NCR_统一平台报错信息中英文对照表

- 格式:doc

- 大小:72.00 KB

- 文档页数:3

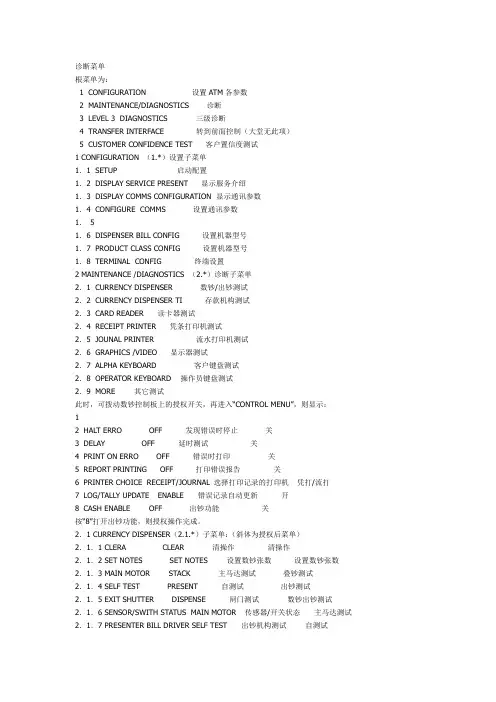

诊断菜单根菜单为:1 CONFIGURATION 设置ATM各参数2 MAINTENANCE/DIAGNOSTICS 诊断3 LEVEL 3 DIAGNOSTICS 三级诊断4 TRANSFER INTERFACE 转到前面控制(大堂无此项)5 CUSTOMER CONFIDENCE TEST 客户置信度测试1 CONFIGURATION (1.*)设置子菜单1.1 SETUP 启动配置1.2 DISPLAY SERVICE PRESENT 显示服务介绍1.3 DISPLAY COMMS CONFIGURATION 显示通讯参数1.4 CONFIGURE COMMS 设置通讯参数1.51.6 DISPENSER BILL CONFIG 设置机器型号1.7 PRODUCT CLASS CONFIG 设置机器型号1.8 TERMINAL CONFIG 终端设置2 MAINTENANCE /DIAGNOSTICS (2.*)诊断子菜单2.1 CURRENCY DISPENSER 数钞/出钞测试2.2 CURRENCY DISPENSER TI 存款机构测试2.3 CARD READER 读卡器测试2.4 RECEIPT PRINTER 凭条打印机测试2.5 JOUNAL PRINTER 流水打印机测试2.6 GRAPHICS /VIDEO 显示器测试2.7 ALPHA KEYBOARD 客户键盘测试2.8 OPERATOR KEYBOARD 操作员键盘测试2.9 MORE 其它测试此时,可拨动数钞控制板上的授权开关,再进入“CONTROL MENU”,则显示:12 HALT ERRO OFF 发现错误时停止关3 DELAY OFF 延时测试关4 PRINT ON ERRO OFF 错误时打印关5 REPORT PRINTING OFF 打印错误报告关6 PRINTER CHOICE RECEIPT/JOURNAL 选择打印记录的打印机凭打/流打7 LOG/TALLY UPDATE ENABLE 错误记录自动更新开8 CASH ENABLE OFF 出钞功能关按“8”打开出钞功能,则授权操作完成。

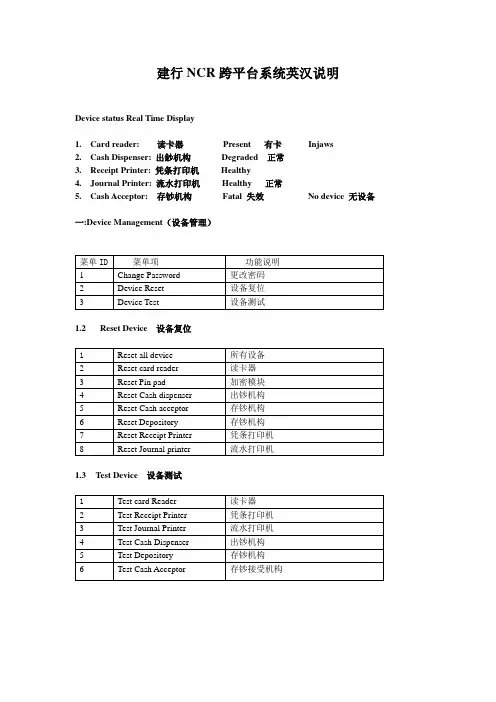

建行NCR跨平台系统英汉说明Device status Real Time Display1. Card reader: 读卡器Present 有卡Injaws2. Cash Dispenser: 出鈔机构Degraded 正常3. Receipt Printer: 凭条打印机Healthy4. Journal Printer: 流水打印机Healthy 正常5. Cash Acceptor: 存钞机构Fatal 失效No device 无设备一:Device Management(设备管理)1.2Reset Device 设备复位1.3Test Device 设备测试二Accout Management(清机管理)三System Management (系统管理)四: Vendor Mode 厂家模式4.1-1 Maintenance维护选项/ Imcrw智能读卡器4.1-1/24.2-1 Device self tests 设备自测4.2-24.2-3 Cash Handler 出钞模块(粗体为授权后菜单)1 CLERA 清操作 CLEAR 清操作2 SET NOTES 设置数钞张数 SET NOTES 设置数钞张数3 MAIN MOTOR 主马达测试 STACK 叠钞测试4 SELF TEST 自测试 PRESENT 出钞测试5 EXIT SHUTTER闸门测试 DISPENSE 数钞出钞测试 6 SENSOR/SWITH STATUS 传感器/开关状态 MAIN MOTOR 主马达测试 7 PRESENTER BILL DRIVER 出钞机构测试 SELF TEST 自测试 8 LERN BILL 自学钞票参数 EXIT SHUTTER 闸门测试4.6-1 Device servicing 设备服务4.6-24.6-34.8 Self-service configuration 设置选项4.8.3 Set Device Config设备配置设置4.8.3-1/2 Set Device Config 设备配置设置4.8.3-1/3 Set Device Config 设备配置设置13.8.3.3Cash Hadler 出钞模块五Other Management (其他管理)六Quit Operator panel(退出管理员)下图为588xATM的操作员面板:开关1. 对外服务与管理状态切换。

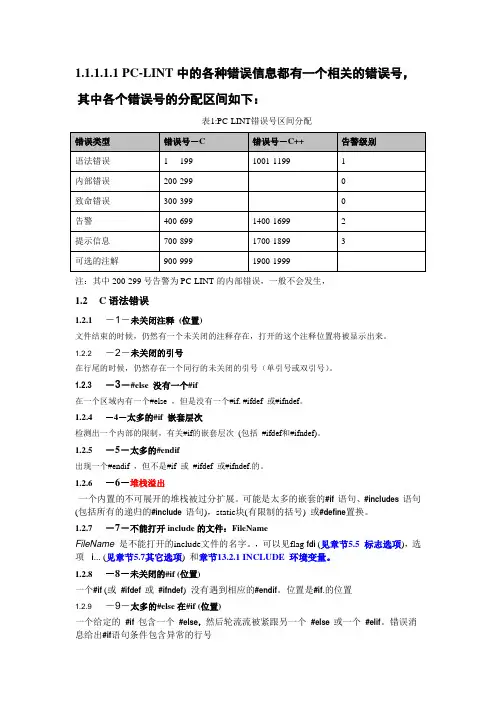

1.1.1.1.1PC-LINT中的各种错误信息都有一个相关的错误号,其中各个错误号的分配区间如下:表1:PC-LINT错误号区间分配注:其中200-299号告警为PC-LINT的内部错误,一般不会发生,1.2C语法错误1.2.1-1―未关闭注释(位置)文件结束的时候,仍然有一个未关闭的注释存在,打开的这个注释位置将被显示出来。

1.2.2 ―2―未关闭的引号在行尾的时候,仍然存在一个同行的未关闭的引号(单引号或双引号)。

1.2.3 -3-#else 没有一个#if在一个区域内有一个#else ,但是没有一个#if, #ifdef 或#ifndef。

1.2.4-4-太多的#if 嵌套层次检测出一个内部的限制,有关#if的嵌套层次(包括#ifdef和#ifndef)。

1.2.5-5-太多的#endif出现一个#endif ,但不是#if 或#ifdef 或#ifndef.的。

1.2.6-6-堆栈溢出一个内置的不可展开的堆栈被过分扩展。

可能是太多的嵌套的#if 语句、#includes 语句(包括所有的递归的#include 语句),static块(有限制的括号) 或#define置换。

1.2.7-7-不能打开include的文件:FileNameFileName 是不能打开的include文件的名字。

,可以见flag fdi (见章节5.5 标志选项),选项-i... (见章节5.7其它选项) 和章节13.2.1 INCLUDE 环境变量。

1.2.8-8-未关闭的#if (位置)一个#if (或#ifdef 或#ifndef) 没有遇到相应的#endif。

位置是#if.的位置1.2.9 -9-太多的#else在#if (位置)一个给定的#if 包含一个#else,然后轮流流被紧跟另一个#else 或一个#elif。

错误消息给出#if语句条件包含异常的行号1.2.10-10-期望的字符串字符串是期望的记号,期望的记号不能被发现。

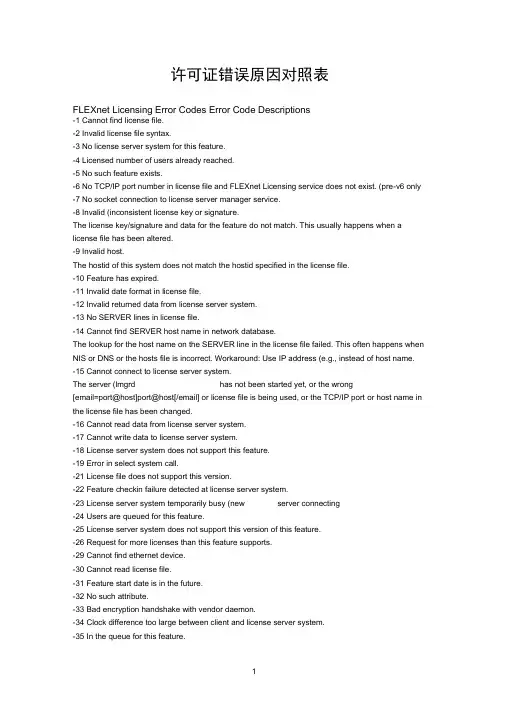

许可证错误原因对照表FLEXnet Licensing Error Codes Error Code Descriptions-1 Cannot find license file.-2 Invalid license file syntax.-3 No license server system for this feature.-4 Licensed number of users already reached.-5 No such feature exists.-6 No TCP/IP port number in license file and FLEXnet Licensing service does not exist. (pre-v6 only -7 No socket connection to license server manager service.-8 Invalid (inconsistent license key or signature.The license key/signature and data for the feature do not match. This usually happens when a license file has been altered.-9 Invalid host.The hostid of this system does not match the hostid specified in the license file.-10 Feature has expired.-11 Invalid date format in license file.-12 Invalid returned data from license server system.-13 No SERVER lines in license file.-14 Cannot find SERVER host name in network database.The lookup for the host name on the SERVER line in the license file failed. This often happens when NIS or DNS or the hosts file is incorrect. Workaround: Use IP address (e.g., instead of host name. -15 Cannot connect to license server system.The server (lmgrd has not been started yet, or the wrong[email=port@host]port@host[/email] or license file is being used, or the TCP/IP port or host name in the license file has been changed.-16 Cannot read data from license server system.-17 Cannot write data to license server system.-18 License server system does not support this feature.-19 Error in select system call.-21 License file does not support this version.-22 Feature checkin failure detected at license server system.-23 License server system temporarily busy (new server connecting-24 Users are queued for this feature.-25 License server system does not support this version of this feature.-26 Request for more licenses than this feature supports.-29 Cannot find ethernet device.-30 Cannot read license file.-31 Feature start date is in the future.-32 No such attribute.-33 Bad encryption handshake with vendor daemon.-34 Clock difference too large between client and license server system.-35 In the queue for this feature.-36 Feature database corrupted in vendor daemon.-37 Duplicate selection mismatch for this feature. Obsolete with v8.0+ vendor daemon.-38 User/host on EXCLUDE list for feature.-39 User/host not on INCLUDE list for feature.-40 Cannot allocate dynamic memory.-41 Feature was never checked out.-42 Invalid parameter.-47 Clock setting check not available in vendor daemon.-52 Vendor daemon did not respond within timeout interval.-53 Checkout request rejected by vendor-defined checkout filter.-54 No FEATURESET line in license file.-55 Incorrect FEATURESET line in license file.-56 Cannot compute FEATURESET data from license file.-571 socket( call failed.-59 Message checksum failure.-60 License server system message checksum failure.-61 Cannot read license file data from license server system.-62 Network software (TCP/IP not available.-63 You are not a license administrator.-64 lmremove request before the minimum lmremove interval.-67 No licenses available to borrow.-68 License BORROW support not enabled.-69 FLOAT_OK can' t run standalone on license server system.-71 Invalid TZ environment variable.-73 Local checkout filter rejected request.-74 Attempt to read beyond end of license file path.-751 SYS$SETIMR call failed (VMS .-76 Internal FLEXnet Licensing error —please report to MacrovisionCorporation.-77 Bad version number must be floating-point number with no letters.-82 Invalid PACKAGE line in license file.-83 FLEXnet Licensing version of client newer than server.-84 USER_BASED license has no specified users - see license server system log.-85 License server system doesn ' t support this request.-87 Checkout exceeds MAX specified in options file.-88 System clock has been set back.-89 This platform not authorized by license.-90 Future license file format or misspelling in license file.The file was issued for a later version of FLEXnet Licensing than this program understands.-91 Encryption seeds are non-unique.-92 Feature removed during lmreread, or wrong SERVER line hostid.-93 This feature is available in a different license pool.This is a warning condition. The server has pooled one or moreINCREMENT lines into a single pool, and the request was made on an INCREMENT line that hasbeen pooled.-94 Attempt to generate license with incompatible attributes.-95 Network connect to THIS_HOST failed.Change this_host on the SERVER line in the license file to the actual host name.-96 License server machine is down or not responding.See the system administrator about starting the server, or make sure that you' re referring to the right host (see LM_LICENSE_FILE environment variable .-97 The desired vendor daemon is down.1 Check the lmgrd log file, or2 Try lmreread.-98 This FEATURE line can ' t be converted to decimal format.-99 The decimal format license is typed incorrectly.-100 Cannot remove a linger license.-101 All licenses are reserved for others.The system administrator has reserved all the licenses for others. Reservations are made in the options file. The server must be restarted for options file changes to take effect.-102 A FLEXid borrow error occurred.-103 Terminal Server remote client not allowed.-104 Cannot borrow that long.-106 License server system out of network connections.The vendor daemon can't handle any more users. See the debug log for further information.-110 Cannot read dongle: check dongle or driver.Either the dongle is unattached, or the necessary software driver for this dongle type is not installed. -112 Missing dongle driver.In order to read the FLEXid hostid, the correct driver must be installed.These drivers are available from your software vendor.-114 SIGN= keyword required, but missing from license certificate. You need to obtaina SIGN= version of this license from your vendor.-115 Error in Public Key package.-116 TRL not supported for this platform.-117 BORROW failed.-118 BORROW period expired.-119 lmdown and lmreread must be run on license server machine.-120 Cannot lmdown the server when licenses are borrowed.-121 FLOAT_OK requires exactly one FLEXid hostid.-122 Unable to delete local borrow info.-123 Returning a borrowed license early is not supported. Contact the vendor for further details.-124 Error returning borrowed license.-125 A PACKAGE component must be specified.-126 Composite hostid not initialized.-127 A item needed for the composite hostid is missing or invalid.-128 Error, borrowed license doesn't match any known server license.-135 Error enabling the event log.-136 Event logging is disabled.-137 Error writing to the event log.-139 Communications timeout.-140 Bad message command.-141 Error writing to socket. Peer has closed socket.-142 Error, cannot generate version specific license tied to a single hostid, which is composite.-143 Version-specific signatures are not supported for uncounted licenses.-144 License template contains redundant signature specifiers.-145 Bad V71_LK signature.-146 Bad V71_SIGN signature.-147 Bad V80_LK signature.-148 Bad V80_SIGN signature.-149 Bad V81_LK signature.-150 Bad V81_SIGN signature.-151 Bad V81_SIGN2 signature.-152 Bad V84_LK signature.-153 Bad V84_SIGN signature.-154 Bad V84_SIGN2 signature.-155 License key required but missing from the license certificate. The application requires a license key in the license certificate. You need to obtain a license key version of this certificate from your vendor.-156 Invalid signature specified with the AUTH= keyword.-500 Invalid server port number.-501 Invalid value in license where an integer was expected.-502 Invalid value supplied for count.-503 Invalid hostid supplied in license.-504 Invalid hostid type supplied.-505 Bad feature line syntax.-506 Internal FLEXnet Licensing error.-507 Bad date format in license file.-508 Bad SERVER line.-509 Bad license string.-510 Server's feature doesn't authenticate on client side.-511 No license checked out.-512 License already checked out.-513 Error list returned.-514 No certicom module available.-515 Wrong or incomplete certicom module.-516 SIGN or SIGN2 required in license certificate.-517 Feature object has no license sources.-518 An Identical license is already checked out on this license source.-519 This license has an asynchronously-queued checkout pending.-521 Library for native hostid couldn't be loaded-522 Already connected to another vendor daemon.-523 No such user, host, or display.-524 Shutdown of license server system failed.-525 Shutdown failed —already connected to license server system.-526 Invalid license source string.-527 Log file switch error.译成中文(简体)FLEXnet许可错误代码错误代码说明-1 找不到许可证文件。

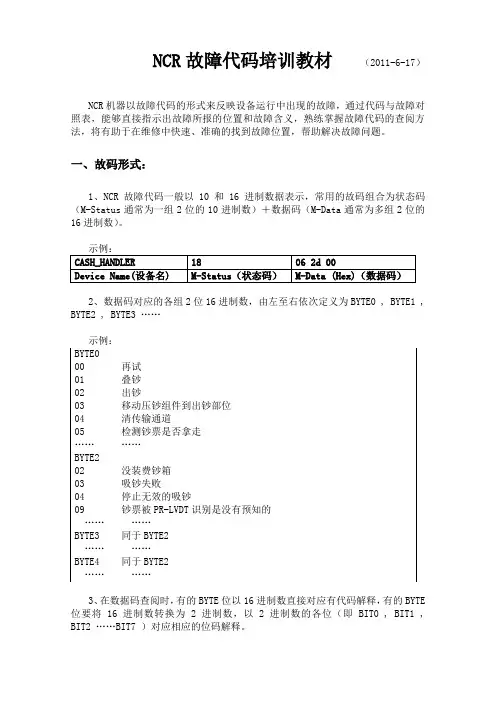

NCR故障代码培训教材(2011-6-17)NCR机器以故障代码的形式来反映设备运行中出现的故障,通过代码与故障对照表,能够直接指示出故障所报的位置和故障含义,熟练掌握故障代码的查阅方法,将有助于在维修中快速、准确的找到故障位置,帮助解决故障问题。

一、故码形式:1、NCR故障代码一般以10和16进制数据表示,常用的故码组合为状态码(M-Status通常为一组2位的10进制数)+数据码(M-Data通常为多组2位的16进制数)。

2、数据码对应的各组2位16进制数,由左至右依次定义为BYTE0 , BYTE1 , BYTE2 , BYTE3 ……示例:BYTE000 再试01 叠钞02 出钞03 移动压钞组件到出钞部位04 清传输通道05 检测钞票是否拿走…………BYTE202 没装费钞箱03 吸钞失败04 停止无效的吸钞09 钞票被PR-LVDT识别是没有预知的…………BYTE3 同于BYTE2…………BYTE4 同于BYTE2…………3、在数据码查阅时,有的BYTE位以16进制数直接对应有代码解释,有的BYTE 位要将16进制数转换为2进制数,以2进制数的各位(即BIT0 , BIT1 , BIT2 ……BIT7 )对应相应的位码解释。

示例:16进制查阅BYTE000 再试01 叠钞02 出钞03 移动压钞组件到出钞部位04 清传输通道05 检测钞票是否拿走06 废钞07 设置钞票宽度08 设置钞票透光度09 设置钞票的出钞顺须0A 读点秒记数0B 清点秒记数…………示例:2进制查阅BYTE1BIT7=1 第三钱箱钱少BIT6=1 第四钱想钱少BIT5=0 这位总是零BIT4=1 吸钞失败BIT3=1 多功能的INOP设置失败BIT2=1 自检命令BIT1=1 第一钱箱钱少BIT0=1 第二钱箱钱少二、故码手册的编排形式1、按故障代码手册的编排方法,查阅代码时要先对应设备名,即不同的设备查阅不同的代码表(在故码手册中,每个代码表前都标识有所对应的设备名称)。

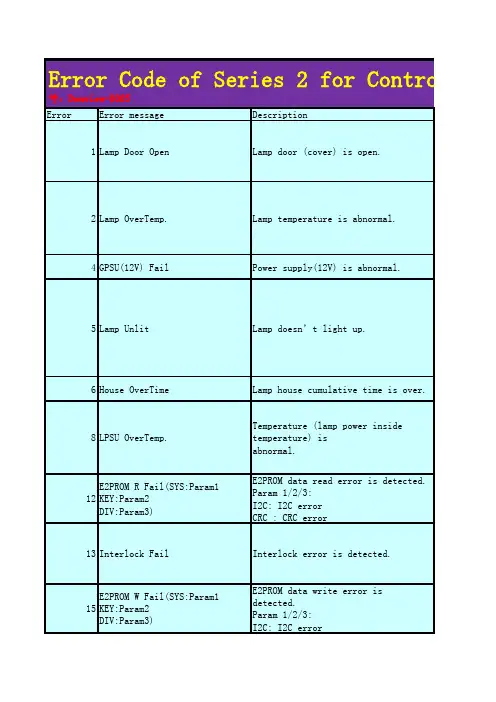

Error Error message Description1Lamp Door Open Lamp door (cover) is open.2Lamp mp temperature is abnormal.4GPSU(12V) Fail Power supply(12V) is abnormal.5Lamp Unlit Lamp doesn’t light up.6House OverTime Lamp house cumulative time is over.8LPSU OverTemp.Temperature (lamp power inside temperature) isabnormal.12E2PROM R Fail(SYS:Param1KEY:Param2DIV:Param3)E2PROM data read error is detected.Param 1/2/3:I2C: I2C errorCRC : CRC error13Interlock Fail Interlock error is detected.15E2PROM W Fail(SYS:Param1KEY:Param2DIV:Param3)E2PROM data write error isdetected.Param 1/2/3:I2C: I2C errorError Code of Series 2 for Control 号:Donview-000517Pump Stop(Param1)Stopped for pump error.Param1: Rotating Speed(Decimal)120DLP Ack Fail(Param1, Param2)ICP board failed the operation. Param1: 2nd portion of ICP command. Param2: 3rd portion of ICP command. ICP failed operation to the command, “CMD1,Param1, Pram2, …”.121Lens Fail(Param1)(Param2,Param3)Lens unit control error(NC1200/NC2000)Param1: Detailed error informationas followsEEPROM R/W FailV-Sensor Read FailH-Sensor Read FailComm Send FailComm Recv FailComm TimeoutRestart(In this case, no Param2/3)Param2/3: Lens unit controlparameters.123Bulb OverTime Lamp bulb cumulative time is over.125LPSU Fail(Param1)LPSU Fail(Param1, Param2)LPSU communication error.LPSU is on abnormal status.Param1:“No Lamp” :Never communicationswith LPSUafter AC-ON.“Power”: Communication failduring regularLPSU status check.Communication error with LPSUoccurs.Param1:Failed LPSU command codeParam2: Error type“ErrTx”, “ErrRx”, “Tout”, “ErrCmd”128OutRange(Param1, Param2,Param3, Pram4)Adjusting lamp output value has setout of range.Param1: Caused operationLamp M: Manual adjustmentLamp D: Douser operationLamp FW: FeedBack(to keep watt)processLamp FB: FeedBack(to keepilluminance)processLamp LM: Lamp memory processParam2: Lamp current tried to setby projector(in 0.1A)Param3: Lamp current get from LPSU(in A)Param4: Lamp wattage get from LPSU(in W)129Down Lamp Power(Param1,Param2, Param3)Down lamp power to decrease setinsidetemperature.Param1: Measured point(Out/Intake/Exhaust/DMD-B)Param2: Temperature(in deg)Param3: Lamp outputLamp current (in 0.1A)130MMS CommFail(Param1:Param2:Param3)MMS communication error isdetected.Param1: Failed MMS command codeParam2: Error type (“Con”, “Tx”, “Rx”, “Tout”)Param3: Error code131MMS Fan Stop Built-in MMS fan has stopped. 132MMS Fail Built-in MMS internal error.133MM Reset (Command:Param1)Executed to reset Built-in MMS Param1: When executed to resetBuilt-in MMS.001: Executed to reset Built-in MMS when nocommunications between projector main system and MMS.T-001: Executed to reset Built-in MMS when nocommunication between external projector and MMS.140DLP CommRFail(Param1Param2Param3:Param4)Communication failure with the ICPboard.(Communication I/F is RS-232C)Param1: First portion of ICPcommand.Param2: Second portion of ICPcommand.Param3: Third portion of ICPcommand.Param4: Error type (“Con”, “Tx”, Rxn”, “Nack”,“Tout”)e.g.) DLP CommRFail(010203:Nak=0001H)ICP returns “NAK” response to thecommand, “01,02, 03, …”.132MMS Fail Built-in MMS internal error.141DLP CommEFail(Param1Param2Param3:Param4)Communication failure with the ICPboard.(Communication I/F is Ethernet)Param1: First portion of ICPcommand.Param2: Second portion of ICPcommand.Param3: Third portion of ICPcommand.Param4: Error type (“Con”, “Tx”, Rxn”, “Nack”,“Tout”)e.g.) DLP CommRFail(010203:Nak=0001H)ICP returns “NAK” response to thecommand, “01,02, 03, …”.145SensorFail OutsideAir(Param1)Sensor (Outside Air) read error.Param1: Get/SetFailed to get/set data from/tosensor board.146SensorFail LPSUIntake(Param1)Sensor (LPSU Intake) read error.Param1: Get/SetFailed to get/set data from/tosensor board.147SensorFail Exhaust(Param1)Sensor (Exhaust) read error. Param1: Get/SetFailed to get/set data from/to sensor board.148SensorFail DMD-B(Param1)Sensor (DMD-B) read error. Param1: Get/SetFailed to get/set data from/to sensor board.150Fan0 Stop(Param1) 151Fan1 Stop(Param1)152Fan2 Stop(Param1) 153Fan3 Stop(Param1) 154Fan4 Stop(Param1) 155Fan5 Stop(Param1)Fan0 has stopped.Param1: Rotating Speed(Decimal)156Fan6 Stop(Param7)Fan0 has stopped.Param1: Rotating Speed(Decimal)157Fan7 Stop(Param8)158Fan8 Stop(Param9)159Fan9 Stop(Param10)160GPSU Fan Stop GPSU Fan has stopped.162Lamp Fan0 Stop(Param1)Lamp cooling fan0 has stopped. Param1: Rotating Speed (Decimal) or HW Prt(Hardware protection)165Lamp Fan1 Stop(Param1)Lamp cooling fan1 has stopped. Param1: Rotating Speed (Decimal) or HW Prt(Hardware protection)164ICP Fan Stop(Param1)ICP fan has stopped.Param1: Rotating Speed(Decimal)165GPI MACRO(n) SelectionInvalidSelection of preset button (n)through GPI is invalidbecause metadata is enabled.n: Preset Button Number(1-8)166GPI Control(Param1) InvalidProjector control through GPI isinvalid becauseprojectoris busy.Param1: Canceled GPI control:Lamp Off/ On , Mute Off/ On/Power On/OffSelection of preset button n (n=18)170OverTemp.Outside Air(Param1)Set inside temperature (Outside Air) is abnormal.Param1: Temperature(in deg) Fan7 has stopped. (Only forNC3200S)Param1: Rotating Speed(Decimal)171OverTemp.Precaution(Param1)Set inside temperature(LPSU Intake) is close to overtemperature.Param1: Precaution temperature(in deg)172OverTemp.Exhaust(Param1)Set inside temperature (Exhaust) is abnormal.Param1: Temperature(in deg)173OverTemp.DMD-B(Param1)Set inside temperature (DMD-B) is abnormal.Param1: Temperature(in deg)174Bulb Entry No selection of current bulb.177Tamper Fail(Param1)Service door tamper switch of projector is open.Param1 : Location of tampering switch.(Param1 is encrypted)LCD: Decrypted while projector is service mode orhigher.Log: Decrypted to view while DCC is servicemode or higher.178Marriage Tamper Fail(Param1)Marriage tamper switch of projector is open.Param1 : Location of tampering switch.(Param1 is encrypted)LCD: Decrypted while projector is service mode orhigher.Log: Decrypted to view while DCC is servicemode or higher.180CPU Fail(Mem) Param1:Param2<->Param3System Test Failed.(Memory)Param1-3: Detailed Test results.187GPSU(24V) Fail Power supply is abnormal.(24V)201Error Log Write Fail Failed to store logs into projector system.210Unknown LPSU Model(Param1)Unexpected LPSU is attached. Param1: Unexpected LPSU Product Model211LPSU Fan Stop LPSU fan has stopped.21312V Outside range(Param1)12V supply is out of range.Param1: Captured voltage value.LCD: invalidLog : valid21424V Outside range(Param1)24V supply is out of range.Param1: Captured voltage value.LCD: invalidLog : valid215Lamp Filter Time Over(Param1)The time to exchange lamp filter. (Future use)Param1: usage hours216Body Filter Time Over(Param1)The time to exchange body filter. (Future use)Param1: usage hours220AC On Fan Exchange Time The time to exchange Fan(AC On) 221Power On Fan Exchange Time The time to exchange Fan(Power On) 222Lamp Fan Exchange Time The time to exchange Lamp Fan230Router Fail(Param1)Failed to control router.Param1:“Connect” : Failed to connect to router“Tx” : Transmit error“Rx” : Receive error“Tout” : Communication timeout “Msg Format” : Unexpected data received“Data”: No data to setup router “Verify”: Setting verify error231SensorFail Opt Failed to control light sensor.232MAC Write Fail Failed to setup MAC address of CPUboard.233Illegal MAC Address Router WAN MAC address is illegal.235Router Self Check Fail(Param1, Param2, Param3)Router health-check error.Param1 : Health check error timing“INIT”: After AC-ON“STBY”: During standby“ RUN”: During power-onParam2: Health check result“2”: Factory default“3”: No responses(Dead lock orsomething)“4”: Unstable status“5”: Factory default and unstablestatus“6”: Defective(possibly “2” to“5”)Param3: router response result(Valid when Param2 is “4” and “5”)N of 4 ping responses240SIB CommFail(Param1Pram2Param3Param4)Failed to communicate with SIB.Param1:“Connect”, “Tx”, “Rx”, “Nack”, “Tout”Param2: First portion ofSIBcommand.Param3: Second portion of SIBcommand.Param4: Third portion of SIBcommand.When Param1 is “Nack”, nack datais added afterParam4.e.g.) SIB Comm241SIB Error(Param1)SIB internal error.Param1: SIB internal error status “FPGA Open”: Failed to openserial I/F“FPGA Tx:nnn”: FPGA send error (nnn: failed send command)“FPGA Rx:nnn”: FPGA receive error (nnn: failed receive command)“MEM Open”: Device driver open error“MEM Read”: Device driver read error242SIB FPGA Reboot Executed to re-boot SIB FPGA for recovery.246Fan11 Stop(Param1)Fan11 has Stopped (NC3240) 250Fan0 Stop Precaution(Param1)251Fan1 Stop Precaution(Param1)252Fan2 Stop Precaution(Param1)253Fan3 Stop Precaution(Param1)254Fan4 Stop Precaution(Param1)255Fan5 Stop Precaution(Param1)256Fan6 Stop Precaution(Param1)257Fan7 Stop Precaution(Param1)258Fan8 Stop Precaution(Param1)259Fan9 Stop Precaution(Param1)260Lamp Fan0 StopPrecaution(Param1)Lamp Fan0 Stop PrecautionParam1: Rotating Speed(Decimal)261Lamp Fan1 StopPrecaution(Param1)Lamp Fan1 Stop PrecautionParam1: Rotating Speed(Decimal)262Pump Stop Precaution(Param1)Pump Stop PrecautionParam1: Rotating Speed(Decimal)Fan0~9 Stop PrecautionParam1: Rotating Speed(Decimal)263ICP Fan StopPrecaution(Param1)ICP Fan Stop Precaution265Fan11 Stop Precaution(Param1)Fan11 Stop Precaution (NC3240) Param1: Rotating Speed(Decimal)270SD Tamper Terminate(Param1)Terminated service door tamper event latched byEnigmaboard.LCD: Not supportedLog: Supported271IMB:SD TamperTerminate(Param1)Terminated service door tamperevent latched byIMB.LCD: Not supportedLog: Supported280Bulb Warranty Over Bulb warranty time over 301System Error302Self Test Error303Install Release Package Error304Load Release Package Error305Key Error306Certificate Error317ICP Normal Configuration318ICP Boot Configuration Error319FMT Normal Configuration Error320FMT Boot Configuration Error321FMT Satellite Configuration Error3221.20V Supply out of range 3231.80V Supply out of range 3242.50V Supply out of range 3253.30V Regulator out of range326ICP FPGA Temperature out of range327FMT FPGA Temperature out of range328ICP Flash Update Error329FMT Sequence Data File Mismatch330FMT DMD Data File Mismatch331FMT Flash Checksum Error -Sequence Data332FMT Flash Checksum Error -DMD Data333Satellite Hardware Mismatch 334FMT Flash Update Error335Red Satellite Reports Reset336Red Satellite Serial Link Error337Red Satellite Firmware Configuration Error338Red DAD1000 Bias Under Voltage Error339Red DAD1000 Reset Under Voltage Error340Red DAD1000 Offset Under Voltage Error341Red DAD1000 Thermal Shutdown Error342Green Satellite Reports Reset343Green Satellite Serial Link Error344Green Satellite Firmware Configuration Error345Green DAD1000 Bias Under Voltage Error346Green DAD1000 Reset UnderVoltage ErrorICP board error347Green DAD1000 Offset Under Voltage Error348Green DAD1000 Thermal Shutdown Error349Blue Satellite Reports Reset350Blue Satellite Serial Link Error351Blue Satellite Firmware Configuration Error352Blue DAD1000 Bias Under Voltage Error353Blue DAD1000 Reset Under Voltage Error354Blue DAD1000 Offset Under Voltage Error355Blue DAD1000 Thermal Shutdown Error356RTC Error400Enigma CommFail(Param1Param2Param3:Param4)No communication with the Enigmaboard.Param1: First portion of Enigmacommand.Param2: Second portion of Enigmacommand.Param3: Third portion of Enigmacommand.Param4: Error Type“Conn=x”, “Tx”, “Rxn”, “Nack=xxxxH”,“Tout=xxxx”410System Error Enigma Status error411Self Test Error412Install Release Package Error413Load Release Package Error414TI Login List Package ErrorEnigma Status error415Security Officer Login List Package Error419Certificate or Key Error 420ICP Communications Status 426User Loader Integrity Error427Main Application Integrity Error428RNG Hardware Integrity Error 429DRNG Algorithm Integrity430RSA Algorithm Integrity Error431AES Algorithm Integrity Error 432HMAC Algorithm Integrity433SHA Algorithm Integrity Error 434TLS Integrity Error435FPGA Configuration Integrity Error436FPGA CineLink 2 Decryption Integrity Error437RTC Error442FPGA Configuration Error443FPGA Temperature out of range446RNG Hardware Duplicate Output Error447DRNG Algorithm Duplicate Output Error4501.20V Supply out of range 4511.80V Supply out of range 4522.50V Supply out of range 4533.30V Regulator out of range458SelfTest User Loader Integrity Error459SelfTest Main Application Integrity Error460SelfTest RNG Hardware Integrity Error461SelfTest DRNG Algorithm Integrity Error462SelfTest RSA AlgorithmIntegrity ErrorEnigma Status errorEnigma is in FIPS errorstate.(Integrity check error)Enigma Status errorEnigma is in FIPS errorstate.(Integrity check error)Enigma Status error463SelfTest AES Algorithm Integrity Error464SelfTest HMAC Algorithm Integrity Error465SelfTest SHA Algorithm Integrity Error466SelfTest TLS Integrity Error467SelfTest FPGA Configuration Integrity Error468SelfTest FPGA CineLink. 2 Decryption Integrity Error474Security Tamper475Top Side Security Enclosure Open476Bottom Side Security Enclosure Open477Security Battery Event Battery tamper condition exists.478Software CommandedZeroizationDestroyed Enigma key by softwarecommand.481Security Enclosure Not Armed Enigma security not armed.482Physical Marriage Tamper Latched physical marriage tamper condition on Enigma board483Logical Marriage Tamper Logical marriage tamper condition exists.484Marriage NOT Active Marriage has NOT been established (active).486Service Door Tamper Latched service door tamper condition on Enigma board487Security Log ErrorSecurity log is full.488Security Battery Low Warning Close to “Security Battery Low”. 489Security Log Warning Close to “Security Log Error”.500IMB Comm Fail(Param1Param2Param3:Param4)No communication with the IMB.510IMB:System Error511IMB:Self Test Error519IMB:Certificate or Key Error Enigma Status errorSecurity tamper condition exists. IMB Status error520IMB:ICP Communications Status IMB fails to do logical marriage to ICP when IMBpowersup. Because of no communications with ICPduring537IMB RTC is “invalid”IMB RTC is “invalid”543IMB:FPGA Temperature out of range550IMB:Supply voltage out of range574IMB:Security Tamper Security tamper condition exists in IMB577IMB:Security Battery Even Battery tamper condition exists in IMB581IMB:Security Enclosure NotArmedSecurity tamper condition exists inIMB582IMB:Physical Marriage Tamper Latched physical marriage tamper condition on583IMB:Logical Marriage Tamper Logical marriage tamper condition exists in IMB584IMB:Marriage NOT Active Marriage between ICP and IMB has NOT beenestablished (active).586IMB:Service Door Tamper Latched service door tampercondition on IMB588IMB:Security Battery LowWarningClose to “(577) IMB: SecurityBattery Event”IMB Status errortrol Command list Rev3.0 文档编Checking point1. Verify if the lamp door is closed and locked properly.2. Is there any physical damage in the switch?3. Check the connection between POCO on COVER PWB and POCN3 onPJDIVPWB.1. Check the ambient temperature. It should be 35 degC or lower.2. Check if there is any problem on suction air and exhaust air.3. Check the air filter and verify that it is not clogged.4. Check that the ventilation system is being operated withinrequired specification.5. Check the connection between Thermostat and POCN5 on PJDIV PWB.1. Check the DC power supply voltage.2. Check the connection between GPSU and POPSM on PJDIV PWB.1. Check if the current bulb usage time is over limit. If yes,replace the bulb.2. Check if there are loose screw connections on the igniter andcathode cable on thelamp holder.3. Check if an electric blackout has occurred.4. Check if the LPSU is turned on.5. Check the connection between POCN2 on PJDIV PWB and PEDE-A PWB.1. Replace the reflector and reset lamp (except for house) usagehours.1. Check the ambient temperature. It should be 35 degC or lower.2. Check if there is any problem on suction air and exhaust air.3. Check the air filter and verify that it is not clogged.4. Check that the ventilation system is being operated withinrequired specification.5. Replace the LPSU.1. Check CPU PWB/ PJDIV PWB/KEY I/O PWB.2. Check the cable between POIF on PJDIV PWB and KEY IO PWB.1. Verify that external control is working properly.2. Check the connection between POIL on PEDE-A PWB and INTER PWB.3. Check the connection between POCI on PEDE-A PWB and POCN2 onPJDIVPWB.1. Check CPU PWB/ PJDIV PWB/KEY I/O PWB.2. Check the cable between POIF on PJDIV PWB and KEY IO PWB.1. Check the connection between POCN5 on PJDIV PWB and the pump.2. Check the 12v voltage to control the pump.3. Check the coolant of the unit.1. Check if the ICP version is the latest.2. Launch the "Macro File Tools" to check if there are any problems with the ICPconfiguration files.3. Retry the projector operation.4. Reset the ICP board and retry the projector operation.5. Check the connection between FSB and MOTHER PWB.6. Check the power supply voltage for the ICP board.7. If new ICP board was installed, restore the setting data in icp cfg files in Relese1. Check the connection between POCN2 on PJDIV PWB and MOTOR I/F PWB.2. Replace the MOTOR I/F PWB.1. Check the usage time of lamp bulb and replace the lamp bulb if needed.2. Verify that New Entry Bulb Setting was set when the lamp bulb was replaced.3. Replace CPU PWB.LPSU Fail(No Lamp):1. Check if the LPSU is powered on.2. Check the connection of RS-232C cable between PEDE-A PWB and LPSU.3. Check the connection between POCN2 on PJDIV PWB and PEDE-A PWB. LPSU Fail(Power):1. Power-cycle the LPSU. If problem is not gone, replace the LPSU. LPSU Fail(Param1, Param2):1. Check if the LPSU is powered on.2. Check the connection of RS-232C cable between PEDE-A PWB and LPSU.3. Check the connection between POCN2 on PJDIV PWB and PEDE-A PWB.1. The requested lamp output adjustment is out of range.1. Check the ambient temperature. It should be 35 degC or lower.2. Check if there is any problem on suction air and exhaust air.3. Check the air filter and verify that it is not clogged.4. Check that the ventilation system is being operated within required specification.1. Check the connection between MM3000B and Mother PWB.2. Check LAN connectors and LAN cable.3. Check that the projector is powered on, and not in stand-by mode.1. Check fan cable connection.2. Replace FAN.In regard to MMS Fail, there are three types of errors as shown below.The respective methods of taking measures are described below.1) FPGA***This is a configuration error of FPGA. If the associated FPGA is of an inputboard, try to remount the board or check the flexible cable connections orreinstall the FPGA data.In the case of the other FPGA errors, also try to reinstall the FPGA data. Ifthis check is difficult to perform, replace the associated board completely.2) Default DataThe data contained some deficiency at the time of shipment from the factory.Reinstall the data.3) User DataThis error is caused by a certain deficiency in the user data. Copy the user data into the PC so that further checks can be made. Execute a factory default to see if the default signal data eliminates the problem.Since part of or all of the previously copied user data may have been corrupted,reuse of these data is not recommended.If the data is used for the purpose of setup data checks, they should be cleared later.1. This message shows that the projector reset the MM3000B because of no responsemessages.If MMS Comm Fail occurs, see the MM3000B service manual.1. If ICP is being updated by ICP & Enigma Control Program without "Special Mode",this message will be shown.2. If ICP is reset by ICP & Enigma Control Program, this message will be shown.3. Retry the projector operation.4. Reset the ICP board and retry the projector operation.5. Check the connection between FSB and MOTHER PWB.6. Check the power supply voltage for the ICP board.1. If ICP is being updated by ICP & Enigma Control Program without "Special Mode",this message will be shown.2. If ICP is reset by ICP & Enigma Control Program, this message will be shown.3. Retry the projector operation.4. Reset the ICP board and retry the projector operation.5. Check the connection between FSB and MOTHER PWB.6. Check the power supply voltage for the ICP board.1. Check the connection between T-SENSE PWB and POCN1 on PJDIV PWB.2. Check the TSENS PWB.1. Check the failed fan and replace failed fan.2. Check connector POCN5 on PJDIV PWB.For fan layout, see the appendix.1. When the projector is NC3200S, refer to items 2 to 4 item first.2. (NC3200S) Check the system log.3. (NC3200S) When the GPSU(24V) fail was occurred, update the firmware to releasepackage 2.31.4. (NC3200S) or temporary countermeasure is to re-start (cold start) the projector.5. Check the failed fan and replace failed fan.6. Check connector POCN5 on PJDIV PWB.For fan layout, see the appendix.1. Check the failed fan and replace failed fan.2. Check connector POCN5 on PJDIV PWB.For fan layout, see the appendix.1. Check the connection between POPSM on PJDIV PWB and GPSU.2. Check the connection between AC PWB and GPSU.3. Replace GPSU Fan.4. Check GPSU.1. Check the connection between Fan unit and POCN5 on PJDIV PWB. For fan layout, see the appendix.2. Check LED on driver PWB.3. Check the failed fan and replace the fan.1. Check the fan attached on CPU PWB.2. Replace fan.3. Replace CPU PWB.1. When the GPI title selection is requested during operation is not allowed,this message will be shown.1. When the GPI control is requested during when the projector is busy,this message will be shown.2. Check if there is any problem on suction air and exhaust air.3. Check the air filter and verify that it is not clogged.4. Check that the ventilation system is being operated within required specification.5. Check the connection TSENS PWB.1. Check the ambient temperature. It should be 35 degC or lower.2. Check if there is any problem on suction air and exhaust air.3. Check the air filter and verify that it is not clogged.4. Check that the ventilation system is being operated within required specification.5. Check the connection TSENS PWB.1. Setup the new bulb entry while the projector is in standby.1. Check the (Param1) which indicates which switch is activated.2. Check if the side covers and lens cover are closed properly.3. Check if the tamper switch lever is broken.4. Check the connection between TAMPER PWB and POCN2/POCN7 on PJDIVPWB.5. Check TAMPER PWB.If Param1=0, reseat Circuit Box.If Param1=1,1. Check if cover plate or option PWB is seated at option slot A.2. Check the connection between TAMPER PWB and PO6012 on PJDIV PWB.3. Check TAMPER PWB.4. Check if ICP PWB/SIB is seated on MOTHER PWB properly.1.Check the CPU PWB1. When the projector is NC3200S, refer to items 2 to 4 item first.2. (NC3200S) Check the system log.3. (NC3200S) When the GPSU(24V) fail was occurred, update the firmware to releasepackage 2.31.4. (NC3200S) or temporary countermeasure is to re-start ( cold start ) the projector.5. Check the DC power supply voltage.6. Check the connection between GPSU and POPSM on PJDIV PWB.1. Replace CPU PWB.1. Check if the proper LPSU is used.2. Replace LPSU.1. Check if the LPSU is powered on.2. Replace LPSU.1. Check the 12v line.2. Check the connection between GPSU and PO6010 on MOTHER PWB.1. When the projector is NC3200S, refer to items 2 to 4 item first.2. (NC3200S) Check the system log.3. (NC3200S) When the GPSU(24V) fail was occurred, update the firmware to releasepackage 2.31.4. (NC3200S) or temporary countermeasure is to re-start ( cold start ) the projector.5. Check the 24v line.6. Check the connection between GPSU and POP24 on PJDIV PWB.1. Change filters1. Replace AC On Fan(Fan6) and clear AC On Fan usage time.NC2000C/NC1200C1. Replace Power On Fan(Fan0..5 and 7) and clear Power On Fan usage time.NC3200S1. Replace Power On Fan(Fan0..5 and 7..9) and clear Power On Fan usage time.1. Replace Lamp Cooling Fan 0 and 1 and clear Lamp Cooling Fan usage time.1. If the router unit is replaced with a new one, execute "NewRouterSetup" forprojector use.2. Power-cycle the projector.3. Check the LAN cable connection between Router unit and MOTHER PWB.4. Execute Factory Default - LAN.5. (Old router )If the router firmware is Version1.3 Release01, update toVersion1.4 Release01.(NEC router)If the router firmware is 1.0.1 (BR-CP1400N), do not need to update the firmware ofrouter.1. Check the connection between POCN3 on PJDIV PWB and LSENS PWB.2. Check the LSENS PWB.1. Replace CPU PWB.1. Power-cycle the projector.2. Replace the Router unit and execute "NewRouterSetup."1. Check the connection of LAN cable.2. Check router.1. Check LAN cable between Router and Mother(PO6201)2. Check connection of between SIB PWB (IC1600,IC1604) and Mother PWB1. Check SIB PWB1. Check SIB PWBDetermine DC fan causing error and replace it with a new DC fan.1. Check tamper SW1. Change the lamp bulb to new one.1. Check connection between ICP PWB and Mother PWB.2. Check connection between SIB PWB and ENIGMA PWB.3. Check Firmware version of both SIB PWB and ENIGMA PWB.4. Check ICP board.1. Check connection between ICP PWB and Mother PWB.2. Check connection between SIB PWB and ENIGMA PWB.3. Check Firmware version of both SIB PWB and ENIGMA PWB.4. Check ICP board.1.Check ICP board.1. Check connection between ICP PWB and Mother PWB.2. Check connection between SIB PWB and ENIGMA PWB.3. Check Firmware version of both SIB PWB and ENIGMA PWB.4. Check ICP board.1. Check connection between ICP PWB and Mother PWB.2. Check Firmware version of both SIB PWB and ENIGMA PWB.3. Check ICP board.。

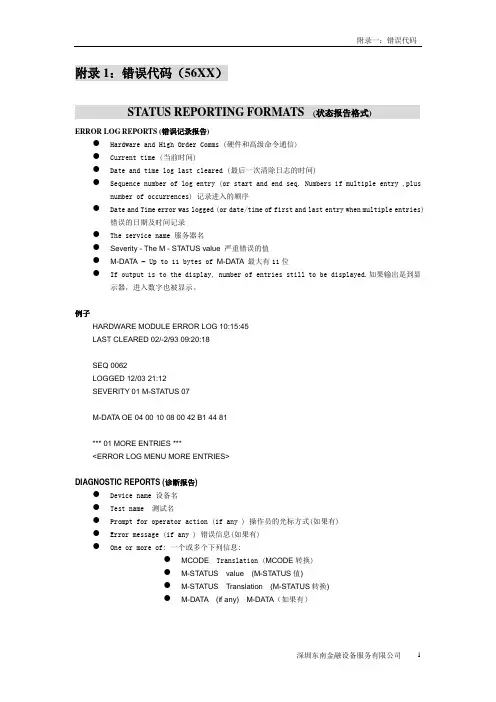

附录1:错误代码(56XX)STATUS REPORTING FORMATS(状态报告格式)ERROR LOG REPORTS (错误记录报告)●Hardware and High Order Comms (硬件和高级命令通信)●Current time (当前时间)●Date and time log last cleared (最后一次清除日志的时间)●Sequence number of log entry (or start and end seq. Numbers if multiple entry ,plusnumber of occurrences) 记录进入的顺序●Date and Time error was logged (or date/time of first and last entry when multiple entries)错误的日期及时间记录●The service name 服务器名●Severity - The M - STATUS value 严重错误的值●M-DATA– Up to 11 bytes of M-DATA 最大有11位●If output is to the display, number of entries still to be displayed.如果输出是到显示器,进入数字也被显示。

例子HARDWARE MODULE ERROR LOG 10:15:45LAST CLEARED 02/-2/93 09:20:18SEQ 0062LOGGED 12/03 21:12SEVERITY 01 M-STATUS 07M-DATA OE 04 00 10 08 00 42 B1 44 81*** 01 MORE ENTRIES ***<ERROR LOG MENU MORE ENTRIES>DIAGNOSTIC REPORTS (诊断报告)●Device name 设备名●Test name 测试名●Prompt for operator action (if any ) 操作员的光标方式(如果有)●Error message (if any ) 错误信息(如果有)●One or more of: 一个或多个下列信息:●MCODE Translation (MCODE转换)●M-STATUS value (M-STATUS值)●M-STATUS Translation (M-STATUS转换)●M-DATA (if any) M-DATA(如果有)STATUS REPORTING FORMATS(状态报告格式) 例子1CURRENCY DISPENSERPURGEEVENT EXPECTEDM-STATUS=00GOODTEST PASSEDM-STATUS=00GOODMDATA06 00 00例子2CURRENCY DISPENSERPRESENTTEST FAILEDM-STATUS=34NO BILLS PROVIDED FOR OP.ALARMS(报警)M-STATUS00 No error 无故障03 Turnaround test 环路测试146 SDC link failed SDC 连接失败M-DATA (M-STATUS=00)Byte 0 Sensor number 0 (composite) :0号传感器(复合)30 Inactive 未激活31 Active 激活Byte 1 Sensor number 1 (Safe door) :1号传感器(保险柜门)30 Inactive 未激活31 Active 激活Byte 2 Sensor number 2 (Silent Alarm) :2号传感器(SILENT 报警器)30 Inactive 未激活31 Active 激活Byte 3 Sensor number 3 (Tamper) :3号传感器(TAMPER)30 Inactive 未激活31 Active 激活Byte 4 Sensor number 4 (Not Allocated) :4号传感器(未分配)30 Inactive 未激活31 Active 激活Byte 5 Sensor number 5 (Not Allocated) :5号传感器(未分配)30 Inactive 未激活31 Active 激活M-DATA (M-STATUS=03)The turnaround tests for the miscellaneous interface devices are run from the INDICATORS menu (用于杂接口设备的环路测试是从INDICATORS菜单开始运行的。

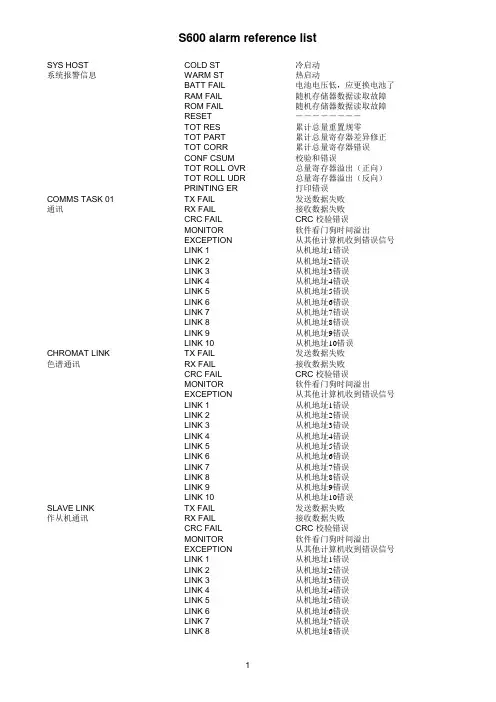

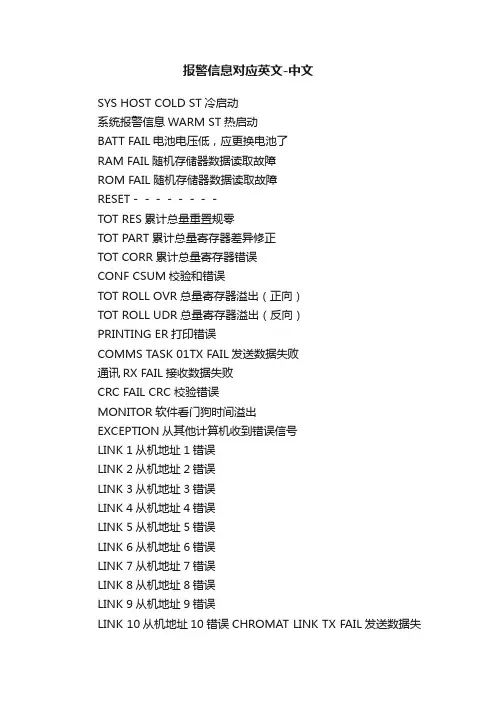

SYS HOST COLD ST冷启动系统报警信息WARM ST热启动BATT FAIL电池电压低,应更换电池了RAM FAIL随机存储器数据读取故障ROM FAIL随机存储器数据读取故障RESET--------TOT RES累计总量重置规零TOT PART累计总量寄存器差异修正TOT CORR累计总量寄存器错误CONF CSUM校验和错误TOT ROLL OVR总量寄存器溢出(正向)TOT ROLL UDR总量寄存器溢出(反向)PRINTING ER打印错误COMMS TASK 01TX FAIL发送数据失败通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误CHROMAT LINK TX FAIL发送数据失败色谱通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误SLAVE LINK TX FAIL发送数据失败作从机通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误PRINTER CONF ERR配置错误或I/O板故障打印机ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BKGND TASK CONF ERR配置错误或I/O板故障后台任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DIO SCAN TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DISPLAY TASK CONF ERR配置错误或I/O板故障显示任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误IO CONNS TASK CONF ERR组态错误IO通讯ZERO DIV零点误差TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FAIL IO1IO 板1 通讯故障FAIL IO2IO 板2 通讯故障FAIL IO3IO 板3 通讯故障FAIL IO4IO 板4 通讯故障FAIL IO5IO 板5 通讯故障FAIL IO6IO 板6 通讯故障FAIL IO7IO 板7 通讯故障TSK ERR任务出错IO CONNS TASK CONF ERR配置错误或I/O板故障IO通讯ZERO DIV零除错误TSK OFLOW写保护NONITOR软件看门狗时间溢出CALC FAIL计算错误REPORTS TASK CONF ERR配置错误或I/O板故障报告AERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误TOTALS TASK CONF ERR配置错误或I/O板故障总量ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CONPRESS TASK CONF ERR配置错误或I/O板故障气体压缩ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CV TASK CONF ERR配置错误或I/O板故障气体热值ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CORRECT TASK CONF ERR配置错误或I/O板故障气体修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP COND TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP INC TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP FLOW TASK CONF ERR配置错误或I/O板故障气体差压流量任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS PTZ TASK CONF ERR配置错误或I/O板故障气体PTZ计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CHROMAT TASK CONF ERR配置错误或I/O板故障气相色谱仪ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS TURB INCTASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DENS COPY TASK CONF ERR配置错误或I/O板故障气体密度拷贝ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ KF/MF TASK CONF ERR配置错误或I/O板故障液体 KF/MF 系数ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ M CORR TASK CONF ERR配置错误或I/O板故障液体M系数修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ LIQ CON TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ TURB TASK CONF ERR配置错误或I/O板故障液体涡轮ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ VOL CORR TASK CONF ERR配置错误或I/O板故障液体体积修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV SEQ TASK CONF ERR配置错误或I/O板故障标定顺序ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV BIDI TASK CONF ERR配置错误或I/O板故障双向标定ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ULT CONTROL TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ULT FLOWRATE TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STN SUM FLOW TASK CONF ERR配置错误或I/O板故障总计流量ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DENSITY TASK CONF ERR配置错误或I/O板故障密度ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STR STATUS TASK CONF ERR配置错误或I/O板故障管线状态ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FWA CALC TASK CONF ERR配置错误或I/O板故障正向计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BVM TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STN AVE TASK CONF ERR配置错误或I/O板故障平均值ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DISCREP TASK CONF ERR配置错误或I/O板故障差异ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误CALC TASK CONF ERR配置错误或I/O板故障计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PID CTL TASK CONF ERR配置错误或I/O板故障比例微分调节计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ALM SUPPRESS TASK CONF ERR配置错误或I/O板故障警报抑制ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BATCH/FSW TASK CONF ERR配置错误或I/O板故障批控ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误AGA8FULL TASK CONF ERR配置错误或I/O板故障AGA8全组分ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误CALIB TASK CONF ERR配置错误或I/O板故障标定任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误US LIQ TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误SAMPLER TASK CONF ERR配置错误或I/O板故障取样任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LOGICALC TASK CONF ERR配置错误或I/O板故障逻辑任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR IO TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR IF TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR FLOW TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV CPRV TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FAULT TASK CONF ERR配置错误或I/O板故障故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FLOWTIME TASK CONF ERR配置错误或I/O板故障流量时间ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误SGERG TASK CONF ERR配置错误或I/O板故障SGERG计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV MMPRV TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS GCFWA TASK CONF ERR配置错误或I/O板故障色谱正向任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误I/O01 ADC 01 (E.G. PRESSURE)LL低低位报警模拟输入通道1(如压力)L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN设配开U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻输入电流超限SCALING数值范围DEV ERR设备故障I/O01 ADC 02LL低低位报警模拟输入通道1L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN IO板通讯故障U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻输入电流超限SCALING数值范围DEV ERR设备故障I/O01 DAC 01U-RANGE欠量程数字量输入通道1O-RANGE超量程SCALING数值范围DEV ERR设备故障I/O01 DAC 02U-RANGE欠量程数字量输入通道2O-RANGE超量程SCALING数值范围DEV ERR设备故障I/O01 FREQ 01LOW PRD测量周期小于低限频率输入通道1HIGH PRD测量周期超过高限DEV-OPEN IO板通讯故障DEV-ERR设备故障I/O01 PID 01CONF ERR配置错误或I/O板故障比例积分微分控制输入通道1DEV ERR设备故障I/O01 PRT 01LL低低位报警铂电阻温度计输入通道1L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN IO板通讯故障U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻电流输入超限SCALING数值范围DEV ERR设备故障I/O01 PIP 01A-FAIL A脉冲故障脉冲输入通道1B-FAIL B脉冲故障O-FLOW过流量BAD PULSE失效的脉冲DEV ERR设备故障I/O01 POP 01OVERFLOW过流量脉冲输出通道1DEV ERR设备故障I/O01 STATUS RAM FAIL随机存储器故障IO板通道状态ROM FAIL只读存储器故障PIC FAIL IO板硬件故障TPU FAIL IO板硬件故障EEPROM FIAL可擦写存储器故障TASK ERR任务出错CONF ERR组态错误TASK FAIL IO板故障WARM ST冷启动DEV ERR设备故障STR01 DP STACK CALC CONF ERR配置错误或I/O板故障管线1差压计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 DOWN/UP CALC CONF ERR配置错误或I/O板故障管线1下/上计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01GAS INC CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 PIPE COR CALC CONF ERR配置错误或I/O板故障管线1管路修正系数计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 STATUS CALC CONF ERR配置错误或I/O板故障管线1状态计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 LFC CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 MAINT CALC CONF ERR配置错误或I/O板故障管线1主计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.P CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.S CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.T CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 I/L VLV CALC CONF ERR配置错误或I/O板故障管线1入口阀门计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 O/L VLV CALC CONF ERR配置错误或I/O板故障管线1出口阀门计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 AGA8 CALC CONF ERR配置错误或I/O板故障管线1AGA8计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 ISO5167 CALC CONF ERR配置错误或I/O板故障管线1ISO5167计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 ISO6976 CALC CONF ERR配置错误或I/O板故障管线1ISO6976计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 TFWA FWD CALC CONF ERR配置错误或I/O板故障管线1TFWA正向计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 TFWA REV CALA CONF ERR配置错误或I/O板故障管线1TFWA反向计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 MASS FR LL低低位报警管线1瞬时质量流量L低位报警H高位报警HH高高位报警STR01 UVOL FR LL低低位报警管线1瞬时工况体积流量L低位报警H高位报警HH高高位报警STR01 CVOL FR LL低低位报警管线1瞬时标况体积流量L低位报警H高位报警HH高高位报警STR01 ENGY FR LL低低位报警管线1瞬时能量流量L低位报警H高位报警HH高高位报警STR01 UPSTR DENS LL低低位报警管线1上游管线密度L低位报警H高位报警HH高高位报警STR01 DWNSTR PRESS LL低低位报警管线1下游管线压力L低位报警H高位报警HH高高位报警STR01 RECOVD PRESS LL低低位报警管线1恢复压力L低位报警H高位报警HH高高位报警STR01 UPSTR TEMP LL低低位报警管线1上游管线温度L低位报警H高位报警HH高高位报警STR01 STD DENS LL低低位报警管线1标准密度L低位报警H高位报警HH高高位报警STR01 DWNSTR DENS LL低低位报警管线1下游管线密度L低位报警H高位报警HH高高位报警STR01 UPSTR PRESS LL低低位报警管线1上游管线压力L低位报警H高位报警HH高高位报警STR01 DWNSTR TEMP LL低低位报警管线1下游管线温度L低位报警H高位报警HH高高位报警STR01 REAL RDENS LL低低位报警管线1真实密度L低位报警H高位报警HH高高位报警ROC变化率超限DSCRP与前一数值差异过大FAIL A A通道开路或短路FAIL B B通道开路或短路STR01 PRESS LOSS LL低低位报警管线1压损L低位报警H高位报警HH高高位报警STR01 CORR PIPE DIAM LL低低位报警管线1管径修正L低位报警H高位报警HH高高位报警STR01 CORR ORIF DIAM LL低低位报警管线1孔板直径修正L低位报警H高位报警HH高高位报警STR01 UPSTR COMPRESS LL低低位报警管线1上游管线压缩系数L低位报警H高位报警HH高高位报警STR01 STD COMPRESS LL低低位报警管线1标准压缩系数L低位报警H高位报警HH高高位报警STR01 MOL WEIGHT LL低低位报警管线1摩尔权重系数L低位报警H高位报警HH高高位报警STR01 COMPONENT TOT LL低低位报警管线1组分摩尔总量L低位报警HH高高位报警STR01 NORMAL LL低低位报警L低位报警H高位报警HH高高位报警STR01 BETA LL低低位报警管线1BETA系数L低位报警H高位报警HH高高位报警STR01 REYNOLDS NO LL低低位报警管线1雷诺数L低位报警H高位报警HH高高位报警STR01 EXP FACTOR LL低低位报警管线1指数因子L低位报警H高位报警HH高高位报警STR01 DISCH COEFF LL低低位报警L低位报警H高位报警HH高高位报警STR01 FLOW COEFF LL低低位报警管线1流量系数L低位报警H高位报警HH高高位报警STR01 VEL OF APP FAC LL低低位报警L低位报警H高位报警HH高高位报警STR01 IDEAL RDENS LL低低位报警L低位报警H高位报警HH高高位报警STR01 IDEAL DENS LL低低位报警管线1理想密度L低位报警H高位报警HH高高位报警STR01 IDEAL CV LL低低位报警管线1理想热值L低位报警H高位报警HH高高位报警STR01 REAL CV LL低低位报警管线1真实热值L低位报警H高位报警HH高高位报警STR01 PID PV COEFF LL低低位报警管线1比例微分调解系数L低位报警H高位报警HH高高位报警STR01 BASE COMPRESS LL低低位报警管线1基本压缩系数L低位报警H高位报警HH高高位报警STR01 THERMAL EXP FAC LL低低位报警管线1L低位报警HH高高位报警STR01 INLET VLV ILLEGAL不合理的操作位置或指令管线1入口阀门SEAL FAIL密封失效MOVE FAIL阀门动作没有到位MOVE UNCM无指令动作UNAVAIL无效的操作STR01 OUTLET VLV ILLEGAL不合理的操作位置或指令管线1出口阀门SEAL FAIL密封失效MOVE FAIL阀门动作没有到位MOVE UNCM无指令动作UNAVAIL无效的操作STR01 MOLE SELECT K_COMP键盘模式管线1气体摩尔量方式选择ADDNLS色谱模式SPLITS分离模式DL COMP下载气体组分模式USER COMP用户模式STR01 CHROM TELEM RX FAIL接收数据失败管线 1色谱通信CONFIG配置错误CRITICAL临界NCRITICAL非临界MOLE LO摩尔量低MOLE HI摩尔量高MOLE DV摩尔量有误差REP TOUT通讯失败STR01 DP CELL LL低低位报警管线1压差单元L低位报警H高位报警HH高高位报警WARNING警告SELECT选择错误DISCREP有差异的DENIED否定的COMMON普通报警。

报警信息对应英文-中文SYS HOST COLD ST冷启动系统报警信息WARM ST热启动BATT FAIL电池电压低,应更换电池了RAM FAIL随机存储器数据读取故障ROM FAIL随机存储器数据读取故障RESET--------TOT RES累计总量重置规零TOT PART累计总量寄存器差异修正TOT CORR累计总量寄存器错误CONF CSUM校验和错误TOT ROLL OVR总量寄存器溢出(正向)TOT ROLL UDR总量寄存器溢出(反向)PRINTING ER打印错误COMMS TASK 01TX FAIL发送数据失败通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误CHROMAT LINK TX FAIL发送数据失败色谱通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误SLAVE LINK TX FAIL发送数据失败作从机通讯RX FAIL接收数据失败CRC FAIL CRC 校验错误MONITOR软件看门狗时间溢出EXCEPTION从其他计算机收到错误信号LINK 1从机地址1错误LINK 2从机地址2错误LINK 3从机地址3错误LINK 4从机地址4错误LINK 5从机地址5错误LINK 6从机地址6错误LINK 7从机地址7错误LINK 8从机地址8错误LINK 9从机地址9错误LINK 10从机地址10错误PRINTER CONF ERR配置错误或I/O板故障打印机ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BKGND TASK CONF ERR配置错误或I/O板故障后台任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DIO SCAN TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DISPLAY TASK CONF ERR配置错误或I/O板故障显示任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误IO CONNS TASK CONF ERR组态错误IO通讯ZERO DIV零点误差TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FAIL IO1IO 板1 通讯故障FAIL IO2IO 板2 通讯故障FAIL IO3IO 板3 通讯故障FAIL IO4IO 板4 通讯故障FAIL IO5IO 板5 通讯故障FAIL IO6IO 板6 通讯故障FAIL IO7IO 板7 通讯故障TSK ERR任务出错IO CONNS TASK CONF ERR配置错误或I/O板故障IO通讯ZERO DIV零除错误TSK OFLOW写保护NONITOR软件看门狗时间溢出CALC FAIL计算错误REPORTS TASK CONF ERR配置错误或I/O 板故障报告AERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误TOTALS TASK CONF ERR配置错误或I/O板故障总量ZERO DIV 零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CONPRESS TASK CONF ERR配置错误或I/O板故障气体压缩ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CV TASK CONF ERR配置错误或I/O板故障气体热值ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CORRECT TASK CONF ERR配置错误或I/O板故障气体修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出GAS DP COND TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP INC TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS DP FLOW TASK CONF ERR配置错误或I/O板故障气体差压流量任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS PTZ TASK CONF ERR配置错误或I/O板故障气体PTZ计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS CHROMAT TASK CONF ERR配置错误或I/O板故障气相色谱仪ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS TURB INCTASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出GAS DENS COPY TASK CONF ERR配置错误或I/O板故障气体密度拷贝ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ KF/MF TASK CONF ERR配置错误或I/O板故障液体 KF/MF 系数ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ M CORR TASK CONF ERR配置错误或I/O板故障液体M系数修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ LIQ CON TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ TURB TASK CONF ERR配置错误或I/O板故障液体涡轮ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ VOL CORR TASK CONF ERR配置错误或I/O板故障液体体积修正ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出PRV SEQ TASK CONF ERR配置错误或I/O板故障标定顺序ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV BIDI TASK CONF ERR配置错误或I/O板故障双向标定ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ULT CONTROL TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ULT FLOWRATE TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STN SUM FLOW TASK CONF ERR配置错误或I/O板故障总计流量ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DENSITY TASK CONF ERR配置错误或I/O板故障密度ZERO DIV 零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出STR STATUS TASK CONF ERR配置错误或I/O板故障管线状态ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FWA CALC TASK CONF ERR配置错误或I/O板故障正向计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BVM TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误STN AVE TASK CONF ERR配置错误或I/O板故障平均值ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误DISCREP TASK CONF ERR配置错误或I/O 板故障差异ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误CALC TASK CONF ERR配置错误或I/O板故障计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PID CTL TASK CONF ERR配置错误或I/O板故障比例微分调节计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误ALM SUPPRESS TASK CONF ERR配置错误或I/O板故障警报抑制ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误BATCH/FSW TASK CONF ERR配置错误或I/O板故障批控ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误AGA8FULL TASK CONF ERR配置错误或I/O板故障AGA8全组分ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误CALIB TASK CONF ERR配置错误或I/O板故障标定任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误US LIQ TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误SAMPLER TASK CONF ERR配置错误或I/O板故障取样任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LOGICALC TASK CONF ERR配置错误或I/O 板故障逻辑任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR IO TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR IF TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误LIQ COR FLOW TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV CPRV TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FAULT TASK CONF ERR配置错误或I/O板故障故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误FLOWTIME TASK CONF ERR配置错误或I/O板故障流量时间ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误SGERG TASK CONF ERR配置错误或I/O板故障SGERG计算ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误PRV MMPRV TASK CONF ERR配置错误或I/O板故障ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误GAS GCFWA TASK CONF ERR配置错误或I/O板故障色谱正向任务ZERO DIV零除错误TSK OFLOW写保护MONITOR软件看门狗时间溢出CALC FAIL计算错误I/O01 ADC 01 (E.G. PRESSURE)LL低低位报警模拟输入通道1(如压力)L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN设配开U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻输入电流超限SCALING数值范围DEV ERR设备故障I/O01 ADC 02LL低低位报警模拟输入通道1L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN IO板通讯故障U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻输入电流超限SCALING数值范围DEV ERR设备故障I/O01 DAC 01U-RANGE欠量程数字量输入通道1O-RANGE超量程SCALING数值范围DEV ERR设备故障I/O01 DAC 02U-RANGE欠量程数字量输入通道2O-RANGE超量程SCALING数值范围DEV ERR设备故障I/O01 FREQ 01LOW PRD测量周期小于低限频率输入通道1HIGH PRD测量周期超过高限DEV-OPEN IO板通讯故障DEV-ERR设备故障I/O01 PID 01CONF ERR配置错误或I/O板故障比例积分微分控制输入通道1DEV ERR设备故障I/O01 PRT 01LL低低位报警铂电阻温度计输入通道1L高位报警H低位报警HH高高位报警ROC变化率超限DSCRP当前值与前一数值差异过大DEV OPEN IO板通讯故障U-RANGE欠量程O-RANGE超量程INTEG-FAIL铂电阻电流输入超限SCALING数值范围DEV ERR设备故障I/O01 PIP 01A-FAIL A脉冲故障脉冲输入通道1B-FAIL B脉冲故障O-FLOW过流量BAD PULSE失效的脉冲DEV ERR设备故障I/O01 POP 01OVERFLOW过流量脉冲输出通道1DEV ERR设备故障I/O01 STATUS RAM FAIL随机存储器故障IO板通道状态ROM FAIL只读存储器故障PIC FAIL IO板硬件故障TPU FAIL IO板硬件故障EEPROM FIAL可擦写存储器故障TASK ERR任务出错CONF ERR组态错误TASK FAIL IO板故障WARM ST冷启动DEV ERR设备故障STR01 DP STACK CALC CONF ERR配置错误或I/O板故障管线1差压计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 DOWN/UP CALC CONF ERR配置错误或I/O板故障管线1下/上计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01GAS INC CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 PIPE COR CALC CONF ERR配置错误或I/O板故障管线1管路修正系数计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 STATUS CALC CONF ERR配置错误或I/O板故障管线1状态计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 LFC CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护管线1主计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.P CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.S CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 CHROM.T CALC CONF ERR配置错误或I/O板故障I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 I/L VLV CALC CONF ERR配置错误或I/O板故障管线1入口阀门计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 O/L VLV CALC CONF ERR配置错误或I/O板故障管线1出口阀门计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护管线1AGA8计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 ISO5167 CALC CONF ERR配置错误或I/O板故障管线1ISO5167计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 ISO6976 CALC CONF ERR配置错误或I/O板故障管线1ISO6976计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 TFWA FWD CALC CONF ERR配置错误或I/O板故障管线1TFWA正向计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 TFWA REV CALA CONF ERR配置错误或I/O板故障管线1TFWA反向计算I/P ERR计算过程中的变量超出范围O/P ERR计算过程中的变量超出范围CALC FAIL计算出错NO PERMIT写保护STR01 MASS FR LL低低位报警管线1瞬时质量流量L低位报警H高位报警HH高高位报警STR01 UVOL FR LL低低位报警管线1瞬时工况体积流量L低位报警H高位报警HH高高位报警STR01 CVOL FR LL低低位报警管线1瞬时标况体积流量L低位报警H高位报警HH高高位报警STR01 ENGY FR LL低低位报警管线1瞬时能量流量L低位报警H高位报警HH高高位报警STR01 UPSTR DENS LL低低位报警管线1上游管线密度L低位报警H高位报警HH高高位报警STR01 DWNSTR PRESS LL低低位报警管线1下游管线压力L低位报警H高位报警HH高高位报警STR01 RECOVD PRESS LL低低位报警管线1恢复压力L低位报警HH高高位报警STR01 UPSTR TEMP LL低低位报警管线1上游管线温度L低位报警H高位报警HH高高位报警STR01 STD DENS LL低低位报警管线1标准密度L低位报警H高位报警HH高高位报警STR01 DWNSTR DENS LL低低位报警管线1下游管线密度L低位报警H高位报警HH高高位报警STR01 UPSTR PRESS LL低低位报警管线1上游管线压力L低位报警H高位报警HH高高位报警STR01 DWNSTR TEMP LL低低位报警管线1下游管线温度L低位报警H高位报警HH高高位报警STR01 REAL RDENS LL低低位报警管线1真实密度L低位报警H高位报警HH高高位报警ROC变化率超限DSCRP与前一数值差异过大FAIL A A通道开路或短路FAIL B B通道开路或短路STR01 PRESS LOSS LL低低位报警管线1压损L低位报警H高位报警HH高高位报警STR01 CORR PIPE DIAM LL低低位报警管线1管径修正L低位报警H高位报警HH高高位报警STR01 CORR ORIF DIAM LL低低位报警管线1孔板直径修正L低位报警H高位报警HH高高位报警STR01 UPSTR COMPRESS LL低低位报警管线1上游管线压缩系数L低位报警H高位报警HH高高位报警STR01 STD COMPRESS LL低低位报警管线1标准压缩系数L低位报警H高位报警HH高高位报警STR01 MOL WEIGHT LL低低位报警管线1摩尔权重系数L低位报警H高位报警HH高高位报警STR01 COMPONENT TOT LL低低位报警管线1组分摩尔总量L低位报警HH高高位报警STR01 NORMAL LL低低位报警L低位报警H高位报警HH高高位报警STR01 BETA LL低低位报警管线1BETA系数L低位报警H高位报警HH高高位报警STR01 REYNOLDS NO LL低低位报警管线1雷诺数L低位报警H高位报警HH高高位报警STR01 EXP FACTOR LL低低位报警管线1指数因子L低位报警H高位报警HH高高位报警STR01 DISCH COEFF LL低低位报警L低位报警H高位报警HH高高位报警STR01 FLOW COEFF LL低低位报警管线1流量系数L低位报警H高位报警HH高高位报警STR01 VEL OF APP FAC LL低低位报警L低位报警H高位报警HH高高位报警STR01 IDEAL RDENS LL低低位报警L低位报警H高位报警HH高高位报警STR01 IDEAL DENS LL低低位报警管线1理想密度L低位报警H高位报警HH高高位报警STR01 IDEAL CV LL低低位报警管线1理想热值L低位报警H高位报警HH高高位报警STR01 REAL CV LL低低位报警管线1真实热值L 低位报警H高位报警HH高高位报警STR01 PID PV COEFF LL低低位报警管线1比例微分调解系数L低位报警H高位报警HH高高位报警STR01 BASE COMPRESS LL低低位报警管线1基本压缩系数L低位报警H高位报警HH高高位报警STR01 THERMAL EXP FAC LL低低位报警管线1L 低位报警HH高高位报警STR01 INLET VLV ILLEGAL不合理的操作位置或指令管线1入口阀门SEAL FAIL密封失效MOVE FAIL阀门动作没有到位MOVE UNCM无指令动作UNAVAIL无效的操作STR01 OUTLET VLV ILLEGAL不合理的操作位置或指令管线1出口阀门SEAL FAIL密封失效MOVE FAIL阀门动作没有到位MOVE UNCM无指令动作UNAVAIL无效的操作STR01 MOLE SELECT K_COMP键盘模式管线1气体摩尔量方式选择ADDNLS色谱模式SPLITS分离模式DL COMP下载气体组分模式USER COMP用户模式STR01 CHROM TELEM RX FAIL接收数据失败管线 1色谱通信CONFIG配置错误CRITICAL临界NCRITICAL非临界MOLE LO摩尔量低MOLE HI摩尔量高MOLE DV摩尔量有误差REP TOUT通讯失败STR01 DP CELL LL低低位报警管线1压差单元L低位报警H高位报警HH高高位报警WARNING警告SELECT选择错误DISCREP有差异的DENIED否定的COMMON普通报警。

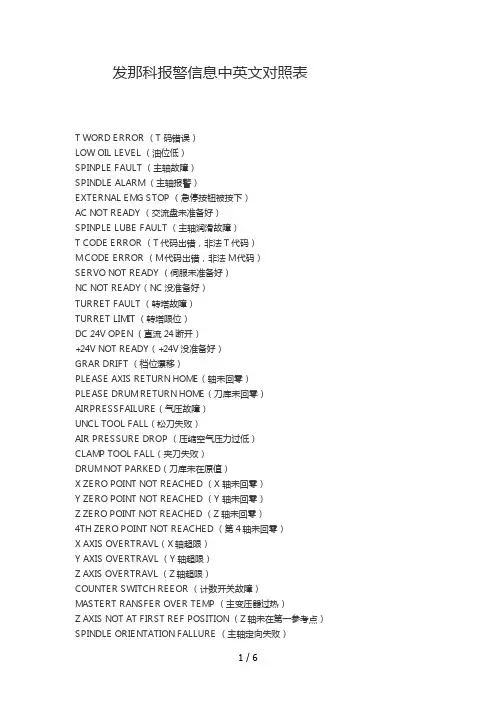

发那科报警信息中英文对照表T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTRAVL(X轴超限)Y AXIS OVERTRAVL (Y轴超限)Z AXIS OVERTRAVL (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERROR(刀库移动限位开关故障)SPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR(主轴刀具UNLAMP位置限位开关故障)MAGAZINE NOT IN POSITION OR SENSOR ERROR(刀库不在位或传感器错误)AIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTRAVER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误)SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS HAVE GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭) SPINDLE ORIENTATION INCOMPLETE(主轴定位不完全)M FUNCTION NOT COMPLETE(M 功能无法完成)SPINDLE NOT IN GEAR POSITION(齿轮不在主轴位置)SPINDLE NOT CHANGED TO LOW GEAR(主轴没有变为低档)SPINDLE NOT CHANGED TO HIGH GRAR(主轴没有变为高档)MAG NOT BACKWARDSPINDLE TOOL NOT CLAMPSPINDLE TOOL NOT UNCLAMPMAG NOT IN POSITIONMAG DOES NOT ROTATEMAG DOES NOT STOP RUNNINGA AXIS HAVE NOT CLAMPEDA AXIS HAVE NOT UNCLAMPEDSET D499=1,"MAG.JOG" SWITCH ONHYDRAULIC MOTOR QF7 OFF(液压马达QF7关闭)HYDRAULIC TEMPRETURE HIGH(液压使用温度高)HYDRAULIC FILTER BLOCKED(液压过滤器阻止)HYDRAULIC OIL LEVEL LOW(液压油位低)HYDRAULIC FAN QF8 OFF(液压风扇QF8关闭)HELIX CONYER QF9 OR QF10 OFFCHAIN CONYER QF11 OFFCOOLANT MOTOR QF12 OFF(冷却液电机QF12关闭)COOLNT LEVEL LOW,CYCLE STOP AFTER 20 MINUTESINNER COOLANT BLOCK(内冷却堵塞)SPINDLE COOLANT MOTOR QF14 OFF(主轴冷却液电机QF14关闭)INNER COOLANT QF13 OFF(内冷却液QF13关闭)MAG MOTOR QF15 OFFCABINET COOLANT EQUIP QF20 OFFOIL GATHER QF24 OFFAIR PRESSURE LOW(低气压)SPINDLE COOLANT MOTOR FAULT(主轴冷却液电机故障)LUB.OIL IS LOW(润滑油低)DOOR OPEN(门打开)FRONT DOOR(R) OPEN(前门打开)LEFT DOOR OPEN(左门打开)LUBRICATION OIL QF23 OFF(润滑油QF23关闭)LUBRICATION PRESS LOW(润滑油位低)IN ADJUST,MAG CAN'T EXCHANGE T(在调整,刀库不能交换T)NOT ALL DOOR CLOSED(门没有全部关闭)IN M06,MAG NOT READY(在M06,刀库未准备好)MAGAZINE NOT READY(刀库未准备好)POCKET NOT HORIZANTALIN M06,Z NOT BACK TO 2ND REFIN M06,Z AXIS NOT IN PSW1ATC NOT IN ZERO POSITIONSPINDLE ORIENTATION UNCOMPLETEPOCKET NOT HOR./MAG NOT BCKWRDPOCKET NOT VER./MAG NOT FORWRDUNCLAMP TOOL HAS NOT COMPLETEDCLAMP TOOL HAS NOT COMPLETEDAIM TOOL NO. IS WRONGMAG NOT BACKWARDAFTER RETRACT,SET R.T.BACK OFFZ NOT IN PSW2,FORBID ATC RUNNINGD499 EQUAL 1MAG.JOG SOFT SWITCH IS ONZ NOT IN PSW2,FORBID MAG FORWARDCHEKE SPINDLE MODULE ALARMOIL WATER SEPARATOR QF24 OFFSET THE SOFT SWITCH MAG.JOG OFFSET D499 TO 0 设定D499为0K PARAM ABOUT MAG SET IS WRONG 关于MAG的K参数设定错误MECHANICAL BRAKE NOT RELEASED机床抱闸没有松开MECHANICAL BRAKE IS WRONG 机床抱闸错误PLEASE ADD LUB.OIL 请加润滑油PROBE BATTERY VOLTAGE IS LOW 探头电池电压低PROBE IS ERR 探头错误PARAMETER WRITE ENABLE(参数写使能)PMC EDIT ENABLE(PMC编辑使能)CHECK LUB ROUTINSPINDLE GEAR SIGNAL MISS 主轴档位信号消失T_CLAMPED_SIGNAL MISS T夹紧信号消失SP OVERRIDE SWITCH DISCONNECTION 主轴倍率开关断路FEED OVERRIDE SWITCH DISCONNECTION 进给倍率开关断路THE TOTAL NUMBER OF POCKETS SET ERRCHANGE T STOPED BECAUSE NO AIR 因为缺少压空交换停止THE COOLANT WATER TOO LOW,ADD COOLANT WATER AT ONCE 冷却水少立即加水COOLANT LEVEL LOW,ADD COOLANT WATER 冷却水液位低PLEASE REPLACE CNC BATTERY QUICKLY 请立即更换CNC电池(注:范文素材和资料部分来自网络,供参考。

MARK点错误

其他错误

窗口偏出

窗口抽出偏移

没有检查

抽出错误

焊盘抽出错误

元件本体抽出错误

引脚抽出错误

缺件(本体测出)

缺件(焊锡测出)

缺件(引脚测出)

没有极性标识(极性错误)没有标志(丝印标识测试)横向偏移

纵向偏移

引脚弯曲

翘脚

丝印偏移

文字错误

文字读取错误

锡桥

引脚锡桥

吹孔

粘合剂错误

成型角异常(焊锡角度)成型角异常(焊锡缺口)浸润异常

浸润异常(焊锡整体)

浸润异常(引脚上锡)

浸润异常(引脚部分)

锡球

锡球引脚部分

焊盘露出

条码错误

条码读取错误

少锡

X方向偏移

Y方向偏移

X方向偏移(焊盘)Y方向偏移(焊盘)横向偏移

纵向偏移

锡桥(自动抽出)锡桥(单独的)

脏污

多锡。

致命错误1.bad call of in-line function 内部函数非法调用2.irrducible expression tree 不可约表达式树3.register allocation failure 存储器分配失效1.#operator not followed by macro argument name #运算符后无宏变量名。

2.'****'not an argument '****'不是函数参数。

3.ambiguous symbol '****' 二义性符号'****'。

4.argument #missing name 参数表出现语法错误。

5.argument list error 参数表出现语法错误。

6.array bounds missing ] 数组的界限符"]"丢失。

7.array size too large 数组太大。

8.assembler statement too long 汇编语句太长。

9.bad configuration file 配置文件不正确。

10.bad file name format in include directive 使用include指令时,文件名格式不正确。

11.bad ifdef directive syntax ifdef指令语法错误。

#indef必须包含一个标识符(不能是任何其他东西)作为该指令体。

12.bad ifndef directive syntax ifndef 指令语法错误。

13.ad undef directive syntax undef 指令指令语法错误。

14.bad file size syntax 位字段长度语法错误。

一个位字段必须是1-16位的常量表达式。

15.call of non-function 调用未定义函数。

计算机常见报警错误信息中英文对照表-电子电路图,电子技术资料网站计算机常见报警错误信息中英文对照表-电子电路图,电子技术资料网站 ;计算机常见报警错误信息中英文对照表一、BIOS中的提示信息Drive A error 驱动器A错误System halt 系统挂起Keyboard controller error 键盘控制器错误Keyboard error or no keyboard present 键盘错误或者键盘不存在BIOS ROM checksum error BIOS ROM 校验错误Single hardisk cable fail 当硬盘使用Cable选项时硬盘安装位置不正确FDD Controller Failure BIOS 软盘控制器错误HDD Controller Failure BIOS 硬盘控制器错误Driver Error 驱动器错误Cache Memory Bad, Do not Enable Cache 高速缓存Cache损坏,不能使用Error: Unable to control A20 line 错误提示:不能使用A20地址控制线Memory write/Read failure 内存读写失败Memory allocation error 内存定位错误CMOS Battery state Low CMOS没电了Keyboard interface error 键盘接口错误Hard disk drive failure 加载硬盘失败Hard disk not present 硬盘不存在Floppy disk(s) fail (40)软盘驱动器加载失败,一般是数据线插反,电源线没有插接,CMOS内部软驱设置错误CMOS checksum error-efaults loaded. CMOS校验错误,装入缺省(默认)设置二、BIOS刷新失败后,Bootblock启动时出现的提示信息Detecting floppy drive A media... 检测软驱A的格式Drive media is : 1.44Mb1.2Mb 720Kb 360K驱动器格式是1.44Mb、12Mb、720kb、360kb的一种DISK BOOT FAILURE, INSERT SYSTEM DISK AND PRESS ENTER磁盘引导失败,插入系统盘后按任意键继续三、MBR主引导区提示信息Invalid partition table 无效的分区表Error loading operating sy stem 不能装入引导系统Missing operating system 系统引导文件丢失说明:如果在计算机启动过程中,在硬件配置清单下方(也就时在平时正常启动时出现Starting Windows98…的地方)出现不可识别字符,此时可判断硬盘分区表损坏。

1、cash handlerpurge Bin full一般是废钞箱满或废钞传感器挡住,清除废钞和卡钞后清除记录2、cash handlercass 3 remover是指3号通道是空的,不会造成机器故障,不用理会。

3、cash handlercass 2 identify是指2号通道有钞箱但机器不能识别钞箱,一般由于钞箱吸空钞箱故障引起。

如钞箱空需加几张钞票进去可以解决,钞箱故障需把钞箱拔出后清除错误记录。

4、cash handlernote jam or tsen 3 failure指tsen3传感器有卡钞,传感器位置可以咨询工程师,清除卡钞后清除错误记录。

5、cash handlercass 4 ( type 3) pick fails指4号通道的3号钞箱吸钞失败,检查钞箱里面钞票和4号通道有无卡钞,清除错误记录。

6、cash handlercass 2 ( type 3 ) low指2号通道3号钞箱钞票少,可以不用理会。

7、bunch note acceptorreject unit jam退钞失败,有卡钞在退钞口或退钞口传感器脏,取出卡钞后清除错误记录8、bunch note acceptorfeed unit jam进钞口卡钞或进钞口传感器脏,取出卡钞后清除错误记录9、bunch note acceptornote bin removed可能钞箱没有推好或者钞箱门扣没关好。

10、bunch note acceptorescrow jam暂存模块卡钞,用手工卷出钞票后,清除错误记录。

注意不要卷过头会损坏暂存模。

11、bunch note acceptortransport jam通道卡钞,清除卡钞后清除错误记录。

电力安全月工作总结[电力安全月工作总结]电力安全月工作总结2011年3月1日至3月31日为我公司的安全生产月,**变电站围绕;夯实基储提高素质、树立标杆、争创一流;的主题,开展了丰富多彩、形式多样的具体行动:通过看板形式宣传安全第一、预防为主的方针;通过48+4的学习机会,进行安全生产大讨论;通过安全活动进行查找本站的隐患的活动,电力安全月工作总结。

NCR 机器错误代码出钞模块:M-状态说明00 正常01 从一个未装的钱箱中发送钞票或者是在自检时未装钱箱。

02 太多的废钞03 吸钞失败04 钞票少,吸钞失败。

05 传感器故障或在输送通道中卡钞。

06 保留07 未装废钞箱。

08 废钞箱满,传感器被遮挡住了。

09 在命令和执行软件之间通讯失败,当前信息也许未被确定。

10 前一次操作设备或一个钱箱编号无效,因而不执行当前操作(要复位一下清除此条件)11 由于以下其中之一原因而未能执行操作:*前一次操作中还有钞票留在通道中*在以前的操作中由于不可恢复的故障使得钞票未能从通道中全部取走*发钞模块在加电后未接受到CLEAR/CLEAR—DIAG信号,必须执行一下CLEAR命令12 现金发放夹钞机构失败或被卡住。

13 出钞口在打开时被卡住。

14 出钞口在关闭时被卡住。

15 保留16 主传输测时盘工作不正常或主电机发生故障。

17 保留18 在送钞通道中卡钞或通道中传感器故障。

19 在现金发送结束后,出钞口传感器始终有遮挡信号(可能钞票未取走)20-27 保留28 NVRAM的一个区无法存取(SOH不能被更新数据)。

29 送钞测时盘工作不正常或送钞步进电机故障。

30 送钞通道电眼其中之一有故障。

31 保留32 出钞控制板上的80652处理器发生故障。

33 出钞控制板上的80652处理器的I2C总线通讯失败。

34 在堆钞器上没有钞票时试图执行发钞操作或是在通道中没有钞票时,试图回收钞票操作。

35 由于保险柜门未关或关门开关失效,致使交流电和24V直流电掉电,因而操作无法完成。

36 因为钱箱已经插上,所以吸盘阀的测试未执行。

37 T1伺服开关打开38 T1伺服开关关闭39 钞票厚度检测传感器或相关电路工作不正常。

40 钞票参数未设定146 SDC通讯失败。

磁卡读写器:M-状态说明00 正常01 空白卡02 无效卡,磁道不支持。

03 读错误。

04 写错误。

05 卡不存在。

NCR 统一平台报错信息中英文对照表

NCR 统一平台管理菜单中英文对照表

NCR 统一平台“清错”操作

1 “清错”的必要性:

在ATM的使用过程中,有时一些小故障(如打印机无纸)虽然在硬件上已经排除,但在软件上必须先进行“清错”操作后才能恢复正常使用。

2 “清错”的步骤:

1)在主菜单下执行11 DIAGNOSTICS + “ENT” (系统诊断);

2)在诊断菜单下执行5 device status list (设备状态清单);

3)在设备状态清单列表里执行液晶屏左边第三个功能键(CLEAR ALL),此时系统依次对出现故障的模块进行自检清错;

4)清错完毕后可连续按”CNL”键返回主菜单。