烧结厂主抽风机变频调速节能案例分析_何青

- 格式:pdf

- 大小:249.07 KB

- 文档页数:4

烧结系统主抽风机的变频生产与节能应用摘要随着自动化控制技术的不断进步,冶金行业对自动化高效化、节能化有了更高的要求,本文采用高压变频控制技术对烧结主抽风机同步电动机在启动过程中实现降压、降噪、减少电网高次谐波,并在生产时可控调速,以达到节能省电效果。

关键词:高压变频器变频控制节能环保1前言高压大功率同步电动机是当前烧结主抽风机的常规配置,也是钢铁企业烧结工序中的核心设备。

烧结主抽风机的起动多采用降压起动,起动电流通常是额定电流的 3~5 倍,不仅严重冲击电网和电网中的其他用电设备,而且冲击电流导致电动机振动大、发热快、绝缘易老化。

因烧结工艺参数或配料变化,通常采用调节主抽风机风门开起度的方式来调节烧结机风箱的风压和风量,但是电动机的输出功率几乎不变,导致电能较大浪费。

因此,采用先进的高压变频技术实现主抽风机的起动和调速控制,是烧结生产提高产量和质量、降低能耗的重要措施。

2高压变频器的工作原理和系统组成2.1高压变频器的工作原理变频器主要由整流(交流变直流)、滤波、逆变(直流变交流)、制动单元、驱动单元、检测单元等组成,三相高压电进入高压开关柜,经输入降压和移相等处理后为功率柜中功率单元供电;其次,变频控制柜中的控制单元对功率柜中功率单元进行整流、逆变控制、检测等处理,使得频率可以根据需要通过操作界面给出;最后,控制柜中控制单元将控制信息发送至功率单元中进行整流、逆变等调整,输出所需等级的电压,基本控制原理如图1所示。

图1电机的转速满足如下的关系式:n =(1-s)60f/P=F×(1-s)(P:电机极对数;f:电机运行频率;s:滑差)从式中看出,电机的同步转速F(F=60f/P)正比于电机的运行频率f,由于滑差s一般情况下比较小(0~0.05),电机的实际转速n约等于电机的同步转速n。

,所以调节了电机的供电频率f,就能改变电机的实际转速。

电机的滑差s和负载有关,负载越大则滑差增加,所以电机的实际转速还会随负载的增加而略有下降。

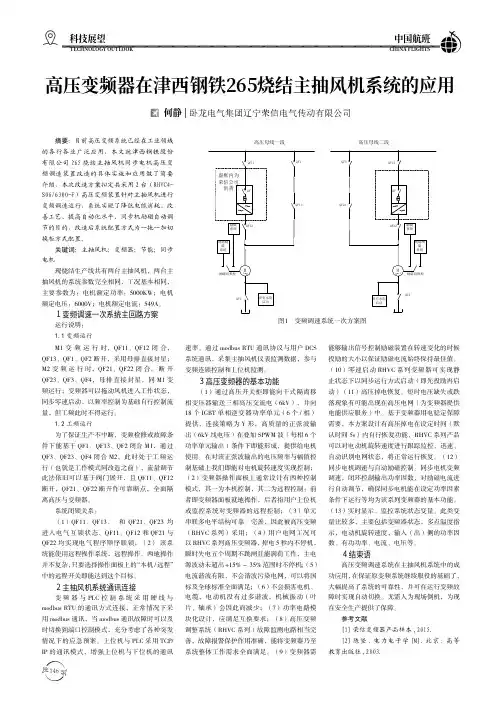

烧结主抽风机从变频运行切换到工频运行过程问题的解决陈主成【摘要】对烧结主抽风机的同步电机,因故需要从变频启动运行切换到工频运行过程中高压主回路开关发生跳闸的原因进行了简要分析,提出了解决措施;经过试车实践证明是有效的.【期刊名称】《冶金动力》【年(卷),期】2016(000)008【总页数】2页(P44-45)【关键词】切换;跳闸;差动保护;励磁;延时【作者】陈主成【作者单位】中冶华天工程技术有限公司,江苏南京210019【正文语种】中文【中图分类】TM3青岛钢铁有限公司环保搬迁工程,2台4800 kW的烧结主抽电机选用同步电机,驱动电机的2台5000 kW的10 kV高压变频器由安川电机(中国上海)有限公司供货;设计方案如图1所示;图1中,VCB2是向1#电机供给10 kV工频电源的高压柜内部真空断路器,是高压柜内部的10 kV主回路开关(为了叙述方便,后面用VCB2代表对应的高压开关柜,其他序号的VCB符号含义与此类似);VCB3是向高压变频器供电的高压柜内部真空断路器;VCS1~VCS9是变频柜内部的10 kV高压主回路开关;母线供电电压是10 kV。

为了讨论的方便,现对本方案的功能简要说明如下:高压供电分别设Ⅰ段和Ⅱ段母线,Ⅰ段高压母线通过1#或2#变频器,都能驱动1#电机,但不能驱动2#电机(2#主电机的驱动电路未画出);Ⅱ段高压母线通过2#或1#变频器,都能驱动2#电机,但不能驱动1#电机。

两台电机正常生产由高压变频驱动;但如果变频器发生故障或生产需要,可以切换到工频状态运行;例如:1#变频器把1#电机启动完毕后,可以切换到VCB2高压柜供电,电机在工频状态下运行。

通过试车发现,从变频运行切换到工频运行,有两个问题需要解决,否则,高压主回路会跳闸,切换功能无法实现。

下面以1#电机从变频切换到工频为例进行讨论。

1#电机启动和切换回路由VCB2、VCB3、VCS2、高压变频器、VCS3、VCS4、隔离电抗器组成;其中VCB2是向1#电机供给10 kV工频电源的高压开关柜。

烧结主抽风机电动机变频调速改造及故障处理彭凌云(江西新余钢铁有限公司新余338001)使用与维护 第38卷2020年第3期(总第207期)【摘要】阐述了大功率电动机串液态电阻降压启动的优、缺点。

在保留原有液态电阻降压起动作为备用 起动方式基础上,采用了西门子高压变频交流调速技术,对烧结机主抽风机大功率同步电动机的起动及控制系 统进行升级改造,并对运行中出现的故障进行跟踪分析。

【关键词】电动机峰压起动志汪文洗史類调速洗结机Variable-frequency Variable-speed Reform of Sintering Main ExhaustFan Electric Motor and Faults TreatmentPENG Ling-yun(Jiangxi Xinyu Iron & Steel Co., Ltd., Xinyu 338001)【Abstract】The advantages and disadvantages of the series liquid resistance voltage dropping start of the high power motor are described.O n the basis of retaining the original liquid resistance voltage dropping start as a standby starting mode,Siemens high-voltage variable-frequency AC variable-speed technology is*adopted.And the starting and control system of the high-power synchronous m otor of the sintering main exhaust fan are upgraded and modified.The faults occurred in the operation are tracked and analyzed.【Key words】Electric m otor,voltage dropping start,high voltage AC variable-frequency variable- speed,sintering machine1前言烧结厂于2008至2011年投产3台360m2烧结机,每台烧结机配套2台型号为TD6400-6/1730的 同步电动机,额定功率_kW,额定电压10kV,额 定电流422A,额定转速lO O O r/min,功率因数0.95。

146科技展望TECHNOLOGY OUTLOOK中国航班CHINA FLIGHTS高压变频器在津西钢铁265烧结主抽风机系统的应用何静|卧龙电气集团辽宁荣信电气传动有限公司摘要:目前高压变频系统已经在工业领域的各行各业广泛应用,本文就津西钢铁股份有限公司265烧结主抽风机同步电机高压变频调速装置改造的具体实施和应用做了简要介绍,本次改造方案拟定共采用2台(RHVC4-S06/6300-F)高压变频装置针对主抽风机进行变频调速运行,系统实现了降低电能消耗、改善工艺、提高自动化水平、同步机励磁自动调节的目的,改造后系统配置方式为一拖一加切换柜方式配置。

关键词:主抽风机;变频器;节能;同步电机现烧结生产线共有两台主抽风机,两台主抽风机的系统参数完全相同,工况基本相同,主要参数为:电机额定功率:5000KW;电机额定电压:6000V;电机额定电流:549A。

1变频调速一次系统主回路方案运行说明:1.1变频运行M1变频运行时,QF11、QF12闭合,QF13、QF1、QF2断开,采用母排直接封星;M2变频运行时,QF21、QF22闭合,断开QF23、QF3、QF4,母排直接封星,同M1变频运行;变频器可以拖动风机进入工作状态,同步零速启动,以频率控制为基础自行控制流量,但工频此时不得运行。

1.2工频运行为了保证生产不中断,变频检修或故障条件下能基于QF1、QF13、QF2闭合M1,通过QF3、QF23、QF4闭合M2,此时处于工频运行(也就是工作模式同改造之前),流量调节此法依旧可以基于阀门展开,且QF11、QF12断开,QF21、QF22断开作可靠断点,全面隔离高压与变频器。

系统闭锁关系:(1)QF11、QF13、和QF21、QF23均进入电气互锁状态,QF11、QF12和QF21与QF22均实现电气程序顺序联锁;(2) 该系统能使用远程操作系统,远程操作、两地操作并不复杂,只要选择操作面板上的“本机/远程”中的远程开关即能达到这个目标。

马钢烧结主抽风机变频节能改造张云;杨进【摘要】马钢烧结系统使用的抽风机耗电较高,为降低电耗,决定实施节能改造.在分析、研制的基础上,结合现代科技,采取了切实可行的措施,并成功地实施了改造,达到了节能降耗的效果,取得了明显的经济效益.【期刊名称】《冶金动力》【年(卷),期】2018(000)001【总页数】3页(P17-19)【关键词】风机;变频系统;节能;电耗【作者】张云;杨进【作者单位】马鞍山钢铁股份有限公司设备部,安徽马鞍山 243000;马鞍山钢铁股份有限公司设备部,安徽马鞍山 243000【正文语种】中文【中图分类】TM34马钢股份公司第三炼铁总厂现有A、B两台烧结机,每台烧结机由2台主抽风机组成,每台主抽风机由一台功率为7800 kW的同步电机拖动运行,采用西门子变频软启动方式启动电机。

每台烧结机月耗电量约600万kW·h左右,在烧结生产中耗电比重较高。

为了降低烧结生产的电耗,我们在此方面进行了探索,将传统的大风机电机采用软启动方式启动,工频运行模式,改为既具有软启动功能,又具备调速功能的变频方式,从而有效地降低了烧结生产的用电成本,效果较好,值得推广。

2.1 设备元器件老化,故障率较高,影响正常生产。

马钢股份公司第三炼铁总厂A、B烧结机自2006年投产至今已有十多年,变频器等电气设备控制元器件老化,部分模块损坏,出现无法正常开机情况,对烧结生产影响较大。

2.2 通过对风机运行工况数据分析,烧结生产负荷的波动以及风门挡板的调节存在着较大的电量损耗。

第三炼铁总厂A、B烧结机主抽风机共4台,均为工频运行和挡板调节风量,根据现场数据的统计,风机风门平均开度为74%,负压为15 kPa,因此,当生产负荷波动时,需要经常调节风门挡板,这期间存在着较大的电量损耗。

利用变频控制技术,改风门调节风量为电机调速调节风量,降低电机电量的消耗,降低风门损耗,预计每台风机电机年总节电率达到20%左右。

昆钢草铺新区新区烧结厂1#、2#烧结主抽风机高压同步电机变频改造方案昆钢草铺新区烧结厂1#、2#烧结主抽风机高压同步电机变频节能改造技术方案目录1.概述 (1)2.项目概况 (3)2.1. ·································································工程概况32.2. ······················································烧结厂现场数据调研32.2.1. ···································草铺新区烧结厂主要技术参数32.2.2. ··············································主抽风机技术参数43.系统节能改造分析 (7)3.1. ························································变频改造节能原理83.2. ·················································烧结厂主抽风机能耗分析93.3. ······················································1#烧结风机节电分析103.4. ······················································2#烧结风机节电分析113.5. ······················································变频改造后经济效益114.改造工程设计方案 (12)4.1. ·································································改造目的124.2. ····························································电气技术方案124.3. ······················································变频器散热冷却方案134.3.1. ············································空水冷却器功率确定134.3.2. ·········································空水冷却系统控制方式134.3.3. ····················································循环水参数144.4. ···················································变频励磁装置技术要求144.5. ·············································上位机DCS自动控制改造方案144.5.1. ···································上位机DCS自控系统改造要求144.5.2. ·····································DCS自控系统改造设备清单155.ES9000S高压变频技术规格 (17)6.改造工程施工建筑安装方案 (18)6.1. ··························································高压变频器安装186.2. ·················································高压变频室建设施工设计196.2.1. ················································高压变频室施工196.2.2. ··············································配套电缆沟的建设196.3. ······················································空水冷系统施工方案196.3.1. ·········································水冷柜与风道系统施工206.3.2. ··················································冷却循环水塔206.4. ····························································励磁柜的安装217.供货范围 (22)7.1. ····························································设备供货清单227.2. ·················································备品备件及专用工具清单227.3. ···············································空水冷却循环系统供货清单227.4. ······················································电缆及电缆附件清单227.5. ························································自控系统设备清单228.深圳市库马克新技术股份有限公司优势简介 (23)8.1. ·································································公司简介238.2. ······························································资质优势:238.3. ·····································ES9000系列高压变频器产品技术优势248.4. ··E S9000系列高压变频器产品研发、生产、检测、工程实施及售后服务优势258.5. ········································E S9000系列高压变频器技术特点:278.6. ········································深圳库马克公司在该项目的优势:321.概述钢铁生产企业是国民经济生产中的能源消耗大户,钢铁行业已被列为国家节约资源的重点领域之一。

河钢唐钢烧结主抽风机变频节能改造与实践张丹【摘要】能源短缺和环境污染是人类当前共同面临的世纪性难题.我国自然资源总量排世界第七位,能源资源总量约4万亿吨标准煤,居世界第三位,但我国人口众多,能源资源相对匮乏.而作为我国在电力方面重点推广的节能技术之一的高压大功率变频调速技术,对于节能方面有着明显的效果.我国高压电动机总容量在1.5亿千瓦以上(不包括低压电动机),大部分为风机泵类负载,这些电动机大都由6kV/10kV驱动,它们大多工作在高能耗、低效率状态.如可根据所需的流量调节转速,就可获得很好的节电效果,一般可节电20%~50%.%Energy shortage and environmental pollution are the century problems that human beings are facing.China's total natural resources ranked seventh in the world,the total energy resources of about 4 trillion tons of standard coal,ranking third in the world,but China's population is large,the energy resources are relatively scarce.As one of the key energy-saving technologies in China,high voltage and high power variable frequency speed regulation technology has obvious effect on energy saving.China's high voltage motor total capacity of 150 million kilowatts or more (not including low voltage motor),the majority of fan and pump load,the motor is mostly driven by6kV/10kV,most of them work in the high energy consumption and low efficiency.If you can adjust the speed according to the required flow,you can get very good power-saving effect,generally can save electricity 20%~50%.【期刊名称】《电子测试》【年(卷),期】2017(000)014【总页数】2页(P97-98)【关键词】烧结;主抽风机;变频;节能;改造【作者】张丹【作者单位】河钢集团唐钢公司炼铁部,河北唐山,063000【正文语种】中文唐钢炼铁部南区烧结车间360m2烧结机是与南区高炉车间3200m³高炉配套的生产设施,于2006年8月份开始筹建,并于2007年8月份正式投产运行。