SOR压力开关

- 格式:pdf

- 大小:3.27 MB

- 文档页数:32

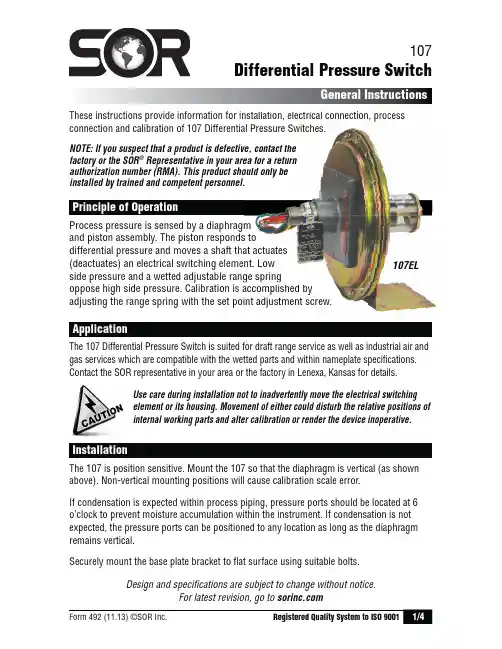

These instructions provide information for installation, electrical connection, process connection and calibration of 107 Differential Pressure Switches.107Differential Pressure Switch Process pressure is sensed by a diaphragm and piston assembly. The piston responds to differential pressure and moves a shaft that actuates (deactuates) an electrical switching element. Low side pressure and a wetted adjustable range springoppose high side pressure. Calibration is accomplished by adjusting the range spring with the set point adjustment screw.Design and specifications are subject to change without notice.For latest revision, go to NOTE: If you suspect that a product is defective, contact the factory or the SOR ® Representative in your area for a returnauthorization number (RMA). This product should only be installed by trained and competent personnel.stallation, electrical connection, process Pressure Switches. ms tohat actuates ent. Low nge springs accomplished byoint adjustment screw.e, contact thea for a return uld only be107ELUse care during installation not to inadvertently move the electrical switchingelement or its housing. Movement of either could disturb the relative positions ofinternal working parts and alter calibration or render the device inoperative.The 107 Differential Pressure Switch is suited for draft range service as well as industrial air and gas services which are compatible with the wetted parts and within nameplate specifications. Contact the SOR representative in your area or the factory in Lenexa, Kansas for details.InstallationThe 107 is position sensitive. Mount the 107 so that the diaphragm is vertical (as shown above). Non-vertical mounting positions will cause calibration scale error.If condensation is expected within process piping, pressure ports should be located at 6o’clock to prevent moisture accumulation within the instrument. If condensation is not expected, the pressure ports can be positioned to any location as long as the diaphragm remains vertical.Securely mount the base plate bracket to flat surface using suitable bolts.Hazardous Locations - 107EL ❶❷❸❹❺❻❶❷❸❼❽Non-Hazardous Locations - 107ALThe high-pressure side (marked HIGH) and the low pressureside (marked LOW) have 1/8” NPT(F) process connectionsunless 1/4” NPT(F) adapters were specified.❶ Set point adjustment screw (not shown)❷ High side process connection❸ Low side process connection ❹ Hermetically sealed switching element capsule❺ 18 AWG wire leads (not shown)❻ 1/2” NPT(M) electrical conduit connection❼ 3/4” NPT(F) electrcial conduit connection❽ Weatherproof switching element housingEnsure that wiring conforms toall applicable local and nationalelectrical codes and install unit(s)according to relevant national andlocal safety codes.The SOR pressure switches have been evaluated as Type-A safety related hardware. To meet the necessary installation requirements for the SIL system, the following information must be utilized:Proof Test Interval shall be one year.Units may only be installed for use in Low Demand Mode.Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a1oo1 (one out of one) configuration.Form 1538 (03.12) ©2012 SOR Inc.107AL (weatherproof):Interrupt electrical power. Remove top cover plate.107EL (explosion proof): Hermetically sealed switching element capsule has18” - 18 AWG wire leads color coded and markedC - Common, NO - Normally Open, NC - Normally Closed and G - Ground (earth). (See below.)Wire Lead Color CodeSee SOR Catalog 459 for reference dimension drawings. For certified dimension drawings, contact the factory.Units in hazardous locations-prior to removal from service, make surethat the work area is declassifi ed. Failure to do so could result in severepersonal injury or substantial property damage.DPDT (2 SPDT)SPDT Blue (C) Red (NO) Black (NC)Yellow (C2)Orange (NO2)Brown (NC2)Blue (C)Red (NO)Black (NC)Green (GND)Green (GND)LO HI NO 1NO 2Differential PressureHI LO Differential PressureNormal Calibration: Turn set point adjustment screw to move spring guide plateinto alignment with desired set point on calibration scale.Precise Calibration: Device calibrated without reference to calibration scaleand low side vented.Test apparatus: ManometerVariable pressure sourceTest light or ohmmeter ❶ Connect variable pressure source to manometer and high side pressure port.❷ Connect test light or ohmmeter to C-Common and NO - Normally Open switching element contacts.❸ Raise pressure and note manometer reading when circuit closes.❹ Slowly drop pressure and note manometer reading when circuit opens.❺ Use a screwdriver to turn set point adjusting screw: counterclockwise to increase set point, or clockwise to decrease set point.❻ Repeat steps 3, 4 and 5 until contacts change at desired increasing or decreasing differential pressure set point.Do not remove other covers or attempt to adjust other parts of themechanism. All have been precisely positioned at the factory andshould not be moved in the fi eld.。

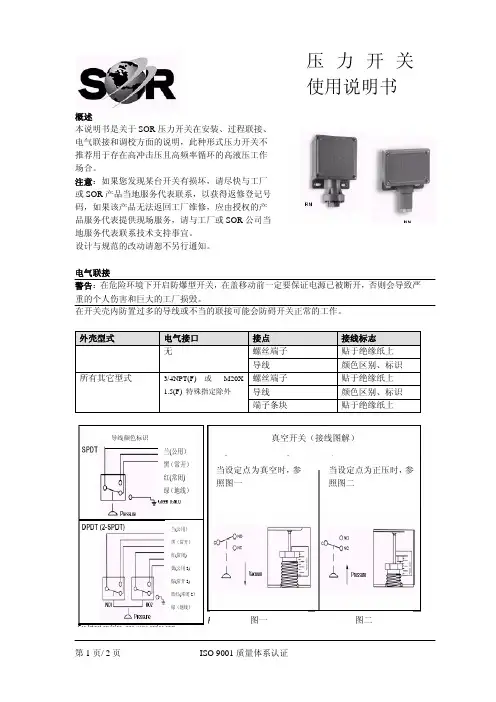

压力开关使用说明书

概述

本说明书是关于SOR压力开关在安装、过程联接、电气联接和调校方面的说明,此种形式压力开关不推荐用于存在高冲击压且高频率循环的高液压工作场合。

注意:如果您发现某台开关有损坏,请尽快与工厂或SOR产品当地服务代表联系,以获得返修登记号码,如果该产品无法返回工厂维修,应由授权的产品服务代表提供现场服务,请与工厂或SOR公司当地服务代表联系技术支持事宜。

设计与规范的改动请恕不另行通知。

电气联接

警告:在危险环境下开启防爆型开关,在盖移动前一定要保证电源已被断开,否则会导致严重的个人伤害和巨大的工厂损毁。

在开关壳内防置过多的导线或不当的联接可能会防碍开关正常的工作。

真空开关(接线图解)

当设定点为真空时,参

照图一当设定点为正压时,参照图二

兰(公用)黑(常开)红(常闭) 黄(公用2) 棕(常开2) 桔红(常闭2)绿(地线)

图一

第1页/ 2页 ISO 9001质量体系认证

图二。

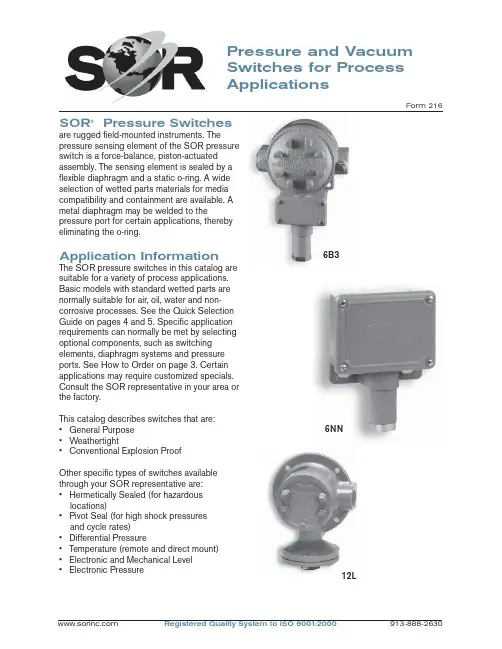

Pressure and Vacuum Switches for Process ApplicationsForm 216SOR ® Pressure Switchesare rugged fi eld-mounted instruments. Thepressure sensing element of the SOR pressure switch is a force-balance, piston-actuated assembly. The sensing element is sealed by a fl exible diaphragm and a static o-ring. A wide selection of wetted parts materials for media compatibility and containment are available. A metal diaphragm may be welded to thepressure port for certain applications, thereby eliminating the o-ring.Application InformationThe SOR pressure switches in this catalog are suitable for a variety of process applications. Basic models with standard wetted parts are normally suitable for air, oil, water and non-corrosive processes. See the Quick Selection Guide on pages 4 and 5. Specifi c application requirements can normally be met by selecting optional components, such as switching elements, diaphragm systems and pressure ports. See How to Order on page 3. Certain applications may require customized specials. Consult the SOR representative in your area or the factory.This catalog describes switches that are: • General Purpose • Weathertight• Conventional Explosion ProofOther specifi c types of switches available through your SOR representative are:• Hermetically Sealed (for hazardous locations)• Pivot Seal (for high shock pressuresand cycle rates)• Differential Pressure• Temperature (remote and direct mount)• Electronic and Mechanical Level • Electronic Pressure12L6B36NNFeatures SwitchesComplete Product LineStandard models and customized specials cover pressure range from30 inches Hg VAC to 4000 psi.Robust ConstructionRugged, high-cycle rate tolerance, long life, not critical to vibration, high overrange and proof pressures, excellent corrosionresistance to hostile environments. Instrument QualityHigh resolution of Set Points, high repeatability, narrow dead band,negligible temperature effect.Wetted PartsWide selection materials, process connection confi gurations and sizes.Optional “fi re-safe” pressure sensor.Snap-Action Electrical SwitchingWide selection UL Listed and CSA Certifi ed switching elements for ACand DC service. Optional “hermeticallysealed” capsule for hazardous and hostile environments.Field AdjustableSelf-locking adjustment, no special tools required. No-charge factory calibration.Cost EffectiveSimple and fast installation without special tools, long service life, norequired periodic service or spareparts.UL Listed, CSA Certifi ed, ATEXCertifi ed, FM, JIS/RIIS Approved ModelsMeets most code and customer requirements.Built-In QualityRigid quality standards maintained from raw material to fi nished product.ServiceFactory sales engineers and area SOR representatives provideeffective and prompt worldwideservice.DeliveryRoutine shipments 7 to 10 working days. Emergency shipments via sameday air.Warranty3 years from date of manufacture.Quick Selection GuideBasic SOR pressure switches with standard wetted parts are normally suitable for air, oil, water and non-corrosive processes. The Quick Selection Guide on pages 4 and 5 shows these basic SOR pressure and vacuum switches. Corrosive service and particular customer requirements may require optional components. Refer to How to Order section below to build a customized model number or the dedicated page to locate optional components, such as switching elements, diaphragm systems, pressure ports and accessories. Each position in the model number, except Accessories, must have a designator.Design and specifi cations are subject to change without notice. For latest revision, see .6NN-K5-M4-C2A-YYModel Number SystemDiaphragmHousingPistonSwitching Element Range SpringPressure PortAccessoriesApplicationsSOR pressure switches in this catalog are suitable for a wide variety of continuous pressure applications. Specifi c application requirements can normally be met by selecting optional components, such as, switching elements, diaphragm systems and pressure ports. Certain applications may require customized specials. Consult the SOR representative in your area or the factory.How to OrderInformation and data in this catalog are formatted to provide a convenient guide to assistinstrument engineers, plant engineers and end users in selecting pressure switches for their unique applications.Steps 1 through 5 are required. Step 6 is optional. Orders must have complete Model Numbers, i.e. each component must have a designator.Step 1: Select Piston-Spring adjustable range/Set Point from Specifi cations (pages 7 & 8). (Piston/Spring combination determines adjustable range.)Step 2: Select Housing for type of pressure switch and service (page 9).Step 3: Select electrical Switching Element for electrical service (pages 10 & 11).Step 4: Select Diaphragm and O-Ring for process compatibility and containment (pages 12 & 13).Step 5:Select Pressure Port for process compatibility and connection (page 14).Step 6: Select Accessories required for service (page 16).How to OrderSwitchesExplosion ProofWeathertightBasic SOR pressure switches with standard wetted parts are normally suitable for air, oil, waterand non-corrosive processes. Corrosive service and particular customer requirements may require optional components. Refer to How to Order on page 3 to locate optional components, such as, housing, switching elements, diaphragm systems, pressure ports and accessories. Each position in the model number, except Accessories, must have a designator.WeathertightExplosion ProofStandard Construction• Housing: NN - aluminum; L - cast iron• Switching Element: SPDT; N - 10 amps @ 250 VAC; K - 15 amps @ 250 VAC• Diaphragm & O-ring: N4 - primary (wetted)diaphragm, TCP; o-ring (wetted) Buna-N• Pressure Port: 1/4” NPT(F); B1A - aluminum; F1A - carbon steelNotes1. See balance of catalog for construction options.2. Dead band values are expressed as typical expected at mid-range for a particular model number. See Dead Band Considerations on page 8.3. Design and specifi cations subject to changewithout notice. For latest revision, see.Standard Construction• Housing: NN - aluminum; L - cast iron• Switching Element: SPDT; K - 15 amps @ 250 VAC• Diaphragm & O-ring: N4 - primary (wetted)diaphragm, TCP; o-ring (wetted) Buna-N• Pressure Port: 1/4” NPT(F); B1A - aluminum; F1A - carbon steelNotes1. See balance of catalog for construction options.2. Dead band values are expressed as typical expected at mid-range for a particular model number. See Dead Band Considerations on page 8.3. Design and specifi cations subject to change without notice. For latest revision, see .WeathertightExplosion ProofExplosion ProofWeathertightStandard Construction• Housing: NN - aluminum; L - cast iron• Switching Element: SPDT; K - 15 amps @ 250 VAC • Diaphragm & O-ring: N4 - primary (wetted) diaphragm, TCP; o-ring (wetted) Buna-N. Piston 56 primary (wetted) diaphragm, 316SS.• Pressure Port: 1/4” NPT(F); B1A - aluminum; F1A - carbon steelNotes1. See balance of catalog for construction options.2. Dead band values are expressed as typical expected at mid-range for a particular model number. See Dead Band Considerations on page 8.3. Design and specifi cations subject to change without notice. For latest revision, see .Quick Selection Guide - VacuumPressure SwitchA bi-stable electromechanical device that actuates/deactuates one or more electrical switching element(s) at a predetermined discrete pressure/vacuum (Set Point) upon rising or falling pressure/vacuum.Adjustable RangeThe span of pressure between upper and lower limits within which the pressure switch can be adjusted to actuate/deactuate. It is expressed for increasing pressure.Set PointThat discrete pressure at which the pressure switch is adjusted to actuate/deactuate on rising or falling pressure. It must fall within the adjustable range and be called out as increasing or decreasing pressure.Dead BandThe difference in pressure between theincreasing Set Point and the decreasing Set Point. It is expressed as typical, which is an average with the increasing Set Point at mid-range for a pressure switch with the standard K switching element. It is normally fi xed (non-adjustable).Fire-SafeThe ability of a welded seal pressure sensor to contain the process at elevated temperatures up to 1200°F at the rated overrange pressure, unsupported by the body of the pressure switch.Hermetically SealedA welded steel capsule with glass-to-metal, factory-sealed electrical leads that isolates the electrical switching element(s) from the environment.OverrangeThe maximum input pressure that can be continuously applied to the pressure switch without causing permanent change of Set Point, leakage or material failure.SwitchesGlossary of T ermsSOR recognizes that there is no industry convention with respect to terminology and defi nitions pertinent to pressure switches. This glossary applies to SOR pressure switches.Proof PressureThe maximum input pressure that can be continuously applied to the pressure switch without causing leakage or catastrophic material failure. Permanent change of Set Points may occur, or the device may be rendered inoperative.RepeatabilityThe ability of a pressure switch to successively operate at a Set Point that is approached from a starting point in the same direction and returns to the starting point over three consecutive cycles to establish a pressure profi le.Repeatability on SOR switches will be smaller than 1% of full scale per ISA/ANSI S51.1. SPDT Switching ElementSingle-Pole, Double Throw (SPDT) has three connections: C — Common, NO — Normally Open and NC — Normally Closed, whichallows the switching element to be electrically connected to the circuit in either NO or NC state.DPDT Switching ElementDPDT is two synchronized SPDT switching elements which actuate together at increasing Set Point and deactuate together at decreasing Set Point. Discrete SPDT switching elements allow two independent circuits to be switched; i.e., one AC and one DC.The synchronization linkage is factory set, and is not fi eld adjustable. Synchronization is verifi ed by connecting test lamps to the switching elements and observing them go “On” simultaneously at actuation and “Off” simultaneously at deactuation.6NN-K5-M4-C2A-YY This table is a listing of piston-spring combinations and the corresponding adjustable ranges, dead bands, overrange and proof pressures. Adjustable range is expressed for increasing pressure; the Set Point must be within the adjustable range. Dead band is expressed as typical. See Dead Band Considerations on page 8.1. Dead band values are expressed as typicalexpected at mid-range with the standard Kswitching element assembly installed. Whenoptional switching elements are specifi ed,corresponding dead band multipliers shownon pages 8 and 10 must be applied.2. The 12/66 piston/spring combination isavailable with the N switching element only.3. Adjustable range becomes 10 to 45 in. wcwhenever switching elements other than K, KA,W or D are used.4. Special ranges may be possible. Consult thefactory or the SOR representative in your area. 5. Diaphragms may have an additional effect ondead band. See page 13, Note 9.6. Diaphragm life may be limited by using T or Hswitching elements with Numbers 1 and9pistons.7. Metric bar (mbar) values are practicalequivalents of the reference English values; notnecessarily exact mathematical conversions.This data appears on the product nameplatewhen metric engineering units are specifi ed.8. A breather drain (Accessory KK, see page 16)should be specifi ed when low pressureadjustable ranges are used in environmentswith signifi cant ambient temperature changes.9. Filled isolators attached to the pressure switchwill affect dead band.This table is a listing of piston–spring combinations and the corresponding adjustable ranges, dead bands, overrange and proof pressures. SOR vacuum switches are compound; they will operate in either vacuum or pressure modes. Adjustable range is expressed from maximum vacuum decreasing to zero gauge andincreasing to maximum pressure. Dead band is expressed as typical. See dead band considerations below. The Set Point must be within the adjustable range. A vacuum switch is generally better suited than a pressure switch for Set Points very near zero gauge.Notes1. Dead band values are expressed as typical expected at mid-range with the standard K switching element assembly installed. When optional switching elements are specifi ed, corresponding dead band multipliers shown below must be applied.2. Special ranges may be possible. Consult the factory or the SOR representative in your area.3. Diaphragms may have an additional effect on dead band. See page 13, Note 9.4. Metric bar (mbar) values are practical equivalents of the reference English values; not necessarily exact mathematical conversions. This data appears on the product nameplate when metric engineering units are specifi ed.1. Dead band values are expressed as typical expected atmid-adjustable range using the standard K switching element. When optional switching elements are specifi ed, corresponding dead band multipliers must be applied.2. Dead bands are fi xed (non-adjustable), except when T or H switching elements are used.3. Dead band can be adjustable by selecting T or H switching element. (Diaphragm life may be limited when used with Numbers 1 and 9 pistons.)4. Dead band multipliers must be applied to the typical dead band value shown for piston-spring combination in specifi cations, pages 7 and 8, whenever optional switching elements other than K, KA or W are used.5. Dead band can be widened by selecting an optional switching element with a multiplier greater than 1.0. Example: Model 6NN-G5-M4-C2A-YY Typical Dead Band 1.4 psi G-Switching Element multiplier = 3 Corrected Typical Dead Band 1.4 x 3 = 4.2 psi6. See item #9, page7.Dead Band Considerations52NN-K 116-M4-C2A-YYClass II, Group E, F, & G; Divisions 1 *L*S*LC*T A*J4NNN6P3Electrical: 3/4” NPT(F) - Left, Right Material: AluminumSee Agency Listings pages 17 & 18.See Switching Element Groups 1, 2, 3 & 4 below.N3N4RN RBSwitchesStep 2: Housing*BD only available with RN, RT housings.*C micro switch is not available in L, S and TA housings.*CA micro switch only available in PP, NN, N3 and N4 housings.Switches Step 3: Switching Element6NN-K5-M4-C2A-YYCross reference compatibility chart on page 9 to ensure that switching element will fi t in housing. Review notes on page 11 for more details.SwitchesStep 3: Switching Element6NN-K 5-M4-C2A-YYNotes1. Double switching elements have wire leads except when supplied in housings RB, RM, RN, RS, RT, B3, B4, B5, B6 and J4. Terminal blocks are standard in these housings.2. Dead band multipliers must be applied to thetypical dead band fi gures given in the specifi cation tables on pages 7 and 8.3. Switching element ambient temperature limits:-65 to 400o F (-54 to 200o C) B, Y, W-65 to 250o F (-54 to 120oC) A, E, & J-40 to 167o F (-40 to 75oC) AF, AG, E F , EG,JF, JG-13 to 158o F (-25 to 70o C) BD-65 to 180o F (-54 to 80o C) All others4. The hermetically sealed switching elementcapsule is ATEX Approved, UL Listed, CSA Certifi ed and SAA Approved as an explosion-proof snap switch according to the following table with conditions and exceptions specifi ed in Note 3.5. Switching elements W, & Y have Elgiloy springs.6. Certain switching elements can handle greater voltage and/or amperage. Consult the factory should your requirements exceed catalog values. All switching elements above except BD are UL Recognized and CSA Certifi ed. The DC current ratings marked with an asterisk (*) are not UL Listed but have been verifi ed by testing and/or experience.7. Ambient temperature is reduced to 200°F (93°C) for J, JJ, A, AA, E, EE, B, BB, Y, YY, & W switching elements when CV accessory is selected.CAUTION: The switching element assemblyhas been precisely positioned in the housing at the factory for optimum performance. Any inadvertent movement or replacement in the fi eld will degrade performance, could render the device inoperative, and can void the warranty unless factory authorized proceduresare followed.Notes Array1. N4 diaphragm system is standard, but requiresa designator in the model number. It is normallysuitable for air, oil, water and noncorrosiveprocesses. M2 diaphragm system is standardon Number 56 vacuum switches. (See notes10 & 13.)2. U7 designates a welded fl ush-type diaphragm.Available only in 1” NPT(M) 316SS onNumbers 5 & 6 pistons with K switchingelement. See page 15.3. U8 designates the welded fi re-safe diaphragmsystem. 316SS is stocked. Not available onNumber 1 piston or vacuum switches.Example: U8-C2A is a 316SS fi re-safe weldeddiaphragm system. See page 15.4. U9 designates a welded diaphragm system.Not available on vacuum switches.Example: U9-A1A is a Monel weldeddiaphragm system. See page 15.5. Other diaphragm and o-ring combinations maybe available. Consult the factory or the SORrepresentative in your area for more information.6. Wetted parts have been selected asrepresenting the most suitable commerciallyavailable material for use in the service intended.However, they do not constitute a guaranteeagainst corrosion or permeation, since processes vary from plant to plant and concentration ofharmful fl uids, gases or solids vary from time totime in a given process. Empirical experienceby users should be the fi nal guide. Alternatematerials are generally available.(Continued on page 13.)7. N3 diaphragm system utilizes a durableback-up diaphragm for high cycle-rate, highshock applications where Buna-N and TCP are compatible with the process. Consult factory if process temperatures are well below freezing.8. This table shows allowable minimum andmaximum temperatures for o-rings. Consult the factory for temperatures down to –65°F onfi re- safe and welded metal diaphragmsystems.9. Dead bands are slightly higher when usingH, J, N3, N6, U or W series diaphragmoptions. Consult the factory.10. Diaphragm systems N1, N3, N4, N5, N6, N7,N8, P1, R1, S1, S2, W2, W4, W5, W6, Y1,U8, U9 are not available on Number 56vacuumswitches.11. M9 diaphragm system is suggested for steamapplications up to 400°F.12. If Kalrez, EPR or Viton is selected for hightemperature process media or ambienttemperature requirements, the A, B, E, J, W or Y switching elements are suggested withreference to the table in Note 3, page 11. 13. Only diaphragm systems N1, N4, N5, N7, N8and P1 are available on the 12-66 piston-springcombination.SwitchesStep 5: Pressure Port6NN-K5-M4-C2A -YYNotes1. Select designators for material and connection size. Large bold-face letters denote those items generally available from stock. Small light-face letters denote items with limited stock and possible long delivery.2. 1/4” and 1/2” tapered BSP(F) pressure ports are available. Consult factory.3. Combinations are possible when a particular connection size is not available for the range (piston/spring) desired. For example, if 2” NPT(F) is desired for a Number 4 piston, the Number 12 pressure port can be supplied. The piston would be designated as Number 124 and the overrange and proof pressures for Number 12 apply. Note: 124, 125 and 126 are the only available combinations.4. Many other materials such as PVC, Kynar, etc., are available. Denote materials not shown by specifying an X followed by the required connection size, and describe the material.Examples:X2A = PVC pressure port with 1/2” NPT(F) connection.X1A = Titanium pressure port with 1/4” NPT(F) connection.Non-metal pressure ports generally reduce proof pressure and may reduce overrange pressure. The pressure port material may limit the process temperature. Delivery may be longer than normal.5. Raised-face and fl at-face fl anges to match ASA 150 and ASA 300 lb. in commercially available materials can be supplied on Series 12 and 4 pistons by adding an X suffi x to the model numbers and specifying “X - (size) inch (material) (raised- or fl at-) face fl ange to match ASA (rating) lb.”6. Brass not available on Piston Numbers 9 and 1.7. 1/4” NPT(F) Flushing Port standard on C6A pressure ports.*C4A only available with Pistons 5 & 6 when U7 diaphragm is specifi ed. See page 15.See next page for presentation of welded diaphragm and FM Approved fire-safe systems.Pressure and Vacuum SwitchesWelded Diaphragm & Fire-Safe SystemsFactory Mutual System Approved - U.S Patent Number 4,438,305Two-inch Pressure PortThe wide pressure port minimizes the possibility of clogging when the process media is sludgy or viscous. See page 20 for dimensions. A 2” NPT(F) pressure port with a 1/4” NPT(F) fl ushing port can be supplied with a welded diaphragm, or with a conventional diaphragm and o-ring combination.ConnectionPiston ShaftDiaphragmSwitches Step 6: Accessories6NN-K5-M4-C2A-YY*Consult the factory for materials other than 316/316L.CSATIISATEXBASEEFASOR Pressure Switches in this catalog may be specifi ed with manual reset electrical switching elements D or M. D actuates automatically on increasing pressure. M actuates automatically on decreasing pressure. Depress the button to manually reset. Housings must be RB (weathertight) or S (explosion proof) because of the requirement of a hub for the manual reset assembly. Refer to page 3 for How to Order instructions.Shipping WeightsManual Reset ButtonRB - Weathertight S - Explosion ProofSwitchesManual ResetActual shipping weights may vary from the charted values because of product material, confi guration and packaging requirements.NotePK Pipe Kit adds approximately 1.5 lbs. (0.7 kgs). TB Junction box adds approximately 5 lbs (2.25 kgs).Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Notes 1. Dimensions in this catalog are expressed as millimeters over inches (Linear = mm/in.). 2. Dimensions marked with an asterisk (*) on housing dimension drawings (pages 20 through 31) vary with respect to process connection size. The chart below lists these dimension variances. 3. Electrical Connection Size: 3/4” NPT(F) standard. 1/2” NPT(F), 1/2” NPT(M), M20 x 1.5, PG 13.5, PF 3/4” optional. Consult the factory for compatibility with selected housing or agencylisting.DimensionsSwitchesDimensionsDimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Wide Pressure Port: C6ASee description on page 15.Pipe Mounting Kit: PKDrawing # 0091354Drawing # 0090300Drawing # 0091353Junction Box with T erminalBlock:TBDimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Weathertight - NEMA 4, 4X, IP65Housing PP, P3 and PF are General Purpose.(Cover gasket is not installed.)Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Piston Numbers 5, 6, 1, 9, 56Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Open BracketDesignators: H3Piston Numbers 5, 6, 9, 1, 56Drawing # 0090027Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Weathertight - NEMA 4, 4X, IP65Designators: N6Piston Numbers Drawing 0090020Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Conventional Explosion ProofDimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Conventional Explosion ProofDesignators: SPiston Numbers 5, 6, 9, 1, 56Drawing # 0090147Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Conventional Explosion ProofPiston Numbers 5, 6, 9, 1, 56SC shown. LC identical except right-handelectrical connection only.Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Conventional Explosion ProofPiston Numbers 5, 6, 9, 1, 56Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Explosion ProofDimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Weathertight - NEMA 4, 4X, IP65Drawing # 0090271Designators: RB Manual ResetPiston Numbers 5, 6, 1, 9, 56Pressure and VacuumSwitches Dimensions Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certifi ed drawings for a particular model number.Conventional Explosion ProofDrawing # 0090169Designators: S Manual ResetPiston Numbers 5, 6, 1, 9, 56*Refer to Dimensions table on page 19 for changes in length due to process connection size, including A dimension.Registered Quality System to ISO 9001:200032/32Form 913-888-2630echOsonix Level TransmittersT emperature SwitchesP r e s s u r eFlowLevelLevel SwitchesFlow SwitchesPressure SwitchesSOR ®offers a full line of commercial-grade process instruments.TemperatureRegistered Quality System to ISO 9001:2000Form 216 (04.08) ©2008 SOR Inc.We Deliver Quality On TimeSOR Europe, Ltd.Star RoadPartridge Green, Sussex RH13 8RA, United Kingdom Phone +44-140-371-1331Fax +44-140-371-0177sales@SOR - ChinaRoom 903, No. 10 Building Wan Da PlazaNo. 93 Jian Guo Road Chao Yang District Beijing, China 100022Phone +86 (10) 5820 8767Fax +86 (10) 5820 8770SOR Inc.14685 West 105th Street Lenexa, Kansas 66215Phone 913-888-2630Toll Free 800-676-6794Fax 913-888-0767Process Instrumentation。

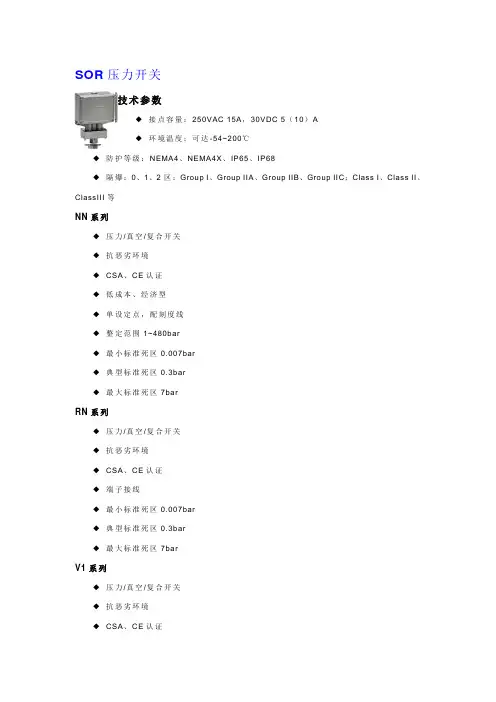

SOR压力开关技术参数◆接点容量:250VAC 15A,30VDC 5(10)A◆环境温度:可达-54~200℃◆防护等级:NEMA4、NEMA4X、IP65、IP68◆隔爆:0、1、2区;Group I、Group IIA、Group IIB、Group IIC;Class I、Class II、ClassIII等NN系列◆压力/真空/复合开关◆抗恶劣环境◆CSA、CE认证◆低成本、经济型◆单设定点,配刻度线◆整定范围1~480bar◆最小标准死区0.007bar◆典型标准死区0.3bar◆最大标准死区7barRN系列◆压力/真空/复合开关◆抗恶劣环境◆CSA、CE认证◆端子接线◆最小标准死区0.007bar◆典型标准死区0.3bar◆最大标准死区7barV1系列◆压力/真空/复合开关◆抗恶劣环境◆CSA、CE认证◆双设定点,配刻度线◆整定范围1~275bar◆最小标准死区0.007bar◆典型标准死区0.3bar◆最大标准死区7barV2系列◆压力/真空/复合开关◆防爆抗恶劣环境◆UL/CSA Class I、Group◆A、Div 1和DEMKO Eex◆m II以及SAA Ex s IIC◆T6认证◆双设定点,配刻度线◆整定范围1~275bar◆最小标准死区0.007bar◆典型标准死区0.3bar◆最大标准死区7bar型号设定值范围kg/cm2回程差kg/cm2防爆产品型号K 型开关EF型开关44V-K2-N4-B1A0.14~0.560.010.0444V2-EF2-N4-B1A 44V-K4-N4-B1A0.14~1.760.020.0644V2-EF4-N4-B1A 44V-K5-N4-B1A0.21~3.520.030.0844V2-EF5-N4-B1A 44V-K45-N4-B1A0.28~5.270.040.1144V2-EF45-N4-B1A 66V-K2-N4-B1A0.49~5.620.040.1166V2-EF2-N4-B1A 66V-K3-N4-B1A0.84~7.030.060.1766V2-EF3-N4-B1A 66V-K5-N4-B1A 1.41~12.660.080.2766V2-EF5-N4-B1A 66V-K45-N4-B1A 1.76~19.330.110.3266V2-EF45-N4-B1A 55V-K3-N4-B1A 1.76~16.870.140.4255V2-EF3-N4-B1A 55V-K5-N4-B1A 2.46~26.370.210.6355V2-EF5-N4-B1A 55V-K45-N4-B1A 3.16~38.670.250.7455V2-EF45-N4-B1A 99V-K4-N4-B1A7.03~56.250.49 1.4899V2-EF4-N4-B1A 99V-K5-N4-B1A14.06~70.310.63 1.9099V2-EF5-N4-B1A 99V-K45-N4-B1A14.06~123.040.98 2.9599V2-EF45-N4-B1A 11V-K45-N4-C1A35.15~281.23 6.3318.9811V2-EF45-N4-C1A。

SOR流量开关SOR压力开关采用国际标准的连接部件,标准型可用于空气、油、水和各种非腐蚀性介质,对于腐蚀性介质的特殊应用,SOR压力开关同时也提供了可选择的功能部件。

SOR压力开关突出的宽整定范围和低死区性能和多接点选项完全可以替代传统的接点压力表应用,大接点容量,可以直接控制水泵和电动机等动力设备,简化控制回路,减少系统维护量,进而提高系统的可靠性和安全性。

中国传感器交易网提供技术参数□ 接点容量:250VAC 15A,30VDC 5(10)A□环境温度:可达-54~200℃□ 防护等级:NEMA4、NEMA4X、IP65、IP68□ 隔爆:0、1、2区;Group I、Group IIA、Group IIB、Group IIC;Class I、Class II、ClassIII等NN系列□ 压力/真空/复合开关□ 抗恶劣环境□ CSA、CE认证□ 低成本、经济型□ 单设定点,配刻度线□ 整定范围1~480bar□ 最小标准死区0.007bar□ 典型标准死区0.3bar□ 最大标准死区7barRN系列□ 压力/真空/复合开关□ 抗恶劣环境□ CSA、CE认证□ 端子接线□ 最小标准死区0.007bar□ 典型标准死区0.3bar□ 最大标准死区7barV1系列□ 压力/真空/复合开关□ 抗恶劣环境□ CSA、CE认证□ 双设定点,配刻度线□ 整定范围1~275bar□ 最小标准死区0.007bar□ 典型标准死区0.3bar□ 最大标准死区7barV2系列□ 压力/真空/复合开关□ 防爆抗恶劣环境□ UL/CSA Class I、Group□ A、Div 1和DEMKO Eex□ m II以及SAA Ex s IIC□ T6认证□ 双设定点,配刻度线□ 整定范围1~275bar□ 最小标准死区0.007bar□ 典型标准死区0.3bar□ 最大标准死区7bar1.压力开关:可提供普通压力开关、真空开关、电器单元密闭型开关、双设定点开关及可调切换差式开关。

sor压力开关工作原理

Sor压力开关(也称为静压力开关)是一种用于监测液体或气体压力的开关装置。

它的工作原理基于压力的变化来控制电气电路的开闭。

当压力施加在Sor压力开关上时,内部的感应元件(通常是一个弹簧或膜片)会受到压力的影响而发生形变。

这种形变会导致感应元件内部的接点发生移动,从而改变开关的状态。

当压力达到设定值时,开关会闭合或打开,从而触发相应的电气信号。

Sor压力开关通常用于控制液体或气体系统中的压力,以确保系统在安全范围内运行。

例如,当压力超过设定值时,Sor压力开关可以自动切断供应液体或气体的流动,以防止系统过载或损坏。

它还可以用于监测液体或气体的压力变化,并触发相应的报警或控制信号。

总的来说,Sor压力开关的工作原理是基于压力的变化来控制内部接点的状态,从而实现对液体或气体压力的监测和控制。

这种设备在工业自动化和流体控制系统中起着重要作用,保障了系统的安全运行和稳定性。

SOR开关简介SOR公司是美国著名的压力开关生产厂商,是世界上唯一的可生产压力、差压、温度、液位及流量开关的厂商,它生产的开关广泛应用于电厂及石油化工领域。

目前该厂商生产的多种类型高品质开关,在我国的大、中型火力发电厂有着极为广泛的使用,对电厂发电机组系统的保护和可靠运行起到了很好的作用。

SOR开关符合国际质量标准ISO9001,此产品的高可靠性和精度得到所有用户的肯定。

在2001年年度中,国内的300MW以上火力发电新建机组几乎全部采用SOR 逻辑开关来对全厂系统进行保护。

由此可见,此品牌开关在电力行业的用户信誉是其他品牌开关所无法比拟的。

1、压力开关工作范围广(-15--4000psi),设点稳定,重复率高,死区小,几乎不受温度影响。

开关品种齐全,范围设计合理,并对各种使用环境均有专业工况。

2、差压开关重复率高,死区小,受温度及静力影响小。

107系列是低压差压开关,其设点稳定,精度高,是电厂的炉保系统应用广泛的一种差压开关。

102/103系列可承受较高静压,而所测压差可很微小,且精确度很高,故在电厂管道滤网上广泛应用。

3、温度开关受环境温度影响小,反应快速,重复率高,死区小。

工作范围:-45℃--540℃4、液位开关有机械式和电子式等多种形式,其机械式开关利用磁吸合原理,工作可靠,无毒,不使用水银等有毒物质,完全符合当今的环保要求。

其独特的陶瓷开关,使SOR的液位开关的适用温度得以大大提高,完全满足电力行业的各种工况。

5、超声波物位变送器-高能量在苛刻的工况下(粉尘,泡沫,蒸汽)有很强的穿透能力高能量的声波确保所接收的回波在能量衰减后仍可用于测量-低频低频声脉冲波比高频有更强的穿透力,距离更远低频比高频受到更少的质体干扰最大的测量范围可达80m-自动增益调节无需进行空罐操作来消除虚假回波的干扰,始终能够锁定真实物位回波,不会造成回波信号的丢失唯一可根据工况情况自行调节的产品可以在其他产品失败的工况下工作SOR部分电厂用户清单上海外高桥电厂4×300MW √√√上海吴泾热电厂2×300MW√√上海华能石洞口第二电厂2×600MW √√上海杨树浦电厂2×125MW √√上海闸北电厂4×100MW燃机√上海金山石化自备电厂2×200MW √√浙江嘉兴电厂一期2×300MW √√浙江嘉兴电厂二期5#/6#机2×600MW √浙江台州电厂2×300MW √√浙江北仑港电厂2×600MW √√浙江宁波纸厂自备电厂2×50MW√浙江温州电厂2×300MW √浙江长兴电厂2×300MW √浙江秦山核电厂二期2×600MW √√√浙江秦山核电厂三期2×600MW √江苏利港电厂2×600MW √江苏徐塘电厂(以大代小)2×300MW √√江苏彭城电厂2×300MW √江苏南化自备电厂2×50MW √√江苏扬子石化自备电厂2×125MW √江苏金陵石化自备电厂2×50MW √√江苏华能南京电厂2×300MW √江苏华能南通电厂2×300MW √√江苏华能太仓电厂2×300MW √江苏华能淮阴电厂2×200MW √江苏华能淮阴电厂二期2×300MW √√江苏新海电厂2×125MW √江苏南京下关电厂2×135MW √江苏镇江高姿电厂4×135MW √√江苏盐城电厂2×135MW √江苏扬州电厂2×200MW √√江苏扬州第二电厂2×600MW √√江苏江阴夏港苏龙电厂4×135MW √江苏江阴夏港苏龙电厂二期2×300MW √江苏太仓港环保电厂一期2×135MW √√江苏太仓港环保电厂二期2×300MW √√江苏太仓港环保电厂三期2×300MW √√江苏南通天生港电厂4×135MW √√江苏南通天生港电厂二期2×300MW √√江苏南京扳桥电厂2×135MW √江苏镇江谏壁电厂2×300MW √√江苏贾旺电厂4×135MW √√√江苏大屯发电厂2×135MW √江苏华润常熟电厂3×600MW √√安徽平圩电厂2×600MW √安徽田家庵电厂1×300MW √安徽铜陵电厂1×300MW √√安徽淮北电厂2×300MW √安徽洛河电厂4×300MW √安徽马钢自备电厂2×50MW √√√安徽安庆电厂2×300MW √福建厦门嵩屿电厂2×300MW √√√福建漳平电厂2×100MW √福建邵武电厂2×125MW √广东华能汕头电厂2×300MW √√广东珠江电厂2×300MW √√广东沙角B厂,C厂2×600MW √√广东珠海电厂2×600MW √√大亚湾核电站√湖南石门电厂2×300MW √√湖南湘潭电厂2×300MW √√湖南株州电厂2×300MW √√湖南益阳电厂2×300MW √√湖南鲤鱼江电厂2×300MW √√湖北襄樊电厂4×300MW √√湖北汉川电厂2×300MW √√湖北武钢自备电厂2×200MW √√湖北黄石电厂2×300MW √√湖北蒲圻电厂2×300MW √河南首阳山电厂2×300MW √√河南安阳电厂2×300MW √河南信阳电厂2×300MW √√河南登封电厂2×300MW √√√河南永城电厂2×300MW √√河南新乡电厂2×135MW √河南神火电厂2×135MW √河南周口电厂2×135MW √山东石横电厂4×300MW √山东胜利油田自备电厂2×300MW √山西阳泉电厂2×300MW √√山西太原第一热电厂2×300MW √√山西太原第一热电厂二期2×600MW √√山西河曲电厂一期2×600MW √√北京石景山热电厂2×100MW √北京第二热电厂2×200MW √河北沙岭子电厂4×300MW √√河北定州电厂2×600MW √√天津大港电厂2×300MW √天津大唐盘山电厂二期2×600MW √√哈尔滨第三热电厂2×300MW √√吉林省吉林热电厂2×200MW √华能大连电厂2×300MW √√陕西渭河电厂2×300MW √陕西蒲城电厂2×300MW √√√陕西神木电厂2×100MW √√陕西宝鸡电厂4×300MW √陕西西郊热电厂2×300MW √√甘肃靖远电厂2×300MW √√甘肃西固电厂2×125MW √√甘肃平凉电厂4×300MW √√内蒙达旗电厂2×300MW √√√内蒙国华准格尔电厂2×600MW √√内蒙托克多电厂二期2×600MW √√宁夏大坝电厂2×300MW √√云南曲靖电厂2×300MW √√贵州安顺电厂2×300MW √√√四川成都热电厂2×142MW √√巴基斯坦恰希玛核电站一期2×350MW √巴基斯坦木扎法戈电厂2×300MW √越南协福电厂2×100MW √√√伊朗萨汉姆燃机电厂2×350MW √√孟加拉巴库电厂2×125MW √√主要OEM配套厂家名称压力开关液位开关电子式液位产品北京良乡√√北京重型机器厂√√√上海汽轮机厂√√上海电机厂√√上海锅炉厂√上海电站辅机厂√√上海电力修造厂√上海水泵厂√上海鼓风机厂√√上海重型机器厂√√杭州汽轮机厂√√杭州锅炉厂√东方汽轮机厂√东方电机厂√东方锅炉厂√哈尔滨汽轮机厂√哈尔滨电机厂√哈尔滨锅炉厂√沈阳鼓风机厂√√沈阳水泵厂√。

压力开关使用说明书概述本说明书是关于SOR 压力开关在安装、过程联接、 电气联接和调校方面的说明,此种形式压力开关不 推荐用于存在高冲击压且高频率循环的高液压工作 场合。

注意:如果您发现某台开关有损坏,请尽快与工厂 或SOR 产品当地服务代表联系,以获得返修登记号 码,如果该产品无法返回工厂维修,应由授权的产 品服务代表提供现场服务,请与工厂或SOR 公司当 地服务代表联系技术支持事宜。

设计与规范的改动请恕不另行通知。

电气联接警告:在危险环境下开启防爆型开关,在盖移动前一定要保证电源已被断开,否则会导致严重的个人伤害和巨大的工厂损毁。

在开关壳内防置过多的导线或不当的联接可能会防碍开关正常的工作。

外壳型式 电气接口 接点 接线标志 螺丝端子 贴于绝缘纸上无导线颜色区别、标识 螺丝端子 贴于绝缘纸上 导线 颜色区别、标识 所有其它型式3/4NPT(F) 或 M20X 1.5(F) 特殊指定除外端子条块贴于绝缘纸上第1页/ 2页 ISO 9001质量体系认证真空开关(接线图解)当设定点为真空时,参照图一 当设定点为正压时,参照图二图一图二兰(公用) 导线颜色标识黑(常开) 红(常闭) 绿(地线)兰(公用) 黑(常开) 红(常闭) 黄(公用2) 棕(常开2) 桔红(常闭2) 绿(地线)安装1.用两个适当长度的1/4英寸螺栓,牢固地将开关外壳通过安装孔与仪表架或安装柱装配在一起。

2.不推荐通压力接口或电气接口的在线安装。

3.建议安装位置为电气接口竖直向下,以避免收集冷凝液,尽管如此,开关仍可全位置安装。

保证导线的电气性能符合所有应用的国家和场合,并且根据相关国家和场合的安全要求安装产品。

过程联接采用两个扳手安全地将引压管与压力接口联接:一个扳手夹住六角形压力接口,另一个扳手旋紧引压管或管接头。

重要:小心勿使压力接口松,压力接头从壳体上脱落。

警告:将外壳安装平板表面可能会导致外壳受到扭力,从而使压力开关不能正常工作。

压力开关产品主要采用静态O型圈密封的活塞膜片式结构,具有抗震、抗过压能力强,测量范围广泛且回差小,使用寿命长等特点。

其生产的高静压低压差开关是世界上独一无二的。

其核极压力产品也是世界上唯一取得IEEE 认证的产品。

·控制范围从负压力1kg/cm2到680kg/cm2,分多级控制;

·控制压力最大为680kg/cm2

·微压控制为15mm水柱

·真空-0-压力控制为:1kg/cm2(负压)-0-5.5kg/cm2

·双设置点压力开关可以独立控制两点不同的压力值

·切换差分可调与不可调两种

SOR公司(中文名称索尔公司)成立于1946年,是世界上唯一一家集生产各类机械及电子压力、差压、温度、流量、液位开关及变送器于一体的专业化国际公司,其压力开关类产品产量位居世界第一.

美国SOR公司主要产品为压力、差压、温度、流量及液位开关,所有产品全部采用ISO9001质量标准,分普通型和防爆型两大类产品,产品的主要认证机构有:美国UL、加拿大CSA、澳大利亚ASS、日本的JIS、欧洲CENELEC等。

SOR公司的开关量仪表主要采用膜片活塞式结构,有耐高压、高温、防震、防腐蚀、抗冲击力、切换差小等特点、广泛应用于石油、化工、电力冶金、药品、造纸、食品、水处理等行业.。

sor压⼒开关检修规程SOR压⼒开关检修规程⽬录1.0⽬的 (2)2.0范围 (2)3.0参考 (2)4.0HSE (2)5.0定义 (2)6.0责任 (3)7.0规程步骤 (3)7.1压⼒开关主要性能指标: (3)7.2压⼒开关的校验: (3)7.2.1严格执⾏本规程4.0HSE (3)7.2.2检定条件 (3)7.2.3校验项⽬ (4)7.2.4进⾏正确的填写校验单 (5)7.2.5记录保存 (5)7.3压⼒开关的使⽤和维护 (5)1.0⽬的制定本规程的⽬的在于为本规程的最终⽤户提供明确的内容和步骤,确保仪表维护检修⼈员在执⾏任务时能够在没有监督或很少监督的情况下,按照赛科规定的标准,以安全有效可靠的⽅式履⾏⾃⾝的职责。

2.0范围本规程适⽤于:SOR压⼒开关型号:6RN-EG3-M4-C2A-HB3.0参考本规程参考了以下⽂件:中华⼈民共和国航空航天⼯业部航空⼯业标准压⼒开关通⽤规范HB6680-92SOR压⼒开关说明书4.0HSE在执⾏规程时,你若确认出未知的HSE风险,向你的直接主管进⾏汇报。

为了确保检修⼈员以及仪表设备本体的安全,在执⾏相关操作之前必须了解和参考以下的安全提⽰:1.建议在⼯作和环境条件许可的情况下选择在仪表校验室执⾏。

2.必须严格检查检修仪表(压⼒开关)的状况。

3.严格检查检修仪表(压⼒开关)的清洁度,不准仪表本体或内部带⼯艺介质,以免造成检修⼈员和标准仪器的伤害。

4.禁⽌在爆炸性环境中打开处于带电⼯作状态的压⼒开关接线盖。

5.严格检查供电电源的安全状况,防⽌漏电事故发⽣。

6.严格检查⼯作环境状况,以免发⽣⼈员伤害事故发⽣。

7.检修⼈员必须在⾝体健康状况允许的情况下执⾏本规程。

5.0定义压⼒开关:通过压⼒变化驱动触点的开关耐压压⼒:能够承受⽽不引起零件破裂,泄漏,永久变形和功能失效以及其他损坏的最⼤压⼒驱动点:压⼒开关的触点从初始状态切换到相反状态时的压⼒回动点:压⼒开关的触点从驱动状态返回到初始状态时的压⼒死区:驱动点和回动点之间的压⼒差⼯作循环:压⼒从零(绝对压⼒或表压)升⾄需要的系统正常压⼒,然后从系统正常压⼒降⾄零的过程称为⼯作循环。

SORSOR公司(中文名称索尔公司)成立于1946年,是世界上唯一一家集生产各类机械及电子压力、差压、温度、流量、液位开关及变送器于一体的专业化国际公司,总部位于美国勘萨斯州州府,现有员工300人,其压力开关类产品产量位居世界第一。

SOR压力开关产品主要采用静态O型圈密封的活塞膜片式结构,具有抗震、抗过压能力强,测量范围广泛且回差小,使用寿命长等特点。

其生产的高静压低压差开关是世界上独一无二的。

其核极压力产品也是世界上唯一取得IEEE认证的产品。

SOR的机械液位开关全部满足ANSIB31.1和B31.3标准,包括机械式浮球及浮筒两类,其独特的分级冷凝球降温措施能够很好地保证液位开关的开关单元部分免受高温蒸汽的影响,可以可靠地应用于高温工况,越来越受到客户的青睐。

除机械类产品外,SOR的电子产品种类也是非常丰富的,包括热差式流量开关,接触式超声波开关,射频导纳开关及变送器,开关与变送器及显示三位一体的SGT以及非接触式超声波变送器。

其生产的非接触式超声波变送器具有高能量、低频率、自动增益调节三大特点使其能够应用于诸如碳黑、干灰、啤酒、石膏等高粉尘、高泡沫及高雾气的复杂环境中,帮助很多用户解决了多年来用其他超声波产品甚至是雷达产品都解决不了的难题。

由于SOR产品的多样性、高质量、良好的售后服务,赢得了客户的大力支持,使其广泛应用于电力、石油天然气、化工、水处理、造纸、冶金等行业,从1997年至今,SOR在中国过程工业尤其是电力行业中,其市场占有率已稳坐第一,并长达五年之久,在中国已经形成了以北京代表处为核心的强大销售及售后服务网络,销售及服务人员遍及全国各省、直辖市和自治区。

美国SOR公司主要产品为压力、差压、温度、流量及液位开关,所有产品全部采用ISO9001质量标准,分普通型和防爆型两大类产品,产品的主要认证机构有:美国UL、加拿大CSA、澳大利亚ASS、日本的JIS、欧洲CENELEC等。

SOR公司的开关量仪表主要采用膜片活塞式结构,有耐高压、高温、防震、防腐蚀、抗冲击力、切换差小等特点、广泛应用于石油、化工、电力冶金、药品、造纸、食品、水处理等行业。

101/121 differential pressure switches are rugged, field-mounted instrumentsthat incorporate a flexible modular design providing cost effective sensing solutions. The two-piece piston design allows for complete differential pressure reversal without damage. See Principle description on page 2.Application InformationBasic models with standard wetted parts are normally suitable for air, oil, water and non-corrosive process fluids. See the Quick Selection Guide on page 4.Corrosive service and special requirements may require optional components. See How to Order on page 3.101/121 differential pressure switches are suited for low-to-high differential pressure, fluid power or process applications where high and varying static pressures, high overrange, proof, shock pressure or cycle rates are expected.101NN 121NN101AG 121AG101L 121L101/121 Differential Pressure SwitchesSEE MORE AT Request QuoteF h = Force, Hi Pressure F l = Force, Lo PressureF s = Force, Range SpringF d = Force, Resultant DifferentialF d = F h - (F l + F s )Process pressure is sensed by a diaphragm-piston combination. Hi-side system pressure acts on the piston to product force F h . It is counteracted by the adjustable range spring force F s and Lo-side system pressure acting on the backside of the piston to produce force F l . The resultant force F d acts on the piston and overcomes the force of the adjustable range spring [F d = F h – (F l + F s )] and moves a shaft that actuates (deactuates) an electrical switching element.AF hF lF sF dNCNOCDifferential Pressure SwitchPrincipleQuick Selection GuideBasic Series 101/121 differential pressure switches with standard wetted parts are normallysuitable for air, oil, water and non-corrosive processes. Refer to the Quick Selection Guide section on page 4. Corrosive service and particular customer requirements may require optionalcomponents. Refer to the How to Order section on this page or the dedicated page to locate optional components, such as: housings, switching elements, diaphragm systems, pressure ports and accessories. Each position in the model number, except Accessories, must have a designator.101NN-K3-N4-C1A-YYModel Number SystemSeriesHousingDiaphragm& O-RingSwitching Element Adjustable RangePressure PortAccessoriesApplicationsThe Series 101/121 differential pressure switches in this catalog are suitable for a wide variety of process and fluid power applications. Specific application requirements can normally be met by selecting optional components, such as, switching elements and diaphragm systems. Certain applications may require customized specials. Consult local representative or the factory.Weathertight, conventional explosion proof and hermetically sealed explosion proof models are presented in this catalog.How to OrderSteps 1 through 5 are required; Step 6 is optional. Orders must have complete model numbers, i.e. each component must have a designator.Order information must include:a) Set Point (increasing or decreasing)b) If decreasing Set Point, state from what greater Set Point is approached c) Normal system (static) pressureStep 1: Select Housing for type of service (pages 5 & 6).Step 2: Select electrical Switching Element for housing and electrical service (pages 6 & 7).Step 3: Select Adjustable Range according to Set Point (page 8).Step 4:Select Diaphragm and O-Ring for process compatibility and containment (page 9).Step 5:Select Pressure Port for process connection (page 9). Step 6: Select Accessories as required for service (page 10).If Agency Listed, Certified or Approved differential pressure switches are required, see page 11 for components that must be specified.Differential Pressure SwitchHow to OrderDifferential Pressure Switch Principle Specify model number from table below.WeathertightNEMA 4, 4X, IP65Hazardous LocationsClass I, Groups C & D;Class II, Groups E, F & G;Divisions 1 & 2Hazardous LocationsClass II, GroupsE, F & G; Divisions 1 & 2See Agency Listings page 11.See Switching Element Groups 1, 2, 3, 4 page 6.See Agency Listings page 11.See Switching Element Groups 1, 2, 3, 4 page 6.Contains UL Listed, CSA Certified, ATEX and SAA Approved Electrical: 1/2” NPT(M)-Top Material: See Switching Element Group 5 page 6.See Switching Element Groups 1, 2, 3, 4 page 6.See Agency Listings page 11.See Switching Element Groups 1, 2, 3, 4 page 6.Open bracket with exposed switchingelement does not meet NEMA 1.See Switching Element Groups 1 & 3 page 6.See Agency Listings page 11.See Switching Element Group 7 page 6.Weathertight —NEMA 4, 4X, IP65Electrical: 3/4” NPT(F)- Right Material: AluminumCover: heavy duty with Viton gasketN4See Agency Listings page 11.See Switching Element Groups 1, 2, 3, 4 page 6.See Switching Element Groups 1 & 3 page 6.RN RM Electrical-RT: 3/4” NPT(F)-Right Electrical-RS: M20 x 1.5-Right Six-place compression type terminal block Material: 316SSRT RSContains UL Listed, CSA Certified and SAA Approved hermetically sealed switching elements. Electrical: 3/4” NPT(F)-TopMaterial: Copper-free** aluminumWeathertight: NEMA 4/4XSee Switching Element Group 6 page 6.Class II, Groups E, F & G; Divisions 1 101NN -K3-N4-C1A-YYSeparate electrical and set point adjustment compartments. WeathertightSix-place compression type terminal blockSee Agency Listings page 11.Class II, Groups E, F & G; Divisions 1 & 2 as an outlet box only.Electrical: 3/4” NPT(F)-Left, Right, TopSix-place compression type terminal block with Optional LL Material: Copper-free** aluminum Class I, Groups A, B, C, D; Class II,See Switching Element Groups 1 & 3 page 6.*B3* Not recommended for direct mount where vibration is expected. Housing should be securely mounted to a flat surface (bulkhead or panel rack) or pipe stanchion. ** Consult the factory.See Switching Element Groups 1 & 3 page 6.See Switching Element Groups 1, 2, 3, 4 page 6.See Switching Element Groups 1 , 3, 7 page 6.See Switching Element Groups 1, 2, 3, 4, 7 page 6.Hazardous Locations — Conventional Explosion ProofATEX and SAA Approved Electrical: 1/2” NPT(M)-TopMaterial: See Switching Element Group 5 page 6.101NN-K3-N4-C1A-YYCross reference compatibility chart above to ensure that switching element will fit in housing.Notes1. AC/DC electrical ratings for switchingelements K, KK, KA, J, JJ, G, GG, A, AA, L, LL, E, EE, C, S, B, BB, Y, YY, W, T, H, D and M are UL Recognized and CSA Certifiedwith conditions and exceptions specified in Note 3.2. The hermetically sealed switching elementcapsule is UL Listed, CSA Certified, ATEXand TestSafe Approved as a snap switch in accordance with the following table withconditions and exceptions specified inNote 3.3. DC electrical ratings are for resistive loadsonly. DC ratings marked with an asterisk (*) are not agency recognized or certified buthave been verified by testing or experience.Switching Element101NN-K3-N4-C1A-YY 4. DPDT switching elements have wire leadsexcept when supplied in housings RN, RT,RM, RS, RB, B3, B4, B5, B6.5. Switching element minimum/maximumambient temperatures:-40 to 167o F (-40 to 75o C) AF, AG, EB,EF, EG, JB,JF, JG, JR, KB -65 to 400o F (-54 to 204o C) B, Y, W-65 to 250o F (-54 to 120o C) A, E, J-65 to 180o F (-54 to 80o C) All others 6. Dead band multipliers must be applied to thetypical dead band figures given in thespecification tables on page 8.7. Switching elements B, W and Y have anElgiloy spring. Experience indicates goodservice in atmospheres with corrosivegases - H2S, ammonia, etc.CAUTION: The switching element assembly has been precisely positioned in the housing at the factory for optimum performance. Any inadver-tent movement or replacement in the field will degrade performance, could render the device inoperative and may void the warranty unless factory authorized procedures are followed.Differential Pressure SwitchAdjustable Range101NN-K 3-N4-C1A-YYThis table lists designators for corresponding adjustable ranges, dead bands, maximum system pressure and maximum differential pressure. Adjustable range is expressed for increasing pressure: the Set Point must be within the adjustable range. Dead band is expressed as typical at mid-range. See dead band considerations at the bottom of this page.Notes1. Ambient temperature range: -30 to 180o F (-34 to 80o C). Check restrictions, page 7, for optional electrical switching elements and page 9 for optional diaphragm systems.2. Metric bar (mbar) values are practical equivalents of the mathematical conversions. This data appears on the product nameplate when metric engineering units are specified.3. CAUTION: When the process could be considered dirty in terms of suspended particles, it is recommended that 20-micron in-line filters be installed on the Hi and Lo pressure ports.4. To achieve optimum performance, the 101/121 should be calibrated under simulated system operating conditions.Dead Band Considerations1. Dead band values are expressed as typical expected at mid-adjustable range and 50% maximum system pressure (static pressure) using the standard K switching element.2. Dead bands are fixed (non-adjustable), except when T or H switching elements are used.3. A dead band multiplier must be applied to the typical dead band value shown in adjustable range above whenever an optional switching element is specified.4. Dead band can be widened by selecting an optional switching element with a multiplier greater than 1.0.5. Use of metal diaphragms may have additional impact on Dead band values. Contact thefactory for details.Differential Pressure SwitchExample: Model 101NN-G3-N4-C1ATypical Dead Band 0.7 psid G-Switching Element muliplier 2 Corrected Typical Dead Band0.7 x 2 = 1.4 psidDiaphragm & O-Ring101NN-K3-N4-C1A-YY Notes1. N4 diaphragm system is standard. It isnormally suitable for air, oil, water andnon-corrosive processes.2. Other diaphragm and o-ring combinationsmay be available. Consult the factory or the SOR representative in your area for more information.3. Wetted parts have been selected asrepresenting the most suitable commercially available material for use in the serviceintended. However, they do not constitute a guarantee against corrosion or permeation, since processes vary from plant to plant and concentration of harmful fluids, gases orsolids vary from time to time in a givenprocess. Empirical experience by usersshould be the final guide. Alternate materials based on this are generally available.4. Differential pressures exceeding 100 psidmay affect Set Point when M2, M4, or H4diaphragm and o-ring combination is used. 5. Dead bands are higher when using metaldiaphragm options. Consult the factory.6. This table shows allowable minimum andmaximum temperatures for o-rings.Step 5: Pressure Port101NN-K3-N4-C1A-YYNotes1. C1A pressure port is standard. It is normallysuitable for air, oil, water and non-corrosive processes.2. Other pressure port materials and connectionsizes may be available. Consult the factory or the SOR representative in your area for more information.Material & SystemsDifferential Pressure SwitchStep 6: Accessories101NN-K3-N4-C1A-YY101/121Differential Pressure SwitchAgency ListingsULCSAATEX/ IECEx orINMETRODifferential Pressure SwitchManual Reset101RB -D 3-N4-C1A-YYSeries 101/121 Differential Pressure Switches in this catalog may be specified with manual reset electrical switching elements D or M.D actuates automatically on increasing pressure. M actuates automatically on decreasingpressure. Depress the button, covered by the weathertight boot to manually reset. Housings must be RB weathertight or S explosion proof because of the requirement of a hub for themanual reset assembly. Refer to page 3 for order instructions.Approximate WeightsActual shipping weights may vary from the charted values because of product material,configuration and packaging requirements.RB-WeathertightS-Explosion ProofDifferential Pressure SwitchSOR recognizes that there is no industry convention with respect to terminology and definitions pertinent to pressure switches. This glossary applies to SOR Pressure Switches.Adjustable RangeThe span of pressure between upper and lower limits within which the pressure switch may be adjusted to actuate/deactuate. It is expressed for increasing differential pressure.Dead BandThe difference in pressure between the increasing Set Point and the decreasing Set Point. It is expressed as “typical,” which is an average with the increasing Set Point at mid- adjustable range for a pressure switch with the standard K switching element. It is normally fixed (nonadjustable).Differential Pressure SwitchA bi-stable electromechanical device that actuates/deactuates one or more electrical switching element(s) at a predetermined discrete differential pressure (Set Point) upon rising or falling differential pressure.DPDT Switching ElementDPDT is two synchronized SPDT switching elements that actuate together at increasing Set Point and deactuate together at decreasing Set Point. Discrete SPDT switching elements allow two independent circuits to be switched; i.e., one AC and one DC.The synchronization linkage is factory set, and is not field adjustable. Synchronization is verified by connecting test lamps to the switching elements and observing them go “On” simultaneously at actuation and “Off” simultaneously at deactuationHermetically SealedA welded steel capsule with glass-to-metal, factory-sealed, electrical leads that isolatesthe electrical switching element(s) from the environment.Maximum Differential PressureThe maximum difference in pressure that may be continuously applied between the Hi and Lo (Lo and Hi) pressure ports without causing permanent change of Set Point, leakage or material failure.OverrangeThe maximum input pressure that may be continuously applied to the pressure switch without causing permanent change of Set Point, leakage or material failure.Proof PressureThe maximum input pressure that may be continuously applied to the pressure switch without causing leakage or catastrophic material failure. Permanent change of Set Points may occur, or the device may be rendered inoperative.RepeatabilityThe ability of a pressure switch to successively operate at a Set Point that is approached from a starting point in the same direction and returns to the starting point over three consecutive cycles to establish a pressure profile. The closeness of the measured Set Point values is normally expressed as a percentage of full scale (maximum adjustable range pressure).Set PointThat discrete pressure at which the pressure switch is adjusted to actuate/deactuate on rising or falling pressure. It must fall within the adjustable range and be called out as increasing or decreasing differential pressure. SPDT Switching ElementSingle-Pole, Double Throw (SPDT) has three connections: C — Common, NO — Normally Open and NC — Normally Closed, which allows the switching element to be electrically connected to the circuit in either NO or NC state.Glossary of T ermsDifferential Pressure Switch6.40.25 MIN TO 76.23.00 MAX3/4 NPT(F)(STD)1/2 NPT(F)(OPT)7.10.281/4 NPT(F) HI SIDE1/4 NPT(F) LO SIDEDimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certified drawings for a particular model number. Dimensions are expressed as millimeters over inches (Linear = mm/in.)Housing: Weathertight - Nonhazardous Service (NEMA 4, 4X IP65)Housing: NN, N3, N4Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certified drawings for a particular model number. Dimensions are expressed as millimeters over inches (Linear = mm/in.)Housing: RB Manual ResetWeathertight - Non-hazardous Service (NEMA 4, 4X IP65)Drawing 00906046.40.25 MIN TO 76.23.00 MAX Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certified drawings for a particular model number. Dimensions are expressed as millimeters over inches (Linear = mm/in.)Housing: H3 Open BracketGeneral Purpose - Non-hazardous ServiceHousing: PP, P3 NEMA 1Drawing 0090601Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certified drawings for a particular model number. Dimensions are expressed as millimeters over inches (Linear = mm/in.)Housing: LHousing: LCConventional Explosion Proof - Hazardous ServiceClass I, Group C, D; Class II, Group E, F, G: Divisions 1 & 2Drawing 0090606Housing: SCDimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certified drawings for a particular model number. Dimensions are expressed as millimeters over inches (Linear = mm/in.)Conventional Explosion Proof - Hazardous ServiceClass I, Group C, D; Class II, Group E, F, G: Divisions 1 & 2Conventional Explosion Proof - Hazardous ServiceClass I, Groups C, D; Class II, Groups E, F, G: Divisions 1 & 2Housing: B3, B4, B5, B6Class I, Groups B, C, D; Class II, Groups E, F, G; Divisions 1 & 2Housing: T AClass I, Groups A, B, C, D; Class II, Groups E, F, G; Divisions 1 & 2Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certified drawings for a particular model number. Dimensions are expressed as millimeters over inches (Linear = mm/in.).Drawing 0090610PROCESS CONNECTION CONNECTION OPTIONALDrawing 0090611PROCESS CONNECTIONPRODUCT CERTIFICATION DRAWING ALL DIMENSIONS ARE ±1/16 IN UNLESS OTHERWISE SPECIFIEDMMLINEAR =INK MITCHELLM SMITHS BOAL14 SEP 2011DIMENSION DRAWING 101/121 BA EO NUMBER: 5095SCALE: 0.7000906125SHEET 1 OF 1BMODEL #SALES ORDER #LINE ITEM #PURCHASE ORDER #SALES PAGEPROCESS CONN SIZE LENGTH A 1/4 NPTM SHOWN 29.71.171/2 NPTF37.61.481/2 NPTM 34.81.373/4 NPTF 39.91.5741.6ADDFOR M20 X 1.5 F 1.64ELECTRICAL CONNECTION6.40.25457.218.00Hermetically Sealed Explosion Proof - Hazardous ServiceClass I, Groups A, B, C, D; Class II, Groups E, F, G; Divisions 1 & 2Housing: BAHousing: AG, AH Dimensions in this catalog are for reference only. They may be changed without notice. Contact the factory for certified drawings for a particular model number. Dimensions are expressed as millimeters over inches (Linear = mm/in.)Drawing 0090612Drawing 0091067。

SOR开关简介SOR公司是美国著名的压力开关生产厂商,是世界上唯一的可生产压力、差压、温度、液位及流量开关的厂商,它生产的开关广泛应用于电厂及石油化工领域。

目前该厂商生产的多种类型高品质开关,在我国的大、中型火力发电厂有着极为广泛的使用,对电厂发电机组系统的保护和可靠运行起到了很好的作用。

SOR开关符合国际质量标准ISO9001,此产品的高可靠性和精度得到所有用户的肯定。

在2001年年度中,国内的300MW以上火力发电新建机组几乎全部采用SOR 逻辑开关来对全厂系统进行保护。

由此可见,此品牌开关在电力行业的用户信誉是其他品牌开关所无法比拟的。

1、压力开关工作范围广(-15--4000psi),设点稳定,重复率高,死区小,几乎不受温度影响。

开关品种齐全,范围设计合理,并对各种使用环境均有专业工况。

2、差压开关重复率高,死区小,受温度及静力影响小。

107系列是低压差压开关,其设点稳定,精度高,是电厂的炉保系统应用广泛的一种差压开关。

102/103系列可承受较高静压,而所测压差可很微小,且精确度很高,故在电厂管道滤网上广泛应用。

3、温度开关受环境温度影响小,反应快速,重复率高,死区小。

工作范围:-45℃--540℃4、液位开关有机械式和电子式等多种形式,其机械式开关利用磁吸合原理,工作可靠,无毒,不使用水银等有毒物质,完全符合当今的环保要求。

其独特的陶瓷开关,使SOR的液位开关的适用温度得以大大提高,完全满足电力行业的各种工况。

5、超声波物位变送器-高能量在苛刻的工况下(粉尘,泡沫,蒸汽)有很强的穿透能力高能量的声波确保所接收的回波在能量衰减后仍可用于测量-低频低频声脉冲波比高频有更强的穿透力,距离更远低频比高频受到更少的质体干扰最大的测量范围可达80m-自动增益调节无需进行空罐操作来消除虚假回波的干扰,始终能够锁定真实物位回波,不会造成回波信号的丢失唯一可根据工况情况自行调节的产品可以在其他产品失败的工况下工作SOR部分电厂用户清单上海外高桥电厂4×300MW √√√上海吴泾热电厂2×300MW√√上海华能石洞口第二电厂2×600MW √√上海杨树浦电厂2×125MW √√上海闸北电厂4×100MW燃机√上海金山石化自备电厂2×200MW √√浙江嘉兴电厂一期2×300MW √√浙江嘉兴电厂二期5#/6#机2×600MW √浙江台州电厂2×300MW √√浙江北仑港电厂2×600MW √√浙江宁波纸厂自备电厂2×50MW√浙江温州电厂2×300MW √浙江长兴电厂2×300MW √浙江秦山核电厂二期2×600MW √√√浙江秦山核电厂三期2×600MW √江苏利港电厂2×600MW √江苏徐塘电厂(以大代小)2×300MW √√江苏彭城电厂2×300MW √江苏南化自备电厂2×50MW √√江苏扬子石化自备电厂2×125MW √江苏金陵石化自备电厂2×50MW √√江苏华能南京电厂2×300MW √江苏华能南通电厂2×300MW √√江苏华能太仓电厂2×300MW √江苏华能淮阴电厂2×200MW √江苏华能淮阴电厂二期2×300MW √√江苏新海电厂2×125MW √江苏南京下关电厂2×135MW √江苏镇江高姿电厂4×135MW √√江苏盐城电厂2×135MW √江苏扬州电厂2×200MW √√江苏扬州第二电厂2×600MW √√江苏江阴夏港苏龙电厂4×135MW √江苏江阴夏港苏龙电厂二期2×300MW √江苏太仓港环保电厂一期2×135MW √√江苏太仓港环保电厂二期2×300MW √√江苏太仓港环保电厂三期2×300MW √√江苏南通天生港电厂4×135MW √√江苏南通天生港电厂二期2×300MW √√江苏南京扳桥电厂2×135MW √江苏镇江谏壁电厂2×300MW √√江苏贾旺电厂4×135MW √√√江苏大屯发电厂2×135MW √江苏华润常熟电厂3×600MW √√安徽平圩电厂2×600MW √安徽田家庵电厂1×300MW √安徽铜陵电厂1×300MW √√安徽淮北电厂2×300MW √安徽洛河电厂4×300MW √安徽马钢自备电厂2×50MW √√√安徽安庆电厂2×300MW √福建厦门嵩屿电厂2×300MW √√√福建漳平电厂2×100MW √福建邵武电厂2×125MW √广东华能汕头电厂2×300MW √√广东珠江电厂2×300MW √√广东沙角B厂,C厂2×600MW √√广东珠海电厂2×600MW √√大亚湾核电站√湖南石门电厂2×300MW √√湖南湘潭电厂2×300MW √√湖南株州电厂2×300MW √√湖南益阳电厂2×300MW √√湖南鲤鱼江电厂2×300MW √√湖北襄樊电厂4×300MW √√湖北汉川电厂2×300MW √√湖北武钢自备电厂2×200MW √√湖北黄石电厂2×300MW √√湖北蒲圻电厂2×300MW √河南首阳山电厂2×300MW √√河南安阳电厂2×300MW √河南信阳电厂2×300MW √√河南登封电厂2×300MW √√√河南永城电厂2×300MW √√河南新乡电厂2×135MW √河南神火电厂2×135MW √河南周口电厂2×135MW √山东石横电厂4×300MW √山东胜利油田自备电厂2×300MW √山西阳泉电厂2×300MW √√山西太原第一热电厂2×300MW √√山西太原第一热电厂二期2×600MW √√山西河曲电厂一期2×600MW √√北京石景山热电厂2×100MW √北京第二热电厂2×200MW √河北沙岭子电厂4×300MW √√河北定州电厂2×600MW √√天津大港电厂2×300MW √天津大唐盘山电厂二期2×600MW √√哈尔滨第三热电厂2×300MW √√吉林省吉林热电厂2×200MW √华能大连电厂2×300MW √√陕西渭河电厂2×300MW √陕西蒲城电厂2×300MW √√√陕西神木电厂2×100MW √√陕西宝鸡电厂4×300MW √陕西西郊热电厂2×300MW √√甘肃靖远电厂2×300MW √√甘肃西固电厂2×125MW √√甘肃平凉电厂4×300MW √√内蒙达旗电厂2×300MW √√√内蒙国华准格尔电厂2×600MW √√内蒙托克多电厂二期2×600MW √√宁夏大坝电厂2×300MW √√云南曲靖电厂2×300MW √√贵州安顺电厂2×300MW √√√四川成都热电厂2×142MW √√巴基斯坦恰希玛核电站一期2×350MW √巴基斯坦木扎法戈电厂2×300MW √越南协福电厂2×100MW √√√伊朗萨汉姆燃机电厂2×350MW √√孟加拉巴库电厂2×125MW √√主要OEM配套厂家名称压力开关液位开关电子式液位产品北京良乡√√北京重型机器厂√√√上海汽轮机厂√√上海电机厂√√上海锅炉厂√上海电站辅机厂√√上海电力修造厂√上海水泵厂√上海鼓风机厂√√上海重型机器厂√√杭州汽轮机厂√√杭州锅炉厂√东方汽轮机厂√东方电机厂√东方锅炉厂√哈尔滨汽轮机厂√哈尔滨电机厂√哈尔滨锅炉厂√沈阳鼓风机厂√√沈阳水泵厂√。

Sor压力开关设定、调试步骤

具体内容,请参考工厂英文版操作手册,如两者内容有出入,以英文版为准。

在校验设定值时,在常压压状态下将压力开关引压口与压力台相应管道对接,要求压力系统必须有压力表等似可以实时观察压力数据的装置。

然后给系统缓慢增压,要求系统增压最高压力不得超过压力开关铭牌上标定的over range值。

当压力值处于量程范围(adjustable range)时,可进行压力开关设定。

设定压力开关时,将开关单元外壳面板打开,用扳手按照压力值得高低旋转设定螺栓即可。

如图

使设定螺栓和刻度盘的对应压力值对齐即可。

压力开关设定完毕,即可安装使用。

将压力开关引压口安装到管道上,信号线由开关单元接出,根据需要连接到控制是或者相关的控制管道上。

接线时,需严格按照说明书进行操作。

如图:

通常情况下,下降报警时接常闭(C-NC),上声报警接常开(C-NO)。

如果实际使用中发现信号反转,将接线NC与NO对调即可。

SOR美国SOR型号大全及采购询价1381851684黄经理SOR公司(中文名称索尔公司)成立于1946年,是世界上唯一一家集生产各类机械及电子压力、差压、温度、流量、液位开关及变送器于一体的专业化国际公司,总部位于美国勘萨斯州州府,现有员工300人,其压力开关类产品产量位居世界第一。

美国SOR开关量仪表SOR防爆开关询~价SOR流量开关SOR询~价SOR差压开关SOR询~价SOR变送器SOR询~价SOR压力开关SORSOR液位开关询~价询~价SOR温度开关SOR询~价1710A-G2A-C-A4-H1-CLSOR询~价9NN-K45-M4-C1A-TTYYWSOR询~价107AL-K40-P1-F0ASOR询~价9NN-K4-N4-F1ASOR询~价9NN-K5-N4-F1ASOR询~价9NN-K45-N4-F1ASOR询~价6NN-K2-N4-F1ASOR询~价6NN-K3-N4-F1ASOR询~价6NN-K5-N4-F1ASOR 6NN-K45-N4-F1A 询~价询~价44V-K2-N4-B1ASOR询~价44V-K4-N4-B1ASOR询~价44V-K5-N4-B1ASOR询~价44V-K45-N4-B1ASOR询~价66V-K2-N4-B1ASOR询~价66V-K3-N4-B1ASOR询~价66V-K5-N4-B1ASOR询~价66V-K45-N4-B1ASOR询~价55V-K3-N4-B1ASOR询~价55V-K5-N4-B1ASOR 55V-K45-N4-B1A 询~价询~价99V-K4-N4-B1ASOR询~价99V-K5-N4-B1ASOR询~价99V-K45-N4-B1ASOR询~价11V-K45-N4-C1ASOR询~价12NN-N66-N4-B1ASOR询~价12NN-N614-N4-B1ASOR询~价12NN-K2-N4-B1ASOR询~价12NN-K4-N4-B1ASOR询~价12NN-K5-N4-B1ASOR询~价12Nn-K45-N4-B1ASOR 4NN-K2-N4-B1A 询~价询~价4NN-K4-N4-B1ASOR询~价4NN-K5-N4-B1ASOR询~价4NN-K45-N4-B1ASOR询~价6NN-K2-N4-F1ASOR询~价6NN-K3-N4-F1ASOR询~价6NN-K5-N4-F1ASOR询~价6NN-K45-N4-F1ASOR询~价5NN-K3-N4-F1ASOR询~价5NN-K5-N4-F1ASOR询~价5NN-K45-N4-F1ASOR 9NN-K5-N4-F1A 询~价询~价9NN-K45-N4-F1ASOR询~价1NN-K45-N4-F1ASOR询~价5RN-EE3-N4-C2A-XSOR询~价757A-F4C-B-A8-N8-SCMRC1C4XSOR询~价733A-F4C-B-A5-N7-WVSCMRC1C4XSOR询~价54RN-KK118-M4-C2A-TTSOR询~价6RN-K5-M9-C2A-TTSOR询~价52L-K116-M9-C2A-TTSOR询~价66V1-K45-N4-B1ASOR询~价6NN-K3-M4-C2ASOR 6NN-K5-M4-C2A 询~价询~价54NN-K118-M4-C2ASOR询~价99VI-K5-N4-C2A-200-1000PSISOR询~价102AD-EG405-P1-C1A-VVYYSOR询~价9BH-JF45-U8-C2ASOR询~价5RN-K3-M4-C2A-TTX373SOR询~价56RN-K316-M4-C2A-TTX373SOR询~价6RN-K3-M4-C2A-TTX373SOR询~价4RN-K45-M4-C2A-TTX373SOR询~价12RN-K5-M4-C2A-TTX373SOR询~价6RN-K5-M4-C2A-TTX373SOR 107EL-EF40-P1-F0A 询~价询~价99V1-K5-N4-C1ASOR询~价12NN-K614-N4-B1ASOR询~价103W1-K805-N4-C1ASOR询~价4NN-EE4-N4-C1A-X373SOR询~价101RN-EE3-M4-C1A-TTX5(X=NOSOR询~价MEANS)SOR询~价5NN-EE5-M9-C2A-TTX4(X=NOSOR询~价MEANS)SOR询~价1NN-T45-N3-C2A-TTSOR询~价101NN-EE3-N4-C1ASOR 4RN-KK45-M2-C1A-CSRRTT 询~价询~价15RB-K5-M2-C1A-CSRRTTSOR询~价1RN-BD45-M4-C1ASOR询~价5RN-BD3-M4-C1ASOR询~价74V1-K118-N4-C1ASOR询~价54RN-KK118-N4-C1ASOR询~价101NN-K45-N4-C1ASOR询~价12NN-K5-N4-C1A-TTX373SOR询~价5AC-AD45-M2-F1ASOR询~价102W1-K912-P1-C2A-TTSOR询~价5NN-K45-W4-F1ASOR 205V1-EE125-U9-C7A-TTX 询~价询~价107AL-K12-P1-F1ASOR询~价101NN-K3-N4-C1ASOR询~价54RN-KK118-N4-C2ASOR询~价54NN-EE118-M4-C2ASOR询~价4NN-EE45-N4-C2ASOR询~价203NN-W105-U9-C7A-C4XSOR询~价54NN-K118-M4-B1ASOR询~价5NN-K3-M4-C2ASOR询~价4NN-K5-M4-C2ASOR询~价103W1-K212-N4-C1ASOR 731A-F7A-B-A2-N4 询~价询~价101NN-KK45-N4-C1A-X1TTSOR询~价12NN-YY4-M4-B1ASOR询~价107EL-EG12-P1-F0ASOR询~价4V3-AG4-N4-B1A-X1TTSOR询~价205NN-T125-U9-C7ASOR询~价301A-F1A-B-A4-N4SOR询~价101LC-EE3-N4-C1A-LLSOR询~价205LC-T125-U9-C7ASOR询~价4BA-KB4-N4-B1ASOR询~价15RB-EE2-N4-C2ASOR 6NN-KK5-N4-F1A 询~价询~价54NN-K118-N4-B1ASOR询~价107AL-N40-P1-F1A-x800SOR询~价107AL-N12-P1-F0A-TTSOR询~价201NN-K115-U9-C7A-TTSOR询~价107AL-N40-P1-F1ASOR询~价107EL-EG12P1-F1A-TT0SOR询~价56RN-EE216-M4-C2ASOR询~价55V1-K3-N4-B1ASOR询~价44V1-K4-N4-B1ASOR询~价99V1-K4-N4-B1ASOR 12NN-K2-N4-C1A 询~价询~价6NN-K5-N4-C1ASOR询~价4NN-EE4-N4-C2ASOR询~价52NN-K116-M4-C1ASOR询~价13RB-K5-N4-F1ASOR询~价203NN-K105-U9-C7ASOR询~价107AL-K12-P1-FOASOR询~价1LC-K45-M4-C2A-RRSOR询~价101NN-K3-N4-F1ASOR询~价66V1-K3-N4-B1ASOR询~价6NN-T5-N4-C1ASOR 103W1-EE212-N4-C2A 询~价询~价15RB-K2-N4-C2A-TTPKSOR询~价4NN-K2-M4-C2A-YY5SOR询~价4NN-K118-M4-C2A-YYSOR询~价6NN-K5-U9-C1ASOR询~价9NN-K5-M4-C1ASOR询~价107AL-N12-P1-F1ASOR询~价12NN-K4-N4-C1ASOR询~价6NN-K5-M4-C1ASOR询~价4NN-KK2-N4-C1ASOR询~价5NN-KK45-N4-C1ASOR 6VV1-K45-N4-C1A 询~价询~价4NN-K2-M4-C1ASOR询~价9L-K4-N4-F1ASOR询~价9L-K5-N4-F1ASOR询~价9L-K45-N4-F1ASOR询~价6L-K2-N4-F1ASOR询~价6L-K3-N4-F1ASOR询~价6L-K5-N4-F1ASOR询~价6L-K45-N4-F1ASOR询~价44V2-EF2-N4-B1ASOR询~价44V2-EF4-N4-B1ASOR 44V2-EF5-N4-B1A 询~价询~价44V2-EF45-N4-B1ASOR询~价66V2-EF2-N4-B1ASOR询~价66V2-EF3-N4-B1ASOR询~价66V2-EF5-N4-B1ASOR询~价66V2-EF45-N4-B1ASOR询~价55V2-EF3-N4-B1ASOR询~价6L-K5-N4-F1ASOR询~价5RN-EE3-N4-C2A-XSOR询~价757A-F4C-B-A8-N8-SCMRC1C4XSOR询~价733A-F4C-B-A5-N7-WVSCMRC1C4XSOR 54RN-KK118-M4-C2A-TT 询~价询~价1NN-K45-M4-C1ASOR询~价6RN-K5-M9-C2A-TTSOR询~价52L-K116-M9-C2A-TTSOR询~价66V1-K45-N4-B1ASOR询~价6NN-K3-M4-C2ASOR询~价6NN-K5-M4-C2ASOR询~价54NN-K118-M4-C2ASOR询~价99VI-K5-N4-C2A-200-1000PSISOR询~价102AD-EG405-P1-C1A-VVYYSOR询~价9BH-JF45-U8-C2A-TTX3SOR 5RN-K3-M4-C2A-TT 询~价询~价56RN-K316-M4-C2A-TTSOR询~价6RN-K3-M4-C2A-TTSOR询~价4RN-K45-M4-C2A-TTSOR询~价12RN-K5-M4-C2A-TTSOR询~价6RN-K5-M4-C2A-TTSOR询~价107EL-EF40-P1-F0ASOR询~价99V1-K5-N4-C1ASOR询~价103W1-K805-N4-C1ASOR询~价4NN-EE4-N4-C1ASOR询~价101NN-EE3-N4-C1ASOR 101RN-EE3-M4-C1A-TTX5(X=NOMEANS) 询~价询~价5NN-EE5-M9-C2A-TTX4(X=NOMEANS)SOR询~价1NN-T45-N3-C2A-TTSOR询~价4LC-EE4-N4-C1A-LLSOR询~价4RN-KK45-M2-C1A-CSRRTTSOR询~价15RB-K5-M2-C1A-CSRRTTSOR询~价1RN-BD45-M4-C1ASOR询~价5RN-BD3-M4-C1ASOR询~价74V1-K118-N4-C1ASOR询~价54RN-KK118-N4-C1ASOR询~价17RB-EE2-N4-C1A-TTSOR 101NN-K45-N4-C1A 询~价询~价12NN-K5-N4-C1A-TTSOR询~价5AC-AD45-M2-F1ASOR询~价102W1-K912-P1-C2A-TTSOR询~价5NN-K45-W4-F1ASOR询~价205V1-EE125-U9-C7A-TTXSOR询~价107AL-K12-P1-F1ASOR询~价101NN-K3-N4-C1ASOR询~价54RN-KK118-N4-C2ASOR询~价54NN-EE118-M4-C2ASOR询~价4NN-EE45-N4-C2ASOR 203NN-W105-U9-C7A-C4X 询~价询~价54NN-K118-M4-B1ASOR询~价5NN-K3-M4-C2ASOR询~价4NN-K5-M4-C2ASOR询~价103W1-K212-N4-C1ASOR询~价731A-F7A-B-A2-N4SOR询~价101NN-KK45-N4-C1A-X1TTSOR询~价12NN-YY4-M4-B1ASOR询~价107EL-EG12-P1-F0ASOR询~价4V3-AG4-N4-B1A-X1TTSOR询~价205NN-T125-U9-C7ASOR 301A-F1A-B-A4-N4 询~价询~价101LC-EE3-N4-C1A-LLSOR询~价4LC-EE4-N4-C1A-LLSOR询~价205LC-T125-U9-C7ASOR询~价4BA-KB4-N4-B1ASOR询~价15RB-EE2-N4-C2ASOR询~价6NN-KK5-N4-F1ASOR询~价54NN-K118-N4-B1ASOR询~价107AL-N40-P1-F1A-x800SOR询~价14RB-KK5-M4-C2ASOR询~价651-K6SOR 5NN-L3-S1-F1A 询~价询~价2NN-L3-S1-D1ASOR询~价203A-A1B-B-B4-N4-TTETXSOR询~价201NN-K115-U9-C7A-TTSOR询~价107AL-N40-P1-F1ASOR询~价12NN-K2-N4-C1ASOR询~价4NN-EE4-N4-C2ASOR询~价107AL-K12-P1-FOASOR询~价1LC-K45-M4-C2A-RRSOR询~价4NN-K2-M4-C2A-YY5SOR询~价6NN-K5-U9-C1ASOR 12RN-KK5-N4-C1A 询~价询~价101RN-EE3-N4-C1ASOR询~价103W1-EE502-N4-C1ASOR询~价15RB-EE2-N4-C1ASOR询~价54NN-KK118-N4-C2A-XITTYYSOR询~价54RN-KK118-M4-C2A-TTYYRKX3X866SOR询~价52RN-KK116-M1-C2A-TTVVYYSOR询~价17S-K2-N4-C2A-TTPKSOR询~价107AL-N12-P1-F0ASOR询~价99V1-K45-S1-C1ASOR询~价44V1-K4-N4-C1ASOR 13RB-K5-N4-F1A 询~价询~价103W1-EE212-N4-C2ASOR询~价9NN-K5-M4-C1ASOR询~价12NN-K4-N4-C1ASOR询~价4NN-K4-N4-C1ASOR询~价102W1-K603-P1-C1A-TTSOR询~价5NN-KK45-N4-F1ASOR询~价201NN-EE125-U9-C7ASOR询~价303A-F1A-B-A4-N4SOR询~价201V1-EE125-U9-C7ASOR询~价107AL-N12-P1-F0A-TTSOR 107EL-EG12-P1-F1A-TT 询~价询~价56RN-EE216-M4-C2ASOR询~价55V1-K3-N4-B1ASOR询~价44V1-K4-N4-B1ASOR询~价101RM-EE3-M4-C1ASOR询~价4RM-EE45-M4-C2ASOR询~价361214-SYW145SOR询~价203NN-K105-U9-C7ASOR询~价54NN-KK118-N4-C1ASOR询~价1NN-K45-M4-C1ASOR询~价5NN-K45-M4-C1A-TTSOR 201NN-KK135-U9-C7A-X 询~价询~价52NN-K116-M4-C2A-TTSOR询~价201NN-K135-U9-C7A-XSOR询~价201NN-K125-U9-C7A-XSOR询~价201NN-K115-U9-C7A-XSOR询~价203NN-K105-U9-C7A-XSOR询~价101NN-EE3-N4-C1ASOR询~价9NN-KK45-U9-C2A-TTYYPKXSOR询~价9NN-K45-M4-C2A-TTYYSOR询~价11V1-K45-N4-C1ASOR询~价12NN-EE4-M4-C1ASOR 4LC-EE4-M4-C1A 询~价询~价5NN-EE45-M4-C1ASOR询~价6NN-EE3-M4-C1ASOR询~价107AL-N40-P1-F1ASOR询~价107AL-N40-P1-F1A-X2SOR询~价4L-K5-M4-C2A-CGSOR询~价52NN-EE116-N4-B1ASOR询~价54NN-K118-M4-C2A-YYSOR询~价99V1-K4-N4-B1ASOR询~价6NN-K5-N4-C1ASOR询~价52NN-K116-M4-C1ASOR 66V1-K3-N4-B1A 询~价询~价6NN-T5-N4-C1ASOR询~价15RB-K2-N4-C2A-TTPKSOR询~价107AL-N12-P1-F1ASOR询~价5NN-KK45-N4-C1ASOR询~价66V1-K45-N4-C1ASOR询~价17RB-EE3-M4-D1ASOR询~价4NN-K2-M4-C1ASOR询~价107EL-EG12P1-F1A-TTSOR询~价1NN-EE45-N4-F1ASOR询~价6NN-K5-M4-C1ASOR 4NN-K5-M4-C1A-RR 询~价询~价1NN-EE45-N4-F1ASOR询~价9NN-K5-N4-C1A-X373SOR询~价6LC-K5-N4-C2A-371SOR询~价20-180PSISOR询~价4NN-K5-M4-C1A-YYSOR询~价9AG-EF45-N1-F1ASOR询~价203RN-EE125-U9-C7ASOR询~价107AL-N12-P1-F0A-X2SOR询~价201V1-K125-U9-C7ASOR询~价4RN-EE45-M1-C1A-PPSOR 107AL-K12-P1-F0A-X 询~价询~价6NN-K3-N4-C2ASOR询~价54L-K118-M4-C2ASOR询~价208A-E1B-F-Z1-N4-ETX2SOR询~价1510B-G5A-C-W9-ES-XSOR询~价12NN-KK4-N4-B1ASOR询~价6L-K3-N4-C2ASOR询~价5NN-K3-N4-C2ASOR询~价303A-F1A-B-A1-N4SOR询~价414864-510382SOR询~价387162-510835SOR 318642-510337 询~价询~价534CR-TN51-P9-Z1A-VTRRSOR询~价101NN-T3-N4-C1ASOR询~价4NN-K4-M4-C2ASOR询~价54RN-EE118-N4-C1ASOR询~价1NN-EE45-N4-C2ASOR询~价6NN-KK5-N4-D1ASOR询~价12NN-K2-M4-B1ASOR询~价12NN-K614-N4-C1ASOR询~价4NN-K4-N4-C2ASOR询~价54NN-K117-N4-C2ASOR 5NN-K5-N4-C2A 询~价询~价651-K8SOR询~价6NN-K5-N4-C2ASOR询~价12L-KK5-M4-C2A-HBSOR询~价17RB-113-M4-D1ASOR询~价6L-KK3-M4-C2A-HBSOR询~价9NN-K45-N1-F1ASOR询~价6RN-EE5-N4-C1ASOR询~价103W1-K502-N4-C1A-TTSOR询~价4NN-EE5-N4-C1ASOR询~价101NN-EE3-N4-C1ASOR 6NN-K3-M4-C2A-TT 询~价询~价44V1-K4-N4-B1ASOR询~价54NN-KK118-N4-C1ASOR询~价4NN-KK4-N4-C1A-XX616SOR询~价9NN-KK45-N1-C1A-XX618SOR询~价5NN-K5-N4-F1ASOR询~价52NN-K116-M4-B1ASOR询~价6NN-K3-N4-F1ASOR询~价12NN-K5-N4-B1ASOR询~价12L-K45-M4-C2A-TTPKSOR询~价5L-K45-M4-C2A-TTPKSOR 4L-K45-M4-C2A-TTPK 询~价询~价9NN-K5-M1-C1A-TTSOR询~价12NN-K614-N4-B1ASOR询~价12NN-K2-N4-B1ASOR询~价BH-009024-009SOR询~价52NN-K116-M4-C2A-TTSOR询~价12NN-K45-N4-B1A-TTSOR询~价101RN-K3-N4-C1A-RRSOR询~价103W1-EE502-N1-C1ASOR询~价101NN-T3-N4-C1ASOR询~价107AL-N40-P1-F1ASOR 201V1-K125-U9-C7A 询~价询~价99V1-K5-N4-C2ASOR询~价403212-SZB712SOR询~价10PSISOR询~价107AL-K40-PI-F0ASOR询~价9NN-K4-M2-C1A-XSOR询~价208A-E1B-F-Y4-N4-CPC4MRC7XSOR询~价BH-003001-003SOR询~价733A-F3D-B-A2-S3SOR询~价720mmSOR询~价431557-0AL100SOR 0-200PSI 询~价询~价SORSOR询~价418252-29LYQISOR询~价638183-SEMDQ1SOR询~价431168-SACZSOR询~价SORSOR询~价201V1-EE125-U9-C7ASOR询~价SORSOR询~价107AL-N12-P1-F1A-TTX3X371SOR询~价SORSOR询~价5NN-K45-W4-F1ASOR SOR 询~价询~价5B3-K5-M4-C1ASOR询~价SORSOR询~价6AG-EG3-M2-C2ASOR询~价34.5-413.7KPaSOR询~价SORSOR询~价403213-QDD005SOR询~价SORSOR询~价15RB-EE2-N4-CIA-X371SOR询~价12NN-N66-N4-B1ASOR询~价12NN-K614-N4-B1ASOR 12NN-K2-N4-B1A 询~价询~价12NN-K4-N4-B1ASOR询~价12NN-K5-N4-B1ASOR询~价12NN-K45-N4-B1ASOR询~价12L-N66-N4-B1ASOR询~价12L-K614-N4-B1ASOR询~价12L-K2-N4-B1ASOR询~价12L-K5-N4-B1ASOR询~价12L-K45-N4-B1ASOR询~价4NN-K2-N4-B1ASOR询~价4NN-K4N4-B1ASOR 4NN-K5-N4-B1A 询~价询~价4NN-K45-N4-B1ASOR询~价12LC-K614-M4-C1A,TTA373SOR。