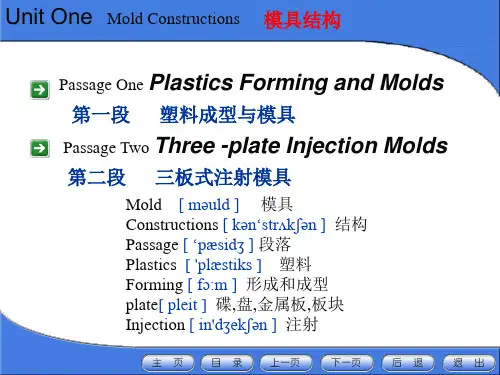

塑料模具专业英语[1]1 PPT课件

- 格式:ppt

- 大小:2.15 MB

- 文档页数:31

Chapter 1 General mould construction1. 1 Basic TerminologyImpression: The injection mould is an assembly of parts containing within it an ‘impression’ into which plastic material is injected and cooled . It is the im- pression which gives the moulding its form. The impression may, therefore, be defined as that part of the mould which imparts shape to the moulding. ①The impression is formed by two mould members:(I) The cavity, which is the female portion of the mould, gives the mould-Ing its external form.(II) The core, which is the male portion of the mould, forms the internal shape of the moulding.Cavity and core plates: This is illustrated for a simple container in Figure1.1. The basic mould in this case consists of two plates. Into one plate is sunkthe cavity which shapes the outside form of themoulding and is therefore known as the cavityplate. ②Similarly, the core which projects fromthe core plate forms the inside shape of themoulding. When the mould is closed, the twoplates come together forming a space between 图the cavity and core which is the impression.Sprue bush: During the injection processplastic material is delivered to the nozzle of themachine as a melt; it is then transferred to theimpression through a passage. ③In the simplestcase this passage is a tapered hole within a bush as shown in Figure 1. 2. The ma- terial in this passage is termed the sprue, and the bush is called a sprue bush.Runner and gate systems: The material may be directly injected into the im- pression through the sprue bush (Figure 1. 2) or for moulds containing several impressions(multi-impression moulds) it may pass from the sprue bush hole through a runner and gate system ( Figure 1. 3 ) before entering thePage 1 图图impression. ④Register ring:If the material is to pass without hindrance into the mould the nozzle and sprue must be correctly aligned. To ensure that this is so the mould must be central to the machine and this can be achieved by including a register ring (Figure 1.4).⑤图Guide pillars and bushes:To mould an even-walled article it is necessary toPage 2ensure that the cavity and core are kept in alignment. This is done by incorpora-ting guide pillars on one mould plate which then enter corresponding guide bu-shes in the other mould plate as the mould closes. ⑥An example with guide pil-lars mounted on the core side and corresponding guide bushes in the cavity side isshown in Figure 1. 4. The size of the guide pillars should be such that they main-tain alignment irrespective of the applied moulding force; this they are normallyable to do. All the constituent parts of the basic mould have now been describedand a cross-section drawing of the assembled mould illustrated (Figure 1. 4).Fixed half and moving half: It can be seen (Figure 1. 2) that the variousmould parts fall naturally into two sections or halves. Hence, that half attachedto the stationary platen of the machine (indicated by the chain dotted line) istermed the fixed half.The other half of the mould attached to the moving paltenof the machine is known simply as the moving half. ⑦Now it has to be decided inwhich of the two halves the cavity or core is to be situated. Generally the core issituated in the moving half and the overriding reason why this is so, is asfollows:The moulding, as it cools will shrink on to the core and remain with it as themould opens. This will occur irrespective of whether the core is in the fixed halfor the moving half. ⑧However,this shrinkage on to the core means that someform of ejector system is almost certainly necessary. Motivation for this ejectorsystem is easily provided if the core is in the moving half. Moreover, in the caseof our single-impression basic mould, where a direct sprue feed to the undersideof the moulding is desired the cavity must be in the fixed half and the core in themoving half (Figure 1. 2).New Words and Expressionsimpression 模腔integer 整体的female 凹陷的sprue bush 主流道衬套,浇口套inject 注射,注塑fixed half 定半模core 型芯stationary platen 固定模板shrinkage 收缩Multi-impression 一模多腔runner 分流道guide pillar 导柱feed 进浇moulding 塑件Page 3male 凸出的insert 镶块cavity型腔register ring 定位环bolster 支撑moving half 动半模sprue 主流道single-impression 一模一腔gate 浇口keep in alignment 对中,对齐nozzle注塑机喷嘴guide bush 导套Notes①The injection mould is an assembly of parts containing within it an 'im-pression' into which plastic material is injected and cooled. It is the impressionwhich gives the moulding its form. The impression may. therefore. be definedas that part of the mould which imparts shape to the moulding. 注塑模是一些零件的组合,其中包含了一个型腔。