机电一体化专业英语

- 格式:ppt

- 大小:54.35 MB

- 文档页数:410

第1部分材料和热处理第1单元金属附1: Exercise参考答案Exercise I1.F2. T3. T4. T5.FExercise II1. ferrous metals2.铜基合金3. nonferrous alloys4.自硬钢(风钢)5. plain carbon steels6.零点几7. stainless steels8.修(理)模(具)9. high-speed steel10.布氏硬度Exercise III1. stronger2. strong3. an alloy of iron and carbon4. lighter5. betterExercise IV1. which is also known as machine steel2. Some alloying elements cause steel to resist corrosion3. The largest parts of the blast furnace4. the limitations become restrictive5. the high fatigue and toughness of the low-carbon material being in good compromise with the strength and hardness that comes with higher carbon content附2:课文参考译文众所周知黑色金属是铁和碳的合金,这类合金还可能含有一些其它元素,如Si、P等等,但黑色金属所存在的各种元素中,要数碳最为重要。

在工业上应用的黑色金属有两大类:铸铁和钢。

这两类黑色金属通常由生铁炼得,但它们的含碳量不一样。

钢是含碳量为0.0218%至2.11%的铁碳合金;而铸铁是含碳量超过2.11%的铁碳合金。

工业上不用纯铁,因为它太软。

钢是一种包含铁和碳且添加了其他元素来得到更优性能的合金。

科目:机电一体化专业英语使用班级:使用班级:单选题单选题1 、10xx means that it is a plain carbon steel 1,10XX意味着它是一个普通的碳素钢 C the second digit indicates that there is no modification in the alloys. 第二个数字表明,有没有修改的合金。

A 、which A,这B 、when B,当C 、where C,其中D 、that ,,2 、These steels 2,这些钢材 B high strength and also high strength to weight ratio, good c orrosion resistance. 高强度和高强度重量比,好的C orrosion电阻。

A 、exhibits 一,展品B 、exhibit ,表现出C 、exhibited C,展出D 、are exhibiting D ,展示3 、This property, also called 3,此属性,也被称为C , is related to the resistance of the steel to the softening effect of heat. ,是有关钢材的耐热软化效应。

A 、cold-hardness 一,冷硬度B 、cold-shortness B,冷,气短C 、hot-hardness 热硬度,D 、brittle condition D ,脆条件4 、These metals 4,这些金属 A in a soft condition, heat-treated to gain hardness, and then finish machined with a grinding or lapping process that can handle the hardness. 在软条件下,热后获得的硬度,然后完成加工与磨削或研磨的过程中,可以处理的硬度。

1.机电一体化专业A安装,组装assemble按钮buttonB半导体元件semiconductor element 白炽灯泡incandescent bulb保险丝、熔断器fuse保险盒fuse holder避雷器arrester变压器transformerC插针/插头pin (plug)柴油发电机diesel generator超声传感器 ultrasonic sensor超高压extra-high voltage触电electric failure传导conduct传送带,输送机conveyor传感器sensor串联series磁铁magnetD导体,导线conductor.电的electric电火化electric spark电的、电气的electrical电机electrical machine供电electrical service电工electrician电极electrode电子的、电子学的electronic静电的electrostatic电工学、电工技术electrotechnics电池battery.电路circuit电路断路器circuit breaker电路图circuit diagram电动机electromotor电机 motor电感inductance电感器,感应器inductor电感镇流器inductive / magnetic ballast 电流,水流current电流互感器current transformer电流表ammeter .电线electric wire / power cored电子镇流器electronic Ballasts电刷,刷子brush电缆cable电容capacitance电容器capacitor端子台terminal短路short circuitF发电机generator发光二极管fluorescent light /lamp 放大器,扩音器amplifierG感应器sensor隔板baffle汞灯mercury Lamps锅炉boilerH恒定的constant缓冲器buffer活扳手adjustable wrenchJ机器,机械machine机械的、力学的mechanical机械、力学mechanism机械零件 mechanical parts机电一体化 mechanotronics / mechanical-electrical integration 集成电路 integrate circuit交流电alternating current交流电路AC circuit绝缘insulation节能灯energy saving lamp接地、触地、碰地contact to earth接触器、触头contactorK开关switch控制盘control panel控制器controllerL冷凝、使凝结condensate冷却器、冷冻器congealer离心风机centrifugal fan连接connect联接器、接线盒connector螺栓、拧螺丝boltM模拟analog模拟量输入analog input模拟量输出analog output模拟信号analog signal模数转换analog-to-digitalP排气扇air exhaust fanQ启辉器starter气体放电灯gas discharge lamp 汽缸cylinder起重机craneR熔断的blownS三相交流电 three-phase AC适配器adapterT调光器dimmer调整螺钉adjusting screw调节阀control valve调制解调器modem跳闸线路breaker coil铁心、核心、磁心coreW万用表avometer五金配件hardware fitting雾化atomizingX线圈coil .Y压缩compress压缩机compressor荧光灯fluorescent light /lamp Z整流器commutator直流电源 DC electrical source 自耦变压器autoformer自动automatic自动调压器automatic voltage regulator 轴承bearing制动器,闸brake转换convert .2. 电子专业B闭路电视close-circuit television并联电容器shunt capacitor变压器transformerC彩色监视器colour monitorD低压low voltage低频low frequency低频响应low frequency response低频振荡器low frequency oscillator电动机motor电感inductance电流current电流放大器current amplifier电压voltage电压等级voltage grade电阻resistor电抗reactance电导conductance电纳susceptance电容器capacitor电抗器reactor电力系统power system电厂power plant电子束electron beam电子数据交换electronic data exchange电子现场节目制作electronic field production 电子信息系统electronic information system定子stator断路器breakerF发电厂power plant发电机generator分线盒、分组终端block terminalG高压high voltage高级音频编码advanced audio coding高级通信业务advanced communication service 高清晰度high definition高密度调制high density modulation高清晰度电视high definition television高清晰度视频系统high definition video system 高频high frequency高保真high-fidelity功率:powerH缓冲放大器buffer amplifierJ基本输入输出系统basic input/output system 基准脉冲发生器basic pulse generator激光唱片compact disc集成电路integrated circuit接线盒junction box接入条件access conditions接入控制系统access control systemL励磁excitation励磁器excitorM模拟analog模-数转换analog to digital模拟输出analog output母线bus barP平衡电流balanced currentQ区域通信系统area communication systemR人工智能artificial intelligenceS输电线transmission line输电系统power transmission system输入/输出控制系统input-output control system 数据脉冲data pulse数字卫星广播digital satellite broadcasting数字演播室控制digital studio control数字环绕声surround digital数字特技digital special effect数字信号处理digital signal processing数字声音处理器digital sound processor数字卫星系统digital satellite system数字技术digital technique数字电视digital television数据终端data terminal数据传输data transmission数字地面广播digital terrestrial broadcasting数字时基校正器digital time-base corrector数字电视摄像机digital television camera数字影院系统digital theater system数字调谐系统digital tuning system数字电视标准digital television standard数字视频广播digital video broadcasting数字视频压缩digital video compression数字视频特技digital video effect数字磁带录像机digital video tape recorder三双绕组变压器:double-column transformer DblClmnTrans 双绕组变压器:three-column transformer ThrClnTransT天线antenna调幅amplitude modulation条件接收conditional access条件接收控制conditional access control条件接收系统conditional access system同轴电缆concentric cable通用接口common interfaceY音频中心audio center音频分配系统audio distribution system音频(声音擦除)audio erasing音频audio frequency音频放大器audio frequency amplifier音频编码器automatic frequency coder音频电平表audio-level meter有线电视,电缆电视cable televisionZ闸刀Isolator转子电流magnetizing current自动黑平衡automatic black balance自动低音补偿automatic bass compensation自动亮度控制automatic brightness control自动黑电平automatic black level自动亮度限制电路automatic brightness limiter circuit 自动中心控制automatic centering control自动色度automatic chroma control自动消色器automatic chroma killer自动消磁电路automatic degaussirng circuit自动频率控制automatic frequency control自动微调automatic fine tuning自动频率跟踪automatic frequency track自动额率微调automatic frequency trim自动增益控制automatic gain control自动音乐传感装置automatic music sensor自动噪声消除器automatic noise canceller自动节目搜索automatic program search自动节目暂停系统automatic program pause system 自动节目搜索系统automatic program search system 音频响应audio response自动遥控automatic remote control自动扫描跟踪automatic scanning tracking自动定时控制automatic timing control自动音频校正automatic tone correction自动寻迹automatic track finding自动测试系统automatic test system自动音量控制automatic volume control自动稳压器automatic voltage regulator自动白平衡automatic white balance自动变焦控制automatic zooming control 自动调零automatic zero setting3.电气专业B办公自动化office automation避雷器lightning arrester变频器inverter变压器transformer变电站substation波导wave guideC传感器sensor传输线transmission line触发电极trigger electrode充油电力电缆 o il-filled power cable充电(阻尼)电阻charging(damping) resistor 磁场magnetic fieldD导体conductor单片机single chip microprocessor地下电缆underground cable电力电子power electronics电路原理principles of electric circuits 电场electric field电容capacitance电动机驱动motoring电压控制系统voltage control system 电压互感器potential transformer电路元件circuit components电路参数circuit parameters电气设备electrical device电能electric energy电力变压器power transformer电力系统power system电力网络power network电能转换器energy converter电压互感器potential transformer电流表ammeter电流互感器current transformer电热器heating appliance电缆cable电弧放电arc discharge叠片铁芯laminated core定子stator定子绕组stator winding多相整流器polyphase rectifier短路试验short circuit testing断电deenergizeF发光二极管light emitting diode发电generating放电discharge分压器voltage divider风动发电机wind-driven generatorG感应电动机induction motor感应式电机induction machine感生电流induced current高电压工程highvoltage engineering隔离开关disconnector工控机industrial personal computer工厂自动化factory automation管理信息系统management information system光纤optical fiberH核电站nuclear power station互感mutual-inductor火力发电站thermal power station混合分压器mixed dividerI漏磁电抗leakage reactanceJ记录仪recorder集散控制系统distributed control system架空线overhead line监控及数据采集系统supervisory control and data acqusition 检修overhauling交流电alternating current交流输电系统AC transmission system绝缘insulation绝缘子insulator接地线earth(ground) wire接地开关earthing switch解调器demodulator晶体管transistor静电电压表electrostatic voltmeterK可编程序控制器programmable logic controller可编程计算机控制器programmable computer controller 客户/服务器client/serverL励磁系统excitation system励磁电流field current流量计flowmeterM马蹄形磁铁horseshoe magnet模糊控制fuzzy control母线bus barO耦合电容coupling capacitorQ汽轮机steam turbine汽轮发电机turbogeneratorR绕组winding人工智能artificial intelligent软起动器soft starterS上位机supervisory computer设备网device net示波器oscilloscope水轮发电机hydrogenerator水轮机hydraulic turbine水力发电站hydro power stationT调制器modulator调谐器tuner调节器regulator调谐电路tuned circuit同步发电机synchronous generatorW网络network稳定变压器stabilizing transformer涡流eddy currentX现场总线控制系统fieldbus control system 线圈绕组coil winding限波器line trap旋转磁场rotating magnetic field蓄电池storage batteryY阳极(阴极)anode (cathode)以太网ether net异步电机asynchronous machine原生电池primary cell远仪表instrument程测控终端remote terminal unit杂散电容stray capacitanceZ杂散电感stray inductance直流电direct-current直流电动机dc motor直流发电机dc generator智能传感器smart sensor智能变送器smart transducer智能终端intelligent terminal整流器rectifier主站/从站master station/slave station转子rotor转子电阻rotor resistance自动电压调整器automatic voltage regulator自感self-inductor组态configuration4.数控专业B扳手wrenches刨床planing machines变速箱 gearbox变速器speed changer变形力deforming force变形deformationC插齿gear shaping车间 workshop车刀 lathe tool车床 lathe车削 turning齿轮 gear齿轮加工gear machining齿轮齿条 pinion and rack齿轮切削机gear cutting machines 冲压机stamping parts冲子研磨器punch formers传动 drive/transmission传动链transmitted chains磁路 magnetic circlesD带传动belt drive带锯saws,band带锯床sawing machines,band断裂 fracture挡板orifice plate刀片blades刀具 cutter刀尖 nose of tool电火花线切割加工 electrical discharge wire - cutting电脑数控镗床CNC boring machines电脑数控弯折机CNC bending presses电脑数控铣床CNC milling machines电脑数控线切削机CNC wire-cutting machines电脑数控磨床CNC grinding machines电脑数控车床CNC lathes电脑数控电火花线切削机CNC EDM wire-cutting machines 电脑数控电火花机CNC electric discharge machines电脑数控雕刻机CNC engraving machines电脑数控机床配件CNC machine tool fittings 电脑数控剪切机CNC shearing machines电脑数控钻床CNC drilling machines电动刀具electric power tools电火花机electric discharge machines雕刻机engraving machines定位 allocation锻 forge锻铝forging,aluminium锻压机presses,forging锻模forging dies多轴钻床drilling machines,multi-spindleF阀门 valve发生器generatorG高速车床lathes,high-speed高速钻床drilling machines,high-speed弓锯saws,hack滚动轴承 rolling bearing滚齿 hobbing功率 power工件 workpieceH焊 weld虎钳vises滑动轴承 sliding bearingJ机械加工余量 machining allowance机床 machine tool机床夹具 jig激光切割laser cutting激光雕刻机engraving machines,laser激光钢板切割机laser cutting for SMT stensil 集合管manifolds加工 machining夹盘chucks夹具fixture夹具/支持系统clamping/holding systems剪切 shear绞孔 fraising绞刀 reamer截面 section金属板成型机sheet metal forming machines 金属板加工机sheet metal working machines 金属切削 metal cutting金属工艺学 technology of metals锯片blades,saw锯床sawing machinesK卡口bayonet卡盘 chuck开关及按钮switches & buttons孔加工 spot facing machiningL冷却机coolers冷锻forging,cold冷锻冲压机presses,cold forging冷加工 cold machining离合器 clutch拉伸pulling拉床broaching machine拉孔broaching离心压力机presses eccentric立式铣床milling machines,vertical立式油压拉床vertical hydraulic broaching machine立式刨床planing machines vertical立式车床lathes,vertical立式带锯saws,vertical band立式加工中心machining centers,vertical立式及卧式铣床milling machines,vertical & horizontal立式钻床drilling machines,vertical联轴器 coupling联结 link链 chain链传动chain drive连续冲模dies-progressive六角立式铣床milling machines,turret vertical六角车床lathes,turret螺栓,螺帽及螺丝bolts,screws & nuts螺纹磨床grinders,thread螺纹 thread螺旋 helix螺纹加工 thread processing螺钉 screw铝轮冒口切断机overflow cutting machines for aluminium wheels M摩擦 friction磨床 grinder磨损 wearN耐用度 durability内力 internal force扭力 torsion扭转 twistQ气压 air pressure pneumatic pressure气油压虎钳pneumatic hydraulic clamps 气动冲床presses,pneumatic气动工具pneumatic power tools钳工 locksmith铣头milling heads铣床milling machines铣削mill铣刀 milling cutter前刀面 rake face强度 intensity切断机cutting-off machines切削深度cutting depth切线 tangent曲柄crank曲柄压力机presses,crankR热处理 heat treatment热加工 hotwork润滑系统lubrication systems润滑液lubricants熔热处理炉heating treatment funacesS砂轮修整器wheel dressers三爪、分割工具头3-Jaws indexing spacers 舍弃式刀头disposable toolholder bits渗碳carburization蚀刻机etching machines输送链conveying chainsT弹簧 spring弹性 elasticity镗床 boring machine退火 anneal脱碳 decarburizationV弯曲机bending machines弯管机tube bending machinesW万能铣床milling machines,universal万能磨床grinding machines,universal弯曲机bending machines弯管机tube bending machines弯曲应力 bending stress卧式铣床milling machines,horizontal卧式带锯saws,horizontal band卧式加工中心machining centers,horizontal卧式及立式加工中心machining centers,horizontal & vertical 误差error无心磨床grinding machines,centerless无心精研机lapping machines,centerlessX销 pin修整机finishing machinesY压模pressing dies压铸冲模die casting dies压铸机die casting machines摇杆 racker异步电动机asynchronous motor压缩 hitting液压 hydraulic pressure液压泵hydraulic pump液压元件hydraulic components液压冲床presses,hydraulic液压动力元件hydraulic power units 液压工具hydraulic power tools液压回转缸hydraulic rotary cylinders 应力stress硬度 rigidityZ钻石刀具diamond cutters钻头drills钻模jigs钻床drilling machines钻床工作台drilling machines bench 钻削镗削 bore造链机chain making tools造线机cable making tools造钉机nail making machines正火 normalizing制动器 arrester brake主轴spindle主轴箱 headstock铸造found铸铝casting,aluminium铸铜casting,copper铸造设备foundry equipment铸钢casting,steel铸灰口铁casting,gray iron转台rotary tables转向器 redirector轴 shaft轴承bearings轴承配件bearing fittings轴自动压力机presses,transfer自动车床lathes,automatic承加工机bearing processing equipment 钻床 drill machine装配 assembling5.模具专业B波子弹弓ball catchC插头connector plug撑头support pillar插座connector socketD大水口edge gate导边leader pin/guide pin导套bushing/guide bushing 挡板stop plate定位圈locating ring顶针板ejector retainner plate 顶板eracuretun弹弓柱spring rodE二板模2-plate moldF发热管cartridge heater分流锥spure sperader复位键、提前回杆early return barG隔片buffle管钉dowel pinH活动臂lever arm喉塞line lpug喉管tube换模系统mold changing systemsJ激光切割laser cutting激光雕刻机engraving machines,laser激光钢板切割机laser cutting for SMT stensil 集合管manifolds唧嘴sprue bushing夹盘chucks夹具fixture剪切机shearing machines矫直机straightening machines金属板成型机sheet metal forming machines 金属板加工机sheet metal working machines锯片blades,saw锯床sawing machines卷边工具crimping toolsK卡口bayonet开模槽ply bar scot扣机(尼龙拉勾)nylon latch lockL垃圾钉stop pin流道平衡runner balance螺丝screwM毛坯 rough模芯mold core模具mold模具维修mold repair模具打磨/磨纹mold polishing/texturing 模具单元mold & die components 模具加热器/冷却器mold heaters/chillers 模胚(架)mold base磨轮grinding wheels磨削工具grinding tools磨床grinding machines磨床工作台grinder bench密封/封料sealN耐磨板/油板wedge wear plate内圆磨削 internal grindingP平面磨削 plane grindingQ气阀valvesR热流道hot runner,hot manifold 热嘴冷流道hot sprue/cold runner S三板模3-plate mold上内模cavity insert水口形式gate type水口大小gate size水口司bush司筒ejector sleeve司筒针ejector pin锁扣latch锁模块lock plate塑胶管plastic tube数模 digital analogyT探针thermocouples推板stripper plate托板support plateW外圆磨削external grindingX下内模core insert镶件insert斜导边angle pin斜顶lifterY压条plateZ中托司shoulder guide bushing 中托边guide pin注油机lubricators自动压力机presses,transfer自动车床lathes,automatic钻石刀具diamond cutters钻头drills钻模jigs钻床drilling machines钻床工作台drilling machines bench转台rotary tables6.制冷专业B冰箱用温度控制器thermostat for refrigeratorC程序指令式能量调节系统capacity regulation system of program order D单向阀check valve导阀pilot valve低压控制器low pressure controller低压浮球阀low pressure float valve单机能量调节capacity regulation of single unit电磁阀solenoid valve电动吸气阀electro inlet valveF分解decomposition浮球调节阀float regulation valve浮球阀float valveG高压控制器high pressure controller高压浮球阀high pressure float valve隔膜阀diaphragm valve工业制冷装置industrial refrigerating plant过热温度调节superheat temperature regulation H恒压膨胀阀constant pressure expansion valve J减压阀pressure-reducing valve截止阀shut-off valve节流阀throttle valve交*充注cross chargeK库温调节storage room tempurature regulation L冷凝压力调节器condensing pressure regulator 冷藏链cold chain冷藏refrigerated prvservation能量增强剂energy booster流量调节flow regualation流体流动指示器liquid indicator浓溶液rich solution,concentrated solutionN内平衡热力膨胀阀internal equalizer thermostaice expansion valve 内平衡管internal equalizer pipe能量调节capacity regulatorP旁通型能量调节器bypass capacity regulator膨胀阀expansion valve膨胀阀过热度superheat degree of expansion valve膨胀阀容量expansion valve capacityQ气体充注gas chargeR热力膨胀阀thermostatic expansion valve热源调节法energy source control method热电膨胀阀thermal electric expansion valve热平衡heat balance溶液流量调节solution flow regulation溶液solution溶解度solubility溶剂solvent溶质soluteS三通电磁阀three way magnetic valve三通调节阀three way control valve商业制冷装置commercial refrigerating plant释压装置pressure relief device湿度调节器humidity controller水量调节阀water regulation valve水解hydrolysis手动膨胀阀hand expansion valveT调节风门control damper同工质充注same material chargeW外平衡热力膨胀阀external equalizer thermostaice expansion valve 外平衡管external equalizer pipe温度式水量调节阀temperature-controlled water valveX吸收absorption吸附adsorption吸收剂absorbent,absorbing agent吸附剂adsorbent吸收式制冷absorption refrigeration吸附式制冷adsorption refrigeration吸附充注absorptive charge稀溶液weak solution,diluted solution限压装置pressure-limiting deviceY压力式水量调节阀pressure-controlled water valve压力控制器pressure controller压差控制器differential pressure controller易熔塞fusible plugZ制冷refrigeration制冷回路refrigerating circuit制冷剂控制器refrigerant control制冷装置refrigerating installation,refrigerating plant 制冷机refrigerating machine制冷机械refrigerating machinery制冷工程refrigeration engineering制冷工程承包商refrigeration contractor制冷工作者refrigerationist制冷工程师refrigeration engineer制冷技术员refrigeration technician制冷技师refrigeration technician制冷技工refrigeration mechanic制冷安装技工refrigeration installation mechanic制冷维修技工refrigeration serviceman制冷与空调维修店refrigeration and air conditioning repair shop 主阀main valve自动膨胀阀automatic expansion valve。

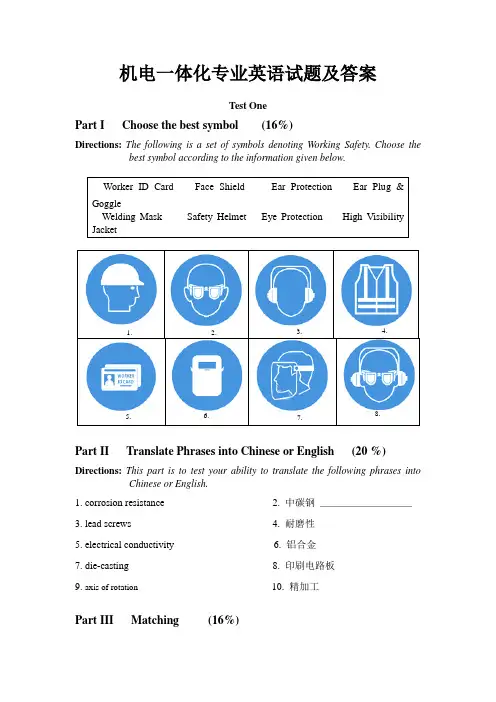

机电一体化专业英语试题及答案Test OnePart I Choose the best symbol (16%)Directions:The following is a set of symbols denoting Working Safety. Choose the best symbol according to the information given below.Worker ID Card Face Shield Ear Protection Ear Plug & GoggleWelding Mask Safety Helmet Eye Protection High Visibility Jacket1. 2. 3. 4.5. 6. 7. 8.Part II Translate Phrases into Chinese or English (20 %) Directions: This part is to test your ability to translate the following phrases into Chinese or English.1. corrosion resistance ___________________2. 中碳钢_____________________3. lead screws __________________________4. 耐磨性___________________5. electrical conductivity ________________6. 铝合金___________________7. die-casting__________________________8. 印刷电路板________________ 9. axis of rotation_________________________ 10. 精加工___________________Part III Matching (16%)Directions: This part is to test your ability to choose the interpretations given in Column C match the Functions given in Column A, and then put thefunctions into Chinese in Column B.A. Vee BlockB. Tool Maker ClampC. Surface PlateD. Bench ViceE. Angle PlateF. Hand ViceG. Vice ClampH. Pipe Vice1.(平板)2.(角板)3.(V型块三角槽铁)4.(手钳)5.(老虎钳)6.(管子台虎钳)7.(虎钳夹)8.(工件夹钳)Part IV Translate English into Chinese (28%)Directions: This part is to test your ability to translate English into Chinese.There are many kinds of machining operations, each of which is capable of generating a certain part geometry and surface texture.In turning, a cutting tool with a single cutting edge is used to remove material from a rotating work-piece to generate a cylindrical shape. The speed motion in turning is provided by the rotating work-part, and the feed motion is achieved by the cutting tool moving slowly in a direction parallel to the axis of rotation of the work-piece.Drilling is used to create a round hole. It is accomplished by a rotating tool that typically has two cutting edges. The tool is fed in a direction parallel to its axis of rotation into the work-part to form the round hole.In boring, the tool is used to enlarge an already available hole. It is a fine finishing operation used in the final stages of product manufacture.In milling, a rotating tool with multiple cutting edges is moved slowly relative to the material to generate a plane or straight surface. The direction of the feed motion is perpendicular to the tool’s axis of rotation. The speed motion is provided by the rotating milling cutter.Part V Translate Chinese into English (20 %) Directions: This part is to test your ability to do practical writing.1. 这些机器都是由中国人造出的。

机电一体化专业英语English Answer:Mechatronics is an interdisciplinary field that combines mechanical, electrical, computer, and software engineering to design, build, and operate systems. It has become increasingly important in modern engineering due to the growing demand for automated and intelligent systems.中文回答:机电一体化是一门综合了机械、电气、计算机和软件工程的交叉学科,用于设计、建造和操作系统。

随着对自动化和智能系统需求的不断增长,它在现代工程中变得越来越重要。

Components of Mechatronics.The core components of mechatronics include:Sensors: Collect data from the physical world.Actuators: Convert electrical signals into physical movement.Controllers: Process sensor data and generate control signals.Software: Designs and implements control algorithms.Applications of Mechatronics.Mechatronics has a wide range of applications, including:Industrial automation: Assembly lines, robotic welding, and automated material handling.Automotive systems: Engine control, brake systems, and advanced driver assistance systems.Aerospace engineering: Flight control systems, navigation systems, and life support systems.Medical engineering: Surgical robots, diagnostic instruments, and prosthetics.Benefits of Mechatronics.Mechatronics offers several benefits over traditional engineering approaches:Increased productivity: Automated systems can work faster and more accurately than humans.Improved quality: Automated systems can produce products with consistent quality.Reduced costs: Automated systems can eliminate the need for manual labor and reduce maintenance costs.Enhanced flexibility: Mechatronic systems can be easily reconfigured to adapt to changing requirements.Challenges in Mechatronics.Despite its advantages, mechatronics also faces some challenges:Complexity: Mechatronic systems can be highly complex, making design and implementation difficult.Cross-disciplinary nature: Mechatronics engineers must have knowledge in multiple engineering disciplines.Integration: Integrating different components from different disciplines can be challenging.Career Prospects in Mechatronics.The demand for mechatronics engineers is expected to continue to grow in the coming years. Mechatronics engineers can work in a variety of industries, including automotive, manufacturing, aerospace, and medical engineering.中文回答:机电一体化的组成部分。

《机电一体化专业英语》(English for Mechatronics)授课教案Teaching PlanMajor (专业):机电一体化XXXX专业(相关专业)Lecturer(任课教师):__________________________Mechatronics SectionChangchun Automobile Industry Institute《机电一体化专业英语》授课计划_ _______ 学院___ 专业班20 -20 学年第学期授课时间:第周ensure that…又引导出一个状语从句。

全句可译为:在把花盘安装在主轴上后, 常规作法是对断面进行一次性地轻切削以确保花盘表面与车床主轴垂直。

Period1The following is the machine tool structures.Explanations of the Machine Tool TermsNo.NameExplanation1 Spindle speed selector 主轴速度转换开关2 Headstock assembly 主轴箱3 Spindle with chuck 附有夹具主轴 4Tool post 刀架 5 pound rest 复式刀架 6 Cross slide 横向拖板 7 Carriage 滑鞍,滑座 8 Ways 导轨 9 Dead center 死顶尖 10 Tailstock quill 尾架顶尖套筒 11 Tailstock assembly 尾架 12 Hand-wheel 手轮 13 Bed 底座,床身 14 Lead screw 丝杠 15 Feed rod 进刀杠,光杠 16 Clutch离合器17 Longitudinal & transverse feed control 纵向与横向进给控制 18 Split-nut control 开合螺母控制 19 Apron 溜板箱,进给箱 20 Chip pan 承屑盘 21Feed selector进给选择开关机床构造 Section II Glance at Machine Tool StructuresThe following is the conventional machine tool. You are required to choose the suitable words or phrases given below.7. Body G. 公英制转换键8. Calibration sticker H. 液晶显示屏9. Depth bar I. 外径测量面10. Zero-setting key J. 滑尺11. On/Off key K. 电池盖12. Slider L. 清零键13. Outside measuring face M. 测深杆Period 1Practice扩大您地视野(实践部分)Section IV BroadenYour Horizon—Practical Activity(Practice) The micrometer screw gaugeThe micrometer screw gauge is used to measure even smaller dimensions than the vernier caliper. The micrometer screw gauge also uses an auxiliary scale (measuring hundredths of a millimeter) which is marked on a rotary thimble. Basically it is a screw with an accurately constant pitch. The micrometers in our laboratory have a pitch of 0.50 mm. The rotating thimble is subdivided into 50 equal divisions. The thimble passes through a frame that carries a millimetre scale graduated to 0.5 mm. The jaws can be adjusted by rotating the thimble using the small ratchet knob. The thimble must be rotated through two revolutions to open the jaws by 1 mm. Here is a useful applet to learn how to use the micrometer screw gauge (Figure 1-19).Figure 1-19 The micrometer screw gaugeIn order to measure an object, the object is placed between the jaws and the thimble is rotated using the ratchet until the object is secured. Note that the ratchet knob must be used to secure the object firmly between the jaws, otherwise the instrument could be damaged or give an inconsistent reading.Note that an additional half scale division (0.5 mm) must be included if the mark below the main scale is visible between the thimble and the main scale division on the sleeve. The remaining two significant figures (hundredths of a millimeter) are taken directly from the thimble opposite the main scale.In Figure 1-20 the last graduation visible to the left of the thimble is 7 mm and the thimble lines up with the main scale at 38 hundredths of a millimeter (0.38 mm); therefore the reading is 7.38 mm.In Figure 1-21 the last graduation visible to the left of the thimble is 7.5 mm; therefore the reading is 7.5 mm plus the thimble reading of 0.22 mm, giving 7.72 mm.Figure 1-20 The reading is 7.38mm Figure 1-21 The reading is 7.27mm In Figure 1-22 the main scale reading is 3 mm while the reading on the drum is 0.46 mm; therefore, the reading is 3.46 mm.In Figure 1-23 the 0.5 mm division is visible below the main scale; therefore the reading is 3.5 mm + 0.06 mm = 3.56 mm.Figure 1-22 The reading is 3.46mm Figure 1-23 The reading is 3.56mm Try the following bg yourselfFigure 1-24 Figure 1-25 Figure 1-26A: Do exercise 1, 2, 3, 4 and 7.AssignmentB: Ask students to collect some external machine tools.《机电一体化专业英语》授课计划_ _______ 学院___ 专业班20 -20 学年第学期授课时间:第周Key Points unit.2. Machine tool practice cognition.教学难点Difficult Points 1. Understand the key words, phrases and sentences in the passage.2. Translate the simple material or specification.教学方法Teaching Methods • Explanation • Group discussion • Questions and answers • Performance (Role-play) • Machine tool specification教学手段TeachingMeans• Multi-media • Videos • work Resource教学安排Teaching Arrangement教学内容Contents of Course学时Period精读Section I Technical and Practical Reading2机床构造Section II Glance at the Structure of the Machine Tool1试试身手(实践部分)Section III Simulated Writing (Practice)2扩大您地视野(实践部分)Section IV Broaden Your Horizon—Practical Activity (Practice)1授课内容与要点Teaching Contents and Main PointsUnit 2 Metal MaterialsPeriod2精读Section I Technical and Practical Reading Part I. Leading in1. RevisionAsk several students if they know the machine tool structures, metal materials and important machine tool manufacturers.Arouse students to answer teacher’s questions according to the Passage A /B for introduction to meta materials in Unit 2.2. Warming up questions1) Ask students to work in groups of four to read new words and phrases.5. ________(工具铣床)6. ________ (单柱铣床)Single-column Milling Machine Plano-milling MachineTool Milling MachineKnee-and-Column Milling Instrument milling machine Single-arm Milling MachinePeriod2Have a TrySample 1Explanations of TermsNameExplanationOuter frame 外框 Scale mark plate刻度盘 Spring 弹簧 Arm测量臂 Gauge head 侧头 Dial window 刻度盘 Indicator 指针 Clamp screw夹紧螺丝Choose the best answer.试试身手 (实践部分) Section III Simulated Writing (Practice)AB1. Dial windowA. 限制器 2. Long handB. 短指针 3. Top pointC. 刻度盘 4. LimiterD. 刻度盘 5. ClumpE. 长指针 6. Outer frameF. 底座 7. Short handG. 顶针8. BaseH. 螺丝紧固座 9. Scale mark plate I. 紧固件 10. Screw fastening base J. 测头 11.Gauge headK. 外框Period1Practice扩大您地视野 (实践部分)Section IV BroadenFacing OperationsFacing is the process of removing metal from the end of a work-piece to produce a flat surface.Preparing for the Facing CutYour Horizon—Practical Activity (Practice) First, make sure the tumbler gear lever on the back of the headstock is in the neutral (middle) position so that the lead-screw does not rotate.Clamp the work-piece tightly in the three-jaw chuck. To get the work properly centered, close the jaws until they just touch the surface of the work, then rotate the work-piece by hand in the jaws to seat it; then tighten the jaws (Figure 2-17). Beginning the Facing CutUse the pound handwheel to advance the tip of the tool until it just touches the end of the work-piece. Use the cross feed crank to back off the tool until it is beyond the diameter of the work-piece. Turn the lathe on and adjust the speed to a few hundred RPM — setting of the speed control knob. Now slowly advance the cross feed hand-wheel to move the tool towards the work-piece. When the tool touches the work-piece it should start to remove metal from the end (Figure 2-18). Continue advancing the tool until it reaches the center of the work-piece and then crank the tool back in the opposite direction (towards you) until it is back past the edge of the work-piece (Figure 2-19).Figure 2-18 Figure 2-19 Since we started with the tool just touching the end of the work-piece, you probably removed very little metal on this pass. This is a good idea until you get used to how aggressively you can remove metal without stalling the lathe.The Roughing CutUse the pound crank to advance the tool towards the chuck about 0.010". If the pound is set at a 90 degrees to the cross slide (which is how I usually set mine) then each division you turn the crank will advance the tool 0.001 (one-thousandth of an inch) toward the chuck.If the pound is set at some other angle, say 30 degrees, to the cross slide, then it will advance the tool less than 0.001 for each division. The exact amount is determined by the trigonometric sine of the angle. Here’s a picture of the first pass of a facing operation (Figure 2-20).Cutting on the Return PassIf you crank the tool back towards you after it reaches the center of the work-piece you will notice that it removes a small amount of metal on the return pass. This is because the surface is not perfectly smooth and it is removing metal from the high spots. If you need to remove a lot of metal, to reduce the work-piece to a specific length, for example, you can take advantage of this return cut to remove more metal on each pass by advancing the tool a small ways into the work-piece on the return pass. Since the tool must plunge into the face of the work-piece, this works best with a fairly sharp pointed tool.The Finishing CutDepending on how rough the end of the work-piece was to begin with and how large the diameter is, you may need to make three or more passes to get a nice smooth finish across the face. These initial passes are called roughing passes and remove a relatively large amount of metal.When you get the face pretty smooth you can make a final finishing cut to remove just 0.001 to 0.003" of metal and get a nice smooth surface. Figure 2-21 shows removingabout 0.002" of metal at around 1 000 RPM. Figure 2-22 shows the finished face of thework-piece. Figure 2-21 Figure 2-22Figure 2-23 shows what happens if the tip of your cutting tool is below the center line of the lathe — a little nub is left at the center of the work-piece. The same thing happens ifthe tool is too high but the nub will have more of a cone shape in that case. If the tool is toolow, place a suitable thickness of shim stock underneath the tool in the tool holder. If it’s toohigh, grind the top down a few thous.Filing the EdgeFacing operations leave a rather sharp edge on the end of the work-piece. It’s a good idea to smooth this edge down with a file to give it a nice chamfer and to avoid cuttingyourself on it. With the lathe running at fairly low speed, bring a smooth cut file up to theend of the work-piece at a 45 degree angle and apply a little pressure to the file. Figure2-24: Right — left hand holding tang end of file. Figure 2-25: Wrong — left hand reachingover spinning chuck!Figure 2-23 Figure 2-24Figure 2-26 shows the finished surface and beveled edge. This is what a good facing cut should look like: smooth even surface with no raised bump in the center. Lay anaccurate straight edge across the surface of the face and you should not be able to seeany light under the edge. If you detect a slight convex shape, the carriage may be movingback away from the headstock during the cut.Figure 2-25 Figure 2-26A: Do exercise 1, 2, 3, 4 and 7.AssignmentB: Ask students to collect some external machine tools.《机电一体化专业英语》授课计划_ _______ 学院___ 专业班20 -20 学年第学期授课时间:第周教学难点Difficult Points 1. Understand the key words, phrases and sentences in the passage.2. Translate the simple material or specification.教学方法Teaching Methods • Explanation • Group discussion • Questions and answers • Performance (Role-play) • Machine tool specification教学手段TeachingMeans• Multi-media • Videos • work Resource教学安排Teaching Arrangement教学内容Contents of Course学时Period精读Section I Technical and Practical Reading2机床构造Section II Glance at the Machine Tool Structures1试试身手(实践部分)Section III Simulated Writing (Practice)2听说练习(实践部分)Section IV Broaden Your Horizon—Practical Activity (Practice)1授课内容与要点Teaching Contents and Main PointsUnit 3 Machining OperationsPeriod2精读Section I Technical and Practical Reading Part I. Leading in1. RevisionAsk several students if they know the basic machine tool and its function.Arouse students to answer teacher’s questions according to the Passage A /B for introduction to basic machine tools in Unit 3.2. Warming up questions1) Ask students to work in groups of four to read new words and phrases.2) Talk about the basic boring machines.Part II. prehension and PracticingSentences:1. Conventional machining, one of the most important material removal methods, is a collection of material-working processes in which power-driven machine tools, such as lathes, milling machines, and drill presses are used with a sharp cutting tool to mechanically cut the material to achieve the desired geometry. 在这个长句中,主语是Conventional machining,由is引导出合成谓语;one of the most…methods是插入语;in which 引导定语从句,其先行词为processes。

Mechatronic1. IntroductionMechatronics is a design process that includes a combination of mechanical engineering, electronic engineering, material engineering, chemical engineering and industrial engineering. Mechatronics is a multidisciplinary field of engineering, that is to say, it rejects splitting engineering into separate disciplines.Nowadays, with the increasing of economy, Interdisciplinary research becomes an irreversible tendency. Which means mechatronic is facing unprecedented challenges. The old mechanics cannot catch the pace of new world, so they need to be changed. In order to stand steady from the competition, they must provide high value by being innovative during the process of transformation and upgrading.2. Mechatronic system applicationMechatronics are useful on so many fields, such as Machine vision, Automation and robotics, Servo-mechanics and so on.Mechatronic system apply to Machine vision (MV)Mechatronic make the possibilities of MV, technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance in industry, came true.Mechatronic system apply to Automation and roboticsImagine that just push some simple bottoms lightly can you control a huge, smart, intelligent robots. Is it only dreamed? No, it is reality. When mechatronic system applies to automation and robotics we can meet that easily.Mechatronic system apply to Servo-mechanicsCommon type of servo provides position control. Servos are commonly electrical or partially electronic in nature, using an electric motor as the primary means of creating mechanical force. Other types of servos use hydraulics, pneumatics, or magnetic principles. Whatever type it is, it can be separate as feedback system, transducer system and control system. And all of it cannot be kept in functional order without mechatronic system engineering.3. Future challengesMechatronic products -- products that blend mechanical, electrical and software technologies -- have exploded far beyond such industries as high-tech, aerospace and consumer product goods. That means more and more product development teams that once may have been comprised of mechanical engineers and electrical engineers are now adding software to the mix.Multiple engineering disciplines are being challenged to work together in mechatronic product development, such as on this printed circuit board assembly created in PTC's Pro/Engineer.Additional challenges of mechatronic product development noted by PTC include MCAD changes not reaching electrical engineers quickly enough, ECAD designers working ahead of the mechanical engineer and failing to relay that information, and software development largely removed from the product development change management process.。

1、机电一体化技术是一门关于机械学、电子学和信息技术的跨学科技术。

Mechatronics is the interdisciplinary of mechanics,electronics and information technology.2、机器人是机电一体化技术发展的产物,它涉及机械学、电子学、智能控制技术等。

Robot is the evolutional outcome of mechatronics,which includes mechanics,electronics and intelligent control technology,etc3、机电一体化技术广泛英语于汽车工业、机械工业及国防工业。

Mechtronics has been applying widely to auto industry, mechanical industry and nationa defense industry.4、今天,机电一体化技术已成为研制机器人的关键技术Today, mechatronics has become the key technology of developing robots.5、一般来说,自从20世纪80年代计算机技术和信息技术就已经发展的很快。

In general, computer technology and information technology have rapidly developed ever since the 1980s.6、借助自动调节系统,这个生产线生产的产品质量已经越来越高,生产成本越来越低。

By virtue of the automatic self—regulating system, the quality of products made by this mass—produced line has become higher and higher, and lower and lower in the productive cost。

练习答案第一单元Exercise 11. B2. D3. C4. AExercise 21.中心钻2. packing grease3.加工性能4. carbon steel5. 铸铁6. feeler gage7.固定支架8. follower restExercise 31. C2. E3. A4. H5. D6. F7. B8. GExercise 41. 交流电2. 自动检测读出设备3. 绝对误差4. 自动化工程设计5. 自动—手动6. 自动比率控制7. 基本汇编程序8. 斜齿轮Exercise 51. Double Turret Lathe2. Automatic Lathe3. Vertical Lathe4. Special Purpose Lathe5. Horizontal Lathe6. Pipe Screw-cutting LatheExercise 61. E2. C3. H4. G5. A6. K7. D8. B9. M 10. L 11.F 12. J 13. IExercise 71. Facing2. Taper turning3. Contour turning4. Form turning5. Chamfering6. Cutoff7. Threading8. Boring9. Drilling 10. Knurling第二单元Exercise 11. C2. D3. A4. BExercise 21. 耐腐蚀性2. Medium Carbon Steels3. 丝杆4. wear resistance5. 导电性6. aluminum alloys7. 压铸件8. printed circuit boardsExercise 31. D2. A3. E4. B5. H6. C7. G8. FExercise 41. 缓冲件2. 反压力3. 计算机辅助设计4. 计算机辅助制造5. 电路断续器6. 铸铁7. 合金铸铁8. 中心轴线Exercise 51. Knee-and-Column Milling Machine2. Plano-milling Machine3. Single-arm Milling Machine4. Instrument Milling Machine5. Tool Milling Machine6. Single-column Milling MachineExercise 61. C2. E3. G4. A5. I6. K7. B8. F9. D 10. H 11. JExercise 71. Peripheral milling2. Face milling3. Slab milling4. Slotting5. Straddle milling6. End milling7. Profile milling8. Pocket milling第三单元Exercise 11. B2. C3. D4. AExercise 21. 常规加工2. milling machines3. 数控4. electrical discharge machining5. 化学腐蚀6. engineering drawings7. 表面纹理8. feed motionExercise 31. C2. F3. A4. D5. H6. E7. B8. GExercise 41. 计算机管理指令2. 冷轧钢3. 全自动防护4. 铜镍合金5. 直流电6. 直流电继电器7. 测距设备8. 电位差Exercise 51. Horizontal Milling and Boring Machine2. Vertical Diamond Fine Boring Machine3. Double Boring Machine4. Deep Hole Boring Machine5. CNC Gantry-Boring and Milling Machine6. Jig Boring MachineExercise 61.C2. E3. G4. A5. F6. B7. DExercise 7(1) Boring a hole (2) Boring coaxial bore (3) Boring a big hole(4) Milling flat (5) Turning inner ring groove (6) Turning end face第四单元Exercise 11. D2. B3. C4. AExercise 21. 液压机械2. power transmission3. 并联装置4. charge pump5. 换向阀6. hydraulic pump7. 密封垫8. power densityExercise 31. C2. E3. A4. F5. D6. H7. G8. BExercise 41. 差动继电器2. 电子仪器3. 气油比4. 大功率5. 热处理6. 高速钢7. 渐开线齿轮8. 输入/输出Exercise 51. Two Uprights Drawing Presses2. Four Column Hydraulic Deep Drawing Press3. Servo-hydraulic Press4. Hydraulic Cutting Presses5. High Performance Large Presses6. Cold Forging PressExercise 61. C2. E3. A4. G5. B6. I7.D8. J9.F 10.HExercise 71. Upsetting operation2. Forging operation3. Bending operation4. Rolling operation5. Extrusion operation6. Swaging operation7. Punching operation8. Drawing operation第五单元Exercise 11. B2. D3. A4. CExercise 21. 计算机数字控制2. conventional machine3. 步进电机4. positional accuracy5. 加工中心机6. spindle speed7. 直接联轴器8. automatic tool changerExercise 31. C2. D3. H4. A5. B6. G7. E8. FExercise 41. 界面压力2. 局部电池3. 测漏器4. 动能5. 总长6. 可锻铁7. 手工操作8. 维修部门Exercise 51. Internal Grinding Machine2. Surface-Grinding Machine3. Slideway Grinding Machine4. Centerless Grinding Machine5. Tool Grinding Machine6. Jig Grinding MachineExercise 61. D2. F3. A4.G5. B6. C7. H8. EExercise 71. Horizontal surface grinding2. Internal grinding3. Honing4. Vertical surface grinding5. Centerless grinding6. Cylindrical grinding第六单元Exercise 11. B2. C3. A4. DExercise 21. 视图投影2. engineering drawing3.剖视图4. descriptive geometry5. 专利图6. three-dimensional model7. 分解图8. visual appearanceExercise 31. D2. F3. A4. G5. C6. H7. E8. BExercise 41. 机械工程师2. 可变轴距3. 主控振荡器4. 结构钢5. 安全系数6. 测量设备7. 中性轴8. 操作系统Exercise 51. Digital Controlled Lathe2. Digital Controlled Drill3. CNC Grinding Machine4. CNC Milling Machine5. CNC Boring Machine6. CNC Combined Punch PressExercise 51. D2. F3. A4. G5. B6. H7. C8. I9. EExercise 71. CNC machine tool body2. Column3. Control panel4. Motor assembly for Z axis5. Linear guide rail6. Automatic tool changer7. Working table8. Column base第七单元Exercise 11. D2. B3. A4. CExercise 21. 电子元件2. metallic pads3. 单向闸4. electrical current5. 电流脉冲6. semiconductor device7. 双稳开关8. light-emitting diodeExercise 31. D2. F3. A4. H5. B6. J7. C8. I9. E 10. GExercise 41. 脉码编制2. 位差3. 压力元件4. 功率方向继电器5. 功率因数6. 管路7. 功率输出8. 电压互感器Exercise 51. Gear Shaving Machine2. Gear Shaper3. Gear Grinding Machine4. Slotting Machine5. Gear Milling Machine6. Wheel Gear Milling MachineExercise 61. D2. F3. A4. G5. B6. H7. C8. EExercise 71. Slotting with a straight-tooth side-milling cutter2. Slotting with a concave slitting saw3. Plain milling4. Angle milling5. Profile milling with an end mill6. Form milling7. Straddle milling8. Concave milling第八单元Exercise 11. C2. D3. A4. BExercise 21.快闪存储器2.Single Chip Microprocessor3.地址总线4.Radom Access Memory5.发光二极管6. clock generator7. 通用串行总线8. analog-to-digital converterExercise 31. C2. E3. A4. B5. H6. D7. F8. GExercise 41. 质量控制2. 滚动轴承3. 电抗耦合4. 基本误差5. 轴马力6. 钢板7. 表面/质量比8. 平方律Exercise 51. V ertical D riller2. Radial Drilling Machine3. G un D rilling M achine4. Multiple Spindle Drilling Machine5. Horizontal Drilling Machine6. Milling and Drilling MachineExercise 61. C2. E3. B4. A5. H6. D7. I8. F9. GExercise 71. Reaming2. Tapping3. Counterboring4. Countersinking5. Center drilling6. Spot facing7. Drilling8. Redrilling9. Step drilling 10. Tapered drilling 11. Deep hole drilling 12. Trepanning第九单元Exercise 11. B2. D3. A4. CExercise 21. 磁通2.electromagnetic force3. 永久磁铁4.right-handed screw rule5.磁场6.line of magnetic force7.松紧带8. straight lineExercise 31. B2. E3. D4. A5. C6. G7. F8. HExercise 41. 标准压2. 斜距3. 不锈钢4. 主轴转速5. 半钢铸件6. 标准温度7. 钢铸件8. 结构钢Exercise 51. Shaping Machine2. CNC Gantry Milling Machine3. CNC Gantry Milling & Boring Machine4. Double Housing Planer5. Open-side Planing Machine6. Vertical Slotting MachineExercise 61. D2. F3. A4. I5. B6. H7. C8.E9. GExercise 71. Machining horizontal surface2. Machining vertical surface3. Machining inclined surface4. Slot cutting5. Keyway cutting6. Irregular machining第十单元Exercise 11. C2. D3. A4. BExercise 21. 时滞继电器2.switching device3.功能模块4.program blocks5.限位开关6. data block7.梯图er programExercise 31. C2. E3. A4. D5. B6. F7. I8. G9. HExercise 41. 安全阀2. T型弯头3. 技术条令4. 每英寸齿数5. 技术规程6. 工具钢7. 甚高频8. 轴距Exercise 51. Vertical External Broaching Machine2. Side B roaching Machine3. Horizontal Broaching Machine4. Gear Broaching Machine5. Hydraulic Spline Broaching Machine6. CNC Broaching MachineExercise 61. H2. E3. K4. F5. J6. B7. A8. I9. G 10. D 11. CExercise 71. Linear broach2. Push broach3. Pot broach4. Spline broach5. Straddle broach6. Rotary braoch7. Fir tree slot broach8. Dove tail broach。

《机电专业英语》考试题一.翻译词汇mechatronic 机电一体化(技术)sensor传感器actuator执行元件,执行结构Feedback反馈deviation偏差hydraulic液压的machine tool机床geometric modeling 几何建模job-lot amount单批量maintenance维护pallet随行夹具robot机器人drill钻床,钻头Lathe车床mill 铣床shaper牛头刨床planer龙门刨床grinder磨床tap攻丝pulley滑轮shaft轴bore 镗削screw螺杆tolerance公差torque转矩nut螺母spring弹簧key键bearing轴承coupling联结器clutch离合器diode二极管transistor三极管transistors 晶体管integrated circuit 集成电路chip 芯片capacitor 电容器resistor 电阻digital 数字(式)的lever杠杆Servomechanism伺服机构closed-loop闭环actuator 传动装置following device随动装置troubleshoot故障排除二.汉译英1.机电一体化技术,电子学,机械学,智能数控,机器人学,信息技术,科学术语。

Mechatronics , electronics, mechanics, intelligent control, robotics.information technology , scientific term .2.机电一体化技术广泛用于汽车工业、机械工业以及国防工业。

Mechatronics has been applying widely to auto industry, mechanical industry and national defense industry.3.大多数的机加工主要是由五种基本的机床来完成。

机电一体化专业英语实践报告范文英文版 **I. Introduction**In the era of rapid technological advancement, Mechatronics Engineering has emerged as a pivotal fieldthat bridges the gap between mechanical engineering, electronics, computer science, and control engineering. As an integral part of my academic journey, I participated in an English-based practical training program in Mechatronics Engineering, aimed at enhancing my proficiency in the field and its related terminologies. This report documents my experience, learnings, and reflections from this enriching practice.**II. Objectives and Scope**The primary objective of this practical training was to familiarize myself with the latest trends and applications in Mechatronics Engineering, specifically through the lens of English-speaking environments. The scope encompassed various aspects of mechatronics, including but not limited to automation systems, robotics, sensor technologies, and control algorithms.**III. Activities Conducted**1. **Literature Review**: I embarked on a comprehensive literature review, focusing on recent research papers and technical articles in English related to Mechatronics Engineering. This exercise helped me understand the latest developments and innovations in the field.2. **Practical Workshops**: Participating in workshops conducted by industry experts, I had the opportunity to engage with hands-on activities that showcased the integration of mechanical, electronic, and software components.3. **System Simulations**: Using simulation software, I simulated various mechatronic systems, analyzing their performance and optimizing their designs. This experience provided valuable insights into the design and implementation processes.4. **Project Development**: I worked in a team to develop a small-scale robotic system, applying theprinciples of mechatronics. This project involved the design, programming, and testing of the robot, enhancing my understanding of the practical applications of mechatronics.**IV. Challenges and Solutions**During the practical training, I encountered several challenges, primarily related to language barriers and technical complexities. The terminologies and specialized jargon in Mechatronics Engineering were initially daunting, but regular consultation with mentors and peers, along with active participation in discussions, helped me overcome these obstacles. Additionally, I utilized online resources and dictionaries to clarify any uncertainties.**V. Learnings and Insights**This practical training has been an immensely enriching experience. I have gained a deeper understanding of the principles and applications of Mechatronics Engineering, particularly in English-speaking environments. The hands-on activities and project development have reinforced my theoretical knowledge and improved my practical skills. Furthermore, the experience has honed my ability to work in a team, communicate effectively, and solve complex problems. **VI. Conclusion**In conclusion, this English-based practical training in Mechatronics Engineering has been a transformative experience. It has not only broadened my horizons in the field but has also equipped me with the necessary skills and knowledge to navigate the global mechatronics industry.I am confident that this experience will serve as a solid foundation for my future endeavors in this exciting and dynamic field.**机电一体化专业英语实践报告范文中文版****一、引言**在科技飞速发展的时代,机电一体化工程已经成为一个至关重要的领域,它融合了机械工程、电子工程、计算机科学和控制工程等多个学科。