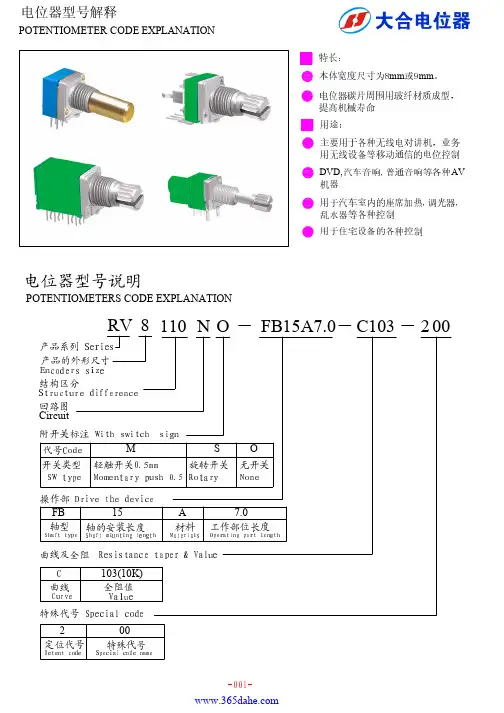

097型电位器

- 格式:pdf

- 大小:242.03 KB

- 文档页数:1

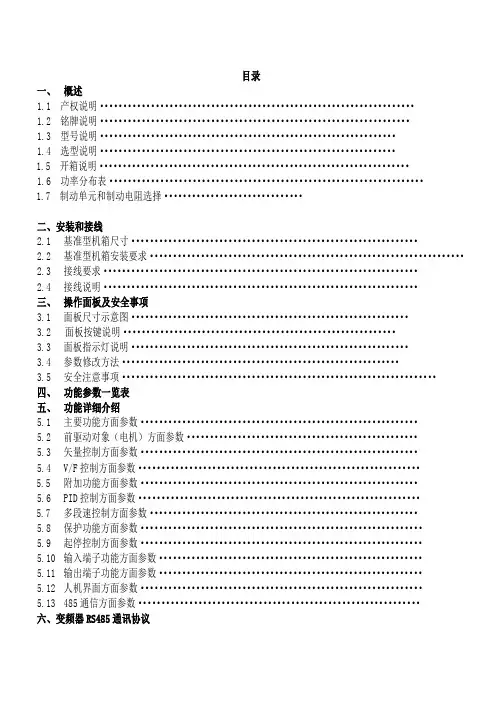

目录一、概述1.1 产权说明····································································1.2 铭牌说明···································································1.3 型号说明································································1.4 选型说明································································1.5 开箱说明···································································1.6 功率分布表····································································1.7 制动单元和制动电阻选择······························二、安装和接线2.1 基准型机箱尺寸······························································2.2 基准型机箱安装要求····································································2.3 接线要求····································································2.4 接线说明····································································三、操作面板及安全事项3.1 面板尺寸示意图····························································3.2 面板按键说明···························································3.3 面板指示灯说明····························································3.4 参数修改方法····························································3.5 安全注意事项····································································四、功能参数一览表五、功能详细介绍5.1 主要功能方面参数····························································5.2 前驱动对象(电机)方面参数··················································5.3 矢量控制方面参数····························································5.4 V/F控制方面参数·····························································5.5 附加功能方面参数····························································5.6 PID控制方面参数·····························································5.7 多段速控制方面参数··························································5.8 保护功能方面参数·····························································5.9 起停控制方面参数·····························································5.10 输入端子功能方面参数·························································5.11 输出端子功能方面参数·························································5.12 人机界面方面参数·····························································5.13 485通信方面参数·····························································六、变频器RS485通讯协议6.1 通讯协议····································································6.2 协议内容····································································6.3 应用方法····································································6.4 总线结构····································································6.5 协议说明····································································6.6 通讯帧结构··································································6.7 命令码及通讯资料描述························································七、故障咨询及对策7.1 故障类型及处理办法··························································7.2 其它故障案列分析··························································八、标准规范8.1 规格型号····································································8.2 公共特性····································································8.3 显示········································································九、选件9.1 选件表······································································9.2 周边选件与变频器的连接图····················································9.3 外引线及连接示意图················十、变频器的维护10.1 日常检查····································································10.2 定期检查····································································10.3 除尘········································································10.4 零部件的更换································································十一、品质承诺11.1 保修范围···································································11.2 三包规定····································································11.3 维权规定········································································第一章概述1.1产权说明本公司生产的系列变频器已申请有以下专利,未经本公司授权请不要侵权,否则将予以法律追究。

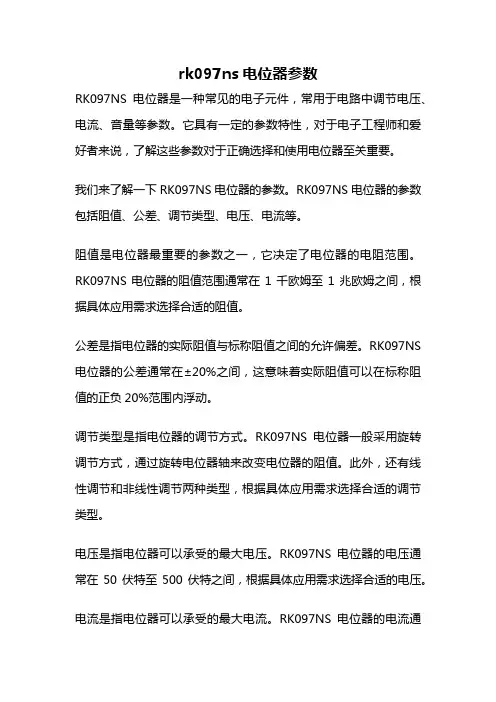

rk097ns电位器参数RK097NS电位器是一种常见的电子元件,常用于电路中调节电压、电流、音量等参数。

它具有一定的参数特性,对于电子工程师和爱好者来说,了解这些参数对于正确选择和使用电位器至关重要。

我们来了解一下RK097NS电位器的参数。

RK097NS电位器的参数包括阻值、公差、调节类型、电压、电流等。

阻值是电位器最重要的参数之一,它决定了电位器的电阻范围。

RK097NS电位器的阻值范围通常在1千欧姆至1兆欧姆之间,根据具体应用需求选择合适的阻值。

公差是指电位器的实际阻值与标称阻值之间的允许偏差。

RK097NS 电位器的公差通常在±20%之间,这意味着实际阻值可以在标称阻值的正负20%范围内浮动。

调节类型是指电位器的调节方式。

RK097NS电位器一般采用旋转调节方式,通过旋转电位器轴来改变电位器的阻值。

此外,还有线性调节和非线性调节两种类型,根据具体应用需求选择合适的调节类型。

电压是指电位器可以承受的最大电压。

RK097NS电位器的电压通常在50伏特至500伏特之间,根据具体应用需求选择合适的电压。

电流是指电位器可以承受的最大电流。

RK097NS电位器的电流通常在0.01安培至1安培之间,根据具体应用需求选择合适的电流。

了解了RK097NS电位器的参数,接下来我们来了解一下这些参数对电位器的使用有哪些影响。

首先是阻值对电位器的影响。

阻值决定了电位器的电阻范围,不同的阻值适用于不同的电路需求。

如果电路需要调节范围较大的电压或电流,就需要选择较大阻值的电位器。

其次是公差对电位器的影响。

公差决定了电位器实际阻值与标称阻值之间的偏差范围,公差越小,电位器的精度越高。

在一些对电阻值精度要求较高的电路中,需要选择公差较小的电位器。

调节类型对电位器的影响也很重要。

线性调节类型的电位器可以实现线性的电阻变化,适用于一些需要精确调节的电路。

非线性调节类型的电位器则可以实现非线性的电阻变化,适用于一些需要非线性调节的电路。

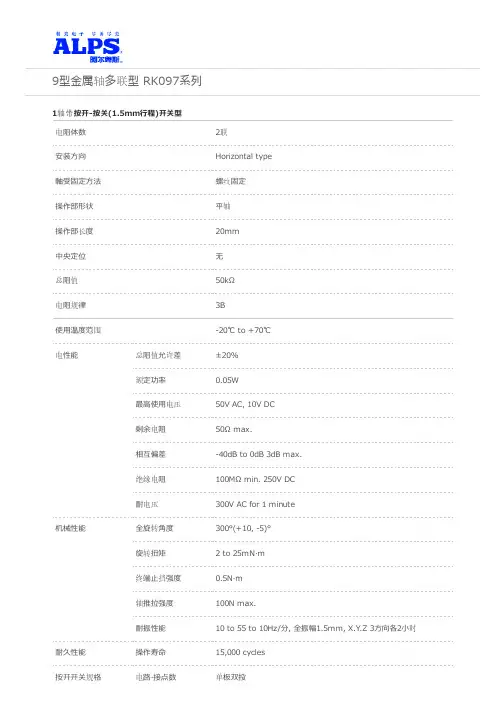

9型⾦属轴多联型 RK097系列1轴带按开-按关(1.5mm⾏程)开关型电阻体数2联安装⽅向Horizontal type軸受固定⽅法螺纹固定操作部形状平轴操作部长度20mm中央定位⽆总阻值50kΩ电阻规律3B使⽤温度范围-20℃ to +70℃电性能总阻值允许差±20%额定功率0.05W最⾼使⽤电压50V AC, 10V DC剩余电阻50Ω max.相互偏差-40dB to 0dB 3dB max.绝缘电阻100MΩ min. 250V DC耐电压300V AC for 1 minute机械性能全旋转⾓度300°(+10, -5)°旋转扭矩 2 to 25mN·m终端⽌挡强度0.5N·m轴推拉强度100N max.耐振性能10 to 55 to 10Hz/分, 全振幅1.5mm, X.Y.Z 3⽅向各2⼩时耐久性能操作寿命15,000 cycles按开开关规格电路·接点数单极双投⾏程 1.5±0.5mm切换动作⼒12±8N负载寿命特性10,000 cycles额定3A 16V DC(10mA 16V DC min. rating)接触电阻初期100mΩ max. 寿命后200mΩ max.绝缘电阻100MΩ min. 250V DC耐电压300V AC for 1 minute最⼩订货单位(pcs.)⽇本600出⼝1,200外形图安装孔尺⼨图⾃插⼊侧看端⼦尺⼨轴承尺⼨附加零部件是附加到各产品上的零部件。

包装规格托盘包装数(pcs.)1箱/⽇本6001箱/出⼝包装1,200出⼝包装箱尺⼨(mm)373×540×225焊接条件浸焊⽅式的参考举例预热焊接⾯表⾯温度100℃ max.加热时间 2 min. max.浸焊焊接温度260±5℃ max.焊接时间5±1s焊接次数 2 time max.⼿⼯焊接⽅式的参考举例烙铁头温度350℃ max.焊接时间3s max.焊接次数 1 time表⽰本系列共通的注释。

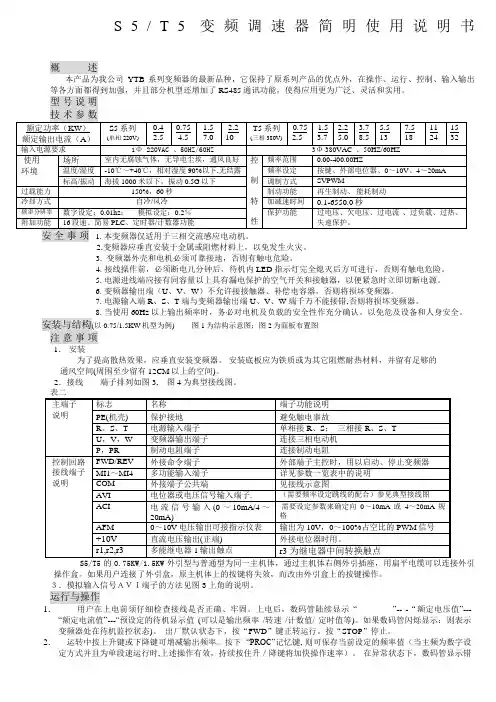

S5/T5变频调速器简明使用说明书概述本产品为我公司YTB系列变频器的最新品种,它保持了原系列产品的优点外,在操作、运行、控制、输入输出3. 变频器外壳和电机必须可靠接地,否则有触电危险。

4. 接线操作前,必须断电几分钟后,待机内LED 指示灯完全熄灭后方可进行,否则有触电危险。

5. 电源进线端应接有同容量以上具有漏电保护的空气开关和接触器,以便紧急时立即切断电源。

6. 变频器输出端(U、V、W)不允许接接触器、补偿电容器,否则将损坏变频器。

7. 电源输入端R、S、T端与变频器输出端U、V、W端千万不能接错,否则将损坏变频器。

8. 当使用60Hz以上输出频率时,务必对电机及负载的安全性作充分确认。

以免危及设备和人身安全。

安装与结构(以0.75/1.5KW机型为例) 图1为结构示意图;图2为面板布置图注意事项1.安装为了提高散热效果,应垂直安装变频器。

安装底板应为铁质或为其它阻燃耐热材料,并留有足够的通风空间(周围至少留有12CM以上的空间)。

2.接线端子排列如图3, 图4为典型接线图。

操作盒。

如果用户连接了外引盒,原主机体上的按键将失效,而改由外引盒上的按键操作。

3.模拟输入信号AVI端子的方法见图3上角的说明。

运行与操作1.用户在上电前须仔细检查接线是否正确、牢固。

上电后,数码管陆续显示“”-- -“额定电压值”---“额定电流值”---“预设定的待机显示值(可以是输出频率/转速/计数值/ 定时值等)。

如果数码管闪烁显示:则表示变频器处在待机监控状态)。

出厂默认状态下,按“FWD”键正转运行。

按“STOP”停止。

2.运转中按上升键或下降键可增减输出频率。

按下“PROC”记忆键, 则可保存当前设定的频率值(当主频为数字设定方式并且为单段速运行时,上述操作有效,持续按住升/降键将加快操作速率)。

在异常状态下,数码管显示错误代码。

直流制动时显示“ 各种状态灯指示当前的运行情况。

点动功能:可以设置外端子点动和面板上REV 键做为点动,设置方法请参阅参数一览表 。

®YYF94-Q氧化锆氧量变送器产品说明书上海晓舟电子仪表工贸有限公司版权所有©YYF94——Q氧化锆氧量变送器1.工作原理氧量变送器的作用是根据“能斯脱”公式,把氧量探头的氧电势和热电偶温度信号转换成与被测氧量成线性关系的电流输出。

本氧量变送器分为墙挂式和盘装式两种,这二种氧量变送器的电气部分完全一样,仅机械结构和安装方法不同。

氧量变送器按是否需要分为加热式和直插式二种,由于本氧量变送器的温度信号始终参与氧量运算,只要探头在其正常的工作温度范围内,探头温度的小范围变化不会影响氧量的测量,所以直插式变送器仅少—用于加热的固态继电器,探头少一加热炉。

按图1变送器硬件布置图由主机板、显示操作器和电源三部分组成,显示操作提供了一个强有力的人机接口,有关的信号都在上面显示,有关的可调参数都能在上面显示和修改。

本氧量变送器的主机是以单片机为基础的智能仪表,所有的运算、处理和控制都由软件完成。

氧电势、温度信号的输入转换和电流输出的转换采用模块化元件,这些元件具有可靠性强,精度高的特点,由于本仪表使用的元件集成度较高,使得整机结构简单,可靠性提高,使用、维护和维修方便。

氧电势和温度信号经各自的处理模块转换成0~5V信号,并由多路开关和A/D转换成数字量,单片机根据“能斯脱”公式计算出氧量。

计算出来的氧量值通过D/A转换成0~5V信号,并由隔离电流输出模块转换成4~20mA或0~10mA电流输出,电流输出最多2路。

变送器设有PI温度调节功能,并通过固态继电器控制加热炉。

变送器还设有组态开关,能使表计工作在不同的方式下。

2.仪表功能本氧量变送器除对氧电势和温度信号按“能斯脱”公式运算外,还具有以下其他功能:2.1 本底电势调整置于自然空气或旋开标准气接口,探头温度为650~750℃时,在显示操作器上读到的氧电势数值即为探头的本底电势。

先把变送器切到调整方式,在显示操作器上用“SEL”键调出本底电势(编号为04),通过“增”、“减”键来设置测得的探头本底电势值,并用“ENT”键来确认。

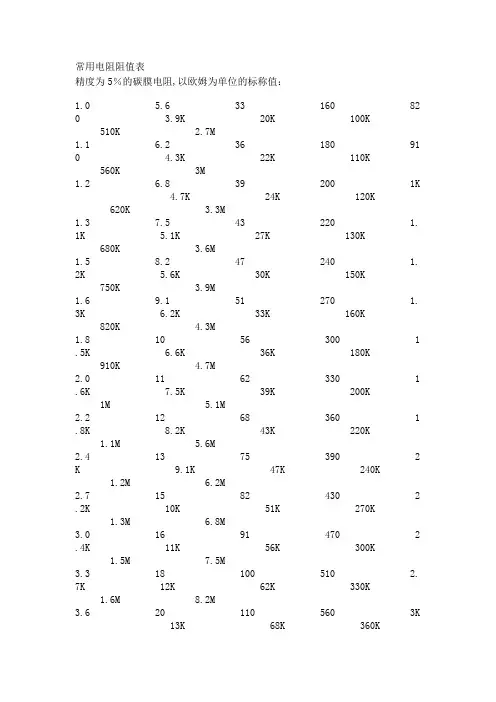

常用电阻阻值表精度为5%的碳膜电阻,以欧姆为单位的标称值:1.0 5.6 33 160 82 0 3.9K 20K 100K510K 2.7M1.1 6.2 36 180 91 0 4.3K 22K 110K560K 3M1.2 6.8 39 200 1K4.7K 24K 120K620K 3.3M1.3 7.5 43 220 1. 1K 5.1K 27K 130K 680K 3.6M1.5 8.2 47 240 1. 2K 5.6K 30K 150K 750K 3.9M1.6 9.1 51 270 1. 3K 6.2K 33K 160K 820K 4.3M1.8 10 56 300 1 .5K 6.6K 36K 180K 910K 4.7M2.0 11 62 330 1 .6K 7.5K 39K 200K 1M 5.1M2.2 12 68 360 1 .8K 8.2K 43K 220K1.1M 5.6M2.4 13 75 390 2 K 9.1K 47K 240K1.2M 6.2M2.7 15 82 430 2 .2K 10K 51K 270K1.3M 6.8M3.0 16 91 470 2 .4K 11K 56K 300K1.5M 7.5M3.3 18 100 510 2. 7K 12K 62K 330K1.6M 8.2M3.6 20 110 560 3K13K 68K 360K1.8M 9.1M3.9 22 120 620 3. 2K 15K 75K 390K 2M 10M4.3 24 130 680 3. 3K 16K 82K 430K2.2M 15M4.7 27 150 750 3. 6K 18K 91K 470K2.4M 22M5.1 30精度为1%的金属膜电阻,以欧姆为单位的标称值:10 33 100 3321K 3.32K 10.5K 34K 107K 357K10.2 33.2 102 340 1.0 2K 3.4K 10.7K 34.8K110K 360K10.5 34 105 348 1 .05K 3.48K 11K 35.7K 113K 365K10.7 34.8 107 350 1.0 7K 3.57K 11.3K 36K115K 374K11 35.7 110 357 1 .1K 3.6K 11.5K 36.5K 118K 383K11.3 36 113 360 1 .13K 3.65K 11.8K 37.4K120K 390K11.5 36.5 115 365 1.1 5K 3.74K 12K 38.3K121K 392K11.8 37.4 118 374 1.1 8K 3.83K 12.1K 39K124K 402K12 38.3 120 383 1 .2K 3.9K 12.4K 39.2K 127K 412K12.1 39 121 390 1 .21K 3.92K 12.7K 40.2K130K 422K12.4 39.2 124 392 1.2 4K 4.02K 13K 41.2K133K 430K12.7 40.2 127 402 1.2 7K 4.12K 13.3K 42.2K137K 432K13 41.2 130 412 1 .3K 4.22K 13.7K 43K 140K 442K13.3 42.2 133 422 1.3 3K 4.32K 14K 43.2K143K 453K13.7 43 137 430 1 .37K 4.42K 14.3K 44.2K147K 464K14 43.2 140 432 1 .4K 4.53K 14.7K 45.3K150K 470K14.3 44.2 143 442 1.4 3K 4.64K 15K 46.4K154K 475K14.7 45.3 147 453 1.4 7K 4.7K 15.4K 47K158K 487K15 46.4 150 464 1 .5K 4.75K 15.8K 47.5K160K 499K15.4 47 154 470 1 .54K 4.87K 16K 48.7K 162K 511K15.8 47.5 158 475 1.5 8K 4.99K 16.2K 49.9K165K 523K16 48.7 160 487 1 .6K 5.1K 16.5K 51K 169K 536K16.2 49.9 162 499 1.6 2K 5.11K 16.9K 51.1K174K 549K16.5 51 165 510 1 .65K 5.23K 17.4K 52.3K178K 560K16.9 51.1 169 511 1.69K 5.36K 17.8K 53.6K180K 562K17.4 52.3 174 523 1.7 4K 5.49K 18K 54.9K182K 576K17.8 53.6 178 536 1.7 8K 5.6K 18.2K 56K187K 590K18 54.9 180 549 1 .8K 5.62K 18.7K 56.2K191K 604K18.2 56 182 560 1 .82K 5.76K 19.1K 57.6K196K 619K18.7 56.2 187 562 1.8 7K 5.9K 19.6K 59K200K 620K19.1 57.6 191 565 1.9 1K 6.04K 20K 60.4K205K 634K19.6 59 196 578 1 .96K 6.19K 20.5K 61.9K210K 649K20 60.4 200 590 2 K 6.2K 21K 62K 215K 665K20.5 61.9 205 604 2.0 5K 6.34K 21.5K 63.4K220K 680K21 62 210 6192.1K 6.49K 22K 64.9K221K 681K21.5 63.4 215 620 2.1 5K 6.65K 22.1K 66.5K226K 698K22 64.9 220 634 2 .2K 6.8K 22.6K 68K 232K 715K22.1 66.5 221 649 2.2 1K 6.81K 23.2K 68.1K237K 732K22.6 68 226 665 2 .26K 6.98K 23.7K 69.8K240K 750K23.2 68.1 232 680 2.3 2K 7.15K 24K 71.5K243K 768K23.7 69.8 237 681 2.3 7 7.32K 24.3K 73.2K249K 787K24 71.5 240 698 2 .4K 7.5K 24.9K 75K 255K 806K24.3 73.2 243 715 2.4 3K 7.68K 25.5K 76.8K261K 820K24.7 75 249 732 2 .49K 7.87K 26.1K 78.7K267K 825K24.9 75.5 255 750 2.5 5K 8.06K 26.7K 80.6K270K 845K25.5 76.8 261 768 2.6 1K 8.2K 27K 82K 274K 866K26.1 78.7 267 787 2.6 7K 8.25K 27.4K 82.5K280K 887K26.7 80.6 270 806 2.7 K 8.45K 28K 84.5K287K 909K27 82 274 8202.74K 8.66K 28.7K 86.6K294K 910K27.4 82.5 280 825 2.8 K 8.8K 29.4K 88.7K300K 931K28 84.5 287 845 2 .87K 8.87K 30K 90.9K 301K 953K28.7 86.6 294 866 2.9 4K 9.09K 30.1K 91K309K 976K29.4 88.7 300 887 3.0 K 9.1K 30.9K 93.1K316K 1.0M30 90.9 301 909 3 .01K 9.31K 31.6K 95.3K324K 1.5M30.1 91 309 910 3 .09K 9.53K 32.4K 97.6K330K 2.2M30.9 93.1 316 931 3.1 6K 9.76K 33K 100K332K31.6 95.3 324 953 3.2 4K 10K 33.2K 102K340K电阻本身的阻值常用的有161种1,1.1,1.2,1.3,1.5,1.6,1.82,2.2,2.4,2.7,3,3.3,3.6,3.94.3,4.75.1,5.66.2,6.87.58.29.110,11,12,13,15,16,1820,22,24,2730,33,36,3943,4751,5662,687582,81100,110,120,130,150 ,160,180 200,220,240,270300,330,360,390430,470510,560620,6807508209101K,1.1K,1.2K,1.3K,1.5K,1.6K,1.8K 2K,2.2K,2.4K,2.7K3K,3.3K,3.6K,3.9K4.3K,4.7K5.1K,5.6K6.2K,6.8K,7.5K8.2K9.1K10K,11K,12K,13K,15K,16K,18K20K,22K,24K,27K30K,33K,36K,39K43K,47K51K,56K62K,68K75K82K91K100K,110K,120K,130K,150K,160K,180K200K,220K,240K,270K,300K,330K,360K,390K430K,470K510K,560K620K,680K750K,820K910K1M,1.1M,1.2M,1.3M,1.5M,1.6M,1.8M2M,2.2M,2.4M,2.7M3M,3.3M,3.6M,3.9M4.4M,4.7M几种常用电位器型号与规格1.有机实芯电位器由导电材料与有机填料、热固性树脂配制成电阻粉,经过热压,在基座上形成实芯电阻体。

电位器相连,引脚2与单片机的P1.1相连。

当脉冲电位器左旋或右旋时,P1.0和P1.1就会周期性地产生所示的波形,如果是12点的脉冲电位器旋转一圈就会产生12组这样的波形,24点的脉冲电位器就会产生24组这样的波形;一组波形(或一个周期)包含了4个工作状态。

因此只要检测出P1.0和P1.1的波形,就能识别脉冲电位器是否旋转是左旋还是右旋。

编辑本段识别进一步分析右的波形并按时间轴展开可以看出,虽然脉冲电位器左旋和右旋的波形都相同。

但左旋时,在第1状态,脚1先比脚2变为低电平;在第2状态,脚2也变为低电平;在第3状态,脚1先比脚2变为高电平;在第4状态,脚2也变为高电平;脉冲电位器右旋时,脚1和脚2输出波形的变化规律正好与左旋相反。

故可根据时间识别法(比较P1.0与P1.1低电平出现和结束的时差)来识别脉冲电位器是左旋还是右旋。

在动态扫描中,因采样频率操作速度等因素的影响,实际上很难测出P1.0和P1.1的波形;也很难测准P1.0与P1.1低电平出现和结束的时差,只能快速地对P1.0和P1.1电平采样。

对应图1所示波形按时间轴展开,每当P1.0和P1.1的组合电平依次为01 00 10 11四种状态码组成一个字节即4BH 时,就表示左旋一位音量减1。

而每当P1.0和P1.1的组合电平依次为10 00 01 11四种状态码组成一个字节即87H时;就表示右旋一位音量加1。

这里将“4BH”称为左旋一位的特征码,“87H”称为右旋一位的特征码。

编程的任务就是要在脉冲电位器旋转过程中识别出这两种特征码,并以此为依据,对音量进行增减控制。

实际编程时可以用不同的方法识别出这两种特征码。

但我们在实践中经过比较,用状态(位置)采样法实现编程是较为理想的一种方法。

这种方法对采样频率和操作速度没有特别要求,也可不用定时器和中断资源,只需在主程序里面就能完成,而且具有编程简单抗干扰能力强工作可靠的优点。

由于脉冲电位器在工作过程中有三种情形:一是没有被旋转而停留在某一状态(位置);二是虽然被旋转但没有完成一个周期(4个状态)而停留在某一状态;三是不停地被旋转而超过一个周期。

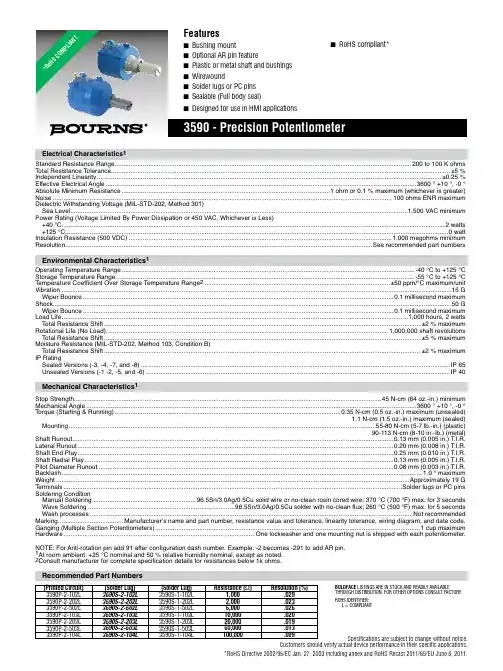

Specifi cations are subject to change without notice.Customers should verify actual device performance in their specifi c applications.*RoHS Directive 2002/95/EC Jan. 27, 2003 including annex and RoHS Recast 2011/65/EU June 8, 2011.Stop Strength..............................................................................................................................................................................45 N-cm (64 oz.-in.) minimum Mechanical Angle ...........................................................................................................................................................................................3600 ° +10 °, -0 °Torque (Starting & Running) ................................................................................................................................0.35 N-cm (0.5 oz.-in.) maximum (unsealed) 1.1 N-cm (1.5 oz.-in.) maximum (sealed) Mounting ..............................................................................................................................................................................55-80 N-cm (5-7 lb.-in.) (plastic) 90-113 N-cm (8-10 in.-lb.) (metal)Shaft Runout......................................................................................................................................................................................0.13 mm (0.005 in.) teral Runout ...................................................................................................................................................................................0.20 mm (0.008 in.) T.I.R.Shaft End Play ...................................................................................................................................................................................0.25 mm (0.010 in.) T.I.R.Shaft Radial Play ...............................................................................................................................................................................0.13 mm (0.005 in.) T.I.R.Pilot Diameter Runout .......................................................................................................................................................................0.08 mm (0.003 in.) T.I.R.Backlash ............................................................................................................................................................................................................1.0 ° maximum Weight ........................................................................................................................................................................................................Approximately 19 G Terminals ................................................................................................................................................................................................Solder lugs or PC pins Soldering ConditionManual Soldering...........................................................96.5Sn/3.0Ag/0.5Cu solid wire or no-clean rosin cored wire; 370 °C (700 °F) max. for 3 seconds Wave Soldering ...................................................................................96.5Sn/3.0Ag/0.5Cu solder with no-clean fl ux; 260 °C (500 °F) max. for 5 seconds Wash processes .......................................................................................................................................................................................Not recommended Marking .....................................Manufacturer’s name and part number, resistance value and tolerance, linearity tolerance, wiring diagram, and date code.Ganging (Multiple Section Potentiometers) ......................................................................................................................................................1 cup maximum Hardware ............................................................................................................One lockwasher and one mounting nut is shipped with each potentiometer.NOTE: For Anti-rotation pin add 91 after confi guration dash number. Example: -2 becomes -291 to add AR pin.1At room ambient: +25 °C nominal and 50 % relative humidity nominal, except as noted. 2Consult manufacturer for complete specifi cation details for resistances below 1k ohms.BOLDFACE LISTINGS ARE IN STOCK AND READILY AVAILABLETHROUGH DISTRIBUTION. FOR OTHER OPTIONS CONSULT FACTORY.ROHS IDENTIFIER: L = COMPLIANTRecommended Part Numbers(Printed Circuit)(Solder Lug)(Solder Lug)Resistance (Ω)Resolution (%)3590P-2-102L 3590S-2-102L 3590S-1-102L 1,000.0293590P-2-202L 3590S-2-202L 3590S-1-202L 2,000.0233590P-2-502L 3590S-2-502L 3590S-1-502L 5,000.0253590P-2-103L 3590S-2-103L 3590S-1-103L 10,000.0203590P-2-203L 3590S-2-203L 3590S-1-203L 20,000.0193590P-2-503L 3590S-2-503L 3590S-1-503L 50,000.0133590P-2-104L3590S-2-104L3590S-1-104L100,000.009*Ro H S C O MP L I A N TPanel Thickness Dimensions(For Bushing Mount Only)1.60 +.08/-.03(.063 +.003/-.001)DIA.ANTI-ROTATION PINAnti-rotation pin hole is shown at six o'clockposition for reference only. The actual location isdetermined by the customer's application. Referto the front view of the potentiometer to see thelocation of the optional A/R pin.Panel thickness and hole diameters arerecommended for best fit. However, customersmay adjust the dimensions to suit their specificapplication.Product DimensionsSpecifi cations are subject to change without notice.Customers should verify actual device performance in their specifi c applications.REV. 06/12 MOUNTING SURFACE-2, -4, -6, -8 Confi gurations-1, -3, -5, -7 Confi gurationsRecommended PCB LayoutHOLE DIAMETER5.08(.200)5.08(.200)6.99(.275)SchematicTOLERANCES: EXCEPT WHERE NOTED.508 .127DECIMALS: .XX ±(.02),.XXX ±(.005)FRACTIONS: ±1/64MMDIMENSIONS:(IN.)Shaft & Bushing Confi gurations(Bushing - DxL, Shaft - D):(-1) Plastic Bushing (3/8 ” x 5/16 ”)and Shaft (.2480 + .001, - .002)(-2) Metal Bushing (3/8 ” x 5/16 ”)and Shaft (.2497 + .0000, - .0009)(-3) Sealed, Plastic Bushing (3/8 ” x 5/16 ”)and Shaft (.2480 + .001, - .002)(-4) Sealed, Metal Bushing (3/8 ” x 5/16 ”)and Shaft (.2497 + .0000, - .0009)(-5) Metric, Plastic Bushing (9 mm x 7.94 mm)and Shaft (6 mm + 0, - .076 mm)(-6) Metric, Metal Bushing (9 mm x 7.94 mm)and Shaft (6 mm + 0, - .023 mm)(-7) Metric, Sealed, Plastic Bushing (9 mm x7.94 mm) and Shaft (6 mm + 0, - .076 mm)(-8) Metric, Sealed, Metal Bushing (9 mm x7.94 mm) and Shaft (6 mm + 0, - .023 mm)Terminal Styles“P” Terminal Style“S” Terminal Style。

目录第一章、概述1.1前言 (1)1。

2检查与安全注意事项 (1)1.3规格型号表 (4)1。

4制动单元与制动电阻 (5)第二章、安装与接线2。

1机箱结构和尺寸 (6)2.2安装要求 (8)2.3接线要求 (8)2。

4接线说明 (9)第三章、运行操作3。

1操作面板 (13)3。

2操作键盘说明 (13)3.3显示内容说明 (14)3.4参数修改方法 (14)3.5试运行 (15)第四章、功能参数一览表 (16)附表1 多段速一、二、三通断状态与频率的对应关系表 (36)附表1 加减速时间选择一、二通断状态与加减速时间的对应关系表 (36)第五章、故障处理方法5。

1维护检查注意事项 (37)5.2定期检查专案 (37)5。

3故障信息及故障排除 (37)5。

4故障及分析 (39)5。

5常见异常现象及对策 (41)第六章、品质承诺 (43)第一章概述1。

1前言FC300系列变频器是针对各种专用场合而精心设计的一款多功能高性能产品。

调试参数简单实用,只须一键设置便可改为您需要的专用机型,再加上参数拷贝功能,使您在使用本变频器时变得异常的简单。

使用之前请务必熟读此说明书,便于您更好的使用此变频器,阅读后请妥善保管,对以后的维护,保护及其他使用场合有很好的帮助。

如在使用过程中存在着无法解决的问题,请务必由合格的专业电机工程人员安装调试及修改参数。

本手册中有频器使用更加安全。

1。

2检查与安全注意事项FC300系列变频器在出厂之前已经过测试和品质检验,在购买之后。

拆箱之前请检查产品包装是否因运输不慎而造成损失,产品的规格和型号,是否与定购机种相符,如有问题请与本公司联系。

1.2。

1 拆箱后检查1 内含本机使用说明书一本,保修卡及合格证一张。

2检测变频器侧面的铭牌,以确定在您手上的产品是您说定购的产品。

变频器铭牌说明变频器型号说明:1。

2.2安全注意事项注意事项,它们对我们的个人安全都很重要1。

2。

3搬运和放置注意事项送电前● 所选用电源电压必须与变频器输入电压规格相同。