光刻胶MSDS-东进

- 格式:pdf

- 大小:326.97 KB

- 文档页数:9

光刻胶知识简介光刻胶知识简介:一.光刻胶的定义(photoresist)又称光致抗蚀剂,由感光树脂、增感剂(见光谱增感染料)和溶剂三种主要成分组成的对光敏感的混合液体。

感光树脂经光照后,在曝光区能很快地发生光固化反应,使得这种材料的物理性能,特别是溶解性、亲合性等发生明显变化。

经适当的溶剂处理,溶去可溶性部分,得到所需图像(见图光致抗蚀剂成像制版过程)。

二.光刻胶的分类光刻胶的技术复杂,品种较多。

根据其化学反应机理和显影原理,可分负性胶和正性胶两类。

光照后形成不可溶物质的是负性胶;反之,对某些溶剂是不可溶的,经光照后变成可溶物质的即为正性胶。

利用这种性能,将光刻胶作涂层,就能在硅片表面刻蚀所需的电路图形。

基于感光树脂的化学结构,光刻胶可以分为三种类型。

①光聚合型采用烯类单体,在光作用下生成自由基,自由基再进一步引发单体聚合,最后生成聚合物,具有形成正像的特点。

②光分解型采用含有叠氮醌类化合物的材料,经光照后,会发生光分解反应,由油溶性变为水溶性,可以制成正性胶.③光交联型采用聚乙烯醇月桂酸酯等作为光敏材料,在光的作用下,其分子中的双键被打开,并使链及链之间发生交联,形成一种不溶性的网状结构,而起到抗蚀作用,这是一种典型的负性光刻胶。

柯达公司的产品KPR胶即属此类。

三.光刻胶的化学性质a、传统光刻胶:正胶和负胶。

光刻胶的组成:树脂(resin/polymer),光刻胶中不同材料的粘合剂,给及光刻胶的机械及化学性质(如粘附性、胶膜厚度、热稳定性等);感光剂,感光剂对光能发生光化学反应;溶剂(Solvent),保持光刻胶的液体状态,使之具有良好的流动性;添加剂(Additive),用以改变光刻胶的某些特性,如改善光刻胶发生反射而添加染色剂等。

负性光刻胶。

树脂是聚异戊二烯,一种天然的橡胶;溶剂是二甲苯;感光剂是一种经过曝光后释放出氮气的光敏剂,产生的自由基在橡胶分子间形成交联。

从而变得不溶于显影液。

负性光刻胶在曝光区由溶剂引起泡涨;曝光时光刻胶容易及氮气反应而抑制交联。

光刻胶知识简介光刻胶知识简介:一.光刻胶的定义(photoresist)又称光致抗蚀剂,由感光树脂、增感剂(见光谱增感染料)和溶剂三种主要成分组成的对光敏感的混合液体。

感光树脂经光照后,在曝光区能很快地发生光固化反应,使得这种材料的物理性能,特别是溶解性、亲合性等发生明显变化。

经适当的溶剂处理,溶去可溶性部分,得到所需图像(见图光致抗蚀剂成像制版过程)。

二.光刻胶的分类光刻胶的技术复杂,品种较多。

根据其化学反应机理和显影原理,可分负性胶和正性胶两类。

光照后形成不可溶物质的是负性胶;反之,对某些溶剂是不可溶的,经光照后变成可溶物质的即为正性胶。

利用这种性能,将光刻胶作涂层,就能在硅片表面刻蚀所需的电路图形。

基于感光树脂的化学结构,光刻胶可以分为三种类型。

①光聚合型采用烯类单体,在光作用下生成自由基,自由基再进一步引发单体聚合,最后生成聚合物,具有形成正像的特点。

②光分解型采用含有叠氮醌类化合物的材料,经光照后,会发生光分解反应,由油溶性变为水溶性,可以制成正性胶.③光交联型采用聚乙烯醇月桂酸酯等作为光敏材料,在光的作用下,其分子中的双键被打开,并使链与链之间发生交联,形成一种不溶性的网状结构,而起到抗蚀作用,这是一种典型的负性光刻胶。

柯达公司的产品KPR胶即属此类。

三.光刻胶的化学性质a、传统光刻胶:正胶和负胶。

光刻胶的组成:树脂(resin/polymer),光刻胶中不同材料的粘合剂,给与光刻胶的机械与化学性质(如粘附性、胶膜厚度、热稳定性等);感光剂,感光剂对光能发生光化学反应;溶剂(Solvent),保持光刻胶的液体状态,使之具有良好的流动性;添加剂(Additive),用以改变光刻胶的某些特性,如改善光刻胶发生反射而添加染色剂等。

负性光刻胶。

树脂是聚异戊二烯,一种天然的橡胶;溶剂是二甲苯;感光剂是一种经过曝光后释放出氮气的光敏剂,产生的自由基在橡胶分子间形成交联。

从而变得不溶于显影液。

负性光刻胶在曝光区由溶剂引起泡涨;曝光时光刻胶容易与氮气反应而抑制交联。

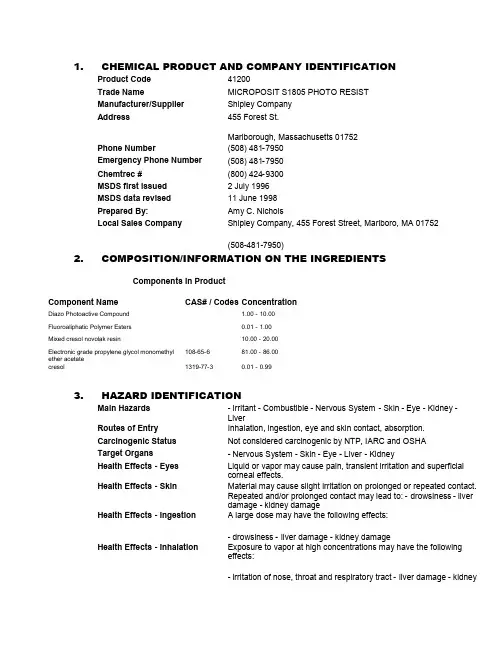

1.CHEMICAL PRODUCT AND COMPANY IDENTIFICATIONProduct Code41200Trade Name MICROPOSIT S1805PHOTO RESISTManufacturer/Supplier Shipley CompanyAddress455Forest St.Marlborough,Massachusetts01752Phone Number(508)481-7950Emergency Phone Number(508)481-7950Chemtrec#(800)424-9300MSDS first issued2July1996MSDS data revised11June1998Prepared By:Amy C.NicholsLocal Sales Company Shipley Company,455Forest Street,Marlboro,MA01752(508-481-7950)POSITION/INFORMATION ON THE INGREDIENTSComponents in ProductComponent Name CAS#/Codes ConcentrationDiazo Photoactive Compound 1.00-10.00Fluoroaliphatic Polymer Esters0.01-1.00Mixed cresol novolak resin10.00-20.00Electronic grade propylene glycol monomethyl108-65-681.00-86.00ether acetatecresol1319-77-30.01-0.993.HAZARD IDENTIFICATIONMain Hazards-Irritant-Combustible-Nervous System-Skin-Eye-Kidney-LiverRoutes of Entry Inhalation,ingestion,eye and skin contact,absorption.Carcinogenic Status Not considered carcinogenic by NTP,IARC and OSHATarget Organs-Nervous System-Skin-Eye-Liver-KidneyHealth Effects-Eyes Liquid or vapor may cause pain,transient irritation and superficialcorneal effects.Health Effects-Skin Material may cause slight irritation on prolonged or repeated contact.Repeated and/or prolonged contact may lead to:-drowsiness-liverdamage-kidney damageHealth Effects-Ingestion A large dose may have the following effects:-drowsiness-liver damage-kidney damageHealth Effects-Inhalation Exposure to vapor at high concentrations may have the followingeffects:-irritation of nose,throat and respiratory tract-liver damage-kidneydamage4.FIRST AID MEASURESFirst Aid-Eyes Immediately flush the eye with plenty of water for at least15minutes,holding the eye open.Obtain medical attention if sorenessor redness persists.First Aid-Skin Wash skin with water.Obtain medical attention if blistering occurs orredness persists.First Aid-Ingestion Wash out mouth with water.Obtain medical attention.First Aid-Inhalation Remove from exposure.If there is difficulty in breathing,giveoxygen.Seek medical attention if symptoms persist.Advice to Physicians Treat symptomatically.5.FIRE FIGHTING MEASURESExtinguishing Media Use water spray,foam,dry chemical or carbon dioxide.Keepcontainers and surroundings cool with water spray.Special Fire-Fighting Procedures This product may give rise to hazardous vapors in a fire.Vapors cantravel a considerable distance to a source of ignition and result inflashback.Unusual Fire&Explosion Hazards Pressure may build up in closed containers with possible liberation of combustible vapors.Protective Equipment for Fire-FightingWear full protective clothing and self-contained breathing apparatus.6.ACCIDENTAL RELEASE MEASURESSpill Procedures Contain and absorb using earth,sand or other inert material.Transfer into suitable containers for recovery or disposal.Finallyflush area with plenty of water.Personal Precautions Wear appropriate protective clothing.Wear respiratory protection.Eliminate all sources of ignition.Environmental Precautions Prevent the material from entering drains or water courses.7.HANDLING AND STORAGEHandling Use local exhaust ventilation.Avoid contact with eyes,skin andclothing.Keep container tightly closed when not in use.Storage Store in original containers.Store away from sources of heat orignition.Storage area should be:-cool-dry-well ventilated-out of direct sunlightOtherProprietary photoresist film contains approximately2-4%of2,3,4-trihydroxybenzophenone(THBP),which may sublime during soft-bake or hard-bake processing.THBP has low acute toxicity(LD50>5g/kg).Contact with eyes,skin or mucous membranes cause irritation.To prevent accumulation of THBP on equipment surfaces and ventilation ducts,preventative maintenance program including regular cleaning should be implemented.Wipe surfaces using an appropriate cleaning solvent when possible.Provide adequate general or local exhaust ventilation during the cleaning process.In situations where this is not possible or where solvent or dust concentrations become excessive,use an air purifying respirator with an organic vapor/toxic particulate cartridge.When cleaning residual THBP,wear protective gloves and adequate protective clothing to prevent skin contact.Practice good personal hygiene to prevent accidental exposure.Clean all protective clothing and equipment thoroughly after each use.8.EXPOSURE CONTROLS/PERSONAL PROTECTIONOccupational Exposure StandardsElectronic grade propylene glycol monomethyl ether acetate Manufacturer recommends30ppm8h TWA and90ppm15min STEL.cresol ACGIH:TLV5ppm(22mg/m3)8h TWA.OSHA:PEL5ppm(22mg/m3)8h EH40:OES5ppm(22mg/m3)8h TWA.Canbe absorbed through skin.Engineering Control Measures Engineering methods to prevent or control exposure are preferred.Methods include process or personnel enclosure,mechanicalventilation(local exhaust),and control of process conditions.Respiratory Protection Respiratory protection if there is a risk of exposure to high vaporconcentrations.The specific respirator selected must be based onthe airborne concentration found in the workplace and must notexceed the working limits of the respirator.Hand Protection Butyl rubber gloves.Eye Protection Chemical goggles.Body Protection Normal work wear.9.PHYSICAL AND CHEMICAL PROPERTIESPhysical State Viscous liquidColor RedOdor SweetVOC(g/l)839.80Specific Gravity 1.010pH NeutralBoiling Range/Point(°C/F)145.8/295Flash Point(PMCC)(°C/F)40.5-46.1/105-115Explosion Limits(%)Lower limit1.5at20°C.Upper limit7.0at20C..Solubility in Water Insoluble.Vapor Density(Air=1)Heavier than air.Evaporation Rate Slower than etherVapor Pressure Propylene Glycol Monomethyl Ether Acetate:3.7mmHg at20°C. 10.STABILITY AND REACTIVITYStability Stable under normal conditions.Conditions to Avoid-High temperatures-Static dischargeIncompatibilities-Oxidizing agentsHazardous Polymerization Will not occur.Hazardous DecompositionProductsCombustion will generate:-carbon monoxide-Carbon Dioxide-phenols-toxic fluorinecompounds-aldehydes-oxides of nitrogen-acrid smoke andirritating fumes11.TOXICOLOGICAL INFORMATIONAcute Data Propylene Glycol Monomethyl Ether Acetate:Oral LD50(rat)8532mg/kg.Dermal LD50(rabbit)5000mg/kg.Chronic/Subchronic Data No data.Genotoxicity It was not mutagenic when tested in bacterial or mammaliansystems.Reproductive/Developmental Developmental effects were seen in laboratory animals only at doseToxicity levels that were maternally toxic.Additional Data None known.12.ECOLOGICAL INFORMATIONMobility Propylene Glycol Monomethyl Ether Acetate:Koc is0-50.Persistence/Degradability The product is partially or slowly biodegradable.BOD20greater than40%Bio-accumulation No data.Ecotoxicity The product is rated as practically non-toxic to aquatic species.Tests on the following species gave a LC50of161mg/litre:-fatheadminnowsTests on the following species gave a LC50of408mg/litre:-daphnia 13.DISPOSAL CONSIDERATIONSProduct Disposal Incineration is the recommended method of disposal.Dispose of inaccordance with all applicable local and national regulations.Container Disposal Labels should not be removed from containers until they have beencleaned.Empty containers may contain hazardous residues.Dispose of containers with care.14.TRANSPORT INFORMATIONDOT Ground:Not Regulated per49CFR173.150(f)(2)UN Proper Shipping Name Flammable liquid,n.o.s.UN Class(3)Flammable LiquidUN Number UN1993UN Packaging Group IIIN.O.S.1:Propylene Glycol Monomethyl Ether AcetateN.O.S.2:Subsidiary Risks None.ADR/RID SubstanceIdentification NumberCLASS3-31(c)CERCLA RQ Cresol(100#)Marine Pollutant No.15.REGULATORY INFORMATIONTSCA Listed YesTSCA ExemptionsWHMIS Classification D.2.B B.3MA Right To Know Law All components have been checked for inclusion on theMassachusetts Substance List(MSL).Those components present atthe de minimus concentration have been identified in the hazardousingredients section of the MSDS.California Proposition65This product does not contain materials which the State of Californiahas found to cause cancer,birth defects or other reproductive harm.SARA TITLE III-Section311/312Categorization(40CFR370)Immediate,delayed,flammability hazardSARA TITLE III-Section313(40 CFR372)This product does not contain a chemical which is listed in Section 313at or above de minimis concentrations.16.OTHER INFORMATIONNFPA Rating-FIRE2NFPA Rating-HEALTH2NFPA Rating-REACTIVITY0NFPA Rating-SPECIAL None.Revisions Highlighted Flash Point(PMCC)(°C/F)Abbreviations CAS#:Chemical Abstract Services NumberACGIH:American Conference of Governmental Industrial HygienistsOSHA:Occupational Safety and Health AdministrationTLV:Threshold Limit ValuePEL:Permissible Exposure LimitSTEL:Short Term Exposure LimitNTP:National Toxicology ProgramIARC:International Agency for Research on CancerR:RiskS:SafetyLD50:Lethal Dose50%LC50:Lethal Concentration50%BOD:Biological Oxygen DemandKoc:Soil Organic Carbon Partition Coefficient.TLm:Median Tolerance LimitDisclaimerThe data contained herein is based on information that Shipley Company believes to be reliable,but no expressed or implied warranty is made with regard to the accuracy of such data or its suitability for a given situation.Such data relates only to the specific product described and not to such products in combination with any other product and no agent of Shipley Company is authorized to vary any of such data.Shipley Company and its agents disclaim all liability for any action taken or foregone on reliance upon such data.。

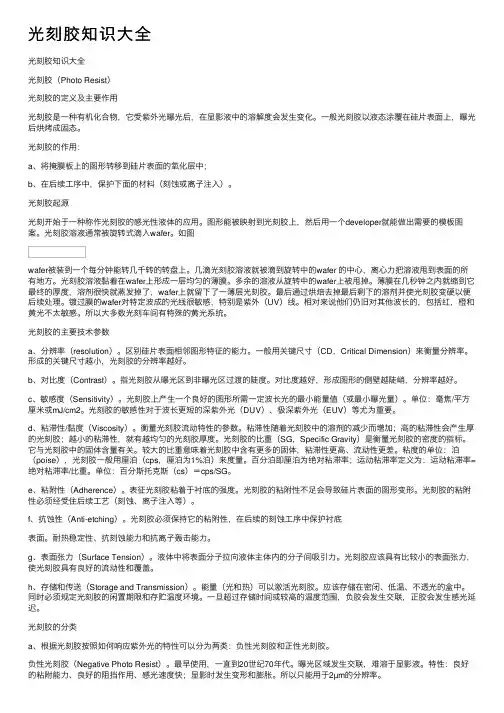

光刻胶知识⼤全光刻胶知识⼤全光刻胶(Photo Resist)光刻胶的定义及主要作⽤光刻胶是⼀种有机化合物,它受紫外光曝光后,在显影液中的溶解度会发⽣变化。

⼀般光刻胶以液态涂覆在硅⽚表⾯上,曝光后烘烤成固态。

光刻胶的作⽤:a、将掩膜板上的图形转移到硅⽚表⾯的氧化层中;b、在后续⼯序中,保护下⾯的材料(刻蚀或离⼦注⼊)。

光刻胶起源光刻开始于⼀种称作光刻胶的感光性液体的应⽤。

图形能被映射到光刻胶上,然后⽤⼀个developer就能做出需要的模板图案。

光刻胶溶液通常被旋转式滴⼊wafer。

如图wafer被装到⼀个每分钟能转⼏千转的转盘上。

⼏滴光刻胶溶液就被滴到旋转中的wafer 的中⼼,离⼼⼒把溶液甩到表⾯的所有地⽅。

光刻胶溶液黏着在wafer上形成⼀层均匀的薄膜。

多余的溶液从旋转中的wafer上被甩掉。

薄膜在⼏秒钟之内就缩到它最终的厚度,溶剂很快就蒸发掉了,wafer上就留下了⼀薄层光刻胶。

最后通过烘焙去掉最后剩下的溶剂并使光刻胶变硬以便后续处理。

镀过膜的wafer对特定波成的光线很敏感,特别是紫外(UV)线。

相对来说他们仍旧对其他波长的,包括红,橙和黄光不太敏感。

所以⼤多数光刻车间有特殊的黄光系统。

光刻胶的主要技术参数a、分辨率(resolution)。

区别硅⽚表⾯相邻图形特征的能⼒。

⼀般⽤关键尺⼨(CD,Critical Dimension)来衡量分辨率。

形成的关键尺⼨越⼩,光刻胶的分辨率越好。

b、对⽐度(Contrast)。

指光刻胶从曝光区到⾮曝光区过渡的陡度。

对⽐度越好,形成图形的侧壁越陡峭,分辨率越好。

c、敏感度(Sensitivity)。

光刻胶上产⽣⼀个良好的图形所需⼀定波长光的最⼩能量值(或最⼩曝光量)。

单位:毫焦/平⽅厘⽶或mJ/cm2。

光刻胶的敏感性对于波长更短的深紫外光(DUV)、极深紫外光(EUV)等尤为重要。

d、粘滞性/黏度(Viscosity)。

衡量光刻胶流动特性的参数。

粘滞性随着光刻胶中的溶剂的减少⽽增加;⾼的粘滞性会产⽣厚的光刻胶;越⼩的粘滞性,就有越均匀的光刻胶厚度。

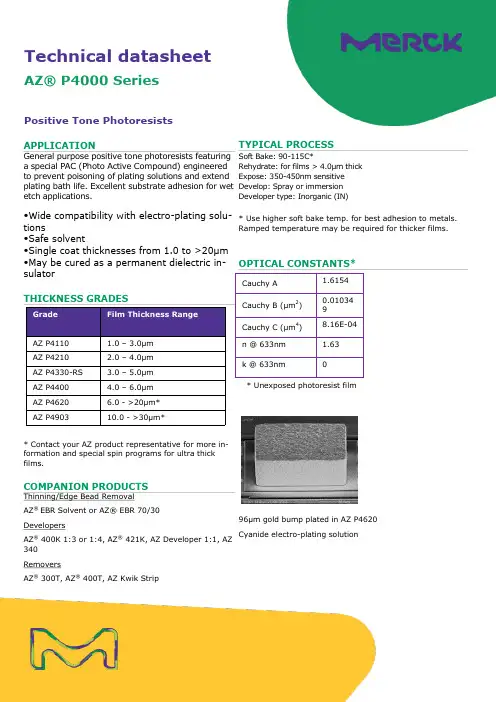

Technical datasheetAPPLICATIONGeneral purpose positive tone photoresists featuring a special PAC (Photo Active Compound) engineered to prevent poisoning of plating solutions and extend plating bath life. Excellent substrate adhesion for wet etch applications.•Wide compatibility with electro -plating solu-tions•Safe solvent•Single coat thicknesses from 1.0 to >20µm •May be cured as a permanent dielectric in-* Contact your AZ product representative for more in-formation and special spin programs for ultra thick films.COMPANION PRODUCTSThinning/Edge Bead RemovalAZ ®EBR Solvent or AZ® EBR 70/30 DevelopersAZ ® 400K 1:3 or 1:4, AZ ® 421K, AZ Developer 1:1, AZ 340 RemoversAZ ® 300T, AZ ® 400T, AZ Kwik StripAZ® P4000 SeriesPositive Tone PhotoresistsTYPICAL PROCESSSoft Bake: 90-115C*Rehydrate: for films > 4.0µm thick Expose: 350-450nm sensitive Develop: Spray or immersionDeveloper type: Inorganic (IN) * Use higher soft bake temp. for best adhesion to metals. Ramped temperature may be required for thicker films.OPTICAL CONSTANTS*96µm gold bump plated in AZ P4620 Cyanide electro -plating solutionTYPICAL SPIN CURVES (150MM SUBSTRATE)Note: Thicker films will be coated by varying spin times and other dispense parameters (or via multiple coats). Single films above 7.0µm are not spun to equilibrium.TYPICAL AU PLATING RESULTS (CYANIDE PLATING SOLUTION; PH = 5.5)Resist: AZ P4620Thickness: 24µmDevelop: AZ 400K 1:3Plating Temp: 45CPlating Time: 50 min.Metal Thickness: 20µmStrip: AZ 400TREFERENCE PROCESS (12µM THICK AZ P4620 FILM)* Thicker films may require a ramped soft bake process to avoid bubble formation due to rapid outgassing ofsolvents. Contact your AZ product representative for ultra-thick coat and bake processing guidelines.EXPOSURE LATITUDE FOR 20µM LINES AZ P4620 AT FT = 12µM EXPOSURE LATITUDE FOR 40µM LINES AZ P4620 AT FT = 24µMABSORBANCE SPECTRA OF P4000 SERIES PHOTORESISTS (UNBLEACHED, NORMAL-IZED TO 1µM)PROCESSING P4000 AS A DIELECTRIC INSULATORAZ P4000 Series photoresists may be thermally cured after develop to form stable dielectric isolators. The die-lectric properties are cure temperature dependent as shown in the table below.EXAMPLE COATING SEQUENCE FOR 20+ µM THICK FILMSAZ P4000 SERIES FLUID VISCOSITIESDILL MODELLING PARAMETERSAPPROXIMATE EXPOSURE DOSE REQUIRE-MENT VS. FILM THICKNESS (SUSS MA -200)PROCESS CONSIDERATIONSSUBSTRATE PREPARATIONSubstrates must be clean, dry, and free of organic residues. Oxide forming substrates (Si, etc.) should be HMDS primed prior to coating AZ P4000. Contact your AZ product representative for detailed information on pre-treating with HMDS.COATINGFilms up to 8.0µm thick (depending upon wafer size) may be set and spun to equilibrium using the spin curve graphs as a reference. Thicker films require special coat programs using carefully timed spread and spin cycles. Contact your AZ products representative for additional information.SOFT BAKESoft bake times and temperatures may be application specific. Process optimization is recommended to ensure stable lithographic and adhesion performance. Soft bake temperatures for AZ P4000 should be in the 95-115C range. Temperatures towards the high end of this range will improve adhesion to most metals. Thick films may require gradual ramping of the soft bake temperature to prevent bubbling.FILM REHYDRATIONP4000 photoresist films thicker than 4.0µm require a rehydration hold between soft bake and exposure. Hold times are typically 30-60 minutes (depending upon film thickness) @ relative humidity 40 - 45%.EXPOSUREAZ P4000 is sensitive to exposure wavelengths between 310 and 450nm. 365-436nm is recommended.POST EXPOSE BAKEA PEB is not generally required for P4000 but may be employed to maximize process latitudes and to mitigate standing wave effects caused by monochromatic exposure. PEB temperatures and times may be application specific. As a general rule, PEB temperatures should be in the 100 to 115C range.DEVELOPINGSpray or immersion developing in AZ 400K series developers is recommended. AZ 400K 1:3 or AZ 421K (unbuffered) are recommended for resist film thicknesses above 12µm. AZ 400K 1:4 provides improved devel-oper selectivity for thinner films. AZ Developer 1:1 may be used in applications requiring zero etch rate on Alu-minum substrates.HARD BAKEHard baking (post develop bake) improves adhesion in wet etch or plating applications and improves pattern stability in dry etch processes. Hard bake temperatures should be in the 100 to 110C range to ensure minimal thermal distortion of the pattern. Higher temperatures may be used to cure the pattern (cross link the resin) for use as a permanent insulator.COMPATIBLE MATERIALSAZ P4000 Series materials are compatible with all commercially available lithography processing equipment. Compatible materials of construction include glass, quartz, PTFE, PFA, stainless steel, HDPE, polypropylene, and ceramic.Rev. (08/21)Products are warranted to meet the specifications set forth on their label/packaging and/or certificate of analysis at the time of shipment or for the expressly stated duration. MERCK MAKES NO REPRESENTATION OR WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE REGARDING OUR PRODUCTS OR ANY INFORMATION PROVIDED IN CONNECTION THEREWITH. Customer is responsible for and must independently determine suitability of Merck´s products for customer ’s products, intended use and processes, including the non -infringement of any third parties´ intellectual property rights. Merck shall not in any event be liable for incidental, consequential, indirect, exemplary or special damages of any kind resulting from any use or failure of the products: All sales are subject to Merck ’s complete Terms and Conditions of Sale. Prices are subject to change without notice. Merck reserves the right to discontinue products without prior notice.The information on our trademarks is available in the Trademarks section on . Detailed information on our trademarks is also available via publicly accessible resources. All other trademarks are the property of their respective owners. © 2021 Merck KGaA, Darmstadt, Germany and/or its affiliates.DisclaimerHANDLING/DISPOSALAZ P4000 Series materials are flammable liquids containing PGMEA (1-Methoxy -2-propanol acetate). Refer to the current version of the MSDS and to local regulations for up to date information on safe handling and proper disposal. AZ P4000 is compatible with drain lines handling similar organic solvent based materials.。

此之前约1950年发明了重氮萘醌—酚醛树脂系光刻胶,它最早应用于印刷业,目前是电子工业用用最多的光刻胶,近年随着电子工业的飞速发展,光刻胶的发展更是日新月异,新型光刻胶产品不断涌现。

光刻胶按其所用曝光光源或辐射源的不同, 又可分为紫外光刻胶、深紫外光刻胶、电子束胶、离子束胶、X射线胶等。

2. 光刻技术及工艺电子工业的发展离不开光刻胶的发展, 这是由电子工业微细加工的线宽所决定的。

众所周知,在光刻工艺中离不开曝光。

目前采用掩膜版的曝光方式主要有接触式曝光和投影式曝光两种。

光刻工艺过程光刻胶的种类虽然很多,使用主艺条件依光刻胶的品种不同而有很大的不同,但大体可遵从如下步骤:a.基片处理:该工序包括脱脂清洗、高温处理等部分,有时还需涂粘附增强剂进行表面改性处理。

脱脂一般采用溶剂或碱性脱脂剂进行清洗,然后再用酸性清洗剂清洗,最后用纯水清洗。

高温处理通常是在150-160℃对基片进行烘烤去除表面水分。

粘附增强剂的作用是将基片表面亲水性改变为憎水性, 便于光刻胶的涂布, 增加光刻胶在基片上的粘附性电。

b.涂胶:光刻胶的涂布方式有旋转涂布、辗涂、浸胶及喷涂等多种方式。

在电子工业中应用较多的是旋转涂布。

该方式的涂胶厚度一般取决于光刻胶的粘度及涂胶时的转速。

膜厚-转速曲线是光刻胶的一个重要特性。

c.前烘:前烘的目的是为了去除胶膜中残存的溶剂,消除胶膜的机械应力。

在电子工业中烘烤方式通常有对流烘箱和热板两种。

前烘的温度和时间根据光刻胶种类及胶膜的厚度而定。

以北京化学试剂研究所BN308系列紫外负性光刻胶为例,当胶膜厚度为1-2μm时,对流烘箱,70-80℃,20min;热板,100℃,1min。

d.曝光:正确的曝光量是影响成像质量的关键因素。

曝光不够或曝光过度均会影响复制图形的再现性。

曝光宽容度大有利于光刻胶的应用。

光刻胶的曝光量同样取决于光刻胶的种类及膜厚。

以BN308系列负胶为例,当膜厚为1-2μm时,曝光20-30mJ/cm2e.中烘:曝光后显影前的烘烤,对于化学增幅型光刻胶来说至关重要,中烘条件的好坏直接关系到复制图形的质量。

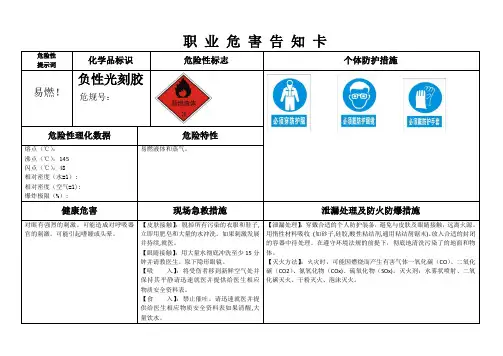

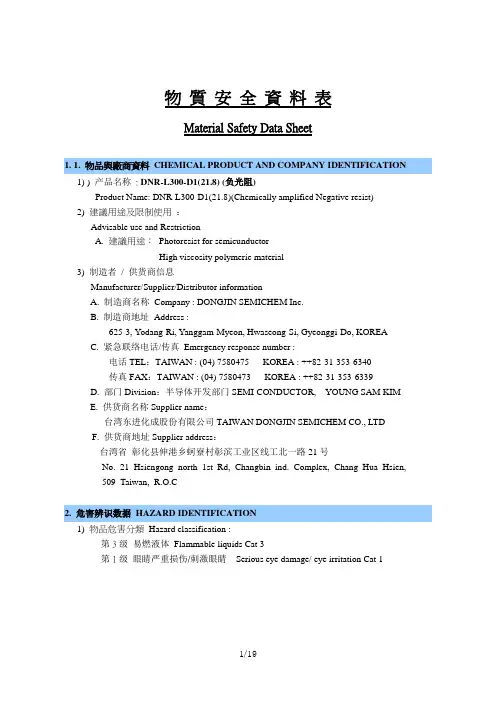

物質安全資料表Material Safety Data Sheet1) ) 产品名称: DNR-L300-D1(21.8) (负光阻)Product Name: DNR-L300-D1(21.8)(Chemically amplified Negative resist)2) 建議用途及限制使用:Advisable use and RestrictionA. 建議用途:Photoresist for semicunductorHigh viscosity polymeric material3) 制造者/ 供货商信息Manufacturer/Supplier/Distributor informationA. 制造商名称Company : DONGJIN SEMICHEM Inc.B. 制造商地址Address :625-3, Yodang-Ri, Yanggam-Myeon, Hwaseong-Si, Gyeonggi-Do, KOREAC. 紧急联络电话/传真Emergency response number :电话TEL:TAIWAN : (04) 7580475 KOREA : ++82-31-353-6340传真FAX:TAIWAN : (04) 7580473 KOREA : ++82-31-353-6339D. 部门Division:半导体开发部门SEMI-CONDUCTOR, YOUNG SAM KIME. 供货商名称Supplier name:台湾东进化成股份有限公司TAIWAN DONGJIN SEMICHEM CO., LTDF. 供货商地址Supplier address:台湾省彰化县伸港乡蚵寮村彰滨工业区线工北一路21号No. 21 Hsiengong north 1st Rd, Changbin ind. Complex, Chang Hua Hsien, 509 Taiwan, R.O.C1) 物品危害分類Hazard classification :第3级易燃液体Flammable liquids Cat 3第1级眼睛严重损伤/刺激眼睛Serious eye damage/ eye irritation Cat 12) 標示內容Allocation label elementsA. 象征符号Symbol :B. 警示语Signal word: 危險DangerC. 危害险声明Hazard statements- 导致严重的眼睛损伤Causes serious eye damage- 易燃液体和蒸气Flammable liquid and vapourD. 危害防範措施Precautionary statements- 预防Prevention•P210远离热/火花/明火/热的表面- 禁止抽烟。

SUZHOU RUIHONG ELECTRONIC CHEMICALS CO. LTDMaterial Safety Data SheetSection 1 - Product and Company IdentificationProduct Identification: RZJ-300(RZJ-390,RZJ-390PG.RZJ-390H,RZJ-304,RZJ-306) Manufacturer's Name: Suzhou Ruihong electronic chemicals co.,ltd.Manufacturer's Address: 81,Suli Road, Wuzhong district, Suzhou City, P. R. China. Manufacturer's Country: P. R. China.General Information Telephone: 0086-512-65284373, 65281007/FAX:0086-512-65279925 Emergency Telephone: 0086-512-65284373Section 2 - Composition/Information on IngredientsCOMPONENT CAS-NO. CONCENTTRATION Propyleneglycolmonomethyletheracetate 108-65-6 73%Cresol-Formaldehyde Novolak Resin 9016-83-5 21%6-Dizao-5, 6-Dihydoro-5-Oxo-1-Naphthalenesulfonic acid, Ester with 68510-93-0 6%2,3,4-TrihydroxybenzophenoneSection 3 - Hazards IdentificationFLAMMABLEIrritating to eyes.Classified as hazardous according to regulatory criteria.Japan Chemical Industry Association ClassificationFlammable liquidSection 4 - First Aid MeasuresINHALATION: Remove from exposure. If there is difficulty in breathing. Seek medical attention if symptoms persist.SKIN CONTACT: Wash skin with soap and water for at least 15 minutes while removing contaminated clothing and shoes. Get medical attention, if needed. Thoroughly clean and dry contaminated clothing and shoes before reuse.EYE CONTACT: Flush eyes with plenty of water for at least 15 minutes. Then get immediate medical attention.INGESTION: If person is unconscious, turn head to side. Never make an unconscious person vomit or drink fluids. When vomiting occurs, keep head lower than hips to help prevent aspiration. Contact local poison control center or physician immediately. Get medical attention. NOTE TO PHYSICIAN: Treat symptomatically.Section 5 - Fire Fighting MeasuresSUITABLE EXTINGUISHING MEDLA: Use water spray, foam, dry chemical or carbon dioxide . Keep containers and surroundings cool with spray.SPECIFIC HAZARDS DURING FIRE FLGHTING: This product may give rise to hazardous vapors in a fire. Vapors can travel a considerable distance to a source of ignition and result in flashback.SPECIAL PROTECTIVE EQUIPMENT FOR FIRE-FIGHTERS: Wear full protective clothing and self-contained breathing apparatus.FURTHER INFORMATION: Pressure may build up in closed containers with possible liberation of combustible vapors.Section 6 - Accidental Release MeasuresPERSONAL PRECAUTIONS:Wear suitable protective clothing.Wear respiratory protection.Eliminate all ignition sources.ENVIRONMENTAL PRECAUTIONS:Prevent the material from entering drains or water courses.Do not discharge directly to a water source.Advise Authorities if spillage has entered watercourse or sewer or has contaminated soil or vegetation .METHODS FOR CLEARING UP:Cover with absorbent or contain. Collect and dispose.Section 7 - Handling and StorageHANDLINGUse local exhaust ventilation. Avoid contact with eyes, skin and clothing. Keep container tightly Closed. Further information on storage conditions; Proprietary photo resist film contains approximately 2-4% of 2.3.4-trihydroxybenzophenone (THBP).Which may sublime duringsoft-bake or hard-bake processing. THBP has low acute toxicity (LD50>5g/kg). Contact with eyes. Skin or mucous membranes cause irritation. To prevent accumulation of THBP on equipment surfaces and ventilation ducts, preventative maintenance program including regular cleaning should be implemented. Wipe surfaces using an appropriate cleaning solvent when possible. Provide adequate general or local exhaust ventilation during the cleaning process. In situations where this is not possible or where solvent or dust concentrations become excessive. Use an air purifying respirator with an organic vapor/toxic particulate cartridge. When cleaning residual THBP, wear protective gloves and adequate protective clothing to prevent skin contact. Practice good personal hygiene to prevent accidental exposure. Clean all protective clothing and equipment thoroughly after each use.STORAGEStorage conditions; Store in original container. Keep away from heat and sources of ignition,Storage area should be cool dry well ventilated out of direct sunlightSection 8 - Exposure Controls & Personal ProtectionEXPOSURE LIMITS:Exposure limits are listed below, if they exist.Component Regulation Type of listing Value2-methoxy-1-methylethyl Rohm and Haas TWA 30ppm AcetateRohm and Haas STEL 90ppmRohm and Haas Absorbed via SkinOEL (EU) TWA 275mg/m3 50ppmOEL (EU) STEL 550mg/m3100ppmOEL (EU) SkinEXPOSURE CONTROLSEYE PROTACTION: gogglesHAND PROTECTION: Butyl rubber gloves. Other chemical resistant gloves may be recommended by your safety professional.SKIN AND BODY PROTECTION: Normal work wear.RESPIRATORY PROTOCTION: Respiratory protection if there is a risk of exposure to high vapor concentrations. The specific respirator selected must be based on the airborne concentration found in the workplace and must not exceed the working limits respirator. ENGINEERING MEASURES: Engineering methods to prevent or control exposure are preferred. Methods include process or personnel enclosure, mechanical ventilation (local exhaust), and control of process conditions.Section 9 - Physical & Chemical PropertiesPHYSICAL STATE: liquidCOLOR: Red AmberODOUR: Ester-likeBOILING POINT: ca.146℃FLASH POINT: 40-46℃VAPOR PRESSURE: 3.7 mmHg at 20℃RETATIVE DENSITY: 0.80-1.00WATER SOLUBILITY: InsolublePH: neutralEVAPORATION RATE: Slower than etherVOC’S:727-950 g/lNOTE: The Physical date presented above are typical values and should not be construed as a specification.Section 10 - Stability & Reactivity DataMATERLALS TO AVOID: Oxidizing agents.CONDITIONS TO AVOID: High temperatures Static discharge.HAZARDOUS: Combustion will generate; carbon monoxide, phenols.HAZARDOUS REACTIONS: Stable under normal conditions.POLYMERIZATION: Will not occur.DECOMPOSITION PRODUCTS: Nitrogen oxides (NOX), aldehydes, acrid smoke and irritating fumes.Section 11 - Toxicological InformationToxicological information on this product or its components appears in this section when such data is available.COMPONENT: 2-methoxy-1-methylethyl acetateAcute oral toxicity LD50 rat 8,532mg/kgCOMPONENT: 2-methoxy-1-methylethyl acetateAcute inhalation toxicity LC50 rat 6h 23.49mg/lCOMPONENT: 2-methoxy-1-methylethyl acetateAcute dermal toxicity LD50 rabbit >5,000 mg/kgCOMPONEN T: CresolAcute dermal toxicity LD50 rabbit >5,000 mg/kgCOMPONENT: 2-methoxy-1-methylethyl acetateTOXICITY TO REPRODUCTIONDermal teratology testing of this solvent (with less than 3% beta isomer) revealed no maternally toxic, teratogenic or fetotoxic responses in rats or rabbits exposed to concentrations of 1,000 and 2,000 mg/kg per day.COMPONENT: 2-methoxy-1-methylethyl acetateMUTAGENLELTYNo significant mutagenic response was observed and the carcinogenic potential of the material is therefore considered to be low.Section 12 - Ecological InformationEcotoxicologioal information on this product or its components appear in this section when such date is available.2-methoxy-1-methylethyl acetateEcotoxicity effectsToxicity to fish LC50 Fathead minnow (Pimephales promelas) 86h 161 mg/l Toxicity aquatic EC50 Daphnia magna 48hInvertebrates >500mg/lSection 13 - Disposal ConsiderationsENVIRONMENTAL PRECAUTIONS: Prevent the material from entering drains or water courses.Do not discharge directly to a water source.Advise Authorities if spillage has entered watercourse or sewer or has contaminated sell or vegetation.DISPOSALDispose in accordance with all local, state (provincial), and federal regulation.Do not remove label until container is thoroughly cleaned. Empty containers may contain hazardous residues. This material and its container must be disposed of in a safe way.Section 14 - MSDS Transport InformationTransport In Accordance With Fire Service Law etc.CLASSIFICATION FOR ROAD ANG RAIL TRANSPORT:Proper shipping name RESIN SOLUTIONUN-No. UN 1866Class 3Packing group ⅢCLASSIFICATION FOR SEA TRANSPORT (IMO-IMDG):Proper shipping name RESIN SOLUTIONUN-No. UN 1866Class 3Packing group ⅢCLASSIFICATION FOR TRANSPORT (IATA/ICAO):Consult current IATA regulations prior to shipping by air. Transportation classifications may vary by container volume and may be influenced by regional or county variations in regulationsSection 15 - Regulatory InformationLabelClassification and labeling have been performed according to regulations.Hazard symbol and indication of dangerXi IrritantContains: 2-methoxy-1-methylethyl acetateR-phrase(s)R10 FlammableR36 Irritating to eyesS-phrase(s)S26 Incase of contact with eyes, rinse immediately with plenty of water and seek Medical advice.S43 Incase of fire. Use sand, dry chemical or alcohol-resistant foam.S63 This material and its container must be disposed of as hazardous waste. JAPAN. KASHIN-HOU LAW LIST (ENCS): All intentional components are listed on the inventory, are exempt, or are supplier certified.US. TOXIC SUBSTANCES CONTROL ACT (TSCA): All components of this product are incompliance with the inventory listing requirements of the U.S. Toxic Substances Control Act (TSCA) Chemical Substance Inventory.JAPAN FIRE SERVICE LAWArticle 2, Dangerous Substance, Class 4 Second oil type, risk gradeⅢNo FireJAPAN WASTE DISPOSAL AND PUBLIC CLEANING LAWJapan Specific Controlled Industrial wasteSection 16 - Other InformationSuzhou Ruihong makes no express or implied warranties, guarantees or representations regarding the product or the information herein, including but not limited to any implied warranty of merchantability or fitness for use. Suzhou Ruihong shall not be liable for any personal injury, property or other damages of any nature, whether compensatory, consequential, exemplary, or otherwise, resulting from any publication, use or reliance upon the information herein.正性光刻胶组成成分: 6 Dizao - 5,6 - Dihydoro - 5 -氧- 1 -萘磺酸,与2,3,4酯,羟基二苯甲酮(6%);甲酚甲醛酚醛树脂(21%);2-甲基丙醇乙酸酯(73%)四甲基氢氧化胺显影液: CH13NO4负胶漂洗液:C6H12O2。

光刻胶参数及光刻工艺1、正性光刻胶RZJ-304●规格RZJ-304:25mpa·s,50mpa·s(粘稠度),配用显影液:RZX-3038●匀胶曲线注:粉色为50cp,蓝色为25cp●推荐工艺条件①涂布:23℃,旋转涂布,膜厚1.0~3.5μm②前烘:热板100℃×90sec③曝光:50~75mj/cm2(计算方法:取能量60mj/cm2取光强400×102um/cm2,则60/40=1.5s)④显影:23℃,RZX-3038,1min,喷淋或浸渍⑤清洗:去离子水30sec⑤后烘:热板120℃×120sec●规格S1813,配用显影液为ZX-238●匀胶曲线●推荐工艺条件1(以具体工艺为参考)①涂布:23℃,旋转涂布,膜厚1.23um(1.1~1.9μm)②前烘:热板115℃×60sec③曝光:150mj/cm2④显影:21℃,ZX-238,65sec,喷淋或浸渍⑤清洗:去离子水30sec⑥后烘:热板125℃×120sec●规格AZ-5214,配用显影液AZ-300●匀胶表格(单位:微米)●推荐工艺条件1(以具体工艺为参考)①涂布:23℃,旋转涂布,膜厚1.47um(1.14~1.98μm)②前烘:热板100℃×90sec③曝光:240mj/cm2④后烘:115℃×120sec⑤泛曝光:>200mj/cm2⑥显影:21℃,AZ-300,60sec,喷淋或浸渍⑦清洗:去离子水30sec⑧坚膜:热板120℃×180sec注意:紧急救护措施(对于光刻胶)①吸入:转移至空气新鲜处,必要时进行人工呼吸或就医。

②皮肤接触:肥皂水清洗后自来水清洗。

③眼睛接触:流动清水清洗15分钟以上,必要时就医。

化学品安全技术说明书1. 化学品及企业标识产品信息贸易名称: AZ SLD-2530(39cP) 0004物质/制剂的使用: 电子产业生产制造过程中使用2. 危险性概述GHS-分类: 易燃液体, 类别3眼刺激, 类别2B特定的靶器官系统毒性- 单次暴露, 类别3 GHS-标签图形符号:信号词: 警告危险性说明: 易燃液体和蒸气。

刺激眼。

可能造成对呼吸器官的刺激。

可能引起嗜睡或头晕。

防范说明: 预防:远离热源/火花/明火/热表面。

- 禁止吸烟。

戴防护手套/ 穿防护服/ 戴防护眼罩/ 戴防护面具。

措施: 眼睛刺激持续:就医。

火灾时:用干的砂子,干的化学品或耐醇性的泡沫来灭火。

1/7储存:在通风良好处储存。

保持容器密闭。

处置: 将本品及其容器交由经批准的废物处理厂处置。

3. 成分/组成资料危险组分化学品名称化学文摘登记号(CAS No.) 浓度或浓度范围丙二醇甲醚醋酸酯108-65-6 >= 70%4. 急救措施一般的建议: 如果接触产品后感觉不适,立即就医吸入: 将受伤者移到新鲜空气处并保持其平静如果呼吸微弱、不规则或者停止,迅速解开领子,松开皮带,进行人工呼吸尽快将患者送往最近的医疗中心接受医生的检查和治疗。

请迅速就医并提供给医生相应物质安全资料表皮肤接触: 如果接触皮肤,立即用肥皂水清洗接触部位尽快脱下沾有化学品的衣服、鞋子和袜子,如有必要可用刀除去衣物如有持续刺激,请尽快送往最近的医疗中心接受医生的检查和治疗眼睛接触: 使用大量清水冲洗眼睛至少15分钟,并将眼皮保持张开状态。

迅速就医如化学品不慎溅入眼睛,立即用大量清水冲洗眼睛至少15分钟食入: 如果病人有意识,可以饮用水或者牛奶稀释胃中的物质禁止催吐。

让病人休息并立刻寻求医疗救助。

请迅速就医并提供给医生相应物质安全资料表对医生的特别提示处理: 无适用资料。

5. 消防措施灭火方法及灭火剂: 二氧化碳,水雾,干粉的,抗酒精泡沫2/7。

正庚烷化学品安全技术说明书第一部分:化学品名称化学品中文名称:正庚烷化学品英文名称:n-heptane中文名称2:庚烷技术说明书编码:444CAS No.:142-82-5分子式:C7H16分子量:100.21第二部分:成分/组成信息有害物成分含量 CAS No.正庚烷 142-82-5第三部分:危险性概述健康危害:本品有麻醉作用和刺激性。

急性中毒:吸入本品蒸气可引起眩晕、恶心、厌食、欣快感和步态蹒跚,甚至出现意识丧失和木僵状态。

对皮肤有轻度刺激性。

慢性影响:长期接触可引起神经衰弱综合征。

少数人有轻度中性白细胞减少,消化不良。

燃爆危险:本品易燃,具刺激性。

第四部分:急救措施皮肤接触:脱去污染的衣着,用肥皂水和清水彻底冲洗皮肤。

眼睛接触:提起眼睑,用流动清水或生理盐水冲洗。

就医。

吸入:迅速脱离现场至空气新鲜处。

保持呼吸道通畅。

如呼吸困难,给输氧。

如呼吸停止,立即进行人工呼吸。

就医。

食入:饮足量温水,催吐。

就医。

第五部分:消防措施危险特性:易燃,其蒸气与空气可形成爆炸性混合物,遇热源和明火有燃烧爆炸的危险。

与氧化剂接触发生化学反应或引起燃烧。

高速冲击、流动、激荡后可因产生静电火花放电引起燃烧爆炸。

其蒸气比空气重,能在较低处扩散到相当远的地方,遇火源会着火回燃。

有害燃烧产物:一氧化碳、二氧化碳。

灭火方法:喷水冷却容器,可能的话将容器从火场移至空旷处。

处在火场中的容器若已变色或从安全泄压装置中产生声音,必须马上撤离。

灭火剂:泡沫、二氧化碳、干粉、砂土。

用水灭火无效。

第六部分:泄漏应急处理应急处理:迅速撤离泄漏污染区人员至安全区,并进行隔离,严格限制出入。

切断火源。

建议应急处理人员戴自给正压式呼吸器,穿防静电工作服。

尽可能切断泄漏源。

防止流入下水道、排洪沟等限制性空间。

小量泄漏:用活性炭或其它惰性材料吸收。

也可以用不燃性分散剂制成的乳液刷洗,洗液稀释后放入废水系统。

大量泄漏:构筑围堤或挖坑收容。

用泡沫覆盖,降低蒸气灾害。