贝克休斯快磨式桥塞磨铣

- 格式:pdf

- 大小:1.12 MB

- 文档页数:18

国外页岩气水力压裂技术及工具一览页岩储层具有超低孔低渗特性,钻完井后需要压裂改造后才得到经济产量。

国外油田服务公司最新工具达到了很高水平,水平井裸眼封隔器投球滑套分段压裂技术用高强度低密度球级差达到1/16in,封隔器耐压差达到70MPa,TAM公司自膨胀封隔器最高可达302 °C ;泵送桥塞射孔分段压裂技术所用桥塞可分为:堵塞式、单流阀式和投球式复合桥塞,桥塞耐压差达103.4MPa,耐温232 °C ;哈里伯顿CobraMax H连续油管喷射工具系统,目前最多达到44段。

这些为国内页岩气水力压裂完井方式与压裂工具的选用打下基础。

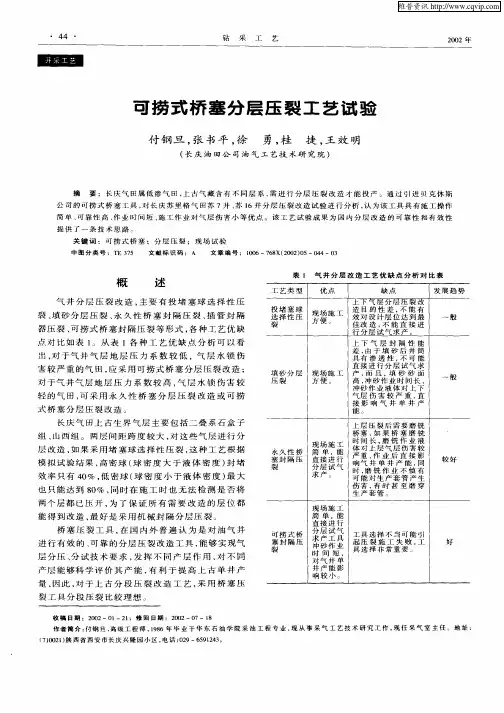

从应用工具角度看,分段压裂工艺方面主要包括:水平井裸眼封隔器投球滑套分段压裂技术,泵送桥塞分段压裂技术,水力喷射分段压裂技术。

从压裂工具方面分析,目前页岩气压裂技术有可膨胀封隔器/裸眼封隔器+滑套多级压裂,泵送桥塞射孔压裂联作多级压裂,水力喷射压裂等。

在美国的页岩气开发技术中,可膨胀封隔器/裸眼封隔器+滑套多级压裂,泵送桥塞射孔压裂联作多级压裂技术比较成熟,使用比较广泛,可适用于较长的水平段;水力喷射压裂可实现准确定位喷射,无需机械封隔,节省作业时间,非常适合用于裸眼井、筛管井以及套管中井。

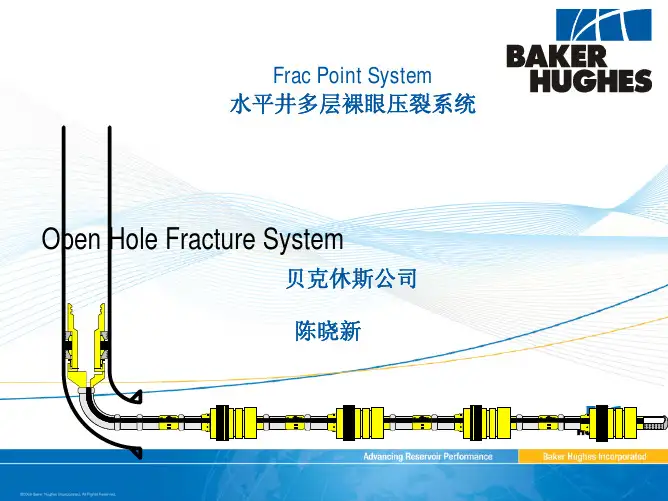

1、水平井裸眼封隔器投球滑套多级压裂系统封隔器投球滑套多级压裂技术一般采用可膨胀封隔器或者裸眼封隔器分段封隔。

根据页岩气储层开发的需要,使用封隔器将水平井段分隔成若干段,水力压裂施工时水平段最趾端滑套为压力开启式滑套,其它滑套通过投球打开,从水平段趾端第二级开始逐级投球,进行有针对性的压裂施工。

水平裸眼井多级压裂目前已经是北美页岩气压裂开采主要技术手段,并越来越受到作业者的欢迎。

水平井多级压裂技术关键在于封隔器(压裂封隔器和可膨胀封隔器)和滑套可靠性和安全性能,尤其是管外封压裂管柱的可膨胀封隔器和开启滑套的高强度低密度球材料决定技术的成功与否。

目前国外油田服务公司都有自己成熟的工具,高强度低密度球级差达到1/16in,封隔器耐压差达到70MPa,TAM公司耐高温自膨胀封隔器最高可达30 °C 。

TAML4级分支井钻、完井技术 级分支井钻、 级分支井钻王 新西部钻探克拉玛依钻井工艺研究院 2009年6月 年 月1概 要分支井技术是继水平井技术之后发展起来的的一项前沿钻井技 提高油气开采效率 术,由于分支井技术在大幅度提高油气开采效率及降低油藏开采 由于分支井技术在大幅度提高油气开采效率及 成本方面所具有的无可比拟的优势, 成本方面所具有的无可比拟的优势,目前国外分支井技术已成为 方面所具有的无可比拟的优势 油气井增产和提高油藏采收率的重要技术手段之一。

油气井增产和提高油藏采收率的重要技术手段之一。

分支井技术 成为21世纪油气开发最受重视的优先发展技术。

成为 世纪油气开发最受重视的优先发展技术。

世纪油气开发最受重视的优先发展技术2分支井主要应用于以下几方面: 分支井主要应用于以下几方面:多个目的层 增加单井产量,提高综合开发效益 多种泄油模式 多层油藏 尺寸受限制的油藏 处理油藏的地质问题 限制水和气的产出 注入井3应用多断快油藏SAGD进行海上钻井多层油层开发开发扇形体蒸汽吞吐油藏开发透镜体油藏4分支井技术的关键因素分支点的力学完整性 分支点的水力完整性 重入能力钻主、 钻主、分支井眼不是分支井的难点所在核心技术分支点的处理5分支井技术:国际分级标准( 分支井技术:国际分级标准(TAML)1 2 3 4主井眼和分支井 都是裸眼主井筒注水泥 分支井为裸眼主井筒注水泥 分支井下套管主井筒和分支井 都注水泥56技术特点: 技术特点:• • • • 主分支均下套管固井完成; 主分支均下套管固井完成; 分支连接处机械支撑; 分支连接处机械支撑; 有限的水力密封能力; 有限的水力密封能力; 可选择重入; 可选择重入;水泥封固主井筒 和分支井, 和分支井 各层压力分隔井下分叉装置• •四级完井 TAML 4 四级完井的主井眼和分支井眼都下套管 并注水泥固井, 并注水泥固井,这就提供了机械支承连 但没有水力分隔性。

Rotary steerable systems should deliver smooth, precise, fast drilling.Unfortunately, too many don’t…Get the superior performance you expectAutoTrak rotary steerable systemsand it's because they don't deliver on a rotary steerable's full potential.When you choose a rotary steerable system, you expect it to deliver:•a smooth, in-gauge hole•a precisely placed wellbore and fast, reliable drilling operations.Because efficiently drilling a smooth wellbore and precisely placingit in the most productive zones helps you keep costs down while enhancing your production.But most rotary steerable systems aren’t that smooth… or very precise. And you may not even know it, because instead of talking about these problems...debating the relative merits of “push-the-bit” steering versus “point-the-bit” steering. Or vice-versa.too many service providers waste your time These debates miss the point.Neither technique can consistently deliver the premium performance you need because both use a “pseudo steering” approach.pseu•do steering PUSH-THE-BIT“Push-the-bit” systems use steering pads that deflect against the wellbore in an on/off cycle that creates doglegs and an angular wellbore.POINT-THE-BIT “Point-the-bit” systems use a BHA with a fixed tilt which causes hole spiraling and a consistently over-gauge wellbore.attempting to steer with a fixed-tilt BHA or on/off pad cyclesPseudo-steering can’t consistently deliver the superior rotary steerable performance you need.High local doglegs. But it does deliver some things with consistency.And, because most systems that use pseudo-steering also restrict bit selection and flow rates, they artificially limit ROP and overall performance.That won’t deliver the results you need. Instead, you get higher well construction costs and lost production.One that delivers the quality wellbore and drilling performance you expect.There’s a better approachCONTINUOUS PROPORTIONAL STEERING Over-gauge wells.Hole spiraling. Angular wellbores.When you steer with precision-controlled pads that maintain a continuous proportional steering vector, you get superior control and a quality wellbore.And when you have the flexibility to optimize the system for the application, you get faster, more reliable drilling performance.AutoTrak systems are the only ones that use continuous proportional steering.REDUCE WELL CONSTRUCTION COSTS WITHUNSURPASSED HOLE QUALITY EXACT WELL PLACEMENTENHANCE PRODUCTION WITH FASTER, MORE RELIABLE PERFORMANCE WITH OPTIMIZED DRILLINGand completion runs.And because holes stay in-gauge, you collecthigh-quality FE data to optimize drilling, placement, and reserve estimation. In-gauge holes also minimizecuttings and maximize hole cleaning velocity.ENHANCE PRODUCTION WITH EXACT WELL PLACEMENTUsing continuous proportional steering, AutoTraksystems check azimuth and inclination everymillisecond and automatically adjust steer forcessecond-by-second for precise control.Using real-time formation evaluation, coursecorrections can be implemented with ease—adjusting the AutoTrak system’s well path withsmooth precision to keep you on target throughall formation types.The result: maximized reservoir exposure andenhanced recovery.GET FASTER, MORE RELIABLE PERFORMANCE WITH OPTIMIZED DRILLINGBecause AutoTrak systems use internal hydraulicsto power independent ribs mounted on adecoupled, slowly rotating sleeve, their steeringcontrol is not affected by drilling dynamics.As a result, the systems operate independentlyof bit pressures, flow rates and drilling fluidproperties—allowing you to optimize your bitand program design to formation challengesas opposed to competitive rotary steerableswhich often restrict BHA design and bit selection.Continuous proportional steering also providesenormous versatility and reliability in allformation types—from soft to hard—allowing you todrill the vertical, curve, and lateral in a single run.CLICK OR TAP THE TABS BELOW TO LEARN MOREA customer in the Middle East wanted to test available rotary steerable system technologies to establish which provided the best hole quality. The customer compared data from over 700 wells to isolate the effectiveness of the three types of rotary steerable system (RSS) technologies—push-the-bit systems, point-the-bit systems, and the only continuous proportional steering system on the market, the AutoTrak RSS .Results overwhelmingly concluded that using continuous proportional steering reduced tortuosity by magnitudes of 4 to 6 times when compared to push-the-bit and point-the-bit RSS methods. The AutoTrak RSS consistently delivered better hole quality in horizontal drilling.That translates into fewer stuck pipe incidents, less chance of encountering problems during completion installation, and greater production potential in both the short- and long-term.MIDDLE EASTMEASURED DEPTH (FT)W E L L B O R E I N C L I N A T I O N (D E G )Point the Bit Push the Bit Continuous Proportional Steering 93.592.591.590.589.588.587.586.585.584.583.58,5008,7008,9009,1009,3009,5009,7009,90010,10010,300Comparison of well tortuosity from the study using high resolution wireline surveys from three offset wells. The difference is unmistakable when comparing wells drilled with push-the-bit (yellow), point-the-bit (orange), and continuous proportional steering (green) technologies. The AutoTrak RSS clearly delivers substantially superior hole quality.UNSURPASSED HOLE QUALITYREAD THE FULL CASE STUDY EXACT WELL PLACEMENT OPTIMIZED DRILLINGCLICK OR TAP THE TABS BELOW TO LEARN MORE EXACT WELL PLACEMENTAn operator needed to drill a challenging well profile thatincluded a BUR of 5.8°/100 ft (30 m) and a turn rate of up to7°/100 ft (30 m), including two ESP tangent sections.The operator previously experienced steering issues inoffset wells due to the stick-slip-inducing chalk. Theoperator also required precise control to ensure exact linerplacement and avoid nearby wells in the congested field.Baker Hughes used a 6¾ in. AutoTrak eXact system withcontinuous proportional steering to execute the complexdirectional plan (a total azimuthal turn >370° was achievedwhile building from 23° to 91° inclination) with no stick-slipissues in 166 hours.UK CONTINENTAL SHELFUsing continuous proportional steering, an AutoTrak eXact system efficiently drilled a complex,corkscrew-shaped well profile that required a long turn of >370° while building from 23°-91°.READ THE FULL CASE STUDYOPTIMIZED DRILLING UNSURPASSED HOLE QUALITY11OPTIMIZED DRILLING An operator needed to drill an extended-reach lateral totaling 21,548 ft MD, targeting two different layers in a field containing hard and abrasive sands. Torsional stick-slip and high wear-and-tear on drilling equipment were expected. Working with Baker Hughes, the client chose the new 4¾ in. AutoTrak eXact system because its steering capabilities best matched the operational requirements.Despite the challenging conditions and highly-deviated well path, the system set three new records and saved 1.5 days compared to a previous record-setting run. The AutoTrak eXact system used continuous proportional steering to:• Drill up to 5% faster than the best offset• Extend the average run length by up to 15%• Achieve 7,296 ft of pay zone exposure MIDDLE EAST CLICK OR TAP THE TABS BELOW TO LEARN MOREThese operators got the performance they needed from their RSS New field re cords f or ROP and r un le ngth with AutoTrak eXact Previous ROP record (competitor RSS)Previous run length record (competitor RSS)AutoTrak eXact ROP on same deployment 05811141720500100015002000RUN LENGTH (FT)A V E R A G E R A T E O F P E N E T R A T I O N (F T /H R )2500Using an AutoTrak eXact system, an operator in the Middle East set three new records while drilling a highly deviated well path through a challenging formation.READ THE FULL CASE STUDYUNSURPASSED HOLE QUALITYEXACT WELL PLACEMENTGet the superior drilling performance you deserve. Smooth. Fast. Precise.Contact your Baker Hughes representative today to learnmore about how an AutoTrak system—the only RSS capableof delivering Continuous Proportional Steering—can help youget the drilling performance you crave.© 2020 Baker Hughes Company. All rights reserved. 81541。

POLISHING 5” TIEBACK SLEEVEFOR KOC WELL – RA-222.Page 1Date :- 2015-5-24 Revision :- 00By :- Phil Whyte. File :- polish mill.docRunning ProcedureItems to be checked at the workshop prior to being sent to the rig:1. All OD and ID’s.2. Confirm with the rig site the size, weight and grade the equipment is to be run in.3. Ensure all equipment is compatible with the liner that has been installed.At the rig site:1. Run in hole with Polish Mill to 10-15 feet above Tieback Sleeve.2. Establish circulation/rotation and slowly lower Polish Mill into the Tieback Sleeve.3. With the Polish Mill entering the Tieback Sleeve, a pressure increase should benoted. Mark Drill Pipe at this point. Begin rotation w/10 RPM and slowly lower Polish Mill down XX ft. until the Dress Mill takes weight. Set Down A Max Of 2000 # And Mark Pipe. Pick Up To 1st Mark and Increase To 20 RPMS and Repeat. Increase Rotation To 30,40,50 + 60 RPMS. Cleaning out should be performed with approx. 50 - 60 rpm @ 3bbl/min. With A Max Set Down Weight On The Dress Mill With. 5000#. Make 4 to 5 passes with the Polish Mill Assembly. On The Last Pass Pick Up So That The Polish Mill Is At The Liner Top. Rotate W/ 60 RPM+ Circ. For 5 Mins. Observe Well.4. Pull out of hole.。

页岩气水平井泵送桥塞射孔联作常见问题及对策刘祖林;杨保军;曾雨辰【摘要】泵送桥塞+射孔联作分段压裂近年来在国内外页岩气藏及致密气藏开发中广泛应用。

在页岩气水平井泵送桥塞射孔联作分段压裂实践中遇到了泵送桥塞因压力高而不能泵送、桥塞坐封不丢手、桥塞坐封时电缆不点火、电缆点火后桥塞不坐封、射孔枪不响或2簇射孔只射1簇、连续油管射孔意外丢手等各种问题。

针对所出现的问题进行原因分析,制定了防范措施和解决方案,现场实施后各页岩气井水平井段的压裂改造施工得以完成,所取得的经验和教训可供今后同类井施工借鉴和参考。

%In recent years, the pumping bridge plug and clustering perforation technique has been widely used in staged fracturing of shale gas and tight gas reservoirs at home and abroad. In practical operations in horizontal shale gas wells, various problems have been found, such as failed pumping or release of pumping bridge plug due to high pressure, plug setting without cable igniting, plug not set after cable igniting, dumb shooting of the perforating gun or only 1 of 2 clusters shot, and accidental release in coiled tubing perforat-ing. Based on cause analysis for these problems, appropriate preventive measures and solutions are proposed. They have been applied practically to facilitate the fracturing treatment of horizontal shale gas wells. The experiences and lessons thereof will be meaningful references for staged fracturing operations in similar wells.【期刊名称】《石油钻采工艺》【年(卷),期】2014(000)003【总页数】4页(P75-78)【关键词】页岩气;水平井;泵送桥塞射孔联作;事故处理;预防措施【作者】刘祖林;杨保军;曾雨辰【作者单位】中原石油工程有限公司井下特种作业公司,河南濮阳 457164;中原石油工程有限公司井下特种作业公司,河南濮阳 457164;深圳市百勤石油技术有限公司,广东深圳 518054【正文语种】中文【中图分类】TE357.1页岩储层具有典型的低孔低渗物性特征,国外页岩气开发的成功经验表明,水平井及分段大型压裂改造是页岩气开发的主体技术[1-3]。

贪吃蛇技术哪家强?国内外七大公司旋转导向技术盘点旋转导向钻井技术已经逐渐成为定向井、水平井钻井的主要工具,但主流技术依然以国外油服产品为主。

在多年持续攻关下,国产自主创新技术现已取得多项重大突破,国内外技术差距正在逐步缩小。

当前,油气勘探开发过程正面临的挑战日益严峻。

在资源品质劣质化、勘探目标多元化、开发对象复杂化等愈发恶劣的勘探开发大环境下,我国油气勘探开发领域正在由常规油气资源向“三低”、深层及超深层、深水及超深水等非常规资源拓展。

而作为油气资源勘探开发过程中的关键环节,现有的钻井技术在应对上述挑战时却略显勉强。

中石油经研院石油科技研究所总结出了“未来10年极具发展潜力的20项油气勘探开发新技术”(点击查看:颠覆传统!未来十年这些油气勘探开发新技术最具潜力),其中,“智能钻井技术”位列其中。

未来的智能钻井主要由智能钻机、智能导向钻井系统、现场智能控制平台、远程智能控制中心组成。

智能导向钻井系统主要利用随钻数据的实时获取、传输与处理,通过井下控制元件对钻进方向进行智能调控,从而提高钻井效率和储层钻遇率。

作为页岩气开发的“芯片”式技术,旋转导向钻井尚且年轻,但实际上从上世纪90年代起,国际各大油服公司便相继实现了旋转导向系统的现场应用。

经过20余年的技术发展,油服巨头均取得了阶段性进展,并形成了各自的核心技术体系(点击查看:五大油服的旋转导向系统大比拼)。

目前的主流旋转导向技术主要来自几大国际油服巨头,并基本形成了两大发展方向:一是以贝克休斯AutoTrak系统为代表的不旋转外筒式闭环自动导向钻井系统,这类系统以精确的轨迹控制和完善的地质导向技术为特点,适用于开发难度高的特殊油藏导向钻井作业;二是以斯伦贝谢PowerDrive系统为代表的全旋转自动导向钻井系统,这类系统以同样精确的轨迹控制和特有的位移延伸钻井能力为特点,适用于超深、边缘油藏的开发方案中的深井、大位移井的导向钻井作业。

01. 各大油服核心技术对比大宗商品价格暴跌给服务公司的定价和付款时间表带来了下行压力。