手持式多功能校准器 (U1401B 系列)

- 格式:pdf

- 大小:4.78 MB

- 文档页数:157

产品样本 05.2014高压变频器满足最高要求的变频器选择—— 可靠、精确、耐用西门子变频器是世界上最畅销的高压交流变频器,具有下列显著的综合优势:• 较低的运行成本• 精确的过程控制• 较低的维护成本• 提高生产效率• 杰出的可靠性• 直观的人机界面SINAMICS 完美无谐波GH180变频器应用在电力、石油、化工、采矿、冶金、市政等各种工业行业,帮助您显著提高生产率、增强能源利用率和降低运行成本。

使其成为高可靠性、高精度、长使用寿命的变频应用之首选。

SINAMICS 完美无谐波 GH180 系列高压变频器性能和价值的完美结合能源机构研究资料表明,工业电机每年耗费数万亿度的电能,超过全球全部用电量的50%。

优化的系统设计,效率更高的传动系统以及变频调速设备的应用等都将有助于降低能量消耗。

这意味着选择合适的变频器可以实现对电机、风机、泵和其他设备更为精确、有效的控制,从而有助于降低运行成本。

如果您的生产工艺过程使用了电机、风机或泵类,并且未安装变频器,您会由于过程效率低下而使每月能源成本达上千万美元。

2西门子可提供为客户量身定制的SINAMICS 完美无谐波GH180变频器,从而尽可能的提高效率。

我们是唯一一家可提供功率范围为225至120,000kW变频器的公司。

完美无谐波GH180变频器在全球总装机容量超过220万千瓦,久经考验的完美无谐波GH180 变频器可以承担您所交付的重任。

光明的前途建立在坚实的基础之上完美无谐波GH180变频器于1994年问世,是变频器行业的一次重大技术变革,在可靠性和创新方面不断树立工业标准。

伴随着电力电子功率器件技术进步,西门子对完美无谐波GH180变频器进行了持续的改进,表现在以下三个方面:提高可靠性和可用性、提高效率和减小变频器尺寸。

我们保持了完美无谐波GH180变频器的核心拓扑,并不断提高其性能,确保为产品提供支持。

通过保持相同的拓扑,降低了客户的维护、备件方面的成本,提高了产品质量,降低全周期成本。

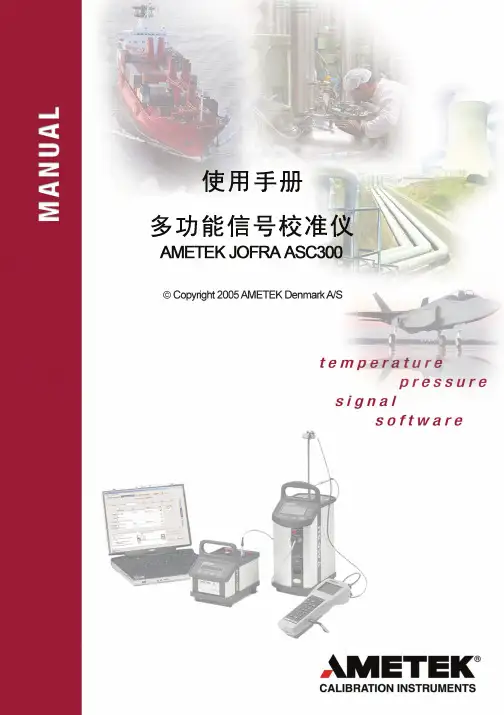

AMETEKASC300手持式多功能校准仪使用手册美国阿美特克公司图1 输入输出端子1.仪表布局表1 输入输出端子NO. 名称功能1,2 测量V, mA端子测量电流电压并提供回路电源3 TC测量和输出测量或模拟输出热电偶信号4,5 测量/输出V,RTD 2W,Hz测量或输出电压,频率,脉冲,2线热电阻6,7 测量/输出mA,3w,4wRTD 测量或输出电流,3线,4线热电阻8 压力模块接口连接外接压力模块测量压力9 串行通讯接口连接计算机实现远方控制图2显示了键盘的布局NO 名称功能1 F1,F2,F3功能键用来操作屏幕底部显示的菜单.2 BACK LIGHT背景光打开或关闭背景光3 HOME主菜单回到屏幕上的主菜单4 POWER电源校准仪电源开关5 0% 将键盘输入的一个值作为量程的0%.从内存中调出0%量程的值并作为输出值输出信号.6 25%以满量程25%增量的比例循环输出7 100% 将键盘输入的一个值作为量程的100%.从内存中调出100%量程的值并作为输出值输出信号.8 数字键允许用户直接输入数字图2 键盘2.屏幕和菜单2.1.屏幕显示图3 屏幕显示整个屏幕被划分为三个部分,上面的显示用来测量电压,电流和压力,下面的显示用来测量和输出各种参数,底部的菜单用来设置上面和下面屏幕的各种功能.表3 屏幕显示NO 名称功能1 主参数将要被输出或测量的参数.上面的屏幕主参数包括:VOLTS IN(电压输入),PRESSURE(压力),mA IN(测量电流),mA LOOP(测量电流内置回路电源)中间的屏幕的主参数包括:VOLT(电压),TC(热电偶),RTD(热电阻),FREQ(频率),PULSE(脉冲),PRESSURE(压力),MA(电流),MA 2W SIM(2线电流模拟)2 测量/输出控制切换中间的屏幕到测量(输入)或输出状态3 附加设置仅对TC和RTD有效.在TC状态下可以打开或关闭CJC(冷端补偿). 在RTD IN状态下指示2,3,4线制.4 量程百分比指示仅在mA和mA LOOP状态下有效.4mA对应0%,20mA对应100%.5 单位表示测量或输出值的单位,例如℃,℉,Hz,KHz,CPM6 温度探头类型表示热电阻和热电偶的分度号.也表示输出脉冲和频率的幅值以及压力单位7 数字显示显示信号的数字值.”OL”表示超出量程2.2 操作菜单屏幕上的各种参数需要通过菜单来控制调整.功能键F1,F2,F3用来设置菜单,这三个键分别对应菜单条的左,中,右三个菜单栏.任何时候按下HOME键可进入如下菜单,即总菜单.在总菜单中按F1可进入下一层菜单.总菜单中又包括三种总菜单:输入总菜单,输出总菜单和脉冲总菜单.在输入总菜单中只有MENU 一个键有效.输出总菜单下有三个有效的选项.除了MENU以外还有上下箭头用来调整输出值.频率总菜单下也有三个有效键,参见4.2-6总菜单下就是主菜单,主菜单中UPPER用来选择上面的屏幕,LOWER选择中间的屏幕.按下MORE可以进入设置状态,可以设置CONTRAST(屏幕对比度)按下NEXT可进入自动关机设置(AUTO OFF),调整自动关机时间.当校准仪处于频率状态时,从主菜单按MORE可进入频率幅值设置(FREQ LEVEL),用来调整输出频率的幅值.当校准仪处于RTD CUSTOM(自定义热电阻)状态时,通过主菜单按MORE可进入热电阻自定义菜单(SET CUSTOM),这项功能可以自定义热电阻参数.从主菜单按MORE 可进入压力清零菜单,可以对外接压力模块清零.在主菜单中选择了LOWER或UPPER后就进入了参数选择菜单.在这个菜单中SELECT用来用来改变参数内容,NEXT可以切换到下一个变量,DONE用来确认所选择参数和状态并回到主菜单.图4 菜单树3.使用测量模式(下屏幕)3.1测量电压和频率1.从主菜单中按LOWER进入中间的屏幕设置2.选择需要测试的参数3.如图5接线.图5 使用输入/输出端子测量电压或频率3.2测量mA电流1.切换到中间屏幕选择mA IN.2.如图6接线图6 测量mA3.3测量温度3.3.1使用热电偶校准仪支持B,C,E,J,K,L,N,R,S,T,U,BP,XK分度号的热电偶.CJC(冷端补偿)应该打开,这样测试的温度就是真实温度,只有在外部使用了冰点器时才可以关闭冷端补偿.1.如图7接线,将小插头插入校准仪接口.补偿导线必须和分度号对应.(最好等2到5分钟后进行测试,这样可以使小插头和校准仪的温度稳定.2.从主菜单按LOWER切换到中间屏幕.3.选择TC IN测试功能,并选择适当的分度号和温度单位.(校准仪也可以测试mV值,这样可以测试校准仪不支持的分度号.在探头种类参数中可以找到mV测量).图7使用热电偶测试温度3.3.2使用热电阻(RTD)可以使用2,3,4线制.如下图所示.(电阻测量功能可以通过选择探头种类而实现)图8使用热电阻测试温度3.4测试压力注意:高的压力系统存在危险,注意缓慢泄压.给压力模块加压不能超过最高限压.1.如图接线.压力可以在上屏幕和中间屏幕测量,这就可以同时使用两种单位测压.2.选择屏幕和压力测量,以及压力单位,测试之前对压力模块清零.(绝压模块清零参见模块说明)图9压力测试连接4.使用输出模式(下屏幕)ASC300校准仪可以输出标准信号用来测试和校准过程仪表.它可以输出电压,电流,电阻,频率,脉冲,和RTD,TC的电信号.4.1设置0%和100%输出参数1.从主菜单选择LOWER进入中间屏幕,选择合适参数.2.选择输出模式并给出具体值,例如选择VOLT OUT电压输出.3.用键盘输入5V,之后不按ENTER确认键,而是按0%键,这样就设置5V作为0%点4.输入20V并按100%,这就定义20V就是100%的值.5.使用25%键就可以在5V到20V之间以25%的增量循环.4.1.1电流输出步进使用mA输出25%步进功能如下操作1.选择中间的屏幕并选择mA.2.使用25%键就可以在4-20mA之间循环步进.4.2输出mA1.从主菜单选择中间屏幕并选mA作为主参数.2.选择OUT输出模式3.如下图连接电路4.用键盘直接输入电流值.图10输出电流4.3模拟变送器ASC300可以在电路中代替变送器并控制回路中的电流.1.从主菜单选择中间屏幕2.选择mA 2W SIM电流模拟功能并输入电流值3.如图接线图11模拟变送器4.4输出电压在中间屏幕选择电压输出VOLT OUT功能并如图接线.图12输出电压和频率4.5输出频率如上图接线,选择中间屏幕频率输出功能并选择单位,如果需要可改变频率幅值.4.6输出脉冲串1.选择下屏幕设置主参数为PULSE脉冲2.选择合适的单位并用键盘输入频率值3.从主菜单选择COUNTS功能并输入脉冲串数.使用TRIG功能开始或停止信号输出.4.脉冲的幅值可以调整,和频率幅值的调整方法一样.4.7输出热电偶如图接线并设置校准仪到TC OUT状态,选择合适的分度号和单位.图13 输出热电偶的连接图14输出热电阻接线4.8输出电阻/热电阻如图14接线,选择下屏幕,并设置状态到RTD OUT,选择合适的分度号和单位.图15 使用3线制和4线制测试热电阻接线4.8.1自定义RTD用户可以输入自定义分度表,步骤如下:1.切换到下屏幕,选择RTD并将探头种类选择为CUSTOM2.进入RTD自定义设置菜单,选择SET CUSTOM3.使用键盘输入各种参数:最小温度,最大温度,R0,以及每一个温度系数.5.使用测量功能(上屏幕)5.1测量电压和mA电流如下图接线并设置上屏幕到相应参数.图16隔离输入连接5.2内部回路电源供电测量电流测试2线制变送器可以用ASC300校准仪给变送器供电同时测量电流,如下图连接电路并设置上屏幕到mA LOOP状态.图17使用电流回路5.3测量压力如下图连接线路,在上屏幕选择PRESSURE参数进行压力测试.图18测试压力6.同时使用上下屏幕进行校准和测试图19输出信号给其它仪器6.1测试一个测量或指示设备利用ASC300输出功能可以测试和校准执行器,记录仪或其它指示设备.1.选择下屏幕并设定相应输出参数2.选择OUT输出信号3.连接线路如图19进行测试和校准6.2校准一个温度变送器1.以热电偶变送器为例,选择上屏幕测量电流mA LOOP.2.选择下屏幕,设置TC OUT进行热电偶输出并选择合适的分度号和温度单位3.根据温度量程设置0%和100%范围4.如图接线5.用25%键步进测试变送器0-25-50-75-100各点.6.如果需要调整变送器,并纪录校准数据图20校准温度变送器6.4校准压力变送器1.选择上屏幕,设置mA LOOP进行电流测量2.选择下屏幕选择PRESSURE测试压力3.如图22接线4.对压力模块清零5.测试压力变送器0%和100%,如果需要进行调整.图21校准压力变送器7.计算机控制ASC300可以和计算机连接进行通讯,通过WINDOWS操作系统的超级终端软件可以控制ASC300校准仪实现各种输入输出功能.图22与计算机连接8.指标如无特殊说明,指标是在环境温度23°C ±5°C进行测试得到的结果. 超过此温度范围的补偿系数为± 0.005%读数/°C.一般指标操作温度-10°C to 50°储存温度-20°C to 70°C电源 4 X AA 电池低电压报警Yes串行通讯接口Yes, A SCIICE – EMC认证EN50082-1: 1992 and EN55022: 1994 Clas s B 安全CSA C22.2 No. 1010.1: 1992DC 电压测量/输出量程准确度(% 读数±基数)0.000V– 30.000V0.015% ± 2mV测量:隔离(上屏幕)0.000V – 20.000V0.015% ± 2mV测量:非隔离(下屏幕)输出0.000V – 20.000V0.015% ± 2mV 在电压量程内最大输出电流 1mA,输出内阻 <= 1Ω.DC mA测量/输出量程准确度(% 读数±基数)0.000mA – 24.000mA0.015% ± 2µA测量:隔离(上屏幕)0.000mA – 24.000mA0.015% ± 2µA测量:非隔离(下屏幕)输出0.000mA – 24.000mA0.015% ± 2µA 最大负载 1000Ω.在电流模拟状态下电压输入范围5V – 30V.频率测量/输出量程准确度(% 读数±基数) 测量 2.0CPM – 600.0CPM 0.05% ± 0.1CPM1.0Hz – 1000.0Hz 0.05% ± 0.1Hz1.00KHz – 10.00KHz 0.05% ± 0.01KHz输出 2.0CPM – 600.0CPM 0.05%1.0Hz – 1000.0Hz 0.05%1.00KHz – 10.00KHz 0.125%测量频率电压幅值1V to 20V.输出幅值 1V to 20V可调电阻测量量程准确度(% 读数±基数) Ohms low 0.00Ω - 400.0Ω0.025% ± 0.05ΩOhms high 401.0Ω - 4000.0Ω0.025% ± 0.5Ω电阻输出量程激励电流准确度(% 读数±基数) Ohms low 5.0Ω - 400.0Ω0.1mA – 0.5mA 0.025% ± 0.1Ω5.0Ω - 400.0Ω0.5mA – 3mA0.025% ± 0.05ΩOhms high 400Ω - 1500Ω0.05mA – 0.8mA 0.025% ± 0.5Ω1500Ω - 4000Ω0.05mA – 0.4mA 0.025% ± 0.5ΩNote:兼容智能变送器和plcs. 频响 <= 5ms.热电偶测量/输出量程准确度(% 读数±基数) 测量(mV) -10.000mV – 75.000mV 0.02% ± 10µV输出 (mV) -10.000mV – 75.000mV 0.02% ± 10µV最大输出电流1mA,内阻 <= 1Ω热电偶测量/输出( °C)TC 类型量程(°C) 准确度J -210.0 – 0.0 0.60.0 – 800.0 0.4800.0 – 1200.0 0.5K -200.0 – 0.0 0.80.0 – 1000.0 0.51000.0 – 1372.0 0.7T -250.0 – 0.0 0.8E -250.0 – -100.0 0.8-100.0 – 1000.0 0.4 R 0.0 – 1767.0 1.4S 0.0 – 1767.0 1.4B 600.0 – 800.0 1.4800.0 – 1000.0 1.51000.0 – 1820.0 1.7C 0.0 – 1000.0 0.81000.0 – 2316.0 2.5 XK -200.0 – 800.0 0.4BP 0.0 – 800.0 1.1800.0 – 2500.0 2.5 L -200.0 – 0.0 0.450.0 – 900.0 0.4TC 类型量程(°C) 准确度U -200.0 – 0.0 0.70.0 – 600.0 0.45N -200.0 – 0.0 1.00.0 – 1300.0 0.6 包括冷端补偿冷端补偿误差在 23 ± 5°C 之外 0.05°C/°C热电阻测量/输出RTD 类型量程(°C) 准确度Ni120 (672) -80.0 – 260.0 0.2 Cu10 -100.0 – 260.0 1.4Cu50 -180.0 – 200.0 0.4Cu100 -180.0 – 200.0 0.3YSI400 15.00 – 50.00 0.1 Pt100 (385) -200.0 – 100.0 0.2100.0 – 300.0 0.3300.0 – 600.0 0.4600.0 – 800.0 0.5 Pt200 (385) -200.0 – 100.0 0.8100.0 – 300.0 0.9300.0 – 630.0 1.0 Pt500 (385) -200.0 – 100.0 0.4100.0 – 300.0 0.5300.0 – 630.0 0.6 Pt1000 (385)-200.0 – 100.0 0.2100.0 – 300.0 0.3300.0 – 630.0 0.4 Pt385-10 -200.0 – 100.0 1.4300.0 – 600.0 1.8600.0 – 800.0 2.0 Pt385-50 -200.0 – 100.0 0.4100.0 – 300.0 0.5300.0 – 600.0 0.6600.0 – 800.0 0.7 Pt100 (3926)-200.0 – 100.0 0.2100.0 – 300.0 0.3300.0 – 630.0 0.4 Pt100 (3916) -200.0 – 100.0 0.2100.0 – 300.0 0.3300.0 – 630.0 0.4 4线制接线. 3线制误差加± 0.05Ω .阿美特克北京代表处地址:北京建国门外大街19号国际大厦2305室邮编:100004电话:************传真:************网址:。

DPI 610/615 Series is a Druck product. Druck has joined other GE high–technology sensing businesses under a new name—GE Sensing.g•Ranges -14.7 to 10,000 psi•Accuracy from 0.025% full scale (FS)•Integral combined pressure/vacuum pump •Dual readout: input and output•4 to 20 mA loop test: auto step and ramp •Intrinsically safe (IS) version•RS232 interface and fully documenting version •Remote pressure sensorsFeaturesDruck PortablePressure CalibratorsDPI 610/615 SeriesThe technically advanced Druck DPI 610 and DPI 615portable calibrators are the culmination of many years of field experience with the company’s DPI 600 series.These self-contained, battery powered packages contain a pressure generator, fine pressure control, device energizing (not IS version) and output measurement capabilities, as well as facilities for 4 to 20 mA loop testing and data storage. The rugged weatherproof design is styled such that the pressure pump can be operated and test leads connected withoutcompromising the visibility of the large dual parameter display. The mA step and ramp outputs and a built-in continuity tester extend the capabilities to include the commissioning and maintenance of control loops.Setting the Standard for Portable Pressure CalibratorsA highly accurate and easy to use calibrator is only part of the solution for improving overall data quality and working efficiency. The DPI 610 and DPI 615, with data storage and RS232 interface, reduce calibration times and eliminate data recording errors. The DPI 615 also provides error analysis for field reporting of calibration errors and pass/fail status. In addition, procedures downloaded from a PC automatically configure theDPI 615 to pre-defined calibration and test routines. Improved performanceThe DPI 610/615 Series combine practical design with state-of-the-art performance, summarized as follows: Accuracy0.025% FS for ranges 2.5 to 10,000 psiRanges 1 psi to 10,000 psi including gauge, absolute anddifferential versionsIntegral Pneumatic–22 inHg to 300 psiPressure SourceIntegral Hydraulic0 to 6000 psiPressure SourceMeasure Pressure, mA, V, switch state (open/closed) andambient temperatureOutput: Pressure, mA step, mA ramp, mA value Energizing Supplies10 and 24 VDC (not IS version)Data Storage92 KbytesDocumenting (DPI 615 only)Error analysis with pass/fail status and graphs.Two-way PC communication for transferringprocedures and resultsRemote pressure sensors Up to 10 digitally characterized sensors percalibratorSimplified OperationGE’s knowledge of customer needs, combined with innovative design, results in high performance,multi-functional calibrators that are simple to use. The key to simple operation is the Task Menu. Specific operating modes such as P-I, switch test and leak test are configured at the touch of a button by menu selection.Featuring highly reliable pneumatic and hydraulic assemblies and self-test routines, the DPI 610/615 Series can be relied upon time and time again for field calibration in the most extreme conditions.The DPI 610 and DPI 615 have been designed for ease of use while meeting a wide range of application needs including calibration, maintenance and commissioning. The Intrinsically Safe versions, certified to European and North American standards for use in hazardous areas,reduce response times to breakdowns and emergencies by removing the need for ’Hot Permits‘ and gas detection equipment. This gives peace of mind to all those responsible for safety within hazardous areas.The dual parameter display shows the Input and Output values in large clear digits. A unique built-in handle provides a secure grip for on-site use in addition to a shoulder strap which is also designed to allow the instrument to be suspended for hands-free operation.Any technician can use these calibrators without formal training, such as a novice on an emergency call out, or those familiar with the DPI 601. By selecting basic mode the calibrator is configured to source pressure and measure mA or V, with all non-essential keys disabled.Dedicated Task MenuThe dedicated task key gives direct access to the task menu. Select the required test, for example P-I for a pressure transmitter, and with a single key press, the calibrator is ready.Use the advanced mode for custom tasks and add to the user task menu for future use.Some of the CapabilitiesP mA V10 V*24 V*Switch°FMeasure __Source _ __P = PressureF = Local ambient temperature* = Not ISPressure Transmitter CalibrationThe P-I task configures the DPI 610/615 Series to simultaneously display the output pressure and the input current. The pressure unit can be chosen to suit the transmitter and a 24 V supply is available forloop-power (not IS version).For process transmitters reading in percentage, use % span to scale the pressure accordingly.The DPI 610/615 Series pneumatic calibrator hand-pump can generate pressure from -12 to 300 psi. The volume adjuster gives fine pressure setting and the release valve also allows gradual venting for falling calibration points.Reduce the burden imposed by quality systems such as ISO 9000, simply store results in memory and leave bothpen and calibration sheet back at the office.Pressure Switch Testing and Leak TestingFor switch set-up and fault finding, the display shows the output pressure and switch state open or closed.Continuity is declared by an audible signal.Verify pressure switch performance using the automatic procedure. The DPI 610/615 Series displays the switch points and the contact hysteresis.Leak test will check for pressure leaks prior tocalibration or during routine maintenance. Define the test times or use the defaults and wait. The DPI 610/615Series will report the start and stop pressures, the pressure change and the leak rate.Take a ‘snapshot’ of the working display; all details are stored in a numbered location for later recall.Loop Testing and Fault FindingThe DPI 610/615 Series can generate a continuous mA step or mA ramp output, allowing a single technician to commission control loops.Feed the loop using mA step or mA ramp and at the control room, check the instrumentation.Use mA value for alarm and trip circuit tests. Any mA output can be set and adjusted from the prehensive process features aid flow and levelmeasurement and help with troubleshooting. Select tare,maximum/minimum, filter, flow or %span and the function will be applied to the input parameter.Save time in fault finding, by leaving the DPI 610/615Series to monitor system parameters. Use periodic data log or the maximum/minimum process function tocapture intermittent events.Remote Pressure SensorsBy adding up to 10 external sensors (one at a time) the working ranges of the DPI 610 and DPI 615 can be extended. Modules from 1 inH 2O to 10,000 psi are available to suit most applications.As a leading manufacturer of pressure sensors GE has applied the latest silicon technology and digital compensation techniques to develop these sensors.Remote sensors offer a cost-effective means ofexpanding the capabilities of the DPI 610 and DPI 615, for example, in the following applications:•Low pressure•Pressure-to-pressure •Differential pressure•Wide range, high-accuracy •Test-point monitoring•To prevent cross contamination•To configure pneumatic calibrators for high pressure hydraulic systems•To configure hydraulic calibrators for low pressurepneumatic systemsDPI 615 Portable Documenting Pressure CalibratorThe DPI 615 adds powerful time saving and erroreliminating features to the comprehensive functionality of the DPI 610. These include field error calculations with PASS/FAIL analysis and two way PC communications for downloading procedures and uploading results.Reporting Errors in the FieldThe DPI 615 calculates errors and reports the pass/fail status during field tests. Problems and failures can be analyzed graphically for immediate assessment and correction. This simple to use feature reduces calibration and maintenance times and eliminates human errors.Completing the Paper TrailIt takes longer to fill out a calibration report, calculate the errors and assess the results than it does to calibrate the transmitter. With the DPI 615, documents can be quickly completed either on site or, at a more convenient time and location, by recalling the information from the DPI 615’s memory.Calibration Management SystemsWhen used in conjunction with calibration management software the DPI 615 greatly reduces the financial and resource burden imposed by quality systems such as ISO 9000. As work orders are issued, object lists and procedures are downloaded to the DPI 615. In the field these procedures configure the instrument for the tests.The errors and pass/fail status are reported and recorded in memory (as found or as left results) for later upload to the software. Calibration certificates can then be printed and plant maintenance systems updated. The wholedocumenting process is completed in a fraction of the time it takes using manual systems and without human error.For information on Intecal calibration software please visit . The DPI 615 is also compatiblewith many third party software systems.DPI 610/615PC Pneumatic CalibratorHand-Pump-22 inHg to 300 psi capability Volume AdjusterFine pressure adjustment Release ValveVent and controlled release Pressure Port 1/8 NPT female MediaMost common gasesDPI 610/615LP Low Pressure CalibratorVolume AdjusterDual piston for coarse/fine pressure setting Release ValveVent and controlled release Pressure Ports 1/8 NPT female MediaNo corrosive gasesPlease refer to the specifications page for more information.DPI 610/615SpecificationsDPI 610/615HC Hydraulic CalibratorPriming PumpFeeds from external source Shut-off ValveOpen for system priming Screw Press0 to 6000 psi capability Pressure Port 1/8 NPT femaleMediaDemineralized water and most hydraulic oilsDPI 610/615I IndicatorRelease ValveVent and controlled release Pressure Port 1/8 NPT femaleMediaMost common fluids compatible with stainless steelPressure RangesThe DPI 610/615 PC, HC, LP and I include an integral sensor, the range of which should be specified from the list below. Up to 10 remote sensors (option B1) may also be ordered per calibrator.Stability0.015% of reading/annumSpan Shift0.5%/500 psi of line pressure for differential ranges Temperature Effects±0.002% reading/°F averaged over –15°F to 105°F and w.r.t. 68°FRemote Sensor MediaStainless steel and hastelloy compatibility. Negative Differential: stainless steel and quartz compatibility.OverpressureSafe to 2 x FS except (1) 500 psi maximum, (2) 9000 psi maximum, (3) 5000 psi maximum(1), (2) and (3) refer to pressure range table Electrical Stability0.03% of reading/annumPressure Pneumatic HydraulicIndicator Remote Accuracy Range DPI 610PC/DPI 610HC/DPI 610I/Option % FS DPI 615PCDPI 615HC DPI 615I (B1)1 psi (-1) G —G G or D 0.052.5 psi (-2.5) G —G G or D 0.0255 psi (-5) G or A —G or A G, A or D 0.02510 psi (-10) G or A —G or A G, A or D 0.02515 psi (-15) G or A —G or A G, A or D 0.02530 psi (-15) G or A —G or A G, A or D 0.02550 psi (-15) G or A —G or A G, A or D 0.025100 psi (-15) G or A —G or A G, A or D 0.025150 psi (-15) G or A —G or A G, A or D 0.025300 psi (-15) G orA (1)—G or A G, A or D 0.025500 psi (-15) ——G or A G,A or D 0.0251000 psi (-15) ——G or A G or A 0.0251500 psi ——SG or A SG or A 0.0252000 psi ——SG or A SG or A 0.0253000 psi —SG or A SG or A SG or A 0.0255000 psi —SG or A SG or A (3)SG or A 0.0256000 psi —SG or A (2)——0.02510000 psi ———SG or A0.025•Values in ( ) indicate negative calibration for gauge and differential ranges•A = Absolute, D = Differential (500 psi) line pressure, G = Gauge, SG = Sealed Gauge •(1), (2) and (3) refer to over pressure•Accuracy is defined as non-linearity, hysteresis and repeatabilitySpecial FeaturesPressure Units25 scale units plus one user-defined mA stepContinuous cycle at 10 sec intervalsmA rampContinuous cycle with configurable end values and 60 second travel timeData LogMulti-parameter with internal memory for 10,000 values.Variable sample period or log on key pressSnapshotPaperless notepad. Stores up to 20 complete displays Computer Interface RS232Process FunctionsTare, maximum/minimum, filter, flow, % spanLanguagesEnglish, French, German, Italian, Portuguese and SpanishElectrical InputsInput Range AccuracyResolution RemarksVoltage*±50 VDC±0.05% reading 100 μV Autoranging, > ±0.004% FSmaximum10 M Ω±30 VDC(IS version)Current*±55 mA±0.05% reading 0.001 mA10Ω, 50 V ±0.004% FSmaximum(30 V maximum IS version)Temperature 15°F to 105°F ±2°F 0.2°FLocal ambient Switch Open/closed ____5 mA*Temperature coefficient ±0.004% reading/°F wrt 68°FElectrical OutputsOutput Range Accuracy ResolutionRemarks Voltage 10 VDC±0.1%__Maximum (Not IS load 10 mA version)24 VDC ±5%__Maximum load 26 mACurrent*0 to 24 mA±0.05% reading 0.001 mA__±0.01% FS*Temperature coefficient ±0.004% reading/°F wrt 68°FFor IS version Ui = 30 V maximum, Ii = 100 mA maximum, Pi = 1 W maximum and Uo = 7.9 V maximumElectricalFunctionmA Output 4 to 20 mA linear 48121620____0 to 20 mA linear 05101520____4 to 20 mA flow 4581320____0 to 20 mA flow 0 1.25511.2520____4 to 20 mA valve3.844.212192021Please refer to specifications for ranges and associated accuracy.At least one mating cable is required per DPI 610 when ordering remote pressure sensors. See Option (B2).(B2)Mating Cable for Remote SensorsA 6 ft mating cable for connecting remote sensors to the calibrator. At least one cable should be ordered when ordering Option (B1).(B3)Calibration of Special Remote Pressure Sensor(150 mV maximum) (Not available on IS version)(C)1/8 NPT Female AdaptorA stainless steel adaptor and bonded seal toconvert the standard G 1/8 female pressure port to 1/8 NPT female.(D1)Intecal BasicDeveloped to meet the growing demand on industry to comply with quality systems and calibration documentation. Test procedures are created in a Windows ®based application and devices aregrouped into work orders for transfer to the DPI 325, DPI 335, DPI 605, DPI 615, TRX II and MCX II. Calibration results are uploaded to the PC for analysis and to print calibration certificates.(D2)Intecal AdvancedBuilds on the concept of Intecal for Industry supporting both portable calibrators and on-line workshop instruments. Intecal is a simple-to-use calibration management software, which enables a high productivity of scheduling, calibration and documentation.Visit for more information and free 30 day download.(E1)Dirt/Moisture TrapWhere a clean/dry pressure media cannot beguaranteed, the IDT 600 dirt/moisture trap prevents contamination of the DPI 610/615 pneumatic system and eliminates cross-contamination from one device under test to another.AccessoriesThe DPI 610 is supplied with carrying case, test leads,user guide and calibration certificate with data, asstandard. The DPI 610HC also has a 8 oz polypropylene fluid container and priming tube. (Alkaline batteries supplied for the IS version).Power ManagementAuto power off, auto backlight off, battery low indicator and status on key pressDisplayPanel2.36 in to 2.36 in graphic LCD with backlight. (Backlight not available on IS version)Readout± 99999 capability, two readings per secondEnvironmentalTemperature•Operating: 15°F to 120°F •Calibrated: 15°F to 105°F Humidity0 to 90%, non-condensing SealingGenerally to Type 12/IP54ConformityEN61010, EN50081-1, EN50082-1, CE marked Intrinsically safe version: Supplied certified for use in hazardous areasEEx ia IIC T4 certificate 2000.1003130To CAN/CSA-E79-11-95 and CAN/CSA E79-0-95 (Class 1,Division I, Groups A,B,C&D)PhysicalWeight: 6.6 lb, size: 11.8 in x 6.7 in x 5.5 inPower Supply•Six 1.5 V 'C' cells, alkaline (up to 65 hours nominal use at 68°F). Rechargeable battery pack and charger are supplied as standard (20 hours nominal use)•Rechargeable batteries and charger/power supply not available for the IS version that uses alkaline batteries only.Options(A)Rechargeable Batteries and ChargerRechargeable battery pack (P/N 191-A022) and 110 VAC charger/power supply (P/N 191-A023). A 220 VAC charger/power supply is also available (P/N 191-129). (Not available for IS version)(B1)Remote Pressure SensorThe DPI 610 and 615 have a second pressure channel that can be configured with up to 10remote sensors (one at a time). For ease of use the sensors are fitted with an electrical connector and 1/4 NPT female pressure port.Calibration StandardsInstruments manufactured by GE Sensing are calibrated against precision equipment traceable to the National Institute of Standards and Technology (NIST). Related Products•Portable field calibrators•Laboratory and workshop instruments•Pressure transducers and transmitters Ordering InformationStandard complete packages are available for ranges 5, 30, 100 and 300 psig. These include user guide, test leads, pressure/vacuum pump, volume adjuster, release valve, carrying case, rechargeable battery pack and charger. When ordering, please state type, pressure range and “complete”, e.g. DPI 610 PC, range 30 psig complete.For other ranges please state the following (where applicable):1.DPI 610 type number, i.e. DPI 610 PC. For IS versionuse the suffix 'S' after the basic model number,e.g. DPI 610S PC or DPI 610S I. (Intrinsically safehydraulic version not available)2.Built-in pressure range; gauge or absolute.3.Options, including range for remote sensors.4.Supporting Services (order as separate items) Options B1 and D should be ordered as separate line items.Supporting ServicesGE sensing provides Services to enhance, supportand complement the Aviation GSE range. Our highly trained staff can support you, no matter where youare in the world. Further details can be found in/productservices/service.htm Pressure measurement trainingGE Sensing's training and education program offers comprehensive standard and customized curricula focusing on operation, application, maintenance and technology.Quality training enables your engineers & technicians to optimize your business' performance.Nationally accredited calibrationNew product is supplied with factory calibration certificates with measurements traceable back to international standards. For applications where initial nationally accredited calibration certificates are required or periodic re-calibration is desired GE sensing can provide the solution.Extended warranty termsNew product is supplied with an industry benchmarked initial warranty. For peace of mind particularly if final installation is months away from your product purchase, extend coverage on your equipment beyond the initial period up to 4 years term.•Improved cost predictability•Increased assuranceMulti-year calibration and repair services agreements Multi-year service agreements increase cost predictability by providing fixed rates for extended periods.RentalGE's rental program offers a simple, quick and affordable solution for unexpected measurement need. Rentals allow customers to be fully operational when challenges that are not foreseen arise. We can provide measurement, test and calibration instruments, from simple pressure indicators to sophisticated air data test systems. The rental fleet is available from inventory, Factory tested & calibrated with a minimum rental period only 1 week. With larger scope undertakings any product can be made available for rental.MaintenanceShould your equipment need maintenance our global repair facilities are happy to serve. Work is conducted by trained approved technicians, using controlled original equipment parts and procedures so restoring the product to design condition. This is particularly important with Intrinsically Safe products operated in hazardous environments and aviation ground support equipmentg©2008 GE. All rights reserved.920-107C All specifications are subject to change for product improvement without notice.GE®is a registered trademark of General Electric Co. Windows®is a registeredtrademark of Microsoft Corporation, which is not affiliated with GE, in the U.S. andother countries. Other company or product names mentioned in this documentmay be trademarks or registered trademarks of their respective companies, whichare not affiliated with GE.。

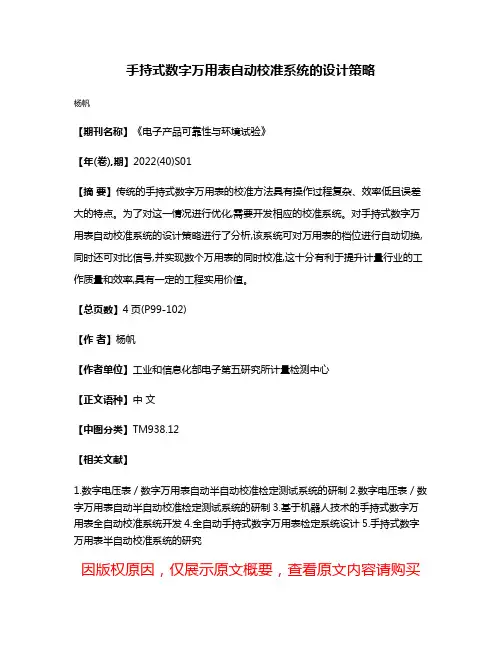

手持式数字万用表自动校准系统的设计策略

杨帆

【期刊名称】《电子产品可靠性与环境试验》

【年(卷),期】2022(40)S01

【摘要】传统的手持式数字万用表的校准方法具有操作过程复杂、效率低且误差大的特点。

为了对这一情况进行优化,需要开发相应的校准系统。

对手持式数字万用表自动校准系统的设计策略进行了分析,该系统可对万用表的档位进行自动切换,同时还可对比信号,并实现数个万用表的同时校准,这十分有利于提升计量行业的工作质量和效率,具有一定的工程实用价值。

【总页数】4页(P99-102)

【作者】杨帆

【作者单位】工业和信息化部电子第五研究所计量检测中心

【正文语种】中文

【中图分类】TM938.12

【相关文献】

1.数字电压表/数字万用表自动半自动校准检定测试系统的研制

2.数字电压表/数字万用表自动半自动校准检定测试系统的研制

3.基于机器人技术的手持式数字万用表全自动校准系统开发

4.全自动手持式数字万用表检定系统设计

5.手持式数字万用表半自动校准系统的研究

因版权原因,仅展示原文概要,查看原文内容请购买。

数字万用表产品大全美国福禄克∙Fluke 28-II 工业多用表新型Fluke 28 II数字多用表树立了在困难情况下进行测量的新标准,它具有优异的功能和准确度,可以轻松解决大多数电气故障。

...∙Fluke 27-II 工业多用表新型Fluke 27 II数字多用表树立了在困难情况下进行测量的新标准,它具有优异的功能和准确度,可以轻松解决大多数电气故障。

...∙Fluke 87V 真有效值数字多用表新推出的Fluke 87V大大改进了测量功能、诊断功能、分辨率和精度,能够更多地解决马达驱动、工厂自动化设备、配电和机电等设备的故障。

...∙Fluke 8062A 四位半数字万用表Fluke 8062A四位半数字多用表具有比一般的手持式数字表更多的测量功能.特别适用于音频、视频、电讯和计算机工业.结合了高准确度,高分辨率,宽频响和坚固耐用等一系列特点,Fluke 8062A为几乎的所有测量提供了理想的工具....∙Fluke 8060A 四位半数字万用表Fluke 8060A四位半数字多用表具有比一般的台式数字表更多的测量功能.特别适用于音频、视频、电讯和计算机工业.结合了高准确度,高分辨率,宽频响和坚固耐用等一系列特点,Fluke 8060A为几乎的所有测量提供了理想的工具....∙Fluke 115C 数字万用表Fluke 115C 数字万用表是供现场维护技术人员使用的紧凑型真有效值仪表,Fluke 115C 是用于广泛的电气和电子测试应用的解决方案....∙Fluke-62IR HVAC电工组合工具包作为一款综合全面的Fluke-62IR HVAC 检修解决方案,Fluke-62IR超值型HVAC 电工组合工具包放在一个精巧的便携包内,随附了HVAC 专业人员需要的所有附件,能够更加高效地排除和解决问题....∙Fluke-116 DMM电工组合工具包作为一款综合全面的HVAC 检修解决方案,Fluke-116超值型HVAC 电工组合工具包放在一个精巧的便携包内,Fluke-116随附了HVAC 专业人员需要的所有附件,Fluke-116能够更加高效地排除和解决问题....∙Fluke 116C 温度及微安电流测量HVAC万用表Fluke 116C 专门为HVAC 专业人员设计.它具有HVAC 仪表所需的各种功能,包括用于对HVAC 设备和火焰传感器进行快速故障排查的温度和微安测量....∙Fluke 18B新型数字万用表Fluke 18B创新的测试发光二极管(LED)功能实现了通过两种模式(插孔检测模式和表笔测试模式)测量2-6V的2脚发光二极管,并且只需要插入或者测量一次,就能判断LED的好坏,同时提示正负管脚位置,Fluke 18B表笔模式还可以在点量LED的同时测量LED的正向导通电压Vf....∙Fluke 233 远程显示多用表新型Fluke 233真有效值远程显示数字多用表让您可以极其灵活地处理那些不同寻常的测量情形.只需把可拆卸的显示屏放在您可以查看的地方,然后把Fluke 233多用表放在任何一个方便的地方—无需为了伸入狭窄的场所而不断地挪动梯子和多用表....∙Fluke 15B数字万用表Fluke 15B是福禄克(FLUKE)生产的一款高性价比数字万用表,由福禄克授权代理商浚海提供.关于Fluke 15B数字万用表价格,欢迎来电咨询....∙Fluke 17B数字万用表Fluke 17B是福禄克(FLUKE)生产的一款高性价比数字万用表,由福禄克授权代理商浚海提供.关于Fluke 17B数字万用表价格,欢迎来电咨询....∙Fluke 179 数字万用表(带红外温度计)Fluke 179 数字万用表是福禄克FLUKE最为通用的数字多用表,Fluke 179 数字万用表同时也是一款可以测量温度的万用表,它是精度、功能性、易用型、安全性和可靠性的最佳组合,为多用表建立了新的标准。