Cellulose acetate butyrate as multifunctional additive for poly(butylene succinate) by melt blending

- 格式:pdf

- 大小:659.41 KB

- 文档页数:8

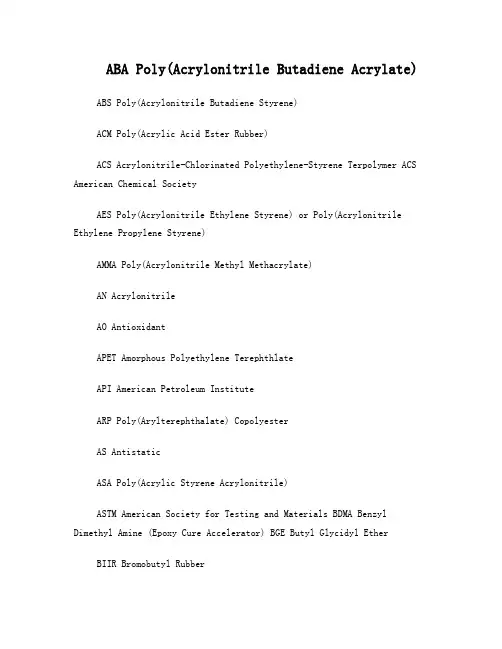

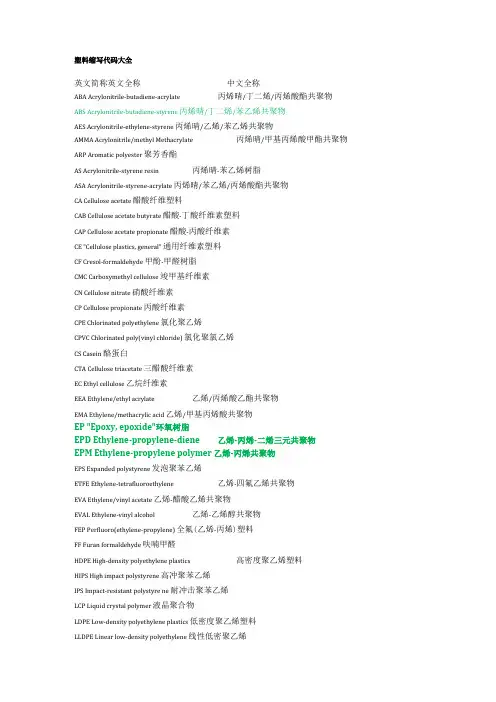

ABA Poly(Acrylonitrile Butadiene Acrylate)ABS Poly(Acrylonitrile Butadiene Styrene)ACM Poly(Acrylic Acid Ester Rubber)ACS Acrylonitrile-Chlorinated Polyethylene-Styrene Terpolymer ACS American Chemical SocietyAES Poly(Acrylonitrile Ethylene Styrene) or Poly(Acrylonitrile Ethylene Propylene Styrene)AMMA Poly(Acrylonitrile Methyl Methacrylate)AN AcrylonitrileAO AntioxidantAPET Amorphous Polyethylene TerephthlateAPI American Petroleum InstituteARP Poly(Arylterephthalate) CopolyesterAS AntistaticASA Poly(Acrylic Styrene Acrylonitrile)ASTM American Society for Testing and Materials BDMA Benzyl Dimethyl Amine (Epoxy Cure Accelerator) BGE Butyl Glycidyl EtherBIIR Bromobutyl RubberBMC Bulk Molding CompoundBMI BismaleimideBOPP Biaxially Oriented Polypropylene (Film)BR Polybutadiene RubberCA Cellulose AcetateCAB Cellulose Acetate ButyrateCAP Cellulose Acetate PropionateCF Cresol FormaldehydeCFR Code of Federal Regulations (21 CFR has provisions dealing with food contact of polymers)CGE Cresol Glycidyl Ether CHDM CyclohexanedimethanolCIIR Chlorobutyl RubberCM Chlorinated Polyethylene RubberCM Compression MoldedCMC Carboxymethyl CelluloseCN Cellulose NitrateCO Epichlorohydrin Rubber (Homopolymer)COF Coefficient of FrictionCP Cellulose PropionateCPE Chlorinated PolyethyleneCPVC Chlorinated Polyvinyl ChlorideCR Polychloroprene RubberCS CaseinCSA Canadian Standards AssociatesCSM Chlorosulfonated Polyethylene RubberCTE Coefficient of Thermal ExpansionCTFE ChlorortrifluoroethyleneCTI Comparative Tracking IndexCVD Chemical Vapor DepositionDAM Dry As Molded (often applied to nylon)DAP Diallyl PhthalateDDS Diaminodiphenyl Sulfone (Epoxy Cure Agent) DGEBA Diglycidyl Ether of Bisphenol ADIN Deutches Institut f NormungDTUL Deflection Temperature Under LoadEAA Ethylene/Acrylic Acid CopolymerEBAC Poly(Ethylene Butyl Acrylate)EC Ethyl CelluloseECN Epoxy Cresol NovolacECO Epichlorohydrin Rubber (Ethylene Oxide Copolymer) ECTFEPoly(Ethylene Chlorotrifluoroethylene)EEA Poly(Ethylene-Ethyl Acrylate)EEW Epoxy Equivalent Weight (Also called WPE)EMAAA Ethylene Acid TerpolymerEMAC Poly(Ethylene Methyl Acrylate)EMCM Ethylene Methyl Acrylate Cyclohexene Methyl Acrylate EMI Electromagnetic InterferenceEP Epoxy; EpoxideEPA Environmental Protection Agency (US Government) EPDM Ethylene Propylene Terpolymer RubberEPM Ethylene Propylene CopolymerEPN Epoxy Phenol NovolacEPS Expanded PolystyreneESCR Environmental Stress Cracking Resistance ETFE Poly(Ethylene Tetrafluoroethylene)ETPU Engineering Thermoplastic PolyurethaneEVA Ethylene Vinyl Acetate CopolymerEVAC Ethylene-Vinyl Acetate CopolymerEVAL Poly(Ethylene-Vinyl Alcohol)EVOH Poly(Ethylene Vinyl Alcohol)FDA Food and Drug Administration (US Government) FEP Fluorinated Ethylene PropyleneFF Furan FormaldehydeFMQ Fluorosilicone RubberFPM Fluorocarbon RubberFPVC Flexible Polyvinyl ChlorideFR Flame RetardantFVMQ Fluorosilicone RubberFZ Fluorinated Polyphosphazene RubberGFR Glass Fiber ReinforcedGP General PurposeGPO Propylene Oxide RubberGPPS General Purpose PolystyreneHAI High Amp Arc IgnitionHALS Hindered Amine Light StabilizerHDPE High Density PolyethyleneHDT Heat Deflection Temperature or Heat Distortion Temperature HFP HexafluoropropyleneHIPS High Impact PolystyreneHNBR Hydrogenated Nitrile Rubber (Acrylonitrile-Butadiene Rubber) HRE Rockwell E Hardness NumberHRM Rockwell M Hardness NumberHRR Rockwell R Hardness NumberHVAR High Voltage Arc Resistance to IgnitionHVTR High Voltage Tracking RateHWI Hot Wire IgnitionIBS Interactive Blowing SystemIIR Butyl RubberIM Injection MoldedIMR Internal Mold ReleaseISO International Standards OrganizationLCP Liquid Crystal PolymerLDPE Low Density PolyethyleneLLDPE Linear Low Density PolyethyleneLMDPE Linear Medium Density PolyethyleneMD Metal DeactivatorMDPE Medium Density PolyethyleneMEKP Methyl Ethyl Ketone Peroxide (Thermoset Curing Agent) MF Melamine-FormaldehydeMFD Microfloppy DiskettesMFI Melt Flow IndexMVTR Moisture Vapor Transmission RateMWD Molecular Weight DistributionNASA National Aeronautics and Space Administration (US)NB No Break (Applied to Impact Test Results)NBR Nitrile Rubber (Acrylonitrile-Butadiene Rubber)NHFR Non-Halogen Flame RetardantNHT High Temperature NylonNSF National Sanitation Foundation (nonregulatory agency)OB Optical BrightenerODP Ozone Depletion PotentialOEM Original Equipment ManufacturerOPP Oriented Polypropylene (Film)OPS Oriented Polystyrene (Film)OSHA Occupation Safety and Health Administration (US Government) PA PolyacrylatePA Polyamide (Nylon)PAEK PolyaryletherPAEK PolyaryletherketonePAI Polyamide-ImidePAMS Poly(Alpha Methylstyrene)PAN PolyacrylonitrilePARA Polyarylamide (polyaramide)PAS PolyarylsulfonePASA Polyamide, Semi-Aromatic (Nylon)PASU PolyarylsulfonePB PolybutadienePB Polybutene-1PBGA Plastic Ball Grid ArrayPBI PolybenzimidazolePBT Polybutylene TerephthalatePC PolycarbonatePCB Printed Circuit BoardPCP Post-Consumer PlasticPCR Post-Consumer ResinPCT Polycyclohexylenedimethylene Terephthalate PCTFE PolychlorortrifluoroethylenePCTG Glycol-Modified PCTPCU Polycarbonate UrethanePDAP Poly(Diallyl Phthalate)PDSM polydimethylsiloxane (Silicone)PE PolyethylenePEBA Polyether Block AmidePEEK PolyetheretherketonePEF Process Engineered FuelPEG Polyethylene GlycolPEI PolyetherimidePEK PolyetherketonePEKEKK P olyetherketoneetherketoneketone PEKK PolyetherketoneketonePEN Polyethylene NaphthalatePEO Poly(Ethylene Oxide)PEOX Poly(Ethylene Oxide)PES PolyethersulfonePESU PolyethersulfonePET Polyethylene TerephthalatePETG PET Modified with CHDMPEX Cross-linked PolyethylenePF Phenol Formaldehyde (Phenolic)PFA PerfluoroalkoxyPFPE PolyperfluoropolyetherPI PolyimidePIB PolyisobutylenePIR Polyisocyanurate FoamPISU PolyimidesulfonePMMA PolymethylmethacrylatePMP PolymethylpentenePNR Polynorborane RubberPO PolyolefinPOB Poly(p-Oxybenzoate)POM Polyoxymethylene (Acetal)POP Point of Purchase (Marketing Displays) PP PolypropylenePPA PolyphthalamidePPE Polyphenylene EtherPPF Phenol-FurfuralPPG Polypropylene GlycolPPO Polyphenylene OxidePPOX Polypropylene OxidePPS Polyphenylene SulfidePPSU PolyphenylsulfonePRF Plastics Recovery FacilityPS PolystyrenePSU PolysulfonePTFE Polytetrafluoroethylene PTMG Polytetramethylene Glycol PTT Polytrimethylene Terephthalate PU PolyurethenePUR PolyurethenePVAC Poly(Vinyl Acetate)PVAL Poly(Vinyl Alcohol)PVB Poly(Vinyl Butyral)PVC Polyvinyl ChloridePVCA Poly(Vinyl Chloride-Acetate)PVDC Polyvinylidene ChloridePVDF Polyvinylidene FluoridePVFM Poly(Vinyl Formal)PVK PolvinylcarbazolePVOH Polyvinyl AlcoholPVP PolyvinylpyrrolidonePZ Polyphosphazene RubberRH Relative HumidityRIM Reaction Injection MoldingRPVC Rigid Polyvinyl ChlorideRRIM Reinforced Reaction Injection Molding RTI Relative Thermal Index (UL test) RTPU Rigid Thermoplastic PolyurethaneRTV Room Temperature Vulcanizing (Silicone)SAN Poly(Styrene Acrylonitrile)SB Styrene-ButadieneSBC Styrene-Butadiene CopolymerSBS Poly(Styrene Butadiene Styrene)SEBS Poly(Styrene-Ethylene-Butadiene-Styrene) Elastomer SI Silicone SI System International (a subset of metric units)SIS Poly(Styrene-Isoprene-Styrene) ElastomerSMA Poly(Styrene Maleic Anhydride)SMC Sheet Molding CompoundSMMA Styrene Methyl Methacrylate CopolymerSMS Styrene-a-MethylstyreneSPS Syndiotactic PolystyreneSPU Segmented PolyurethaneTAIC Triallyl IsocyanurateTEEE Ether Ester Block Copolymer (Thermoplastic Elastomer) TEEE Thermoplastic Elastomer Ether Ester Block Copolymer TEO Olefinic Thermoplastic ElastomerTES Thermoplastic Styrenic ElastomerTFE PolytetrafluoroethyleneTM Transfer MoldedTP ThermoplasticTPE Thermoplastic ElastomerTPI Thermoplastic PolyimideTPO Thermoplastic Polyolefin (often applied to elastomers) TPU Thermoplastic Polyurethene (often applied to elastomers) TPUR Thermoplastic Polyurethene (often applied to elastomers) TPV Thermoplastic VulcanizateTS ThermosetTYS Tensile Yield StrengthUF Urea FormaldehydeUHMW Ultra High Molecular Weight (often applied to polyethylene) UL Underwriters LaboratoryULDPE Ultra Low Density PolyethyleneUP Unsaturated Polyester (Thermoset)USDA United States Department of AgricultureUTS Ultimate Tensile StrengthUV UltravioletVCE Poly(Vinyl Chloride-Ethylene)VCEMA Poly(Vinyl Chloride-Ethylene-Methyl Acrylate)VCMA Poly(Vinyl Chloride-Methyl Acrylate)VCVAC Poly(Vinyl Chloride-Vinyl Acrylate)VCVDC Poly(Vinyl Chloride-Vinylidene Chloride)VHMW Very High Molecular Weight (often applied to polyethylene) WPE Weight per Epoxide (also called EEW)XLPE Cross-linked Polyethylene。

![[指南]橡胶、塑料、热塑性弹性体中英文称号简码代号](https://uimg.taocdn.com/48bd2ecf6bd97f192379e98c.webp)

[指南]橡胶、塑料、热塑性弹性体中英文称号简码代号橡胶、塑料、热塑性弹性体中英文名称简码代号橡胶、塑料、热塑性弹性体中英文名称简码代号.txt?-一人行,必会发情二人行,必会激情三人行,必有奸情就不会被珍惜。

真实的女孩不完美,完美的女孩不真实。

得之坦然,失之淡然,顺其自然,争其必然。

PVC--聚氯乙烯PE--聚乙烯PPR--无规(随机)聚丙烯PVDF--聚偏二氟乙烯详细管材如下:EVA--乙烯,醋酸乙烯聚物PET 聚对苯二甲酸乙二酯poly(ethylene terephthalate) 01PE-HD 高密度聚乙烯polyethylene, high density 02PVC 聚氯乙烯poly(vinyl chloride) 03PE-LD 低密度聚乙烯polyethylene,low density 04PP 聚丙烯polypropylene 05PS 聚苯乙烯polystyrene 06ABS 丙烯腈,丁二烯,苯乙烯塑料acrylonitrile-butadiene-styrene plastic 07PA 聚酰胺polyamide 08PAN 聚丙烯腈polyacrylonitrile 09PC 聚碳酸酯polycarbonate 10PBT 聚对苯二甲酸丁二酯poly(butylene terephthalate) 11PE-LLD 线性低密度聚乙烯polyethylene,linear low density 12PE-MD 中密度聚乙烯polyethylene,medium density 13PE-UHMW 超高分子量聚乙烯polyethylene,ultra high molecular weight 14 PUR 聚氨酯polyurethane 15PMMA 聚甲基丙烯酸甲酯poly(methyl methacrylate) 16PVAL 聚乙烯醇poly(vinyl alcohol) 17PVC-C 氯化聚氯乙烯poly(vinyl chloride),chlorinated 18PVC-U 未增塑聚氯乙烯poly(vinyl chloride),unplasticized 19PVDC 聚偏二氯乙烯poly(vinylidene chloride) 20PVDF 聚偏二氟乙烯poly(vinylidene fluoride) 21PVF 聚氟乙烯poly(vinyl fluoride) 22UP 不饱和聚酯树脂unsaturated polyester resin 23UF 脲,甲醛树脂urea-formaldehyderesin 24CA 乙酸纤维素cellulose acetate 25PEEK 聚醚醚酮polyetheretherketone 26PEUR 聚醚型聚氨酯polyetherurethane 27PF 酚醛树脂phenol-formaldehyde resin 28PI 聚酰亚胺polyimide 29PHBV 聚羟基丁酸酯戊酸酯poly-(hydroxybutyrate-co-hydroxyvalerate 30PK 聚酮polyketone 30PTFE 聚四氟乙烯poly tetrafluoroethylene 31POM 聚氧亚甲基;聚甲醛;聚缩醛polyoxymethylene;polyacetal;polyformaldehyde 32PLA 聚乳酸polylactic acid or polylactide 33PCL 聚已内酯polycaprolactone 34PPDO 聚对二氧环己酮 35PPC 二氧化碳共聚合物carbon dioxide copolymer 36PBS 聚丁二酸丁二醇酯Polybuthylenesuccinate 37PHA 聚羟基脂肪酸酯polyhydroxyalkanoic or polyhydroxyalkanoates 38PHB 聚-3-羟基丁酸polyhydroxybutyric acid or polyhydroxybutyrate 39PGA 聚乙交酯poly(glycolic acid) 40PEC PolyEster Carbonate or Poly(Butylene Succinate/Carbonate) 41PES Poly(Ethylene Succinate) 42PTMAT Poly(TetraMethylene Adipate/Terephthalate) 43PBAT Poly(Butylene Adipate/Terephthalate) 44AB 丙烯腈,丁二烯塑料acrylonitrile-butadiene plastic 45ABAK 丙烯腈,丁二烯,丙烯酸酯塑料acrylonitrile-butadiene-acrylate plastic 46ACS 丙烯腈-氯化聚乙烯-苯乙烯塑料acrylonitrile-chlorinated polyethylene-styrene 47AEPDS 丙烯腈,(乙烯,丙烯,二烯),苯乙烯塑料acrylonitrile-(ethylene-propylene-diene)-styrene plastic 48 AMMA 丙烯腈,甲基丙烯酸甲酯塑料acrylonitrile-methyl methacryate plastic 49ASA 丙烯腈-苯乙烯-丙烯酸酯塑料acrylonitrile-stytene-acrylate plastic 50CAB 乙酸丁酸纤维素cellulose acetate butyrate 51CAP 乙酸丙酸纤维素cellulose acetate propionate 52CEF 甲醛纤维素cellulose formaldehyde 53CF 甲酚,甲醛树脂cresol-formaldehyde resin 54CMC 羧甲基纤维素carboxymethyl cellulose 55CN 硝酸纤维素cellulose nitrate 56COC 环烯烃共聚物cycloolefin copolymer 57CP 丙酸纤维素cellulose propionate 58CTA 三乙酸纤维素cellulose triacetate 59E/P 乙烯,丙烯塑料ethylene-propylene plastic 60EAA 乙烯,丙烯酸塑料ethylene-acrylic acid plastic 61EBAK 乙烯,丙烯酸丁酯塑料ethylene-butyl acrylate plastic 62EC 乙基纤维素ethyl cellulose 63EEAK 乙烯,丙烯酸乙酯塑料ethylene-ethyl acrylate plastic 64 EMA 乙烯,甲基丙烯酸塑料ethylene-methacrylic acid plastic 65 EP 环氧;环氧树脂或塑料epoxide;epoxy resin or plastic 66ETFE 乙烯,四氟乙烯塑料e thylene-tetrafluoroethylene plastic 67 EVAC 乙烯,乙酸乙烯酯塑料ethylene-vinyl acetate plastic 68 EVOH 乙烯,乙烯醇塑料ethylene-vinyl alcohol plastic 69FEP 全氟(乙烯,丙烯)塑料perfluoro(ethylene-propylene)plastic 70FF 呋喃,甲醛树脂furan-formaldehyde resin 71LCP 液晶聚合物liquid-crystal polymer 72MABS 甲基丙烯酸甲酯,丙烯腈,丁二烯,苯乙烯塑料methyl methacrylate-acrylonitrile-butadiene-styrene plastic 73MBS 甲基丙烯酸甲酯,丁二烯,苯乙烯塑料methyl methacrylate-butadiene-styrene plastic 74MC 甲基纤维素methyl cellulose 75MF 三聚氰胺,甲醛树脂melamine-formaldehyde resin 76MP 三聚氰胺,酚醛树脂melamine-phenol resin 77MSAN α,甲基苯乙烯,丙烯腈塑料α-methylstyrene-acrylonitrile plastic 78PAA 聚丙烯酸poly(acrylic acid) 79PAEK 聚芳醚酮polyaryletherketone 80PAI 聚酰胺(酰)亚胺polyamidimide 81PAK 聚丙烯酸酯polyarylate 82PAR 聚芳酯polyarylate 83PARA 聚芳酰胺poly(aryl amide) 84PB 聚丁烯polybutene 85PBAK 聚丙烯酸丁酯poly(butyl acrylate) 86PBD 1,2,聚丁二烯1,2-polybutadiene 87PBN 聚萘二甲酸丁二酯poly(butylene naphthalate) 88PCCE 亚环己基-二亚甲基-环已基二羧酸酯poly(cyclohexylene dimethylene cyclohexanedicar- boxylate) 89 PCT 聚(对苯二甲酸亚环已基-二亚甲酯)poly(cyclohexylene dimethylene terephthalate) 90PCTFE 聚三氟氯乙烯polychlorotrifluoroethylene 91PDAP 聚邻苯二甲酸二烯丙酯poly(diallyl phthalate) 92 PDCPD 聚二环戊二烯polydicyclopentadiene 93PEC 聚酯碳酸酯polyestercarbonate 94PE-C 氯化聚乙烯polyethylene,chlorinated 95PEEST 聚醚酯polyetherester 96PEI 聚醚(酰)亚胺polyetherimide 97PEK 聚醚酮polyetherketone 98PEN 聚萘二甲酸乙二酯poly(ethylene naphthalate) 99PEOX 聚氧化乙烯poly(ethylene oxide) 100PESTUR 聚酯型聚氨酯polyesterurethane 101PESU 聚醚砜polyethersulfone 102PE-VLD 极低密度聚乙烯polyethylene,very low density 103 PFA 全氟烷氧基烷树脂perfluoro alkoxyl alkane resin 104PIB 聚异丁烯polyisobutylene 105PIR 聚异氰脲酸酯polyisocyanurate 106PMI 聚甲基丙烯酰亚胺polymethacrylimide 107PMMI 聚N,甲基甲基丙烯酰亚胺poly-N-methylmethacrylimide 108 PMP 聚,4,甲基戊烯,1poly-4-methylpentene-1 109PMS 聚,α,甲基苯乙烯poly-α-methylstyrene 110PPE 聚苯醚poly(phenylene ether) 111PP-E 可发性聚丙烯polypropylene,expandable 112PP-HI 高抗冲聚丙烯polypropylene,high impact 113PPOX 聚氧化丙烯poly(propylene oxide) 114PPS 聚苯硫醚poly(phenylene sulfide) 115PPSU 聚苯砜poly(phenylene sulfone) 116PS-E 可发聚苯乙烯polystyrene,expandable 117PS-HI 高抗冲聚苯乙烯polystyrene,high impact 118PSU 聚砜polysulfone 119PTT 聚对苯二甲酸丙二酯poly(trimethylene terephthalate) 120 PVAC 聚乙酸乙烯酯poly(vinyl acetate) 121PVB 聚乙烯醇缩丁醛poly(vinyl butyral) 122PVFM 聚乙烯醇缩甲醛poly(vinyl formal) 123PVK 聚-N-乙烯基咔唑poly-N-vinylcarbazole 124PVP 聚-N-乙烯基吡咯烷酮poly-N-vinylpyrrolidone 125SAN 苯乙烯一丙烯腈塑料styrene-acrylonitrile plastic 126SB 苯乙烯-丁二烯塑料styrene-butadiene plastic 127SI 有机硅塑料silicone plastic 128SMAH 苯乙烯,顺丁烯二酸酐塑料styrene-maleic anhydride plastic 129 SMS 苯乙烯,α,甲基苯乙烯塑料styrene-α-methylstyreneplastic 130VCE 氯乙烯,乙烯塑料vinyl chloride-ethylene plastic 131VCEMAK 氯乙烯,乙烯,丙烯酸甲酯塑料vinyl chloride-ethylene-methyl acrylate plastic 132VCEVAC 氯乙烯,乙烯,丙烯酸乙酯塑料vinyl chloride-ethylene-vinyl acrylate plastic 133VCMAK 氯乙烯,丙烯酸甲酯塑料vinyl chloride-methyl acrylate plastic134VCMMA 氯乙烯,甲基丙烯酸甲酯塑料vinyl chloride-methyl methacrylate plastic 135VCOAK 氯乙烯,丙烯酸辛酯塑料vinyl chloride-octyl acrylate plastic 136 VCVAC 氯乙烯,乙酸乙烯酯塑料vinyl chloride-vinyl acetate plastic 137 VCVDC 氯乙烯,偏二氯乙烯塑料vinylchloride-vinylidene chloride plastic 138VE 乙烯基酯树脂vinyl ester resin 139PE 聚乙烯polyethylene聚乙烯——PE聚丙烯——PP聚丁烯——PB聚氯乙稀——PVC耐热聚乙稀——PE-RT硬聚氯乙稀(增强聚氯乙烯)——PVC-U(UPVC)高密度聚乙烯——HDPE 无规共聚聚丙烯——PP-R 玻纤增强聚丙烯——FRPP低密度聚乙烯——LDPE 聚甲基丙烯酸甲酯——PMMA 聚四氟乙烯——PTFE(F4) 三元乙丙橡胶——EPDM 多孔聚苯乙烯——XPS 腈基丁二烯橡胶(丁腈橡胶)——NBR耐冲击性聚苯乙烯——HIP 聚氟乙烯——PVF纳米复合三型聚丙烯——NFPP-R 塑料光纤——POF丙稀腈,丁二烯,苯乙烯——ABS 氯化聚醚——CPS氯化聚醚丁腈(粉末丁腈橡胶)——PNBR聚全氟乙丙稀(氟化乙丙稀)——FEP 均聚聚丙烯——PPH聚偏氟乙烯——PVDF 共聚酰胺(尼龙)——PA 增强聚丙烯——RPP共聚酯——PES高分子聚丙烯酰胺——PAM 增强氯化聚氯乙稀——CPVC 嵌段共聚聚丙烯——PPB 聚苯乙烯——PS交联聚乙烯——PEX聚烯烃——PO三氟氯乙烯——CTFE 全氟代甲基醚——PMVE 全氟代乙基醚——PEVE全氟代丙基醚——PPVE全氟代辛基醚——POVE全氟代烷氧基——PFA聚对苯二甲酸乙二醇酯——PET 定向聚丙烯——OPP流延聚丙烯——CPP共聚甲醛(聚氧甲烯、缩醛)——POM 茂金属线型低密度聚乙烯——MLLDPE 丙烯酸酯橡胶——ACM氯丁胶——CRPVC--聚氯乙烯PE--聚乙烯PPR--无规(随机)聚丙烯PVDF--聚偏二氟乙烯详细管材如下:EVA--乙烯,醋酸乙烯聚物PET 聚对苯二甲酸乙二酯poly(ethylene terephthalate) 01PE-HD 高密度聚乙烯polyethylene, high density 02PVC 聚氯乙烯poly(vinyl chloride) 03 PE-LD 低密度聚乙烯polyethylene,low density 04PP 聚丙烯polypropylene 05 PS 聚苯乙烯polystyrene 06 ABS 丙烯腈,丁二烯,苯乙烯塑料 acrylonitrile-butadiene-styrene plastic 07 PA 聚酰胺polyamide 08PAN 聚丙烯腈polyacrylonitrile 09PC 聚碳酸酯polycarbonate 10PBT 聚对苯二甲酸丁二酯poly(butylene terephthalate) 11PE-LLD 线性低密度聚乙烯polyethylene,linear low density 12PE-MD 中密度聚乙烯polyethylene,medium density 13PE-UHMW 超高分子量聚乙烯polyethylene,ultra high molecular weight 14 PUR 聚氨酯polyurethane 15PMMA 聚甲基丙烯酸甲酯poly(methyl methacrylate) 16PVAL 聚乙烯醇poly(vinyl alcohol) 17PVC-C 氯化聚氯乙烯poly(vinyl chloride),chlorinated 18PVC-U 未增塑聚氯乙烯poly(vinyl chloride),unplasticized 19PVDC 聚偏二氯乙烯poly(vinylidene chloride) 20PVDF 聚偏二氟乙烯poly(vinylidene fluoride) 21PVF 聚氟乙烯poly(vinyl fluoride) 22UP 不饱和聚酯树脂unsaturated polyester resin 23UF 脲,甲醛树脂urea-formaldehyderesin 24CA 乙酸纤维素cellulose acetate 25PEEK 聚醚醚酮polyetheretherketone 26PEUR 聚醚型聚氨酯polyetherurethane 27PF 酚醛树脂phenol-formaldehyde resin 28PI 聚酰亚胺polyimide 29PHBV 聚羟基丁酸酯戊酸酯poly-(hydroxybutyrate-co-hydroxyvalerate 30PK 聚酮polyketone 30PTFE 聚四氟乙烯poly tetrafluoroethylene 31POM 聚氧亚甲基;聚甲醛;聚缩醛polyoxymethylene;polyacetal;polyformaldehyde 32PLA 聚乳酸polylactic acid or polylactide 33PCL 聚已内酯polycaprolactone 34PPDO 聚对二氧环己酮 35PPC 二氧化碳共聚合物carbon dioxide copolymer 36PBS 聚丁二酸丁二醇酯Polybuthylenesuccinate 37PHA 聚羟基脂肪酸酯polyhydroxyalkanoic or polyhydroxyalkanoates 38PHB 聚-3-羟基丁酸polyhydroxybutyric acid or polyhydroxybutyrate 39PGA 聚乙交酯poly(glycolic acid) 40PEC PolyEster Carbonate or Poly(Butylene Succinate/Carbonate) 41PES Poly(Ethylene Succinate) 42PTMAT Poly(TetraMethylene Adipate/Terephthalate) 43PBAT Poly(Butylene Adipate/Terephthalate) 44AB 丙烯腈,丁二烯塑料acrylonitrile-butadiene plastic 45ABAK 丙烯腈,丁二烯,丙烯酸酯塑料acrylonitrile-butadiene-acrylate plastic 46ACS 丙烯腈-氯化聚乙烯-苯乙烯塑料acrylonitrile-chlorinated polyethylene-styrene 47AEPDS 丙烯腈,(乙烯,丙烯,二烯),苯乙烯塑料acrylonitrile-(ethylene-propylene-diene)-styrene plastic 48 AMMA 丙烯腈,甲基丙烯酸甲酯塑料acrylonitrile-methyl methacryate plastic 49ASA 丙烯腈-苯乙烯-丙烯酸酯塑料acrylonitrile-stytene-acrylate plastic 50CAB 乙酸丁酸纤维素cellulose acetate butyrate 51CAP 乙酸丙酸纤维素cellulose acetate propionate 52CEF 甲醛纤维素cellulose formaldehyde 53CF 甲酚,甲醛树脂cresol-formaldehyde resin 54CMC 羧甲基纤维素carboxymethyl cellulose 55CN 硝酸纤维素cellulose nitrate 56COC 环烯烃共聚物cycloolefin copolymer 57CP 丙酸纤维素cellulose propionate 58CTA 三乙酸纤维素cellulose triacetate 59E/P 乙烯,丙烯塑料ethylene-propylene plastic 60EAA 乙烯,丙烯酸塑料ethylene-acrylic acid plastic 61EBAK 乙烯,丙烯酸丁酯塑料ethylene-butyl acrylate plastic 62 EC 乙基纤维素ethyl cellulose 63EEAK 乙烯,丙烯酸乙酯塑料ethylene-ethyl acrylate plastic 64EMA 乙烯,甲基丙烯酸塑料ethylene-methacrylic acid plastic 65 EP 环氧;环氧树脂或塑料epoxide;epoxy resin or plastic 66ETFE 乙烯,四氟乙烯塑料e thylene-tetrafluoroethylene plastic 67 EVAC 乙烯,乙酸乙烯酯塑料ethylene-vinyl acetate plastic 68 EVOH 乙烯,乙烯醇塑料ethylene-vinyl alcohol plastic 69FEP 全氟(乙烯,丙烯)塑料perfluoro(ethylene-propylene)plastic 70FF 呋喃,甲醛树脂furan-formaldehyde resin 71LCP 液晶聚合物liquid-crystal polymer 72MABS 甲基丙烯酸甲酯,丙烯腈,丁二烯,苯乙烯塑料methyl methacrylate-acrylonitrile-butadiene-styrene plastic73MBS 甲基丙烯酸甲酯,丁二烯,苯乙烯塑料methyl methacrylate-butadiene-styrene plastic 74MC 甲基纤维素methyl cellulose 75MF 三聚氰胺,甲醛树脂melamine-formaldehyde resin 76MP 三聚氰胺,酚醛树脂melamine-phenol resin 77MSAN α,甲基苯乙烯,丙烯腈塑料α-methylstyrene-acrylonitrile plastic 78PAA 聚丙烯酸poly(acrylic acid) 79PAEK 聚芳醚酮polyaryletherketone 80PAI 聚酰胺(酰)亚胺polyamidimide 81PAK 聚丙烯酸酯polyarylate 82PAR 聚芳酯polyarylate 83PARA 聚芳酰胺poly(aryl amide) 84PB 聚丁烯polybutene 85PBAK 聚丙烯酸丁酯poly(butyl acrylate) 86PBD 1,2,聚丁二烯1,2-polybutadiene 87PBN 聚萘二甲酸丁二酯poly(butylene naphthalate) 88PCCE 亚环己基-二亚甲基-环已基二羧酸酯poly(cyclohexylene dimethylene cyclohexanedicar- boxylate) 89 PCT 聚(对苯二甲酸亚环已基-二亚甲酯)poly(cyclohexylene dimethylene terephthalate) 90PCTFE 聚三氟氯乙烯polychlorotrifluoroethylene 91PDAP 聚邻苯二甲酸二烯丙酯poly(diallyl phthalate) 92PDCPD 聚二环戊二烯polydicyclopentadiene 93PEC 聚酯碳酸酯polyestercarbonate 94PE-C 氯化聚乙烯polyethylene,chlorinated 95PEEST 聚醚酯polyetherester 96PEI 聚醚(酰)亚胺polyetherimide 97PEK 聚醚酮polyetherketone 98PEN 聚萘二甲酸乙二酯poly(ethylene naphthalate) 99PEOX 聚氧化乙烯poly(ethylene oxide) 100PESTUR 聚酯型聚氨酯polyesterurethane 101PESU 聚醚砜polyethersulfone 102PE-VLD 极低密度聚乙烯polyethylene,very low density 103PFA 全氟烷氧基烷树脂perfluoro alkoxyl alkane resin 104PIB 聚异丁烯polyisobutylene 105PIR 聚异氰脲酸酯polyisocyanurate 106PMI 聚甲基丙烯酰亚胺polymethacrylimide 107PMMI 聚N,甲基甲基丙烯酰亚胺poly-N-methylmethacrylimide 108PMP 聚,4,甲基戊烯,1poly-4-methylpentene-1 109PMS 聚,α,甲基苯乙烯poly-α-methylstyrene 110PPE 聚苯醚poly(phenylene ether) 111PP-E 可发性聚丙烯polypropylene,expandable 112PP-HI 高抗冲聚丙烯polypropylene,high impact 113PPOX 聚氧化丙烯poly(propylene oxide) 114PPS 聚苯硫醚poly(phenylene sulfide) 115PPSU 聚苯砜poly(phenylene sulfone) 116PS-E 可发聚苯乙烯polystyrene,expandable 117PS-HI 高抗冲聚苯乙烯polystyrene,high impact 118PSU 聚砜polysulfone 119PTT 聚对苯二甲酸丙二酯poly(trimethylene terephthalate) 120 PVAC 聚乙酸乙烯酯poly(vinyl acetate) 121PVB 聚乙烯醇缩丁醛poly(vinyl butyral) 122PVFM 聚乙烯醇缩甲醛poly(vinyl formal) 123PVK 聚-N-乙烯基咔唑poly-N-vinylcarbazole 124PVP 聚-N-乙烯基吡咯烷酮poly-N-vinylpyrrolidone 125SAN 苯乙烯一丙烯腈塑料styrene-acrylonitrile plastic 126SB 苯乙烯-丁二烯塑料styrene-butadiene plastic 127SI 有机硅塑料silicone plastic 128SMAH 苯乙烯,顺丁烯二酸酐塑料styrene-maleic anhydride plastic 129SMS 苯乙烯,α,甲基苯乙烯塑料styrene-α-methylstyreneplastic 130VCE 氯乙烯,乙烯塑料vinyl chloride-ethylene plastic 131VCEMAK 氯乙烯,乙烯,丙烯酸甲酯塑料vinyl chloride-ethylene-methyl acrylate plastic 132VCEVAC 氯乙烯,乙烯,丙烯酸乙酯塑料vinyl chloride-ethylene-vinyl acrylate plastic 133VCMAK 氯乙烯,丙烯酸甲酯塑料vinyl chloride-methyl acrylate plastic134VCMMA 氯乙烯,甲基丙烯酸甲酯塑料vinyl chloride-methyl methacrylate plastic 135VCOAK 氯乙烯,丙烯酸辛酯塑料vinyl chloride-octyl acrylate plastic 136 VCVAC 氯乙烯,乙酸乙烯酯塑料vinyl chloride-vinyl acetate plastic 137 VCVDC 氯乙烯,偏二氯乙烯塑料vinylchloride-vinylidene chloride plastic 138VE 乙烯基酯树脂vinyl ester resin 139PE 聚乙烯polyethylene聚乙烯——PE聚丙烯——PP聚丁烯——PB聚氯乙稀——PVC耐热聚乙稀——PE-RT硬聚氯乙稀(增强聚氯乙烯)——PVC-U(UPVC)高密度聚乙烯——HDPE 无规共聚聚丙烯——PP-R 玻纤增强聚丙烯——FRPP 低密度聚乙烯——LDPE 聚甲基丙烯酸甲酯——PMMA 聚四氟乙烯——PTFE(F4) 三元乙丙橡胶——EPDM 多孔聚苯乙烯——XPS腈基丁二烯橡胶(丁腈橡胶)——NBR 耐冲击性聚苯乙烯——HIP 聚氟乙烯——PVF纳米复合三型聚丙烯——NFPP-R 塑料光纤——POF丙稀腈,丁二烯,苯乙烯——ABS 氯化聚醚——CPS氯化聚醚丁腈(粉末丁腈橡胶)——PNBR 聚全氟乙丙稀(氟化乙丙稀)——FEP 均聚聚丙烯——PPH聚偏氟乙烯——PVDF共聚酰胺(尼龙)——PA 增强聚丙烯——RPP共聚酯——PES高分子聚丙烯酰胺——PAM 增强氯化聚氯乙稀——CPVC 嵌段共聚聚丙烯——PPB聚苯乙烯——PS交联聚乙烯——PEX聚烯烃——PO三氟氯乙烯——CTFE 全氟代甲基醚——PMVE 全氟代乙基醚——PEVE 全氟代丙基醚——PPVE 全氟代辛基醚——POVE 全氟代烷氧基——PFA 聚对苯二甲酸乙二醇酯——PET 定向聚丙烯——OPP流延聚丙烯——CPP共聚甲醛(聚氧甲烯、缩醛)——POM 茂金属线型低密度聚乙烯——MLLDPE 丙烯酸酯橡胶——ACM氯丁胶——CR氟橡胶——FPM端缩基丁腈液体橡胶——HTBN 硅胶——MQ氯磺化聚乙烯橡胶——CSM 丁钠橡胶——S-BR天然橡胶——NR——FPM 端缩基丁腈液体橡胶——HTBN 硅胶——MQ 氯磺化聚乙烯橡胶——CSM 丁钠橡胶——S-BR天然橡胶——NR。

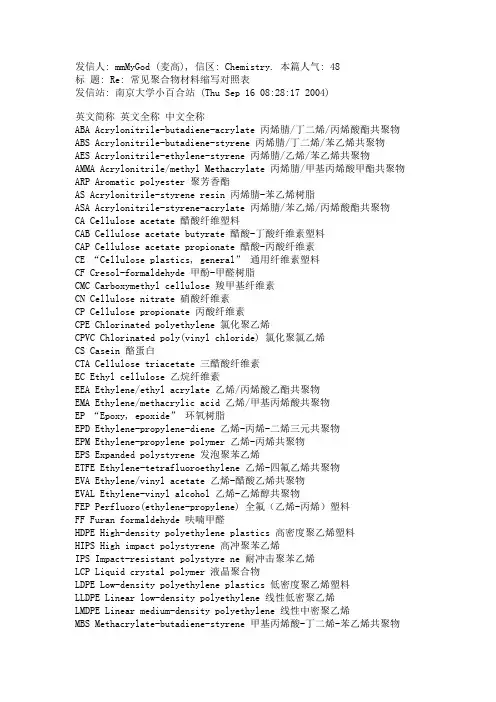

发信人: mmMyGod (麦高), 信区: Chemistry. 本篇人气: 48标题: Re: 常见聚合物材料缩写对照表发信站: 南京大学小百合站 (Thu Sep 16 08:28:17 2004)英文简称英文全称中文全称ABA Acrylonitrile-butadiene-acrylate 丙烯腈/丁二烯/丙烯酸酯共聚物ABS Acrylonitrile-butadiene-styrene 丙烯腈/丁二烯/苯乙烯共聚物AES Acrylonitrile-ethylene-styrene 丙烯腈/乙烯/苯乙烯共聚物AMMA Acrylonitrile/methyl Methacrylate 丙烯腈/甲基丙烯酸甲酯共聚物ARP Aromatic polyester 聚芳香酯AS Acrylonitrile-styrene resin 丙烯腈-苯乙烯树脂ASA Acrylonitrile-styrene-acrylate 丙烯腈/苯乙烯/丙烯酸酯共聚物CA Cellulose acetate 醋酸纤维塑料CAB Cellulose acetate butyrate 醋酸-丁酸纤维素塑料CAP Cellulose acetate propionate 醋酸-丙酸纤维素CE “Cellulose plastics, general” 通用纤维素塑料CF Cresol-formaldehyde 甲酚-甲醛树脂CMC Carboxymethyl cellulose 羧甲基纤维素CN Cellulose nitrate 硝酸纤维素CP Cellulose propionate 丙酸纤维素CPE Chlorinated polyethylene 氯化聚乙烯CPVC Chlorinated poly(vinyl chloride) 氯化聚氯乙烯CS Casein 酪蛋白CTA Cellulose triacetate 三醋酸纤维素EC Ethyl cellulose 乙烷纤维素EEA Ethylene/ethyl acrylate 乙烯/丙烯酸乙酯共聚物EMA Ethylene/methacrylic acid 乙烯/甲基丙烯酸共聚物EP “Epoxy, epoxide” 环氧树脂EPD Ethylene-propylene-diene 乙烯-丙烯-二烯三元共聚物EPM Ethylene-propylene polymer 乙烯-丙烯共聚物EPS Expanded polystyrene 发泡聚苯乙烯ETFE Ethylene-tetrafluoroethylene 乙烯-四氟乙烯共聚物EVA Ethylene/vinyl acetate 乙烯-醋酸乙烯共聚物EVAL Ethylene-vinyl alcohol 乙烯-乙烯醇共聚物FEP Perfluoro(ethylene-propylene) 全氟(乙烯-丙烯)塑料FF Furan formaldehyde 呋喃甲醛HDPE High-density polyethylene plastics 高密度聚乙烯塑料HIPS High impact polystyrene 高冲聚苯乙烯IPS Impact-resistant polystyre ne 耐冲击聚苯乙烯LCP Liquid crystal polymer 液晶聚合物LDPE Low-density polyethylene plastics 低密度聚乙烯塑料LLDPE Linear low-density polyethylene 线性低密聚乙烯LMDPE Linear medium-density polyethylene 线性中密聚乙烯MBS Methacrylate-butadiene-styrene 甲基丙烯酸-丁二烯-苯乙烯共聚物MC Methyl cellulose 甲基纤维素MDPE Medium-density polyethylene 中密聚乙烯MF Melamine-formaldehyde resin 密胺-甲醛树脂MPF Melamine/phenol-formaldehyde 密胺/酚醛树脂NBR 丁晴橡胶PA Polyamide (nylon) 聚酰胺(尼龙)PAA Poly(acrylic acid) 聚丙烯酸PADC Poly(allyl diglycol carbonate) 碳酸-二乙二醇酯· 烯丙醇酯树脂PAE Polyarylether 聚芳醚PAEK Polyaryletherketone 聚芳醚酮PAI Polyamide-imide 聚酰胺-酰亚胺PAK Polyester alkyd 聚酯树脂PAN Polyacrylonitrile 聚丙烯腈PARA Polyaryl amide 聚芳酰胺PASU Polyarylsulfone 聚芳砜PAT Polyarylate 聚芳酯PAUR Poly(ester urethane) 聚酯型聚氨酯PB Polybutene-1 聚丁烯-[1]PBA Poly(butyl acrylate) 聚丙烯酸丁酯PBAN Polybutadiene-acrylonitrile 聚丁二烯-丙烯腈PBS Polybutadiene-styrene 聚丁二烯-苯乙烯PBT Poly(butylene terephthalate) 聚对苯二酸丁二酯PC Polycarbonate 聚碳酸酯PCTFE Polychlorotrifluoroethylene 聚氯三氟乙烯PDAP Poly(diallyl phthalate) 聚对苯二甲酸二烯丙酯PE Polyethylene 聚乙烯PEBA Polyether block amide 聚醚嵌段酰胺PEBA Thermoplastic elastomer polyether 聚酯热塑弹性体PEEK Polyetheretherketone 聚醚醚酮PEI Poly(etherimide) 聚醚酰亚胺PEK Polyether ketone 聚醚酮PEO Poly(ethylene oxide) 聚环氧乙烷PES Poly(ether sulfone) 聚醚砜PET Poly(ethylene terephthalate) 聚对苯二甲酸乙二酯PETG Poly(ethylene terephthalate) glycol 二醇类改性PETPEUR Poly(ether urethane) 聚醚型聚氨酯PF Phenol-formaldehyde resin 酚醛树脂PFA Perfluoro(alkoxy alkane) 全氟烷氧基树脂PFF Phenol-furfural resin 酚呋喃树脂PI Polyimide 聚酰亚胺PIB Polyisobutylene 聚异丁烯PISU Polyimidesulfone 聚酰亚胺砜PMCA Poly(methyl-alpha-chloroacrylate) 聚α-氯代丙烯酸甲酯PMMA Poly(methyl methacrylate) 聚甲基丙烯酸甲酯PMP Poly(4-methylpentene-1) 聚4-甲基戊烯-1PMS Poly(alpha-methylstyrene) 聚α-甲基苯乙烯POM “Polyoxymethylene, polyacetal” 聚甲醛PP Polypropylene 聚丙烯PPA Polyphthalamide 聚邻苯二甲酰胺PPE Poly(phenylene ether) 聚苯醚PPO Poly(phenylene oxide) deprecated 聚苯醚PPOX Poly(propylene oxide) 聚环氧(丙)烷PPS Poly(phenylene sulfide) 聚苯硫醚PPSU Poly(phenylene sulfone) 聚苯砜PS Polystyrene 聚苯乙烯PSU Polysulfone 聚砜PTFE Polytetrafluoroethylene 聚四氟乙烯PUR Polyurethane 聚氨酯PVAC Poly(vinyl acetate) 聚醋酸乙烯PVAL Poly(vinyl alcohol) 聚乙烯醇PVB Poly(vinyl butyral) 聚乙烯醇缩丁醛PVC Poly(vinyl chloride) 聚氯乙烯PVCA Poly(vinyl chloride-acetate) 聚氯乙烯醋酸乙烯酯PVCC chlorinated poly(vinyl chloride)(*CPVC) 氯化聚氯乙烯PVI poly(vinyl isobutyl ether) 聚(乙烯基异丁基醚)PVM poly(vinyl chloride vinyl methyl ether) 聚(氯乙烯-甲基乙烯基醚) RAM restricted area molding 窄面模塑RF resorcinol-formaldehyde resin 甲苯二酚-甲醛树脂RIM reaction injection molding 反应注射模塑RP reinforced plastics 增强塑料RRIM reinforced reaction injection molding 增强反应注射模塑RTP reinforced thermoplastics 增强热塑性塑料S/AN styrene-acryonitrile copolymer 苯乙烯-丙烯腈共聚物SBS styrene-butadiene block copolymer 苯乙烯-丁二烯嵌段共聚物SI silicone 聚硅氧烷SMC sheet molding compound 片状模塑料S/MS styrene-α-methylstyrene copolymer 苯乙烯-α-甲基苯乙烯共聚物TMC thick molding compound 厚片模塑料TPE thermoplastic elastomer 热塑性弹性体TPS toughened polystyrene 韧性聚苯乙烯TPU thermoplastic urethanes 热塑性聚氨酯TPX ploymethylpentene 聚-4-甲基-1戊烯VG/E vinylchloride-ethylene copolymer 聚乙烯-乙烯共聚物VC/E/MA vinylchloride-ethylene-methylacrylate copolymer 聚乙烯-乙烯-丙烯酸甲酯共聚物VC/E/VCA vinylchloride-ethylene-vinylacetate copolymer 氯乙烯-乙烯-醋酸乙烯酯共聚物PVDC Poly(vinylidene chloride) 聚(偏二氯乙烯)PVDF Poly(vinylidene fluoride) 聚(偏二氟乙烯)PVF Poly(vinyl fluoride) 聚氟乙烯PVFM Poly(vinyl formal) 聚乙烯醇缩甲醛PVK Polyvinylcarbazole 聚乙烯咔唑PVP Polyvinylpyrrolidone 聚乙烯吡咯烷酮S/MA Styrene-maleic anhydride plastic 苯乙烯-马来酐塑料SAN Styrene-acrylonitrile plastic 苯乙烯-丙烯腈塑料SB Styrene-butadiene plastic 苯乙烯-丁二烯塑料Si Silicone plastics 有机硅塑料SMS Styrene/alpha-methylstyrene plastic 苯乙烯-α-甲基苯乙烯塑料SP Saturated polyester plastic 饱和聚酯塑料SRP Styrene-rubber plastics 聚苯乙烯橡胶改性塑料TEEE “Thermoplastic Elastomer,Ether-Ester” 醚酯型热塑弹性体TEO “Thermoplastic Elastomer, Olefinic” 聚烯烃热塑弹性体TES “Thermoplastic Elastomer, Styrenic” 苯乙烯热塑性弹性体TPEL Thermoplastic elastomer 热塑(性)弹性体TPES Thermoplastic polyester 热塑性聚酯TPUR Thermoplastic polyurethane 热塑性聚氨酯TSUR Thermoset polyurethane 热固聚氨酯UF Urea-formaldehyde resin 脲甲醛树脂UHMWPE Ultra-high molecular weight PE 超高分子量聚乙烯UP Unsaturated polyester 不饱和聚酯VCE Vinyl chloride-ethylene resin 氯乙烯/乙烯树脂VCEV Vinyl chloride-ethylene-vinyl 氯乙烯/乙烯/醋酸乙烯共聚物VCMA Vinyl chloride-methyl acrylate 氯乙烯/丙烯酸甲酯共聚物VCMMA Vinyl chloride-methylmethacrylate 氯乙烯/甲基丙烯酸甲酯共聚物VCOA Vinyl chloride-octyl acrylate resin 氯乙烯/丙烯酸辛酯树脂VCVAC Vinyl chloride-vinyl acetate resin 氯乙烯/醋酸乙烯树脂VCVDC Vinyl chloride-vinylidene chloride 氯乙烯/偏氯乙烯共聚物PA 聚酰胺(尼龙)PA-1010 聚癸二酸癸二胺(尼龙1010)PA-11 聚十一酰胺(尼龙11)PA-12 聚十二酰胺(尼龙12)PA-6 聚己内酰胺(尼龙6)PA-610 聚癸二酰乙二胺(尼龙610)PA-612 聚十二烷二酰乙二胺(尼龙612)PA-66 聚己二酸己二胺(尼龙66)PA-8 聚辛酰胺(尼龙8)PA-9 聚9-氨基壬酸(尼龙9)PAA 聚丙烯酸PAAS 水质稳定剂PABM 聚氨基双马来酰亚胺PAC 聚氯化铝PAEK 聚芳基醚酮PAI 聚酰胺-酰亚胺PAM 聚丙烯酰胺PAMBA 抗血纤溶芳酸PAMS 聚α-甲基苯乙烯PAN 聚丙烯腈PAP 对氨基苯酚PAPA 聚壬二酐PAPI 多亚甲基多苯基异氰酸酯PAR 聚芳酰胺PAR 聚芳酯(双酚A型)PAS 聚芳砜(聚芳基硫醚)PB 聚丁二烯-[1,3]PBAN 聚(丁二烯-丙烯腈)PBI 聚苯并咪唑PBMA 聚甲基丙烯酸正丁酯PBN 聚萘二酸丁醇酯PBR 丙烯-丁二烯橡胶PBS 聚(丁二烯-苯乙烯)PBS 聚(丁二烯-苯乙烯)PBT 聚对苯二甲酸丁二酯PC 聚碳酸酯PC/ABS 聚碳酸酯/ABS树脂共混合金PC/PBT 聚碳酸酯/聚对苯二甲酸丁二醇酯弹性体共混合金 PCD 聚羰二酰亚胺PCDT 聚(1,4-环己烯二亚甲基对苯二甲酸酯)PCE 四氯乙烯PCMX 对氯间二甲酚PCT 聚对苯二甲酸环己烷对二甲醇酯PCT 聚己内酰胺PCTEE 聚三氟氯乙烯PD 二羟基聚醚PDAIP 聚间苯二甲酸二烯丙酯PDAP 聚对苯二甲酸二烯丙酯PDMS 聚二甲基硅氧烷PE 聚乙烯PEA 聚丙烯酸酯EAM 苯乙烯型聚乙烯均相离子交换膜PEC 氯化聚乙烯PECM 苯乙烯型聚乙烯均相阳离子交换膜PEE 聚醚酯纤维PEEK 聚醚醚酮PEG 聚乙二醇PEHA 五乙撑六胺PEN 聚萘二酸乙二醇酯PEO 聚环氧乙烷PEOK 聚氧化乙烯PEP 对-乙基苯酚聚全氟乙丙烯薄膜PES 聚苯醚砜PET 聚对苯二甲酸乙二酯PETE 涤纶长丝PETP 聚对苯二甲酸乙二醇酯PF 酚醛树脂PF/PA 尼龙改性酚醛压塑粉PF/PVC 聚氯乙烯改性酚醛压塑粉PFA 全氟烷氧基树脂PFG 聚乙二醇PFS 聚合硫酸铁PG 丙二醇PGEEA 乙二醇(甲)乙醚醋酸酯PGL 环氧灌封料PH 六羟基聚醚PHEMA 聚(甲基丙烯酸-2-羟乙酯)PHP 水解聚丙烯酸胺PI 聚异戊二稀PIB 聚异丁烯PIBO 聚氧化异丁烯PIC 聚异三聚氰酸酯PIEE 聚四氟乙烯PIR 聚三聚氰酸酯PL 丙烯PLD 防老剂4030PLME 1:1型十二(烷)酸单异丙醇酰胺 PMA 聚丙烯酸甲酯PMAC 聚甲氧基缩醛PMAN 聚甲基丙烯腈PMCA 聚α-氧化丙烯酸甲酯PMDETA 五甲基二乙烯基三胺PMI 聚甲基丙烯酰亚胺PMMA 聚甲基丙烯酸甲酯(有机玻璃) PMMI 聚均苯四甲酰亚胺PMP 聚4-甲基戊烯-1PNT 对硝基甲苯PO 环氧乙烷POA 聚己内酰胺纤维POF 有机光纤POM 聚甲醛POR 环氧丙烷橡胶PP 聚丙烯PA 聚己二酸丙二醇酯PPB 溴代十五烷基吡啶PPC 氯化聚丙烯PPD 防老剂4020PPG 聚醚PPO 聚苯醚(聚2,6-二甲基苯醚) PPOX 聚环氧丙烷PPS 聚苯硫醚PPSU 聚苯砜(聚芳碱)PR 聚酯PROT 蛋白质纤维PS 聚苯乙烯PSAN 聚苯乙烯-丙烯腈共聚物PSB 聚苯乙烯-丁二烯共聚物PSF(PSU) 聚砜PSI 聚甲基苯基硅氧烷PST 聚苯乙烯纤维PT 甲苯PTA精对苯二甲酸PTBP 对特丁基苯酚PTFE 聚四氟乙烯PTMEG 聚醚二醇PTMG 聚四氢呋喃醚二醇PTP 聚对苯二甲酸酯PTX 苯(甲苯、二甲苯)PTX 苯(甲苯、二甲苯)PU 聚氨酯(聚氨基甲酸酯)PV A 聚乙烯醇PV AC 聚醋酸乙烯乳液PV AL 乙烯醇系纤维PVB 聚乙烯醇缩丁醛PVC 聚氯乙烯PVCA 聚氯乙烯醋酸酯PVCC 氯化聚氯乙烯PVDC 聚偏二氯乙烯PVDF 聚偏二氟乙烯PVE 聚乙烯基乙醚PVF 聚氟乙烯PVFM 聚乙烯醇缩甲醛PVI 聚乙烯异丁醚PVK 聚乙烯基咔唑PVP 聚乙烯基吡咯烷酮。

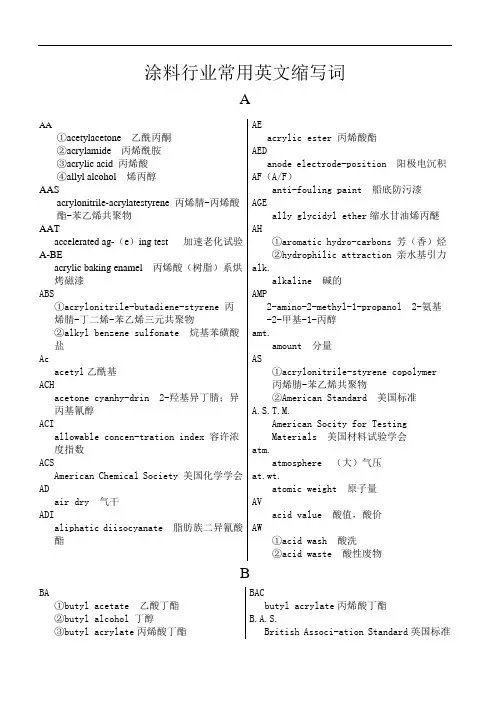

涂料行业常用英文缩写词ABBA①butyl acetate 乙酸丁酯②butyl alcohol 丁醇③butyl acrylate丙烯酸丁酯BACbutyl acrylate丙烯酸丁酯B.A.S.British Associ-ation Standard英国标准AA①acetylacetone乙酰丙酮②acrylamide 丙烯酰胺③acrylic acid丙烯酸④allyl alcohol烯丙醇AASacrylonitrile-acrylatestyrene 丙烯腈-丙烯酸酯-苯乙烯共聚物AATaccelerated ag-(e)ing test 加速老化试验A-BEacrylic baking enamel 丙烯酸(树脂)系烘烤磁漆ABS①acrylonitrile-butadiene-styrene 丙烯腈-丁二烯-苯乙烯三元共聚物②alkyl benzene sulfonate 烷基苯磺酸盐Acacetyl乙酰基ACHacetone cyanhy-drin 2-羟基异丁腈;异丙基氰醇ACIallowable concen-tration index 容许浓度指数ACSAmerican Chemical Society 美国化学学会ADair dry 气干ADIaliphatic diisocyanate 脂肪族二异氰酸酯AEacrylic ester 丙烯酸酯AEDanode electrode-position 阳极电沉积AF(A/F)anti-fouling paint 船底防污漆AGEally glycidyl ether缩水甘油烯丙醚AH①aromatic hydro-carbons 芳(香)烃②hydrophilic attraction 亲水基引力alk.alkaline 碱的AMP2-amino-2-methyl-1-propanol 2-氨基-2-甲基-1-丙醇amt.amount 分量AS①acrylonitrile-styrene copolymer丙烯腈-苯乙烯共聚物②American Standard 美国标准A.S.T.M.American Socity for TestingMaterials 美国材料试验学会atm.atmosphere (大)气压at.wt.atomic weight 原子量AVacid value 酸值,酸价AW①acid wash 酸洗②acid waste 酸性废物协会BBPbutyl benzyl phthalate 邻苯二甲酸丁(基)苄基酯bpboiling point 沸点BPObenzoyl peroxide 过氧化苯甲酰BCbutylcarbitol二乙二醇单丁醚BD①butadiene 丁二烯②butanediol 丁二醇BEDbreakdown voltage击穿电压BEMbutyl etherified melamine 丁基醚化三聚氰胺BGbenzoguanamine 苯代三聚氰二胺,苯鸟粪胺BSCbutadiene-styrene copolymer丁二烯-苯乙烯共聚物;丁苯共聚物CΔCchromaticity difference 色度差CA①cellulose acetate 乙酸纤维素②Chemical Abstracts 化学文摘(美)③cost account 成本计算CABcellulose acetate butyrate 乙酸丁酸纤维素CASS testcopper accelerated acetic acid salt spray test 铜催化乙酸盐雾试验CIECommission Internationale de l’Eclai- rage (法)国际照明委员会CMC①carboxymethyl cellulose 羧甲基纤维素②critical micelle concentration 临界胶束浓度CMRcarbon magnetic resonance 碳核磁共振CNcellulose nitrate 硝酸纤维素;硝化棉C.P.①centi-poises 厘泊(绝对粘度单位)②chemically pure 化学纯cpscentipoise 厘泊(绝对粘度单位)CPVC①critical pigment volume concen-tration 临界颜料体积浓度②chlorinated polyvinyl chloride 氯化聚氯乙烯CR①chlorinated rubber 氯化橡胶②chloroprene rubber 氯丁橡胶;氯丁二烯橡胶③contrast ratio 反差比;对比率CSCRCenter for Surface and Coating Research 表面与涂装研究中心(美)cStcentistoke(s)厘斯(运动粘度单位,=1/100沲);(习称)厘沲CSPchlorosulphonated polyethylene 氯磺化聚乙烯橡胶DD65相关色温6500K的日光光源ddensity 密度DAAdiacetone alcohol 二丙酮醇DAIPdiallyl isophthalate 异苯二甲酸二烯丙酯DAPdiallyl phthalate 邻苯二甲酸二烯丙酯DBA①dibutyl adipate 己二酸二丁酯②dibutyl amine 二丁胺DBCdibutyl cellosolve 二丁基溶纤剂DBP①dibutyl phthalate 邻苯二甲酸二丁酯②dibutyl phosphate 磷酸二丁酯DBS①dibutyl sebacate 癸二酸二丁酯②dodecylbenzene sulfonate 十二烷基苯磺酸盐DDIdimer(fatty)acid diisocyanate 二聚(脂肪)酸二异氰酸酯DDPdidecyl phthalate 邻苯二甲酸二癸酯DDTAderivative differential thermal analy- sis 微商差热分析D.E.degree of esterification 酯化度DEAdiethanolamine 二乙醇胺decomp.decompose(s)分解decompn.decomposition 分解(作用);裂解;分裂DEEAdiethylethanolamine 二乙基乙醇胺DEPdiethyl phthalate 邻苯二甲酸二乙酯DETAdiethylene triamine 二亚乙基三胺;二乙烯三胺DFTdry film thickness 干膜厚度DHP①dihexyl phthalate 邻苯二甲酸二己酯②deheptyl phthalate 邻苯二甲酸二庚酯DIBKdiisobutyl ketone 二异丁酮DIBPdiisobutyl phthalate 邻苯二甲酸二异丁酯D.I.N.Deutsche Industrie-Norm(德)德国工业标准DIOPdiisooctyl phthalate 邻苯二甲酸二异辛酯DIYDo-It-Yourself 自己动手的;自助的D.L.dilution limit 稀释极限(ml/μg)DMA①dimethyl aniline 二甲基苯胺②dimethyl acetamideDMFdimethyl formamide 二甲基甲酰胺DMIdimethyl isophthalate 间苯二甲酸二甲酯DMPdimethyl phthalate 邻苯二甲酸二甲酯DMP-30一种固化剂和活化剂〔2,4,6-三(二甲氨基)苯酚,美国Rohm&Haas公司产〕DMTdimethyl terephthalate 对苯二甲酸二甲酯DNPdinonyl phthalae 邻苯二甲酸二壬酯DOAdioctyl adipate 己二酸二辛酯DOIdistinctness of image 鲜映性,映像清晰度DOP①di-(2-thylhexyl)phthalate 邻苯二甲酸二异辛酯dioctyl phthalate 邻苯二甲酸二辛酯DOSdioctyl sebacate 癸二酸二辛酯d.p.damp proofing 防潮DPAdiphenyl amine 二苯胺DPGdiphenylguanidine 二苯胍DPKdipropyl ketone 二丙基甲酮;庚酮DPM①diphenyl methane 二苯基甲烷②dioxydiphenyl methane 二羟基二苯甲烷;二酚基甲烷DPMDIdiphenylmethane diisocyanate 二苯甲烷二异氰酸酯DPPdiphenyl phosphate 磷酸二苯酯DTA①diethylene triamine 二亚乙基三胺;二乙烯三胺②differential thermal analysis 差热分析DTBCditertiary butyl peroxide 二叔丁基过氧化物;过氧化二叔丁基DTGAdifferential thermal gravimetric analysis 差热重量分析EΔE;Δe总色差;全色差EAKethyl amyl ketone 乙基-戊基甲酮;乙戊酮EAMelectron affinitive molecules 亲电子分子EBC①electron beam curing 电子束固化②ehtyl benzyl cellulose 乙基苄基纤维素E-BEepoxy baking enamel 环氧系烘烤磁漆EC①ehtyl cellulose 乙基纤维素②effective concentration 有效浓度③elasticity coefficient 弹性系数④electrical conductivity 导电性;导电率ECCAEuropean Coil Coating Association 欧洲卷材涂装工业协会ECHepichlorohydrin 1,2-环氧3-氯丙烷(俗);3-氯-1,2-环氧丙烷ED①electro-deposition 电沉积;电泳②effective dose 有效剂量EDAethylene diamine 乙二胺EDBethylene dibromide 二溴化乙烯;二溴乙烷EDC①ethane dichloride 二氯乙烷②electrodeposit coating 电泳涂装EDGethylene diglycol 二甘醇EDMeffective dipole moment 有效偶极距EDP①electrodeposition 电沉积②electronic deta processing 电子数据处理E.D.T.Aethylene diamine tetraacetic acid 乙二胺四乙酸EEW①esterification equivalent weight 酯化当量②epoxide equivalent weight 环氧当量EHA①2-ethyl hexyl acetate 乙酸-2-乙基己酯;醋酸异辛酯②2-ethyl hexyl acrylate 丙烯酸-2-乙基己酯③2-ethyl hexyl amine 2-乙基己胺④2-ethyl hexyl aniline 2-乙基己基苯胺EHECethyl hydroxyethyl cellulose 乙基-羟乙基纤维素EI①Engineering Index 工程技术文献索引②erosion index 侵蚀指数E.L.elastic limit 弹性极限EMMAQUA加速曝晒法EOethylene oxide 环氧乙烷;氧丙环EP①epoxy resin 环氧树脂②environmental protection 环境保护EPIepichlorohydrin 3-氯-1,2-环氧丙烷e.p.m.equivalent parts per million 百万分之几当量(当量/百万)EPR①electron paramagnetic resonance 电子顺磁共振②ethylene propylene rubber 乙丙橡胶EPS①electrostatic powder spray 粉末静电涂装②engineering performance standard 工程性能标准equiv.equivalent 当量;克当量ESBOepoxidised soy(a)-bean oil 环氧化豆油ETC①environmental test chamber 环境试验室②ehtylene tetrachloride 四氯乙烷;四氯化乙烯EV Aethylene-vinyl acetate copolymer 乙烯-乙酸乙烯酯共聚物FFDIdiethyl fumarate diisocyanate 反丁烯二酸二乙酯二异氰酯酯fig.figure 图;数字;数值;形状FIRfar infra red 远红外线f.p.①firing point 燃点;着火点②flash point 闪点③freezing point 冰点;凝固点④fusion point 熔点FSCTFederation of Societies for Coatings Techno-logy 涂料工艺学会联合会FSPTFederation of Societies for Paint Technology (美国)油漆工艺学会联合会Gg.gram 克gal.gallon 加仑GC①gas chromatography 气相色谱法②graft copolymer 接枝共聚物GCMSgas chromatography-mass spectrometry 气相色谱-质谱(分析)法g.d.gravimetric density 重量密度GDCHglycerol dichlorohydrin 二氯甘油GDMEethylene glycol dimethyl ether 乙二醇二甲醚GLCgas-liquid chromatography 气液色谱法GLPC(=GLC)gas-liquid partition chromatography 气液色谱法GP①gaseous polymerization 气相聚合法②glycol phthalate 邻苯二甲酯乙二醇酯③graft polymer 接枝聚合物④graphite paint 石墨涂料GPCgel permeation chromatography 凝胶渗透色法G.T.A.glycerin triacetate 甘油三醋酸酯GWgross weight 总重;全重;毛重HHAWShigh aromatic white spirit 高芳烃类石油溶剂HCOhydrogenated castor oil 氢化蓖麻油HDIhexamethylene diisocyanate 六亚甲基二异氰酸酯;1,6-己二异氰酸酯HDPEhigh density polythylene 高密度聚乙烯HEChydroxy-ethyl cellulose 羟乙基纤维素HEMAhydroxy-ethyl methacrylate 甲基丙烯酸羟乙酯HHPAhexahydro-phthalic anhydride 六氢化邻苯二甲酸酐HLBhydrophile-lipophile balance 亲水亲油平衡值HMhydroxymethylation 羟甲基化HMChydroxymethyl cellulose 羟甲基纤维素HMDAhexamethylene diamine 六亚甲基二胺;1,6-己二胺HMDI(HDI)①hexamethylene diisocyanate六亚甲基二异氰酸酯;1,6-己二异氰酸酯②hydrogenated-4,4′-diphenylmethanediisocyanate氢化-4,4′-二苯基甲烷二异氰酸酯; 4,4′-二环己基甲烷二异氰酸酯HMMhexamethylolmelamine六羟甲基三聚氰胺HMMMhexamethoxy methyl melamine 六甲氧甲基三聚氰胺HMP①high molecular polymer 高聚物;高分子聚合物②hydroxymethyl hydroperoxide 羟甲基化过氧氢HMTAhexamethylene tetramine 六亚甲四胺;乌洛托品HMWhigh molecular weight 高分子量HPChydroxy-propyl cellulose 羟丙基纤维素HPLChigh performance liquid chromatography 高效液体色谱HRPheat resistance paint 耐热涂料HS①heat shield 热屏蔽;防热层②high solid 高固体分H6TDIhydrogenated toluene diisocyanate 六氢化甲苯二异氰酸酯HVChue,value,chroma 色相;亮度;色品IIATMInternational Association for testing Materials 国际材料试验协会IBAisobutyl alcohol 异丁醇ICIInternational Commission on Illumination 国际照明委员会in.inch 英寸IPAisopropyl alcohol 异丙醇IPDIisophorone diisocyanate 异佛尔酮二异氰酸酯IPEisopropyl ether 异丙醚IRSPinfra-red spectrometer 红外光谱仪;红外分光计IViodine value 碘值JJjoule 焦耳JPIAJapanese Paint Industrial Association 日本涂料工业协会JPSJapanese Painting Standard 日本涂装(工业协会)标准KKBVkauri-butanol value 贝壳松脂丁醇(溶液溶解)值K.S.methodKraemer-Sarnow’s method 克雷默-萨尔诺树脂熔点测定法K.U.Krebs Units 克雷布斯粘度单位k.v.kinematic viscosity 运动粘度LLAWSlow aromatic white spirit 低芳烃石油溶剂LDPElow density polyethylene 低密度聚乙烯LElacquer enamel 硝基磁漆LFAlinseed fatty acid 亚麻(仁)油脂肪酸LMWlow molecular weight 低分子量LO①linseed oil 亚麻(仁)油;胡麻油②long oil 长油度MM①molar 体积(摩尔)浓度②melamine三聚氰胺mmolal (重量)摩尔(浓度)的MA①maleic anhydride 顺丁烯二酸酐②methacrylic acid甲基丙烯酸MAA①methacrylic acid甲基丙烯酸②methyl amyl acetate乙酸甲戊酯M.A.C.maximum acceptable concentration 最大容许浓度MAKmethyl n-amyl ketone 甲基-正-戊基甲酮;庚酮-2M-BEmelamine baking enamel 三聚氰胺系烘烤磁漆MBKmethyl butyl ketone 甲基-丁基甲酮;己酮-2 MCmethyl cellulose 甲基纤维素MDAmethylene dianiline 二苯氨基甲烷MDImethylene diphenyl-4,4′-diisocyanate 亚甲基二苯基二异氰酸酯MEAmonoethanolamine 一乙醇胺MEEmethyl ethyl ether 甲基乙基醚MEKmethyl ethyl ketone 甲基乙基(甲)酮;甲乙酮;丁酮-2MEKP(MEKPO)methyl ethyl ketone peroxide 过氧化甲乙酮;过氧化丁酮-2MFPmoisture and fungus proof 防潮防霉的MFTminimum film-forming temperature 最低成膜温度(乳胶漆质量指标)M.I.melt index 熔融指数MIAKmethyl isoamyl ketone 甲基异戊基甲酮MIBKmethyl isobutyl ketone 甲基异丁基甲酮MIOmicaceous iron oxide 云母氧化铁MIPKmethyl isopropenyl ketone 甲基异丙烯基甲酮MMAmethyl methacrylate 甲基丙烯酸甲酯MPCmaximum permissible concentration 最大容许浓度MPDmaximum permissible dose 最大允许剂量MPDAmethaphenylene diamine 间苯二胺MPKmethyl propyl ketone 甲基丙基甲酮;甲丙酮MSmass spectrometer 质谱分析器MSTmineral spirit toleranceM.Wmolecular weight 分子量NNAnadic anhydride 降冰片烯二酸酐NADnon-aqueous dispersion 非水分散体n-BAn-butyl alcohol 正丁醇NBRacrylnitrile-butadiene rubber 丁二烯-丙烯腈橡胶;丁腈橡胶NCnitrocellulose 硝化纤维素;硝基纤维素NDI1,5-naphthylene diisocyanate 1,5-亚萘基二异氰酸酯NIRacrylonitrile-isoprene rubber 丙烯腈-异戊二烯橡胶NMA①nadic methyl anhydride 甲基降冰片烯二酸酐②N-methylolacrylamide N-羟甲基丙烯酰胺NMPN-methyl pyrrolidone N-甲基吡咯烷酮NMRnuclear magnetic resonance 核磁共振NR①natural rubber 天然橡胶②nitrile rubber 丁腈橡胶n.v.m.non-volatile matter 不挥发物N/Znon-zinc epoxy primer 无锌环氧底漆OOBPoctyl benzyl phthalate 邻苯二甲酸辛苄酯OPoil-preparated paint 油性调合漆OEM coatingsoriginal equipment manufacture coatings 工业产品涂料;在线涂装涂料OTCCorganic thermal control coating 温控有机涂层;有机耐热涂层PP①para 对(位)②pint 品脱③poise 泊④pressure 压力PA①polyacetal 聚缩醛②polyacryate 聚丙烯酸酯③polyamide 聚酰胺④phthalic anhydride 邻苯二甲酸酐PAA①polyacrylamide 聚丙烯酰胺②polyacrylic acid 聚丙烯酸③polyallyl alcohol 聚烯丙醇PACpolyaluminium chloride 多氯化铝PAIpolyamide-imide 聚酰胺-酰亚胺PAN①polyacrylonitrile聚丙烯腈②α-pyridyl-β-azonaphtholα-吡啶基-β-偶氮萘酚PAPApolyazelaic polyanhydride 聚壬二酸酐PAPI①polyaryl polyisocyanate 多芳基多异氰酸酯②polymethlene polyphenyl isocyanate 多亚甲基多苯基异氰酸酯P/Bpigment binder ratio 颜基比PBCpropyl benzyl cellulose 丙基苄基纤维素PBDpolybutadiene 聚丁二烯PBGApolybutylene glycol adipate 聚己二酸丁二醇酯PBGSpolybutylene glycol succinate 聚丁二酸丁二醇酯PBIpolybenzimidazole 聚苯并咪唑PBKpropyl benzyl ketone 丙基苄基(甲)酮PBMApoly (n-butyl methacrylate)聚甲基丙烯酸丁酯PBQparabenzoquinone 对苯醌PBR①polybutadiene rubber 聚丁二烯橡胶②propylene-butadiene rubber 丙烯-丁二烯橡胶PBSpolybutadiene styrene 聚丁二烯-苯乙烯PC①paper chromatography纸色谱法plasma chromatography 等离子体色谱法③polycarbonate 聚碳酸酯PCBpolychlorinated biphenyl 多氯联苯PCMprecoating metal 预涂金属PCP①pentachlorophenol 五氯(苯)酚②polychloroprene 聚氯丁烯;氯丁橡胶PCPDpolycyclopentadiene 聚环戊二烯;聚茂PCTFEpolychlorotrifluoro ethylene 聚三氟氯乙烯PCVpost colour value 后色值PD①polymerization degree 聚合度②potential difference 电位差;势差PDApara-phenylene diamine 对苯二胺PDIphenylene diisocyanate 亚苯基二异氰酸酯PDMSpolydimethylsiloxane 聚二甲基硅氧烷PE①pentaerythritol 季戊四醇②permissible error 容许误差③polyelectrolyte 聚合电解质;高(分子)电解质④polyethylene 聚乙烯PEA①phenethyl alcohol 苯乙醇②polyethylene adipate 聚己二酸乙二醇酯PEGpolyethylene glycol 聚乙二醇PEGApolyethylene glycol adipate 聚己二酸乙二醇酯PEHApentaethylene hexamine 五亚乙基六胺;五乙烯六胺PET①pentaerythritol 季戊四醇②polyester 聚酯PETPpolyethylene (glycol)terephthalate 聚对苯二甲酸乙二醇酯PFAperfluoroalkoxy resin 全氟烷氧基树脂PFRphenol formaldehyde resin (苯)酚(甲)醛树脂PG①pigment grade 颜料等级②polyethylene glycol 聚乙二醇③propylene glycol 丙二醇PGEphenyl glycol ether 苯基缩水甘油醚pHhydrogen ion exponent 氢离子(浓度)指数;pH值P.I.①penetration index 针入度指数;贯入度指数②plastic index 塑性指数③performance index 性能指数④polyimide 聚酰亚胺⑤polyisocyanate 多异氰酸酯⑥polyisoprene 聚异戊二烯PMpolymethyl methacrylate 聚甲基丙烯酸甲酯PMA①phenyl mercuric acetate 醋酸苯汞②phosphomolybdic acid 磷钼酸③polymethacrylate 聚甲基丙烯酸酯④pyromellitic acid 均苯四酸⑤pyromellitic anhydride 均苯四酸酐PMMApolymethyl methacrylate 聚甲基丙烯酸甲酯PMTpolymer melting temperature 聚合物熔融温度;聚合物熔体温度PO①polymerizable oligomers 可聚合低聚物②polyolefine 聚烯烃③propylene oxide 环氧丙烷PPpolypropylene 聚丙烯PPA①phenylpyruvic acid 苯基丙酮酸②polyphosphoric acid 多磷酸③polypropylene adipate 聚己酸丙二醇酯ppbpounds per barrel 每桶磅数;磅/桶PPE①polyphenyl ether 聚苯醚②polyphosphate ester 聚磷酸酯PPFpigment-packing factor 颜料吸油系数PPGpolypropylene glycol 聚丙二醇ppgpounds per gallon 磅/加仑PPMSpolyphenylmethylsiloxane 聚苯基甲基硅氧烷PPO①polyphenylene oxide 聚苯醚②polypropylene oxide 聚环氧丙烷PPSpolyphenylene sulfide 聚亚苯基硫醚PS①polystyrene 聚苯乙烯②polysulfide 聚硫;多硫化合物pspoise 泊(绝对粘度单位)PSBpolystyrene-butadiene 聚苯乙烯-丁二烯PTA①phosphoryl trianilide 磷酰三苯胺②phenol tricarboxylic acid 苯酚三羧酸③phosphotungstic acid 磷钨酸PTFEpolytetrafluoroethylene 聚四氟乙烯PTMGpolytetramethylene glycol 聚丁二醇PTMOpolytetramethylene oxide 聚四氢呋喃PTMTpolytetramethylene terephthalate 聚对苯二甲酸丁二醇酯p-TSA(PTSA)p-toluence sulfonic acid 对甲苯磺酸PUpolyurethane 聚氨基甲酸酯;聚氨酯PUFApolyunsaturated fatty acid 多不饱和脂肪酸PVA①polyvinyl acetate 聚乙酸乙烯酯②polyvinyl alcohol 聚乙烯醇PVBpolyvinyl butyral 聚乙烯醇缩丁醛PVC①pigment volume concentration 颜料体积浓度②polyvinyl chloride 聚氯乙烯PVE①phenyl vinyl ether 苯基乙烯基醚②polyvinyl ethyl ether 聚乙烯基乙基醚PVF①polyvinyl fluoride 聚氟乙烯②polyvinyl formal 聚乙烯醇缩甲醛③polyvinyl formate 聚甲酸乙烯酯PVMpolyvinyl methyl ether 聚乙烯基甲基醚PVPpolyvinyl pyrrolidone 聚乙烯基吡咯烷酮PWCpigment weight concentration 颜料重量浓度QQquart 夸脱QACquarternary ammonium compound 季铵(盐)化合物QCquality control 质量控制;质量管理QIquality index 质量指标;质量指数QTqualification test 质量鉴定试验;合格试验QUVquartz ultraviolet light 石英紫外光RR"Redwood seconds 雷氏(粘度)秒数RCresin cation 阳离子树脂RE①relative error 相对误差②resistance to emulsion number 抗乳化值RH①relative humidity 相对湿度②Rockwell hardness 洛氏硬度RN①rating number 分(等)级②Reynolds number 雷诺数ROreverse osmosis 反渗透RT①relative temperature 相对温度②room temperature 室温RVTNrelative viscosity-temperature number比粘度温度数(值)SSA①spectrum analyser 光谱分析仪②stearamide 硬脂酰胺③surface area 表面积Sa瑞典钢材表面处理质量标准SIS055000 SAC①secondary alkyl sulfonate 仲烷基磺酸盐②sodium alkane sulfonate 烷基磺酸钠sap.Eqsaponification number 皂化当量SBstyrene-butadiene 苯乙烯-丁二烯共聚物SBAsecondary butyl alcohol 仲丁醇SBR①styrene-butadiene rubber 苯乙烯-丁二烯橡胶;丁苯橡胶②synthetic butadiene rubber 合成丁二烯橡胶SDBSsodium dodecylbenzene sulfonate 十二烷基苯磺酸钠SISSvensk Industri Standard 瑞典工业标准SMDI (=HMDI)dicyclohexylmethane diisocyanate 4,4-二环己基甲烷二异氰酸酯SPsolubility parameter 溶解度参数sg.specific gravity 比重SR①saponification ratio 皂化值②sensitivity ratio 灵敏度比③silicon rubber 硅橡胶④styrene rubber 苯乙烯橡胶⑤synthetic rubber 合成橡胶SSPCSteel Structures Painting Council (美国)钢结构涂装委员会Ststokes 沲(运动粘度单位)(1 St=100mm2/s)STPPsodium tripolyphosphate 三聚磷酸钠SV①sedimention velocity 沉降速度②silicon varnish 有机硅清漆TT.①temperature 温度②tension 张力③time 时间④toluol 甲苯⑤ton 吨⑥trace 痕迹;微量TAtetrahydrofurfuryl acrylate 丙烯酸氢糖酯;四氢糖醇丙烯酸酯TAPAtriallyl phosphate 磷酸三烯丙酯TBA①tertiary butyl acetate 乙酸叔丁酯②tetrabromophthalic anhydride 四溴代邻苯二甲酸酐③tribenzylamine 三苄基胺TBB①tert-butyl perbenzoate 过苯甲酸叔丁酯②1,2,3,4-tetrabromobutane 1,2,3,4-四溴丁烷③tributyl borane 三丁基甲硼烷TBEtetrabromoethane 四溴乙烷TBEPtributoxyethyl phosphate 磷酸三丁氧基乙酯TBP①tributyl phosphate 磷酸三丁酯②tributyl phosphite 亚磷酸三丁酯TBTFtributyltin fluoride 三丁基氟化锡TBTOtributyl tin oxide 三丁基氧化锡TCAthiocarbanilide 均二苯硫脲TCCMthermal control coating material 温控涂料;调温涂料TCEPtrichloroethyl phosphate 磷酸三氯乙酯TCPtricresyl phosphate 磷酸三甲苯酯TCPAtetrachlorophthalic anhydride 四氯代邻苯二甲酸酐TDItoluene diisocyanate 甲苯二异氰酸酯TEAtriethanolamine 三羟乙基胺;三乙醇胺(俗)TEDAtriethylene diamine 三亚乙基二胺TEFAtotal esterified fatty acid 酯化脂肪酸总量TEG①tetraethylene glycol 四甘醇;三缩四乙二醇②triethylene glycol 三甘醇;二缩三乙二醇TEOStetraethyl orthosilicate 原硅酸四乙酯TEPtriethyl phosphate 磷酸三乙酯TEPAtetraethylene pentamine 四亚乙基五胺;三缩四乙二胺TEPPtetraethyl pyrophosphate 焦磷酸四乙酯TETAtriethylene tetramine 三亚乙基四胺Tgglass transition temperature 玻璃化转变温度TG①thermogravimetry 热重量分析法②triglyceride 甘油三酸酯;(俗)三甘油酯TGAthermogravimetric analysis 热解重量分析(法)TGFAtriglyceride fatty acid 脂肪酸三甘油酯TGICtriglycidyl isocyanurate 异氰脲酸三缩水甘油酯THDItrimethylhexamethyl diisocyanate 三甲基六甲基二异氰酸酯THEICtrihydroxyethyl isocyanurate 三羟乙基异氰脲酸酯THFtetrahydrofuran 四氢呋喃THPAtetrahydrophthalic anhydride 四氢化邻苯二甲酸酐THPCtetrakishydroxymethyl phosphonium chloride 四羟甲基氯化磷TMA①tetramethyl ammonium 四甲铵②trimellitic acid 偏苯三酸③trimellitic anhydride 偏苯三酸酐④trimethyl aluminium 三甲基铝TMBGtetramethylol benzoguanamine 四羟甲基替苯代三聚氰二胺TMDItrimethyl hexamethylene diisocyanate 三甲基六亚甲基二异氰酸酯TMEtrimethylol ethane 三羟甲基乙烷TMP①trimethylol propane 三羟甲基丙烷②trimethyl phosphate 磷酸三甲酯TNOnitrogen tetroxide 四氧化二氮TODI3,3´-tolidine-4,4´-diisocyanate 3,3´-联甲苯胺-4,4´-二异氰酸酯TOFAtall oil fatty acid 妥尔油脂肪酸TOPtrioctyl phosphate 磷酸三辛酯TPAtere-phthalic acid 对苯二甲酸T.P.G.triphenylguanidine 三苯胍TPPtriphenyl phosphate 磷酸三苯酯TTAtriethylene tetramine 三亚乙基四胺;二缩三乙胺TTPtritolyl phosphate 磷酸三甲苯酯TXPtri-xylyl phosphate 磷酸三-二甲苯酯TYtotal yield 总收率;总产量UUAHunsaturated acyclic hydrocarbon 不饱和无环烃;不饱和链烃UF①ultra-filtration 超滤②urea-formaldehyde rein 脲醛树脂③ultrafine 超细的UFAunesterified fatty acid 未酯化脂肪酸UPunsaturated polyesters 不饱和聚酯U.S.S.United States Standard 美国标准VV①velocity 速度②viscosity 粘度③volt 伏④volume 容积;体积V Avinyl acetate 乙酸乙烯酯Vac-AEvinyl acetate-acrylic ester copolymer 乙酸乙烯-丙烯酸酯共聚物V A-MAvinyl acetate-maleic anhydride copolymer 乙酸乙烯-顺丁烯二酸酐共聚物VCvinyl chloride 氯乙烯VCAvinyl chloride-acetate copolymer 氯乙烯-乙酸乙烯共聚物VEvinyl chloride resin enamel 氯乙烯(树脂)磁漆V.M.volatile matter 挥发物;挥发分VOCvolatile organic compound 挥发性有机化合物VP①vinyl paint 乙烯系涂料②vinyl pyrrolidone 乙烯基吡咯烷酮VPCvolumetric pigment concentration 体积颜料浓度WWCPwater cement paint 水(分散)性水泥涂料W/Owater in oil 油包水;油中水WPweather-proof 耐候的w.p.water-proof 防水的;不透水的W/Pwash primer 磷化底漆;洗涤底漆WPEweight per epoxide 环氧当量XXxylol 二甲苯XDIxylylene diisocyanate 亚二甲苯基二异氰酸酯XDNxylylene diamine 亚二甲苯基二胺Xnnumber average degree of polymerization 数(量)平均聚合度ZZrelative viscosity 相对粘度(符号)ZDCzinc diethyl dithiocarbamate 二乙替氨荒酸锌;N-二乙基二硫代氨基甲酸锌Z/Ezinc rich epoxy primer 富锌环氧底漆ZOPzinc oxide pigment 氧化锌颜料Z.R.C.zinc rich coating 富锌涂料。

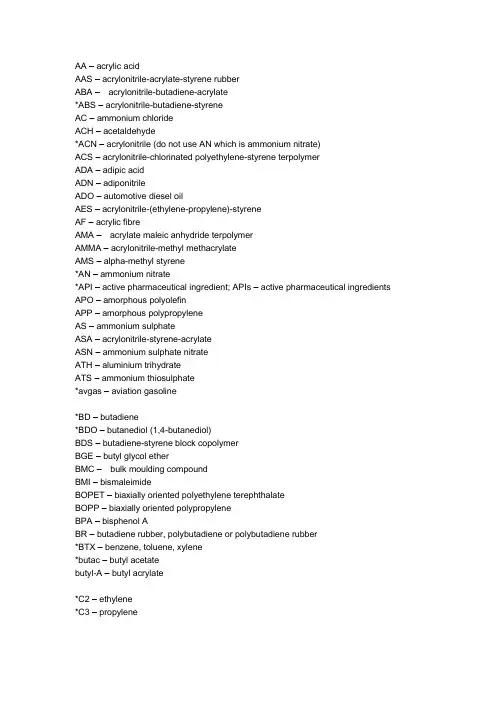

AA – acrylic acidAAS – acrylonitrile-acrylate-styrene rubberABA –acrylonitrile-butadiene-acrylate*ABS – acrylonitrile-butadiene-styreneAC – ammonium chlorideACH – acetaldehyde*ACN – acrylonitrile (do not use AN which is ammonium nitrate)ACS – acrylonitrile-chlorinated polyethylene-styrene terpolymerADA – adipic acidADN – adiponitrileADO – automotive diesel oilAES – acrylonitrile-(ethylene-propylene)-styreneAF – acrylic fibreAMA –acrylate maleic anhydride terpolymerAMMA – acrylonitrile-methyl methacrylateAMS – alpha-methyl styrene*AN – ammonium nitrate*API – active pharmaceutical ingredient; APIs – active pharmaceutical ingredients APO – amorphous polyolefinAPP – amorphous polypropyleneAS – ammonium sulphateASA – acrylonitrile-styrene-acrylateASN – ammonium sulphate nitrateATH – aluminium trihydrateATS – ammonium thiosulphate*avgas – aviation gasoline*BD – butadiene*BDO – butanediol (1,4-butanediol)BDS – butadiene-styrene block copolymerBGE – butyl glycol etherBMC –bulk moulding compoundBMI – bismaleimideBOPET – biaxially oriented polyethylene terephthalateBOPP – biaxially oriented polypropyleneBPA – bisphenol ABR – butadiene rubber, polybutadiene or polybutadiene rubber*BTX – benzene, toluene, xylene*butac – butyl acetatebutyl-A – butyl acrylate*C2 – ethylene*C3 – propylene*C4 – butylenes (strictly a C4 carbon cut)C5, C6, C7 etc – for C5, C6, C7 etc carbon cuts CA – cellulose acetateCAB – cellulose acetate butyrateCAN – calcium ammonium nitrateCAP – cellulose acetate proprionate*capro – caprolactamCBFS – carbon black feedstockCBT – cyclic polybutylene terephthalateCC4 – crude C4 stream*CFC – chlorofluorocarbonCGP – chemical-grade propyleneCHDM – cyclohexane dimethanolCMC – carboxymethyl celluloseCN – cellulose nitrateCNSL – cashew nut shell liquidCOC – cycloolefin copolymerCOP –copolyester thermoplastic elastomer CP – cellulose propionateCNO – coconut oilCPE – chlorinated polyethyleneCPP – chlorinated polypropyleneCPO – crude palm oilCPP – clean petroleum productsCPVC – chlorinated polyvinyl chlorideCSD – carbonated soft drinksCSM – chlorosulphonated polyethylene (rubber) CSS – caustic soda solutionCTA – cellulose triacetateCTC – carbon tetrachlorideCTFE – chlorotrifluoroethyleneCTO – crude tall oil*CX – cyclohexane*DAP – diammonium phosphateDBM – dibutyl maleateDCPD – dicyclopentadieneDDDA – dodecanedioic acidDEA – diethanolamine*DEG – diethylene glycolDEP – diethyl phthalateDIBP – di-isobutyl phthalateDIDP – di-isodecyl phthalateDINP – di-isononyl phthalateDIOP – di-iso-octyl phthalateDMA – dimethylamineDMC – dimethyl carbonate*DME – dimethyl etherDMEA – dimethylethanolamineDMF – dimethyl formamideDMP – dimethyl phthalate*DMT – dimethyl terephthalate*DOP – dioctyl phthalateDPG – dipropylene glycolDPP – dirty petroleum productsDTY – drawn textured/texturised yarnEA – ethylene amineEAA – ethylene acrylic acid copolymer*EB – ethylbenzeneEBM – extrusion blowmoulding (PET)ECH – epichlorohydrinECTFE – ethylene chlorotrifluoroethylene copolymer ECU – electrochemical unitEDA – ethylenediamineEDC – ethylene dichlorideEDTA – ethylenediaminetetraacetic acid*EG – ethylene glycolEGAF – antifreeze grade ethylene glycolEGF – fibre grade ethylene glycolEGI – industrial grade ethylene glycol*2-EH – 2-ethylhexanol2-EHA – 2-ethylhexyl acrylate2-EHTG – 2-ethylhexyl thioglycolateEMAC – ethylene-methyl acrylate copolymer*EO – ethylene oxide*EPDM – ethylene-propylene-diene monomerEPM – ethylene-propylene copolymer rubberEPR – ethylene-propylene rubber*EPS – expandable polystyreneEPVC – emulsion PVCESBO – epoxidised soybean oil*etac – ethyl acetateETP – ethylene-propylene-diene monomer (elastomer) *ETBE – ethyl tertiary butyl etherETFE – ethylene tetrafluoroethyleneethyl-A – ethyl acrylateEVA – ethylene vinyl acetate copolymer*EVOH – ethylene vinyl alcoholFAME – fatty acid methyl esters*FCC – fluid catalytic crackingFDY – fully drawn yarnFEP – fluorinated ethylene-propyleneFRP – fibre reinforced polyester/plasticsGAA – glacial acetic acidGBL – gamma-butyrolactoneGMT – glass mat thermoplasticGNO – groundnut oil*GPPS – general purpose polystyreneGRP – glass reinforced plastic*HCFC – hydrochlorofluorocarbonHCl – hydrochloric acidHDA – hydrodealkylationHDI – hexamethylene diisocyanate*HDPE – high density polyethyleneHEMA – hydroxyethyl methacrylate polymer*HFC – hydrofluorocarbon*HIPS – high impact polystyreneHMDA – hexamethylene diamineHMDI – hexamethylene diisocyanateHMTA – hexamethylene tetramineHMWHDPE – high molecular weight high density polyethylene*IBA – isobutanolIIR – isobutylene-isoprene copolymersINA – isononanol*IPA – isopropanolIPDA – isophorone diamineIPN – interpenetrating polymer networkIR – isoprene rubber*LAB – linear alkyl benzeneLAS – linear alkyl benzene sulphonateLCO – light cycle oilLCP – liquid crystal polymer*LDPE – low density polyethyleneLER – liquid epoxy resinsLFRT – long-fibre-reinforced thermoplastic*LLDPE – linear low density polyethylene*LNG – liquefied natural gasLPE – linear polyethylene*LPG – liquefied petroleum gasLVN – light virgin naphtha*MA – maleic anhydrideMAA – methacrylic acid*MAP – monoammonium phosphatemethyl-A – methyl acrylate (do not use MA which is maleic anhydride) MBS – methacrylate butadiene styrene terpolymerMCAA – monochloroacetic acid*MDI – methyl di-p-phenylene isocyanateMDO – marine diesel oil*MDPE – medium density polyethyleneMEA – monoethanolamine*MEG – monoethylene glycol*MEK – methyl ethyl ketoneMF – melamine formaldehyde*MIBK – methyl isobutyl ketoneMIPS – medium impact polystyrene*MMA – methyl methacrylatemogas – motor gasolineMOP – muriate of potash/potassium chloride*MPG – monopropylene glycolMPPE – modified polyphenylene ether*MTBE – methyl tertiary butyl etherMX – mixed xylenes (not metaxylene which should be written out)NBA – n-butanolNBMA – n-butyl methacrylate*NBR – nitrile rubberNDC – naphthalene dicarboxylate*NGL – natural gas liquidsNMMO – N-methylmorpholine oxideNMP – N-methyl-2-pyrrolidoneNOX – nitrogen oxidesNPE – nonylphenol ethoxylateNPG – neopentyl glycol*NPK – nitrogen phosphorus potassium (fertilizer)NR – natural rubber*OPP – oriented polypropyleneOSA – olefin-modified styrene acrylonitrile*OX – orthoxylenePA – phthalic anhydride (not polyamide, see foot note)PAA – polyacetic acidPAC – polyaluminium chloridePAI – polyamide-imidePAEK – polyaryletherketonePAK – polyester alkydPAL – polyanilinePAM – polyacrylamidePAN – polyacrylonitrilePAS – polyarylsulphonePB – polybutylenePB-1 – polybutene-1PBAN – polybutadiene acrylonitrilePBI – polybenzimidazolePBN – polybutylene naphthalatePBS – polybutadiene styrene*PBT – polybutylene terephthalate*PC – polycarbonatePC/ABS – polycarbonate/acrylonitrile-butadiene-styrene blend *perc – perchloroethylenePCC – precipitated calcium carbonatePCD – polycarbonatediolPCP – pentachlorophenolPCT – polycyclohexyl terephthalatePCT-G – glycol-modified polycyclohexyl terephthalate PCTFE – polymonochlorotrifluoroethylenePDC – propylene dichloridePDO – propanediol*PE – polyethylenePEBA –polyether block amide or polyester block amide*PEEK – polyetheretherketonePEEL – polyester elastomerPEG – polyethylene glycolPEI – polyetherimidePEK – polyetherketone*PEN – polyethylene naphthalatePEO – polyethylene oxidePES – polyethersulfone or polyether sulphone*PET – polyethylene terephthalatePET-G - glycol modified polyethylene terephthalatePF – phenol formaldehydePFA – perfluoroalkoxy alkanePFOA – perfluoro octanoic acidPFY – polyester filament yarnPG – propylene glycolPGAF – antifreeze grade propylene glycolPGE – propylene glycol etherPGI – industrial grade propylene glycolPGP – polymer grade propylenePG USP – pharmaceutical grade propylene glycol2-PH – 2-propylheptanolPHA - polyhydroxyalkanoatePHB – polyhydroxybutyratePI – polyimidePIA – purified isophthalic acidPIB – polyisobutylenePIPA – purified isophthalic acidPIR – polyisocyanurate rigid (foam)PLA – polylactic acidPMA – pyromellitic acidPMAN – polymethacrylonitrile*PMMA – polymethyl methacrylatePMP – polymethylpentene*PO – propylene oxide (not polyolefin)*POM – polyoxymethylene (aka polyacetal)POP – palm oil productsPOSM – propylene oxide styrene monomer (not SMPO) POY – partially oriented yarn*PP – polypropylenePPA – polyphthalamidePPE – polyphenylene etherPPG – polypropylene glycolPPI – polymeric polyisocyanatePPO – polyphenylene oxidePPOX – polypropylene oxidePPS – polyphenylene sulphidePPSS – polyphenylene sulphide sulphonePPSU – polyphenylene sulphone*PS – polystyrenePSF – polyester staple fibrePSU – polysulphone*PTA – purified terephthalic acid*PTFE – polytetrafluoroethylenePTHF – polytetrahydrofuranPTMEG – polytetramethylene ether glycolPTMT – polytetramethylene terephthalatePTT – polytrimethylene terephthalate*PU – polyurethane*PVA – polyvinyl acetate (not polyvinyl alcohol, see PVOH) PVB – polyvinyl butyral*PVC – polyvinyl chloridePVCA – polyvinyl chloride acetatePVCP – polyvinyl chloride plasticisedPVCU – polyvinyl chloride unplasticised*PVDA – polyvinylidene acetate*PVdC – polyvinyl dichloridePVDC – polyvinylidene chloridePVdF – polyvinyl difluoridePVDF – polyvinylidene fluoridePVF – polyvinyl fluoridePVK – polyvinylcarbazole*PVOH – polyvinyl alcoholPVP – polyvinyl pyrrolidone*PX – paraxylene*pygas – pyrolysis gasolineRBOB – reformulated gasoline blendstock for oxygen blending RGP – refinery grade propyleneRP – rock phosphate*SAN – styrene acrylonitrile (copolymer)*SB – styrene butadiene (latex)SBA – sec-butanolSBM – stretch blow moulding (plastics)SBO – soya bean oil*SBR – styrene butadiene rubber*SBS – styrene-butadiene-styrene block copolymerSCU – sulphur coated ureaSDY – spin drawn yarnSEBS – styrene-ethylene-butadiene-styrene copolymerSI – siliconeSIS – styrene-isoprene-styrene*SM – styrene monomerSMA – styrene maleic anhydride copolymerSMC – sheet moulding compoundSMS – styrene/alpha-methyl styreneSOP – sulphate of potash/potassium sulphateSPS – syndiotactic polystyreneSPVC – suspension PVCSRP – self-reinforcing polymer LCP*SSP – single superphosphate*STPP – sodium tripolyphosphate*syngas – synthesis gasTAA – triacetone amineTAEE – tertiary amyl ethyl ether*TAME – tertiary amyl methyl ether*TBA – tertiary butanolTCCA – trichloroisocyanuric acid*TCE – trichloroethyleneTDA – toluene diamine*TDI – toluene di-isocyanate*TDP – toluene disproportionationTEA – triethanolamine*TEG – triethylene glycolTEO – thermoplastic elastic olefin*TFE – tetrafluoroethyleneTFO – transformer oil*THF – tetrahydrofuranTMA – trimethylamineTMC – thick moulding compoundTMP – trimethylolpropane*TPE –thermoplastic elastomerTPE-O – thermoplastic elastomer – olefinicTPE-S – thermoplastic elastomer – styrenicTPO – thermoplastic olefin (rubber)TPU – thermoplastic polyurethane (rubber)*TSP – triple superphosphateTVO –thermoplastic vulcanites*UAN – urea ammonium nitrate solution*UF – urea formaldehydeUFR – urea formaldehyde resinsUHMWPE – ultrahigh molecular weight polyethylene ULDPE – ultra low density polyethyleneULSD – ultra-low sulphur dieselUMS – unleaded motor spiritUP – unsaturated polyester (thermoset)*UPR – unsaturated polyester resinsUSP – United States PharmacopeiaVAE – vinyl acetate ethylene*VAM – vinyl acetate (monomer)*VCM – vinyl chloride (monomer)*vegoil – vegetable oilVLDPE – very low density polyethyleneVP – virgin polymerXLPE – cross-linked polyethyleneXPS – expanded polystyrene (not expandable polystyrene EPS)。

PET聚对苯二甲酸乙二酯poly(ethylene terephthalate) 01PE-HD高密度聚乙烯polyethylene, high density 02PVC聚氯乙烯poly(vinyl chloride) 03PE-LD低密度聚乙烯polyethylene,low density 04PP聚丙烯polypropylene 05PS聚苯乙烯polystyrene 06ABS丙烯腈-丁二烯-苯乙烯塑料acrylonitrile-butadiene-styrene plastic07PA聚酰胺polyamide 08PAN聚丙烯腈polyacrylonitrile 09PC聚碳酸酯polycarbonate 10PBT聚对苯二甲酸丁二酯poly(butylene terephthalate) 11PE-LLD 线性低密度聚乙烯polyethylene,linear low density 12PE-MD中密度聚乙烯polyethylene,medium density 13PE-UHMW超高分子量聚乙烯polyethylene,ultra high molecular weight 14PUR 聚氨酯polyurethane 15PMMA聚甲基丙烯酸甲酯poly(methyl methacrylate)16PVAL聚乙烯醇poly(vinyl alcohol) 17PVC-C氯化聚氯乙烯poly(vinyl chloride),chlorinated 18PVC-U未增塑聚氯乙烯poly(vinyl chloride),unplasticized 19PVDC聚偏二氯乙烯poly(vinylidene chloride) 20PVDF聚偏二氟乙烯poly(vinylidene fluoride) 21PVF 聚氟乙烯poly(vinyl fluoride) 22UP不饱和聚酯树脂unsaturated polyester resin 23UF脲-甲醛树脂urea-formaldehyderesin 24CA乙酸纤维素cellulose acetate 25PEEK聚醚醚酮polyetherketone 26PEUR聚醚型聚氨酯polyetherurethane 27PF酚醛树脂phenol-formaldehyde resin 28PI聚酰亚胺polyimide 29PHBV聚羟基丁酸酯戊酸酯poly-(hydroxybutyrate-co-hydroxyvalerate 30PK聚酮polyketone 30PTFE聚四氟乙烯poly tetrafluoroethylene 31POM聚氧亚甲基;聚甲醛;聚缩醛polyoxymethylene;polyacetal;polyformaldehyde 32PLA聚乳酸polylactic acid or polylactide 33PCL聚已内酯polycaprolactone 34PPDO聚对二氧环己酮35PPC二氧化碳共聚合物carbon dioxide copolymer 36PBS聚丁二酸丁二醇酯Polybuthylenesuccinate 37PHA聚羟基脂肪酸酯polyhydroxyalkanoic or polyhydroxyalkanoates 38 PHB聚-3-羟基丁酸polyhydroxybutyric acid or polyhydroxybutyrate 39 PGA聚乙交酯poly(glycolic acid) 40PEC PolyEster Carbonate or Poly(Butylene Succinate/Carbonate) 41 PES Poly(Ethylene Succinate) 42PTMAT Poly(TetraMethylene Adipate/Terephthalate) 43PBAT Poly(Butylene Adipate/Terephthalate) 44AB丙烯腈-丁二烯塑料acrylonitrile-butadiene plastic 45ABAK丙烯腈-xx-丙烯酸酯塑料acrylonitrile-butadiene-acrylate plastic 46ACS丙烯腈-氯化聚乙烯-苯乙烯塑料acrylonitrile-chlorinated polyethylene-styrene 47AEPDS丙烯腈-(乙烯-丙烯-二烯)-苯乙烯塑料acrylonitrile-(ethylene-propylene-diene)-styrene plastic 48AMMA丙烯腈-甲基丙烯酸甲酯塑料acrylonitrile-methyl methacryate plastic 49ASA丙烯腈-苯乙烯-丙烯酸酯塑料acrylonitrile-stytene-acrylate plastic 50CAB乙酸丁酸纤维素cellulose acetate butyrate 51CAP乙酸丙酸纤维素cellulose acetate propionate 52CEF甲醛纤维素cellulose formaldehyde 53CF甲酚-甲醛树脂cresol-formaldehyde resin 54CMC羧甲基纤维素carboxymethyl cellulose 55CN硝酸纤维素cellulose nitrate 56COC环烯烃共聚物cycloolefin copolymer 57CP丙酸纤维素cellulose propionate 58CTA三乙酸纤维素cellulose triacetate 59E/P乙烯-丙烯塑料ethylene-propylene plastic 60EAA乙烯-丙烯酸塑料ethylene-acrylic acid plastic 61EBAK乙烯-丙烯酸丁酯塑料ethylene-butyl acrylate plastic 62 EC乙基纤维素ethyl cellulose 63EEAK乙烯-丙烯酸乙酯塑料ethylene-ethyl acrylate plastic 64 EMA乙烯-甲基丙烯酸塑料ethylene-methacrylic acid plastic 65 EP环氧;环氧树脂或塑料epoxide;epoxy resin or plastic 66 ETFE乙烯-四氟乙烯塑料e thylene-tetrafluoroethylene plastic 67EVAC乙烯-乙酸乙烯酯塑料ethylene-vinyl acetate plastic 68 EVOH乙烯-乙烯醇塑料ethylene-vinyl alcohol plastic 69FEP全氟(乙烯-丙烯)塑料perfluoro(ethylene-propylene)plastic 70 FF呋喃-甲醛树脂furan-formaldehyde resin 71LCP液晶聚合物liquid-crystal polymer 72MABS甲基丙烯酸甲酯-丙烯腈-丁二烯-苯乙烯塑料methyl methacrylate-acrylonitrile-butadiene-styrene plastic 73MBS甲基丙烯酸甲酯-丁二烯-苯乙烯塑料methyl methacrylate-butadiene-styrene plastic 74MC甲基纤维素methyl cellulose 75MF三聚氰胺-甲醛树脂melamine-formaldehyde resin 76MP三聚氰胺-酚醛树脂melamine-phenol resin 77MSAN α-甲基苯乙烯-丙烯腈塑料α-methylstyrene-acrylonitrile plastic 78PAA聚丙烯酸poly(acrylic acid) 79PAEK聚芳醚酮polyaryletherketone 80PAI聚酰胺(酰)亚胺polyamidimide 81PAK聚丙烯酸酯polyarylate 82PAR聚芳酯polyarylate 83PARA聚芳酰胺poly(aryl amide) 84PB聚xxpolybutene 85PBAK聚丙烯酸丁酯poly(butyl acrylate) 86PBD 1,2-聚丁二烯1,2-polybutadiene 87PBN聚萘二甲酸丁二酯poly(butylene naphthalate) 88 PCCE亚环己基-二亚甲基-环已基二羧酸酯poly(cyclohexylene dimethylene cyclohexanedicar- boxylate) 89 PCT聚(对苯二甲酸亚环已基-二亚甲酯)poly(cyclohexylene dimethylene terephthalate) 90PCTFE聚三氟氯乙烯polychlorotrifluoroethylene 91PDAP聚邻苯二甲酸二烯丙酯poly(diallyl phthalate) 92 PDCPD聚二环戊二烯polydicyclopentadiene 93PEC聚酯碳酸酯polyestercarbonate 94PE-C氯化聚乙烯polyethylene,chlorinated 95PEEST聚醚酯polyetherester 96PEI聚醚(酰)亚胺polyetherimide 97PEK聚醚酮polyetherketone 98PEN聚萘二甲酸乙二酯poly(ethylene naphthalate) 99 PEOX聚氧化乙烯poly(ethylene oxide) 100PESTUR聚酯型聚氨酯polyesterurethane 101PESU聚醚砜polyethersulfone 102PE-VLD极低密度聚乙烯polyethylene,very low density 103 PFA全氟烷氧基烷树脂perfluoro alkoxyl alkane resin 104PIB聚异丁烯polyisobutylene 105PIR聚异氰脲酸酯polyisocyanurate 106PMI聚甲基丙烯酰亚胺polymethacrylimide 107PMMI聚N-甲基丙烯酰亚胺poly-N-methylmethacrylimide 108 PMP聚-4-甲基戊烯-1poly-4-methylpentene-1 109PMS聚-α-甲基苯乙烯poly-α-methylstyrene 110PPE聚苯醚poly(phenylene ether) 111PP-E可发性聚丙烯polypropylene,expandable 112PP-HI高抗冲聚丙烯polypropylene,high impact 113PPOX聚氧化丙烯poly(propylene oxide) 114PPS聚苯硫醚poly(phenylene sulfide) 115PPSU聚苯砜poly(phenylene sulfone) 116PS-E可发聚苯乙烯polystyrene,expandable 117PS-HI高抗冲聚苯乙烯polystyrene,high impact 118PSU聚砜polysulfone 119PTT聚对苯二甲酸丙二酯poly(trimethylene terephthalate) 120 PVAC聚乙酸乙烯酯poly(vinyl acetate) 121PVB聚乙烯醇缩丁醛poly(vinyl butyral) 122PVFM聚乙烯醇缩甲醛poly(vinyl formal) 123PVK聚-N-乙烯基咔唑poly-N-vinylcarbazole 124PVP聚-N-乙烯基吡咯烷酮poly-N-vinylpyrrolidone 125SAN苯乙烯一丙烯腈塑料styrene-acrylonitrile plastic 126SB苯乙烯-丁二烯塑料styrene-butadiene plastic 127SI有机硅塑料silicone plastic 128SMAH苯乙烯-顺丁烯二酸酐塑料styrene-maleic anhydride plastic 129SMS苯乙烯-α-甲基苯乙烯塑料styrene-α-methylstyrene plastic 130VCE氯乙烯-乙烯塑料vinyl chloride-ethylene plastic 131VCEMAK氯乙烯-乙烯-丙烯酸甲酯塑料vinyl chloride-ethylene-methyl acrylate plastic 132VCEVAC氯乙烯-乙烯-丙烯酸乙酯塑料vinyl chloride-ethylene-vinyl acrylate plastic 133VCMAK氯乙烯-丙烯酸甲酯塑料vinyl chloride-methyl acrylate plastic 134 VCMMA氯乙烯-甲基丙烯酸甲酯塑料vinyl chloride-methyl methacrylate plastic 135VCOAK氯乙烯-丙烯酸辛酯塑料vinyl chloride-octyl acrylate plastic 136VCVAC氯乙烯-乙酸乙烯酯塑料vinyl chloride-vinyl acetate plastic 137VCVDC氯乙烯-偏二氯乙烯塑料vinylchloride-vinylidene chloride plastic 138 VE乙烯基酯树脂vinyl ester resin 139PE聚乙烯polyethylene聚乙烯——PE聚丙烯——PP聚丁烯——PB聚氯乙稀——PVC耐热聚乙稀——PE-RT硬聚氯乙稀(增强聚氯乙烯)——PVC-U(UPVC)高密度聚乙烯——HDPE 无规共聚聚丙烯——PP-R玻纤增强聚丙烯——FRPP低密度聚乙烯——LDPE聚甲基丙烯酸甲酯——PMMA聚四氟乙烯——PTFE(F4)三元乙丙橡胶——EPDM多孔聚苯乙烯——XPS腈基丁二烯橡胶(丁腈橡胶)——NBR耐冲击性聚苯乙烯——HIP聚氟乙烯——PVF纳米复合三型聚丙烯——NFPP-R塑料光纤——POF丙稀腈-丁二烯-苯乙烯——ABS氯化聚醚——CPS氯化聚醚丁腈(粉末丁腈橡胶)——PNBR聚全氟乙丙稀(氟化乙丙稀)——FEP均聚聚丙烯——PPH聚偏氟乙烯——PVDF共聚酰胺(尼龙)——PA增强聚丙烯——RPP共聚酯——PES高分子聚丙烯酰胺——PAM增强氯化聚氯乙稀——CPVC嵌段共聚聚丙烯——PPB聚苯乙烯——PS交联聚乙烯——PEX聚烯烃——PO 三氟氯乙烯——CTFE全氟代甲基醚——PMVE全氟代乙基醚——PEVE全氟代丙基醚——PPVE全氟代辛基醚——POVE全氟代烷氧基——PFA聚对苯二甲酸乙二醇酯——PET定向聚丙烯——OPP流延聚丙烯——CPP共聚甲醛(聚氧甲烯、缩醛)——POM茂金属线型低密度聚乙烯——MLLDPE丙烯酸酯橡胶——ACM氯丁胶——CR氟橡胶——FPM端缩基丁腈液体橡胶——HTBN硅胶——MQ氯磺化聚乙烯橡胶——CSM丁钠橡胶——S-BR天然橡胶——NR。

![化学品专业缩写[讲解]](https://uimg.taocdn.com/340b913ebc64783e0912a21614791711cc797991.webp)

A/MMA:丙烯腈/甲基丙烯酸甲酯共聚物AA:丙烯酸AAS:丙烯酸酯-丙烯酸酯-苯乙烯共聚物ABFN:偶氮(二)甲酰胺ABN:偶氮(二)异丁腈ABA:Acrylonitrile-butadiene-acrylate:丙烯腈/丁二烯/丙烯酸酯共聚物ABS:Acrylonitrile-butadiene-styrene:丙烯腈/丁二烯/苯乙烯共聚物AES:Acrylonitrile-ethylene-styrene:丙烯腈/乙烯/苯乙烯共聚物AMMA:Acrylonitrile/methyl Methacrylate:丙烯腈/甲基丙烯酸甲酯共聚物ARP:Aromatic polyester:聚芳香酯AS:Acrylonitrile-styrene resin:丙烯腈-苯乙烯树脂ASA:Acrylonitrile-styrene-acrylate:丙烯腈/苯乙烯/丙烯酸酯共聚物BAA:正丁醛苯胺缩合物BAD:双水杨酸双酚A酯BCD:β-环糊精BE:丙烯酸乳胶外墙涂料BFRM:硼纤维增强塑料BLE:丙酮-二苯胺高温缩合物BMA:甲基丙烯酸丁酯BN:氮化硼BNE:新型环氧树脂BNS:β-萘磺酸甲醛低缩合物BOPP:双轴向聚丙烯BPMC:2-仲丁基苯基-N-甲基氨基酸酯BPTP:聚对苯二甲酸丁二醇酯BR:丁二烯橡胶BROC:二溴(代)甲酚环氧丙基醚BS:丁二烯-苯乙烯共聚物BT:聚丁烯-1热塑性塑料BTX:苯-甲苯-二甲苯混合物CA:Cellulose acetate:醋酸纤维塑料CAB:Cellulose acetate butyrate:醋酸-丁酸纤维素塑料CAP:Cellulose acetate propionate:醋酸-丙酸纤维素CE:"Cellulose plastics, general":通用纤维素塑料CF:Cresol-formaldehyde:甲酚-甲醛树脂CMC:Carboxymethyl cellulose:羧甲基纤维素CN:Cellulose nitrate:硝酸纤维素CP:Cellulose propionate:丙酸纤维素CPE:Chlorinated polyethylene:氯化聚乙烯CPVC:Chlorinated poly(vinyl chloride):氯化聚氯乙烯CS:Casein:酪蛋白CTA:Cellulose triacetate:三醋酸纤维素CA:醋酸纤维素CAB:醋酸-丁酸纤维素CAN:醋酸-硝酸纤维素CAP:醋酸-丙酸纤维素CBA:化学发泡剂CDP:磷酸甲酚二苯酯CF:甲醛-甲酚树脂,碳纤维CFE:氯氟乙烯CFM:碳纤维密封填料CFRP:碳纤维增强塑料CLF:含氯纤维CMC:羧甲基纤维素CMCNa:羧甲基纤维素钠CMD:代尼尔纤维CMS:羧甲基淀粉DAF 富马酸二烯丙酯DAIP 间苯二甲酸二烯丙酯DAM 马来酸二烯丙酯DAP 间苯二甲酸二烯丙酯DATBP 四溴邻苯二甲酸二烯丙酯DBA 己二酸二丁酯DBEP 邻苯二甲酸二丁氧乙酯DBP 邻苯二甲酸二丁酯DBR 二苯甲酰间苯二酚DBS 癸二酸二癸酯DCCA 二氯异氰脲酸DCCK 二氯异氰脲酸钾DCCNa 二氯异氰脲酸钠DCHP 邻苯二甲酸二环乙酯DCPD 过氧化二碳酸二环乙酯DDA 己二酸二癸酯DDP 邻苯二甲酸二癸酯DEAE 二乙胺基乙基纤维素DEP 邻苯二甲酸二乙酯DETA 二乙撑三胺DFA 薄膜胶粘剂DHA 己二酸二己酯DHP 邻苯二甲酸二己酯DHS 癸二酸二己酯DIBA 己二酸二异丁酯DIDA 己二酸二异癸酯DIDG 戊二酸二异癸酯DIDP 邻苯二甲酸二异癸酯DINA 己二酸二异壬酯DINP 邻苯二甲酸二异壬酯DINZ 壬二酸二异壬酯DIOA 己酸二异辛酯E/EA:乙烯/丙烯酸乙酯共聚物E/P:乙烯/丙烯共聚物E/P/D:乙烯/丙烯/二烯三元共聚物E/TEE:乙烯/四氟乙烯共聚物E/VAC:乙烯/醋酸乙烯酯共聚物E/VAL:乙烯/乙烯醇共聚物EAA:乙烯-丙烯酸共聚物EBM:挤出吹塑模塑EC:乙基纤维素ECB:乙烯共聚物和沥青的共混物ECD:环氧氯丙烷橡胶ECTEE:聚(乙烯-三氟氯乙烯)ED-3:环氧酯EEA:乙烯-醋酸丙烯共聚物EC:Ethyl cellulose:乙烷纤维素EEA:Ethylene/ethyl acrylate:乙烯/丙烯酸乙酯共聚物EMA:Ethylene/methacrylic acid:乙烯/甲基丙烯酸共聚物EP:"Epoxy, epoxide":环氧树脂EPD:Ethylene-propylene-diene:乙烯-丙烯-二烯三元共聚物EPM:Ethylene-propylene polymer:乙烯-丙烯共聚物EPS:Expanded polystyrene:发泡聚苯乙烯ETFE:Ethylene-tetrafluoroethylene:乙烯-四氟乙烯共聚物EVA:Ethylene/vinyl acetate:乙烯-醋酸乙烯共聚物EVAL:Ethylene-vinyl alcohol:乙烯-乙烯醇共聚物EO:环氧乙烷EOT:聚乙烯硫醚EP:环氧树脂EPI:环氧氯丙烷EPM:乙烯-丙烯共聚物EPOR:三元乙丙橡胶EPR:乙丙橡胶EPS:可发性聚苯乙烯EPSAN:乙烯-丙烯-苯乙烯-丙烯腈共聚物EPT:乙烯丙烯三元共聚物EPVC:乳液法聚氯乙烯EU:聚醚型聚氨酯EVA:乙烯-醋酸乙烯共聚物EVE:乙烯基乙基醚EXP:醋酸乙烯-乙烯-丙烯酸酯三元共聚乳液F/VAL:乙烯/乙烯醇共聚物F-23:四氟乙烯-偏氯乙烯共聚物F-30:三氟氯乙烯-乙烯共聚物F-40:四氟氯乙烯-乙烯共聚物FEP:全氟(乙烯-丙烯)共聚物FNG:耐水硅胶FPM:氟橡胶FRA:纤维增强丙烯酸酯FRC:阻燃粘胶纤维FRP:纤维增强塑料FRPA-101:玻璃纤维增强聚癸二酸癸胺(玻璃纤维增强尼龙1010树脂) FRPA-610:玻璃纤维增强聚癸二酰乙二胺(玻璃纤维增强尼龙610树脂) GF:玻璃纤维GFRP:玻璃纤维增强塑料GFRTP:玻璃纤维增强热塑性塑料促进剂GOF:石英光纤GPS:通用聚苯乙烯GR-1:异丁橡胶GR-N:丁腈橡胶GR-S:丁苯橡胶GRTP:玻璃纤维增强热塑性塑料GUV:紫外光固化硅橡胶涂料GY:厌氧胶HDPE:低压聚乙烯(高密度)HIPS:高抗冲聚苯乙烯HLA:天然聚合物透明质胶HLD:树脂性氯丁胶HM:高甲氧基果胶HMC:高强度模塑料HOPP:均聚聚丙烯HPC:羟丙基纤维素HPMC:羟丙基甲基纤维素HPMCP:羟丙基甲基纤维素邻苯二甲酸酯HTPS:高冲击聚苯乙烯IEN:互贯网络弹性体IHPN:互贯网络均聚物IIR:异丁烯-异戊二烯橡胶IR:异戊二烯橡胶IVE:异丁基乙烯基醚JSF:聚乙烯醇缩醛胶KSG:空分硅胶LDN:氯丁胶粘剂LDPE:高压聚乙烯(低密度)LDR:氯丁橡胶LHPC:低替代度羟丙基纤维素LIPN:乳胶互贯网络聚合物LJ:接体型氯丁橡胶LLDPE:线性低密度聚乙烯LM:低甲氧基果胶LMWPE:低分子量聚乙稀LSR:羧基氯丁乳胶FEP:Perfluoro(ethylene-propylene):全氟(乙烯-丙烯)塑料HDPE:High-density polyethylene plastics:高密度聚乙烯塑料HIPS:High impact polystyrene:高冲聚苯乙烯IPS:Impact-resistant polystyre ne:耐冲击聚苯乙烯LCP:Liquid crystal polymer:液晶聚合物LDPE:Low-density polyethylene plastics:低密度聚乙烯塑料LLDPE:Linear low-density polyethylene:线性低密聚乙烯LMDPE:Linear medium-density polyethylene:线性中密聚乙烯MBS:Methacrylate-butadiene-styrene:甲基丙烯酸-丁二烯-苯乙烯共聚物MC:Methyl cellulose:甲基纤维素MDPE:Medium-density polyethylene:中密聚乙烯MF:Melamine-formaldehyde resin:密胺-甲醛树脂MPF:Melamine/phenol-formaldehyde:密胺/酚醛树脂PA:Polyamide (nylon):聚酰胺(尼龙)PAA:Poly(acrylic acid):聚丙烯酸PADC:Poly(allyl diglycol carbonate):碳酸-二乙二醇酯• 烯丙醇酯树脂PAE:Polyarylether:聚芳醚PAEK:Polyaryletherketone:聚芳醚酮PAI:Polyamide-imide:聚酰胺-酰亚胺PAK:Polyester alkyd:聚酯树脂PAN:Polyacrylonitrile:聚丙烯腈PARA:Polyaryl amide:聚芳酰胺PASU:Polyarylsulfone:聚芳砜PAT:Polyarylate:聚芳酯PAUR:Poly(ester urethane):聚酯型聚氨酯PB:Polybutene-1:聚丁烯-[1]PBA:Poly(butyl acrylate):聚丙烯酸丁酯PBAN:Polybutadiene-acrylonitrile:聚丁二烯-丙烯腈PBS:Polybutadiene-styrene:聚丁二烯-苯乙烯PBT:Poly(butylene terephthalate):聚对苯二酸丁二酯PC:Polycarbonate:聚碳酸酯PCTFE:Polychlorotrifluoroethylene:聚氯三氟乙烯PDAP:Poly(diallyl phthalate):聚对苯二甲酸二烯丙酯PE:Polyethylene:聚乙烯PEBA:Polyether block amide:聚醚嵌段酰胺PEBA:Thermoplastic elastomer polyether:聚酯热塑弹性体PEEK:Polyetheretherketone:聚醚醚酮PEI:Poly(etherimide):聚醚酰亚胺PEK:Polyether ketone:聚醚酮PEO:Poly(ethylene oxide):聚环氧乙烷PES:Poly(ether sulfone):聚醚砜PET:Poly(ethylene terephthalate):聚对苯二甲酸乙二酯PEUR:Poly(ether urethane):聚醚型聚氨酯PF:Phenol-formaldehyde resin:酚醛树脂PFA:Perfluoro(alkoxy alkane):全氟烷氧基树脂PFF:Phenol-furfural resin:酚呋喃树脂PI:Polyimide:聚酰亚胺PIB:Polyisobutylene:聚异丁烯PIS U:Polyimidesulfone:聚酰亚胺砜PMCA:Poly(methyl-alpha-chloroacrylate):聚α-氯代丙烯酸甲酯PMMA:Poly(methyl methacrylate):聚甲基丙烯酸甲酯PMP:Poly(4-methylpentene-1):聚4-甲基戊烯-1PMS:Poly(alpha-methylstyrene):聚α-甲基苯乙烯POM:"Polyoxymethylene, polyacetal":聚甲醛PP:Polypropylene:聚丙烯PPA:Polyphthalamide:聚邻苯二甲酰胺PPE:Poly(phenylene ether):聚苯醚PPO:Poly(phenylene oxide) deprecated:聚苯醚PPOX:Poly(propylene oxide):聚环氧(丙)烷PPS:Poly(phenylene sulfide):聚苯硫醚PPSU:Poly(phenylene sulfone):聚苯砜PS:Polystyrene:聚苯乙烯PSU:Polysulfone:聚砜PTFE:Polytetrafluoroethylene:聚四氟乙烯PUR:Polyurethane:聚氨酯PVAC:Poly(vinyl acetate):聚醋酸乙烯PVAL:Poly(vinyl alcohol):聚乙烯醇PVB:Poly(vinyl butyral):聚乙烯醇缩丁醛PVC:Poly(vinyl chloride):聚氯乙烯PVCA:Poly(vinyl chloride-acetate):聚氯乙烯醋酸乙烯酯PVCC:chlorinated poly(vinyl chloride)(*CPVC):氯化聚氯乙烯PVI:poly(vinyl isobutyl ether):聚(乙烯基异丁基醚)PVM:poly(vinyl chloride vinyl methyl ether):聚(氯乙烯-甲基乙烯基醚) RF:resorcinol-formaldehyde resin:甲苯二酚-甲醛树脂RIM:reaction injection molding:反应注射模塑RP:reinforced plastics:增强塑料RTP:reinforced thermoplastics:增强热塑性塑料S/AN:styrene-acryonitrile copolymer:苯乙烯-丙烯腈共聚物SBS:styrene-butadiene block copolymer:苯乙烯-丁二烯嵌段共聚物SI:silicone:聚硅氧烷SMC:sheet molding compound:片状模塑料S/MS:styrene-α-methylstyrene copolymer:苯乙烯-α-甲基苯乙烯共聚物TMC:thick molding compound:厚片模塑料TPE:thermoplastic elastomer:热塑性弹性体TPS:toughened polystyrene:韧性聚苯乙烯TPU:thermoplastic urethanes:热塑性聚氨酯TPX:ploymethylpentene:聚-4-甲基-1戊烯VG/E:vinylchloride-ethylene copolymer:聚乙烯-乙烯共聚物VC/E/MA:vinylchloride-ethylene-methylacrylate copolymer:聚乙烯-乙烯-丙烯酸甲酯共聚物VC/E/VCA:vinylchloride-ethylene-vinylacetate copolymer:氯乙烯-乙烯-醋酸乙烯酯共聚物PVDC:Poly(vinylidene chloride):聚(偏二氯乙烯)PVDF:Poly(vinylidene fluoride):聚(偏二氟乙烯)PVF:Poly(vinyl fluoride):聚氟乙烯PVFM:Poly(vinyl formal):聚乙烯醇缩甲醛PVK:Polyvinylcarbazole:聚乙烯咔唑PVP:Polyvinylpyrrolidone:聚乙烯吡咯烷酮S/MA:Styrene-maleic anhydride plastic:苯乙烯-马来酐塑料SAN:Styrene-acrylonitrile plastic:苯乙烯-丙烯腈塑料SB:Styrene-butadiene plastic:苯乙烯-丁二烯塑料Si:Silicone plastics:有机硅塑料SMS:Styrene/alpha-methylstyrene plastic:苯乙烯-α-甲基苯乙烯塑料SP:Saturated polyester plastic:饱和聚酯塑料SRP:Styrene-rubber plastics:聚苯乙烯橡胶改性塑料TEEE:"Thermoplastic Elastomer,Ether-Ester":醚酯型热塑弹性体TEO:"Thermoplastic Elastomer, Olefinic":聚烯烃热塑弹性体TES:"Thermoplastic Elastomer, Styrenic":苯乙烯热塑性弹性体TPEL:Thermoplastic elastomer:热塑(性)弹性体TPES:Thermoplastic polyester:热塑性聚酯TPUR:Thermoplastic polyurethane:热塑性聚氨酯TSUR:Thermoset polyurethane:热固聚氨酯UF:Urea-formaldehyde resin:脲甲醛树脂UHMWPE:Ultra-high molecular weight PE:超高分子量聚乙烯UP:Unsaturated polyester:不饱和聚酯VCE:Vinyl chloride-ethylene resin:氯乙烯/乙烯树脂VCEV:Vinyl chloride-ethylene-vinyl:氯乙烯/乙烯/醋酸乙烯共聚物VCMA:Vinyl chloride-methyl acrylate:氯乙烯/丙烯酸甲酯共聚物VCMMA:Vinyl chloride-methylmethacrylate:氯乙烯/甲基丙烯酸甲酯共聚物VCOA:Vinyl chloride-octyl acrylate resin:氯乙烯/丙烯酸辛酯树脂VCVAC:Vinyl chloride-vinyl acetate resin:氯乙烯/醋酸乙烯树脂VCVDC:Vinyl chloride-vinylidene chloride:氯乙烯/偏氯乙烯共聚物。