循环冷却水系统设计作业指导书

- 格式:doc

- 大小:63.00 KB

- 文档页数:9

1目的指导xxxx电厂一期2×1000MW机组工程B标段#2机发电机定子冷水系统设备、管道安装及冲洗,确保水质质量。

2适用范围仅适用于xxxx电厂一期2×1000MW机组工程B标段#2机发电机定子冷却水系统设备、管道安装及冲洗。

3编制依据3.1《施工组织总设计》xx电建二公司xx项目部3.2《汽机专业施工组织设计》xx电建二公司xx项目部汽机分公司3.3《定冷水系统说明书》(东方电机厂提供)3.4中南电力设计院提供的相关图纸3.5东方电机厂提供的1000MW机组的图纸及相关资料3.6《电力建设施工质量验收及评价规程》第3部分:汽轮发电机组DL/T5210.3-20093.7《电力建设施工质量验收及评价规程》第5部分:管道及系统DL/T5210.5-20093.8《火力发电厂焊接技术规程》(DL /T869-2004)3.9《电力建设施工质量验收及评价规程》焊接部分(DL/T5210.7-2010)3.10《电力建设安全工作规程》(火力发电厂部分)DL5009.1—20023.11《国家电网公司基建安全管理规定》国家电网基建[2010]1020号3.12工程建设标准强制性条文( 电力工程部分)2006年版3.13《手持式电动工器具的管理、使用检查和维修安全技术规程》GB3787-933.14《特种设备安全监察条例》国务院373号和549号令3.15《危险化学品重大危险源辨识》GB18218-2009。

3.16《建筑起重机械安全监督管理规定》建设部166号令4作业项目概述4.1发电机定子冷却水系统的主要功能是保证冷却水不间断地流经定子线圈内部,从而将该部分由于消耗而引起的热量带走,以保证温升符合发电机的有关要求。

同时,系统还必须控制进入定子线圈的压力、温度、水的电导率等参数,使之符合相应规定。

4.2定子冷却水系统主要部套件4.3的管路是以原材料状态供货,管路施工时需现场下料,焊接坡口需现场加工,DN15以下(含DN15)口径的管路一般不提供弯头,需现场弯管。

作业指导书编号:AEPC-RD-034工程名称:定远县生活垃圾焚烧发电项目作业项目名称:1#机组闭式水管道冲洗方案编制单位:中国能源建设集团电力建设第一工程定远垃圾焚烧电站项目部批准:安全:质量:工程:审核:编制:时间:时间:时间:时间:时间:时间:出版日期版次目录1作业任务 (1)1.1作业项目概况及围 (1)1.2 主要工程量 (2)2 编制依据 (2)3冲洗具备条件 (2)3.1冲洗临时管道安装条件 (2)3.2冲洗必备条件 (3)4冲洗前的准备工作 (3)5作业方案 (3)5.1临时管道安装 (3)5.2管道冲洗措施 (3)5.3管道恢复 (4)6作业质量标准及要求 (4)6.1管道恢复作业质量标准 (4)6.2 检验要求 (5)6.3技术资料要求 (5)7安全与文明施工及环境管理 (5)7.1安全文明施工措施 (5)7.2施工安全风险控制措施 (6)7.3应急预案 (6)1作业任务1.1作业项目概况及围定远垃圾发电项目工程#1机组闭式冷却水系统配置两台闭式水泵。

闭式冷却水系统采用化水除盐水作为系统工作介质,除盐水向闭式冷却水膨胀箱充水,然后通过闭式冷却水泵升压,经闭式水换热器冷却后在闭式回路中循环。

闭式冷却水系统由两台闭式冷却水泵、两台闭式水热交换器、一台3m3闭式冷却水膨胀水箱及用户等组成。

闭式水汽机侧主要用户包括:凝结水泵电机冷却水、电泵机冷却水,疏水泵冷却水。

闭式水锅炉房侧主要用户包括:一次风机冷却水、二次风机冷却水、炉墙冷却风机冷却水,密封风机冷却水,启动燃烧风机冷却水,辅助燃烧风机冷却水,炉排液压装置冷却水,空压机冷却水、干燥机冷却水,引风机冷却水,化学取样冷却器冷却水等。

冲洗目的:保证闭式循环冷却水系统设备和管道部清洁度,从而为设备的安全经济运行提供保证。

主要技术参数1.2 主要工程量2 编制依据2.1由中国电力工程顾问集团东北电力提供的安装布置图纸;2.2《电力建设施工质量验收及评价规程第5部分:管道及系统》DL/T 5210.5-20092.3《电力建设施工质量验收及评定规程》(第8部分:加工配制)DL/T5210.8-2009;2.4 电力建设施工技术规第5部分:管道及系统 DL 5190.5-20122.5《火力发电厂焊接技术规程》DL/T 869-2012;2.6《电力建设安全工作规程》第一部分:火力发电DL5009.1-2014;2.7 定远县垃圾发电项目《C标段施工组织总设计》AEPC/ZHCE012.J01-20162.8定远县垃圾发电项目《汽机专业施工组织设计》80-FC12921-01-D03-AEPC-Q-0012.9定远县生活垃圾焚烧发电项目(C标段)合同80-FC00291W-01-I0301/JCB-0032.10其它有关会议纪要3冲洗具备条件3.1冲洗临时管道安装条件3.1.1材料:闭式水所需的临时管道已到货。

CONTENTS1 Objective2 Description to system and main equipment technical specification3 Commission range4 Plant status before commission5 Commission procedures6 Commission steps7 Safety requirement8 AppendixAppendix 1: Checking list to plant status before commissionAppendix 2: checking list for valve drivingAppendix 3: Checking list for circulation water system interlock protection1. Objective1.1 In order to instruct and control the commission work of system and equipments so as to guarantee the system and equipment can be put into operation safety and normally, this commissioning procedure is prepared.1.2 Check the Electrical, C& I signal devices and interlock protection according to this commissioning procedure and make sure the indication is correct and action is reliable.1.3 Check the running condition of the equipment and system according to this commissioning procedures, check the performance of the system so that the possible defectives can be removed.1.4 This procedure is an introduction document. Commission engineer can modify the contents, which are not proper for site situation. As long as the commission purpose is reached and function at performance of turbine generator unit is checked to meet the requirement of design and operation, then all reasonable test, check, measure and operation method and steps are allowed.2. Description to system and main equipment technical specificationSea water open circulation water system is adopted in the project. Set central circulation water pump house and provide circulation cooling water to condenser, oil cooler, generator air cooler, closed water exchanger. Before oil cooler and generator air cooler, set filter to avoid influencing exchange efficiency.Because sea water is adopted as cooling medium, anti-corrosion protection is carried out to equipment and pipes. The titanium is used to the materials of condenser, oil cooler, generator air cooler, closed water exchanger, etc, which directly contact with sea water. The pipes, which diameters are ≤DN300, and filters adopt anti-corrosion protection of in-wall lining. The in-wall of pipes, which diameters are ≥DN300, adopts method of epoxy painting +zinc pipe cathode protection.Circulation water pump:Type: KQSN900-M27JHead:21~11mPump efficiency:79.5~87~81%Shaft power:315KWRotating speed: 585rpmOpen circulation cooling water pumpType:KQSN300-N19/285Flow:720t/hHead:20mMotor power:55KWVoltage:400V3. Commission rangeCirculation water system commission is begun with dynamic handover acceptance after independent equipment commission to circulation water pump is finished, include interlock protection test, system water flushing, system putting into operation and dynamic regulation, etc. Trial run to open circulation cooling water system and circulation water pump should be carried out at the same time.4. Plant status before commissionBefore formally carry out system commission, commission engineer should carry out checking as per the appendix 1 Checking list for the plant status before commission.5. Commission proceduresCommission to circulation water system can be carried out as per the following schedule.6. Commission steps6.1 Valve action test and action duration measuringThe checking list for valve checking test is seen in appendix 2 Checking list to circulation water system valve driving. The test contents include: make sure the MD valve local and CRT operation is normal, state indication is correct, measuring the open and close duration.6.2 Interlock protection and alarm testThe checking list of interlock protection and alarm test is seen in appendix 3 Checking list to circulation water system interlock protection test.6.3 No-load running to circulation water pump motor6.4 Before carry out trial run, confirm the following conditions:a. Confirm that the erection of equipment, pipes and electric cable connecting meet the requirement.b. Electric test and interlock test are finished.c. Interlock test to circulation water pump outlet butterfly valve is finished.d. The water flushing to shaft bearing cooling water pipes and motorcooling water pipes is finished, and the pipes are reset.e. Independent equipment trial run to circulation water pump motor isfinished, shaft adjusting connecting is finished.f. Make sure that the states of circulation water pump pipes and valvesmeet the trial run operation requirement.g. Insulation resistance of MD valve motor is measured to meet the requirement, power supply is charged.6.5 Trial run to circulation water pump6.5.1 Startup preparation of circulation water pumpa. Make sure that water level of circulation water pool reaches to normallevel.b. Check that returning oil in every shaft bearing returning oil window isnormal.c. Check that motor and shaft bearing cooling water is normal, open inlet damper and feed water to pipe, carefully check whether there is leakage. Open all air relief valves and carry out system feeding water. Air inside pump proper and pipes is discharged.d. Open air relief valves of inlet and outlet water cabinet of condenser.e. Check whether connecting MD butterfly valve of circulation water pump outlet header is closed.6.5.2 Trial run to circulation water pumpCharge circulation water pump, DCS start up circulation water pump and confirm the following contents:a. The rotation direction of pump and motor is correct.b. Shaft bearing oil level is normal.c. Vibration is normal, no abnormal noise.d. There is no leakage in system pipes.e. Check the parameters, such as vibration, oil temperature, and shaft bearing metal temperature, etc.f. Carry out stable operating for 4~8h. During trial run operation, if any parameter exceeds limit value, stop trial run.g. During operation process of circulation water pump, if the water level difference before and after cleaner is alarm, immediately stop pump and start up cleaner.h. Carry out recording operating parameters every 30min, trial run duration is 4~8h.i. After trial run is finished, stop pump.j. Record coast time of circulation water pump.k. Operation and stopping of circulation water system.6.6 Put circulation water system into operation.6.6.1 Checking before put system into operationa. Confirm that the interlock test of circulation water system is qualified.b. Carry out integral checking to circulation system equipment and pipes. The operation requirement is confirmed to meet.c. The insulation of relative equipment of circulation water pump and system is qualified and the power supply is charged.d. Check and confirm every kind of gauges valves are open, close all water discharging valves in pump unit and pipes.e. Check that the shaft bearing cooling water of circulation water pump is regulated to be normal.6.6.2 As per this procedure, carry out checking and preparing before start up. 6.6.3 Start up circulation water pump, after pressure is established for about 30s, if the interlock does not open outlet butterfly valve, manually open it. Record the parameters, such as shaft bearing temperature, vibration, motor current, pump inlet and outlet pressure.6.6.4 Check the pipes of circulation water system, supporters and hanger and relative equipment. If abnormal situation is found out, carry out treating in time.6.7 Stop circulation water pump.6.7.1 Stop circulation water pump.6.7.2 Interlock close circulation water pump outlet butterfly valve.6.8 Flushing to circulation water systemFlushing to circulation water system is mainly carried out to circulation water system pipes. Carry out flushing to circulation water system as per the formal pipe flow direction.6.9 System dynamic regulationAfter the trial run to circulation water pump is normal, carry out pressure bearing test to condenser water side, check the tightness and reliability of water side. The test pressure is take condenser water side inlet pressure as standard, if the pressure is lower than 0.2MPa, slightly close outlet butterfly and increase inlet pressure, but the outlet butterfly can not be full closed. During the process of putting circulation water pump system into operation, strengthen supervising to system equipment. If abnormal situation happens, carry out regulation in time and guarantee the system is at best operation state.6.10 Put circulation cooling water system into operation.6.10.1 After circulation water pump and system operate for about 30min, open inlet filter of open circulation water pump and filter blowdown valve, carry out flushing to pipes.6.10.2 After flushing is finished, open the outlet valve of filter and inlet and outlet valves of open circulation cooling pump. Put heat exchanger of one side to feed water to open water system. When carry out feeding water, open the air relief valve in the system, after the air is discharged, close it.6.10.3 After feeding water is finished, close outlet MD valve of open circulation cooling water pump, open inlet valve and start up open circulation cooling water pump, after trial run for 2~4h, switch to operate another pump.6.10.4 During trial run to open circulation cooling system, pay attention to the work situation of open water system, such as leakage, pump vibration, motor current, shaft bearing temperature, etc.7. Safety requirement7.1 Commission engineer should follow relative safety regulation, avoid personal and equipment accident.7.2 During trial run, roll and responsibility should be clear.7.3 The check before trial run should be accordance with the commissioningprocedures.7.4 During operating, carry out checking to system and equipment, if abnormal situation happens, carry out treating in time. If equipment safety is endangered, stop operating immediately.7.5 After water pump is started up for 30s, if the outlet butterfly valve do not open, through DCS emergency interlock stop pump immediately.7.6 The outside part of rotating equipment should be protected with covers.7.7 During trial run period, properly carry out cleaning to inlet water cabinet of water pump. Keep the inlet water cleaning.7.8 When discharge water, pay attention to avoid flooding equipment.8. AppendixAppendix 1: Checking list to plant status before commissionNO. Checkingcontents Requirement CheckingdateCheckingresultRemark1 Erection work ofcirculating water pumpTotally completed withentire technical dataand recording2 Circulating water pipesystemTotally completed withregulated bearers andhangers3 Clean the inside ofcondenser (water side)Finished4 Circulation water pumpmotor and opencirculation coolingpump motorTest is successful andpassed no-load runningfor 4h with correctdirection.5 DCS and DAS system DCS onfiguration is correct, DAS points are completed.6 Instrumentalcompressed air systemPrepare well for puttinginto operation7 MD valve and airdynamic regulatingvalve of subsystemsRemote operatingswitches are flex withcorrect direction.8 Electric and I&C meters Erection is finished and checked and can be put into operation.9 Rotate filter screen tocleanClearly cleaned withtemporary nameplateshanged.10 Road in trial run field Road is smoothly with sufficient illumination. Accident illumination is reliable.11 Communicationequipment in trial runfieldConvenient to be used.12 Fire fighting equipment Sufficient Appendix 2: checking list for valve drivingNo. Valvename CheckingdateTestingresultOpen timeClosetimeRemark1 #1 circulating pump outlet butterfly valve2 #2 circulating pump outlet butterfly valve3 Circulating water inlet MDbutterfly-valve of condenser left side4 Circulating water inlet MDbutterfly-valve of condenser right side5 Circulating water outlet MD butterfly-valve of condenser left side6 Circulating water outlet MDbutterfly-valve of condenser right side7 Outlet MD valve of open water pump A8 Outlet MD valve of open water pump BAppendix 3: Checking list for circulation water system interlock protection (forreference)No. ItemTestresult1 When operating pump A ermergycy trips, standby pump B automatically puts into operation. when operating pump emergency trips and at the same time interlock close outlet butterfly-valve, standup pump automatically put into operation at the same time interlock open outlet butterfly-valve.2 When operating pump B ermergycy trips, standby pump A automatically puts into operation. when operating pump emergency trips and at the same time interlock close outlet butterfly-valve, standup pump automatically put into operation at the same time interlock open outlet butterfly-valve.3 Outlet butterfly valve of A pump position reaches 15° and interlock startupcirculating water pump A. Continually open butterfly valve until full open.4 Outlet butterfly valve of B pump position reaches 15° and interlock startupcirculating water pump B. Continually open butterfly valve until full open.5 Pump A is normally stop operating. Outlet butterfly valve firstly close to 15°, then interlock stop circulating water pump A and continually close until full closed6 Pump B is normally stop operating. Outlet butterfly valve firstly close to 15°, then interlock stop circulating water pump B and continually close until full closed7 Circulating pump thrusting bearing temperature high (>80℃)trip pump( first point)8 Circulating pump thrusting bearing temperature high (>80℃)trip pump( second point)9 Circulating pump thrusting bearing temperature high (>80℃)trip pump( third point)10 Circulating pump thrusting bearing temperature high (>80℃)trip pump( forth point)11 shaft bearing guide bearing in circulating pump temperature circulatingpump high (>80℃)trip pump (first point)12 shaft bearing guide bearing in circulating pump temperature circulatingpump high (>80℃)trip pump (second point)13 the temperature of shaft bearing circulating pump high (>90℃)trip pump14 the temperature of stator coil A in circulating pump motor is high (>120℃)and trip pump (first point).15 The temperature of stator coil A in circulating pump motor is high (>120℃)and trip pump (second point).16 the temperature of stator coil B in circulating pump motor is high (>120℃)and trip pump (first point).17 the temperature of stator coil B in circulating pump motor is high (>120℃)and trip pump (second point).18 the temperature of stator coil C in circulating pump motor is high (>120℃)and trip pump (first point).19 the temperature of stator coil C in circulating pump motor is high (>120℃)and trip pump (second point).20 Circulating pump has been started up. Outlet butterfly valve does not opento position and delay 40s before trip pump.10。

循环冷却水系统施工方案一、施工准备与图纸会审在项目施工前,根据设计要求进行全面的材料采购与调配,确保施工所需的管材、管件、阀门等物资齐全,质量合格。

组织专业技术人员进行图纸会审,理解设计意图,确定施工中的重难点,并提出合理化建议。

制定详细的施工计划,包括施工进度、人员配备、安全防护等内容的规划,确保施工过程的有序进行。

二、作业指导书报审与技术交底编制作业指导书,明确循环冷却水系统的施工工艺、质量标准和安全要求。

将作业指导书报请监理单位审查,根据审查意见进行修改完善。

组织施工人员进行技术交底,确保施工人员掌握施工工艺要求和质量标准。

三、现场预制与安装检查在施工现场进行管道预制,按照设计要求进行切割、焊接等工序,确保预制质量。

在管道安装过程中,严格控制安装位置、坡度、间距等参数,符合设计要求。

定期对安装完成的管道进行检查,确保安装质量符合规范标准。

四、水压试验与管道保温在管道安装完成后,进行水压试验,检查管道系统的密封性和承压能力。

根据设计要求,对管道进行保温处理,选用合适的保温材料,确保管道系统的热效率。

五、管道吹扫冲洗与验收在水压试验合格后,对管道进行吹扫冲洗,清除管道内的杂物和焊渣。

组织相关单位进行验收,确保循环冷却水系统施工质量符合设计要求和相关标准。

六、管材管件验收与标识对进场的管材、管件进行严格的质量验收,确保材质、规格等符合设计要求。

对验收合格的管材、管件进行标识,标明规格、材质、生产厂家等信息,方便后续使用和管理。

七、管道预制与切割要求在管道预制过程中,采用机械化切割,确保管道切割质量,减少人工操作误差。

严格控制管道预制精度,确保管道接口的平整度、圆度等参数符合规范要求。

八、阀门压力测试与记录对阀门进行压力测试,确保阀门的承压能力和密封性能符合设计要求。

对阀门测试过程和结果进行记录,作为阀门验收和使用的依据。

通过上述各项内容的细致安排和实施,可以确保循环冷却水系统施工的质量与安全,为后续设备的正常运行和生产的稳定奠定坚实的基础。

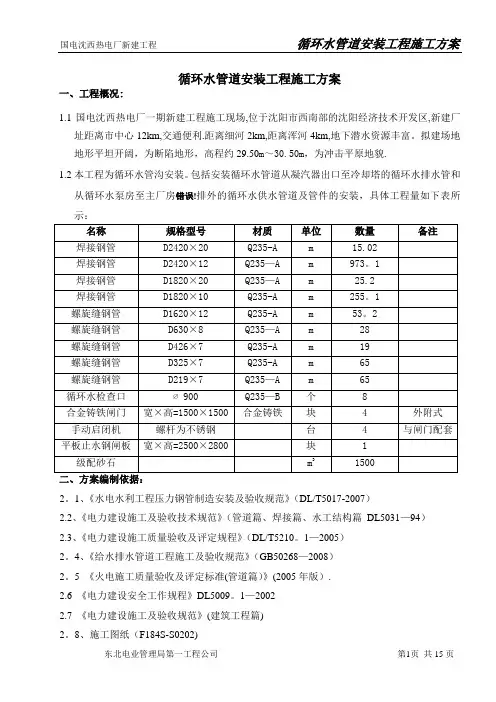

循环水管道安装工程施工方案一、工程概况:1.1国电沈西热电厂一期新建工程施工现场,位于沈阳市西南部的沈阳经济技术开发区,新建厂址距离市中心12km,交通便利.距离细河2km,距离浑河4km,地下潜水资源丰富。

拟建场地地形平坦开阔,为断陷地形,高程约29.50m~30.50m,为冲击平原地貌.1.2本工程为循环水管沟安装。

包括安装循环水管道从凝汽器出口至冷却塔的循环水排水管和从循环水泵房至主厂房错误!排外的循环水供水管道及管件的安装,具体工程量如下表所示:2。

1、《水电水利工程压力钢管制造安装及验收规范》(DL/T5017-2007)2.2、《电力建设施工及验收技术规范》(管道篇、焊接篇、水工结构篇DL5031—94)2.3、《电力建设施工质量验收及评定规程》(DL/T5210。

1—2005)2。

4、《给水排水管道工程施工及验收规范》(GB50268—2008)2。

5 《火电施工质量验收及评定标准(管道篇)》(2005年版).2.6 《电力建设安全工作规程》DL5009。

1—20022.7 《电力建设施工及验收规范》(建筑工程篇)2。

8、施工图纸(F184S-S0202)三、作业进度及劳动力安排:3。

1 作业进度安排:我们工地准备投入6个小组每组4人,完成管道及设备安装任务的工期大约需要90天。

3.2四. 作业准备工作及条件: 4.1 作业人员的资质要求: 4。

1。

1、作业人员必须经入厂三级教育,考试合格方可入厂施工。

4。

1。

2、作业人员必须经体检合格后方可入厂作业。

4.1。

3、特种作业人员必须持证上岗,证件及时上报,如焊工、起重工等。

4.1.4、施工作业人员认真学习、掌握施工图纸。

4.1。

5、焊工应严格按照焊接工艺和焊接技术措施进行施焊,严格遵守规范和焊接工艺细则,认真实行质量自检。

4。

1。

6、焊工不得担任超越其合格项目的焊接工作. 4。

1.8、所有施工人员经技术安全交底,并在交底书上签字。

AC1600B-冷却水循环机操作规程

1. 目的

为规范和指导AC1600B-冷却水循环机操作和使用,特制定本作业指导书。

2. 适用范围

适用于实验室原子吸收分光光度计AA-6880的石墨法操作时,提供循环冷却水。

3. 性能参数

额定电压:220V

额定功率:1KW

调温范围:5~90℃

冷却介质:去离子水、乙醇、乙二醇、甘油(15%)水溶液、硅油等

4. 操作程序

4.1确定水箱冷却液注入到指定位置。

4.2连接电源线,并打开电源开关。

4.3确定调节温度在所需范围内。

否则需要自行按键设定使用温度。

4.4当停止石墨炉法操作后,关闭冷却水循环机电源,长时间不用时,则需要拔下电源线。

5. 仪器维护与注意事项

5.1仪器要放置水平地面上,使用时严禁搬动。

5.2经常检查水箱冷却液液位。

5.3如冷却液出现杂物或污垢时,停止使用仪器,清洁水箱后方可继续使用。

5.4一起使用时,确保冷却液出口压力表指数不低于0.12Mpa。

5.5仪器背面为排风散热面,故仪器背面不能贴墙。

5.6保持仪器的清洁,仪器表面不能积水。

5.7保持水箱盖处于常盖状态。

5.8当过滤器滤芯颜色由白色变黄后,需要更换过滤器滤芯。

QG/10.187-2009 循环水泵检修作业指导书2009-09-30发布 2009-09-30实施发电有限公司发布QG/10.187-2009前言本指导书是根据公司标准化工作要求,结合《汽机检修规程》和设备说明书要求而编制的,对汽轮机EH油系统检修步骤、工艺标准、质量和过程控制等制定规范化要求。

附录A、附录B、附录C、附录D、附录E、附录F、附录G、附录H、附录I是本指导书的规范性附录。

本指导书自2009年9月30日发布实施。

本指导书由设备维护部提出。

本指导书由生技部归口。

本指导书由设备维护部负责起草。

本指导书主要起草人:本指导书审核:本指导书审批:本标准由设备维护部负责解释。

IQG/10.187-2009循环水泵检修作业指导书1 范围本指导书适用范围是:xx电厂2×xxMW机组配套的循环水泵检修。

2 规范性引用文件制定本指导书引用的国家、行业、企业等标准和文件如下:电力建设安全工作规程第1部分:火力发电厂 DL5009.1-2002电力建设施工及验收技术规范汽机篇 DL584-19963 使用记录本指导书使用记录见附录A4 管理内容与要求4.2 安全技术措施1QG/10.187-20094.3检修工具2QG/10.187-20094.4 备品备件和消耗性材料4.5试验设备无4.6检修步骤a)对每一步都应进行风险分析和控制,在必要的步骤中说明“存在风险”和“风险控制”的内容,该部分的内容为了能够醒目,应用“小五,蓝色,粗体”。

b)“简要记录”一般填写检修中需要涉及的检修记录表、调试记录表和技术监督报告编号等。

C)“质量验收”为检修作业设置的对应W点、H点及技术监督项目监控报告“R”点的质量控制实施计划。

d)“完成情况”实际工作中项目完成可以打钩“√”3QG/10.187-20094QG/10.187-20095QG/10.187-20095 作业签证附录a)附录A:指导书使用记录b)附录B:检修记录表c)附录C:质量控制实施计划d)附录D:完工报告e)附录E:质量缺陷报告f)附录F:不符合项报告及验收单(注:有F1、F2)g)附录G:设备及设施异动申请单及报表(注:有G1、G2)h)附录H:设备试转申请单i)附录I:设备功能/品质再鉴定单6QG/10.187-2009附录A(规范性附录)7QG/10.187-2009附录B(规范性附录)循环水泵检修记录8QG/10.187-2009现场记录人:施工单位审核:设备维护部设备专责:生技部专工:9QG/10.187-2009附录C(规范性附录)质量控制实施计划10QG/10.187-200911QG/10.187-200912QG/10.187-2009附录D(规范性附录)完工报告13QG/10.187-2009附录E(规范性附录)质量缺陷报告编号:机/炉/电/热()号时间:年月日14QG/10.187-2009附录F1(规范性附录)不符合项报告15QG/10.187-2009附录F2(规范性附录)不符合项处理验收单16附录G1(规范性附录)生产设备及设施异动申请单部门:编号:锅炉()号时间:年月日批准:审核:申请人(经办人)注:(1)本表及附图、资料一式六份。

中、低压管道水压试验作业指导书要点1.工程概况:1.1工程(系统或设备)概况系统概况。

(包括系统的组成、作用及作业涉及的范围)1.2.工程量和工期.1.2.1工程量:1.2.2施工工期施工工期一般为天2. 编制依据.列出与冷却水系统相关的所有设计图纸,厂家资料、技术、质量、安环相关的规程、规范等。

表格如下:3.作业前条件和准备:3.1技术准备厂家资料齐全图纸会审完毕,会审提出问题已解决制定技术和安全措施,并交底双方签字3.2作业人员:3.2.2 作业人员职责分工和权限3.3作业工机具3.4材料和设备3.5安全器具3.6工序交接3.7其他4. 作业程序、方法和内容4.1 作业程序4.2方法和内容5.作业过程中控制点的设置和质量通病及预防5.1质量目标1)水压一次试验成功;2)根据工程质量总目标和专业目标确定的本作业其他质量目标;5.2保证措施及质量通病预防5.2.1质量保证措施1)加强施工人员施工技术和技艺的培训,并经考核合格方可施工;2)加强施工人员责任心;3)加强过程监督控制,确保本序工作合格后才能进行下序工作;4)保证系统设备及管道内部清洁;5)防止阀门、法兰泄漏所采取的有关措施5.2.2质量通病及预防(见下表)5. 3作业过程中控制点的设置5. 4 质量标准及要求主要执行如下标准:6作业的安全要求和环境条件6.1 作业的安全要求施工危险因素和环境因素辨识及控制表内容见附录6.2环境条件7.附录:7.1监理要点:R记录确认、W见证点、H停工待检点、S连续监视监护7.2施工危险因素和环境因素辨识及控制对策表施工危险因素和环境因素辨识及控制对策表项目名称:循环冷却水系统水压试验作业危险点和环境因素描述:按本工程特点确定(一)厂地和环境(二)作业和人员(三)机械和工具可能产生的危险因素和环境因素监督管理措施:包括(一)确定监督控制办法—R 记录确认点;W 见证点;H 停工待检点;S 连续监视监护;(二)规定监督控制责任—班组、专业队、项目部。

循环冷却池做法

循环冷却池的制作方法如下:

1. 定位:根据预定的位置,确定循环水池的平面位置。

2. 挖掘基坑:挖掘基坑,清理基底,用碎石或砾石铺底,厚度一般为

30~50mm,并填实至高于地面50~80mm。

3. 防水处理:为了便于排水,在循环水池的内侧可以涂刷两遍沥青砂,铺两层油毡。

在池的外侧设置防水隔离层,通常用粘土夯填密实后做

成斜坡。

4. 砌筑:根据循环水池的需要,进行池壁、池底、进出水管、溢流管

等的砌筑。

5. 池内设备安装:进行池内的设备安装,如循环水泵的安装、管道的

铺设等。

6. 循环水的加入和抽出:根据需要确定加入和抽出循环水的办法。

如

果循环水较少,可以用水泵抽出,如果较多,可以在池内用管子引流

抽出。

同时注意定期观察水的流动情况,防止循环水在池内沉淀或溢出。

以上步骤完成后,循环冷却池就可以投入使用了。

注意:在建造和装修循环冷却池的过程中,应确保安全,避免对池内

设备或防水处理造成破坏,导致水源泄漏或污染。

同时,也要确保施

工质量和规范,防止出现安全隐患。

如果有任何疑问或需要进一步的

帮助,可以咨询专业的建筑或装修工程师。

冷却(冻)水不停机清洗预膜作业指导书一、冷却(冻)水系统清洗、预膜:1)冷却水系统清洗48小时清洗指标:PH值:5.00-6.00浊度:30mg/l2)冷却水系统预膜48小时预膜指标:PH值6.00-7.00浊度:20mg/l3)冷冻水系统清洗48小时清洗指标:PH值:5.00-6.00浊度:20mg/l2)冷冻水系统预膜48小时预膜指标:PH值9.00-10.00浊度:20mg/l二、冷却水系统水处理目的:1)清水清洗目的:清除系统中的杂质和污垢操作:系统充满水——开泵运行4小时——根据浊度(较高时)排水置换——测试浊度低于10 mg/l为止。

2)粘泥剥离、去油锈剂目的:剥离粘附在管壁、塔壁上的生物粘泥,以进一步净化金属表面。

操作:投药至冷却塔。

使用药剂为粘泥剥离去油锈剂。

3)化学清洗目的:清除设备内金属表面的水垢污物和油锈等杂质操作:投药至冷却塔。

使用药剂为清洗剂和消泡剂。

4)预膜处理目的:在金属表面形成一层保护膜,以起到防止腐蚀的作用操作::投药至冷却塔。

使用药剂为预膜剂冷冻水系统水处理目的:同上主要是清洗后预膜冷冻水一般将药剂投至膨胀水箱/或用泵压入系统三、通常时间安排(主要做冷却水系统,塔、泵、主机、还可单独清洗)第一天:将冷却系统清洗药剂运至现场第二天:安排人员对冷却塔填料采用化学药剂喷淋方式进行清洗;将盘内污泥进行清扫和冲刷,将悬浮物及污物清除干净。

计划:1)人员需:4+1=52)工具需:高压水枪、雨鞋、防护服、护目镜、橡胶手套、接线盘、水桶、长把刷、笤帚、簸箕、小推车、改锥一字和十字、钳子各1把、活扳手2把、350/600管钳各1把等3)材料需:塑料布或彩条布、绳子、6分塑料带线的水管1盘(50米)、6分喉箍5个麻、 14 #铁丝10米4)备料:DN15、DN20、DN32镀锌钢管短节各2个(约18公分长一头套丝)DN15、DN 20、DN32、DN40闸阀各2个第三天:系统上水——开循环泵——排水置换(4-6小时)第四天:投加去油锈剂和清洗剂。

目录1、适用范围2、编制依据3、工程概况与工程量4、作业人员的资格和要求5、主要机械及工器具6、施工准备7、作业程序8、施工进度9、作业方法、工艺要求及质量标准10、工序交接及成品保护11、职业安全卫生和文明施工措施12、环境管理13、作业条件的主要危险点(源)辨识及控制1、适用范围:本作业指导书适用于江苏华电句容二期(2x1000MW)扩建工程一标段循环水处理系统设备及管道安装。

2、编制依据:2.1《电力建设施工质量验收及评价规程》管道及系统篇DL/T 5210.5-20092.2《电力建设施工及验收技术规范》焊接篇DL/T869-20042.3《电力建设安全健康与环境管理工作规定》 2002版2.4《火电施工质量检验及评定标准》焊接篇 1996年版2.5《电力建设施工质量验收及评价规程》汽轮发电机组篇DL/T 5210.3-20092.6《电力建设施工及验收技术规范》电厂化学篇 DL/T 5190.4-20042.7《电力建设施工质量验收及评价规程》水处理及制氢篇 DL/T 5210.6-20092.8《工程建设标准强制性条文》电力工程部分(2011年版)2.9《电力建设安全工作规程》(火力发电厂部分) DL5009.1—20142.10《汽机专业施工组织设计》 (第一标段) 江苏省电力建设第一工程公司2.11设计院图纸和制造厂图纸及说明书3、工程概况及主要工作量:3.1工程概况:3.1工程概况本工程循环水加药间位于两台冷却塔之间西侧;循环水处理系统通过稳定剂计量泵、次氯酸钠加药泵及有机杀菌剂计量泵通过管道将稳定剂、次氯酸钠及有机杀菌剂注入#3、#4循环水回水内。

次氯酸钠通过卸次氯酸钠泵卸至储罐,而有机杀菌剂及稳定剂则为人工加至溶解箱。

3.2主要工作量:(两台机组)序号设备材料名称型号及规范单位数量备注1 有机杀菌剂溶液箱V=2.0m3,φ=1400mm 台2 钢衬胶2 有机杀菌剂计量泵Q=950L/h,p=1.0MPa 台 2 N=3KW3 稳定剂溶液箱V=1.0m3,φ=1000mm 台 2 钢衬胶4 连续加稳定剂计量泵Q=15L/h,p=1.0MPa 台 3 N=0.55KW5 启动加稳定剂计量泵Q=400L/h,p=1.0MPa 台 1 N=1.5KW6 卸次氯酸钠泵Q=25m3L/h,p=0.2MPa 台 1 N=3KW7 次氯酸钠贮存罐V=25m3,φ=2800mm 台 2 钢衬胶8 次氯酸钠加药泵Q=3500L/h,p=1.0MPa 台 2 N=5.5KW9 安全洗眼淋浴器台 210 不锈钢管道米约30011 衬聚四氟乙烯管米约30012 聚丙烯管道米约30013 支架t 34、作业人员的资格和要求:4.1参加人员的资格和要求。

冷却循环水系统施工组织设计方案一、冷却循环水系统施工方案1.施工程序施工准备——图纸会审——施工作业指导书报审——技术交底——现场预制——现场安装质量检查——水压试验——管道保温——管道吹扫及冲洗——管道交工验收2.管材、管件的验收2.1检验程序检查产品质量证明书——检查出厂标志——外观检查——核对规格、材质——材质复检——无损检验及试验——标识——入库保管2.2检验要求:所有材料必须具有制造厂的质量证明书,其质量要求不得低于现行标准的规定。

钢管、管件、阀门在使用前应进行外观检查,不合格者不得使用。

钢管表面不得有裂缝、折迭、皱折、离层、发纹及结疤等缺陷;钢管无超过壁厚负偏差的锈蚀、麻点、凹坑及机械损伤等缺陷。

除非极个别情况,禁止利用旧管道和管件,否则必须按有关标准的规定进行全面检验合格,并经过设计许可。

法兰密封面应光洁,不得有径向沟槽,且不得有气孔、裂纹、毛刺或其他降低强度和连接可靠性方面的缺陷。

法兰端面上连接的螺栓的支承部位应与法兰结合面平行,以保证法兰连接时端面受力均匀。

螺栓及螺母的螺纹应完整、无伤痕、毛刺等缺陷,螺栓与螺母应配合良好,无松动或卡涩现象。

3.阀门试压3.1该阀门试验应从每批中抽查5%,且不少于1个,举行壳体压力试验和密封试验,当不合格时,应加倍抽查,仍不合格时,该批阀门不得使用;阀门的壳体试验压力不得小于公称压力的 1.5倍,试验时间不得少于5min,以壳体填料无渗漏为合格;密封试验宜以公称压力举行,以阀瓣密封面不漏为合格。

3.2试验合格的阀门,及时排除积水,并吹干。

关闭阀门,做好明显标记,并填写《阀门试验记录》。

3.3阀门壳体压力试验和密封试验应用洁净水进行。

3.4密封试验不合格的阀门,必需崩溃搜检,重做试验。

4.管道预制4.1切割要求:管道切割后应移植原有标记。

切口表面应平整,无裂纹、重皮、毛刺、凸凹、缩口、熔渣、氧化物、铁屑等;切口端面倾斜偏差不应大于管子外径的1%且不得超过3mm。

发电机定子冷却水系统安装及冲洗作业指导书1.适用范围本作业指导书适用于燃煤发电机组工程水氢氢汽轮发电机定子冷却水系统的安装和水冲洗作业。

2.编制依据2.1发电机厂有限责任公司定子冷却水资料(随机文件)2.2《定子冷却水控制系统使用说明书》OEA.466.3752.3《电力建设施工及验收技术规范》汽轮机组篇。

DL5011-922.4《火电施工质量检验及评定标准》汽轮机篇(1998年版)2.5《电力建设安全工作规程》·DL5009.1-2002。

2.6电力设计院图纸:J2206发电机定子线圈水冷系统管道安装图2.7《工程建设标准强制性条文》(电力工程部分)(第一篇)火力发电工程2.8《电力基本建设火电设备维护管理规程》 DL/T855-20042.9《电厂化学规范》 DL/T5190.4-20042.10《防止电力生产重大事故的二十五项重点要求》国电公司2000-9-282.11《电力建设施工及验收技术规范》管道篇DL5031-942.12《火电施工质量检验及评定标准》管道篇2000版2.13《火电施工质量检验及评定标准》焊接篇1996版3. 工程概况及主要工程量3.1工程概况:燃煤发电机组工程机组,由电机厂有限责任公司生产的600QFSN4-600-2型水氢氢汽轮发电机。

其发电机为水氢氢汽轮发电机,定子绕组冷却方式为水内冷。

定子冷却系统为闭式循环系统,主要由水箱、冷却水泵、冷却器、过滤器,离子交换器及管道组成。

3.2主要工程量(一台机)4.作业人员的资格及要求4.1作业人员应经过三级安全教育和考试,懂得安全操作知识。

4.2电焊工等特殊工种必须持证上岗。

4.3从事高空作业人员必须经过体格检查,合格者方可上岗。

4.4作业人员必须有一定的辅助设备及不锈钢管道的安装经验,主责、作业人员按一定的比例配备。

4.5参加作业人员,在作业前应熟悉图纸及有关措施和规范等要求,对作业的内容和要求有足够的了解。

作业指导书控制页:*注:班长负责每项目上交一本已执行完成的、并经过完善有完整签名的作业指导书。

重要工序过程监控表作业指导书(技术措施)修改意见征集表回收签名(日期):目录1 编制依据 (1)2 工程概况及施工范围 (1)2.1工程概况 (1)2.2施工范围 (1)3 施工作业人员配备及人员资格 (1)4 施工所需机械装备及工器具量具、安全防护用品配备 (2)4.1作业所需机械装备及工器具量具 (2)4.2安全防护用品配备 (2)5 施工条件及施工前准备工作 (2)6 作业程序、方法及要求 (2)6.1作业程序流程图如下页方框图所示 (2)6.2作业方法及要求 (2)6.3专项技术措施(技术要点及注意事项) (4)7 质量控制及质量验收 (4)8 安全、文明施工及环境管理要求和措施 (5)表8-1职业健康安全风险控制计划表(RCP) (6)表8-2环境因素及控制措施一览表 (7)9 附录 (8)1 编制依据1.1《电力建设施工及验收技术规范》[DL5031-94](管道篇)1.2《火电施工质量检验及评定标准》[2000年版](管道篇)1.3公司《质量、安全健康、环境管理手册》(第三版)1.4湖南省电力勘测设计院设计图纸“热机部分第十九卷第二册《闭式循环冷却水管道安装图》”1.5《电力建设安全工作规程》(火力发电厂部分) 2002年版1.6本工程安装施工组织总设计1.7 Q/501-103.01-2006《火力发电机组施工创优工艺质量手册》(安装部分)1.8《工程建设标准强制性条文(电力工程部分)》2006年版2 工程概况及施工范围2.1工程概况闭式循环冷却水系统用水为凝结水,经膨胀水箱向系统补水至回水母管,然后经闭式冷却水泵加压后进入压力水母管,经闭式水冷却器冷却后进入厂房各设备,对各系统设备及运转部分进行面式冷却,以保证设备正常运行,闭式冷却水从各设备出来后又回到回水母管上,重复上一过程。

该系统为厂房内水质要求较高的设备提供冷却用水,因此系统内部水质的清洁度直接影响到设备运行状况的好坏,所以必须做好系统的冲洗及试压工作。

目录1.工程概况及主要工作量 (1)2.编制依据 (2)3.作业前的条件和准备 (2)4.作业的程序和方法 (4)5.质量控制点的设置和质量通病的预防 (12)6.作业的安全要求和环境条件 (14)7.本作业中执行的强制性条文 (20)8.危险源辨识及预防控制措施(见附表) (21)施工技术交底记录 (24)安全技术交底记录 (25)1.工程概况及主要工作量1.1工程概况:孟加拉巴瑞萨燃煤电站项目位于孟加拉南部Barguna地区,紧邻孟加拉湾,亦处于孟加拉政府规划建设的深水港Payra Port 区域。

电厂规划 2×350MW 燃煤机组,机组采用表面式凝汽器间接空冷方式,循环水系统为带走汽轮机排到凝汽器的废热,而连续不断的供给冷却水,该系统为开式循环冷却水系统提供水源,从主厂房A列外至冷却塔的循环水回水管及从循环水泵房至主厂房A列外的循环水供水管,循环母水管规格为2640X16(18),从循环水泵房到母管的支管格为1820X12从主厂房到母管的支管规格为1820X12,循环水管道设置刚性环,母管刚性环间距为2.0米和1.5米,支管刚性环同距为20m。

1.22.编制依据2.1设计院提供的《循环水管道安装图》F08411S-S0202 (J1901)2.2《电力建设施工质量验收规程第3部分:汽轮发电机组》(DL/T5210.3-2018) 2.3《工业金属管道工程施工规范》(GB50235-2010)2.4《电力建设施工质量验收及评价规程》(第七部分焊接 DL/T5210.7-2012)2.5《火力发电厂焊接技术规程》DL/T 869-20122.6《电力建设施工技术规范第8部分:加工配制》(5190.8-2019)2.7《管道焊接接头超声波检验技术规程》(DL/T820-2002)2.8《工程建设标准强制性条文》(电力工程部分) 2016版2.9电力建设施工技术规:管道及系统》(DL51905-2012)2.10《火电汽水管道支吊架设计手册》D-ZD20102.11《绿色施工导则》建设部建质〔2007〕223号2.12《承压设备无损检测》NB/T47013-20152.13电力工程地下金属构物反腐技术导则》(DL/T5394-2007)2.14《火力发电厂水工设计规范》(DL/T5339-2018)3.作业前的条件和准备3.1主要作业条件3.2施工人员职责4.作业的程序和方法4.1 作业程序:施工准备→号料及钢板下料→接板(短板对接) →压边、滚压成形→组对、固定焊→直缝(纵缝)焊接(内、外) →探伤(X光、超声波)检验→管与管组对、固定焊→环缝的焊接(内、外) →探伤(X光、超声波)检验→刚性环焊接→整体检验→喷砂防腐→成品检验→堆放待运区→运输至安装现场或料场。