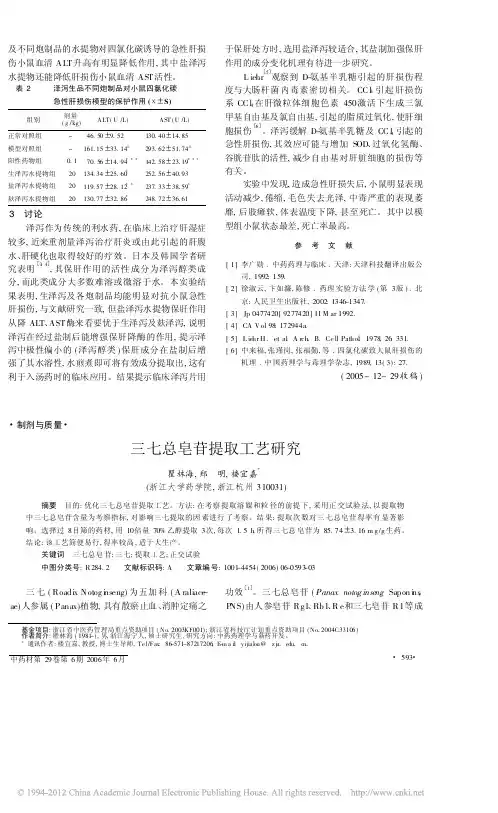

三七渗漉提取工艺的研究

- 格式:pdf

- 大小:148.32 KB

- 文档页数:2

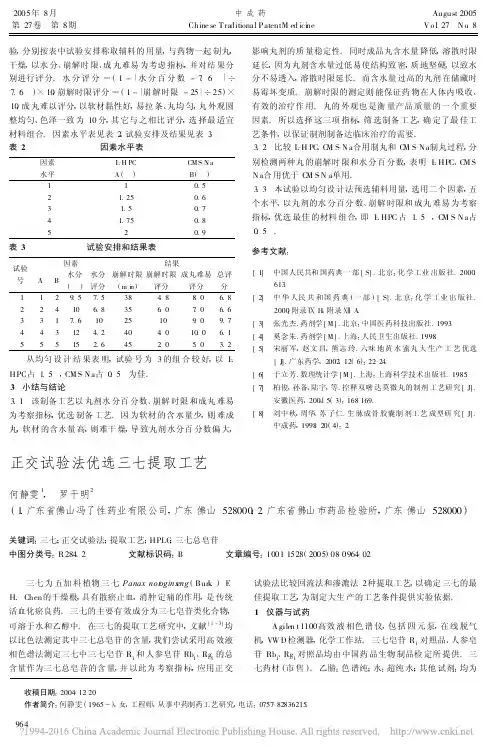

三七提取液中三七总皂苷的分离纯化工艺研究三七提取液中三七总皂苷的分离纯化工艺研究() () 文章编号: 1007-6611(2021) 06-0613-03三七提取液中三七总皂苷的分离纯化工艺研究谢茵, 邢桂琴, 刘秀芬(山西医科大学药学院药剂教研室, 太原030001)摘要: 目的研究影响分离纯化三七总皂苷的几个主要影响因素, 确立三七总皂苷分离纯化工艺。

在确立三七总皂苷测定方法的基础上, 采用HPD 2100型大孔吸附树脂, 以每ml 含0. 4g , 上柱量为1. 5倍柱体积, 并以1柱体积/h 的速度通过树脂柱, 。

,2-3倍柱体积/h 的速度洗脱, 用量为5-6倍柱体积时, %, 79. 6%, 精制度为241%。

结论HPD 2100大孔吸附树脂可用于富集、, 关键词: 三七总皂苷; ; ; 中图分类号: Study on the and purif ication of radix notoginseng saponinXIE Y in , XIN G Gui 2qin , L IU Xiu 2fen (Dept of Pharm aceutics , Pharm acy College , S hanxi Medical U niversity , Taiyuan 030001, China )Abstract : Objective To optimize the major conditions for the separation and purification of radix notoginseng saponin. MethodsOn the basis of determining radix notoginseng saponin , HPD -100macroreticular resin was used for enriching radix notoginsengsaponin. The extraction of 0. 4g material/ml was adsorbed in 1. 5times of column volume at a speed of one column volume per hour.Results The extraction was eluted by 70%ethanol of 5-6times with column volume at a flow rate of 2-3folds column volumeper hour. Elution ratio of radix notoginseng saponin was more than 98%, purity was 79. 6%, polishing was 241%. Conclusion HPD 2100macroreticular resin can be used to enrich , separate and purify radix notoginsensaponin ,and the effect is better. K ey w ords : radix notoginseng saponin ; HPD -100macroreticular resin ; elution ratio ; polishing三七(Radix Notoginsen ) 为五加科人参属植物三七[Panax Notoginseng (Burk. ) F. H. Chen 〗的根, 具止血、活血化瘀和消肿止痛的功效[1]。

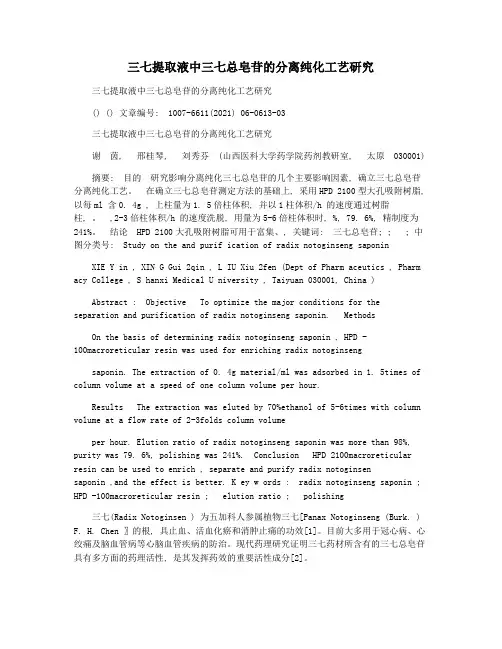

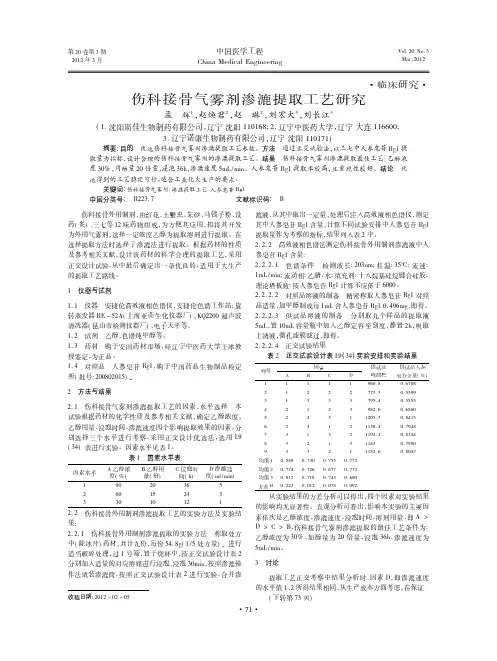

正交法优化三七提取工艺的研究【摘要】目的优选三七的最佳提取工艺。

方法以三七皂苷R1和人参皂苷Rg1为指标进行正交试验,采用胶束毛细管电色谱法测定含量,优化影响三七提取工艺的条件。

结果 4倍量70%乙醇回流提取2次,每次1.5h,乙醚、正丁醇统一处理所得提取液中三七皂苷R1、人参皂苷Rg1的含量最高。

结论试验结果可为三七提取工艺的确定提供实验依据,该优化工艺可为工业生产提供参考。

【关键词】三七;三七皂苷R1;人参皂苷Rg1;胶束毛细管电色谱Study on process for extraction of Panax notoginseng by orthogonal experiments【Abstract】 Objective To optimize the conditions for the extraction of Panax notoginseng.Methods Conditions for the extraction were studied by orthogonal experimental design as guided by the content of notoginsenoside R1 and ginsenosides Rg1 present in theextract.Results The optimum condition for the extraction ofP.notoginseng was to circumfuse the herb in 70% alcohol for 1.5h twice,then collect an amount corresponding to 4 times of the quantity ofP.notoginseng. The most content of ginsenosides Rg1 and notoginsenoside R1 in Panax notoginseng was determinate by MEKC after the collection was treated with ether and n-butanol.Conclusion The experimental results can be used for confirming process for extraction of Panax notoginseng and offering references for it’s industrial production.【Key words】 panax notoginseng; notoginsenoside R1;ginsenoside Rg1; capillary electrophoresis中药三七为五加科植物三七Panax notoginseng(Burk.)F.H.Chen的干燥根,皂苷类是其主要药效成分。

三七总皂苷提取、分离纯化技术的研究进展三七总皂苷(Panax notoginseng saponins,PNS)作为三七(Panax notoginseng)的主要活性成分,具有多种药理作用和临床应用,广泛应用于药品、保健品、日化品等行业。

随着PNS的需求量日益上升,PNS的提取、分离纯化技术显得尤为重要。

目前,PNS的提取、分离纯化技术的研究甚多,综合考虑其提取率、经济效益及规模化生产等因素,常采用乙醇回流提取,经大孔吸附树脂分离纯化,部分联合酶解技术和醇沉技术制备PNS。

本文将对近年来实验研究中常用到的PNS提取、分离纯化技术进行综述,为PNS的进一步研究及工业生产等提供参考。

[Abstract]Panax notoginseng saponins(PNS),as the main active ingredient of Panax notoginseng,which has a variety of pharmacological effects and clinical applications,and it is widely used in medicine,health products,cosmetic products and other industries.With the rising demand for PNS,extracting and separating and purifying technologies of PNS are particularly important.Currently,the studying on extractive,separative and purificative technology for PNS are especially more,considering its extraction rate,economy,large-scale production and other factors,using one of the first and formost method,which is the frequently-use method that of extracting and separating and purifying PNS from Panax notoginseng,firstly adopts the technique of ethanol refluxing extraction,then uses the method of macroporous resin adsorption to separate and purify PNS,and parts of them also combine with enzymolysis approach and alcohol precipitation approach to prepare PNS.In this paper,the commonly used techniques in laboratory research,which are the methods of extracting and separating and purifying PNS from medicinal material Panax notoginseng in recent years,are reviewed to provide the reference to the further studying on PNS and industrial production.[Key words]Panax notoginseng;Panax notoginseng saponins;Extractive technique;Separative and purificative technique三七为五加科人参属植物三七(Panax notoginseng(Burk.)F.H.Chen)的干燥根,又称田七,古代称其为金不换,是我国传统名贵中药材,主产于我国云南文山和广西,目前多用其栽培品。

radices pseudoginseng三七为临床常用中药, 具有广泛的药理作用, 因此, 三七的复方制剂品种甚多, 常以生粉入药, 存在服用量较大, 使用不便等不足。

为了探索合理的生产工艺, 尽可能提取有效成分, 笔者以三七所含人参皂苷Rg 1 为考查指标, 对三七的不同提取工艺进行了比较研究, 现报告如下。

1. 探头式超声提取三七有效成分的工艺研究目的采用单频探头式超声(25 kHz) 技术对三七有效成分进行提取。

方法选择乙醇体积分数、物料粒径、提取固液比、提取温度、提取时间5 个因素进行正交实验。

结果影响三七药材中人参皂苷Rg1 的提取率的因素依次为: 乙醇体积分数>物料粒径>固液比>提取时间>提取温度, 优化工艺参数为: 乙醇体积分数95%,物料粒径80 ~100 目, 固液比1 颐15, 提取时间40 min, 提取温度40 益。

在此条件下, 人参皂苷Rg1 的提取率是69.38%。

结论本研究将为三七工业化生产工艺参数的选择提供实验依据。

据文献[7] 报道, 三七中人参皂苷Rg1 回流提取优化条件为: 药材加体积分数60%乙醇浸泡1郾0 h, 回流提取2 次, 每次2. 0 h, 第1 次加醇量为药材的10 倍量, 第二次加醇量为药材的8 倍量。

在此条件下计算得人参皂苷Rg1 的提取率是60. 75% 。

本研究采用探头式超声提取三七中人参皂苷Rg1 的提取率达到69. 38% 。

对比文献[7] 结果可知, 相对乙醇回流提取, 探头式超声提取三七中人参皂苷Rg1 具有提取时间短、溶剂用量少、提取率高等优点。

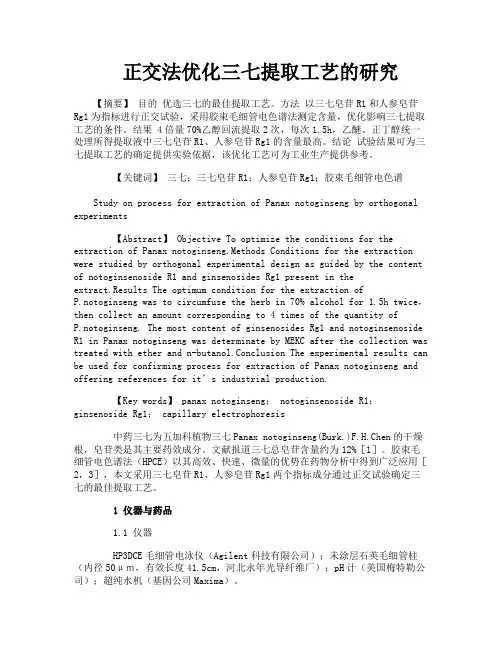

2. 正交试验法研究三七提取工艺目的优选三七的最佳提取工艺。

方法: 采用正交试验法,以提取液中三七总皂苷含量为考察指标, 对影响三七提取工艺的因素进行了研究。

结果实验设计三因素中提取方式有显著影响。

结论三七的最佳提取工艺为用75%乙醇浸渍三七24 h后,以每公斤每分钟1〜3 mL 速度渗漉, 收集相当于三七10 倍量的渗漉液。

三七总皂苷提取工艺研究进展对三七总皂苷的不同提取方法进行综述,其传统提取有渗漉、回流法等;现代提取有超声提取、超临界流体萃取、微波提取、酶提取法等。

笔者论述了当提取工艺变化时tPNS提取率的变化情况,总结了tPNS提取工艺的研究进展。

标签:三七;三七总皂苷;提取工艺;研究进展Abstract:Summary of the different extraction methods of saponins of notoginseng Panax (tPNS,total),The traditional extraction method and reflux percolation;Modern extraction,ultrasonic extraction,supercritical fluid extraction,microwave extraction,enzyme extraction method,etc.The change of tPNS extraction rate is discussed when the extraction process is changed,Research Progress on the extraction process of tPNS.Keywords:Roadix Notoginseng;tPNS;Extract technology;Study progress三七[Panax notoginseng(Burk.)F.H.Chen]为五加科(Araliaceae)人参属(Panax)植物三七的根与根茎[1]。

三七总皂苷(total saponins of panar natoginseng,tPNS)是三七根部提取的有效成分,含有多种皂苷成分包括人参皂甙Rb1、Rb2、Rc、Rd、Re、Rf、Rg1、Rg2、Rh、三七皂甙R1、R2、R3、R4、R5、R6等70多種单体皂甙[2],以三七皂甙R1、人参皂甙Rb1、Rg1含量最高[3],tPNS的特征化合物为三七皂苷R1。

探头式超声提取三七有效成分的工艺研究【摘要】目的采用单频探头式超声(25 kHz)技术对三七有效成分进行提取。

方法选择乙醇体积分数、物料粒径、提取固液比、提取温度、提取时间5个因素进行正交实验。

结果影响三七药材中人参皂苷Rg1的提取率的因素依次为:乙醇体积分数>物料粒径>固液比>提取时间>提取温度,优化工艺参数为:乙醇体积分数95%,物料粒径80~100目,固液比1∶15,提取时间40 min,提取温度40 ℃。

在此条件下,人参皂苷Rg1的提取率是69.38%。

结论本研究将为三七工业化生产工艺参数的选择提供实验依据。

【关键词】探头式超声提取三七人参皂苷Rg1 正交试验Abstract:Objective To extract the active components of Panax notoginseng by single��frequency ultrasound wave.Methods The concentration of alcohol,size of material,ratio of solid to liquor,temperature and time of extraction were optimized by orthogonal design. Results The factors influencing extraction rate of ginsenoside Rg1 in Panax notoginseng included ethanol concentration, particle size,solid/liquor,temperature and extraction time. Their optimal parameters were: 95% of ethanol concentration,particle size 80-100 mu;solid/liquid ratio 1∶15 g/mL,ultrasound time 40 min,ultrasound extraction temperature 40 ℃. Under this optimal condition,the yield of ginsenoside Rg1 was 69.38%. Conclusion This method provided useful parameters for the extraction of Panax notoginseng.Key words:ultrasonic horn; Panax notoginseng; ginsenoside Rg1; orthogonal experiment三七为五加科植物三七(Panax notoginseng)的干燥根,有散淤止血、消肿止痛的功效,用于咯血、吐血、便血、崩漏、外伤出血、胸腹刺痛、跌扑肿痛等[1]。

硕士研究生毕业论文三七药材及提取物农药残留测定分析XXXX年XX月XX日中文摘要三七是我国的名贵中药,为了有效地监测其农药残留情况,控制其内在质量,满足国际市场的要求,本论文建立了三七药材及其提取物和制剂的农药残留分析方法,并制定相应的限度标准,同时为其他中药建立通用的农药残留分析方法与严格完善的农药残留限量标准提供科学依据与方法借鉴,提高中药品质,增强中药在国际市场上的竞争力,使中药早日全面进入国际市场。

本论文结合国内外文献,运用气相色谱-质谱联用技术,建立了三七药材、三七药材提取物三七三醇皂苷及三七通舒胶囊中四大类20种农药同时测定的定性定量分析方法。

首先对色谱柱、进样口温度、特征离子、离子源温度等进行优选研究,确定了色谱、质谱条件,然后再通过对样品提取溶剂、提取方法和净化方法的实验研究,确定了三七药材、三七三醇皂苷原料药及三七通舒胶囊的样品前处理方法,之后对建立的方法进行方法学验证,最后运用建立的分析方法分别对15个批次的三七药材、15个批次的三七三醇皂苷原料药及15个批次的三七通舒胶囊进行20种农药残留量的检测。

结果表明,实验所建立的20种农药残留测定的分析方法准确灵敏、稳定可靠,重复性、专属性和耐用性均很好,可控性强。

15批PTS和15批三七通舒胶囊均未检出20种农药,而三七药材中农药残留现象较为普遍,15批药材有不同程度的农药残留检出。

关键词:三七药材;三七三醇皂苷;三七通舒胶囊;农药残留;气相色谱-质谱联用;固相萃取。

ABSTRACTPanax Notoginseng is a very valuable medicine in China.To monitor its pesticide residues effectively,control its inner quality,meet the requirements of international markets,this thesis established methods of analysis for pesticide residues in Panax Notoginseng,its extract and its herbal preparation,and made limit standards.At the same time,it provided scientific basis and mothods reference for the establishment of universal methods of analysis for pesticide residues and strict,complete limit standards in other Chinese materia medica,improved the quality of Chinese materia medica,enhanced the competitiveness of Chinese materia medica in the international markets and made Chinese materia medica fully enter international markets as soon as possile.This thesis incorporated the literatures at home and abroad, made use of gas chromatography-mass spectrometry(GC-MS),to develop methods of qualitative and quantitative analysis simultaneously for 20 pesticide residues in Panax Notoginseng, its extract PTS and SanQiTongShu Capsules.First,we studied and optimized the chromatographic columns,injection temperature,characteristic ions,ion source temper- ature during the experiment,built the GC and MS condition.Then we studied the extra- ction solvents, extraction methods and purification methods of sample and built the pre-processing methods of Panax Notoginseng,PTS raw materials and SanQiTongShu Capsules.Then we studied method validation.Finally,we used the analytical methods built up to detect 20 pesticide residues in 15 batches of Panax Notoginseng, 15 batch- es of PTS and 15 batches of SanQiTongShu Capsules.The results showed that the analytical methods built up to determine 20 pesticide residues were accurate,stable and reliable,which had a high sensitivity,good repeatability,good specificity,good durability and good controllability.None of 20 pes- ticides were detected in 15 batches of PTS and 15 batches of SanQiTongShu Capsules .But the phenomenon of pesticide residues in Panax Notoginseng was common,and different levels of pesticide residues were detected in 15 batches of Panax Notogin- seng.Keywords:Panax Notoginseng; Protopanaxatriol Saponin(PTS); SanQi TongShu Capsule;pesticide residues;gas chromatography-mass spectrometry;solid phase extrac- tion(SPE).目录中文摘要 (1)ABSTRACT (2)目录 (3)缩略词英汉对照 (5)1.引言 (6)1.1 国内外研究现状 (6)1.2 项目研究的意义与创新点 (7)2.正文 (8)2.1 实验仪器与材料 (8)2.1.1 仪器与设备 (8)2.1.2 标准品 (8)2.1.3 试药 (9)2.1.4 试剂 (10)2.2 实验方法与结果 (10)2.2.1 标准品溶液和内标溶液的制备 (10)2.2.1.1标准品储备溶液的制备 (10)2.2.1.2混合标准品溶液的制备 (11)2.2.1.3内标储备溶液的制备 (12)2.2.1.4内标工作溶液的制备 (12)2.2.2 色谱、质谱条件 (13)2.2.3 供试品溶液的制备 (13)2.2.3.1三七药材供试品溶液的制备 (13)2.2.3.2三七三醇皂苷原料药供试品溶液的制备 (14)2.2.3.3三七通舒胶囊供试品溶液的制备 (14)2.2.4 实验方法的优化研究 (15)2.2.4.1色谱条件的选择 (15)2.2.4.2质谱条件的选择 (15)2.2.4.3样品前处理方法的选择 (17)2.2.5 方法学研究 (19)2.2.5.1系统适应性试验 (19)2.2.5.2检测限和定量限 (19)2.2.5.3线性范围考察 (21)2.2.5.4回收率试验 (26)2.2.5.5重复性试验 (29)2.2.5.6精密度试验 (30)2.2.5.7专属性试验 (33)2.2.5.8耐用性试验 (35)2.2.6 农药残留量测定 (36)2.2.6.1定性测定 (36)2.2.6.2定量测定 (36)2.2.6.3样品测定 (36)2.3 结论 (38)2.4 讨论 (39)2.4.1 三七药材、PTS及三七通舒胶囊20种农药残留量限量标准的制定 (39)2.4.2 基质效应的影响 (40)2.4.3 中药农残残留研究中存在的问题 (41)2.4.4 展望 (41)3.总结 (43)致谢 (44)参考文献 (45)附图 (48)综述 (49)后置部分 (61)缩略词英汉对照缩略词英文名称中文名称EI Electron Ionisation 电子电离GC Gas Chromatography 气相色谱GPC Gel Permeation Chromatography 凝胶渗透色谱LOD Limit Of Detection 检测限LOQ Limit Of Quantitation 定量限MRL Maximum Residue Limit 最大残留限量MS Mass Spectrometry 质谱ND No Detected 未检出PTS Protoparaxotriol Saponins 三七三醇皂苷RSD Relative Standard Deviation 相对标准偏差SCAN SCAN 全扫描SIM Selected Ion Monitoring 选择离子监测SPE Solid Phase Extraction 固相萃取SPME Solid Phase Microextraction 固相微萃取TIC Total Ions Chromatography 总离子流色谱1.引言上世纪八十年代以来,随着人类健康意识的增强和回归大自然的浪潮高涨,人们越来越重视中药中农药的残留问题。

第36卷第1期2019年3月苏州科技大学学报(自然科学版)Journal of Suzhou University of Science and Technology (Natural Science)Vol.36 No.lMar.2019doi:10.12084/jassn.2096-3289.2019.01.012多层模块化抽屉式中药提取渗漉工艺性能李娟\孙志高\汤为民2(1.苏州科技大学环境科学与工程学院,江苏苏州215009;2.江苏七〇七天然制药有限公司,江苏镇江212002)摘要:采用多层模块化抽屉式渗漉工艺提取筋骨疼痛酒中药成分(红花、黄苗、党参、当归)。

利用筛分法测定24 目和100目药粉粒度分布、床层空隙率与渗透率,并以渗漉液总固体含量作为评价指标研究其相对于单渗漉、重渗 漉工艺的性能优势。

结果表明:平均直径为0.559 mm的24目粗粉颗粒占比67.8%,平均直径为0.161 mm的100目细粉颗粒占比95.6%;空隙率和渗透率均随药粉堆高的增加而降低;100目细粉渗漉液总固体含量较24目粗粉高,且多层模块化抽屉式渗漉装置的中药有效成分提取效果最佳。

关键词:筋骨疼痛酒;药粉粒度分布;渗透率;模块化渗漉中图分类号:R284.2;TQ461 文献标志码:A文章编号:2096-3289(2019)01-0058-05渗漉是提取和分离中药有效成分的一道重要工序,其工作原理是利用溶剂渗过药材层浸出药材成分。

传统渗漉装置要求将药材磨碎成粗粉、药粉堆高不得超出渗漉筒直径的6~7倍,否则溶剂流动缓慢,且存在 浸出不完全、溶剂消耗量大的缺点[1]。

近年来,渗漉工艺得到了快速发展和改进,尤其在提高渗漉效率、降低系统能耗、节省溶剂方面[2_3]。

徐玉 玲W和兰保强H分别优选了地龙和金花跌打酊的渗漉工艺参数,结果表明,药材分别被粉碎成粗粉和中粗粉 时渗漉效果最佳。

杨蕊^以指标成分保留率为评价指标,以渗漉液乙醇的体积分数和用量、粉碎粒度、渗漉速 度为影响因素,优化连三叶触变凝胶剂的渗漉提取工艺。