奥贝球铁

- 格式:pdf

- 大小:2.02 MB

- 文档页数:10

磨球市场调查报告1、奥贝球铁简介奥贝球墨铸铁(austempering ductile iron)是基体组织以上贝氏体为主和残留30%〜40%奥氏体的球墨铸铁(简称球铁);也有叫上贝氏体球铁。

奥贝球铁的研究与应用始于20 世纪70年代初,这种材质的抗拉强度达1600MPa,在抗拉强度达1000MPa,其伸长率可达5%以上,广泛应用于机械制造业以及各种结构件。

与合金钢相比,奥贝球墨铸铁具有显著的经济效益和社会效益。

奥贝球铁具有很高的耐磨性与疲劳强度,同时与其它铸铁以及经过热处理的铸钢和锻钢相比,奥贝球铁的弯曲疲劳强度也较高,其接触疲劳强度比珠光体和铁素体铸铁高,实际上与经过气体氮化或渗碳的锻钢的特性相同。

奥贝球铁的强度超过了微合金钢。

奥贝球铁在喷丸处理过程中,铸铁材料所含的剩余奥氏体会转变成马氏体。

由于在表面形成了具有很高硬度的耐磨层,同时在内部保持了塑性和韧度,以及很高的弯曲疲劳强度。

国外奥贝球铁一般在发动机齿轮、汽车发动机曲轴、柴油发动机支承架零件等方面,表现出高强度、低噪声、低价格等优势。

我国现今在奥贝球铁方面应用的产品,大致分为以下3个方面:(1 )普通抗磨件多用于矿山、建筑、电力、农业等机械上的抗磨零件。

如磨球、衬板、锤头、锤片等。

(2)机械承载构件多用于汽车、拖拉机、铁路车辆、农用车辆、农业机械等产品。

这些构件以前多用锻钢、铸钢、可锻铸铁等材料制造,如汽车上的牵引钩支承座、柴油机的凸轮轴等。

(3)高性能、高精度要求的重要构件主要是高疲劳性能的柴油机曲轴和各类高精度、高性能齿轮等。

这些产品受力复杂、负荷大、对材料性能和成品尺寸精度要求高。

纵观国内外,奥贝球铁经过多年的发展,以其价格成本低(与锻钢比较),比重比钢小,综合力学性能优良(b=800~1400MPa,而伸长率可达5%以上)吸震性和减音性能好,以及抗摩擦磨损性强等诸多优良性能,已经成为机械制造业的主要结构材料,也是21 世纪人们所关注的热点材料和新技术之一。

贝氏体球铁的研究现状与展望时间:2008-10-07贝氏体球墨铸铁,由于具有优异的综合力学性能,被誉为近30年来铸铁冶金方面的重大成就之一,被越来越广泛地应用于各工业部门。

本文综合介绍贝氏体球铁的研究和发展概况及其主要生产方法,旨在推动我国贝氏体球铁的研究和应用。

1 贝氏体球铁的产生、发展与应用贝氏体球铁主要分为两大类:一类是以奥氏体+贝氏体为基体组织的贝氏体球铁,称为奥贝球铁(Austempered Ductile Iron),简称ADI。

这种材料具有较高的强度高同时具有一定的耐磨性。

另一类是以贝氏体+少量碳化物为基体组织的贝氏体球铁,称为贝氏体球铁(Bainite Ductile Iron),简称BDI。

这种材料具有很好的耐磨性,同时具有一定的强度和韧性。

1949年W.W.Braidwood就曾预言,针状组织(贝氏体)铸铁可能是机械性能最好的铸铁。

随后,美国国际收割机公司于1952年曾用这种球铁代替铸造高锰钢生产军用履带。

但在此后的20年间,由于这种材料的需要有限,在工业生产中很少应用,致使它的发展基本上处于停滞状态。

直至60年代末70年代初,国际上才重新开始这种材料的研究, 1977年M.Johansson宣布芬兰Kymi-kymmene公司所属的Karkkila铸造厂开发了一种使用性能优异的新型球铁,即奥氏体-贝氏体球墨铸铁,并在美、英、法、加等13个国家申请了专利。

这一报导引起了广泛重视,各国从不同角度进行了规模巨大的研究工作。

目前生产贝氏体球铁的方法已由过去的等温淬火单一方法发展到连续冷却淬火和合金化铸态等多种方法。

我国是最早研究和应用贝氏体球铁的国家之一,一些高等院校和科研单位相继研制成功这种新材质并将其应用于生产实践。

贝氏体球铁优异的综合力学性使其具有非常广泛的用途,如用在耐磨、耐冲击、高强度、高韧性和耐疲劳的场合。

在大齿轮方面,贝氏体球铁甚至可以完全代替渗碳钢,在某些条件下比渗碳钢作用更好。

奥贝球铁工艺性能分析由于等温淬火球铁(ADI)优越可靠的静力学和动力学性能,以及降噪音的独特优势和兼具低成本的吸引力,使其在汽车、机械、建材、铁路、农机、军工、冶金、矿山等机械发挥着越来越重要的作用。

近年来,欧美发达国家的各类等淬球铁件产量正以每年15%的速度飞速增长,并且随着研究的不断深入,应用领域不断扩大,被称为“21世纪最具发展前景的金属材料”。

ADI高的强度/重量比是十分吸引人的,在合适的设计下,用ADI代替铝件可使零件重量相等或更轻。

在北美ADI 代替钢可节省30%以上。

ADI的模量是铝的2~3倍,屈服强度是铝的3倍,疲劳或强度是铝的5倍,而且具有良好的减震降噪效果。

ADI的研究和生产集中在三个主要问题:一是用于进行ADI处理的球铁铸件的生产,二是热处理(等温处理),三是ADI的性能。

所有影响铸态球铁的因素都影响ADI,有质量好的球铁才能有优质的ADI,生产ADI和铸态球铁的关键是要求球墨铸铁具有:稳定的化学成分;石墨球数不低于100个/cm2,球化率不低于90%,碳化物及夹杂不高于0.5%,显微缩松不高于1%,珠光体/铁素体的比例恒定。

只有在稳定的化学成分下才能有确定的热处理规范。

最终的组织是无碳化合物析出的针状组织。

奥氏体等温转变反应过程:第一阶段:工件淬入奥氏体等温盐浴中,起初,奥氏体无变化,短暂孕育期,针状铁素体在奥氏体中生长(增加奥氏体中含碳量),20~30min后,奥氏体中的碳增至1.2~1.6%(室温稳定,力学上不稳定,温度下降会转娈成马氏体),保温1~2小时后,奥氏体中的碳量增至1.8~2.2%(富碳奥氏体,热力学、力学上都稳定,理想的ADI组织),此时,ADI中高碳稳定奥氏体有两种形态:一是存在于针状铁素体之间的近似于等轴形的块状铁素体,二是存在于针状铁素体之间的薄片形的条状铁素体;第二阶段:铸件在盐浴中保温超过2~3小时后,高碳奥氏体将分解为更加稳定的铁素体和碳化物,碳化物的出现对ADI力学性能有害,主要是降低伸长率和韧性。

锰铜合金奥贝球铁齿轮啮合后表面组织特征探讨利用扫描电镜测试研究了锰铜合金奥贝球铁锥齿轮啮合后齿轮表面显微组织的演变。

结果表明,齿轮啮合后其表面残余奥氏体转变成马氏体组织,显著提高了齿轮的表面硬度导致其耐磨性和使用寿命提高。

标签:锰铜合金;奥贝球铁;齿轮;组织特征奥贝球铁(ADI)以贝氏体型铁素体和奥氏体为基体组织,其中含有20-40%的奥氏体,赋予这种球铁较高的塑性和韧性,具有优异的综合机械性能。

而且由于奥氏体具有加工硬化能力,能显著提高其疲劳强度和耐磨性。

这种材料特别适合于替代20CrMnTi合金锻钢制造齿轮,并具有重量轻、噪声小,节省能源等优点。

与20CrMnTi合金锻钢齿轮相比,采用奥贝球铁制造齿轮可使产品重量减少10%,可减少汽车的燃油消耗和尾气排放。

因此,采用奥贝球铁代替20CrMnTi合金钢制造汽车齿轮对节能降耗和汽车工业的发展具有战略意义。

以一种新型的锰铜合金奥贝球铁螺旋锥齿轮为对象,研究台架试验后齿轮啮合表面的显微组织演变规律。

1 锥齿轮制备锰铜合金奥贝球铁的名义化学成分为:3.5C-2.5Si-xMn-0.04P-0.02S-yCu(wt%)。

采用山西生产的Q12生铁为原料,工频炉熔化后采用冲人法球化处理,球化剂为FeSiMn8Re3合金,加人量1.5%。

FeSi75作为孕育剂,并进行了强化孕育处理,孕育总量为0.9%。

采用FeSi75、FeMn65和电解铜板调整化学成分,浇注手工潮模砂铸型获得齿轮毛坯,经机加工后进行等温淬火处理(900℃±10℃×2h+370±5℃×2h)和回火处理(300-350℃×2-4h)。

依据QC/T533-1999《汽车驱动桥台架试样方法》对齿轮进行台架试验,随后对齿轮进行解剖取样。

使用扫描电镜(型号为QUANTA-400)观察并拍摄金相组织。

金相检测按GB/T9441-1988《球墨铸铁金相检验》评级,腐蚀剂为4%的硝酸酒精溶液。

ADI项目简介ADI(Austemped Ductile Iron 的缩写),在国内被称作奥贝球铁,康明斯发动机,卡特彼勒工程用车,一级方程式赛车,英国女王专车,英国工程用车及载重卡车, ROLLR & Royce 轿车公司,德国载重汽车,德国Dailmer-Benz,瑞典SKF,Saab,VOLVO汽车,Automotive Components 公司等等。

还有许多著名公司的知名产品以及军工产品中许多关键件使用了ADI铸件。

即使在北欧严寒气候条件下也得到成功应用。

ADI 的特点由于具有超级的性能,在重要应用领域,ADI 铸件正在快速取代缎钢、焊接结构件、碳钢和铝铸件。

1.强度高。

同样韧性下ADI的抗拉强度是普通球铁的两倍,高于或相当于碳钢、低合金钢的强度。

2.重量轻。

同样尺寸的零件比钢件轻10%。

ADI的强度是铝铸件的3倍,其比重仅是其2.5倍。

因为有多一倍的服役期,所以一个设计合理的ADI铸件相对铝铸件也具有明显优越性。

这对重量及节能敏感的汽车等行业有重要意义。

3.低能耗。

美国通用公司证实,ADI较之同样性能的铸钢产品能节约50%左右的能源,较之锻钢件节能约80%左右。

我国能源紧张,发展ADI 更符合国情。

4.低成本。

欧美一些著名公司经系统核算得出结论:ADI取代铸钢、锻钢、焊接钢件,综合成本可降低23%左右。

5.优良的减震性。

由于ADI含有石墨,其减震性明显优于碳钢。

这对于降低齿轮运转噪音有重要意义。

对于汽车行业将要执行的欧-3标准,无疑是一条捷径。

6.极好的耐疲劳性。

大量研究和实践已经证明,与碳钢、低合金钢相比,ADI具有相当或更好的耐疲劳性,其动力性能超过锻钢、铸钢和低合金钢。

经喷丸处理,ADI的疲劳强度相当或优于淬火钢或表面氮化钢。

与铝不同,ADI的疲劳极限经千万次的循环后仍保持恒定。

7.优越的耐磨性。

ADI较同样硬度的钢具有更好的耐磨性。

在较低的布氏硬度水平上,ADI的耐磨性能超过普通工艺的碳钢。

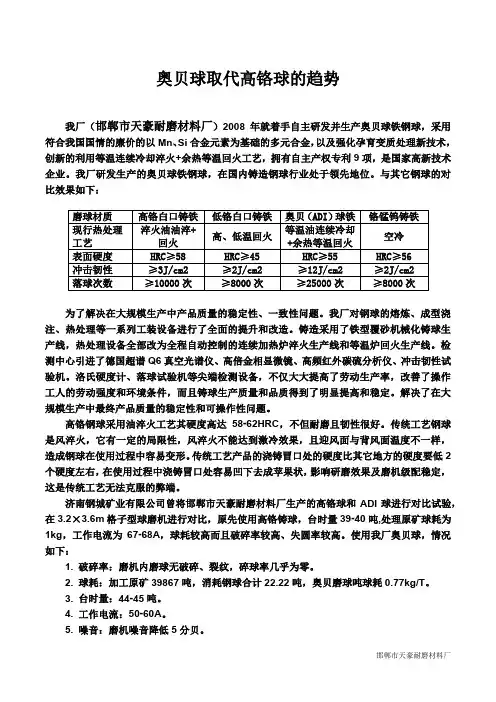

奥贝球取代高铬球的趋势我厂(邯郸市天豪耐磨材料厂)2008年就着手自主研发并生产奥贝球铁钢球,采用符合我国国情的廉价的以Mn、Si合金元素为基础的多元合金,以及强化孕育变质处理新技术,创新的利用等温连续冷却淬火+余热等温回火工艺,拥有自主产权专利9项,是国家高新技术企业。

我厂研发生产的奥贝球铁钢球,在国内铸造钢球行业处于领先地位。

与其它钢球的对比效果如下:为了解决在大规模生产中产品质量的稳定性、一致性问题。

我厂对钢球的熔炼、成型浇注、热处理等一系列工装设备进行了全面的提升和改造。

铸造采用了铁型覆砂机械化铸球生产线,热处理设备全部改为全程自动控制的连续加热炉淬火生产线和等温炉回火生产线。

检测中心引进了德国超谱Q6真空光谱仪、高倍金相显微镜、高频红外碳硫分析仪、冲击韧性试验机。

洛氏硬度计、落球试验机等尖端检测设备,不仅大大提高了劳动生产率,改善了操作工人的劳动强度和环境条件,而且铸球生产质量和品质得到了明显提高和稳定。

解决了在大规模生产中最终产品质量的稳定性和可操作性问题。

高铬钢球采用油淬火工艺其硬度高达58-62HRC,不但耐磨且韧性很好。

传统工艺钢球是风淬火,它有一定的局限性,风淬火不能达到激冷效果,且迎风面与背风面温度不一样,造成钢球在使用过程中容易变形。

传统工艺产品的浇铸冒口处的硬度比其它地方的硬度要低2个硬度左右,在使用过程中浇铸冒口处容易凹下去成苹果状,影响研磨效果及磨机级配稳定,这是传统工艺无法克服的弊端。

济南钢城矿业有限公司曾将邯郸市天豪耐磨材料厂生产的高铬球和ADI球进行对比试验,在3.2×3.6m格子型球磨机进行对比,原先使用高铬铸球,台时量39-40吨,处理原矿球耗为1kg,工作电流为67-68A,球耗较高而且破碎率较高、失圆率较高。

使用我厂奥贝球,情况如下:1.破碎率:磨机内磨球无破碎、裂纹,碎球率几乎为零。

2.球耗:加工原矿39867吨,消耗钢球合计22.22吨,奥贝磨球吨球耗0.77kg/T。

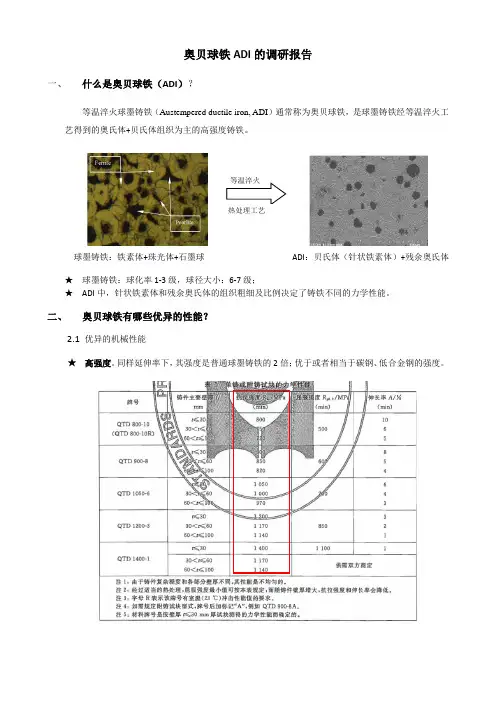

奥贝球铁ADI的调研报告一、什么是奥贝球铁(ADI)?等温淬火球墨铸铁(Austempered ductile iron, ADI)通常称为奥贝球铁,是球墨铸铁经等温淬火工艺得到的奥氏体+贝氏体组织为主的高强度铸铁。

球墨铸铁:铁素体+珠光体+石墨球ADI:贝氏体(针状铁素体)+残余奥氏体★球墨铸铁:球化率1-3级,球径大小:6-7级;★ADI中,针状铁素体和残余奥氏体的组织粗细及比例决定了铸铁不同的力学性能。

二、奥贝球铁有哪些优异的性能?2.1 优异的机械性能★高强度。

同样延伸率下,其强度是普通球墨铸铁的2倍;优于或者相当于碳钢、低合金钢的强度。

等温淬火热处理工艺★高硬度。

大大高于普通球墨铸铁,与中高碳钢相当。

★优越的耐磨性,优越的疲劳强度和断裂韧性,减震吸音性好等,这些特点使得ADI已经代替锰钢、合金钢等应用于车辆、工程机械上。

2.2 优越的材料性能★比重小。

因为含有一定量的石墨,密度约为7.1g/cm3,同样尺寸的零件较钢件轻10%左右。

★成本低。

相比锻件、焊接件等,ADI材料具有优良的铸造性,能够制造出实际形状和尺寸更接近设计要求的无余量零件,既降低了材料成本,也节省了加工成本。

三、如何得到奥贝球铁,其原理如何?3.1 普通球墨铸铁选择合适的化学成分,熔炼→球化→孕育,得到普通球墨铸铁。

3.2 等温淬火工艺★A→B:P+α-Fe→γ-Fe.奥氏体化(>A C1):相变,碳的扩散;★B→C:奥氏体均匀化,碳的扩散;★C→D:淬火,避免得到珠光体★D→E:γ-Fe→下贝氏体(针状铁素体)+A残(残余奥氏体)等温淬火:温度、时间★E→F:空冷。

可能存在残余奥氏体的转化。

3.3分析★设备条件:密闭进行,防止加热过程中铸件与外界反应,影响组织与性能;加热炉与盐浴炉控制稳定:加热过程中铸件变化稳定、可预见,便于设计铸件尺寸。

★淬火介质:常用的热处理淬火介质有:油、气体、熔盐等。

➢油:不能长时间在280度以上工作,不适用于ADI的制备;➢气体:要求:防腐蚀、防氧化;冷却效率低;➢熔盐:优点:温度控制范围宽,操作简单;缺点:腐蚀性、污染环境、铸件需要清洗;常用的淬火介质:(1)55%硝酸钾+45%亚硝酸钠,熔点143℃,应用温度范围:160-550℃;(2)50%硝酸钠+50%硝酸钾,熔点220℃,应用温度范围:280-550℃.四、工艺关键点及其影响4.1 化学成分★化学成分对于ADI组织和性能的影响主要有以下三个方面:(1)偏析;(2)等温处理时ADI组织对时间的敏感性;(3)淬透性;★主要化学元素的影响作用简述及建议值:碳元素:碳能稳定奥氏体;含碳量过高会造成石墨漂浮;建议值:3.5-3.7%硅元素:硅在等温淬火转变时抑制碳化物的析出而产生更多的针状铁素体,并且在等温淬火球墨铸铁中含有更高的硅量可以改善韧性和具有较宽的热处理工艺带。

奥贝球铁(ADI)等温淬火连续生产线摘要:本文介绍了奥贝球铁(ADI)等温淬火连续生产线的工艺流程和设备配置,分析了该生产线的优点和应用前景,同时探讨了在实际生产中遇到的问题及解决方法。

通过实验验证,证明了该连续生产线能够满足ADI的生产需求,提高了生产效率和产品质量。

关键词:奥贝球铁(ADI);等温淬火;连续生产;优点;应用前景;问题解决正文:一、引言奥贝球铁(ADI)是一种新型的高性能材料,在汽车、机械、航空航天等领域得到广泛应用。

ADI具有高强度、高硬度、高韧性和良好的阻尼性能等优点,但传统的生产工艺需要多次处理,生产效率低,成本高。

为此,研究开发了ADI等温淬火连续生产线,能够满足生产的需求。

二、工艺流程该生产线主要包括铸造、等温淬火、热处理和最终加工等步骤。

其中,铸造采用真空铸造或压力铸造,制备出ADI毛坯。

等温淬火是该生产线的核心工艺,将毛坯加热至Austenite区,等温保温,然后急速冷却至贝氏体区。

热处理是通过高温回火或的退火处理,调节ADI材料的硬度和韧性,最终加工则通过机械加工或表面处理等方法进行。

三、设备配置该生产线主要包括:真空或压力铸造设备、等温淬火炉、热处理炉、自动化输送系统、质量检验设备等。

其中,等温淬火炉采用先进的控温系统,保证温度控制精度高,急冷系统采用液氮等媒介,快速降温速率能够达到50℃/s以上。

四、优点和应用前景①生产效率高:该生产线可以实现自动化连续生产,缩短生产周期,提高生产效率。

②产品性能优良:针对不同要求,可以进行适当的热处理和淬火,从而提高产品的硬度、韧性和阻尼性能。

③应用前景广泛:ADI具有强度高、韧性好、耐磨性能强等优点,可广泛应用于汽车、航空航天、机械制造等领域,具有发展潜力。

五、问题与解决在实际生产中,主要遇到以下问题:①等温淬火温度不均匀:采用高精度温控系统和优化的急冷方式,解决了这一问题。

②等温保温时间难以控制:采用先进的生产管理系统,实现对等温保温时间的精确控制。

奥贝球铁件组织、性能与热处理方法简介近两年计量理化室陆续接到材料牌号为A-B QT900-7(奥贝球铁)的铸铁件在安装过程或售后出现质量问题的情况反馈,要求理化室进行失效分析,如:左下支架—第二前减震器。

分析过程中我们发现相关部门及配套生产厂对该牌号铸铁了解甚少,实际送来检验的失效件都是普通球铁(铁素体球铁),没有一例是奥贝球铁。

下面我将对奥贝球铁材料的组织、性能及热处理方法做一简单介绍。

一、奥贝球铁:奥贝球铁是铸造业技术发展的趋势,因其综合机械性能远超现有同类材料,大幅度地降低材料消耗,提高产品质量和寿命,同时价格与同类钢件相比低很多,所以欧美等发达国家已在汽车关键零部件、机械矿山、火车零部件等领域广泛应用。

我们遇到的A-B QT900-7牌号,只是奥贝球铁的一种。

“A-B”是奥氏体和贝氏体组织的简称,表明该球铁的基体组织为奥氏体+贝氏体,以示与其它球铁的区别;“QT 900-7”表明该牌号的球铁抗拉强度要达到900N/mm2以上,延伸率达到7%以上。

我厂常用的铁素铁球铁抗拉强度在450 N/mm2左右,延伸率在10%-15%。

由此可见,奥贝球铁材料具有较高的抗拉强度,较好的综合力学性能。

二、奥贝球铁的热处理工艺:球墨铸铁的一个优点就是可以像钢一样利用各种热处理方法改善金属基体组织,达到提高机械性能的目的。

奥贝球铁就是在铸造得到球墨铸铁后,又对球墨铸铁进行了等温淬火热处理后得到的。

等淬热处理使球墨铸铁的基体组织由铁素铁+珠光体转变成奥氏体+贝氏体,从而提高了机械性能。

奥贝球铁的热处理工艺一般是:在900℃左右保温一段时间,使基体组织奥氏体化,然后再在300℃左右温度等温一段时间(一般在硝盐炉中进行等淬),然后空冷完成的。

不同牌号的奥贝球铁等淬温度不同。

三、奥贝球铁件的质量检验:目前对奥贝球铁件的质量检验,我们依据的是集团公司标准Q/CAYJS-25-1998《奥氏体-贝氏体球墨铸铁铸件技术条件》。

金属陶瓷刀具加工奥贝球铁的切削性能研究的开题报告1. 研究背景与意义金属陶瓷刀具广泛应用于高速切削加工领域,其切削性能直接影响加工效率和质量。

而球铁作为一种常见的材料,在汽车零部件、机床零部件以及道路设施等领域有广泛应用。

因此,研究金属陶瓷刀具加工球铁的切削性能,对于优化加工工艺、提高切削效率,具有重要的理论和实际意义。

2. 研究内容本研究拟通过实验分析金属陶瓷刀具加工球铁的切削力、切削温度、切削表面形貌等切削性能指标。

具体研究内容如下:(1)制备金属陶瓷刀具并对其进行表面处理。

(2)进行球铁的切削试验,记录切削力、切削温度等参数。

(3)通过扫描电子显微镜(SEM)等技术对切削表面形貌进行观察和分析。

(4)对实验结果进行统计和分析,探究金属陶瓷刀具加工球铁的切削性能规律。

3. 研究方法与技术路线(1)制备金属陶瓷刀具,包括选择合适的陶瓷材料、金属材料以及生产工艺等。

(2)设计球铁的切削试验方案,包括切削参数的选择、切削样品的制备以及实验装置的搭建等。

(3)通过实验获得切削力、切削温度等参数,并对数据进行处理分析。

(4)通过SEM等技术对切削表面形貌进行观察和分析。

(5)总结实验结果,探究金属陶瓷刀具加工球铁的切削性能规律。

4. 预期成果和意义本研究的预期成果如下:(1)探究金属陶瓷刀具加工球铁的切削性能规律。

(2)为优化加工工艺、提高切削效率提供参考依据。

(3)为相关领域研究人员提供参考和借鉴。

通过本研究的成果,可以为实际生产和科学研究提供有价值的参考和支持,推动金属陶瓷刀具加工领域的发展。

课题名称Cr奥贝球铁应用的试验研究系部材料工程系专业材料成型及控制工程班级T733-1学号20070330119姓名盛兴涛指导教师饶群章2011 年 3 月 10 日一.课题的来源、目的要求、意义1-1 课题来源:液态成型的浇注过程中应用的螺旋推进式随流孕育装置,由于结构不合理,零件易磨损影响给料精度,孕育的质量得不到保证且能耗大,现结合科研进行新的设计。

1-2 目的和意义:本课题是奥贝球铁材料和消失模铸造技术的一个实际应用。

我们通过实际的装置的选材以及实际生产,既能够掌握消失模铸造技术的基本工艺流程,又能检验奥贝球铁良好的力学性能,而且能够积累实际的生产经验,对将来的发展有较大帮助。

同时这也可以完善实验设备,有利于改善液态金属的质量,保证铸件质量,促进实验室建设。

二.奥贝球铁及消失模铸造技术的发展及应用2-1 奥贝球铁的发展及应用奥贝球铁是球墨铸铁经奥氏体化等温淬火处理后获得的球铁。

其强度和伸长率远远超过普通球墨铸铁。

因此各国都对其进行了深入广泛的研究。

奥贝球铁是由其特殊的热处理工艺而获得奥贝组织而得名,国内则广泛地称为奥贝球铁。

与普通基体的球铁相比,它具有强度,塑性和韧性都很高的综合性能。

此外,奥贝球铁还具有比普通球铁高的冲击韧性,尤其具有高的弯曲疲劳性能和良好的耐磨性,可用于替代某些锻钢件和普通球铁不能胜任的部件,如承受高载荷的齿轮,曲轴,连杆及凹轮轴等,为此受到广泛的重视,被视为70年代以来铸铁冶金领域的重大突破。

2-2 消失模铸造技术的发展及应用消失模铸造(又称实型铸造)是将与铸件尺寸形状相同的泡沫模样粘结组合成模样簇,刷涂耐火涂料并烘干后,埋在干石英砂中振动造型,在负压下浇注,使模样气化,液体金属占据模样位置,凝固冷却后形成铸件的新型铸造方法。

与砂型铸造相比,消失模具有以下特点:1.铸件精度高消失模铸造是一种近无余量、精确成型的新工艺,该工艺无需取模、无分型面、无砂芯,因而铸件没有飞边、毛刺和拔模斜度,并减少了由于型芯组合而造成的尺寸误差。

Applications of Austempered Cast IronsK.L. HayrynenK.R. BrandenbergJ.R. KeoughApplied Process Technologies Division, Livonia, MICopyright 2002 American Foundry SocietyABSTRACTThe Austempering process is a high performance heat treatment that, when applied to cast iron, produces components that, in many cases, have properties superior to those processed by conventional means. Cast irons that can be Austempered include: Ductile Iron, Gray Iron and Carbidic Ductile Iron.This paper will provide examples of applications of Austempered Cast Irons. Product examples will be discussed along with the specific material properties that resulted in their choice over competitive materials. These examples will illustrate why austempered cast irons are being chosen for high performance applications.INTRODUCTIONAustempering is a specialty, isothermal heat treatment process that can be applied to cast iron to increase strength and toughness. Figure 1 shows a schematic isothermal (I-T) diagram that illustrates the austempering process. The castings are initially heated to an austenitizing temperature (A to B), typically in the range of 1550 – 1750°F (840-950°C). The material is then held at the austenitizing temperature for a time sufficient to achieve a uniform matrix of austenite (B to C). This is followed by rapidly cooling to avoid pearlite formation to the austempering temperature (C to D). Isothermal heat treatment at the austempering temperature (450-750°F or 230-400°C) continues until the transformation to ausferrite occurs (D to E). The castings are subsequently cooled to room temperature (E to F).Figure 1: Schematic Isothermal Transformation Diagram illustrating theAustempering Process for Cast IronsFive different grades of ADI can be produced depending upon the choice of heat treatment parameters. Table 1 contains the ASTM 897-90 and 897M-90 specifications for ADI. At this writing, SAE Standard J2477 for Automotive ADI is undergoing balloting but no, recognized standards/specifications for AGI and CADI are available. In the case of AGI and CADI, the desired mechanical properties (and volume of carbide for CADI) are typically specified by the customer.Table 1: ASTM 897-90 and ASTM 897M-90 Specifications for ADI (Properties are minimum values)GradeTensileStrength(ksi/MPa)YieldStrength(ksi/MPa)Elongation(%)RT ImpactEnergy(ft-lbs/J)TypicalHardness(HBW)1125 / 85080 / 5501075 / 100269 – 3212150 / 1050100 / 700760 / 80302 – 3633175 / 1200125 / 850445 / 60341 – 4444200 / 1400155 / 1100125 / 35388 – 4775230 / 1600185 / 1300N/A N/A444 - 555Austempered Ductile Iron has an exceptionally high strength-to-weight ratio with good fatigue strength and fracture toughness. The density of ductile iron is 10% less than that of steel so ADI parts can replace steel forgings and castings at a weight savings. In addition, with strength three times greater than that of aluminum with only two and a half times the density, ADI can replace aluminum at equal weight for a substantial cost savings.Austempered Gray Iron (AGI) has been applied sporadically since the 1930’s. It was found that Austempering did not crack gray irons while quenching and tempering them did. Therefore, the primary application of Austempering of gray iron, until lately, has been to produce crack-free, hardened gray iron components. Today, however, AGI is receiving renewed interest for its good combination of noise damping, strength and wear resistance.Carbidic Austempered Ductile Iron (CADI) is a family of ductile cast irons produced with carbides, (both thermally and mechanically introduced), that are subsequently Austempered to exhibit adequate toughness and excellent wear resistance. The current numbers of applications for CADI are limited, but growing. Agricultural components have been produced in CADI with as-cast carbides since the early 1990’s. A Sandvik licensee has produced limited production quantities of CADI parts with cast-in, crushed carbides as well. In addition, research into chill-carbide applications is ongoing. APPLICATIONS OF ADI, AGI AND CADIADI BRACKET FOR INDEPENDENT TRAILER SUSPENSIONThe Australian trucking industry has interesting challenges in terms of hauling freight over rough and isolated distances that can be exceptionally long. Independent suspensions on large over-the-road box trailers can allow for flat floors and increased cargo space. For this application, the original independent suspension design was a fabrication made from low carbon steel. An on-road test resulted in the welded components failing after approximately 1200 km of service. A second iteration of the welded steel bracket allowed for travel up to 4000 km. As a result, a ductile iron casting was designed and austempered to Grade 2 ADI as shown in Figure 2. This ADI bracket is approximately 900 mm long and 1200 mm high, with a weight of 105 kg. The typical Brinell hardness is 300, along with an un-notched Charpy impact strength in excess of 100 J.Figure 2: ADI Independent Truck Trailer Suspension BracketTable 2 compares the properties of ADI to those of forged steel. ADI has the advantage over steel in tensile strength, yield strength and hardness. However, it has a lower stiffness than steel, which must be addressed in designing the component.Table 2 –Typical Properties of Steel vs. Grade 2 ADI2Forged Steel ADITensile Strength,MPa (KSI)779.1 (113)1034.2 (150)Yield Strength,MPa (KSI)510.2 (74)792.8 (115)Modulus,GPa (MSI)205.4 (29.8)166.8 (24.2)Elongation, %109Hardness, BHN262280These ADI brackets have successfully traveled over 322,000 km with no problems. Along with the added 20 cubic meters of storage space inside the truck trailer, it is expected that these new brackets will also increase tire life by over 80,000 km. CRANKSHAFT FOR TVR TUSCAN SPEED SIX SPORTS CARThe original material of choice for the crankshaft in the TVR inline 6 –cylinder engine was forged steel. However, the high cost to manufacture soon lead to the consideration of other materials. An 800/2 ductile iron was tested, but failed on a bench dynamometer. ADI (Figure 3) became the obvious next choice. This crankshaft is rough machined, austempered and then finish machined.304.8 mm (12 in)Figure 3: ADI Crankshaft for the Tuscan Speed SixMechanical test specimens were machined from steel, ductile iron and ADI crankshafts. The test results are presented in Table 3. Both the steel and ADI crankshaft outperform the ductile iron component. Note that the Grade 1 ADI crankshaft exhibits the best fatigue strength which was the critical property for this application. Other benefits to using ADI over a steel forging included a lower manufacturing cost and a reduction in weight.Table 3: Test Results for the Steel, Ductile Iron and ADI CrankshaftsSteel Ductile Iron ADIYield Strength738 (107)538 (78)827(120)MPa (KSI)Tensile Strength910 (132)903 (131)1083(157)MPa (KSI)Fatigue Strength400 (58)324 (47)427 (62)MPa (KSI)Impact Energy325 (240)75 (55)141(104)Joules (ft – lbs)Elongation (%)23.210.813.7Hardness226-266262-277300BHNADI RAILCAR WHEELSADI has been studied as a suitable alternative material for railcar wheels. When compared to steel, ADI exhibits three times higher damping and, thus, promises a decrease in traveling noise. A further advantage is that ADI has a 10% lower density compared to steel due to the presence of graphite nodules. These graphite nodules also positively influence the wear characteristics by acting as a lubricant between the contacting parts.Figure 4 shows the mass loss after 140,000 cycles for wheel/rail material combinations. Note that the ADI wheel shows the lowest mass loss compared to the steel wheels. Additionally, the steel rail in combination with the ADI wheel has the lowest mass loss versus steel wheel and rail combinations.Figure 4: Mass loss for various wheel/rail material combinations at 3% slip and F N= 1410NFurther work has shown that the mass loss at higher contact forces than 1410 N can be reduced considerably through the use of ADI, especially in the rail sample. The cause of this is primarily believed to be the lubricating action of the graphite; although, the strain-hardening tendency of the ausferrite matrix also plays an important role.Standard railcar wheels are currently produced very cost effectively in steel using a well developed, semi-permanent, graphite mold casting process. It is doubted that the ADI process could cost effectively replace the current process. Furthermore, the Ausferrite microstructure in ADI cannot withstand the overheating that can occur at the brake/wheel interface during hard braking with full contact (block-type) brakes. Therefore, ADI would only be suitable for low speed applications or for those using disc brakes.With the aforementioned limitations ADI may find increased application for wheels in such applications as commuter railcars, overhead cranes, rail repair vehicles and material handling applications such as mining and equipment transfer cars.Figure 5 shows ADI wheels that are used in material handling cranes.Figure 5: ADI Flanged wheels for overhead cranes.ADI CYLINDER LOCK CASEManufacturers of trailers and train cars are continually seeking new ways to keep vandals and thieves out of the secured trailer or boxcar. Thieves are very creative in their approach to breaking locks. They freeze them with fire extinguishers. They also saw them open with hack saws or smash them with sledge hammers.One door manufacturer saw the opportunity for ADI to replace ductile iron in their cylinder lock cases. ADI appealed to the designer for its good strength, strain hardening when being worked and its low temperature properties. The strain hardening results when the carbon stabilized austenite in the Ausferrite transforms locally to martensite when acted upon by a high normal force (such as filing or sawing). At lower temperatures, ADI maintains a rather high percentage of its room temperature toughness. Figure 6 shows that ADI retains nearly 70-80% of its room temperature toughness at –40°C.Figure 6: Impact transition curves for ADI Grades 1.0 and 1.5.The manufacturer provided the tester a sledge hammer and five minutes to break the cylinder lock case. The ductile iron lock case was easily pried open. However, the ADI cylinder lock case resisted penetration. Figure 7 shows an ADI cylinder lock case.Figure 7: ADI cylinder lock case for Postal Service vehiclesADI TOW HOOKSWhen GM switched to hydro-formed rails on their new light truck models, they created a need for a new design of tow hook. The precedent hook had been constructed of bent square steel wire. A new ADI design (Figure 8) allowed the engineers to slide the hook between the frame rails for attachment without the need for a second bracket. The ADI hooks passed all pull testing requirements, (actually doubling the pull capability over bent wire hooks), and improved the crash testing performance of the vehicles equipped with them. These hooks have been in production since the beginning of the 2000 model year and are produced at a rate exceeding two million parts per year.Figure 8: ADI Tow HookAGI CYLINDER LINERAs engine manufacturers are pressed to reduce emissions, diesel engine manufacturers are designing engines to operate at ever increasing injection pressures. As this happens, the traditional gray iron cylinder liner has been pushed beyond its fatigue capabilities.Highly alloyed gray irons have been employed, but the very alloys that produce the higher “as-cast” strength also produce fine, hard metal carbides that reduce machinability and score the piston rings in service.Induction hardening has also been utilized to increase the strength and wear properties of cylinder liners. However, it is difficult to obtain a consistent induction hardened layer in the flange areas of the liner. One after market supplier of cylinder liners supplied AGI cylinder liners for rebuilt diesel engines. Their testing indicated an improved performance of austempered liners versus ones that were induction hardened. The AGI cylinder liners had strength throughout the liner as opposed to a surface layer and exhibited better wear properties as well.In one test, the fatigue strength for Class 30 Gray Iron at 10 million cycles increased from 16 ksi to 24 ksi after being austempered at 600°F (316°C). Thus, AGI liners can give the engine designer the fatigue strength, and wear resistance required without the damaging metal carbides in the matrix. Detroit Diesel has used this process for many years and today produces over one million AGI cylinder liners per year. Other manufacturers are now investigating this method. A typical AGI cylinder liner is shown in Figure 9.Figure 9: Typical AGI diesel engine cylinder linerCARBIDIC ADI IN AGRICULTURAL APPLICATIONSCADI is a relatively new engineering material. However, its visibility has greatly increased of late with the public launch of CADI in programs at John Deere. In the February 2000 issue of SAE Off Highway Magazine, John Deere announced the use of CADI elements in its revolutionary new rotary combine shown in Figure 10. Another public announcement followed in March 2000 in the John Deere’s Owners Circle Magazine regarding the use of CADI in their Lazer Rip ripper points.Figure 10 : John Deere’s new, high performance, rotary combine uses CADI in its critical thrashingelements. (Courtesy of SAE Off Highway Magazine Feb 2000)CADI was chosen for the ripper point application because of its wear properties in combination with adequate toughness. The wear and toughness combination of CADI have also resulted in it being the material of choice for the plow points pictured in Figure 11.In Figure 12, the abrasive wear resistance of CADI is shown versus as-cast and austempered cast irons. Note that the volume loss is the lowest for CADI. Table 4 lists typical un-notched Charpy impact values at room temperature. CADI has an impact strength of 10 ft-lbs (14 J), which is competitive with carburized and hardened steels.Figure 11: Carbidic ADI plow point.Figure 12: Abrasive wear resistance of CADI vs. as-cast and Austempered gray and ductile irons.Table 4: Typical un-notched Charpy impact values.(Tested at 72°F or 22°C)Material Un-notched Charpy Impact Energy(ft-lbs / J)Carb & Hard 8620 Steel13 / 1830 – 45% Carbide 500 CADI10 / 14Pearlitic Malleable Iron13 / 187003 Ductile Iron38 / 52Grade 5 ADI40 / 545506 Ductile Iron45 / 61Grade 3 ADI70 / 95Grade 1 ADI90 / 1224512 Ductile Iron95 / 129SUMMARYAustempered Cast Irons are providing cost effective solutions in many high performance applications. The desired properties of the various Austempered irons can be achieved by modifying the graphite morphology and the metal matrix to produce the desired result for the end user. Creative applications are being found in many market segments. ACKNOWLEDGMENTSThe authors would like to acknowledge the hard work and dedication of the employees of Applied Process Inc, AP Westshore, AP Southridge, ADI Engineering Process and Heat Treatment Ltd., Steele and Lincoln Foundry and ADI Treatments Ltd. Individuals who contributed to the information presented include: Terry Lusk, Doug Maxwell, Mel Ostrander, John Wagner and Jerry Wurtsmith. Additionally, the contributions of the following companies to this paper are sincerely appreciated: Carroll Agricultural Products, John Deere, Machining Enterprises, TVR Engineering Ltd., Waupaca Foundry, and Whiting Door Manufacturing.REFERENCESBoelan, R, “Impact Properties and Plane Strain Fracture Toughness of Two Grades ofAustempered Ductile Iron,” Research Note Monash University, August 2001.Brandenberg, K., Keough, J., Lee, I., Maxwell, D., and Newman, P., “Independent TrailerSuspension Utilizing ADI Bracket,” submitted for publication for 2002 SAE World Congress.Brandenberg, K., Ravenscroft, J., Rimmer, A., and Hayrynen, K., “An ADI Crankshaft Designedfor High Performance in TVR’s Tuscan Speed Six Sports Car,” Automotive Casting Processesand Materials, SAE World Congress March 2001.Keough, J., “Austempered Materials and their Applications to Drive Line and SuspensionComponents,” SAE International Off-Highway & Powerplant Congress & Exposition, Sept2000.Mädler, K., “On the Suitability of ADI as an Alternative Material for (Railcar) Wheels,” EnglishTranslation,GIFA, June 1999, Dusseldorf, Germany.。