fl ow direction.However, we recommend that, if installed in a horizontal run of pipe, the valve should be mounted with the stem pointing vertically upwards. If the valve is installed in a vertical run of pipe, the body half (2) according to fi g. 3 should be at the top to enable the ball and the seat ring to be replaced without the need for removing the valve from the pipework.The pipes should be supported on each side of the valve, in order to relieve the valve of loads and avoid vibrations.Locate the valve so that it will be easily accessible for inspection and service, particularly if the valve is equipped with an actuator and a valve positioner.5. Flange GasketsGaskets with sizes according to ANSI B16.5 1988, Table E1 Figure E2, SS 359 or DIN 2690 are recommended.6. Starting upBefore starting up, fl ush the pipework - with all valvesin the open position - so that any impurities that may damage the sealing surfaces of the valve and impede its operation will be fl ushed away.See also Fi 41.82 - Instruction Manual for NAF valve positioner giving useful hints for starting up. 7. List of Materials and Spare PartsItem No.Qty.Part Material 11Body EN 1.4408/CF8M21Body EN 1.4408/CF8M31Ball hard chrome EN 1.4408/CF8M/Hcr 42Seat ring Alloy 651Stem, assembly EN 1.446061Circlip Spring steel71Backing ring PTFE81Upper lid EN 1.443694Screw A4111Packing box PTFE/PTFE+25%C121Bushing PTFE+1.4401131Anti-friction washer EN 1.4436141Sealing ring PTFE1510Screw A4-801612Nut A4172Screw A4-80182Key A4191Ball EN 1.4408/CF8M201Ball Alloy 6212Seatring EN 1.4436/PTFE+25%C 221Bearing PTFE+1.4401232Trunnion plate EN 1.4470242Spring ASTM A316252Sealing ring PTFE+15%Graphite 261O-ring FPM281Spring ASTM A316291Supporting ring Spring steel301Washer A4311Supporting ring PTFE322O-ring EPDM332Bushing PTFE reinforced carbon 341Sliding washer PTFE reinforced carbon23127893456172223252415182813261211161424252342232343330296932312425252124430319Stem SealingAlloy 6PTFEType 898_EF-XXXX-BABADA Fig. 3NAF-Trunnball Spare partsStem sealings and seatrings versionswith o-rings type 898X9X-XXXX7. Ordering of Spare PartsWhen placing orders for spare parts, specify:1. Product code of the valve, incl. DN according toFk 41.66 and the manuf. No.specifi ed on theidentifi cation plate of the valve.2. Description of the part, item No and the quantityrequired - see table below.Ordering exampleFor NAF 8982EF-0200-BABADA, Manuf. No. 1234567Seat ring, item 4. Qty 2 pcs.Spare partsIten No Description Qty 150 200 250 300 400 450 500 600 7008006” 8” 10” 12” 16” 18” 20” 24” 28” 32”Stem sealing kit7 Supporting ring 1 pc X X X X X11 Packing box 1 pc X X X X X26 O-ring 1 pc X X X X X31 Supporting ring 1 pc X X X X X32 O-ring 2 pcs X X X x X33 Bushing 2 pcs X X X X X34 Sliding washer 1 pc X X X X X Spring kit28 Spring washer 4 pcs X X X X XMetaloplast bearing kit12 Metaloplast bearing 1 pc X X X X X22 Metaloplast bearing 2 pcs X X X X X X X X X X Bodyhalf sealing14 Bodyhalf sealing 1 pc X X X X X X X X X X Seatring4 Alloy 6 1 pc X X X X X X X X X X 20 PTFE 1 pc X X X X X X X X X X (2 pcs for each valve)Sealing behind the seatring25 Sealing 1 pc X X X X X X X X X X (2 pcs for each valve)Wave spring24 Wave spring 1 pc X X X X X X X X X X (2 pcs for each valve)Ball3 EN 1.4408 1 pc X X X X X X X X X X19 EN 1.4408/Hcr 1 pc X X X X X X X X X X20 Alloy 6 1 pc X X X X X X X X X X453. Shut off all compressed air connections and isolate all electrical connections to the actuator.4. Disconnect all compressed air lines and electric cables connected to the actuator.5. Loosen the fl ange joint between the valve and the pipework. Then lift out the valve. Don’t use the actuator for lifting. Apply all lifting forces tothe valve itself and not to the actuator - Fig. 1.N.B . In certain applications, the pipe can be discon- nected from one side of the valve, and the body half (2) - Fig. 3 - can be removed, without the need for removing the whole valve from the pipework.6. Mark the relative positions of the body halves by centre-punching before the dismounting, since the pattern of the holes drilled in the valvefl ange and pipe fl ange may vary.Fig. 4. Lifting the ball with the valve in closed posi- tion - here with the valve on a work bench. It can also be done with mounted actuator and the body (1) mounted in the pipework.8. MaintenanceMany valves are installed in such locations that their performance is of decisive importance to the entire process. Such valves should be inspected regularly and any faults should immediately be corrected.8.1 To remove the valve from the pipeworkNo special tools are needed for the inspection and maintenance.1. Ensure that the recommended spare parts and gaskets for the pipe fl anges are available.2. Close the valve. Before dismounting the valve, make certain that it is completely empty . Operate the valve several times between the open and closed positions to ensure that the space between the valve body and ball is not under pressure.Caution! The liquid in the valve may be harmful.8.2 To inspect and replace the ball and seatrings 1. The actuator does not need to be removed for replacing the seatring and ball.2. Operate the valve to make certain that it is completely empty . Close the valve.3. Remove the bodyhalf (2).4. Remove the ball and the trunnion plates - easy to do when the valve is in closed position.5. Remove the trunnion plates and the metaloplast bearing from the bearing journal of the ball.6. Carefully inspect the ball and the seatrings.7. Clean all parts carefully. First use hot water and then, if necessary, some degreasing compound. Do not scrape any machined surfaces with hard tools.8.3 Valves with seatrings in PTFE1. To ensure good tightness of the valve, change the seatrings, wave springs and sealings if they are worn or damaged.2. Mount the wave spring and sealing ring (pos 24 and 25) behind the seatring (pos 20).3. Inspect the ball. Minor damage to the sealing surface can be removed by polishing with fi ne emery cloth. If the ball has major damages, it must be replaced to ensure satisfactory tightness.4. Change sealing ring (14) between the two body- halves.5. Change the metaloplast bearing in the trunnion plates.6. Mount the bearing plates on the bearing journal of the ball.7. Coat the ball with Molycote U. If the valve is intended for service in an oxygen system, the ball can be coa- ted with silicone grease, which is approved for oxygen applications.8. Lubricate all stainless steel bolts with suitable grease, i.e. Crane Packings’s Thread-Grade or Gleitmo 600.9. Mount the ball and the bearing cage in the bodyhalf (1) and then the upper bodyhalf (2). Make sure that the centrepunch marks made according to section 8.1 item 6 are lined up. Tighten the bolted joint of the two bodyhalves alternately in several stages and tighten them fi nally as per the table below.10. Torque for tightning of the bolted joint:11.Operate the valve between closed and open positions.12. If possible, pressure test the valve with water to check its tightness - Fig. 5. Make sure that the c avities of the valve are properly fi lled with water before the pressure testing. The valve should be pressure tested as follows: Open valve: PN x 1,5Closed valve: Max dp x 1,1Bolt Torque NMBolt Torque NmM1276UNC 1/2”89M16187UNC 5/8”175M20364UNC 3/4”308M24629UNC 7/8”493UNC 1”73768.4 Valves with chromium-plated ball and seatrings in alloy 61. Check the sealing surfaces of the seatrings.A groove on the inside of the ring facilitates with- drawal. Minor damage to the rings can be polished with fi ne emery cloth. Check the rings on a face plate to ensure that they are perfectly fl at. Do not lap the rings and the chromium-plated ball together. Change the rings if they are severely damaged.2. Inspect the sealing surface of the ball. Minor damage may be polished with fi ne emery cloth. If the existing ball must be used for a furtherperiod of time, remove all sharp edges, dents and irregularities with a fi ne fi le or emery cloth. Check the circularity of the ball. The tolerance is 0.04 mm. If the ball is seriously damaged, it must be replaced.3. Mount the wave spring and the sealing ring (24 and 25) behind the seatring.4. Change the sealing ring (14) between the bodyhalves.5. Lubricate the ball with a suitable grease, such as Molykote U.6. Continue assembling the valve as described in section 8.3 item 8-12.Valve open Valve closedSealing fl angeWaterFig. 5. Pressure test of the valve with water8.6To change the stem bearing and sealing on valves with packing box type PSDCL (DN150-DN400) i.e. type 8982EF-XXXX-BABADA1. Dismount the actuator. Remove the screws that from the underside of the mounting plate of the valve keeps the actuator in place.2. Lift off the actuator from the valve. Remove the keys.3. Dismount thte valve according to section 8.2.4. Remove the circlip (6), loosen the screws (9) and remove the upper lid (8). Note! The upper lid is prespringloaded.5. Remove the springs (28).6. Press the stem down into the body and remove it.7. Pick up the anti-friction washer (13), supporting ring (7), o-ring (26) and packing box (11).8. Dismount the bushing (12) by pressing it into the body.9. Mount a new bushing (12) by pressing it up through the body.10. Lubricate a new packing box (11) with silicone grease before you press it down into the body. Note that the broadest of the 5 rings should be on top, see fi g 3 on page 3.11. Mount the stem by pressing if from the inside of the body and out.12. Mount the supporting ring (7) in the anti-friction washer (13), lubricate a new o-ring (26) with silicone grease and mount it in the anti-friction washer. Mount the anti-friction washer with the o-ring downwards against the valve.13. Mount the remaining parts in reverse order from item 5 to 1.8.5 Valves with ball and seatrings in alloy 6.1. The instructions for these valves are the same as those in section 8.4 above.2. If the sealing surfaces are damaged, we recom- mend that the valve is returned to NAF for repair. This applies especially if the ball must be ground before l apping. Assemble the valve before dispat- ching it to NAF.3. The ball and seat rings can be temporarily renova- ted by lapping them together. This can be done manually with a compound with grit size 200. Take great care to ensure that the ball and seat rings do not become oval.4. Balls in alloy 6 must be carefully cleaned andlubricated before they are mounted. Use a suitable solvent for cleaning. Then lubricate the ball with silicone grease, such as Molykote Dow Corning FS3452. The coat of grease must be very thin. Then polish the ball with chamois leather or apiece of soft cloth.WaterWat8.7 Change of the upper stem sealing with o-rings(DN450-DN800) i.e. type 898295-XXXXChange the upper o-ring (32) if the stem sealing is leaking. It is not necessary to remove the valve from the pipe-works. Change the complete stem bearing according to section 8.8 at the next service. Make sure that the valve is pressureless.1. Dismount the actuator. Remove the screws thatfrom the underside of the mountingplate of thevalve keeps the actuator in place.2. Lift off the actuator from the valve. Remove thekeys.3. Remove the circlip (6) and the supporting ring(29).4. Loosen the screws (9) and remove the washer(30) and the anti-friction washer in PTFE (31).5. Change the upper o-ring sealing (32). Lubricatethe new ring with silicone grease before it ismounted.6. Mount in reverse order.8.8 Replacement of stem bearing and sealing(DN450-DN800) i.e. type 898295-XXXX Dismount the valve from the pipeworks. Please note the instructions in sections 2 and 8.2 concerning lifting and emptying of the valve.1. Remove the actuator as described in section8.7, item 1 and 2.2. Remove the Circlip (6) and supporting ring (29).3. Loosen the screws (9) and remove the washer(30) and the anti-friction washer of PTFE (31).4. Dismount the valve according to section 8.2.5. Press the stem down into the body and removeit.6. Pick up the upper o-ring (32).7. Push up both the bearing bushings (33) and theintermediate o-ring (32).8. Mount new bushings and o-rings after they havebeen lubricated with Silicone grease. Changealso the sliding washer (34) on the stem.9. Mount the stem and the other parts in thereverse order.10. Mount the valve according to section 8.3.Before that consider to change the seatrings orlapping of the seatrings and ball.11. If possible, pressure test the valve and retightenthe bolts according to section 8.3.8.9Mounting the actuator to the valve1. Mount the actuator. The actuator may be mountedeither in line with the connected pipes or transversely to them. For mounting in line with the connectedpipes an intermediary plate is required2. Ensure that both the valve and the actuator are inthe closed position before mounting the actuator.The valve is in the closed position when thekeyway on the stem is in the direction of fl ow.(An actuator which uses compressed air to closethe valve and a return spring to open the valveshould be mounted with the actuator and valve in theopen position.)N.B. The direction of closure must always beclockwise, as viewed from the actuator.3. Before fi tting a new actuator, check that theactuator slides easily onto the stem when thekeys are not fi tted. Check also that the keys fi tfreely into the keyways in the hollow shaft of theactuator. Deburr if necessary. Lubricate the hollowshaft of the actuator and push it in over thethreaded sleeve. Mount the actuator onto the stem.Mount the bolts and nuts, and tighten them.4. Check the function and check that the end stopshave been correctly preset. If necessary, makeadjustments.If any accessories such as valve positioner orlimit switches should be mounted, please see thecorresponding manufacturer’s instructions forinstallation and adjustment.7NAF ABSE-581 87 Linköping Telephone +46 13 31 61 00Facsimile +46 13 13 60 54e-mail info@naf.seWebsite: www.naf.seISO 9001 Certifi edWe reserve the right to design modifi cationswithout prior notice8。

MSA, a. s. ASSEMBLY AND OPERATING Sheet No.: 1/23 DOLNÍ BENEŠOV INSTRUCTIONS Issue No.: 6Assembly and Operating Instructions组装和操作说明BALL VALVES球阀此文件是MSA 独有的知识产权,未经MSA技术部门经理同意禁止将此文件复印或提交给其他组织。

This document is an exclusive intellectual property of MSA, a.s. Dolni Benesov. Making copies of this document for other organizations, or submitting it to other organizations without consent of production technical director is forbidden.Manufacturer: MSA, a. s.Hlucinska41DolniBenesov74722CzechRepublic Division Name Date SignatureMade by: Ing. Jindrich GratzaPavel SchiedekDesigners5. 3. 2004Tested by: Ing. Jan KalabzaChief Designer 5. 3. 2004DOLNÍ BENEŠOV INSTRUCTIONS Issue No.: 6 Contents:内容1. 介绍Introduction (3)2. 储存Storage (3)3. 安装Installation (4)4. 操作Operation (6)5. 调试Adjustment (10)6. 故障诊断Trouble Shooting (11)7. 修理Repairs (13)Annexes:附件č. 1 球阀的操作Manipulation with Ball valve (BV) (15)č. 2 球阀型式BV Types (17)č. 3 球阀焊接的温度限制―管线Temperature Restriction for BV Welding – Pipeline (18)č. 4 球阀压力引出位置Position with Pressure Extraction (19)č. 5 球阀安装到管线上BV Installation into Pipeline (20)č. 6 球阀密封元件的更换Replacement of BV Sealing Elements (21)č. 7 球阀执行机构的更换Replacement of BV Actuator (22)DOLNÍ BENEŠOV INSTRUCTIONS Issue No.: 61. 介绍INTRODUCTION1.1 球阀是设计用以全关或全开两位式控制流经管线的介质流动的工业装置。

球阀使用说明书Q41F 浮动式球阀浙江福泰阀门有限公司球阀(Ball Valve)球阀是由旋塞演变而来的,它的启闭件为一个球体,利用球体绕阀杆的轴线旋转90度实现开启和关闭的目的。

球阀在管道上主要用于切断、分配和改变介质流动方向,设计成V 形开口的球阀还具有良好的流量调节功能。

球阀不仅结构简单,密封性好,而且在一定的公称通径范围内体积较、重量轻、材料耗阀门品种之一。

特别是在美、日、德、法、意、西、英等工业发达国家,球阀的使用非常广泛,使用品种和数量仍在继续扩大,并向高温、高压、大口径、高密封性、长寿命、优良的调节性能以及一阀多功能方向发展,其可靠性及其他性能指标均达到较高水平,并已部分取代闸阀、截止阀、节流阀。

随着球阀的技术进步,在可以预见的短时间内,特别是在石油天然气管线上、炼油裂解装置上以及核工业上将有更广泛的应用。

此外,在其他工业中的大中型口径、中低压力领域,球阀也将会成为主导的阀门类型之一。

球阀结构图球阀的优点是:(1)具有最低的流阻(实际上为零)。

(2)因在工作时不会卡住(在无润滑剂时),故能可靠地应用于腐蚀性介质和低沸点液体中。

(3)在较大的压力和温度范围内,能实现完全密封。

(4)可实现快速启闭,某些结构的启闭时间仅为0.05~0.1s,以保证能用于试验台的自动化系统中。

快速启闭阀门时,操作无冲击。

(5)球形关闭件能在边界位置上自动定位。

(6)工作介质在双面上密封可靠。

(7)在全开和全闭时,球体和阀座的密封面与介质隔离,因此高速通过阀门的介质不会引起密封面的侵蚀。

(8)结构紧凑、重量轻,可以认为它是用于低温介质系统的最合理的阀门结构。

(9)阀体对称,尤其是焊接阀体结构,能很好地承受来自管道的应力。

(10)关闭件能承受关闭时的高压差。

(11)全焊接阀体的球阀,可以直埋于地下,使阀门内件不受浸蚀,最高使用寿命可达30年,是石油、天然气管线最理想的阀门。

由于球阀的以上优点,所以适用范围很广,球阀可适用于:(1)公称通径从8mm到1200mm。

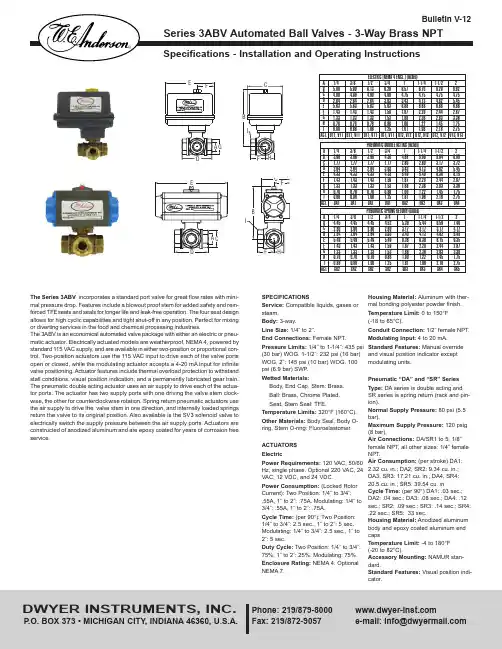

®The Series 3ABV incorporates a standard port valve for great flow rates with mini-mal pressure drop. Features include a blowout proof stem for added safety and rein-forced TFEseats and seals for longer life and leak-free operation. The four seat design allows for high cyclic capabilities and tight shut-off in any position. Perfect for mixing or diverting services in the food and chemical processing industries.The 3ABV is an economical automated valve package with either an electric or pneu-matic actuator. Electrically actuated models are weatherproof, NEMA 4, powered by standard 115 VAC supply, and are available in either two-position or proportional con-trol. Two-position actuators use the 115 VAC input to drive each of the valve ports open or closed, while the modulating actuator accepts a 4-20 mA input for infinite valve positioning. Actuator features include thermal overload protection to withstand stall conditions, visual position indication, and a permanently lubricated gear train.The pneumatic double acting actuator uses an air supply to drive each of the actua-tor ports. The actuator has two supply ports with one driving the valve stem clock-wise, the other for counterclockwise rotation. Spring return pneumatic actuators use the air supply to drive the valve stem in one direction, and internally loaded springs return the valve to its original position. Also available is the SV3 solenoid valve to electrically switch the supply pressure between the air supply ports. Actuators are constructed of anodized aluminum and are epoxy coated for years of corrosion free service.SPECIFICATIONSService:Compatible liquids, gases or steam.Body:3-way.Line Size:1/4˝ to 2˝.End Connections:Female NPT.Pressure Limits:1/4˝ to 1-1/4˝: 435 psi (30 bar) WOG, 1-1/2˝: 232 psi (16 bar)WOG, 2˝: 145 psi (10 bar) WOG. 100psi (6.9 bar) SWP .Wetted Materials:Body, End Cap, Stem: Brass.Ball: Brass, Chrome Plated.Seat, Stem Seal: TFE.Temperature Limits:320°F (160°C).Other Materials:Body Seal, Body O-ring, Stem O-ring: Fluoroelastomer.ACTUATORS ElectricPower Requirements: 120 VAC, 50/60Hz, single phase. Optional 220 VAC, 24VAC, 12 VDC, and 24 VDC.Power Consumption:(Locked RotorCurrent): Two Position: 1/4˝ to 3/4˝:.55A, 1˝ to 2˝: .75A. Modulating: 1/4˝ to 3/4˝: .55A, 1˝ to 2˝: .75A.Cycle Time:(per 90°): Two Position:1/4˝ to 3/4˝: 2.5 sec., 1˝ to 2˝: 5 sec.Modulating: 1/4˝ to 3/4˝: 2.5 sec., 1˝ to2˝: 5 sec.Duty Cycle:Two Position: 1/4˝ to 3/4˝:75%, 1˝ to 2˝: 25%. Modulating: 75%.Enclosure Rating:NEMA 4. Optional NEMA 7.Housing Material: Aluminum with ther-mal bonding polyester powder finish.Temperature Limit:0 to 150°F (-18 to 65°C).Conduit Connection:1/2˝ female NPT.Modulating Input:4 to 20 mA.Standard Features:Manual override and visual position indicator except modulating units.Pneumatic “DA” and “SR” Series Type: DA series is double acting and SR series is spring return (rack and pin-ion).Normal Supply Pressure:80 psi (5.5bar).Maximum Supply Pressure:120 psig (8 bar).Air Connections:DA/SR1 to 5: 1/8˝female NPT, all other sizes: 1/4˝ femaleNPT.Air Consumption:(per stroke) DA1:2.32 cu. in.; DA2, SR2: 9.34 cu. in.;DA3, SR3: 17.21 cu. in.; DA4, SR4:20.5 cu. in.; SR5: 39.54 cu. in. Cycle Time: (per 90°) DA1: .03 sec.;DA2: .04 sec.; DA3: .08 sec.; DA4: .12sec.; SR2: .09 sec.; SR3: .14 sec.; SR4:.22 sec.; SR5: .33 sec.Housing Material:Anodized aluminumbody and epoxy coated aluminum endcaps.Temperature Limit:-4 to 180°F(-20 to 82°C).Accessory Mounting: NAMUR stan-dard.Standard Features:Visual position indi-cator.Page 2I. BASIC INSTALLATION1. Operate valve manually and place in the open position. (NOTE: ALL ELECTRIC ACTUATORS ARE SHIPPED IN THE OPEN POSITION.)2. Remove any mechanical stops the valve might have. (DO NOT REMOVE ANY PARTS NECESSARY FOR THE PROPER OPERATIONOF THE VALVE, SUCH AS THE PACKING GLAND, PACKING NUT, ETC.)3. Ensure that the actuator output shaft and valve stem are aligned properly. If they are not, operate the valve manually until they are correct.4. Mount actuator to valve. Do not tighten nuts and bolts at this time.5. Remove actuator cover.6. Bring power to the actuator. CAUTION: Make sure power is OFF at the main box.7. Wire the actuator per the diagram attached to the inside of the cover. Special actuators (those with positioner boards, etc.) will have diagrams enclosed inside the cover.8. Securely tighten bolts used to mount the actuator to a mounting bracket or directly to the valve mounting pad if it is ISO5211 compliant.9. Cycle the unit several times and check the open and closed positions of the valve. Cams are pre-adjusted at the factory; due to the variety of valve designs and types, however, slight adjustments might be required. (SEE II and III).10. Replace cover and tighten screws.II. TO SET THE OPEN POSITION1. Cycle the valve to the open position by applying power to terminals #1 and #2.The top cam and switch control this position. In the open position, the set screw in the top cam will be accessible.2. If the valve is not open completely:A. Slightly loosen the 8-32 x 1/4” set screw on the top cam.B. Rotate the cam clockwise (CW) by hand until the switchmakes contact. Contact is made when a slight click can be heard. By making incremental CW movements of the topcam, the valve can be positioned precisely in the desired position.C. When the top cam is set, tighten the set screw securely.3. If the valve opens too far:A. Apply power to terminals #1 and #3. This will begin to rotate valve CW. When valve is full open and in the exact position desired, remove power from actuator.B. Loosen the set screw in the top cam.C. Rotate the top cam counterclockwise (CCW) until the switch arm drops off the round portion of the cam onto the flat section. A slight click can be heard as the switch changes state.D. Continue applying power to terminals #1 and #3 until valve is in the desired position.III. TO SET THE CLOSED POSITION1. Apply power to terminals #1 and #3 to move the valve toward the closed posi-tion. The bottom cam and switch control the closed position. In the closed position,the set screw in the bottom cam will be accessible.2. If the valve is not closed completely:A. Slightly loosen the 8-32 x 1/4” set screw on the bottom cam.B. Rotate the cam counter-clockwise (CCW) by hand until the switch makes contact. Contact is made when a slight click can be heard. By making incremental CCW move-ments of the bottom cam, the valve can be positioned pre-cisely in the desired position.C. When the top cam is set, tighten the set screw securely.3. If the valve closes too far:A. Apply power to terminals #1 and #2. This will begin torotate valve CCW. When valve is fully closed and in the exact position desired, remove power from actuator.B. Loosen the set screw in the top cam.C. Rotate the top cam clockwise (CW) until the switch arm drops off the round portion of the cam onto the flat section.A slight click can be heard as the switch is no longer mak-ing contact with the round part of the cam.D. Continue applying power to terminals #1 and #3 until valve is in the desired position.IV. MAINTENANCEOnce the actuator has been properly installed, it requires no maintenance. The gear train has been permanently lubricated and in most cases will never be dis-turbed. In the event it becomes necessary to open the gear box for any reason,however, Darina ®#2 grease is recommended for re-lubricating.V. DUTY CYCLEMost standard electric actuators are rated for 25% duty cycle at 100% ambient temperature at the rated torque.VI. THERMAL OVERLOADAll actuators are equipped with thermal overload protection to guard the motor against damage due to overheating.VII. MECHANICAL OVERLOADAll actuators are deigned to withstand stall conditions. It is not recommended to subject the unit to repeated stall conditions.VIII. SPARE PARTSWhen ordering parts, please specify:A. Model #B. Serial #C. Part Description Recommended spare parts include:A. Standard actuator: set of cams and switches.B. Actuators w/positioner: set of cams and switches; 1K potentiometer; valve posi-tioner board.IX. NEMA 7 ELECTRIC ACTUATORSIn general, operation and maintenance of a NEMA 7 electric actuator is no differ-ent that of a NEMA 4 actuator. However, some precautions must be followed:1. DO NOT under any circumstances remove the cover of the actuator while in a hazardous location. Removal of the cover while in a hazardous location could cause ignition of hazardous atmospheres.ELECTRIC ACTUATORSERIES 3ABV AUTOMATED BALL VALVES - 3-WAY BRASSL-Port 3.263.504.207.0012.8318.6729.7543.76T-Port 3.504.085.027.7014.2419.7230.6944.58Model*3ABV1DA1003ABV1DA1013ABV1DA1023ABV1DA1033ABV1DA2043ABV1DA2053ABV1DA3063ABV1DA407Model*3ABV1SR2003ABV1SR2013ABV1SR2023ABV1SR2033ABV1SR3043ABV1SR3053ABV1SR4063ABV1SR507Model*3ABV1U11003ABV1U11013ABV1U11023ABV1U11033ABV1U12043ABV1U12053ABV1U12063ABV1U1307Model*3ABV1V11003ABV1V11013ABV1V11023ABV1V11033ABV1V12043ABV1V12053ABV1V12063ABV1V1307Cv Double Acting Pneumatic Spring Return PneumaticTwo Position ElectricModulating Electric* Complete model includes Port Configuration - see chart below .Size(in.)1/4˝3/8˝1/2˝3/4˝1˝1-1/4˝1-1/2˝2˝Page 3PNEUMATIC ACTUATORNOTE:For optimal operation, 3ABV actuators should be run with a supply of clean,lubricated air.SPRING RETURN ACTUATORSAir to PORT 2 (the right hand port) causes the actuator to turn CCW. Loss of air to PORT 2 causes air to exhaust and the actuator turns CW. This is the FAIL CLOSE operation.DOUBLE ACTING ACTUATORSAir to PORT 2 (the right hand port) causes the actuator to turn CCW. Air to PORT 1 (the left hand port) causes the actuator to turn CW.DISASSEMBLING STANDARD ACTUATORSIMPORTANT:Before beginning disassembly, ensure that the air supply to the actu-ator has been disconnected, all accessories have been removed and that the actu-ator has been dismounted from the valve.1. Loosen the end cap fasteners (22) with a wrench (size varies depending on actu-ator model). On the spring return actuator, alternate 3 to 5 turns on each fastener until the springs are completely decompressed. Use caution in removing the cap since the springs are under load until the fasteners are fully extended.2. Remove the pinion snap ring (10) with a lock ring tool. The indicator (7) may now be removed.3. Turn the pinion shaft (2) CCW until the pistons are at the full end of travel.Disengage the pistons (11) from the pinion. (NOTE: Low pressure air--3 to 5 P .S.I.MAXIMUM--might be required to force the pistons completely from the body.) Note the position of the pistons before removing them from the actuator body. The part numbers of the pistons are located on the side and should be right-side up on an actuator with a standard orientation.4. Remove the pinion through the bottom of the actuator. The actuator is now com-pletely disassembled. All replacement parts may now be put in. W.E. Anderson rec-ommends that all wear parts (3, 4, 5, 6, 12, 13, 14) be replaced before reassem-bly.REASSEMBLING STANDARD ACTUATORSIMPORTANT: Be sure that the actuator surfaces are free of grit and scratch-es before reassembling.1. Apply a light film of grease to all o-rings and the pinion before replacing.2. Put the pinion (2) back through the actuator with the flats of the pinion shaft run-ning parallel with the body.3. When reassembling the actuator, make sure that the piston racks are square to the actuator body and returned to their original orientation. (NOTE: The normal operation of all BV pneumatic actuators is FAIL CLOSED. To change the orienta-tion to FAIL OPEN, rotate the racks 180º to create a reverse operation.)4. When replacing springs in a spring return actuator, ensure that the springs are replaced in their identical position in the end cap from which they were removed.(NOTE: In some circumstances, you might want to change the standard 80 pound spring set to fit your application and available air pressure. Changing the spring sets on BV pneumatic actuators requires no special tools. Please refer to the spring combination torque chart in our catalog for the inner and outer spring com-binations that will allow you to operate with the spring set that you desire.)4. Seal the end caps with a petroleum lubricant and bolt to actuator body.5. Check the seal of the actuator by covering seal areas (pinion, end caps) with soapy water and using low pressure air to the actuator to ensure that no bubbles are produced.PNEUMATIC ACTUATORXI. TROUBLESHOOTING2. DO NOT under any circumstances use a NEMA 7 electric actuator in a haz-ardous location that does not meet the specifications for which the actuator was designed.3. Always mount and cycle test the actuator on the valve in a non-hazardous loca-tion.4. When removing the cover, care must be taken not to scratch, scar of deform the flame path of the cover and base of the actuator, since this will negate the NEMA rating of the enclosure.5. When replacing the cover on actuators rated for both NEMA 4 & 7, take care that the gasket is in place to assure proper clearance after the cover is secured. After the cover screws are tightened, the clearance between the cover and the base should be checked. A .002” thick by 1/2” wide feeler gauge is used for this; it must not enter between the two mating faces more than .125".6. All electrical connections must be in accordance with the specifications for which the unit is being used.7. Should the unit ever require maintenance, remove from the hazardous location before attempting to work on the unit.If the actuator is in a critical application, it is advisable to have a standby unit in stock.©Copyright 2014 Dwyer Instruments, Inc.Printed in U.S.A. 4/14FR# RV-443400-50 Rev.2Page 4PNEUMATIC ACTUATOR PARTS LIST1. Extruded aluminum housing2. Nickel plated steel anti-blowout pinion3. NBR 70 lower pinion O-ring ◊4. PTFE pinion spacer ring ◊5. NBR 70 top pinion O-ring ◊6. PTFE cam spacer ring ◊7. SS indicator cam8. Nylon position indicator 9. SS pinion washer 10. Pinion snap ring11. Die cast aluminum piston 12. Piston O-ring bushing ◊13. PTFE antifriction ring ◊14. PTFE piston thrust block ◊15. SS stop bolt retaining nut 16. SS stop bolt 17. External spring*18. Internal spring*19. Die cast aluminum end cap (left)20. Die cast aluminum end cap (right)21. NBR end cap seats 22. SS end cap bolt*spring return actuators only ◊parts subject to wear. Please contact the factory or your W.E. Anderson distribu-tor for replacement kits.MAINTENANCEThe Series 3ABV Automated Balll Valves are not field serviceable and should be returned if repair is needed (field repair should not be attempted and may void war-ranty). Be sure to include a brief description of the problem plus any relevant appli-cation notes. Contact customer service to receive a return goods authorization number before shipping.Darina ®is a registered trademark of Shell Oil Company.。

143The compact design of True Union 2000 Ball Valves provides maximum versatility with minimum space requirements. Fully serviceable valve cartridge also mates with Spears ® Union 2000 Schedule 80 pipe unions. Both valves and unions utilize Buttress Thread union nuts for superior strength. All ball valves feature Spears ® self adjusting Floating Seat design for extended service, and Spears ® Safe-T-Shear ® Stem with double O-ring stem seals for assurance of fl uid containment in case of inadvertent valve damage. Available in chemical and corrosion resistant PVC or CPVC with socket, fl anged or Spears ® Patented Special Reinforced (SR) threaded.Actuated package includes polypropylene valve mounting bracket for accurate valve/actuator alignment and support in any position. Premium electric actuator utilizes a reversing type motor with UL approved, built in thermal overload protection. Gear train is permanently lubricated. All hardware is stainless steel. Standard 115 VAC,60 HZ, with voltage options available.Spears ® True Union 2000 Ball Valve Premium Electric Actuation Package True Union 2000 Ball Valve Speci fi cationsStyle Double union • 1/4 turn shut off• Double O-ring stem seals• Safe-T-Shear ® Stem• Blocked seal carrierMaterial PVC or CPVCSize Range 1/2" - 6" & 8" Venturied*Pressure Rating 1/2" - 4" = 235 psi @ 73°F6" - 8" & all fl angedvalves = 150 psi @ 73°FVacuum Service To 26 in-HgSeats PTFEO-rings EPDM or FKMEnd Connector Socket, SR Threaded, or FlangedCerti fi cations E PDM Valves NSF ® Certi fi ed for potablewater use.*8" Venturied is 6" valve fitted with 8 x 6 adapters Standard Actuator Speci fi cations Motor Reversing Thermal Overload Protection V oltage 115 V AC, 60 Hz Lubrication PermanentCustom Electric ActuationOptions & Accessories• Modulating (variable positioning)• Heater & Thermostat• Additional Limit Switch sets• Position Indicator• LED Indicator lights• Torque Sensor• Declutchable Manual Override• Duty Cycle Upgrades (75% & 100%)• NEMA 4x, 7, & 9 Enclosures• Spring Return Operation (Fail Safe)• V oltage Options: 24 V AC, 230 V AC,12 VDC, 24 VDCNote: Modulation requires specialenclosure for 1/2" - 2" valves.Sample Engineering Speci fi cation All ball valves shall be electrically actuated True Union 2000 type constructed from PVC Type I Cell Classi fi cation 12454 or CPVC Type IV Cell Classi fi cation 23447. All O-rings shall be EPDM or FKM. All valves shall have Safe-T-Shear ® stem and double O-ring stem seals. All valve union nuts shall have Buttress threads. All seal carriers shall be Safe-T-Blocked ®. All valve components shall be replaceable. All EPDM valves shall be certi fi ed by NSF ® international for use in potable water service. All 1/2" through 4" valves shall be pressure rated at 235 psi and all 6" through 8" & all fl anged valves shall be pressure rated at 150 psi for water at 73°F. Electric Actuators shall be factory installed, 115 V AC with thermally protected, reversing motor. All mounting fasteners shall be stainless steel. Actuator shall be equipped with [selected options list], as manufactured by Spears ® Manufacturing Company.Declutchable Style ShownELECTRIC ACTUATED TRUE UNION BALL VALVESTypical Illustration。

LB-3R-20220706Copyright 2013 A-T Controls, Inc.Cincinnati, Ohio 45246FAX (513) 247-5462********************See automated data sheets for pre-sized assembliesEasy to Automate!A-T Controls’ Series LB ball valves feature thelatest technology in PFA. These fully lined ballvalves are available with stainless steel or epoxycoated carbon steel body. The superior PFAlining is able to withstand temperatures up to400ºF and demonstrates greater durability thanPTFE. This high purity PFA has extremely low gaspermeability and outperforms other materials incritical services.These split body valves feature adjustablepacking. The lining thickness is at least 3mm.throughout the body and ball. One-piece ball andstem design reduces side loading and extendsstem and packing life.Excellent for:• Pharmaceutical• Food and Beverage• Paints and Solvents• Caustics and Acids• Deionized Water andSemiconductorPneumatic ElectricSERIES LBPFA Lined Ball ValveHigh Performance, Full Port PFA Lined, Split Body Ball ValveASME Class 150 Flanged Endsconsult factory*Regular PortPFA Lined Ball ValveDouble Acting Assembly DIMENSIONS (IN)DIMENSIONS SHOWN ARE FOR ASSEMBLIES SIZED FOR 80 PSI SUPPLYASME Class 150 Flanged PFA Lined Ball ValveOther options available - call for detailsActuators are sized based on full differential pressure with clean water. Consult the Application Sizing Guide for assistance with sizing actuators.SAMPLE PART #LBC-F1-150/3RED-XXSee automated part number matrix on back cover for complete part number and options.Valve SeriesSeat MaterialValve SizeEnd ConnectionCarbon Steel TRIAC Actuator SeriesActuator Size Double ActingSUFFIX 1: Voltage SUFFIX 2: AccessoriesPFA Lined Ball ValveSpring Return Assembly DIMENSIONS (IN)DIMENSIONS SHOWN ARE FOR ASSEMBLIES SIZED FOR 80 PSI SUPPLYASME Class 150 Flanged PFA Lined Ball ValveOther options available - call for detailsActuators are sized based on full differential pressure with clean water. Consult the Application Sizing Guide for assistance with sizing actuators.SAMPLE PART #LBC-F1-150/3RFS-XXSee automated part number matrix on back cover for complete part number and options.Valve SeriesSeat MaterialValve SizeEnd ConnectionCarbon Steel TRIAC Actuator SeriesActuator Size Spring ReturnSUFFIX 1: Voltage SUFFIX 2: AccessoriesSERIES LB PFA Lined Ball ValveElectric Assembly DIMENSIONS (IN)ASME Class 150 Flanged PFA Lined Ball ValveSAMPLE PART #LBC-F1-150/WEA1-XXSee automated partnumber matrix on back cover for complete part number and options. Valve SeriesCarbon Steel Seat MaterialValve SizeEnd ConnectionTRIAC Actuator SeriesActuator SizeOn-Off SUFFIX 1: Voltage SUFFIX 2: AccessoriesActuators are sized based on full differential pressure with clean water. Consult the Application Sizing Guide for assistance with sizing actuators.HOW TO ORDER: Manual ValvesHOW TO ORDER: Automated ValvesSAMPLE PART #(2) Valve Series(4) End Connection(5) Valve Size(6) Seat, Lining, & TrimMaterial(7) Special Designation(8) Additional Specials(9) Special Designation(3) Body/Ball/StemMaterialLBC-F1-150-LXX-X**2500 & 3500 60 psig springLB-3R-20220706Copyright 2013 A-T Controls, Inc.Cincinnati, Ohio 45246FAX (513) 247-5462********************SAMPLE PART #LBC-F1-150/3RFS-XX(2) Valve Series(3) Body/Ball/StemMaterial(6) Valve Size(5) Seat, Lining, & TrimMaterial(4) End Connection(7A) TRIAC Actuator Series(7A) Actuator Size(7B) Spring Return(8) Accessory(9) Accessory3P=Teflon™ (PTFE) Coating。

Product Manual- Operation and Maintenance Manual Product Name:API 6D Ball ValveJanuary 20121ScopeThis manual covers manually/motor/pneumatic operated seat supported /trunnion supported ball valve having tow/three pieces body with nominal sizes DN 15mm-1200mm (1/2”-48”) and class ranges PN1.6MPa-10MPa(ANS1 class 150-2500).Valve ends may be threaded, flanged, butt-welded or socket2 Applications2.1 Ball valves are used to open/close the flow in pipeline.2.2 The nature of applicable fluid depends on valve material:2.2.1 Carbon steel valve applies to non-corrosive fluid, such as water, vapor or oil etc. 2.3 Temperature range depend on sent material:PTFE ≤130℃RPTFE ≤160℃PPL ≤300℃NYLON ≤121℃3. standard:Basic design API 6D-2008Inspe crlon tesring BS EN 12266.1-2003End flange ASME B16.5-2009TEMP. & PRESSURE ASME B16.34-2009Face toface ASME B16.10-2009Main parts and materials ASME materials, see Table 1Figure 1:Trunnion Ball Valve4 Structure4.1 Ball Valve structure is shown in Fig. 1.4.2 List the major components and materials shown in Table 1:Table 1: Major Parts and Materials-29℃~38℃working pressure(bar)50℃working pressure(bar)100℃working pressure(bar)121℃working pressure(bar)6 OperationThe valve can be manually operated by using the handle for manually operated valves or motor-operated by the electric actuator for motor operated valves or pneumatic operated by pneumatic actuator for pneumatic operated valves. The valve open or closes by turning the ball. Clockwise turning to 90ºresults in valve open.6.1 The manually operated valve is opened when the handle and the position mark on stem end are parallel to pipeline. When that is perpendicular to the pipeline, the valve is closed.6.2 For motor/pneumatic operated valves, valve open/close is indicated by the positioner on the electric/pneumatic actuator.7 Storage, maintenance, installation and service7.1 The valve should be stored in dry room with good ventilation. Valve ends should be covered.7.2 For valve stored for a long period of time, regular checkup is required to ensure that the valves are in good conditions. Foreign particles should be removed and special care should be taken to keep the valve seat sealing surface clean and prevent any damage of sealing surface.7.3 Check the conformance of valve identification to the service requirements prior to installation.7.4 Check the cleanness of the valve cavity and sealing surface and sealing surface and wipe off any dirt with white cloth prior to installation.7.5 Before installation, the tightness of packing should be checked to ensure that sealing is secured without affecting the turning of stem.7.6 The valve shall be in full open position when conducting system or pip line pressure test after the valve installation.7.7 Ball valve shall be in full open or full close position while in service. partial opening for controlling the flow is not allowed.7.8 Manually operated valve should be operated by using the handle. Use of lowers or other tools is not allowed.7.9 Valve in service should be examined at prescribed intervals to see whether the wear of sealing surface or stem occurs and the gasket or packing fails. Repair or replacement shall be carried out timely if necessary.7.10 “Electric valve actuator instruction manual” and “Pneumatic valve actuator instruction manual” should be referred with regard to the storage, maintenance, installation and service for motor-operated valve and pneumatic-operated valve respectively.8 Possible troubles, causes and solutions see table9 GuaranteeGuarantee period is one year after service date no later than 18 months after delivery date. Valve failure due to material defectives, manufacturing problems, design unreasonable or any damage under normal operating conditions will be repaired or parts replaced free of charge by manufacturer within the guarantee period.。

The Series BV2IB Bronze Ball Valve with ISO Mounting Pad providesan economical solution for commercial and general industrial use. Buna-N stem o-rings and PTFE seats and seals allow for longer life and leak-free operations. The valve’s stem design provides additional protection against blow outs. The Series BV2IB full port is designed for minimal pressure drops with consistent flow rates. ISO 5211 mounting pad accepts direct mounting of pneumatic and electric actuators. OPERATIONSManual Operations-To open or close the valve, turn the handle 90° (1/4 turn). Valve in OPEN position: the handle is parallel (in line) with the valve pipeline. Valve in CLO SED position: the handle is perpendicular (crossed) with the valve or pipeline.Automated Operation-Valves with actuators should be checked for stem alignment. Most applications are direct mount to the actuator, greatly reducing any sideload or increased torque. Make sure that all insert adapters are properly placed on the valve stem and fully engaged in the actuator.INSTALLATIONGeneral Information for On-Site Installation-The valve may be fitted in any position in the pipeline. For automated operation, W.E. Anderson recommends that the valve and actuator be installed vertically in case of valve leakage, although this is not necessary for proper operation of the valve. Prior to installation, inspect valve and pipe ends to make sure they are free from debris. Materials trapped inside the valve can cause damage to the seats and result in leakage. Clean pipe ends and check for proper threading to prevent damage to valve internals. Use a PTFE based thread sealant applied to the pipe threads. Use a smooth wrench on the hex portion of the valve, not the valve body, to tighten. Use pipe wrenches on pipe and pipe fittings only.SPECIFICATIONSService:Compatible liquids and gases.Line Size: 1/2 to 2˝.End Connection: Female NPT.Pressure Limit: 600 psi (41.4 bar).Wetted Materials:Body: Bronze;Ball: Chrome plated brass;Seat: PTFE.Temperature Limit: 320°F (160°C).Other Materials:Packing gland: Brass;Seat backing: EPDM;O-ring: Buna-N;Mounting pad: Bronze;Stem packing and seal: PTFE;Stem: Brass.WARRANTYThe Series BV2IB warranties from defects in materials andworkmanship are covered for (1) year from the date of purchase. In theunlikely event the valve should fail, the unit can be returned to thefactory for warranty repair if the warranty period has not expired. Besure to include a brief description of the problem plus any relevantapplication notes. Contact our customer service department for anRGA number and to set up the return.©Copyright 2010 Dwyer Instruments, Inc.Printed in U.S.A. 12/10FR# RB-443890-00。

TECHNICAL INFORMATIONEA1 Series Automated TBH Series Ball Valves1/2" TO 2" PVC AND CPVCVALVE FEATURES• System2TM Sealing Technology for longer life cycle • 250 PSI / 16 Bar, non-shock at 70°F / 23°C full pressure rating• Consistent Operating Torque with Adjustment-free Design• ISO5211 Compliant Mounting Flange • Permanent Markings, Eliminates Labels • Integral Footpad for Skid or Panel Mount • EPDM seals• Double O-Ring stem seals• Easy replacement for existing Hayward TB Series • NSF / ANSI 61 and NSF / ANSI 372 listed ACTUATOR FEATURES • ISO5211 Compliant F05 Base • UL/CSA Listed Motor• Thermoplastic NEMA 4 / 4X enclosure • Compact Assembly• 2.5 Second, 90° Cycle Time • Thermal Overload Protection• Permanently Lubricated Gear Train • Actuator Brake• No Need for Manual Adjustments • Blind Leads Connection • Standard 120 VAC• Unidirectional, Not ReversingMATERIALS• PVC Cell Class 12454 per ASTM D1784• CPVC Cell Class 23447 per ASTM D1784• EPDM O-Ring SealsCertified to NSF/ANSI 61 & 372ACTUATION AND CONTROLSEA1 SeriesAutomated TBH Ball Valves1/2” TO 2” PVC AND CPVCDIMENSIONSTECHNICAL INFORMATION, CONTINUEDSIZE in / DN1 in / mm2 in / mm3 in / mm4 in / mm5 in / mmWEIGHT lbs / kg1/2 / 15 4.63 / 118 2.25 / 577.99 / 203 4.88 / 124 4.34 / 110 6.80 / 3.103/4 / 20 4.75 / 122 2.63 / 678.15 / 207 4.88 / 124 4.34 / 1107.00 / 3.201 / 25 5.34 / 136 3.00 / 768.42 / 214 4.88 / 124 4.34 / 1107.10 / 3.201-1/4 / 32 6.83 / 173 4.00 / 1028.84 / 225 4.88 / 124 4.34 / 1108.40 / 3.801-1/2 / 407.39 / 188 4.00 / 1028.84 / 225 4.88 / 124 4.34 / 1108.60 / 3.902 / 507.99 / 2034.75 / 1219.35 / 2374.88 / 1244.34 / 1109.90 / 4.50Dimensions are subject to change without notice – consult factory for installation informationACTUATOR SPECIFICATIONSVALVE SPECIFICATIONSVALVE TYPETRUE UNIONMaterial of ConstructionPVC, CPVC Seals EPDM Seats PTFE End ConnectionsSocket or Threaded Sizes 1/2", 3/4", 1", 1-1/4" 1-1/2" and 2"Pressure Rating 250 PSI @ 70°F non-shockDesignFull PortSIZE in / DNCv VALUESSIZE in / DNCv VALUES1/2 / 158.01-1/4 / 3275.03/4 / 2016.01-1/2 / 4090.01 / 2529.02 / 50150.0Cv VALUESPRESSURE LOSS CALCULATION FORMULA∆P =[]QCv 2∆P = Pressure Drop Q = Flow in GPM Cv = Flow CoefficientMODELEA1Torque Output (in-lbs)120Standard Voltage 120 VAC Duty Cycle 25%Thermal Overload Standard Cycle Time (secs @ 90°)2.5Conduit Entry 1/2" NPT Enclosure NEMA 4 / 4X Enclosure Material PolypropyleneMax Current Amps @ 115 VAC1.8TECHNICAL INFORMATIONEAU1 Series Automated TBH Series Ball Valves1/2" TO 2" PVC AND CPVCVALVE FEATURES• System2TM Sealing Technology for longer life cycle • 250 PSI / 16 Bar, non-shock at 70°F / 23°C full pressure rating• Consistent operating torque with adjustment-free design• ISO mounting flange• Permanent markings, eliminates labels • Integral footpad for skid or panel mount • FPM or EPDM seals• Double O-Ring stem seals• Easy replacement for existing Hayward TB Series • NSF / ANSI 61 and NSF / ANSI 372 listed ACTUATOR FEATURES • UL/CSA Listed Motor• GFPP NEMA 4 / 4X Enclosure • 2.5 Second, 90° Cycle Time• Permanently Lubricated Gear Train • Actuator Brake• 90 or 180° Operation• Unidirectional, Not Reversing • Terminal Block Connections • Standard 120 VAC• End of Travel Dry Contact Limit Switch • Thermal Overload Protection• Lightweight, Compact and InexpensiveOPTIONS • 24VAC / VDC • 230 VACMATERIALS• PVC Cell Class 12454 per ASTM D1784• CPVC Cell Class 23447 per ASTM D1784• FPM or EPDM SealsCertified to NSF/ANSI 61 & 372EAU1 SeriesAutomated TBH Ball Valves1/2” TO 2” PVC AND CPVCDIMENSIONSTECHNICAL INFORMATION, CONTINUEDSIZE in / DN1 in / mm2 in / mm3 in / mm4 in / mm5 in / mmWEIGHT lbs / kg1/2 / 15 4.63 / 118 2.25 / 577.99 / 203 4.88 / 124 4.34 / 110 6.80 / 3.103/4 / 20 4.75 / 122 2.63 / 678.15 / 207 4.88 / 124 4.34 / 1107.00 / 3.201 / 25 5.34 / 136 3.00 / 768.42 / 214 4.88 / 124 4.34 / 1107.10 / 3.201-1/4 / 32 6.83 / 173 4.00 / 1028.84 / 225 4.88 / 124 4.34 / 1108.40 / 3.801-1/2 / 407.39 / 188 4.00 / 1028.84 / 225 4.88 / 124 4.34 / 1108.60 / 3.902 / 507.99 / 2034.75 / 1219.35 / 2374.88 / 1244.34 / 1109.90 / 4.50Dimensions are subject to change without notice – consult factory for installation informationACTUATOR SPECIFICATIONSVALVE SPECIFICATIONSMODELEAUTorque Output (in-lbs)120Standard Voltage 120 VAC Duty Cycle 25%Thermal Overload Standard Cycle Time (secs*) 2.5 / 5.0Conduit Entry 1/2" NPT Enclosure NEMA 4 / 4X Enclosure Material GFPPMax Current Amps @ 115 VAC1.8 (60 Hz),2.8 (50 Hz)* EAU28 = 180° (5.0 sec), , EAU29 = 90° (2.5 sec.)VALVE TYPETRUE UNIONMaterial of ConstructionPVC, CPVC Seals FPM/EPDM Seats PTFE End ConnectionsSocket or Threaded Sizes 1/2", 3/4", 1", 1-1/4" 1-1/2" and 2"Pressure Rating 250 PSI @ 70°F non-shockDesignFull PortSIZE in / DNCv VALUESSIZE in / DNCv VALUES1/2 / 158.01-1/4 / 3275.03/4 / 2016.01-1/2 / 4090.01 / 2529.02 / 50150.0Cv VALUESPRESSURE LOSS CALCULATION FORMULA∆P =[]QCv 2∆P = Pressure Drop Q = Flow in GPM Cv = Flow Coefficient。

Product Manual

- Operation and Maintenance Manual Product Name:API 6D Ball Valve

January 2012

1Scope

This manual covers manually/motor/pneumatic operated seat supported /trunnion supported ball valve having tow/three pieces body with nominal sizes DN 15mm-1200mm (1/2”-48”) and class ranges PN1.6MPa-10MPa(ANS1 class 150-2500).

Valve ends may be threaded, flanged, butt-welded or socket

2 Applications

2.1 Ball valves are used to open/close the flow in pipeline.

2.2 The nature of applicable fluid depends on valve material:

2.2.1 Carbon steel valve applies to non-corrosive fluid, such as water, vapor or oil etc. 2.3 Temperature range depend on sent material:

PTFE ≤130℃

RPTFE ≤160℃

PPL ≤300℃

NYLON ≤121℃

3. standard:

Basic design API 6D-2008

Inspe crlon tesring BS EN 12266.1-2003

End flange ASME B16.5-2009

TEMP. & PRESSURE ASME B16.34-2009

Face toface ASME B16.10-2009

Main parts and materials ASME materials, see Table 1

Figure 1:Trunnion Ball Valve

4 Structure

4.1 Ball Valve structure is shown in Fig. 1.

4.2 List the major components and materials shown in Table 1:

Table 1: Major Parts and Materials

-29℃~38℃working pressure(bar)

50℃working pressure(bar)

100℃working pressure(bar)

121℃working pressure(bar)

6 Operation

The valve can be manually operated by using the handle for manually operated valves or motor-operated by the electric actuator for motor operated valves or pneumatic operated by pneumatic actuator for pneumatic operated valves. The valve open or closes by turning the ball. Clockwise turning to 90ºresults in valve open.

6.1 The manually operated valve is opened when the handle and the position mark on stem end are parallel to pipeline. When that is perpendicular to the pipeline, the valve is closed.

6.2 For motor/pneumatic operated valves, valve open/close is indicated by the positioner on the electric/pneumatic actuator.

7 Storage, maintenance, installation and service

7.1 The valve should be stored in dry room with good ventilation. Valve ends should be covered.

7.2 For valve stored for a long period of time, regular checkup is required to ensure that the valves are in good conditions. Foreign particles should be removed and special care should be taken to keep the valve seat sealing surface clean and prevent any damage of sealing surface.

7.3 Check the conformance of valve identification to the service requirements prior to installation.

7.4 Check the cleanness of the valve cavity and sealing surface and sealing surface and wipe off any dirt with white cloth prior to installation.

7.5 Before installation, the tightness of packing should be checked to ensure that sealing is secured without affecting the turning of stem.

7.6 The valve shall be in full open position when conducting system or pip line pressure test after the valve installation.

7.7 Ball valve shall be in full open or full close position while in service. partial opening for controlling the flow is not allowed.

7.8 Manually operated valve should be operated by using the handle. Use of lowers or other tools is not allowed.

7.9 Valve in service should be examined at prescribed intervals to see whether the wear of sealing surface or stem occurs and the gasket or packing fails. Repair or replacement shall be carried out timely if necessary.

7.10 “Electric valve actuator instruction manual” and “Pneumatic valve actuator instruction manual” should be referred with regard to the storage, maintenance, installation and service for motor-operated valve and pneumatic-operated valve respectively.

8 Possible troubles, causes and solutions see table

9 Guarantee

Guarantee period is one year after service date no later than 18 months after delivery date. Valve failure due to material defectives, manufacturing problems, design unreasonable or any damage under normal operating conditions will be repaired or parts replaced free of charge by manufacturer within the guarantee period.。