机器人学导论分析解析

- 格式:ppt

- 大小:2.71 MB

- 文档页数:30

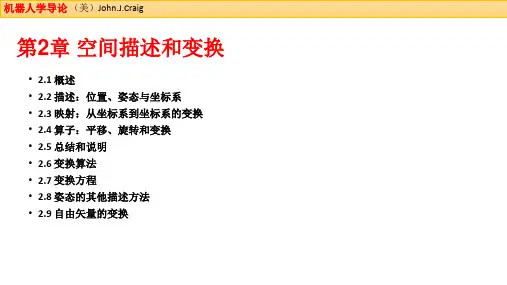

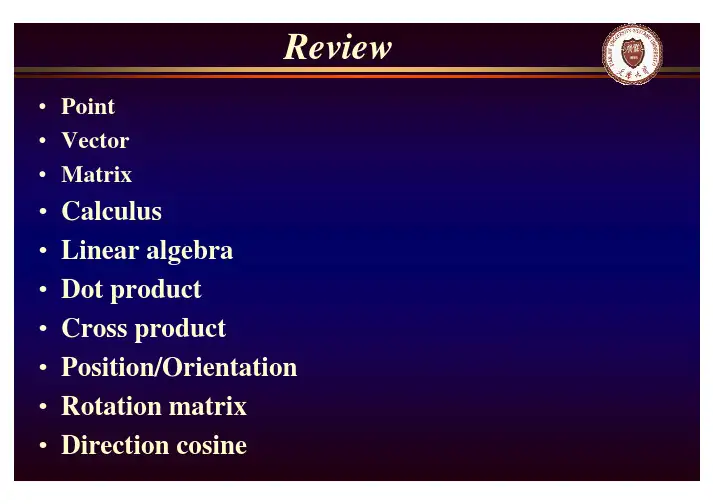

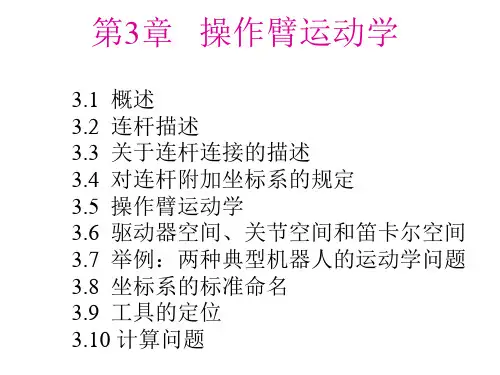

•Point•Vector•Matrix•Calculus•Linear algebra •Dot product •Cross product •Position/Orientation •Rotation matrix •Direction cosine•Coordinate system •Frame•Mapping •Translation •Rotation •Homogeneous transorm •Cross product •Operator •Translational operator •Rotational operator•Transformation operator •Compound transformation •Inverting a transformChapter3 Manipulator Kinematics•What is kinematics ?Kinematics is the sciences of motion that treats the subject without regard to the forces that cause it.•Example:With the knowledge of manipulator’s link length and joint angles, how to compute the position and orientation of the manipulatorsIn kinematics, we consider about the position, the velocity,the acceleration, and the higher derivatives of the position.The study of kinematics refers to all the geometrical and time-based properties of the motion.•Forward kinematicsGiven the joint variables of the robot, determine the position and orientation of the end-effector.[]12...T n θθθΘ=),,,,,(αβγz y x Y =•Kinematic ChainA robot can be treated as a set of right bodies (rigid links) connected together at various joints.•Lower pair:describe the connection between a pair of bodies when relative motion is characterized by two surface sliding over on another.•Joint type (lower pair):1. Revolute2. Prismatic3. Cylindrical4. Planar5. Screw6. Spherical•We consider the joint with 1degree-of-freedom (DOF). A joint with m DOF can be modeled as m joints of 1DOF connected by m-1links of zero length.•The action of joint can be described by a single real number: the angle of rotation in the case of a revolute joint, or the displacement in the case of a prismatic joint.•Number of the links starts from the immobile base (link 0), the first moving body is link 1and so on, out to the freed end of the arm, which is link n .…link1link2link0link6•In kinematics, a link is considered as a rigid body that define the relationship between two neighboring joint axes.1−i a axis i-1axis ilink i-11−i α1−i α:twist angle•Two parameters: link length and link twist angle are used to define the relative location of the two axes.•L ink length: the distance between two axes is measured along a line that is mutually perpendicular to both axes. This line is unique except in the case that two axes are parallel.axis i-1axis ilink i-1a1−ia:link length1−i•Imagine that a plane, whose normal is the mutuallyperpendicular line just constructed, we can project the axis i-1and axis i onto that plane and measure the angle from axis i-1to axis i by the right-hand rule .axis i-1axis ilink n-11−i α:twist angle1−i a•Intermediate links in the chain:Neighboring links has a common joint axis between them. The distance along this common axis from one link to another is defined as “link offset”. It will be variable for prismatic joint.axis i-1axis ilink i-11−iαid1−iaiθiaid:link offset•The angle that rotates about this common axis between one link and its neighboring link is defined as “joint angle ”. It will be variable for revolute joint.axis i-1axis ilink i-11−i αid 1−i a iθia i θ:joint angle•Link length and link twist angle depend on joint axes i and i+1.•For first link in the chain, we set and .00=a 00=α•For last link in the chain, we set and .0=n a 0=n α•If joint 1 is revolute, is set to be 0, zero position ofwill be chosen arbitrarily.1d 1θ•If joint 1 is prismatic, is set to be 0; zero position ofwill be chosen arbitrarily.1θ1d•Link parameters¾For revolute joint, the joint angle is called “joint variable”, and the other three quantities are fixed link parameters.¾For prismatic joint, the link offset is called “jointvariable”, and the other three link quantities are fixed link parameters.θd •Any robot can be described kinematically by giving the values of four quantities for each link, i.e., Denavit-Hartenberg notation[]i i iid a θαvariableconstant• A frame is attached to each link to describe the location of a link relative to its neighbors.•The link frame are named by number according to the link to which they are attached. Step1: frame {i}link {i}link1link2link0link6{0}{1}{2}{6}•Step2: intermediate link in the chain:iZ ˆjoint axis i frame {i}axis i-1axis ilink i-11−i αid 1−i a iθia 1ˆ−i Z 1ˆ−i X 1ˆ−i Y iZ ˆiX ˆiY ˆlink i•Step 3: direction of -along , from joint i to joint i+1iX ˆi a axis i-1axis ilink i-11−i αid 1−i a iθia 1ˆ−i Z 1ˆ−i X 1ˆ−i Y iZ ˆiX ˆiY ˆlink i•Step 4: direction of can be determined by right-hand rule ˆiY•How about if intersect ?is normal to the plane of and .i Z ˆ1ˆ+i Z iX ˆi Z ˆ1ˆ+i Z •First link in the chainsSelection of frame {0} is arbitrarily, will be selected along .0ˆZ 1ˆZ •Last link in the chainsFor revolute joint is chosen along when , the origin of frame {n} is chosen to set . n X ˆ0=n d 1ˆ−n X 0=n θFor prismatic joint, the direction of is chose to make and the origin of {n} is chosen at the intersection of and joint axis n when .0=n θnX ˆ1ˆ−n X 0=n daxis i-1axis ilink i-11−i αid 1−i a iθia 1ˆ−i Z 1ˆ−i X 1ˆ−i Y iZ ˆiX ˆiY ˆlink i•Summary of link parameters: the distance from to measured along : the angle from to measured about : the distance from to measured along : the angle from to measured about iX ˆi a i αi Z ˆ1ˆ+i Z i Z ˆ1ˆ+i Z iX ˆi d i θ1ˆ−i X i X ˆi Z ˆ1ˆ−i X iX ˆi Z ˆ•Summary of link-frame attachment procedure:Step1: identify the join axis (revolute joint/prismatic joint)Step2: identify the common perpendicular between two neighbouring joint axes, at the point of where the common perpendicular meets the i-th axis, assign the link-frame origin. (special case: the two axes intersect)Step3: assign the axis pointing along the i-th joint axis Step4: assign the axis pointing along the common perpendicular (special case: the two axes intersect)iX ˆi Z ˆStep5: assign the axis to complete a right-hand coordinate system.iY ˆStep6: assign the {0} to match {1} when first joint variable is 0.For {n}, chosen origin and directly of freely, but so as to cause as many link parameters as possible to be zero.nX ˆExample 3.3 in the text book(a)(b)Example 3.4 in the text bookwhere two adjacentaxes intersect(a)(b)D-H Tablei1−i a 1−i αid i θ11ˆZ 1ˆX 2ˆZ 2ˆX 3ˆZ 3ˆX 2L Link1Link2Link323D 90000)(2t d 2L )(1t θ)(3t θFrame {0} is coincident with frame {1}.Example 3.5 in the text bookwhere two adjacentaxes intersect•It is possible that there is no unique attachment of frames to link and result in several possible D-H representation.¾There are two choice of direction in which to point .¾In the case of intersecting axes, there are two choices fordirection of . 2ˆZ iX ˆ01=a 901−=α01=d 22L a =02=α12L d =1ˆZ 1ˆX 2ˆZ 2ˆX 3ˆZ 1L 2L case 111()t θθ=22()t θθ=−1=a 901=α01=d 22L a =02=α12L d −=1ˆZ 1ˆX 2ˆZ 2ˆX 3ˆZ 1L 2L case 2•When the direction of is changed, some link parameters willalso be changed. There are four more possible assignments offrames with pointing down.1X 11()t θθ=22()t θθ=1ˆZ•The above problem will be broken into four sub-sub-problems.Each sub-sub problem will be a function of only one link parameter.[]i i i i d a θα11−−Ti i1−•Sub-problem: construct the transform that define frame {i} to frame {i-1}•Problem statement: solve for the position and orientation of link n relative to link 0.•The problem can be broken into n sub-problem. Each sub-problem will involve transformation from one link to its neighboring link.•Introduce three intermediate frames: {P}, {Q}, and {R} for each link for transformationaxis i-1axis ilink n-11−iαid1−iaiθia 1ˆ−iZ1ˆ−iXiZˆiXˆRZˆRXˆQXˆQZˆPZˆPXˆ•Step1: {i}--->{P}, translation transform•Step2: {P}--->{Q}, rotation transform•Step3: {Q}--->{R}, translation transform•Step4: {R}--->{i-1}, rotation transform)(ˆi z P id D T i =)(ˆi z Q Pi R T θ=)(1ˆ1−−=i X R Qa D T i )(1ˆ11−−−=i X i Ri R T α)()()()(ˆˆ1ˆ1ˆ111i Z i Z i X i X i id D R a D R T iii i θα−−−−−=We can write))()()((11T T T T T P iQ P R Q i R i i−−=⎥⎥⎥⎥⎦⎤⎢⎢⎢⎢⎣⎡−−−=−−−−−−−−−−10001111111111i i i i i i i i i i i i i i i i i i i d c c s c s s d s s c c c s a s c T αααθαθαααθαθθθBy substituting the link parameters into above equation, we have•The Unimation Puma 560 is a robot with 6 degree of freedom, and all rotational joints (6R).•The link frames are assigned in the position corresponding to all joint angles equal to 0.forearm•Join axes of joint 4,5,6 intersect at a common point, and the joint axes 4,5,6 are mutually orthogonal. This design is used in many industrial robot.Schematic of the 3R wrist of PUMA 560•Link parameters of the PUMA 560 is listed in the following D-H table.•Transformation of each link can be computed as follows:•The transformation of all six link:•For a manipulator with n DOF, the position of all the links can be specified with a set of n joint variable. This set is often called as joint vector.•The space of joint vectors is referred as joint space.•Cartensian space: position is measured along orthogonal axes, and orientation is described by the rotation matrix wespecified before.•Cartensian space is often called as task-oriented space or operational space.•In the case that joint is not actuated directly by actuator, and the position sensors are often located at the actuators, actuator position should be considered.•Actuator vector: a set of actuator position•Actuator space: the space of actuator vectorsActuator SpaceJoint Space Cartesian Space•Base frame {B}, or frame {0}. It is attached to a non-moving part of the robot, i.e., the base, sometimes called link 0link1link2link0link6{B}{W}{T}{S}{G}link1link2link0link6{B}{W }{T }{S}{G}•The station frame {S}, located in a task-relevant location. Sometimes is called universe frame , task frame or world frame . It is often specified with respect to frame {B} as:TS B S =}{link1link2link0link6{B}{W }{T }{S}{G}•The wrist frame {W}, attached to the last link of themanipulator (frame {N}). It is defined relative to the base frame {B} asTT W N B W 0}{==link1link2link0link6{B}{W }{T }{S}{G}•The tool frame {T}, attached to the end of tool that the robot isholding. It can be defined according to wrist frame {W}.TT W T=}{link1link2link0link6{B}{W}{T }{S}{G}•The goal frame is utilized to describe the location to which therobot is to move the tool. It is specified relative to the station frame {S}.TG S G=}{•Where is the tool?The problem is to locate the position and the orientation of the tool that the robot is holding.))(()(1T T T T W TB W BS ST −=}{}{S T →•Example of the assignment of standard frames:Thank You!。

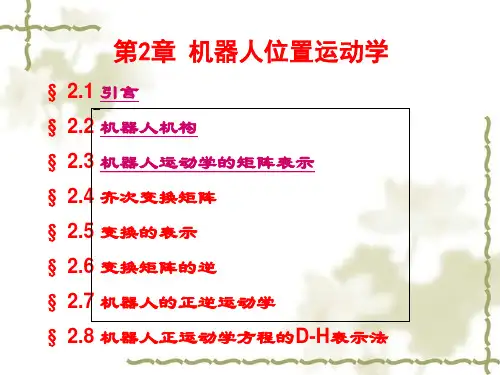

机器人学导论学院:工程机械学院专业:机械工程*名:**学号:**********任课教师:***成绩:目录一、问题重述 (4)1.1、问题重述 (4)1.2 目标任务 (4)二、问题分析 (5)三、模型的假设 (6)四、符号说明 (6)五、模型建立与求解 (7)5.1运动学模型建立与求解 (7)5.1.1机器人运动方程的建立 (7)5.1.2 利用逆运动学方法求解 (10)5.2、问题1—1的模型 (11)5.2.1搜索算法流程图 (12)5.2.2、模型求解 (15)5.3、问题1—2、3的模型 (18)5.3.1、问题1的②、③ (18)5.3.2、问题2的② (20)5.3.3、问题2的③ (22)5.4、问题3 (25)七、模型的评价 (25)7.1.模型的优点 (25)7.2.模型的缺点 (25)参考文献 (26)摘要本文探讨了六自由度机械臂从一点到另一点沿任意轨迹移动路径、一点到另一点沿着给定轨迹移动路径、以及无碰撞路径规划问题,并讨论了设计参数对机械臂灵活性和使用范围的影响,同时给出了建议。

问题一:(1)首先确定初始坐标均为零时机械臂姿态,建立多级坐标系,利用空间解析几何的变换基本原理及相对坐标系的齐次坐标变换的矩阵解析方法,来建立机器人的运动系统的多级变换方程。

通过逆运动学解法和构建规划,来求优化指令(2)假定机械臂初始姿态为Φ0,曲线离散化,每个离散点作为末端位置,通过得到的相邻两点的姿态,利用(1)中算法计算所有相邻两点间的增量指令,将满足精度要求的指令序列记录下来。

(3)通过将障碍物理想化为球体,将躲避问题就转化成保证机械手臂上的点与障碍球球心距离始终大于r的问题。

进而通过迭代法和指令检验法,剔除不符合要求的指令,从而实现避障的目的问题二:将问题二中的实例应用到问题一中的相对应的算法中。

问题三:灵活性与适用范围相互制约,只能根据权重求得较优连杆长度。

关键词:多级坐标变换逆运动学解法遗传搜索算法优化一、问题重述1.1、问题重述某型号机器人(图示和简化图略)一共有6个自由度,分别由六个旋转轴(关节)实现,使机器人的末端可以灵活地在三维空间中运动。

机器人学导论等效旋转矩阵机器人学导论导论机器人学是研究机器人的运动、感知、决策和控制等方面的一门交叉学科。

它涉及多个领域,如计算机科学、电子工程、力学、控制理论等。

机器人学的目标是设计和开发能够完成特定任务的智能化机器人系统。

等效旋转矩阵等效旋转矩阵是机器人运动中常用的一种表示方法。

它可以将三维空间中的旋转变换表示为一个三维矩阵,从而方便进行运动规划和控制。

1. 旋转矩阵的定义在三维空间中,一个点P(x,y,z) 绕坐标轴分别旋转角度α,β,γ 后得到新点P’(x’,y’,z’)。

则可以通过如下公式计算旋转矩阵R:其中,Rx, Ry, Rz 分别表示绕x轴、y轴、z轴旋转的矩阵,α, β, γ 分别表示绕x轴、y轴、z轴旋转的角度。

2. 等效旋转矩阵的定义在机器人运动中,通常需要将多个旋转变换组合起来来实现特定任务。

这时,可以将多个旋转变换合并为一个等效旋转变换,从而简化运动规划和控制。

等效旋转矩阵的定义如下:其中,R1, R2, …, Rn 分别表示多个旋转变换的旋转矩阵。

3. 等效旋转矩阵的计算方法计算等效旋转矩阵的方法有多种,下面介绍两种常用的方法。

(1)欧拉角法欧拉角法是一种将三个绕不同轴的旋转变换合并为一个等效旋转变换的方法。

具体步骤如下:① 将三个绕不同轴的旋转变换分别表示为三个矩阵R1, R2, R3。

② 将这三个矩阵相乘得到一个等效矩阵R = R3 × R2 × R1。

③ 将等效矩阵R分解为三个绕不同轴的旋转变换,即可得到欧拉角表示。

(2)四元数法四元数法是一种将多个旋转变换合并为一个等效旋转变换的方法。

具体步骤如下:① 将多个旋转变换分别表示为四元数q1, q2, …, q n。

② 将这些四元数相乘得到一个等效四元数q = qn × … × q2 × q1。

③ 将等效四元数q转换为等效旋转矩阵即可。

4. 总结等效旋转矩阵是机器人运动中常用的一种表示方法,它可以将多个旋转变换合并为一个等效变换,从而方便进行运动规划和控制。

机器人学导论-分析系统与应用课程设计设计背景机器人学被视为未来科技领域中最为重要的学科之一。

随着科技进步的不断推进,机器人技术也在不断得到发展和应用。

为了满足人们对于机器人学的需求,并推广机器人学的应用,机器人学导论-分析系统与应用课程设计应运而生。

该课程旨在帮助学生掌握机器人学知识,并深入理解机器人学的应用场景,为机器人行业的发展做出贡献。

设计目的机器人学导论-分析系统与应用课程设计旨在通过讲授机器人学的基本原理、应用技术以及实验操作等内容,提高学生的机器人学技能和能力水平,培养学生的创新思维和实践能力,开拓学生的视野和发展空间。

设计内容课程简介机器人学导论-分析系统与应用课程设计主要包括以下内容:1.机器人学基础知识介绍机器人学的基本概念、构成、分类和应用领域等内容,并掌握机器人学的基本知识和常用术语。

2.机器人学应用技术介绍机器人学在各个领域的应用,并讨论机器人学应用技术的发展趋势和应用前景。

3.机器人学实验操作实验操作是机器人学课程中的重点部分之一,通过机器人的程序编写和实验操作帮助学生深入理解机器人的基本原理和应用。

课程安排机器人学导论-分析系统与应用课程设计总共分七个章节,具体安排如下:章节课程内容第一章机器人学概述第二章机器人学基本原理第三章机器人学应用技术第四章机器人感知技术第五章机器人运动规划第六章机器人控制第七章机器人实验操作课程教材本设计采用以下教材进行教学:1.《机器人学:基础、方法与应用》(第三版)导:森永卓郎、黄维毅、吕兆霖、许成龙;2.《机器人学应用》张建新策划编著;3.《机器人学与智能控制》张骏主编;4.《机器人技术与应用》(第二版)铁翼编著;教材中覆盖了机器人学的基本知识和实践技能,为学生提供了较全面的学习资料和方法。

课程评估为了确保机器人学导论-分析系统与应用课程设计的教学质量,我们设计了如下评估方式:1.期中考试(占总成绩30%)2.期末考试(占总成绩40%)3.课程实验作业报告(占总成绩30%)实验作业报告主要考察学生的实验操作能力和对机器人学知识的掌握能力。