石油化工钢储罐地基与基础施工及验收规范(SH∕T3528-2005)

- 格式:ppt

- 大小:4.61 MB

- 文档页数:150

石油天然气建设工程施工质量验收标准

储罐工程

球形储罐焊接过程控制检验批质量验收记录

球形储罐焊后几何尺寸、外观质量、无损检测、整体热处理及压力试验和气密性试验检验批质量验收记录

球形储罐焊后几何尺寸、外观质量、无损检测、整体热处理

立式储罐底板预制验检验批质量验收记录

立式储罐壁板预制验检验批质量验收记录

立式储罐壁板预制验检验批质量验收记录(续)

立式储罐固定顶预制验检验批质量验收记录

立式储罐构件预制验检验批质量验收记录

立式储罐固定顶组装检验批质量验收记录

立式储罐浮顶焊接检验批质量验收记录

防火涂料涂装工程检验批质量验收记录

绝热工程检验批质量验收记录

绝热工程检验批质量验收记录〔续〕。

中国石油内蒙销售公司苏集油库重建工程内蒙古钢制内浮顶储罐充水试验方案中国石油天然气第一建设公司内蒙古项目部2010年9月1日中国石油内蒙销售公司苏集油库重建工程内蒙古钢制内浮顶储罐充水试验方案编制:刘江扬审核:陈广安批准:侯卫强中国石油天然气第一建设公司内蒙古项目部2010年9月1日目录1适应范围 (1)2编制依据 (1)3主要工程实物量 (1)4施工进度计划 (1)5施工程序 (1)6施工准备 (1)7充水试验 (2)8充水试验程序 (3)9内浮盘升降试验 (4)10质量保证措施 (4)11安全技术措施 (5)12施工机具及手段用料 (5)13劳动力需用计划 (6)14试验小组成员 (6)15附件 (6)1 适应范围此充水试验施工技术措施适用于中国石油内蒙销售公司苏集油库重建工程钢制内浮顶储罐的充水试验。

为保证充水试验顺利进行,特编制本施工技术方案。

2 编制依据SH/T3528-2005《石油化工钢储罐地基与基础施工及验收规范》GB50341-2003《立式圆筒形钢制焊接油罐设计规范》GB50128-2005《立式圆筒形钢制焊接储罐施工及验收规范》3 主要工程实物量5000m3内浮顶油罐4台,10000m3内浮顶油罐8台4 施工进度计划充两罐水(11#5千立储罐、12#5千立储罐),从11#5千立储罐,9#5千立储罐倒罐一次(1#,3#,5#,7# 1万立储罐),从12#5千立储罐,10#5千立储罐倒罐一次(2#,4#,6#,8#1万立储罐)。

从7#1万立储罐向(5#1万立储罐或3#1万立储罐,1#1万立储罐)倒罐,从8#1万立储罐向(2#1万立储罐或4#1万立储罐,6#1万立储罐)倒罐完成。

罐上水时间按从2010年9月17日开始考虑,水源井直接上水一台5千立方罐按6天计算,1万立方罐试水按5天计算,试验顺序按储罐完成时间顺序进行。

方案所需时间如下:2010年09月17日到2010年10月10日 4台5千立储罐试水,2010年10月12日到2010年11月02日 8台1万立储罐试水。

1 范围本规范规定了石油化工工程中塔架、管廊和框架等钢结构工程工厂化制造和施工安装的质量标准。

本规范适用于石油化工工程新建、扩建与改建项目碳素结构钢、低合金结构钢制造的塔架、管廊和框架等钢结构工程的施工质量验收。

4一般规定4.1石油化工钢结构工程质量验收处应符合设计文件和本规范要求外,尙应按SH/T3508《石油化工安装工程施工质量验收标准》的规定进行检验批、分项工程、分部工程的验收。

钢结构工程分部工程、分项工程的划分应按SH/T3508《石油化工安装工程施工质量验收统一标准》的规定执行;检验批的划分应按本规范的规定执行。

4.2钢结构工程施工单位应具备相应的钢结构工程施工资质。

条文说明:本条是对从事钢结构工程的施工企业资质和质量管理内容进行检查,强调市场准入制度,是管理方面的要求。

4.3钢结构工程施工质量的检查和检验,应采用经计量检定、校准合格的计量器具。

条文说明:钢结构的制作、安装和质量检验用的计量器具应为检定合格的计量器具,且保证在检定有效期内使用。

不同计量器具具有不同的使用要求,同意计量器具在不同使用状况下,测量精度不同,因此要求严格按有关规定正确操作计量器具。

4.4钢结构工程的原材料、半成品及成品应进行进场验收;半成品、成品应涂装底漆。

条文说明:本条强调了到货检验的重要性。

由于成品、半成品从加工完毕到包装运输再到现场施工可能间隔较长时间,故规定成品、半成品的交付条件应为底漆涂装完毕,以利于成品保护。

4.5 对钢结构材料进行验收时,若抽样检查或复验有一件不合格,可按原规定数量的两倍抽样,在进行检查和复验;若仍有不合格,则该批次钢结构材料不得使用。

4.6钢结构工程的隐蔽工程未经验收,不得进行后续作业。

条文说明:在焊接过程中、焊缝冷却过程及以后的相当长的一段时间可能产生裂纹。

普通碳素钢产生延迟裂纹的可能性很小,因此规定在焊缝冷却到环境温度后即可进行外观检查。

低合金钢结构焊缝的延迟裂纹延迟时间较长,考虑到工厂存放条件、现场安装进度、供需衔接的限制以及随着时间延长,产生延迟裂纹的几率逐渐减小等因素,本规范以焊接完成24h 后外观检查的结果作为验收的依据。

立式圆筒形焊接储罐施工及验收规范GB50128-2005 施工及检验流程一、材料报验所有建造储罐的材料和附件,应具有合格证和质量证明书,并符合相应国家现行标准规定及图纸设计要求.二、储罐构件预制(注:底板、壁板、顶板预制前应绘制排版图)1、下料检查:底板、壁板、顶板(浮顶和内浮顶、固定顶)尺寸允许偏差2、碳素钢板及低合金钢板宜采用机械加工或自动、半自动火焰切割加工,不锈钢板应采用机械或等离子切割加工。

3、钢板坡口加工应平整,不得有夹渣、分层、裂纹等缺陷,火焰及等离子切割坡口产生在表面硬化层应去除。

4、厚度≥12mm的弓形边缘板,应在两侧100mm范围内进行超声波检测。

如采用火焰切割坡口,应对坡口表面进行磁粉检测或渗透检测。

5、如需要防腐则按设计文件及相关规范要求进行防腐质量检查。

6、储罐的所有预制构件完成后,应有编号,并应用油漆或其他方法做出清晰的标识。

三、基础验收复测1、基础中心标高允许偏差为±20mm。

2、支承罐壁的基础表面其高差:(1)有环梁时,每10米弧长内任意两点的高差不得大于6mm,且整个圆周长度内任意两点的高差不得大于12mm。

(2)碎石环梁和无环梁时,每3米弧长内任意两点的高差不得大于6mm,且整个圆周长度内任意两点的高差不得大于20mm.3、沥青砂层表面应平整密实,无突出的隆起、凹陷和贯穿裂纹。

沥青砂表面凹凸度检查方法如下:(1)当储罐直径等于或大于25米时,以基础中心为圆心,以不同半径作同心圆,将各圆心分成若干等分,在等分点测量沥青砂层的标高,同一圆周上的测点其测量标高与计算标高之差不应大于12mm。

(2)当储罐直径小于25米时,可从基础中心向基础周边拉线测量,基础表面凹凸度不应大于25mm.。

4单面倾斜式基础表面倾斜度允许偏差为≤15mm。

四、罐体安装及检查(罐底组装)(1)罐底采用带垫板的对接接头时,垫板应与对接的两块钢板贴紧,并点焊固定,其缝隙不应大于1mm.。

立式圆筒形焊接储罐施工及验收规范GB50128-2005 施工及检验流程一、材料报验所有建造储罐的材料和附件,应具有合格证和质量证明书,并符合相应国家现行标准规定及图纸设计要求。

二、储罐构件预制(注:底板、壁板、顶板预制前应绘制排版图)1、下料检查:底板、壁板、顶板(浮顶和内浮顶、固定顶)尺寸允许偏差2、碳素钢板及低合金钢板宜采用机械加工或自动、半自动火焰切割加工,不锈钢板应采用机械或等离子切割加工。

3、钢板坡口加工应平整,不得有夹渣、分层、裂纹等缺陷,火焰及等离子切割坡口产生在表面硬化层应去除。

4、厚度≥12mm的弓形边缘板,应在两侧100mm范围内进行超声波检测。

如采用火焰切割坡口,应对坡口表面进行磁粉检测或渗透检测。

5、如需要防腐则按设计文件及相关规范要求进行防腐质量检查。

6、储罐的所有预制构件完成后,应有编号,并应用油漆或其他方法做出清晰的标识。

三、基础验收复测1、基础中心标高允许偏差为±20mm。

2、支承罐壁的基础表面其高差:(1)有环梁时,每10米弧长内任意两点的高差不得大于6mm,且整个圆周长度内任意两点的高差不得大于12mm。

(2)碎石环梁和无环梁时,每3米弧长内任意两点的高差不得大于6mm,且整个圆周长度内任意两点的高差不得大于20mm。

3、沥青砂层表面应平整密实,无突出的隆起、凹陷和贯穿裂纹。

沥青砂表面凹凸度检查方法如下:(1)当储罐直径等于或大于25米时,以基础中心为圆心,以不同半径作同心圆,将各圆心分成若干等分,在等分点测量沥青砂层的标高,同一圆周上的测点其测量标高与计算标高之差不应大于12 mm。

(2)当储罐直径小于25米时,可从基础中心向基础周边拉线测量,基础表面凹凸度不应大于25 mm.。

4单面倾斜式基础表面倾斜度允许偏差为≤15mm。

四、罐体安装及检查(罐底组装)(1)罐底采用带垫板的对接接头时,垫板应与对接的两块钢板贴紧,并点焊固定,其缝隙不应大于1mm.。

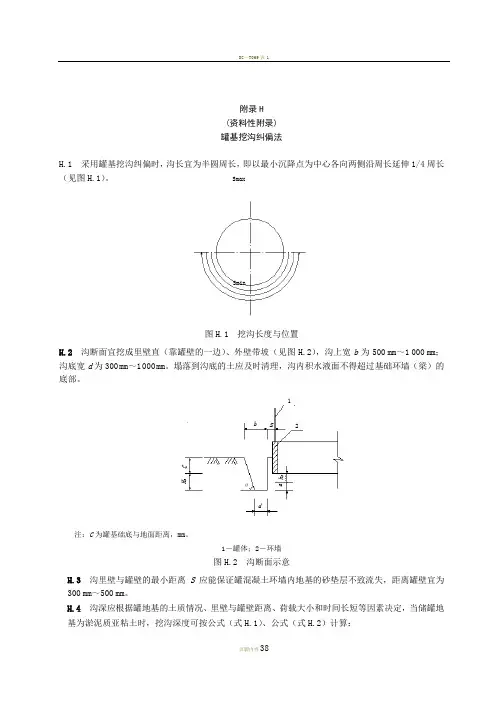

附录H (资料性附录) 罐基挖沟纠偏法H.1 采用罐基挖沟纠偏时,沟长宜为半圆周长,即以最小沉降点为中心各向两侧沿周长延伸1/4周长(见图H.1)。

图H.1 挖沟长度与位置H.2 沟断面宜挖成里壁直(靠罐壁的一边)、外壁带坡(见图H.2),沟上宽b 为500 mm ~1 000 mm ;沟底宽d 为300 mm ~1 000 mm 。

塌落到沟底的土应及时清理,沟内积水液面不得超过基础环墙(梁)的底部。

注:C 为罐基础底与地面距离,mm 。

1-罐体;2-环墙图H.2 沟断面示意H.3 沟里壁与罐壁的最小距离S 应能保证罐混凝土环墙内地基的砂垫层不致流失,距离罐壁宜为300 mm ~500 mm 。

H.4 沟深应根据罐地基的土质情况、里壁与罐壁距离、荷载大小和时间长短等因素决定,当储罐地基为淤泥质亚粘土时,挖沟深度可按公式(式H.1)、公式(式H.2)计算:SmaxSmin12bsCH 3dαh 2aH3=h+H2………………………………………………………(式H.1)h= s·tgα………………………………………………………(式H.2)式中:H3——罐基础底至沟底高差,mm;h——计算因子,mm;H2——常数,通常取400mm~500mm;s——沟里离罐壁距离,mm;α——沟外壁坡度,取45°。

H.5 在罐自重的作用,观测沟侧每天的沉降量并记录。

根据每天沉降量和土方回填夯实所需的时间,确定土方回填夯实的时机。

土方回填后继续观测沉降量,沉降观测结束后,基础不均匀沉降值应符合本规范表22的规定。

用词说明对本规范条文中要求执行严格程度用的助动词,说明如下:(一)表示很严格、非这样做不可并具有法定责任时,用的助动词为“必须”(must);(二)表示要准确地符合规范而应严格遵守时,用的助动词为:正面词采用“应”(shall);反面词采用“不应”或“不得”(shall not)。

(三)表示在几种可能性中推荐特别合适的一种,不提及也不排除其他可能性,或表示是首选的但未必是所要求的,或表示不赞成但也不禁止某种可能性时,用的助动词为:正面词采用“宜”(should);反面词采用“不宜”(should not)。

立式储油罐质量检查标准立式储油罐质量检查标准一、检查依据标准1、SH/T3528-2005《石油化工钢储罐地基与基础施工及验收规范》2、GB 50128-2005《立式圆筒形钢制焊接储罐施工及验收规范》3、SH/T 3530-2001《石油化工立式圆筒形钢制储罐施工工艺标准》4、SH 3022-1999《石油化工设备与管道涂料防腐蚀技术规范》5、SH 3505-1999《石油化工施工安全技术规程》二、质量检查内容控序控制目检验执行标准制控制内容号标方法点1、检查基础施工记录和验收资料。

2、用水准仪检查基础中心标高,允许偏差为?20 mm。

3、支承罐壁的基础表面每10储审阅米弧长内任意两点的高差:罐检查?6 mm。

基报告4、整个圆周长度内任意两点的础SH3528-2005 达到标一高差:?12 mm。

GB50128-2005 准要求检5、沥青砂层表面应平整密实,查无凸出的隆起、凹陷及贯穿验现场裂纹。

实测收6、基础表面凹凸度允许偏差?25 mm。

从基础中心向基础周边拉线测量。

控序控制目检验执行标准制控制内容号标方法点一、板材与型材1、材料进场应具有质量合格证明书。

2、表面不得有气孔、结疤、夹渣、氧化皮压入等缺陷3、表面损伤、减薄等应小于钢审阅板允许的负偏差。

质量4、应有清晰可见的标识。

二、焊接材料证明材1、焊接材料具有出厂质量合格文件料证明书,项目齐全、数据合达到标进格,否则应进行复验。

GB50128-2005 二准要求测厚2、有实物标记。

场或游3、入库验收、保管和发放应符检标卡合规定。

验三、附件尺仪1、接管:切口平整、无裂纹、抽检重皮、氧化物,切口端面倾斜偏差 ?1% d ,且?3 mm。

2、法兰孔跨中,密封面无损伤,法兰密封面与接管的轴线垂直度?0.5 mm。

3、其它附件,按图纸及标准检查。

控控制内容序控制目检验执行标准制号标方法点一、预制准备:1.预制组装和检验过程中所使用样板的制作,应经检查员检GB50128-2005 验确认。

ICS 75.180P 72备案号:J509-2006中华人民共和国石油化工行业标准SH/T 3538—2005石油化工机器设备安装工程施工及验收通用规范General Specification for Construction and Acceptance of PetrochemicalMechanical Equipment Installation Engineering2006-01-17 发布 2006-07-01 实施SH/T 3538-2005目 次前言Ⅲ ······················································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································································1 范围 1 2 规范性引用文件 1 3 术语和定义 1 4 机器设备安装准备 3 4.1 技术文件 3 4.2 开箱检验和保管 3 4.3 施工现场 4 4.4 基础检查、复测及处理 4 5 机器设备的安装 5 5.1 放线 5 5.2 有垫铁安装 5 5.3 无垫铁安装 6 5.4 地脚螺栓7 5.5 就位、找平及找正7 5.6 灌浆8 5.7 转子轴对中9 6 清洗与装配10 6.1 一般规定10 6.2 螺栓、键、定位销装配10 6.3 过盈配合件装配13 6.4 滚动轴承装配14 6.5 滑动轴承装配16 6.6 密封件装配18 6.7 联轴器装配21 6.8 传动齿轮、蜗轮、皮带及链条的装配26 7 附属设备及管道的安装30 7.1 附属设备安装30 7.2 油系统、密封系统管道的安装30 7.3 管道的酸洗、冲洗和吹扫30 7.4 管道与机器的连接30 8 试运转31 8.1 条件及准备31 8.2 附属设备的试运转31 8.3 单机试运转32 9 交工文件33 附录A (资料性附录)地脚螺栓的拧紧力矩及轴向拉力值34 附录B (规范性附录)压浆法与座浆法放置垫铁规则35 附录C (资料性附录)无垫铁安装36 附录D (规范性附录)钢丝直径与重锤重量的选配及钢丝自重下垂度37I。

目录一、编制依据 0二、工程概况 (1)三、人员计划 (2)四、施工准备 (4)五、主要施工方法 (5)六、质量控制措施 (19)七、安全保证措施 (25)八、安全保证体系责任制 (27)九、风雨季施工措施 (29)十、风雨季施工措施 (29)一、编制依据SH/T 3528-2005 石油化工企业钢储罐地基与基础施工及验收规范GB50202-2002 建筑地基基础工程施工质量验收规范GB50204-2002 混您图结构工程施工质量验收规范JGJ107-2010 钢筋机械连接通用技术规程JGJ18-2012 钢筋焊接及验收规程GB50212-2014 建筑防腐蚀工程施工及验收规范GB50164-2011 混凝土质量控制标准GB175-2007 通用硅酸盐水泥GBT14684-2011 建筑用砂GBT14685-2011 建筑用碎石卵石11G101-3 独立基础、条形基础、筏形基础及桩基承台图集二、工程概况2.1工程简介2.1.1项目工程位置位于涠洲岛终端处理厂。

2.1.2涠洲岛是一座位于广西壮族自治区北海市北部湾海域的海岛,处于北部湾中部,在北海市正南面38km,距北海市区66km。

涠洲岛南北方向长6.5km,东西方向宽6km,总面积24.74km2,岛的最高海拔79m,是火山喷发堆凝而成的岛屿。

2.1.3目前涠洲岛与外界的交通主要是轮船,岛上有客运码头、民用码头、军用码头、以及终端厂的原油外输码头。

岛上交通不便,道路狭窄,大型设备运输有一定困难。

2.1.4 土建工程材料资源匮乏。

土建材料,如:水泥、钢筋、沙、石等需从内陆获取。

2.2 工程各称:涠西南油田群陆上终端处理厂新增五万方原油储罐项目2.3 地质概况:新建原油储罐场地的工程地质条件总体上来说是极其复杂。

我方已根据施工图纸完成了CFG桩复合地基处理。

2.4 结构概况:原油储罐基础,罐基础环墙内直径为59460mm,罐基础环墙外直径为60660mm。

目录一、编制依据 (2)二、工程概况 (2)三、人员计划 (3)四、施工准备 (4)五、主要施工方法 (5)六、质量控制措施 (17)七、安全保证措施 (21)八、安全保证体系责任制 (22)九、风雨季施工措施 (24)十、风雨季施工措施 (24)一、编制依据SH/T 3528-2005 石油化工企业钢储罐地基与基础施工及验收规范GB50202-2002 建筑地基基础工程施工质量验收规范GB50204-2002 混您图结构工程施工质量验收规范JGJ107-2010 钢筋机械连接通用技术规程JGJ18-2012 钢筋焊接及验收规程GB50212-2014 建筑防腐蚀工程施工及验收规范GB50164-2011 混凝土质量控制标准GB175-2007 通用硅酸盐水泥GBT14684-2011 建筑用砂GBT14685-2011 建筑用碎石卵石11G101-3 独立基础、条形基础、筏形基础及桩基承台图集二、工程概况2.1工程简介2.1.1项目工程位置位于涠洲岛终端处理厂。

2.1.2涠洲岛是一座位于广西壮族自治区北海市北部湾海域的海岛,处于北部湾中部,在北海市正南面38km,距北海市区66km。

涠洲岛南北方向长6.5km,东西方向宽6km,总面积24.74km2,岛的最高海拔79m,是火山喷发堆凝而成的岛屿。

2.1.3目前涠洲岛与外界的交通主要是轮船,岛上有客运码头、民用码头、军用码头、以及终端厂的原油外输码头。

岛上交通不便,道路狭窄,大型设备运输有一定困难。

2.1.4土建工程材料资源匮乏。

土建材料,如:水泥、钢筋、沙、石等需从内陆获取。

2.2 工程各称:涠西南油田群陆上终端处理厂新增五万方原油储罐项目2.3 地质概况:新建原油储罐场地的工程地质条件总体上来说是极其复杂。

我方已根据施工图纸完成了CFG桩复合地基处理。

2.4 结构概况:原油储罐基础,罐基础环墙内直径为59460mm,罐基础环墙外直径为60660mm。

附录H(资料性附录)罐基挖沟纠偏法H.1 采用罐基挖沟纠偏时,沟长宜为半圆周长,即以最小沉降点为中心各向两侧沿周长延伸1/4周长(见图H.1)。

图H.1 挖沟长度与位置H.2 沟断面宜挖成里壁直(靠罐壁的一边)、外壁带坡(见图H.2),沟上宽b 为500 mm ~1 000 mm ;沟底宽d 为300 mm ~1 000 mm 。

塌落到沟底的土应及时清理,沟内积水液面不得超过基础环墙(梁)的底部。

注:C 为罐基础底与地面距离,mm 。

1-罐体;2-环墙图H.2 沟断面示意H.3 沟里壁与罐壁的最小距离S 应能保证罐混凝土环墙内地基的砂垫层不致流失,距离罐壁宜为300 mm ~500 mm 。

H.4 沟深应根据罐地基的土质情况、里壁与罐壁距离、荷载大小和时间长短等因素决定,当储罐地基为淤泥质亚粘土时,挖沟深度可按公式(式H.1)、公式(式H.2)计算:H 3=h +H 2 ………………………………………………………(式H.1)h= s ·tg α……………………………………………………… (式H.2)式中:Smax Smin1 2 b s CH 3 d α h 2 aSH/T 3528-200530 H3——罐基础底至沟底高差,mm;h——计算因子,mm;H2——常数,通常取400mm~500mm;s——沟里离罐壁距离,mm;α——沟外壁坡度,取45°。

H.5 在罐自重的作用,观测沟侧每天的沉降量并记录。

根据每天沉降量和土方回填夯实所需的时间,确定土方回填夯实的时机。

土方回填后继续观测沉降量,沉降观测结束后,基础不均匀沉降值应符合本规范表22的规定。

用词说明SH/T 3528-2005对本规范条文中要求执行严格程度用的助动词,说明如下:(一)表示很严格、非这样做不可并具有法定责任时,用的助动词为“必须”(must);(二)表示要准确地符合规范而应严格遵守时,用的助动词为:正面词采用“应”(shall);反面词采用“不应”或“不得”(shall not)。

1 范围本规范规定了石油化工工程中塔架、管廊和框架等钢结构工程工厂化制造和施工安装的质量标准。

本规范适用于石油化工工程新建、扩建与改建项目碳素结构钢、低合金结构钢制造的塔架、管廊和框架等钢结构工程的施工质量验收。

4一般规定4.1石油化工钢结构工程质量验收处应符合设计文件和本规范要求外,尙应按SH/T3508《石油化工安装工程施工质量验收标准》的规定进行检验批、分项工程、分部工程的验收。

钢结构工程分部工程、分项工程的划分应按SH/T3508《石油化工安装工程施工质量验收统一标准》的规定执行;检验批的划分应按本规范的规定执行。

4.2钢结构工程施工单位应具备相应的钢结构工程施工资质。

条文说明:本条是对从事钢结构工程的施工企业资质和质量管理内容进行检查,强调市场准入制度,是管理方面的要求。

4.3钢结构工程施工质量的检查和检验,应采用经计量检定、校准合格的计量器具。

条文说明:钢结构的制作、安装和质量检验用的计量器具应为检定合格的计量器具,且保证在检定有效期内使用。

不同计量器具具有不同的使用要求,同意计量器具在不同使用状况下,测量精度不同,因此要求严格按有关规定正确操作计量器具。

4.4钢结构工程的原材料、半成品及成品应进行进场验收;半成品、成品应涂装底漆。

条文说明:本条强调了到货检验的重要性。

由于成品、半成品从加工完毕到包装运输再到现场施工可能间隔较长时间,故规定成品、半成品的交付条件应为底漆涂装完毕,以利于成品保护。

4.5 对钢结构材料进行验收时,若抽样检查或复验有一件不合格,可按原规定数量的两倍抽样,在进行检查和复验;若仍有不合格,则该批次钢结构材料不得使用。

4.6钢结构工程的隐蔽工程未经验收,不得进行后续作业。

条文说明:在焊接过程中、焊缝冷却过程及以后的相当长的一段时间可能产生裂纹。

普通碳素钢产生延迟裂纹的可能性很小,因此规定在焊缝冷却到环境温度后即可进行外观检查。

低合金钢结构焊缝的延迟裂纹延迟时间较长,考虑到工厂存放条件、现场安装进度、供需衔接的限制以及随着时间延长,产生延迟裂纹的几率逐渐减小等因素,本规范以焊接完成24h 后外观检查的结果作为验收的依据。