安盟动态口令认证系统产品说明书

- 格式:doc

- 大小:136.50 KB

- 文档页数:5

ET200智能卡读写器-动态令牌OTP身份认证加密锁USBET200 智能卡读写器ET200 智能卡读写器采用USB 接口,支持遵循T=0 和T=1 协议,符合ISO7816-1/2/3 标准的所有智能卡,它通过USB 线与计算机相连,由单个双色指示灯显示工作状态,重量仅60 克,外型小巧,不占用有限的桌面空间。

ET200 智能卡读写器适用于电子支付系统、身份认证等需要对智能卡信息读写工作的领域,支持ISO7816-1/2/3 标准,提供微软PC/SC 标准驱动,是身份认证、电子商务、家庭银行、信息安全、访问和身份控制以及其它安全应用的理想解决方案。

USB1.1接口符合PC/SC 标准可以读写所有符合ISO 7816-1/2/3的T=0和T=1协议的智能卡读写智能卡支持9,600~250,000bps的PPS(协议和参数选择)支持ISO7816的A类(5V)智能卡具有短路保护功能通过RoHS认证取得生产许可证符合的标准:ISO-7816 Class A (5V),PC/SC, EN 60950/IEC 60950,Microsoft WHQL XP、Vista, EMV 2000 Level 1,CE,FCC 使用微软PC/SC 标准驱动,为PC应用软件开发提供接口示例ET301智能卡读写器ET301读写器是一款应用于PC环境或相关智能环境的高速接触式智能卡读写器。

符合标准CCID 规范,支持USB2.0全速设备(兼容1.1接口)。

可以读写所有符合ISO 7816-1/2/3的A类、B类、C类智能卡。

支持对ISO 7816-3标准尺寸的IC卡,具有很高的系统集成稳定性。

ET301作为智能卡系统集成必备的前端处理设备,极大地提高了应用系统安全性,产品适用于具有IC卡操作和高安全需求的金融、社保、电信、电子支付、网络安全、电子商务、身份认证、电子证务等接触式CPU卡应用系统。

支持USB2.0全速设备接口(兼容1.1/2.0/3.0接口)符合标准CCID规范读写所有符合ISO7816-1/2/3的T=0和T=1协议的A类、B类、C类智能卡对接触卡支持全参数PPS协议,和ICC的数据传输波特率可达344K(此波特率是在IC 卡频率为4M时的结果)具有短路保护功能符合ISO7816、IEC/EN60950、EMV 2000 Level规范接触卡供电控制:1.8V/3V/5V 单独控制,LDO 确保1.8V/3V 供电的稳定性智能卡接口速度(如果智能卡支持):T=0、T=1均支持10.753k ~ 344K(此波特率是在IC卡频率为4M时的结果)(D=32/F=372)操作系统:Windows 2000 SP4/XP SP2 SP3/Server2003/Vista/7/8包括32位和64位以及各种补丁版本、Windows CE 、Linux2.6以上ET502智能卡读写器ET502 NFC高速智能卡读写器是符合标准CCID协议的高速双界面智能卡读写器产品。

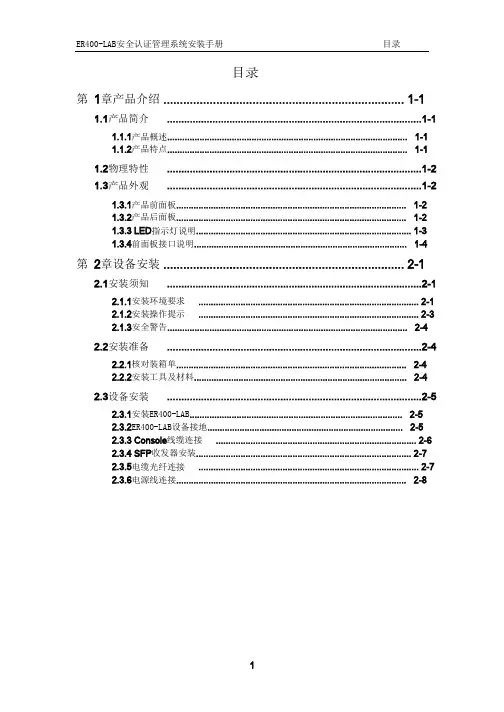

目录第1章产品介绍 ......................................................................... 1-11.1产品简介 ..........................................................................................1-11.1.1产品概述................................................................................................. 1-11.1.2产品特点................................................................................................. 1-11.2物理特性 ..........................................................................................1-21.3产品外观 ..........................................................................................1-21.3.1产品前面板............................................................................................. 1-21.3.2产品后面板............................................................................................. 1-21.3.3 LED指示灯说明....................................................................................... 1-31.3.4前面板接口说明...................................................................................... 1-4 第2章设备安装 ......................................................................... 2-12.1安装须知 ..........................................................................................2-12.1.1安装环境要求......................................................................................... 2-12.1.2安装操作提示......................................................................................... 2-32.1.3安全警告................................................................................................. 2-42.2安装准备 ..........................................................................................2-42.2.1核对装箱单............................................................................................. 2-42.2.2安装工具及材料...................................................................................... 2-42.3设备安装 ..........................................................................................2-52.3.1安装ER400-LAB...................................................................................... 2-52.3.2ER400-LAB设备接地............................................................................... 2-52.3.3 Console线缆连接................................................................................. 2-62.3.4 SFP收发器安装....................................................................................... 2-72.3.5电缆光纤连接......................................................................................... 2-72.3.6电源线连接............................................................................................. 2-8第1 章产品介绍1.1产品简介1.1.1产品概述ER400-LAB 是神州数码网络推出的二层千兆加千兆上行安全认证管理系统。

Rev. NCTABLE OF CONTENTS1.0INTRODUCTION (1)2.0AIRWORTHINESS REQUIREMENTS (2)3.0AAIR SYSTEM DEFINITION (3)3.1AAIR System Overview (3)3.2Seatbelt Airbag Assembly and Belt Extender (4)3.3Inflator Assembly (5)3.4Electronics Module Assembly (7)3.5Cable Interface Assembly (10)3.6System Diagnostic Tool (11)4.0AAIR V23 SYSTEM OPERATION (12)4.1Normal Operation (12)4.2Diagnostics Operation (12)FIGURESFigure 1 – AAIR V23 System Components – Two Seat Placement (3)Figure 2 – Seatbelt Airbag Features (5)Figure 3 – Inflator Assembly Features (6)Figure 4 – Inflation Igniter Connector (7)Figure 5 – EMA Assembly (8)Figure 6 – AAIR V23 System Schematic (9)Figure 7 – EMA with Cable Interface Assembly (10)Figure 8 – V23 System Diagnostic Tool (11)Rev. NC1.0 INTRODUCTIONThis report provides the system description of the AMSAFE Aviation Inflatable Restraint (AAIR®) System, Version V23, using a Three-point Seatbelt Airbag Restraint with Dual Sensor EMA. This description defines all system components, their critical features, and their operation.The AAIR V23 System is comprised of various core components. The core components are equivalent in design and manufacture for all aircraft using this generation product (referred to as AAIR System, Version V23, or AAIR V23 System) using a three-point restraint along with a dual sensor EMA. Certification data for the core components is common to all programs. These core items will be certified through dynamic testing (installation on seat test fixture) and vibration testing of the AAIR System. Refer to Paragraph 3.1 for further information on core components.Rev. NC 2.0 AIRWORTHINESSREQUIREMENTSThe AAIR System will be installed in aircraft to comply with the requirements of Special Condition 1 of the Proposed Special Conditions listed below. The applicable airworthiness requirements are:14 CFR Part 23, up to Amdt 23-55 Federal Aviation RegulationsFAA AC 23.1309 Federal Aviation Administration Advisory Circular –Equipment, Systems, and InstallationsRTCA-DO160D Environmental Conditions and Test Procedures for AirborneEquipmentRTCA-DO183 Minimum Operational Performance Standards for Emergency Locator TransmittersFAA TSO C114 FAA Technical Standard Order C114: Torso Restraint SystemsFAA Notice 23-03-01-SC, 17-Jul-03 Proposed Special ConditionsRev. NC3.0 AAIR SYSTEM DEFINITIONThe AAIR is a self-contained, modular restraint specifically designed to improve occupant protection from serious head injury during a survivable accident. The lapbelt is a three-point restraint system including the AAIR airbag attached to standard webbing, a webbing retractor, fixed anchor point, and buckle anchor point. This AAIR System is primarily located in the front two (pilot and copilot) aircraft seats, and can be used for passenger-only aircraft seating. It is completely independent with no interface to aircraft wiring.The system is divided into the components listed below. These have means to be inspected or replaced as required for continued airworthiness. This design, verification, and certification testing have considered environmental conditions as specified in document RTCA DO-160D, as well as vibration robustness to RTCA DO-183.3.1 AAIR SYSTEM OVERVIEWThe AAIR System contains the following core components corresponding to Figure 1.Seatbelt Airbag Assembly (SAA)Electronics Module Assembly (EMA) Inflator AssemblySystem Diagnostics Tool (not shown) Figure 1 – AAIR V23 System Components – Two Seat PlacementEMA and End-Release Buckle Assy Inflator Assy Diagnostic Connector Airbag Assy w/Inertia ReelRev. NC 3.2 SEATBELT AIRBAG ASSEMBLY AND BELT EXTENDERThe Seatbelt Airbag Assembly (SAA) is the basic lapbelt restraint and is certified to FAA TSO C114. The SAA consists of standard polyester webbing, the packed airbag assembly, a webbing retractor assembly, a fixed anchor point, and a buckle assembly anchor point. The AAIR SAA has the same basic configuration as conventional, three-point, non-inflatable lapbelts, but has the addition of an airbag, a gas delivery hose, and an activation circuit. The buckle is located at a fixed point and uses a push-button type release mechanism. The buckle assembly has a built-in activation system using a magnet and a reed switch. Buckling the lapbelt automatically activates the AAIR System. The lapbelt also includes stiffening device that mechanically resists buckling 180 degrees out of phase, i.e., twisting the belt. Any limitations and information necessary for safe operation of the AAIR are included in the AAIR SMM (Supplemental Maintenance Manual). Special instructions are not required for the passenger to use the device. Child seats are not allowed with pilot/copilot aircraft configurations of the AAIR V23 System. Reference Figures 2, 3, and 7 for seatbelt airbag features and end-release buckle assy features.The AAIR SAA components and their special features are listed below and referenced in Figures 2 and 3:•Standard polyester webbing with standard attachment anchors (ref. 2A).•Airbag sewn to webbing with approximately 30-liter airbag volume made of two fabric panels. The panels consist of a 315-denier nylon 6,6 substrate with an anti-flammability treatment (ref. 2B). The webbing also retracts within an Inertia Reel (ref. 2E) automatically maintaining tight fit of the seatbelt to an individual occupant’s body shape.•Cover with a tearable seam, which opens upon deployment. Cover is constructed of a durable material which protects the internal components from contamination and wear (ref.2B).•Gas delivery hose is tubular woven 1100-denier polyester with Kevlar-like filler and EPDM hose lining. The hose also contains a protective sleeve, which consists of a urethane-type treated, 1100-denier polyester fabric. The hose to inflation device connector is a threaded anodized aluminum fitting with a stainless steel ferrule. The gas hose construction provides resistance to wear and tear and provides safeguards preventing in-service tampering (ref.2C).•Activation circuit consists of a magnetically-activated reed switch and durable magnet mounted onto the end-release buckle assembly. The circuit conductors are strain-relieved, 20-gauge, copper-stranded cables with aerospace-specification connectors (ref. 2D). •Igniter Connector connects the activation circuit to the inflation device’s electrically activated igniter.Rev. NCFigure 2 – Seatbelt Airbag Features• Standard push-button type release mechanism (ref. 2A).• The End-Release Buckle Assembly contains magnet and a reed switch to passively closeactivation circuit. (ref. 2A and 2D).No belt extender is allowed with the AAIR V23 System.The system does not contain sharp or hard surfaces that could cause injury to occupants during normal operation, during a crash, or in secondary impacts. The following design features remove hard points or sharp edges from interfacing with the occupant:• Deployment gas ducted from behind-seat area removes inflation devices from occupantvicinity.• The airbag, belt, and protective cover do not contain any hard points or sharp edges.3.3 INFLATOR ASSEMBLYThe Inflator Assembly is mounted behind each seat position and provides the gas source to inflate the airbag upon command from the EMA. The Inflator Assembly has adhesive labels with appropriate product and shipping information. The Inflator Assembly and its electrical connection are standard automotive components produced and used in high volume with extremely high reliability and safe operation. The Inflator Assembly contains special features for safety and tamper resistance. Reference Figures 3 and 4.The Inflator Assembly components and their special features are listed below:• The inflation device is a stored gas, single-stage, blow-down type using only non-heatedinert helium gas to fill the airbag (ref. 3A).• The inflation device uses a shielded, electrically activated igniter to burst a stainless steelmembrane to release the gas to fill the airbag (ref. 3B). The igniter uses a self-shunting pin clip to automatically safe the Inflator Assembly when the igniter connector is removed. Cover with Airbag folded inside D B A Standard webbing and anchormechanism for three-point seatbelt Retractor DeviceE CRev. NC• The inflation device is a cylindrical, extruded steel, pressure vessel with welded end capsand a welded membrane. Helium gas is contained at a nominal pressure of 6,250 psig. The low carbon alloy steel vessel and all manufacturing processes are specially developed and controlled for high reliability and long-life gas storage (less than 5% gas loss over 15 years). Design values and verification testing are conducted using industry recognized statistical methods. The factors of safety for the pressure vessel are 2.7 at the maximum expected operating pressure and 3.1 at ambient temperature. The Inflator Assembly meets DOT Class 9 and UN3268 requirements for compressed, non-flammable gas devices (ref. 3A).• The inflation device and igniter have independent automatic gas release mechanisms thatare temperature activated (~ +210°C) to protect from vessel fragmentation in the event of prolonged exposure to fire (not shown).• The gas is released from the Inflator through a machined fitting assembly which isconnected to the Inflator via a threaded attachment. It is connected to the gas hose by a threaded end on the fitting (ref. 3C).Figure 3 – Inflator Assembly Features• The Inflator Assembly Igniter Connector (type FCI ABX-3) is attached to the SAA’s activationcircuit by a separate wire cable leg of the End-Release Buckle Assembly (ref. 4A).Inflation Device Body Inflator Fitting Assy and Gas Hose Connection Point A IgniterRev. NCIgniter ConnectorAFigure 4 – Inflation Igniter Connector3.4 ELECTRONICS MODULE ASSEMBLYThe Electronics Module Assembly (EMA) is a plastic box mounted to the aircraft structure on the floor. One EMA is mounted to aircraft floor for each pilot/copilot seat assembly. The EMA enclosure is designed to resist moisture and contamination and can withstand electrostatic discharge. The EMA contains crash sensors, electrical circuits, power, and connectors to service one pilot/copilot seat assembly. Reference Figures 5 and 6 for EMA and AAIR V23 System schematic, respectively.The EMA components and their special features are listed below:•The crash sensors are a spring-mass-damper type inertial switch used in high volume in automotive airbag sensor systems, but calibrated specifically for an aircraft’s operating environment. Proper deployment of the AAIR requires it to deploy at a predetermined threshold. This threshold allows enough time for proper airbag fill, but will not allow inadvertent deployment during normal operations. Below the activation threshold, the AAIR System functions as a conventional seatbelt.•Power is provided by two non-rechargeable, lithium cells with a fused thermal protection circuit. This arrangement precludes short circuits or other failures causing the batteries to release electrolyte or energy into the system in an uncontrolled manner. The system operates nominally at 7.2 VDC, and can maintain functional capability down toRev. NC approximately 7 VDC. The long-life, lithium/thionyl chloride battery system has stand-by capability of 10 years at room temperature.•The electrical connectors have 20-gauge pins and a mistake proof, keyed interface.•The “pigtail” cable consists of 20-gauge, copper-stranded insulated conductors with a woven protective wrap.The EMA assembly has a total mass of approximately .85 pounds. The housing is fabricated from ABS plastic which is lightweight, durable, and rugged. The housing is made up of a body and a lid with the lid held to the body using four machine screws. The internal components consist of a printed circuit board (PCB) onto which are attached the sensors. The battery pack (complete with capacitors and fuse) is connected to the PCB.Under an inertial load of 9g, the internal components could exert a maximum combined force of 5 lbs on the EMA housing, far below the rated capability of the housing or the fasteners including a factor of safety of 1.5. Under extremely severe circumstances, should the internalRev. NC3.5 CABLE INTERFACE ASSEMBLYThe Cable Interface Assembly consists of a connector that interfaces to the EMA pigtail connector on one side and the SAA connector on the other. A Diagnostic Tool Connector leg branches from the EMA connection leg. This diagnostics connector mates with the connector on the System Diagnostic Tool to allow functional testing of the AAIR V23 System. This cable is independent and routed separately from all other aircraft wiring (ref. Figure 7).The connectors have 20-gauge pins and a mistake proof, keyed interface. The cable is 20-gauge, copper-stranded insulated conductors with a woven protective wrap.Diagnostic ToolConnectorEMA ConnectorSAA ConnectorsFigure 7 – EMA with Cable Interface AssemblyRev. NC3.6SYSTEM DIAGNOSTIC TOOLA System Diagnostic Tool (SDT) is used to check the functional status of the AAIR. This small, portable, hand-held device has been designed for use by maintenance personnel at intervals predetermined by the AAIR System Safety Assessment, E508436. The SDT has a connector on the end of a short length of cable and a set of red/green/amber indicator lights. The connector plugs into the Diagnostic Tool Connector on the Electrical Interface Cable. The SDT provides readouts for proper and improper function for the seat position. The SDT has a built-in power supply that does not drain the AAIR battery. The SDT battery is replaceable by the user with a standard, commercially available, 9-volt battery. Figure 8 provides an illustration of the SDT.Figure 8 – V23 System Diagnostic ToolON/OFF SwitchSDT Battery LED SEAT LEDsRev. NC4.0 AAIR V23 SYSTEM OPERATIONThe AAIR V23 System requires no intervention during normal operation. The AAIR is active (able to deploy) upon buckling the seatbelt by the seat occupant and deactivated upon release of the same. The two functional states, active and inactive, both occur in the normal AAIR operational mode. The system has another non-functional, fundamental mode of operation, the diagnostic mode. This mode occurs when the SDT is connected and the system is undergoing a diagnostic test.OPERATION4.1 NORMALThe AAIR System is fully operational and considered “active” when properly installed and buckled. When buckled, the activation switch closes, completing its portion of the deployment circuit. This will allow the system to deploy upon closure of the sensor switch. When active, the AAIR is designed to protect the pilot/copilot occupants seated in the cockpit during emergency landing conditions. Proper deployment of the AAIR requires it to deploy at a predetermined deceleration level, known as the activation point. This is a point in the beginning of a crash that allows enough time for proper airbag fill. Impacts below the activation point will not cause deployment and the system functions as a conventional three-point seatbelt. Decelerations equal to or above the activation point will cause the EMA to sense the crash and initiate the firing sequence and deploy the system as previously described.The inflated airbag acts as a cushion to decelerate the head and torso of the occupant. The kinetic energy of the seat occupant is dissipated on impact with the airbag. The airbag accommodates a range of occupant sizes, and the total time period for inflation and deflation of the airbag poses no hazard to egress.The AAIR System operates within all aspects of the flight envelop environment.OPERATION4.2 DIAGNOSTICSThe system diagnostic check is conducted at pre-determined intervals. This interval must be determined such that the resulting system reliability calculated from the System Safety Assessment (reference AMSAFE document E508436) meets regulatory requirements (FAA AC 23.1309).Maintenance personnel perform the diagnostics check by using a hand-held SDT. First, the seatbelt is buckled to close the circuit and activate the system. Second, the protective cap covering the Diagnostics Tool Connector is removed. Third, the SDT is connected to the Diagnostics Tool Connector and the diagnostics check is performed. Indicators on the SDT provide system status for the seat position’s circuit.。

北京动向体育发展有限公司安全接入与双因素身份认证系统建议解决方案目录第一章现状分析第二章待解决的问题第三章技术方案-VPN安全接入第四章技术方案-双因素身份验证第五章整体设计规划与解决方案第六章产品选型第七章供应商选择第八章实施方案第九章产品报价第十章产品测试安全接入解决方案现状分析●所有业务应用直接开放端口暴露在公网上;●每增加一个业务系统就需要新购买一个域名和一个公网IP地址;●所有数据在传输过程中都是明文,因此容易被截获或者篡改;●对业务系统的登陆验证过于简单,容易被暴力破解;待解决的问题●所有业务系统全部隐藏到安全接入设备之后,不直接暴露在公网上;●在数据传输过程中对数据进行加密封装处理;●对业务系统的权限采用双因素身份验证,加强业务系统的身份验证强度;技术方案第一代IPSEC VPN●第一代VPN目前的应用范围主要是site-to-site端点到端点的网络环境中,部署IPSec需要对网络基础设施进行重大改造,花费的人力物力甚巨,同时IPSec VPN在解决远程安全访问时有几个比较大的缺点:安全性低●无法定位每个用户目前使用资源的情况●需要与网络设备互动控制访问资源●最终端没有安全性检查●无法清楚访问痕迹可用性差●需要当地网络环境允许使用才行维护费用高●客户端配置非常复杂●需要专人维护第二代SSL VPN第二代VPN采用的是SSL协议,与IPSec VPN相比,SSL VPN具有如下优点:●SSL瘦身客户端,支持自动安装;●不需要修改网络设备的配置信息;●支持客户端安全性检查●设备本地访问策略控制第二代VPN采用的是SSL协议,与IPSec VPN相比,SSL VPN具有如下缺点:●性能远比不上ipsec vpn●瘦身客户端导致身份验证过于简单第三代SSL VPN-Plus为了从根本上解决SSL VPN性能瓶颈,以新安捷(NeoAccel,INC)为代表的专业安全接入厂商,凭借强大的研发实力,经过刻苦的攻关,终于研制出了新一代SSL VPN构架——SSL VPN-Plus。

KeySafetyV8.0产品手册国瑞信安终端安全登录与监控审计系统产品手册Version 8.0江苏国瑞信安科技有限公司国瑞信安(北京)科技有限公司KeySafetyV8.0产品手册版权声明非常感谢您使用国瑞信安(北京)科技有限公司的安全产品,我们将竭诚为您的终端信息安全提供全面的服务。

本手册及其中所包含内容的版权属国瑞信安(北京)科技有限公司所有,未经许可,不得对此手册全部或部分内容复制、改编或做其他用途的使用。

本手册所介绍的TM KeySafety TM产品是由国瑞信安(北京)科技有限公司自主开发的信息安全产品,其版权受中华人民共和国版权法保护。

国瑞信安(北京)科技有限公司尽最大的努力保证本手册的准确性和完整性。

如果您在使用中发现问题,希望及时将情况反馈给我们以完善产品,我们将非常感谢您的支持。

国瑞信安(北京)科技有限公司江苏国瑞信安科技有限公司2016年4月目录第一部分KeySafety产品总体介绍 (3)1.1系统总体介绍 (3)第二部分KeySafety单机版产品安装 (4)2.1KeySafety的应用环境 (4)2.2系统安装软硬件需求 (4)2.3安装前准备 (4)2.4KeySafety产品安装步骤 (5)2.4.1 32位Windows XP/Windows 7系统安装步骤 (5)2.4.3 Windows 7 64位系统安装步骤 (11)2.4.4 主机审计单机无Key版(支持XP32位、Win 7 32/64位)安装 (19)第三部分KeySafety单机版产品使用 (23)3.1 系统登录 (23)3.2 KeySafety用户管理中心 (24)3.2.1增加系统用户 (24)3.2.2修改系统用户 (25)3.2.3删除系统用户 (25)3.2.4查看用户信息 (25)3.3 管理平台使用 (26)3.3.1安全保密员 (26)3.3.1.1用户权限设置 (27)3.3.1.2 RierSecDisk初始化(标准版不带此功能) (29)3.3.1.3介质加载(标准版不带此功能) (30)3.3.1.4主机授权中心 (30)3.3.1.5审计管理中心 (31)3.3.1.6资源使用 (32)3.3.1.7 锁屏机制 (32)3.3.2 系统管理员 (33)3.3.3安全审计员 (35)3.4光盘刻录工具使用说明 (36)3.4.1 光盘刻录工具主界面简介 (36)3.4.2 光盘刻录工具主界面简介 (39)3.4.3刻录安全光盘 (40)3.4.4刻录镜像文件到光盘 (41)3.4.5刻录音乐光盘 (42)3.4.6刻录mp3光盘 (43)3.4.7刻录VCD光盘 (44)3.4.8刻录DVD影碟 (45)第四部分产品卸载 (46)第一部分KeySafety产品总体介绍1.1系统总体介绍KeySafetyV8.0产品是国瑞信安(北京)科技有限公司针对网络信息系统开发的内部网络信息防泄密系统,该系统从多方面入手,解决网络中信息泄密的安全性问题。

目录动环FSU门禁安装调测说明 (2)前言 (2)一、接线说明 (2)高新兴接线说明 (2)邦讯接线说明 (3)中兴力维接线说明 (5)艾默生接线说明 (6)二、调试说明 (7)平台增加非智能门禁 (10)高新兴调试说明 (11)邦讯调试说明 (13)中兴力维调试说明 (15)艾默生调试说明 (19)三、功能验证 (20)远程开门验证 (21)门磁、锁舌告警验证 (22)动环FSU门禁安装调测说明前言铁塔门禁设备正确连接调试后,可以在运维监控系统“”实现平台远程开门、门磁告警上报、锁舌告警上报。

一、接线说明高新兴接线说明第一套门锁:门磁1接上排接线端子的IN12通道和GND,锁舌1接IN21和GND,门锁供电接上排接线端子的12V和GND,门锁1DO控制分别接DO3公共,DO3常开串一根线到GND。

第二套门锁:门磁2接上排接线端子的IN13通道和GND,锁舌2接IN22和GND,门锁供电接上排接线端子的12V和GND(IN21通道前的12V),第2套门锁的DO控制分别接DO4公共,DO4常开串一根线到GND。

邦讯接线说明设备左下角的“DC12V输出”为FSU的12V电源输出端,左脚为+、右脚为-,如下图:设备水印上标注的门磁1对应FSU的DI-11通道,设备水印上标注的门磁2对应FSU的DI-12通道,如下图:1设备接线定义门锁电源线:门锁的电源正、负极分别接入FSU12V输出端的正、负极;第一把锁:1、门磁:门磁的两根线,第一把门锁:低电平接入DI-9左侧的GND,高电平接入DI-11通道;2、锁舌:锁舌的两根线,第一把门锁:低电平接入DI-9左侧的GND,高电平接入DI-12通道;3、门锁控制:第一把门锁控制线接入DO-3的NC(常闭)端口,再从DO-3的com(公共)端口接入一根线到FSU12V输出端的负极;第二把锁:门磁:第二把门锁:低电平接入DI-9左侧的GND,高电平接入DI-13通道锁舌:第二把门锁:低电平接入DI-9左侧的GND,高电平接入DI-14通道;门锁控制:第二把门锁控制线接入DO-4的NC(常闭)端口,再从DO-4的com(公共)端口接入一根线到FSU12V输出端的负极。

银安二代证系统终端API使用手册(验证API)银安-二代证系统终端api使用手册(验证api)第二代证书系统终端API用户手册内蒙古银安科技开发有限公司第二代证书系统终端API用户手册1.前言............................................................................ ...............................................................22.系统要求............................................................................ ..................................................23.api列表............................................................................ ...................................................24.api详细说明............................................................................ (3)4.1端口API三4.2sam类api........................................................................... .. (5)4.2.1sdt重置SAM。

54.2.2sdt_uSAMStatus。

64.2.3sdt_uGetsamid。

64.3.4sdt uuSamidToStr。

七4.3身份证卡类api........................................................................... (7)4.3.1sdt开始指示牌。

用户指南安装使用前请仔阅读本说明书目录引言产品外观系统功能主要参数安装接线基本操作联网设置故障检修原装附件软件安装门禁软件考勤软件一、引言:感谢您使用本非接触式感应卡门禁考勤管理系统,在使用本系统之前,请您详细阅读本用户指南,并严格按照手册中的要求来操作。

此用户指南将介绍本系统主要功能及操作使用方法。

本门禁系统采用目前世界上先进的技术-非接触式感应卡技术(也称射频识别卡(RFID)技术,RFID卡具有全球卡号唯一、不易仿制的读写特性和安全性能。

RFID卡片不会产生使用磁卡时因磁头磨损、磁粉脱落、灰尘等影响所带来的麻烦,而且避免了接触式IC卡因芯片与读卡器外露而引起的沾污、接触不良和外物损伤而导致的读卡不良现象,RFID卡适应各种环境,经久耐用。

每一次感应卡读的信息,无论是否向电锁发出开锁指令,系统都自动记录下来,管理者可以通过计算机下载调阅门禁控制系统存储的信息资料,轻松查阅、打印所有的通行事件。

管理软件将根据此原始资料自动统计员工考勤情况、编制考勤报表。

本系统提供了一种智能化的出入口控制及考勤管理方式,适用于需要控制人员出入的通道、商务机构、政府机关、住宅小区等等。

二、产品外观:数字键门铃按钮电源指示灯开门指示灯通讯指示灯三、系统功能:1、存储容量达8000条通行记录,1000张用户卡及密码2、每天自由设定八个限制通行时段3、具备读卡开门、读卡加密码开门、读卡或密码开门三种方式4、内置、外接读卡器,可实时区分进入、外出人次数5、采用RS485总线联网通讯方式,布线简易实用,最多可联网16台6、主要输入/输出功能:电锁、开门按钮、报警器、门磁、门铃7、管理软件集门禁、考勤、人事于一体8、管理软件界面人性化,操作简易,使用方便9、系统图示可导入电子地图,自由设定门的名称、位置10、实时显示通过人员的姓名、相片、卡号、编号等资料11、自定义考勤规则及班次设定等12、自动统计迟到、早退、缺勤的次数及时间13、考勤结果可打印成报表或按Excel导出四、主要参数:五、安装接线:1、接口插座示意图:警告:安装接线时切记先断开电源,确认接线无误后再接通电源!!2、颜色识别接线示意图外接读卡器:系统自动识别外接读卡器读卡为进门,内置读卡器读卡为出门。

OTA系列考勤门禁说明书1. 简介OTA系列考勤门禁是一种基于先进技术实现的门禁系统,具有自动考勤、门禁控制等功能。

该系统使用便捷,界面简洁美观,操作简单。

本文档将详细介绍OTA系列考勤门禁的安装、配置和使用方法。

2. 安装2.1 硬件安装安装OTA系列考勤门禁需要以下硬件设备:•门禁读卡器•控制器•电脑或智能手机•网络连接设备按照以下步骤来安装硬件设备:1.将门禁读卡器固定在门口或需要控制出入的位置。

2.将控制器安装在离读卡器较近的位置,确保网线可以连接到控制器。

3.将控制器用网线连接到网络连接设备。

4.将电脑或智能手机连接到相同的网络。

2.2 软件安装安装OTA系列考勤门禁的软件需要以下步骤:1.下载OTA系列考勤门禁软件安装包。

2.双击安装包,按照向导进行安装。

3.完成安装后,在电脑或智能手机上启动门禁软件。

3. 配置3.1 设备连接配置在开始使用OTA系列考勤门禁之前,需要对设备进行连接配置:1.打开门禁软件,在软件界面上找到设备管理菜单。

2.点击设备管理菜单,进入设备连接配置页面。

3.输入控制器的IP地址和端口号,点击连接按钮。

4.如果连接成功,软件界面上将显示设备的基本信息。

3.2 用户配置为了使门禁系统能够识别和管理用户,需要进行用户配置:1.在门禁软件界面上找到用户管理菜单。

2.点击用户管理菜单,进入用户配置页面。

3.点击添加用户按钮,在弹出的对话框中输入用户的基本信息,如姓名、工号等。

4.通过选择用户权限和时段,来设置用户的出入权限。

5.点击保存按钮,保存用户配置。

4. 使用4.1 考勤打卡当员工进入或离开门禁区域时,需要进行考勤打卡:1.员工将工卡或身份证放置在门禁读卡器上。

2.门禁系统将自动读取卡片信息,并记录员工的出入时间。

3.软件界面上可以查询和查看员工的考勤记录。

4.2 门禁控制门禁系统可以限制和控制进入门禁区域的人员:1.通过用户配置,设置不同用户的出入权限。

2.当有人员尝试进入门禁区域时,控制器将自动判断是否允许其进入。

iKEY双因素动态密码身份认证系统上海众人网络安全技术有限公司(以下简称众人网络)于2007年9月注册成立于浦东新区张江高科技园区国家信息安全基地,注册资金3000万元,现有员工70人左右。

众人网络是国家密码管理局正式批准的商用密码产品生产定点单位和销售许可单位。

公司通过了ISO9001质量管理体系和ISO27001信息安全管理体系认证。

公司主要生产及销售拥有完全自主知识产权的iKEY双因素动态密码身份认证系统,该系统通过了国家密码管理局安审,获得了“SRT0901动态口令系统”产品型号证书,成为国内首款使用国密算法的双因素动态密码产品。

目前,公司已申报国家发明专利6项,承担上海863基地的“信息安全产品测试平台项目”的筹备和搭建,并受国家密码管理部门委托,协助拟定动态密码产品相关技术标准。

众人网络以实力取胜众人网络在公司管理方面以“规范管理,制度授权”为准则,逐步建立和完善基础管理体制,推行经营责任制和管理目标责任制,创建良性互动的运作机制,目前已逐步构筑起市场化和与国际接轨的营运机制,在自主经营过程中,通过树立品牌意识,加大科技创新、管理创新和服务创新,提高产品质量,增强驾驭市场经济的能力。

众人网络汇聚了一大批国内顶尖网络安全技术领域的精英,其核心研发团队成员曾在国内外知名的IT企业和研发机构担任关键性技术职务,研发团队成员70%以上具有研究生以上学历。

公司与交通大学、武汉大学等国内著名高校建立了稳定的战略合作关系,形成了强大的产学研一体化优势模式,并聘请中国人民解放军队伍中对国家有突出贡献的多位国内著名信息安全专家担任公司专家顾问团顾问。

众人网络在上海总部设立了研发及生产基地,在北京设立了营销中心,并已在浙江、四川、深圳等地成立销售服务分支机构。

生产基地建立了中试无尘生产车间、环境测试试验室,购置了高低温环境测试箱、振动测试仪、抗干扰测试、防水等级测试等设备,以解决iKEY令牌等产品的品质及高适应性生产质量保障问题。

ePass FIDO®-NFC PRODUCT MANUALV1.32017-03FEITIAN Technologies Co., Ltd.Website: OverviewFeitian ePass FIDO ®-NFC is a FIDO alliance certified U2F authentication key. Unlike the traditional second factor authentication devices, FIDO U2F provides a much more convenient solution to replace or be a plus of traditional password. A single Feitian ePass FIDO ®-NFC is able to protect unlimited applications. Each application will be assigned an individual key pair.Feitian ePass FIDO ®-NFC employs high-performance NXP secure elements. Besides generating strong keys pairs for FIDO ® U2F application, the JAVA smart card platform in the secure element also provides room for other applications. An OATH one-time password application is also pre-installed in Feitian ePass FIDO ®-NFC.Feitian never forgets the usability needs from users. The Feitian ePass FIDO ®-NFC enables both USB and NFC communications to meet users’ requirements.Core FeaturesOne key for all accounts. Protect an unlimited number of applications.Driver free. Recognize as a HID device, no driver needed for ePass FIDO ®-NFC to work on Microsoft Windows, Mac OS X, Linux over USB.Pre-installed FIDO U2F and OATH HOTP applications. Support both USB and NFC communications. Water proof.Product View1 NFC sensor2 LED and touch button (only needed while using contact authentication)3 Standard USB plug213SpecificationExample: How to Use U2f Security Key with GoogleA U2F security key can protect many different applications in different platforms. As an example, the instructions below will guide you to use the U2F Security Key with your Google account.Bind a U2F key to your account1.Get a PC ready with Chrome browser (Version no less than 41), a ePass FIDO -NFC and a Google accountready.2.Go to . And click “My account” at the very top-right corner.3.Click “” “2-Step Verification”. Then you can follow the Google instruction toactivate the 2-step verification. You will be required to register a phone number with this account.4.Once the 2-step verification is activated. You will be able to see the option of “Security key”. Click “AddSecurity Key” to register the ePass FIDO -NFC to this account. Click “Next” and plug-in the security key.5.When you see the screen as shown below, the security key’s LED indicator should be blinking. Touch theblinking button to process. Then your key will be successfully registered.Use FIDO U2F Security Key to Login to Your Google AccountOver PCBe noted that Google does not require users to login every time as long as you are using your frequently used devices. However, you will need to proof your identity once you are using a new device or in incognito mode.1.Go to 2.Click “Sign in”3.Enter the account ID and password.4.You will be requested to present the security key which you have just registered.5.Plug-in the U2F security key. Tap the button when the LED is blinking.6.Done.Add a Google Account in An Android PhoneAndroid version should be at least 5 (Lollipop) with the latest Google Play Services.1.Go “Setting” → “Account” → “Add Account” → “Google Account"2.Enter Account ID and password.3.You will be asked to present the ePass FIDO security key. Simply attach the key to your NFC sensor.4.Done.。

安盟动态口令身份认证系统产品说明文档1动态口令身份认证系统原理在传统的静态口令验证系统中,由于口令为“一次设置,重复使用”,由于口令的重复使用而增加了口令丢失和破解的危险性,降低了系统的安全系数,特别是在互联网环境下,黑客、木马和病毒泛滥,使得静态口令更加容易被泄露,造成企业信息系统和资源的非授权访问,导致直接经济损失和间接的信誉和商誉损失。

所以,除了用户记忆的静态口令外,还需要增加一个物理因素,如令牌,这样采用你所知道的(记忆的静态密码)和你所拥有的(令牌)两个要素构成有效密码,实现严格身份信息验证,而你所拥有的要素必须具有不可复制和篡改的性能。

动态口令认证即是依据上述原理实现的双因素强身份认证系统:1)本系统以令牌作为信物,实现双因素认证。

令牌显示依据种子密钥和时间随机计算的动态口令,具有不可复制和篡改的性能,而后台认证系统认为,只有持有令牌才可能输入正确的密码,反过来说,只要输入了当前时间点的正确密码,就可以认为持有可信的要素,即令牌。

用户登录时,必须同时验证静态口令(称之为PIN码)和动态口令,只有两者均正确时才能确认用户身份2)令牌与服务器之间的同步。

令牌和认证服务器一般以密钥和时间为基础,每隔一定时间(常见为60妙)就计算出一个口令,由于令牌和认证服务器双方都共享了对称密钥、时间因子和计算方法,所以计算出来的口令就是同步的和唯一的。

3)一次一密。

令牌上显示的密码只有在当前时间点有效,且使用一次即失效,实现高强度的安全性。

系统的部署结构如下:解决的主要问题:1)密码安全管理问题,实现不依赖于客户端安全意识和安全习惯可控的安全性,用户也免于设置复杂密码、记忆并定期更新之苦。

2)密码每分钟变化,只在当前时间点有效,且使用一次即失效,即使黑客在传输过程当中截获或窃听了,只有在一分钟之内解开,且解开之后,必须先于用户或管理员进入系统才构成威胁,这几乎不可能,大大加强了应用系统的安全性和可靠性。

3)通过安盟认证器的日志审计系统可以对所有登录用户的信息进行记录,如用户的登录时间,登录的用户名,使用的哪一块令牌,从而很快可以确认用户的身份。

2技术标准⏹《信息技术安全技术实体鉴别第一部分:概述》 GB/T 15483.1-1999⏹《信息技术安全技术实体鉴别第二部分:采用对称加密算法的机制》 GB/T 15483.2-1997⏹《信息技术安全技术信息技术安全性评估准则第二部分:安全功能要求》 GB/T 18336.2-2001 ⏹《信息技术安全技术信息技术安全性评估准则第三部分:安全保证要求》 GB/T 18336.3-2001 ⏹《计算机信息系统安全保护等级划分准则》 GB 17859-1999⏹《中国人民银行计算机通信网络总体技术规范》3安盟身份认证系统组成整个安盟身份认证系统由三部分组成的,如下图所示:安盟SecurID双因素身份构造图1)安盟SecurID身份认证令牌它是分发给最终用户的,用以证明其身份的硬件或软件设备,是安盟双因素身份认证的一个因素(您所持有的),产生一分钟变化一次的动态令牌码,简单易用,便于随身携带。

令牌每一分钟生成一个唯一识别用户的、无法预知的动态一次性口令。

其硬件和软件版本都具有防篡改能力。

如果某个用户提供了一个正确的令牌代码,就可以高度确信该用户就是拥有安盟SecurID身份认证令牌的合法用户。

每个身份认证令牌拥有一个唯一的种子号,种子号是区分身份认证令牌的根本方法。

一个用户可以绑定多个身份认证令牌(最多三块)。

安盟公司提供的身份认证令牌在产品设计、生产、运输等过程中严格按照国际标准执行,产品符合:ISO 13491-1:银行-安全加解密设备、ISO 8732(密码生成)、ANSI*9.32(数据加密标准)、ISO 11568(密匙管理)、ISO 9797(消息认证码,MAC)。

以及EN61000-6-2标准、Method RS101,MIL-STD-461D、EN55022标准、ISO7816-1等。

安盟身份认证令牌的技术参数如下:●年误差不超过30秒●种子长度为128位●工作极限温度:-20~+70℃●工作湿度范围:5%~90%●工作海拨范围:0到4000米。

●可抗1M的自由跌落●防高频辐射能力达到EN61000-6-2标准的要求●防低频辐射能力达到Method RS101,MIL-STD-461D标准的要求●信号辐射达到EN55022标准的要求●安盟硬件令牌的耐化学性、耐紫外线、耐磁、耐静电等物理特性达到ISO7816-1标准的要求2)安盟身份认证代理软件安盟身份认证代理软件就象安全卫士,可以用它来保护各种网络设备、计算主机平台和应用系统。

安盟身份认证代理软件能够保护NT域及UNIX服务器、大型机、中型系统和一系列传统主机上的资源;它已经嵌入到了目前大多主流网络设备中,并且支持多种应用平台上开发的系统。

安盟身份认证代理软件实施安盟身份认证服务器软件建立的安全策略,在用户和被保护的资源和设备之间,通过安盟身份认证服务器软件来强制实施双因素认证。

要求指定用户或组织在获准访问被保护的企业Intranet 资源之前,通过一个安盟SecurID身份认证令牌向安盟身份认证服务器软件证明其合法身份。

在用户和被保护资源及设备之间,通过安盟身份认证服务器软件强制实施双因素身份认证。

安盟身份认证代理软件与安盟身份认证服务器软件之间的通信是通过加密传输的。

是公共密钥技术的自然补充,对于保护宝贵的或受限的信息尤为有效。

现有的主流网络设备已预装,具有较强的互操作性。

支持现有的大多数主流平台。

配置过程简单,易于安装、运行。

安盟身份认证代理软件 API SDK使用户能够创建定制代理,从而保护其他面向特定的内部应用。

3)安盟身份认证服务器软件安盟身份认证服务器软件是安盟SecurID双因素身份认证解决方案中的安全服务器,包括三个主要部分:包含用户、令牌和客户机信息的数据库;身份认证引擎以及一个管理程序。

安盟身份认证服务器软件用来在选定的网络资源周围建立一个保护环境,对要求访问企业Intranet资源的各种用户进行身份认证。

除了处理用户的访问请求认证,安盟身份认证服务器软件还可进行企业网安全策略管理,它提供了集中式安全管理能力,向信任的个人签发认证令牌证;设置并实施安全策略,保护对专用网络系统、文件及应用的访问,其中包括可以根据每天的时间、星期几或根据小组或用户定义的权限来确定访问权限;创建用户访问日志,进行审计跟踪;定义和报告报警情况,如某个网络端口访问失败重试次数等。

安盟身份认证服务器软件可运行于多种服务器平台上,能够提供强大的认证服务。

4安全性与可靠性说明4.1 安全性保证1)双因素认证机制安盟双因素认证系统采用双因素认证机制来鉴别用户身份。

用户登录时,除了一个记忆在头脑中的口令外,还必须提供他拥有的令牌上显示的动态密码。

只有同时使用正确的用户PIN码和用户本人的动态口令才有可能登陆,使安全性大大提高。

2)动态密码的唯一性和安全性安盟身份认证系统采用伪随机算法,取当前时间和种子密钥产生动态密码,其中当前时间为同步因子,种子密钥是为了保证动态密码的唯一性和随机性的因子,时间相当于公钥,种子密钥相当于私钥,因此保证种子密钥的唯一性和随机性是关键。

安盟身份认证系统采用如下方法生成种子密钥和生命周期安全管理:(1)安盟公司应用私有随机算法产生100亿个随机数记录在数据库。

该随机数应用私有随机算法保证其随机性和不可预测性;随机数生成时包含唯一连续的种子密钥序列号,以此来保证其唯一性。

该数据库中的记录数量足够安盟公司使用100年以上,可以保证在足够长的时间内不必循环使用数据库中的随机数。

(2)生产时,从上述数据库中抽取生产订单需要数量的随机数记录,抽取完后自动从数据库中删除抽取过的随机数。

然后采用国密局128位的SM3杂凑算法对抽取的随机数进行循环加密,生成种子密钥,该加密算法具有不可逆性,保证种子密钥的安全性。

(3)生产订单的一批种子密钥生成后,通过私有加密算法加密打包,只有最终用户通过电话核实必要的信息后,才能获得密码解密,保证物流过程中的种子密钥安全。

(4)种子密钥一经导入安盟身份认证系统,不可导出,并强烈建议用户将种子密钥光盘和解密密码保存在足够安全的地方,如保险柜等,保证在用户处种子密钥的安全管理。

安全性方面,动态口令为6~8位,因此,同一时间产生相同动态口令的概率为10-8到10-6,考虑到用户4~8位的PIN码,同一时间产生相同双因素动态口令的概率将下降为10-16到10-10。

据此概率,加上有限的时间窗口(一般为3分钟),可以保证动态密码不可预测和破解,具有足够的安全性。

同时,令牌或者手机号码(SIM卡)是不可复制和篡改的可信的第二身份信息要素,与相应的账户名绑定,这一动态密码根据时间而变化,每60秒生成一个不同的动态密码,且只在当前事件窗口有效,通过后台认证服务器认证其有效性,如果某个用户提供了一个正确的动态口令,就可以高度确信该用户即是拥有唯一第二身份要素的合法用户。

3)一次一密认证机制认证服务器对访问服务器送来的动态密码,进行一次一密认证。

即使黑客通过工具截获使用过的动态密码,安盟身份认证系统也有效防止口令的重发攻击。

安盟双因素身份认证产品提供了身份鉴别失败的处理功能。

当用户以失败的身份鉴别尝试达到规定的数值时,能够及时终止用户与系统之间的会话过程,将用户帐号锁定,同时在系统登录日志中对身份鉴别失败事件进行审计跟踪。

只有以授权的身份才能对审计跟踪信息进行修改和删除。

安盟双因素身份认证产品提供了有效鉴的鉴别信息,包括用户名和动态密码,每个授权用户都有唯一的用户名和唯一的动态密码密钥,用户的动态密码是通过该密钥生成,为一次性的口令,且不可预知和伪造。

4)加密数据库安盟动态口令身份认证系统采用加密数据库,确保账户信息和种子密钥的安全性。

安盟动态口令身份认证系统数据库只可通过规定的接口进行访问。

5)加密传输协议安盟动态口令身份认证系统与受保护的资源(SSL VPN和应用系统等)之间采用加密传输协议,保证数据传输过程中的安全。

4.2 可靠性保证1)双机热备机制安盟身份认证系统支持双机热备机制,建议部署两台安盟身份认证服务器,一台为主服务器,另一台为备份服务器,这样任何一台服务器的死机不会影响整个认证过程。

同时,最新的安盟身份认证代理软件会自动寻找相应最快的安盟身份认证服务器服务器,认证请求会送到较快的认证服务器处理,既实现了容错,以及自动负载均衡处理。

安盟身份认证服务器可以运行于Solaris、AIX、HP-UX和Windows操作系统平台上。

2)灾难恢复能力如果认证服务器无法工作的话,所有人员均不能够访问到任何受保护的网络资源,对于需要可持续工作网络资源的企业来说,安盟身份认证服务器支持HP ServiceGuard和IBM HACMP两款高可用硬件平台。