bl焊接工艺过程共18页文档

- 格式:ppt

- 大小:1.04 MB

- 文档页数:18

金属材料焊接工艺流程金属材料焊接工艺流程一、焊接前的准备工作1. 准备好所需的焊接材料,包括焊条、焊丝、辅助焊剂等。

2. 对待焊件进行清理,将焊接表面的油脂、氧化物、杂质等物质清除干净,以保证焊接质量。

3. 根据焊接材料的类型和焊接要求,选取适当的焊接设备和工具,进行调试和准备工作。

二、焊接工艺的选择1. 根据焊接材料的类型和要求,选择合适的焊接工艺,常用的有电弧焊、气焊、激光焊等。

2. 根据焊接材料的厚度和形状,选择合适的焊接方法,如焊接角度、焊接位置等。

3. 根据焊接材料的性能和要求,确定焊接参数,如焊接电流、焊接电压、焊接速度等。

三、焊接过程的操作步骤1. 将焊接材料固定在焊接台或夹具上,以保证焊接位置准确和稳定。

2. 根据焊接材料的要求,选择合适的焊接方法和设备,进行预热或预处理工作。

3. 点火并调节焊接电流、电压等参数,使焊接电弧稳定和均匀。

4. 根据焊接材料的型号和要求,选择合适的焊接材料,进行熔化和填充。

5. 控制焊接速度和焊接量,保证焊接质量和效果。

6. 在焊接过程中,根据焊接情况和材料要求,进行适当的调整和处理,以保证焊接质量和效果。

7. 完成焊接后,关闭焊接设备,进行冷却和清理工作,以保证焊接品质。

四、焊接后的处理和检验1. 对焊缝进行处理,如打磨、抛光等,使焊缝平整和光滑。

2. 对焊缝进行检验,如目视检查、磁粉探伤、超声波检测等,以判断焊接质量和可靠性。

3. 对焊接件进行非破坏性和破坏性试验,如拉伸试验、冲击试验等,以确保焊接件的力学性能和可靠性。

4. 对焊接面进行防护和防腐处理,以提高焊接件的耐腐蚀性和使用寿命。

五、焊接工艺的改进和优化1. 根据焊接过程中的问题和需求,进行焊接工艺的改进和优化,如提高焊接质量、提高生产效率等。

2. 对焊接工艺进行持续改进和研究,引入新的技术和设备,以推动焊接技术的发展和进步。

通过以上几个步骤的执行,能够确保金属材料的焊接工艺流程顺利进行。

钢结构焊接通用工艺预览说明:预览图片所展示的格式为文档的源格式展示,下载源文件没有水印,内容可编辑和复制钢结构焊接通用工艺编制:审核:批准:年月1.焊接材料同钢材的匹配1.1 药皮焊条手工电弧焊(SMAW)用药皮焊条注:焊剂型号的含义:●F-焊剂。

●第一位数字――熔敷金属的σb。

●第二位数字――试样状态。

●第三位数字――熔敷金属冲击功≥27J时的试验温度。

第四位数字――焊剂渣系代号。

1.4 实芯焊丝气体保护焊(GMAW)用焊丝1.5药芯焊丝气保护焊(FCAW)用焊丝〔天泰焊材(昆山)有限公司产品〕1.6栓钉焊用栓钉1.7栓钉焊用瓷环2.坡口清洁2.1 清洁工作要求:A. 烘并抹去油渍。

B. 烘去水渍。

C. 刮去油漆、泥土等污垢。

D. 磨去切割硬化层和锈斑,直至呈现金属光泽。

2.2 清洁范围:A. 坡口部位。

B. 上下两边坡口侧面30mm的范围。

C. 坡口两端左右两侧各30mm的范围。

3. 焊接材料的烘焙3.1 药皮焊条A. 酸性焊条:使用前应烘焙到150℃,保温1h,然后存放在手提式保温筒内,盖紧盖子,随用随取。

4h内未用完的焊条,可退库再烘焙。

B. 碱性低氢型焊条:使用前应烘焙350℃,保温2h,然后存放在手提式保温筒内,盖紧盖子,随用随取。

4h内未用完的焊条,可退库再烘焙,但最多只允许烘焙2次。

3.2 焊剂A. 熔炼型焊剂:使用前应烘到250℃,保温1h。

只准在大气中暴露4h,过时的应重新烘焙,但最多只允许烘焙2次。

B. 烧结型焊剂:使用前应烘到300~350℃,保温2h。

只准在大气中暴露4h,过时的应重新烘焙,但最多只允许烘焙2次。

3.3 药芯焊丝:使用前应烘到100℃,不必保温。

(焊丝盘应为钢质,不可用塑料盘。

)3.4 熔化咀:使用前应烘干到100℃。

3.5 瓷环:使用前应烘干到100℃4. 电焊机的保养和鉴定4.1 电焊机的外表应保持清洁。

4.2 电焊机的导线应保持绝缘良好。

4.3 电焊机的电源特性,以及电焊接电流和电弧电压(或焊接电压)的调节功能应保持正常,每三年必须经计量部门检查和鉴定一次,并应贴上鉴定证明标签。

焊接工艺参数(The welding process parameters)The choice of the welding parametersHttp://scutde/t14courses/1412-efmdljiaif/gangjiegou/9.HTM Manual electric arc welding parameters include electrode diameter, welding current, arc voltage, welding layers, power type and polarity etc..1. electrode diameterSelect the diameter of electrode mainly depends on the thickness of welding joint form, welding position and welding level etc.. In general, according to table 6-4 according to the welding thickness choice of electrode diameter, and tend to choose the larger diameter of the electrode. In addition, in the flat, large diameter; welding, the electrode diameter is less than 5mm; horizontal welding and overhead welding, with a diameter of not more than 4mm; groove multilayer welding, in order to prevent the defects of lack of penetration, the first welding seam should adopt 3.2mm diameter electrode.Table 6-4 mm relationship between the diameter of electrode and welding pieces of thicknessWelding thicknessLess than or equal to 23~45~12>12Electrode diameterTwoThree point two4~5More than 152. welding currentThe welding current is too large or too small will affect thewelding quality, so the choice should be based on the electrode type, diameter, thickness, welding joints, weld location and other factors to consider, the electrode diameter and weld position is the key. In general the welding steel structure, welding current and electrode diameter relationship formula was selected following experience available:I=10d2 (6-1)TypeI - welding current (A);D - electrode diameter (mm).In addition, welding, welding current should be higher than the small 15% ~ 20%; horizontal welding and overhead welding, welding current should be higher than the current 10% to 15%.3. arc voltageAccording to the characteristics of the power supply, welding current and arc voltage decided by the corresponding. In addition, the arc voltage and arc length. Long arc arc voltage, arc short arc voltage low. General requirements for arc length is less than or equal to the diameter of electrode, short arc welding. In acidic welding when used to preheat the parts or reduce the temperature of the molten pool, sometimes will be slightly elongated arc welding, which is called arc welding.4. welding layersWelding layers should be considered depending on the thickness of welding pieces. In addition to sheet are generally used, multi-layer welding. The number of welding seam thickness of each layer is too small, too large, has an adverse effect on the ductility of the weld metal. The thickness of each layer of weld construction should not be greater than 4 ~ 5mm. 5. types of power supply and polarityThe DC power supply due to stable arc, small splash, goodwelding quality, generally used in important welding structure or plate stiffness structure. In other cases, we should first consider the AC welder.According to the characteristics of the welding electrode form and different characteristics of anodic arc in high temperature than the cathode, with different polarities to weld various components. With basic electrode or welding of thin plates, using DCRP (the workpiece is connected to the anode by acid electrodes); and, (usually used is then connected with the anode workpiece).6. the weldability of steelThe difference of different kinds of steel welding performance is used to represent the weldability. The weldability of steel refers to the appropriate design and operating conditions, and the welding material is easy to meet the structural performance level. General weldability of specific performance in the following aspects:(1) the welding operation easier;(2) crack and other harmful defects do not occur when welding;(3) the parent material and mechanical, chemical and physical properties of the welded joint;(4) notch toughness of base metal is excellent;(5) of welded joints plasticity and toughness enough. Weldability is often affected by the chemical composition of the steel, rolling method and plate thickness factor. In order to evaluate the effect of chemical composition on welding, general use of carbon equivalent (Ceq) said.Ceq is the chemical composition of the welding heat affected zone of the highest hardness, the International Institute of welding of carbon equivalent formula is recommended: According to the experience:Ceq<0.4%, the steel hardened tendency is very small, good solderability, generally do not need preheating before welding.Ceq = 0.4%~0.6%, the steel hardened tendency gradually increased. Before welding, the need for appropriate preheating, and adopting low hydrogen welding material for welding. Ceq>0.6%, quench hardening trend, difficult welding, welding should be carefully before preheating, and take control of welding process and other measures.1.4 welding parameters1.4 welding parametersWelding parameter refers to welding, various physical quantities are selected to ensure the welding quality (such as: welding current, arc voltage, welding speed, heat input). SMAW welding parameters including electrode diameter, welding current, arc voltage, welding speed and preheating temperature etc..1.4.1 electrode diameterThe electrode diameter is according to the thickness of welding, welding position, welding joints, layer selection.The thickness of the weldment is larger, overlapping and T joint weld should be used for larger diameter electrode. For small groove welding, in order to ensure the bottom of the penetration, should adopt thinner electrode, 3.2mm electrode or Phi Phi 2.5mm is generally used as backing welding. Different welding position, electrode diameter selection is different, usually flat with thick diameter (4 ~ 6) mm welding rod, welding and overhead welding with phi (3.2 ~ 4) mm electrode; transverse welding with phi (3.2 ~ 5) mm electrode. For the special needs of small steel, the welding parameters can be used for small diameter electrode.According to the workpiece thickness selection, refer to table 3-20. For the important structure should be based on the provisions of the scope of the welding current (determined according to the heat input) refer to table 3 - 21 the diameter of the welding current and the relationship between electrode to determine the diameter of electrode.1.4.2 welding currentThe welding current is the main process parameters of arc welding, the welder is only adjusting welding current needs in the process of operation, and the welding speed and arc voltage are controlled by the welder. The welding current selection directly affects the welding quality and productivity.The increase of welding current, weld depth is bigger, melting fast, high welding efficiency, but the current is too large when welding spatter and smoke, electrode tail redness, partial coating to failure or collapse, but also prone to undercut, burn and other defects, increase welding deformation, will make joint coarse grain heat affected zone, reduce welding joint toughness; welding current is too small, it is difficult to arc, welding rod adhesion on the workpiece, the arc is stable, easy to produce welding incomplete fusion defects such as porosity and slag, and low productivity.Therefore, the choice of welding current, should be based on the electrode type, electrode diameter and thickness of welding joints, welding position and welding layers to consider. Should first ensure the welding quality, secondly should be used in the large current, to improve production efficiency. Compared with the plate thickness, T joint and lap joint, the welding environment at low temperature, due to heat faster, so the welding current is bigger. But the main consideration of the electrode diameter, welding position and welding level etc..1) considering the diameter of electrode electrode diameter is thicker, melting the electrode required more heat, to increase the welding current, each electrode has a most suitable current range, table 3-21 welding current reference value of a variety of commonly used suitable electrode diameter.When using carbon steel electrode welding, also can be selected according to the electrode diameter, welding current is calculated by empirical formula below:I=dKType: I - welding current (A):D - electrode diameter (mm):K -- the empirical coefficient (A / CRA), see table 3-20. Table 3-20 current experience coefficient and diameter of electrode welding [9]The electrode diameter D / mm 1.62 ~ 2.5 and 3.24 ~ 6Experience coefficient K 20 ~ 2525 ~ 3030 ~ 4040 ~ 502) position of welding in flat position welding is considered, can choose more large welding current, non flat position welding, easy to control weld, the welding current is 10% ~ 20% small flat position.3) consider welding backing bead welding layer usually, in order to ensure the quality of the use of back bead, the welding current is smaller; the welding bead filling, in order to improve efficiency, ensure good fusion, the use of large welding current: cover weld, prevent undercut and ensure a bead shape, using the current smaller.The welding current can be selected according to the preliminary - electrode diameter, welding current is selected by trial after welding, weld inspection and defect, it can be determined. For the requirements of mechanical properties suchas boilers, pressure vessels and other important structures, to after the qualification of welding process, can finally determine the welding parameters such as current.The arc voltage of 1.4.3When the welding current is adjusted, the characteristic curve of welding machine is decided. In fact, the arc voltage is mainly determined by the arc length. Arc length, arc voltage is high, and vice versa. In the process of welding, the arc should not be too long, otherwise there will be arc combustion instability, spatter, weld depth and undercut, porosity and other defects: if the arc is too short, easy to stick electrode. In general, the arc length is equal to the electrode diameter 0.5 ~ 1 times as well, the arc voltage corresponding to 16 - 25V. The arc length does not exceed the basic electrode electrode diameter, electrode diameter for half the better, as far as possible to choose short arc welding; arc length acid electrode should be equal to the diameter of electrode.1.4.4 welding speedSMAW welding speed refers to the welding process welding rod along the welding direction, moving speed, the length of the weld is completed per unit of time. The welding speed is too fast will cause serious weld narrowing, uneven, prone to undercut and weld waveform taper; welding speed will make the weld width, residual height increase, reduce the effect. The welding speed also directly determines the heat input size, generally selected according to the steel hardened tendency.1.4.5 welding layersThick plate welding, general groove and multi-layer welding or welding. The microstructure of multi layer and multi pass welding head is fine, the heat affected zone is narrow. Before a bead to bead up after a preheating, then a bead has the effectof heat treatment on a bead. Therefore, the joint has good ductility and toughness. Especially for hardened steel, the weld bead after the tempering effect, can improve the microstructure and mechanical properties were investigated. For high strength low alloy steel and other steel, welding layers have obvious influence on the performance of joint. Weld less layers, each layer of the weld thickness is too large, due to grain coarsening, will lead to a decline in the ductility and toughness of welded joints.1.4.6 heat inputWhen welding, the welding energy input to the unit length of weld heat input is called heat. The formula is as follows: Q=NLU/uThe heat input type in Q - unit length of weld (J / cm)I - welding current (A);U - arc voltage (V);U - welding speed (cm / s)N - coefficient of thermal efficiency, SMAW is 0.7 ~ 0.8. The heat input is small, influence on properties of welded joint of low carbon steel for the low carbon steel electrode electric arc welding - generally does not require heat input. For low alloy steel and stainless steel, the heat input is too large, the joint performance may reduce the heat input is too small, there may be cracks in welding steel. Therefore, the welding procedure specification of heat input. After the welding current provisions of heat input and arc voltage arc welding and the welding speed is indirectly determined roughly. General should be determined through test without welding cracks and ensure the heat input range of joint performance qualified.The heat input range is bigger, more convenient for weldingoperation.1.4.7 preheating temperaturePreheating is welding on the welding workpieces all or part of the proper heating before the start. Preheating can decrease of cooling speed of welded joints, avoid the quenched structure, reduce welding stress and deformation. It is the effective measures to prevent cracks. The general structure of low carbon steel and low alloy strength rigid small low strength steel, generally without preheating. But for the rigid or welding the crack structure of the poor, need to be preheated before welding.According to the comprehensive consideration of the preheating temperature of the chemical composition, base material and welding performance, thickness, welding joints and welding restraint degree of ambient temperature and related products, technical standards and other conditions, the minimum preheat temperature of important structure after cracking test for uncertain crack. Choose the preheating temperature is much higher, the better effect to prevent cracks; but more than the preheating temperature required, will cause the metal grain coarsening near the fusion zone, reduce the welding quality, labor conditions will be worse. Usually with a variety of heating stove integral preheating. Local preheating gas used as flame heating or infrared heating. The commonly used surface thermometer temperature.After 1.4.8 heat and heat treatment after welding Immediately after welding welded pieces of all (or local) heating or insulation, the corrosion process measures called heat cold. After the heat is to avoid the formation of hard tissue, and the diffusion of hydrogen escaping the weld surface, so as to prevent the generation of cracks.Post weld heat treatment to improve the microstructure and properties of welded joints or eliminate the welding residual stress is called heat treatment after welding. The main effect of postweld heat treatment is to eliminate the welding residual stress, reduce the hardness of the weld zone, the diffusion of hydrogen evolution, stable organization and improve the mechanical properties and high temperature properties. Therefore, the choice of heat treatment temperature according to the properties, microstructure, steel structure, working temperature and heat treatment to consider, and the microstructure and hardness test to determine.For easy to produce important structural fracture and delayed crack, structure size and high stability, stress corrosion, should be considered for stress relief annealing for boilers and pressure vessels, there are special rules, the thickness exceeds a certain limit to eliminate stress annealing. Stress relieving annealing when necessary to pass a test to determine. Often need high temperature tempering Cr Mo heat-resistant steel after welding, to improve the structure of joints, welding residual stress.The important welding structure, such as boiler, pressure vessel, the welding welding technology evaluation process, according to the design of the welding process and welding test plate of the welding quality and mechanical properties to meet the technical requirements, determine the formal wit. Welding construction, must be strictly in accordance with the provisions of the welding process, not free to change. In strict accordance with the instructions set out before baking, remove oil, welding on the welding water, reduce the content of hydrogen in the weld welding: reasonable process parameters and reduce the weld heat input, harden tendency of welding:immediately after hydrogen treatment, hydrogen escape from the welded joints: for hardenability high steel, preheating before welding, welding time after heat treatment, improve the microstructure and mechanical properties of the welding process by reducing stress measures.(3) reheat crack after welding, welding in a certain temperature range once again heating (stress relief heat treatment or other heating process) crack generated called reheat crack.Causes: reheat crack usually occurs in V, Cr, Mo, containing B alloy elements of low alloy high strength steel,heat-resistant steel and stainless steel, subjected to a welding heat cycle, and then heated to a sensitive region (550 to 650 DEG C) generated. This is because the solid solution carbide saturated first heating process (V, Mo, Cr, carbide) again caused by precipitation, grain strengthening, the slip strain concentration in the original austenite grain boundaries,When the grain boundaries of plastic strain lack the ability to withstand the strain relaxation during the loading process, reheat crack will. The crack originated in the welding heat affected zone of coarse grain zone. Reheat cracking occurred mostly in thickness and stress concentration, multilayer welding can sometimes produce reheat crack.Preventive measures: on the premise of meet the design requirements, selection of low intensity electrode, the weld strength is lower than the parent material, the stress relaxation in the weld heat affected zone, avoid cracks: reducing welding residual stress and stress concentration; the welding heat input control, reasonable selection of heat treatment temperature, as far as possible avoid sensitive zonetemperature.Welding technology measure:1) welding process test of more use in engineering or joint form representative, to determine the optimum operation method and welding specification, welding technology and welding laboratory test by full charge.2) assembly positioning weldingThe A. assembly location before welding, welding groove and oil inside and outside on both sides of the 20mm range must be wiped clean with solvent wipe, and portable grinder grinding impurity removing rust, oxide, the welding base metal surface with metallic luster.B. served as the location of welding work must be certified welder welder.The C. assembly quality meets the technical requirements before the pattern positioning welding (such as the requirement of preheating before welding seam must be preheated to the required temperature only after the positioning welding.) The position of welding, welding rod (should be dried), and the weld wire must be used when welding consumables are consistent, weld positioning should fill the crater.D. weld length is generally 20 - 50mm, 400 - 600mm long distance, leg size should be no more than half of the design size of welds, and should not be greater than 8mm, from the design of positioning welding weld end more than 30mm. (except for special circumstances)E. no weld crack, shall not exceed the standard of slag, porosity and other defects, if there is a welding defect, must be completely removed, re positioning welding.The change of F. in the cross weld and weld direction is not sharp positioning weld, weld positioning should leave the areamore than 50mm.3) the general provisions of weldingA. served as the project welder welding must be certified welders, and shall be subject to special training examination (for the training and assessment of the project).B. worked as a welder welding should be familiar with the technical documents of the project and construction technology requirements, and must be in strict accordance with the welding parameters, the welding procedure specification. The welding sequence and welding direction welding.C. components to prevent too large deformation in the welding process, welding pieces must be placed flat, not allowed to be placed for welding, and shall be in strict accordance with the provisions of the welding sequence and welding direction welding.D. before welding should carefully check whether it meets the requirements of welding groove, and welding groove and the impurities should pay nearly water, oil, rust, oxide etc. thoroughly cleaned before welding.E. of weld preheating and heat requirements, in strict accordance with the provisions of the welding process of preheating temperature, preheating temperature and time range, after the heat to preheat, heat and cold work. A weld preheat requirement, the lowest layer (Road) room temperature not less than the preheating temperature, the top of all welds (Road) room temperature should be less than or equal to 250 DEG C.F. in the waste steel before welding should be allowed to officially welding products in good welding current after debugging.The power supply wire and welding pieces of base metal fasteners should be welded g., ensuring good contact.H. arc in arc plate or welding groove, does not allow any damage on the surface of base metal arc.I. welding should pay attention to the weld solder joints, solder joints and weld joint will not produce welding defects, multi pass welding, each layer (Road) for the electrode joints should be staggered, welding after finishing each weld, slag and spatter and other impurities must be cleaned, and carefully check the weld confirm quality, defect free, then welding a welding seam. (if it is found that the former weld defects must be allowed to completely remove the welding defects after welding.)J.In the welding plate fillet weld, the weld must be around the end of the wrap angle of welding.K. welding "automatic submerged arc welding, arc cutting" in the process of welding is not allowed in principle. If in the welding process for broken arc, it should be the end of the bead planing to more than 50mm, and the portable grinder grinding into the slope shaped was allowed to continue welding.L. "welding gas welding", should be in accordance with the provisions of the gas flow and gas debugging, about half a minute, the air transport emissions tracheal clean, allowed welding in welding.M. uses "arc gouging" Qing root, gouging tool of wind should be concentrated, the pressure of compressed air should be 0.39 0.6MPa, and according to the rod diameter, the thickness of welding current to avoid gouging aerobic debugging, "carbon" and "stick slag" phenomenon should be gouging process. Gouging, must put the shavings and allowed the removal, welding gouging and polished to expose the metal gloss after using a hand-held grinder.N. welding completed, should be the weld surface slag and spatter clean of impurities, carefully check the weld appearance quality, and the provisions on the play and to order inspection mark welder, (including the appearance and internal quality of full-time inspection).O. welding joint welding defects, without treatment, should be timely analysis to identify the reasons, according to the repair process in the field and under the guidance of technical staff, can handle welding defects.P. arc plate on the workpiece and the leading board application of flame cutting removal, prohibit the hammer down.The welding process of main nodesAccording to the structure of "boarding bridge fixed corridor" project and material specifications, introduces several main node part of the welded joint welding method:(1) BH350 * 200 H steel web double butt full penetration welding (thickness 8mm)Methods: MIG welding MIG welding (GMAW)Downhand welding position:Welding material: ER50-6 wire diameter of 1.2; the protective gas Ar 80% + CO2 20%Welding power supply: DC reverse(2) wing plate 200 BH350 * H steel butt double full penetration welding (thickness 12mm)The A. level of welding joint formMethods: MIG welding MIG welding (GMAW)Downhand welding position:Welding material: ER50-6 wire diameter of 1.2; the protective gas Ar 80% + CO2 20%Welding power supply: DC reverseThe B. level of welding joint formMethods: MIG welding MIG welding (GMAW)Welding position: overhead welding, weldingWelding material: ER50-6 wire diameter of 1.2; the protective gas Ar 80% + CO2 20%Welding power supply: DC reverseThe C. level of welding joint formMethods: MIG welding MIG welding (GMAW)Welding position: flat, overhead weldingWelding material: ER50-6 wire diameter of 1.2; the protective gas Ar 80% + CO2 20%Welding power supply: DC reverseOf which: all full penetration welding on both sides, with the back arc gouging welding root qing.(3) BH350 * 200 H welding steel flange and web plate (fillet) Joint welding sequenceWelding method: automatic submerged arc welding (SAW) Welding position: boat shaped weldingWelding material: H08MnA wire diameter 4 - HJ350;Welding power supply: DC reverseNote: the welding layer is a layer of A.The H shaped steel after welding using the "machine" or "oxyacetylene flame correction".(3) 150 x 150 x 8 tube (the vertical and oblique abdominal rod) welding and single side welding with backing full penetration Joint welding levelsMethods: MIG welding MIG welding (GMAW)Welding position: welding (up)Welding material: ER50-6 wire diameter of 1.2; the protective gas Ar 80% + CO2 20%Welding power supply: DC reverse(4) 150 x 150 x 8 tube (vertical, oblique abdominal rod) andone side welding of 200 BH350 * H steel flange plate group welding full penetration jointJoint welding levelsMethods: MIG welding MIG welding (GMAW)Downhand welding position:Welding material: ER50-6 wire diameter of 1.2; the protective gas Ar 80% + CO2 20%Welding power supply: DC reverseAnother location for the overhead position welding, cover layer is divided into two pass welding, welding should be reduced. Joint welding levelsMethods: welding arc welding (SMAW)Downhand welding position:Welding material: J427 Phi 3.2, Phi 4 electrodeWelding power supply: DC reverseAnother form of joint welding position for overhead welding position, welding cover layer and fill the layer with the same, the welding current cover layer shall be appropriately reduced, the corresponding change to D1-25J welder.The above form of welded joints have a few to be welded in the on-site installation, in the field of welding with SMAW (SMAW). Welding quality requirements:A. weld appearance quality should be consistent with the GB50250-2019 "steel structure construction quality acceptance standard" and the relevant provisions of the engineering drawings technical documents.B. weld appearance should be uniform and dense, the surface does not allow arc burn, cracks and pores, slag inclusion, incomplete fusion, pits, unfilled, beading and exceed the standard welding defects such as undercut.Size of the C. weld shall comply with the relevant regulations,to weld transition and uniform surface of base metal, weld the same height, width or height of weld leg should be uniform. The requirements of the internal quality and inspection of D. welded joints, according to the relevant provisions of drawing technical document and related standards.Repair welding process:The repair process of A. weld according to the evaluation rules for qualified welding process.B. weld NDT that exceed the standard defects, the welding defect should be repaired should analyze the causes of the defects, put forward the improvement measures, and according to welding process for the repair process. The performance of the weld and repair quality should be the same with the original weld.C. weld repair is completed, according to the inspection requirements should be identical with the original standard of welding seam and rechecking, repair times should not be the same welding line of more than two times.Welding environment:A. part of the production in the factory, all in the workshop, welding installation.B. welding environment should meet the following conditions: The relative humidity is less than 90%, wind speed: gas welding is less than 2m/s; the SMAW is less than 10m/s. If it does not meet the above requirements, should take appropriate measures (preheating before welding, occlusion etc.). Rainy days do not allow open welding operation.。

不锈钢焊接工艺技术要点及焊接工艺规程焊接时,为保证焊接质量,必须选择合理的工艺参数,所选定的焊接工艺参数总称为焊接工艺规范。

例如,手工电弧焊的焊接工艺规范包括:焊接电流、焊条直径、焊接速度、电弧长度(电压)和多层焊焊接层数等,其中电弧长度和焊接速度一般由操作者在操作中视实际情况自行掌握,其他参数均在焊接前确定。

1.焊条直径焊条直径根据焊件的厚度和焊接位置来选择。

一般,厚焊件用粗焊条,薄焊平焊对接时焊条直径的选择件用细焊条。

立焊、横焊和仰焊的焊条应比平焊细。

如表4-3所示:焊条直径的选择(mm)4-3 表13 ~12 ≥工件厚度 2 3 4~7 85.8 ~~2.0 2.53.2 3.2~4.0 4.0~5.0 4.0焊条直径 1.6~.焊接电流和焊接速度2金属熔化快,焊接电流是影响焊接接头质量和生产率的主要因素。

电流过大,易产生未焊透、电流过小,熔深大、金属飞溅大,同时易产生烧穿、咬边等缺陷;夹渣等缺陷,而且生产率低。

确定焊接电流时,应考虑到焊条直径、焊件厚度、接头型式、焊接位置等因素,其中主要的是焊条直径。

一般,细焊条选小电流,焊接电流和焊条直径的关系可由下列经验公式粗焊条选大电流。

焊接低碳钢时,确定:( 4-3 ) d )~(I=3060 ),)。

d为焊条直径(mmAI 式中:为焊接电流(焊接速度是指焊条沿焊缝长度方向单位时间移动的距离,它对焊接质量影响很大。

焊速过快,易产生焊缝的熔深浅、熔宽小及未焊透等缺陷;焊速过慢,焊缝熔深、熔宽增加,特别是薄件易烧穿。

确定焊接电流和焊接速度的一般在保证焊透且尽量采用较大的焊接电流值,原则是:在保证焊接质量的前提下,焊缝成形良好的前提下尽可能快速施焊,以提高生产率。

.手工电弧焊重要的工艺及参数.焊条直径主要依据焊件的厚度,焊接位置,焊道层数及接头形式来决定。

焊1接件厚度较大时,选用较大直径焊条。

平焊时,可采用较大电流焊接。

焊条直径焊条直径也相应小些。

立焊或仰焊时,因焊接电流比平焊小,横焊、也相应选大。

第七章立式储罐的焊接立式储罐是由罐底、罐壁、罐顶及附件等部分通过焊接方式连接而成,焊接是储罐建造的主要工序,对储罐的施工质量具有决定性意义。

第一节概述一、储罐焊接的一般要求储罐建造对焊接的主要质量要求是:焊缝强度、韧性达到设计要求,焊接变形控制在规定范围之内,焊缝外观及内在质量符合设计标准等。

为保证储罐焊接质量符合要求,需在人、机、料、法、环等方面严格控制。

储罐焊接的一般要求如下。

1.人员要求从事储罐焊接的焊工,必须按TSG Z6002-2019《特种设备焊接操作人员考核细则》的规定考核合格,并应取得相应项目的资格后,方可在有效期间内担任合格项目范围内的焊接工作。

2.设备要求选用的焊接设备应能满足焊接工艺要求,焊机配备的电流表、电压表应在计量检定周期内。

3.焊接材料要求(1)储罐焊接施工选用的焊接材料应符合设计文件及焊接工艺规程的要求。

不同强度等级钢号的碳素钢、低合金钢钢材间的焊接,选用的焊接材料应保证焊缝金属的抗拉强度高于或等于强度较低一侧母材抗拉强度下限值,且不超过强度较高一侧母材标准规定的上限值。

(2)焊接材料应有专人负责保管、烘干和发放。

焊材库房的设置和管理应符合JB/T 3223-1996《焊接材料质量管理规程》的有关规定;(3)焊条和焊剂应按产品说明书的要求烘干;(4)焊条电弧焊时,焊条应存放在合格的保温筒内;焊丝在使用前应清除铁锈和油污等。

4.焊接工艺要求(1)焊接前,施工单位必须有合格的焊接工艺评定报告。

焊接工艺评定应符合NB/T 47014-2019《承压设备焊接工艺评定》的有关规定;但当单道焊厚度大于19mm时,应对每种厚度的对接接头单独进行评定。

(2)焊接工艺评定应包括T形接头角焊缝。

T形接头角焊缝试件的制备和检验,应符合GB 50128-2019《立式圆筒形钢制焊接储罐施工及验收规范》附录A的规定。

(3)不同强度等级钢号的碳素钢、低合金钢钢材间焊接时,焊接工艺应与强度较高侧钢材的焊接工艺相同。

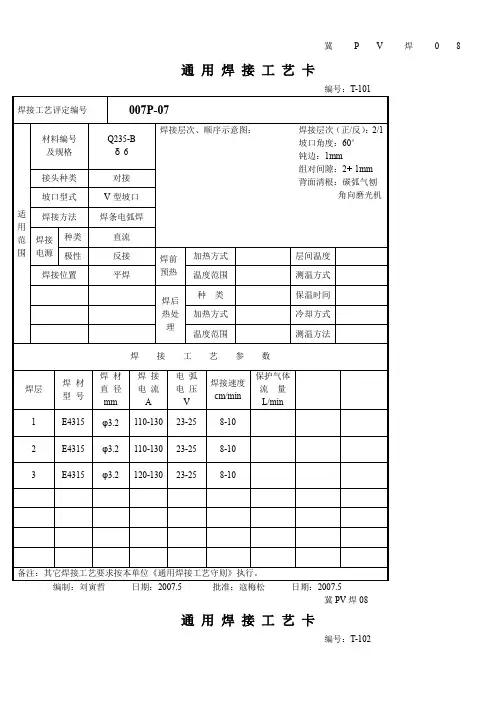

冀P V焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编号:T-102编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编号:T-112编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡编号:T-161编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡冀PV焊08 通用焊接工艺卡编制:刘寅哲 日期:2007.5 批准:寇梅松 日期: 2007.5冀PV 焊08通 用 焊 接 工 艺 卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡冀PV焊08 通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08通用焊接工艺卡编制:刘寅哲日期:2007.5 批准:寇梅松日期:2007.5冀PV焊08 通用焊接工艺卡冀PV焊08 通用焊接工艺卡编号:T-178。

钢结构焊接工艺流程(1)焊工①参加该工程焊接的焊工应持有行业指定部门颁发的焊工合格证书。

严格持证上岗从事与其证书等级相应的等级工作。

②重要结构装配定位焊时,应由持定位焊工资格证的焊工进行操作。

③持证焊工无论其原因如何,如中断焊接工作连续时间超过半年者,该焊工再上岗前应重新进行资格考试。

④行工考核管理由质管部归口。

(2)焊接工艺方法及焊接设备①本工程焊接用埋弧自动焊、手工电弧焊、CO2气体保护半自动焊等焊接工艺方法。

②为保证钢结构工程具有优良的焊接质量,本工程施工使用的主要焊接设备有:埋弧自动焊机、埋弧半自动焊机、CO2气体保护半自动焊机等。

(3)钢材焊接材料订购、进库、检验及管理要求钢材焊接材料订购、进库、检验及管理,按公司制定的程序文件规定,并严格做到:①焊材的选用必须满足本钢结构工程的设计要求。

②本钢结构工程的焊接材料必须具有材料合格证书,每批焊接材料入厂后,应由公司质量部门按采购要求和检验标准进行检验,合格后方可使用。

③焊接材料(焊剖、焊条、焊丝)的存、运输、焊前处理(烘干、焊丝油锈处理等)。

烘培和领用过程中都要有标识,标明焊接材料的牌号、规格、厂检号或生产批号等(若焊材本身的标识可满足正常的话,则可免做此工作)。

焊接材料的使用应符合制造厂的说明书和焊接工艺评定试验结果的要求。

④焊接材料使用过程中应可以追踪控制,产品施工选用的焊接材料型号与工艺评定所用的型号一致。

⑤焊条从烘箱和保温筒中取出并在大气中放置四小时以上的焊条需要放回烘箱重新烘培。

重复烘培次数不允许超过两次。

⑥关于本钢结构工程所用焊接材料的管理和发放等规定按公司有关的焊接管理方法和发放条执行。

4.2 焊接施工要求(1) 定位焊①装配精度、质量符合图纸和技术规范的要求才允许定位焊。

②若焊缝施焊要求预热时,则一定要预热到相应的温度以后才能允许定位焊;③定位焊完毕后若产生裂纹,分析产生原因并采取适当措施后才能在其附近重新定位焊,并将产生裂纹的定位焊缝剔除。

深圳市瑞昌电力技术有限公司不锈钢焊接工艺规范生产部/质检部不锈钢焊接工艺标准一氩弧焊接1。

目的为规范焊工操作,保证焊接质量,不断提高焊工的实际操作技术水平,特编制本指导书。

2.编制依据2.1.设计图纸2.2.《手工钨极氩弧焊技术及其应用》2。

3.《焊工技术考核规程》3。

焊接准备3.1.焊接材料焊丝:H1Cr18Ni9Tiφ1、φ1。

5、φ2.5、φ3焊丝应有制造厂的质量合格证,领取和发放有焊材管理员统一管理。

焊丝在使用前应清除油锈及其他污物,露出金属光泽。

3。

2.氩气氩气瓶上应贴有出厂合格标签,其纯度≥99。

95%,所用流量6—9升/分钟,气瓶中的氩气不能用尽,瓶内余压不得低于0.5MPa,以保证充氩纯度.3.3。

焊接工具3。

3。

1。

采用直流电焊机。

3.3。

2.选用的氩气减压流量计应开闭自如,没有漏气现象。

切记不可先开流量计、后开气瓶,造成高压气流直冲低压,损坏流量计;关时先关流量计而后关氩气瓶。

3.3。

3。

输送氩气的胶皮管,不得与输送其它气体的胶皮管互相串用,可用新的氧气胶皮管代用,长度不超过30米。

3.4。

其它工器具焊工应备有:手锤、砂纸、扁铲、钢丝刷、电磨工具等,以备清渣和消缺.4.工艺参数不锈钢焊接工艺参数选取表表一壁厚mm 焊丝直径mm钨极直径mm焊接电流A氩气流量L/min焊接层次喷嘴直径mm电源极性焊缝余高mm焊缝宽度mm11。

0230—50616正接13 2 1.2240-60616正接1431。

6-2.4360—9081—28正接1—2.5541。

6—380—10081-28正接1—62.4 2.05.工序过程5.1.焊工必须按照“考规”规定经相应试件考试合格后,方可上岗位焊接。

5.2。

严禁在被焊件表面随意引燃电弧、试验电流或焊接临时支撑物等.5.3。

焊工所用的氩弧焊把、氩气减压流量计,应经常检查,确保在氩弧焊封底时氩气为层流状态。

5.4。

接口前应将坡口表面及母材内、外壁的油、漆、垢锈等清理干净,直至发出金属光泽,清理范围为每侧各为10-15mm,对口间隙为2.5~3。