复蓝海华腾vtv5说明手册

- 格式:docx

- 大小:10.91 KB

- 文档页数:4

WORD下载可编辑CAV/5U分米波电视激励器用户手册技术资料精心整理WORD下载可编辑技术资料精心整理WORD下载可编辑目录目录。

3 警告。

5 保修。

6 介绍。

7 手册内容。

7 触电救护。

9第一章产品介绍。

13 1.1 简介。

14 1.2 技术指标。

16 1.3 方框图。

18第二章安装。

19 2.1 设备安装。

20 2.2 初装要点。

20 2.3 测试接口。

21 2.4 RS232接口。

21 2.5 操作显示菜单介绍。

22 2.6 保护门限,告警及其设置。

24 2.7 改频步骤。

24 2.8 预防措施。

25 前面板。

26 后面板。

27第三章图表。

29 ATP150A CAV/5U 接线图。

30技术资料精心整理WORD下载可编辑MTF0096AR0 放大模块元件清单。

31 ATP150A CAV/5U 元件清单。

32 SCH0291AR0(主板)。

33- 音频处理电路。

34 - 视频处理电路。

35 - 视频予校正电路。

36 - 音/视频调制电路。

37 - 中频载频振荡电路。

38 - 中频予校正电路。

39 - 中频校正电路。

40 - 上变频电路。

41 - 电源电路。

42 - 校正调试点。

48 - 外部AGC 设置。

58SCH0123AR1(控制板和显示)。

59-调试要点。

62 SCH0136AR0(IV-V波段 VCO器)。

63-调试要点。

63 MTG0050AR0(40Ddb UHF 滤波器)。

66-调试步骤。

66 SCH0300AR0(接口板)。

69 SCA0302AR0(5W 放大模块)。

71 SCA0311AR0(2W 放大模块)。

72E0004 (S-150-24 开关电源)。

73 技术资料精心整理WORD下载可编辑提示本手册所描述的产品在设计和生产中都采用了对用户的保护措施。

在安装,维护和调试时需要关机。

使用者须采取的预防措施为避免高压伤害,操作时请穿着专用衣服,戴保护手套。

注意事项零件清单附在相关电原理图后面,标明每一项的参数、说明以及常用类型。

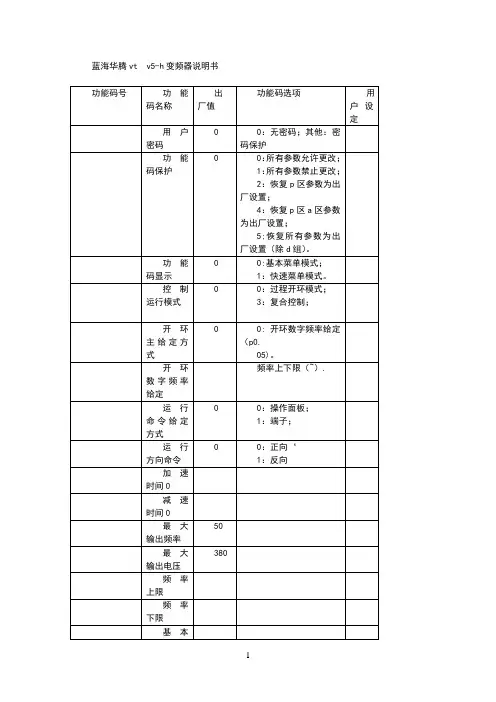

最新深圳蓝海华腾变频器参数V5.pdf深圳蓝海华腾变频器参数V5P0.01=3 恢复出厂设置d0.00=0故障记录类型 2d0.01=0故障记录类型 1d0.02=0最近一次故障类型记录0P0.05=25(开环数字频率给定:25Hz)Digital open-loop frequency:25HZP0.06=1(运行命令给定方式:端子)Running command issuance model: terminal P0.06=0 手动模式P0.07=0 正转P0.07=1 反转P0.08=3(加速时间:3秒)Acceleration time:3 secondsP0.09=1.2(减速时间:1.2秒)Deceleration time:1.2 seconds.P0.16=1.00(转矩提升)Torque increaseP3.03=1.00(起始频率)Initial frequencyP3.09=0(防反转选择:允许反转)Backward turning prevention choice: backward turning permittedP4.22=25(多断频率一)Multi-section frequency 1:P4.23=25(多断频率二)Multi-section frequency 2P4.24=50(多断频率三)Multi-section frequency 3P5.00=02(正转)Forward turningP5.01=03(反转)Backward turningP5.02=26(紧急停车)Emergence stopP5.03=09(多断频率一)Multi-section frequency 1P5.04=10(多断频率二)Multi-section frequency 2P7.00=02(Y1端子输出功能选择:制动)Y1 terminal output function choice: brake. P7.01=14(Y2端子输出功能选择:变频器故障)Y2 terminal output function choice: frequency converterfaultP7.20=2.10(FDT1电平上界)Voltage upper limitP7.21=2.00(FDT1电平下界)Voltage lower limitP9.01=4 电机级数PA.09=1(能耗制动选择)Energy dissipation brake choicePA.11=700(制动单元动作电压)Braking cell actuation voltageP9.01=4电机级数P9.02=1500电机额定转速P9.03=厂家电机额定功率P9.04=厂家电机额定电流。

蓝海华腾变频器说明书V5- H系列变频器深圳市蓝海华腾技术股份有限公司V5- H 系列变频器是高性能矢量控制型变频器。

产品采用了与目前国际最领先技术完全同步的无速度传感器矢量控制技术,不仅具有与国际高端变频器同样优异的控制性能,同时还结合中国的应用特点,进一步强化了产品的可靠性和环境的适应性以及客户化和行业化的设计,能够更好地满足各种传动应用的需求。

产品优点:■高性能的开环矢量控制技术;■超强的负载能力,在任意加减速时间和任意冲击负载条件下,变频器稳定无跳闸运行;■提供独立的高速脉冲输入和输出端口,可实现高速脉冲级联功能;■精确的速度辨识和转子磁链定向,在0.25Hz 负载突变时转矩也能快速地响应和稳定运行;■高精度的电流检测和保护,采用高精度的霍尔进行输出电流的检测、满足软硬件的快速实时控制和保护要求,保证了整机的性能和可靠性。

典型行业:如印刷包装、石油化工、纺织、线缆机械、机床设备、食品包装、电动汽车、洗涤设备、塑料机械、金属制品设备、离心机及要求开环矢量的应用场合。

如长庆油田、辽河油田、胜利油田、奥力通起重机、开山压缩机、德曼压缩机、中铁桥梁、江苏海狮。

第一章V5-H 系列变频器介绍 (1)1.1产品型号说明 (1)1.2产品铭牌说明 (1)1.3产品系列. (2)1.4产品技术规格 (4)1.5产品各部分的名称 (5)1.6产品外形和安装尺寸及大概重量 (5)1.7操作面板的外形和安装尺寸 (7)1.8托板的外形和安装尺寸 (7)1.9制动电阻选型 (8)第二章变频器的安装 (9)2.1产品的安装环境 (9)2.2安装方向和空间 (9)2.3操作面板及盖板的拆卸和安装 (10)第三章变频器的配线 (13)3.1产品与外围器件的连接 (13)3.2主回路外围器件的说明 (14)3.3主回路外围器件选型 (14)3.4产品端子配置 (15)3.5主回路端子的功能 (16)3.6主回路配线注意事项 (17)3.7端子配线. (19)3.8控制回路端子功能 (20)3.9控制板示意图 (23)3.10控制回路外围器件选型 (23)3.11跳线功能说明 (23)第四章操作面板使用说明 (24)4.1操作面板介绍 (24)4.2指示灯说明. (24)4.3操作面板按键说明 (25)4.4菜单风格. (26)4.5密码操作. (30)4.6按键锁定及解锁 (31)4.7操作面板显示及按键操作 (31)4.8操作实例. (32)4.9首次运行. (33)第五章参数一览表 (35)5.1基本菜单功能码参数简表 (35)用户参数记录表 (49)5.3用户接线图 .......................................... 50 第六章参数详解 (51)6.1基本功能参数(P0 组) (51)6.2主辅给定参数(P1 组) (55)6.3按键及显示参数(P2 组) (58)6.4起停参数(P3 组) (60)6.5多段参数(P4 组) (62)6.6多功能输入参数(P5 组) (65)6.7模拟给定参数(P6 组) (70)6.8多功能输出参数(P7 组) (72)6.9过程PID 闭环参数(P8 组) (78)6.10电机参数(P9 组) (80)6.11控制参数(PA 组) (82)6.12增强功能参数(Pb 组) (87)6.13通讯参数(PC 组). (91)6.14矢量控制参数(Pd 组) (92)6.15故障记录参数(d0 组) (94)6.16产品识别参数(d1 组) (95)6.17运用显示参数(d2 组) (96)6.18用户定义功能码显隐区参数(A0 组)96 第七章故障诊断987.1故障及告警信息列表 (98)7.2故障诊断流程 (101)第八章日常保养及维护 (102)8.1 日常保养 (102)8.2定期维护 (103)8.3部件更换 (103)8.4绝缘测试 (103)附录A Modbus 通讯协议 (105)1支持协议 (105)2接口方式 (105)3协议格式 (105)4功能解释 (106)5变频器寄存器地址分布. (108)6CRC16 函数 (111)7Modbus 通讯控制举例 (111)8通讯网络的组建 (112)5.2附录B 各种控制方式设置流程 (113)1参数自整定的设置流程. (113)2过程开环的设置流程.. 错误!未定义书签。

Thanks for purchasing viliv.Please read the precautions throughly before using the product.Yukyung Technologies Corp. has the copyright for this guide.Contents of this manual may not be copied or produced in any form or means without prior authorization from Yukyung Technologies Corp.©2010 Yukyung Technologies Corp. All rights reserved.This device has acquired EMC certification for home use (Class B)and is designed not only for use in residential area but anywhere.viliv is the registered trademark of Yukyung Technologies Corp.Windows7, Windows Vista, Windows XP , Windows 2000, Windows CE are the registered trademarks of Microsoft Corporation.Infringement of Intellectual Property Rights: Playing, copying or distributing any part or all of any copyrighted contents such as software, music or video with this device may infringe on a third party’s legitimate intellectual property rights or violate copyright law. All legal responsibilities for the infringement of copyright or intellectual property rights from the use of this device lie with the user.Improper Use: The manufacturer of this device is not liable for any damage or improper use and operation by using this device and infringement of copyright and portrait right by user when taking photos In addition, the manufacturer is not liable for bodily injury or property damage that may occur arising from inappropriate use other than operation standards or conditions.Data Loss: Any audio, video or photo files stored in this device may be deleted due to damage or operational error caused by user’s careless handling or unknown failure or when the device undergoes warranty repair. Therefore, the files must be backed up in a separate place.In these cases, the manufacturer is not liable for the loss or damage of data stored in the device.Specification Change: The standards, accessories, embedded software and manual contents of this device may be changed without user's prior consent or prior notice to the user.Grade B Device (Broadcast Communication Device for Residential Area)CertificationRegistered TrademarkLiability DisclaimerCopyright$POUFOUTSafety Precautions for Use (4)Names of Parts (7)Basic Components (7)Accessories (Optional) (7)Front View (8)Keyboard (9)Left / Right View (10)Lower Side (11)Rear View (11)Installation and Cable Connection (12)Connecting Earphone (12)Multi-IO Port AV-OUT, D-SUB (Optional) (13)Multi I/O Port USB Link (14)USB HOST Connection (14)Power Connection (Charging Adaptor) (15)Inserting . Extracting MicroSD Memory Card (16)Separating . Attaching Battery (17)Separating Battery (17)Attaching Battery (18)Basic Operation (19)Turning the Power On/Off (19)Touch Screen (19)Set Up for viliv Manager (20)Recovery Solution (AMI Rescue) Guide (21)Way to Use Recovery Solution (AMI Rescue) (21)Specifications (22)General Specifications (22)English4Safety Precautions for UseThis device complies with Part 15 of FCC Rules. Operation is subject to the following two conditions:(1) This device may not cause harmful interference, and(2) This device must accept any interference received.Including interference that may cause undesired operation.FCC Compliance Information Modifications not expressly approved by the partyresponsible for compliance could void the user’s authority to operate the equipment.CautionIf the battery can be seen to be swollen, there maybe imminent danger. Immediately contact themanufacturer or sales representative.Only use an eligible specified charger.Keep the device away from open flames. (Do not put itin a microwave.)Do not leave the device in a car in summer.Do not store or use the device in a hot and wet placelike a bathroom.Do not put the device on bedclothes, electric mattressor carpet and use it for a long time.Do not store the device powered on in a closed space. Do not allow metal products, such as a necklace, coil, key or watch, to touch the battery port. Use a lithium secondary battery guaranteed by a portable device manufacturer.Do not disassemble or pierce the device and do not apply excessive strength.Do not apply excessive impact like dropping the device from a high place.Do not expose the device to temperatures of 60°C or higher.Avoid humidity.This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used inaccordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:- Reorient or relocate the receiving antenna.- Increase the separation between the equipment and receiver.- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.- Consult the dealer or an experienced radio/ tv technician for help.Information to UserIn August 1996 the Federal Communications Commission(FCC) of the United States with its action in Report and order 96-326 adopted an updated safety standard for human exposure the ra-dio frequency electromagnetic energy emitted by FCC regulated transmitters. Those guidelines are consistent with the safety standard previously set by both U.S. and international standards bodies. The design of ‘N5’ complies with the FCC guidelines and those international standards. Use only the supplied or an approved antenna. Unauthorized antennas, modifications, or attachments could impair call quality, damage your ‘N5’, or result in violation of FCC regulations.‘N5’ was tested for typical body-wom operation using the optional belt-clip / holster placed touch(0cm) from the body. The use of non-tested accessories or other body-wom operations may not comply with FCC exposure requirements and should be avoided.FCC RF Exposure InformationEnglish5Safety Precautions for UseThe precautions below are provided to prevent bodily injury or property damage by using this product correctly. Please observe the precautions.Do not touch the power adapter with wet hands.Plug the power cord into an outlet with grounded jack.Be sure the plug goes in all the way and is not loose.Do not use your device if it is damaged, including an exposed or peeled power cord.If lightning occurs nearby or if you are absent for a long time, unplug the plug from the outlet.Precautions on Power Do not apply strong impacts or make a hole with a sharp object.Do not leave the battery in a hot place such as sauna or bathroom or otherwise heat it.Do not let the battery become wet or immersed in liquid.Do not allow children or pets to bite or suck the battery.Keep the battery charging port away from metals.When disposing of the battery, do not burn it or throw it away in domestic trash.Dispose of the battery at the nearest disposal place for batteries after contacting your local waterdisposal agency.Precautions on Battery Avoid exposing to direct sunlight and do not leave in a closed car.Do not leave the device in a dusty place or a humid place such as a bathroom.Keep the device away from credit cards, bankbooks, or a communication ticket.Do not use accessories that are not provided with this device.Do not touch the LCD screen with a sharp object.Precautions for the Device Do not listen to music at a high volume for a long time.Do not watch the video for too long a time.Do not apply strong impacts on the LCD.If the device begins to smoke or become deformed by heating, stop using it immediately andcontact your nearest Customer Service.Do not use the device in a hospital, on board a plane or while driving.Do not directly put and use the device frame or the power adapter on your bare skin for a longtime. The temperature of the station may rise even during normal operation.If you continue to use the device on your bare skin (in particular, when the adapter isconnected), you may feel uncomfortable or receive a burn.Precautions in UseIf the device is wet, do NOT turn on the power. Separate the battery and wipe it with a soft drycloth. After that, contact Customer Service.When cleaning the device, wipe it with a soft dry cloth and do NOT use chemicals, such asbenzene or thinner.Do not repair, disassemble or alter in any manner.Do not allow any liquid or foreign materials to get inside the device.Do not drop the device.Other PrecautionsEnglish6Safety Precautions for UseThe device functions vary depending on model.Read the relevant precautions for the provided function before using the device.WiFi and 3G Modem (or HSDPA, HSUPA) do not operate simultaneously.Do not attempt to operate the Bluetooth while driving. Accidents caused by such improperhandling are the sole responsibility of driver.To prevent electromagnetic problems or other dangers, turn off the Bluetooth setting whereverthe use of Bluetooth is prohibited.If you use a certain medical device, such as a pacemaker or a hearing aid, ask the manufacturerof the relevant device if it is correctly cut off from energy sources before using it. If necessary,you may ask for some assistance from your regular doctor.This device satisfies Bluetooth standards 2.0. Some Bluetooth devices may not be fullycompatible with this device. For detailed information on compatibility, contact themanufacturer of the relevant device or our Customer Service.This wireless equipment may experience electromagnetic interference, so it is not permittedfor use by a life-saving service.Precautions for the BluetoothEnglish7Names of PartsThe appearance of the components below may differ from the actual components and some components are subject tochange.Main BodyUSB-link Cable(Professional only)User’s ManualD-SUB Cable(Professional only)AV-out Cable(Professional only)Battery AC/DC Power Adapter Accessories (Optional)English8Names of PartsWEBCAMEquipped with webcam.TFT LCD/Touch ScreenUsers can operate the device using the touch screen.SpeakerSpeaker is built in.Power Button/Power LampFor turning the power on/off, and checking the status of power.Optical JoystickFor moving the mouse pointer.Operation Status Indicator P ower Save Mode Indicator/Disk Device Indicator/Battery Charging Status Indicator/Wireless LAN IndicatorPower Save Mode Indicator This light is turned on while the device is in power save mode. Disk Device Indicator This light is turned on while the disk drive is being accessed. Battery Charging Status Indicator Indicates the battery charging statusWireless LAN indicatorIndicates the operation status of the wireless LAN device.Keyboard Status Indicators Indicates the status of Num Lock, Caps Lock, and Scroll Lock.English9Names of PartsThe keyboard may be different for each country.In order to use the orange colored keys on the keyboard, press the keys and the Fn key together.Use these keys for left or right mouse click.Esc KeyIt is usually used for terminating or interrupting programs.Function Keys (F1~F12) and Number Keys U sages are different depending on the operatingsystem used and application program. Functionkeys and numbers from 0 to 9.PrtSc Key (Print Screen) This key is used for printing the screen or temporarily saving the screen.Enter Key E nter key is used to indicate to the computer that one command input is completed,and it is also used for making a new line.Shift Key T his key is used when entering the character shown on the upper part of each key,upper or lower case of English characters, or hot keys.Fn KeyThis key is used together with function keys.Caps Lock Key E nglish characters will be in upper case when entered with Caps Lock light on.Pressing this key one more time will turn off the light. This key has no effectwhen entering Korean.Windows Key I t is a Start Menu button provided by Microsoft Windows, and pressing thebutton will display Start Menu.Text Keys Includes text entry keys, space key for entering space, and keys for other special symbols.C ursor Moving Keys These are to move the cursor while using programs.Edit Keys PgUP/Home/PgDn/End Keys for moving pages while using programs.English10Names of PartsEnglish11Names of PartsRear ViewThe figure below shows the rear side of the main body without the battery. (Refer to Page 17~18 for Separating/Attaching battery.)English12Installation and Cable ConnectionInsert the earphone to the earphone port on the lower side of the handset.English13Installation and Cable Connection(Optional)For connecting TV or monitor. (Professional only)English14Installation and Cable ConnectionConnect the USB link cable to the multi-IO port on the left side of the handset. (Professional only)English15English16Installation and Cable ConnectionHow to Insert :English17Separating · Attaching BatteryHow to Remove the BatteryPress the Battery Open button on the right side of the handsetPush the button in the direction of the arrow.Hold the tip of the battery and lift it up.18Separating · Attaching BatteryHow to Insert the BatteryPush the battery in the directionof the arrow.EnglishEnglish19Basic Operationmay not be saved.Turning off the power with the button works depending on the power option configuration of Windows.Dragwhile holding the finger on the screen, and release at the final destination.It has the same effect as the drag function with a PC mouse.Touch ScreenEnglish20Basic Operation1Wireless LAN Power Activate the wireless LAN.2Bluetooth PowerActivate the Bluetooth function.3Camera PowerActivate the webcam.4Modem PowerActivate the Modem function.5Optional Setting (Professional only)Speaker OFF: T o turn on/off the internal speakerwhile using AV-OUT6System InformationTo check the product information.7ConfigConfigure the environment settings.WiFi and 3G Modem (or HSDPA, HSUPA) do not operate simultaneously.viliv Manager is executed by double touching vilivManager on the screen.1234567English21Recovery Solution (AMI Rescue) GuideAs an image-based OS recovery solution, it recovers to the initial status of shipment from factory when HDD of user cannot be booted from OS or it has problems.Execution of Recovery Solution (AMI Rescue)press the F10 key 1-2 times.As the logo disappears, Pre-Boot Menu window appears.ⷀI Fn key on the lower right side of the keyboard.Pre-Boot MenuService.AMI Rescue Lite-WizardWhen clicking Restore OS the recovery of OS.(Partition 0 on disk 0 was successfully restored.)If you press OK button, the system is booted againautomatically.N ow, if you boot to Windows, OS will be in the initial status ofshipment from factory.English22Product Name N5CPU & Chipset Intel® Atom TM 1.33 (Z520) + SCH US15W LCD 4.8-type WSVGA (1024 x 600) / Touch Panel RAM 1GB StorageSSD 32GB LANIEEE 802.11b/g WWLAN (Optional)WiMAX, HSDPA BluetoothBluetooth Ver2.0 + EDR ConnectorEarphone Port x1, USB x1, Multi I/O (USB Link, D-sub, AV-out) x1 (Professional only), MicroSD Slot x1AudioInternal speakers BatteryLithium Polymer (Removable) Voltage 3.7V Capacity : 4250mAh CameraWebcam Built in Dimension172 (W) x 86.5 (H) x 25.5 (T) mm OSMicroSoft Windows Operation Temperature 0°C ~ 40°CSpecificationsThe specifications below may be changed for enhancement of product performance without prior notice.English23MemoEnglish24Memo。

中庆V5系列产品说明书系列产品说明书————LED LED 管理工具V5.5使用说明书使用说明书北京中庆微数字设备开发有限公司北京中庆微数字设备开发有限公司ZHONGQING DIGITAL ZHONGQING DIGITAL EQUIPMENT CO., LTD EQUIPMENT CO., LTD..二零零六年七月二零零六年七月北京市海淀区上地东路1号盈创动力园E402A,100085 Page 1 Tel:(010)5885 1581/1582,Fax:(010)5885 1593LED 管理工具V5.5使用说明书使用说明书为了配合LED 显示屏连机系统的应用,我公司针对V5连机控制系统开发了一套LED 管理工具软件。

1、简介、简介LED 管理工具V5.5版本可支持V5-A02、V5-B 系列系统,应用于实像素显示屏和虚拟像素显示屏,对于虚拟像素显示屏,可以支持虚实转换功能。

运行本软件,可以使LED 显示屏同步显示微机监视器屏幕上任意位置的显示内容,而且每种基色还可作256级梯度的亮度调整,不但可以重新设置显示屏的画面颜色,还使LED 显示屏具有节能的绿色效果;此外,还可对整个LED 屏作画面锁定、黑屏的操作。

2、系统要求、系统要求2.1 2.1 运行环境运行环境运行环境操作系统操作系统中文WINXP/2000/NT4.0/9x/ME最低配置最低配置CPU: 奔腾133MHz 以上内存:32M显卡:标准VGA 256显示模式以上其它:无建议配置建议配置CPU:奔腾233MHz 或更高内存:128M 以上显卡:SVGA 16位色以上显示模式设置要求设置要求适用于分辨率1024×768以内的屏体设置,通过串口控制。

2.2 2.2 安装安装安装步骤:双击LedV5.5_Setup_Chs_vip.exe,进入安装界面,如图:点击【下一步】,然后按照设置向导,进行安装即可。

如须更改安装目录和程序项文件夹,在相应步骤进行修改即可。

model PERSONAL HEATER OWNER’S GUIDEREAD AND SAVE THESE INSTRUCTIONS2English 800.234.0604****************We expect this product to beperfect.If it is not, we will make it right.Important Safety Instructions (4)Safety Features (8)Controls (9)How To Use (10)Cleaning (11)Storage (12)Reset Heater .....................................................................................12Troubleshooting . (13)Warranty (14)CONTENTS3EnglishREAD ALL INSTRUCTIONS BEFORE USING THIS HEATER IMPORTANT SAFETY INSTRUCTIONSThis owner’s guide and any additional inserts are considered part of the product. They contain important information about safety, use and disposal. Before using the product, please familiarize yourself with all operating and safety instructions. Please keep all documents for future reference and pass these documents on, together with the product, to any future owner. See to view, download and print the most current version of this owner’s guide.INTENDED USE: This product is intended to heat and circulate the air in indoor living spaces only. This product is not intended for commercial or industrial use. This heater is not intended for use in bathrooms, laundry areas, and similar damp locations. The manufacturer assumes no responsibility for damage or injury due to unauthorized use or product modification. Failure to follow these directions will void the product warranty. WARNING: When using electrical appliances, basic precautions should always be followed to reduce the risk of fire, electric shock, injury to persons, and hyperthermia, including the following:WARNING: Risk to Children and Impaired Persons- Extreme caution is required during the installation, operation, cleaning and maintenance of this product by or around children 12 years of age and younger and anyone with reduced physical, sensory or mental capabilities, and whenever the heater is left operating and unattended. Children should be supervised to ensure that they do not play with the appliance, its parts and packaging material. WARNING: Risk for Heat Stroke (Hyperthermia)- Hyperthermia can result in death. Symptoms of hyperthermia include high body temperature, headache, nausea, vomiting, tiredness, dizziness, fainting, and rapid pulse. If you begin to experience symptoms related to hyperthermia, turn off the heater and seek medical attention.- To avoid excessive room temperatures which can cause hyperthermia: DO NOT leave product running unattended in a confined space around infants, or individuals with reduced physical, sensory, or mental capabilities.4EnglishINSTALLATION WARNING—To reduce risk of fire, electrical shock and injury to persons, observe the following:- A heater has hot and arcing or sparking parts inside. Do not use it in areas where gasoline, paint, or flammable liquids are used or stored.- Do not use this heater in an RV, boat or during any application where battery power is converted to AC power.- Place this product at least 3 feet away on all sides from electrical outlets, furniture, pillows, bedding, papers, clothes, curtains and other objects that may cause or catch on fire. Do not place the heater near a bed because objects such as pillows or blankets can fall off the bed and be ignited by the heater.- To prevent a possible fire, do not place the heater on soft surfaces, like a bed, where air intakes or exhaust can be blocked in any manner.- No part of this product (the appliance, power cord, plug, packaging, etc.) should be placed near furnaces, fireplaces, stoves or other high temperature heat sources.- Do not use on an uneven or unstable surface.- Operate only in the upright position.- This appliance, power supply, power cord and plug cannot come into contact with water. Do not use this product on wet surfaces. Do not use this product in a bathtub or shower or position where it may fall into a bathtub, shower, laundry, swimming pool or other water container. Do not use in a window, outdoors, or exposed to weather or elements.- Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or similar coverings. Do not route underfurniture or appliances. Arrange cord away from traffic area and where it will not be tripped over. The cord should not hang over edges of counters or be placed where it can be crimped or closed in doors. Place appliance near an easily accessible outlet so the product can be unplugged quickly during an emergency.- Do not modify the product with any aftermarket accessory. SAFE USE WARNING—To reduce risk of fire, electrical shock and injury to persons, observe the following:- Use this heater only as described in this manual. Any other use not recommended by the manufacturer may cause fire, electric shock, or injury to persons.- Extreme caution is required at all times a heater is in operation. Always unplug heater when not in use. Vornado does not recommend unattended and unsupervised use of this heater. - This heater is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. If provided, use handles when moving this heater.- Always plug heaters directly into a wall outlet/receptacle. Never use with an extension cord or relocatable power tap (outlet/power strip).- Do not use this heater on a surge-protected unit or Ground Fault Circuit Interrupted (GFCI) outlet.- Before plugging power cord into electrical outlet, be sure that all electrical information on the rating label, including voltage, is compatible with your outlet’s power supply.- To reduce likelihood of circuit overload, fire and electric shock, do not operate with a solid state speed device, such as5Englisha dimmer control switch. Do not use this heater with a timer designed to automatically turn the unit on or off, as this may accidentally disable the heater’s thermal cutout safety feature. - Use of this appliance on the same electrical circuit as another high energy use product, such as a vacuum cleaner, blender, variable speed fan or circular saw is not advised.- Risk of fire. Do not operate any heater with a damaged cord or plug or after the heater malfunctions, has been dropped or damaged in any manner. Discard heater, or return to a Vornado authorized service facility for examination and/or repair.- Do not sit or stand on product.- Never use the cord as a handle or otherwise yank, strain or stretch the power cord.- Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause an electric shock or fire, or damage the heater.- Check your heater cord and plug connections. A loose fitting outlet can cause the plug to overheat or cause a fire. Be sure plug fits tight in the outlet. Check frequently during use to make sure plug and outlet are not hot. If so, discontinue using heater and have outlet replaced by a qualified electrician.- Never ignore the signs of an electrical problem, such as: warm outlet coverplates, sparks when plugging in or operating, lights flickering/dimming during operation. Immediately turn off and unplug the appliance if any such problems are noticed. Contact a qualified electrician to investigate possible causes before operating the appliance again.- Note: Heaters draw more current than small appliances, overheating of the outlet may occur even if it has notoccurred with the other appliances.- Before moving, repositioning, servicing, cleaning and when not in use, use the product controls to turn off the power and then unplug. To disconnect from outlet, grasp and pull only the plug. Also, power off and unplug if the product will be left unattended for an extended period of time or during electrical storms.- This appliance has a polarized plug (one blade is wider than the other.) To reduce the risk of electrical shock, this plug is intended to fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician. Do not attempt to defeat this safety feature.- If your heater suddenly stops working:• This heater is equipped with a thermal cutout safety feature designed to automatically shut off when overheating isdetected. See the “RESET HEATER” instructions in thisguide to determine how to check and reset the heater. • If the heater and other electrical products suddenly stopworking at the same time, your home circuit breakeror fuse may have tripped due to an overload of power.Consider only running your heater on the “low” setting,only running one heater at once and unplugging all other electrical products while running the heater, and/or hiring an electrician to install an additional circuit to your home’s electrical system.SERVICING WARNING—To reduce risk of fire, electrical shock and injury to persons, observe the following:6English- Clean your product regularly, only as is instructed in thismanual. Prior to cleaning, turn off the power on yourproduct and unplug. Do not use gasoline, thinners, solvents,ammonias or other chemicals for cleaning. Refer to theCLEANING instructions provided.- Do not open appliance housing while product is plugged in.To avoid risk of shock, all service and/or repairs must be doneby a Vornado Authorized Service Center.SAVE THESEINSTRUCTIONSEnglish78EnglishSAFETY FEATURESTIP-OVER: If heater tips over, safety shut-off system cuts power to heater. The red indicator light will not illuminate again until you position the heater back in upright position and power is restored.AUTOMATIC SAFETY SHUT -OFF SYSTEMIf airflow becomes blocked, power to heater is shut off to prevent overheating.AUTOMATIC TIP-OVER PROTECTION If tipped more than 10 degrees in any FINGER-FRIENDLY DESIGN Resists curious fingers.COOL-TOUCH CASE Safe to touch, even on high heat setting.9English CONTROLSPOWER On ( I )Off (O)MODEHigh Heat (II) 750 watts,Low Heat (I) 375 watts or Fan Only .10EnglishHOW TO USEBefore use, check appliance for visible damage. DO NOT USE THIS HEATER if there is evidence of damage. If any damage is found, contact Vornado Air LLC at 1-800-234-0604.3. Plug power cord into standard grounded wall outlet.2. Position heater so airflow is not obstructed.1. Use the slight recess onback of heater for lifting and carrying.4. Press Power switch and select Mode. The red light illuminates to indicate the heater is on. To use as personal fan, select the centerposition on the switch for Fan Only .11English CLEANINGYou should periodically blow out the heater with pressurized air to keep heat element and motor clear of dust, hair and debris that can build up inside the heater as it moves air during use. This also eliminates unwanted odors caused by accumulation of these particles inside the unit.Because your heater moves a substantial amount of air, it will need regular cleaning. Cleaning the outside of the heater is recommended on a weekly basis. If service is required, return your heater to Vornado. See WARRANTY for instructions.1. Unplug heater before cleaning.2. Use brush attachment on household vacuum cleaner to vacuum any accumulated dust off Air Inlets on back of heater.3. Use brush attachment on household vacuum cleaner to vacuum any accumulated dust off the Front Outlet Grill.4. Wipe down the entire heaterwith a soft, dry cloth.Note: Do not modify the product with any aftermarket accessory.12EnglishRESETTING YOUR VORNADO HEATERYour Vornado Heater has a multilevel safety shut-off system designed to prevent overheating. Overheating may occur when the inlets or outlet are blocked. If this happens, the safety shut-off system cuts power to the heater and you must to manually reset the heater.1. Power heater off, then unplug power cord.2. Remove any obstructions.3. Wait 5–10 minutes, allowing heater to cool down.4. Plug in power cord and place heater in desired position.5. Press Power switch On. Your Vornado Heater should now function normally.Note: If the safety shut-off system repeatedly shuts off your heater or if it will not reset after following the above procedure, call Vornado Consumer Services Department toll-free at 1-800-234-0604.During the off-season or after extended periods of non-use, you may choose to store your heater. To ensure long life of the product, it is recommended to store your heater by following these instructions:1. Unplug power cord and bundle loosely.2. Cover, or place back in retail carton if available. This preventsheater from accumulating dust over time.3. Store heater in cool and dry location.STORAGERESET HEATERCleaning is recommended before storage.DISPOSALDispose of all packagingmaterials in an environmentally responsible manner.TROUBLESHOOTINGEnglish13Vornado Air LLC (“Vornado”) warrants to the original consumer or purchaser this Vornado® Whole Room Heater (“Product”) is free from defects in material or workmanship for a period of three (3) years from the date of purchase. If any such defect is discovered within the warranty period, Vornado, at its discretion, will repair or replace the Product at no cost.Forwarrantyservice:******************************************************** Authorization (“RA”). Please have or include your Product’s model number and serial number, as well as your name, address, city, state, zip code, e-mail, and phone number when contacting Vornado for warranty service. Or to file a contactless warranty claim, visit /contact-us.After receiving the RA form, ship your Product to: Vornado Air LLC Attn: Warranty & Repair 415 East 13th Street Andover, KS 67002. For your convenience, please have your model number and serial number when contacting Vornado with service inquiries. To assure proper handling, packages must be clearly marked with the RA number. Packages not clearly marked with the RA number may be refused at the receiving dock. Please allow 2-3 weeks for warranty service and return of your Product after the Product is received.This warranty does not apply to defects resulting from abuse of the Product, modification, alteration, mishandling, improper maintenance, commercial use or repair or service of the Product by anyone other than Vornado; damages which occur in shipment or are attributed to acts of God. Improper product use, which includes using an external device thatalters or converts the voltage or frequency of electricity, or shipping a Vornado productto a country not intended for use will void all warranties. Any unauthorized product modification, repair by unauthorized repair center, or use of non-approved replacement parts is not recommended and any consequences will not be covered by support services or product warranties. The product warranty will be honored only on models that are being used in the country intended. REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE CONSUMER. VORNADO SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON THIS PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ON THIS PRODUCT IS LIMITED IN DURATION TO THE DURATION OF THIS WARRANTY. Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how long an implied warranty lasts, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may have other rights that vary from state to state. The manufacturer assumes no responsibility for damage caused by failureto follow these instructions or improper product use. Any such actions will invalidate the product warranty.All company names and product names are trademarks of their respective owners. ©All rights reserved. All technical information, data, and instructions for the installation, connection, and operation contained in these instructions for use correspond to the latest available information at time of printing. The contents of this manual may differ slightly from the actual product. Observe any additional supplements.WARRANTYWe expect this product to be perfect. If you’re not satisfied with this product, let us know.We’re Here to Help 800.234.0604 ****************14English。

INVERTEC V250-SOPERATOR’S MANUALIM490-CFebruary, 2001Safety Depends on YouLincoln arc welding and cutting equipment is designed and b uilt with safety in mind. However, your overall safety can be increased by proper installation ... and thought-ful operation on your part.DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS CONTAINED THROUGHOUT.And, most importantly, think b efore you act and be careful.™Copyright © 2001 Lincoln Global Inc.ISO 9001Designed and Manufactured Under aQuality Program Certified by This manual covers equipment which is nolonger in production by The Lincoln Electric Co. Speci cations and availability of optional features may have changed.Mar ‘95for selecting a QUALITY product by Lincoln Electric. We want you to take pride in operating this Lincoln Electric Company product ••• as much pride as we have in bringing this product to you!Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.The level of seriousness to be applied to each is explained below:vvvi---------------------------------------------------------------------Figure A.1 Input Voltage Reconnect InstructionsQUICK DISCONNECT PLUGSA quick disconnect system is used for the welding cable connections. The welding plug included with the machine is designed to accept a welding cable size of 1/0 to 2/0.1.Remove 1 in. (25mm) of welding cable insulation.2.Slide rubber boot onto cable end. The boot endmay be trimmed to match the cable diameter.Soap or other lubricant will help to slide the boot over the cable.3.Slide the copper tube into the brass plug.4.Insert cable into copper tube.5.Tighten set screw to collapse copper tube. Screwmust apply pressure against welding cable. The top of the set screw will be well below the surface of the brass plug after tightening.6.Slide rubber boot over brass plug. The rubberboot must be positioned to completely cover all electrical surfaces after the plug is locked into the receptacle.25 mm1 in.WELDING CABLEBOOTTRIMSET SCREWBRASS PLUGCOPPER TUBEThe Invertec V250-S is a 250 amp arc welding power source that utilizes single or three phase input power, to produce constant current output. The welding response of this Invertec has been optimized for stick (SMAW) and TIG (GTAW).OPERATIONAL FEATURESThe Invertec V250-S provides continuous total range output current adjustment, selectable welding modes and local or remote output control. Welding character-istics can be controlled via an arc force control. Additionally, starting characteristics can be adjusted via a “hot start” control.WELDING CAPABILITYThe Invertec V250-S is rated at 250 amps, 35% duty cycle (based on a 10 minute cycle). It is also rated at 165 amps, 100% duty cycle, and 200 amps, 60% duty cycle.LIMITATIONSThe V250-S is not recommended for pipe thawing. The V250-S should not be powered from the auxiliary power supply of an engine welder. Special protectioncircuits may operate causing loss of output.1. Power Switch - Place the lever in the “ON” position toenergize the machine. When the power is on, the fan will operate and the output will be energized in SMAW modes. GTAW mode requires remote trigger to energize the output.2. Output Control - This controls the output current. Controlis provided over the entire output range of the power source with 1 turn of the control knob. This control may be adjusted while under load to change power source output. When using remote control this function becomes the limit setting.3. Local/Remote Switch - Place in the “LOCAL” position toallow output adjustment at the machine. Place in the “REMOTE” position to allow output adjustment at remote pot or amptrol. In Remote, the machine output control pot is the limit setting for remote control.4. Mode SwitchGTAW Optimized for touch start use. Triggering at amphenol is required using an Arc Start Switch, Amptrol or similar means. Short circuit current is limited to approx-imately 25 amps to aid in touch starting.CC Soft Best for EXX18 thru EXX28 stick electrodes.Output energized when machine is on.CC Crisp Use this mode for stick welding with EXX10 thru EXX14 electrodes. Output energized when machine is on.5. Hot Start - Controls the amount of starting energy inSMAW. The Hot Start setting will set the amount of extra power given during the initial strike.A Hot Start setting of 100% will give you an additionalstriking current 100% above the welding set current*.(Striking current in this example will be 200% of the set current). For a Hot Start setting of 100%, the current will decrease back to the set current in one second.A Hot Start setting of 50% will give you an additionalstriking current 50% above the welding set current*.(Striking current in this example will be 150% of the set current). For a Hot Start setting of 50%, the current will decrease back to the set current in .5 second.* The maximum striking current is 300 Amps.CONSTANT CURRENT PROCESSES MANUAL ARC WELDING (STICK)The Invertec may be utilized as a manual DC arc welder with the electrode cable, work cable, and elec-trode holder being the only equipment required.AIR CARBON ARC CUTTINGAir carbon arc cutting may be performed with the Invertec within its output rating using 5/32" (3.9mm) and 3/16" (4.7mm) diameter carbon rods. Output cables, an air carbon arc electrode cable assembly, and a source of compressed air are required.NOTE:1.Best performance will be at settings of 200 ampsand below.2.The electronic protection circuit in the V250S willlimit the current to approximately 290 amps.TIG WELDINGThe V250S is capable of touch start TIG welding. An electrode cable, work cable, Arc Start Switch or Amptrol, TIG torch, and gas supply with regulator are required. Refer to Accessories section of this manual.Touch starting is done as follows:1. Place the shield cup edge on the work piece.2. Rock the tungsten down to touch.3. Trigger the output.4. Gently rock back the tungsten from the work-piece.Note: The short circuit current is limited to 25 amps to aid in touch starting. Panel output controlbecomes the current limit setting when inremote controlPARALLEL OPERATIONThe Invertec’s are operable in parallel. For best results, the currents of each machine should be rea-sonably well shared. As an example, with two machines set up in parallel for a 300 amp procedure, each machine should be set to deliver approximately 150 amps, not 200 amps from one and 100 amps from the other. This will minimize nuisance feedback conditions. In general, more than two machines in par-allel will not be effective due to the voltage require-ments of procedures in that power range.To set machine outputs, start with output control pots and arc force pots in identical positions. Adjust out-puts and arc forces to maintain current sharing while establishing the proper output current. OVERLOAD PROTECTIONThe machine is electrically protected from producing high output currents. Should the output current exceed 290A, an electronic protection circuit will reduce the current to less than 200A. The machine will continue to produce this low current until the pro-tection circuit is reset. Reset occurs when the output load is removed.THERMAL PROTECTIONThermostats protect the machine from excessive operating temperatures. Excessive temperatures may be caused by a lack of cooling air or operating the machine beyond the duty cycle and output rating. If excessive operating temperature should occur, the thermostats will prevent output voltage or current. Thermostats are self-resetting once the machine cools sufficiently. If the thermostat shutdown was caused by excessive output or duty cycle and the fan is operating normally, the Power Switch may be left on and the reset should occur within a 15 minute period. If the fan is not turning or the air intake louvers were obstructed, then the power must be switched off for 15 minutes in order to reset. The fan problem or air obstruction must also be corrected.OPTIONS / ACCESSORIESCABLE PLUGSK852-70 -Cable Plug Kit for 1/0-2/0 cable. Attaches to welding cable to provide quick disconnect from machine.K852-95 -Cable Plug Kit for 2.0-3/0 cable.NOTE: Two K852-70 plugs are included with the V250-S.REMOTE CONTROLSK857 - Remote Output Control for stick welding.K963 - Hand Amptrol tm for TIG welding. When the V250-S’s Output Control is in the “Remote” position, the hand Amptrol energizes the output and controls the output remotely. The Hand Amptrol connects directly to the 6 pin Amphenol.Note:When used with the V250-S, the grounding strap on the connector end of K963 must be discon-nected to avoid electrical noise problems. Details are listed under REMOTE CONTROL RECEPTACLE in INSTALLATION section in this manual.K870 - Foot Amptrol tm for TIG welding. When the V250-S’s Output Control is in the “REMOTE” position, the foot Amptrol energizes the output and controls the output remotely. The Hand Amptrol connects directly to the 6 pin Amphenol.K814 -Arc Start Switch. Energizes the output for TIG welding if remote output control of the amperage is not desired. When using the Arc Start Switch set the Output Control to the “LOCAL” position.INPUT FILTER CAPACITOR DISCHARGE PROCEDURE1.Turn off input power or disconnect input powerlines.2.Remove the 5/16" hex head screws from the sideand top of the machine and remove wrap-around machine cover.3.Be careful not to make contact with the capacitorterminals that are located in the top and bottom of the Power Board.4.Obtain a high resistance and high wattage resistor(25-1000 ohms and 25 watts minimum). This resis-tor is not supplied with machine. NEVER USE A SHORTING STRAP FOR THIS PROCEDURE.5.Locate the four capacitor terminals (large hex headcap screws) shown in Figure D.1. One pair at the top and one pair at the bottom of the Power Board.e electrically insulated gloves and insulated pli-ers. Hold body of the resistor and connect resistor leads across the two capacitor terminals. Hold resistor in place for 10 seconds. DO NOT TOUCH CAPACITOR TERMINALS WITH YOUR BARE HANDS.7.Repeat discharge procedure for the capacitor onother two terminals.8.Check voltage across terminals of all capacitorswith a DC voltmeter. Polarity of capacitor terminals is marked on PC board above terminals. Voltage should be zero. If any voltage remains, repeat this capacitor discharge procedure.FIGURE D.1 — LOCATION OF INPUT FILTER CAPACITOR TERMINALS.ROUTINE MAINTENANCE1.Perform the following preventive maintenanceprocedures at least once every six months. It is good practice to keep a preventive maintenance record; a record tag attached to the machine works best.2.Remove the machine wrap-around cover and per-form the input filter capacitor discharge procedure (detail at the beginning of this chapter).3.Keeping the machine clean will result in cooleroperation and higher reliability. Be sure to clean the following areas with a low pressure air stream. See figure D.2 for component locations.•Power and control printed circuit boards•Power switch•Main transformer•Input rectifier•Heat sink fins•Input Filter Capacitors•Output Terminals4.Examine capacitors for leakage or oozing. Replaceif needed.5.Examine the sheet metal case for dents or break-age. Repair the case as required. Keep the case in good condition to ensure that high voltage parts are protected and correct spacings are maintained. All external sheet metal screws must be in place to assure case strength and electrical ground continuity.6.Check electrical ground continuity. Using an ohm-meter, measure resistance between either output terminal and an unpainted surface of the machine case. (See Figure D.2 for locations.) Meter reading should be 500,000 ohms or more. If meter reading is less than 500,000 ohms, check for electrical components that are not properly insulated from the case. Correct insulation if needed.7.Replace machine cover and screws.FILTER CAPACITOR CONDITIONING A protection circuit is included to monitor the voltage across filter capacitors C1 and C2. In the event that the capacitor voltage is too high, the protection circuit will prevent output. Nominal trip setting is at 230/460 VAC +15%. Reset occurs about 3% lower (230/460 VAC +12%).On new installations, the protection circuit may also prevent output providing all these circumstances are met:1.Machine is connected for 380-415 or 440-460VAC input.2.Machine did not have power applied for manymonths.3.Machine will not produce output when power isfirst switched on.If these circumstances apply, the proper action is to switch the machine on and let it idle for up to 30 min-utes. This is required to condition the filter capacitors after an extended storage time. The protection circuit will automatically reset once the capacitor conditioning and resultant voltage levels are acceptable. It may be necessary to turn the power switch off and back on again after this period.FIGURE D.2 — LOCATION OF MAINTENANCE COMPONENTS.L 9280N O T E : T h i s d i a g r a m i s f o r r e f e r e n c e o n l y . I t m a y n o t b e a c c u r a t e f o r a l l m a c h i n e s c o v e r e d b y t h i s m a n u a l. T h e s p e c i f i c d i a g r a m f o r a p a r t i c u l a r c o d e i s p a s t e di n s i d e t h e m a c h i n e o n o n e o f t h e e n c l o s u r e p a n e l s . I f t h e d i a g r a m i s i l l e g i b l e , w r i t e t o t h e S e r v i c e D e p a r t m e n t f o r a r e p l a c e m e n t . G i v e t h e e q u i p m e n t c o d e n u m b e r ..WIRING DIAGRAM- CODES:10102,10103D I ME N S I O N P R I N TM 172298-5-94Now Available...12th EditionThe Procedure Handbook of Arc WeldingWith over 500,000 copies of previous editions published since 1933, the Procedure Handbook is considered by many to be the “Bible ” of the arc welding industry.This printing will go fast so don ’t delay. Place your order now using the coupon below.The hardbound book contains over 750 pages of welding information, techniques and procedures. Much of this material has never been included in any other book.A must for all welders, supervisors, engineers and designers. Many welding instructors will want to use the book as a reference for all students by taking advantage of the low quantity discount prices which include shipping by 4th class parcel post.$15.00postage paid U.S.A. MainlandHow To Read Shop DrawingsThe book contains the latest information and application data on the American Welding Society Standard Welding Symbols. Detailed discussion tells how engineers and draftsmen use the “short-cut ” language of symbols to pass on assembly and welding information to shop personnel.Practical exercises and examples develop the reader ’s ability to visualize mechanically drawn objects as they will appear in their assembled form.187 pages with more than 100 illustrations. Size 8-1/2” x 11”Durable, cloth-covered board binding.$4.50postage paid U.S.A. MainlandNew Lessons in Arc WeldingLessons, simply written, cover manipulatory techniques;machine and electrode characteristics; related subjects,such as distortion; and supplemental information on arc welding applications, speeds and costs. Practice materials,exercises, questions and answers are suggested for each lesson.528 pages, well illustrated, 6” x 9” size, bound in simulated,gold embossed leather.$5.00postage paid U.S.A. MainlandNeed Welding Training?The Lincoln Electric Company operates the oldest and most respected Arc Welding School in the United States at its corporate headquarters in Cleveland, Ohio. Over 100,000stu-dents have graduated. Tuition is low and the training is “hands on ”For details write:Lincoln Welding School 22801 St. Clair Ave.Cleveland, Ohio 44117-1199.and ask for bulletin ED-80 or call 216-383-2259 and ask for the Welding School Registrar.Lincoln Welding SchoolBASIC COURSE $700.005 weeks of fundamentalsThere is a 10%discount on all orders of $50.00 or more for shipment at one time to one location.Orders of $50 or less before discount or orders outside of North America must be prepaid with charge, check or money order in U.S. Funds Only.Prices include shipment by 4th Class Book Rate for U.S.A. Mainland Only.Please allow up to 4 weeks for delivery.UPS Shipping for North America Only.All prepaid orders that request UPS shipment please add:$5.00For order value up to $49.99$10.00For order value between $50.00 & $99.99$15.00For order value between $100.00 & $149.00For North America invoiced orders over $50.00 & credit card orders, if UPS is requested, it will be invoiced or charged to you at cost.Outside U.S.A. Mainland order must be prepaid in U.S. Funds. Please add $2.00 per book for surface mail or $15.00 per book for air parcel post shipment.METHOD OF PAYMENT:(Sorry, No C.O.D. Orders)CHECK ONE:Name:_______________________________________________Please Invoice (only if order is over $50.00)Address:_______________________________________________Check or Money Order Enclosed, U.S. Funds only _______________________________________________Credit Card - Telephone:_______________________________________________Signature as it appears on Charge Card:Account No.Exp Date|_|_||_|_|______________________Month YearUSE THIS FORM TO ORDER:Order from:BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199BOOKS OR FREE INFORMATIVE CATALOGS Telephone: 216-383-2211 or, for fastest service, FAX this completed form to: 216-361-5901.Lincoln Welding School Titles:Price Code QuantityCost(ED-80)New Lessons in Arc Welding $5.00L Seminar Information Procedure Handbook “Twelfth Edition ”$15.00PH (ED-45)How to Read Shop Drawings $4.50H Educational Video Information Incentive Management $5.00IM (ED-93) A New Approach to Industrial Economics $5.00NA James F. Lincoln Arc Welding The American Century of John C. Lincoln $5.00AC Foundation Book Information Welding Preheat Calculator $3.00WC-8(JFLF-515)Pipe Welding Charts $4.50ED-89SUB TOTALAdditional Shipping Costs if anyJapaneseChineseKoreanArabicREAD AND UNDERSTAND THE MANUFACTURER’S INSTRUCTION FOR THIS EQUIPMENT AND THE CONSUMABLES TO BE USED AND FOLLOW YOUR EMPLOYER’S SAFETY PRACTICES.SE RECOMIENDA LEER Y ENTENDER LAS INSTRUCCIONES DEL FABRICANTE PARA EL USO DE ESTE EQUIPO Y LOS CONSUMIBLES QUE VA A UTILIZAR, SIGA LAS MEDIDAS DE SEGURIDAD DE SU SUPERVISOR.LISEZ ET COMPRENEZ LES INSTRUCTIONS DU FABRICANT EN CE QUI REGARDE CET EQUIPMENT ET LES PRODUITS A ETRE EMPLOYES ET SUIVEZ LES PROCEDURES DE SECURITE DE VOTRE EMPLOYEUR.LESEN SIE UND BEFOLGEN SIE DIE BETRIEBSANLEITUNG DER ANLAGE UND DEN ELEKTRODENEINSATZ DES HER-STELLERS. DIE UNFALLVERHÜTUNGSVORSCHRIFTEN DES ARBEITGEBERS SIND EBENFALLS ZU BEACHTEN.JapaneseChineseKoreanArabicLEIA E COMPREENDA AS INSTRUÇÕES DO FABRICANTE PARA ESTE EQUIPAMENTO E AS PARTES DE USO, E SIGA AS PRÁTICAS DE SEGURANÇA DO EMPREGADOR.。

Industrial Drive for Fan and Pump0.75~30kW (1~40HP) 3Phase 200~230Volts 0.75~450kW (1~600HP) 3Phase 380~480Volts 5.5~110kW (7.5~150HP) 3Phase 525~600VoltsStarvert ip5aip5aLS Starvert SV-iP5A has been specifically designedand created to provide competitive solutions for fanand pump applications2Overview Model & TypeStandard Specifications WiringTerminal Configurations (Power Circuit Terminal)Terminal Configurations (Control Circuit Terminal)Programming KeypadProgramming Keypad (Parameter Navigation)Parameter Description Trial Run DimensionsDB (Dynamic Braking) UnitExternal DB Resistor / Peripheral Device48913171922232437394550C o n t e n t sStarvertip5aMarine type Certification From DNv Specialized Functions for Fan and pump energy Saving and High efficiencyUser-friendly Interface and easy MaintenanceIntelligent Control Mechanism3Drive Starvert iP5A SeriesSpecialized Functions for Fan and PumpThe iP5A, specifically designed for HVAC application, provides stable and cost-effective system performance.PID ControlDual PIDMulti Motor Control (0.75~450kW)The iP5A MMC function provides cost-effective, simultaneous control of up to eight motors, without requiring external controllers.Marine Type Certification From DNVThe iP5A has been tested and certified by DNV to comply with International Marine requirements4In the centrifugal fan and pump field, PID control is provided as a standard function in order to maintain a constant control of pressure, flow and oil level. This function includes Pre-PID, Sleep and Wake up and output inverse sub-functions.Where external or cascaded PID control is required, the built-in dual PID algorithm of the iP5A can be utilized to satisfy various system requirements.0.750.500.400.250.200.1010203040506070Load %Conventional drive controlip5aDamper controlreduction percentage600RPMv/F30% manual energy saving automatic energy savingEnergy Saving and High EfficiencyThe iP5A, specifically designed for fan and pump applications, guarantees energy savings by optimizing the system.Load change may incur energy losses but the optimized flux control of iP5A results in more outstanding energy saving compared to previous models.Automatic Energy SavingSleep and Wake-up FunctionWhen using the drive in damp conditions, this function protects both the motor and the drive's outputPre Heating FunctionWhen 2 or more fans, or a high inertia load are connected to the drive, the iP5A detects the motor speed after a momentary power failure, enabling the motors to be smoothly reaccelerated without mechanical and electrical shock-loading to the system.Flying Start FunctionpID referencepID feedbackrun commandOutput frequencyWake-up mode returning to normal stateSleep mode adjusting output with detecting load(energy saving)Industrial Drive for Fan and Pump Starvert ip5a5Drive Starvert iP5A SeriesEnergy savings are obtained through the Sleep and Wake-Up functions of the iP5A, which enable the drive to automatically switch off during user-programmed low-load conditions and then to start up again when process demand increases.During unexpected power failure conditions, the iP5A can bring the load to a controlled stop, by utilizing the inertial energy. This can prevent further process problems or accidents.Safety StopThis algorithm reduces deceleration time, thereby improving system efficiency.Flux Braking AlgorithmIntelligent ControlBy taking ambient temperature into account, the iP5A can automatically adjust the Carrier (Modulation) Frequency.Automatic Carrier Frequency ChangeProtectionBecause of effectual functions and protection algorithms, the iP5A provides constant performance,in spite of external power fluctuations.During Power Dips or Momentary Power Outage, the drive output can be maintained by utilizing the residual mechanical energy in the load as a regenerative source. The duration of the power-dip ride-through depends on the load characteristics.Improved System Management during Power Dips and Momentary Power OutagesIn spite of external voltage fluctuations and lightning surges, the iP5A optimizes motor performance.Constant and Stable PerformanceUnder damp conditions, leakage currents can occur when using drives. These currents can cause a system failure. The iP5A low-leakage PWM algorithm reduces these leakage currents to ensure reliability of operation.Current Leakage Reduction AlgorithmZero vector Zero vectorvalid vector pWMvalid vectorpower failure for 1 secondpower failure for 3 secondsMecha -nical energyLoadMechanical energyConsumed energye m i t t e d e n e r g ythe mechanical energy stored during blackout can be used for driveユs power.6The iP5A has optimized protective functions, such as safety stop and pre-excitation of the motor, amongst others.Easy StartWhen pushing ‘STOP ’ key for 2~3 seconds in case drive turns on, the drive turns into ‘Easy Start Mode ’ with FWD, REV, and STOP command. ‘SHIFT/ESC ’ can return it to previous mode.Control method: V/F Control frequency: JogUser-friendly Keypad & Easy MaintenanceNPN/PNP InputiP5A has both NPN and PNP input, and you can select one of them easily.Abundant I/O SuggestionVarious Units of I/O DisplayThe iP5A display can be calibrated in many different types of process units.Built-in RS485 and Optional CommunicationThe built-In RS485 allows for communication without external option.However, the optional communication boards enable the iP5A to talk to BMS and most Industrial SystemsLong-life Condenser and Simple FrameworkiP5A adopts long-life condenser and enables easy maintenance in simple framework.Consumption Time DisplayiP5A displays consumption time of components so that users can replace them in time.Others•Removable terminal board •External fan available •Cooling fan on/off control3145672384126The iP5A construction allows for easy maintenance, with ease-of-access to all components.579Digital Input/OutputAnalog Input (Voltage + Current)/Output Pulse Input NTC/PTC Input8 points / 4 points (1+1) points /4 points 1 point 1 pointIndustrial Drive for Fan and Pump Starvert ip5a7Drive Starvert iP5A SeriesSV 0055iP5A2--NE200~230V Class380~480V ClassMotor Rating0.75kW (1Hp)1.5kW (2Hp)2.2kW (3Hp)3.7kW (5Hp)5.5kW (7.5Hp) 7.5kW (10Hp)11kW (15Hp) 15kW (20Hp) 18.5kW (25Hp) 22kW (30Hp) 30kW (40Hp) 37kW (50Hp) 45kW (60Hp) 55kW (75Hp) 75kW (100Hp) 90kW (125Hp) 110kW (150Hp) 132kW (200Hp) 160kW (250Hp)220kW (300Hp) 280kW (350Hp) 315kW (400Hp)375kW (500Hp) 450kW (600Hp)Sv0008ip5a-4Ne Sv0015ip5a-4Ne Sv0022ip5a-4Ne Sv0037ip5a-4Ne Sv0055ip5a-4Ne Sv0075ip5a-4Ne Sv0110ip5a-4Ne Sv0150ip5a-4NO Sv0185ip5a-4NO Sv0220ip5a-4NO Sv0300ip5a-4NO Sv0370ip5a-4O Sv0450ip5a-4O Sv0550ip5a-4O Sv0750ip5a-4O Sv0900ip5a-4O Sv1100ip5a-4OL Sv1320ip5a-4OL Sv1600ip5a-4OL Sv2200ip5a-4OL Sv2800ip5a-4OL Sv3150ip5a-4O Sv3750ip5a-4O Sv4500ip5a-4O380~480V Class (Classification)Sv0055ip5a-4Ne (CLaSS)Sv0075ip5a-4Ne (CLaSS)Sv0110ip5a-4Ne (CLaSS)Sv0150ip5a-4NOL (CLaSS)Sv0185ip5a-4NOL (CLaSS)Sv0220ip5a-4NOL (CLaSS)Sv0300ip5a-4NOL (CLaSS)Sv0370ip5a-4OL (CLaSS)Sv0450ip5a-4OL (CLaSS)Sv0550ip5a-4OL (CLaSS)Sv0750ip5a-4OL (CLaSS)Sv0900ip5a-4OL (CLaSS)Sv1100ip5a-4OL (CLaSS)Sv1320ip5a-4OL (CLaSS)Sv1800ip5a-4OL (CLaSS)Sv2200ip5a-4OL (CLaSS)Sv2800ip5a-4OL (CLaSS)Sv3150ip5a-4O (CLaSS)Sv3750ip5a-4O (CLaSS)Sv4500ip5a-4O (CLaSS)525~600V ClassSv0055ip5a-6Sv0075ip5a-6Sv0110ip5a-6Sv0150ip5a-6Sv0185ip5a-6Sv0220ip5a-6Sv0300ip5a-6Sv0370ip5a 6Sv0450ip5a-6Sv0550ip5a-6Sv0750ip5a-6Sv0900ip5a-6Sv1100ip5a-6Sv0008ip5a-2Ne Sv0015ip5a-2Ne Sv0022ip5a-2Ne Sv0037ip5a-2Ne Sv0055ip5a-2Ne Sv0075ip5a-2Ne Sv0110ip5a-2Ne Sv0150ip5a-2NO Sv0185ip5a-2NO Sv0220ip5a-2NO Sv0300ip5a-2NOModel & Type(CLASS)N: No Keypad Input VoltageMotor RatingSeries NameClassification8Industrial Drive for Fan and Pump Starvert ip5aStandard Specifications380~480V Class (0.75~90kW / 1~125HP)200~230V Class (0.75~30kW / 1~40HP)9Drive Starvert iP5A SeriesNote 1) Rated capacity (v 3。。V 。。I) is based on 220V for 200V class and 460V for 400V class. 2) Indicates the maximum applicable capacity when using a 4-Pole LS motor.3) Maximum output voltage will not exceed the input voltage. An output voltage less than the input voltage may be programmed if necessary. 4) IP20/UL Type1 with optional conduit, it can be modified to UL Type1.Standard Specifications525~600V Class (5.5~110kW /7.5~150HP)Note 1) Rated capacity (v 3 X V X I) is based on 220V for 200V class and 460V for 400V class. 2) Indicates the maximum applicable capacity when using a 4-Pole LS motor.3) Maximum output voltage will not exceed the input voltage. An output voltage less than the input voltage may be programmed if necessary.4) IP20/UL Type1 with optional conduit, it can be modified to UL Type1.10Industrial Drive for Fan and Pump Starvert ip5a(1) Rated capacity (√3×V×I ) is based on 220V for 200V class and 460V for 400V class. (2) Indicates the maximum applicable capacity when using a 4-Pole standard motor.(3) IP20 or UL Enclosed Type1 can be provided by the option. (4) IP20 or UL Enclosed Type1 is not provided.(5) Overload rating 120%, 1 min is based on ambient 25℃Common SpecificationsStandard Specifications Common Specifications (External)Industrial Drive for Fan and Pump Starvert ip5a WiringNote 1) 5G is Common Ground for Analog Input / Output.2) Use terminal V1 for V1, V1S (0~12V, -12~12V) input.WiringNote 1) 5G is Common Ground for Analog Meter Output (SO, S1) and External motor thermal detection (ET).2) Use terminal V1 for V1, V1S (0~12V, -12~12V) input.3) DC Reactor is built basically in drives for 15~280kW.Industrial Drive for Fan and Pump Starvert ip5aWiringNote) P1 (+) is not provided for wiring.Industrial Drive for Fan and Pump Starvert ip5a Terminal Configurations (Power Circuit Terminal)0.75~30kW (1~40HP) <200V/400V Class>37~90kW (50~125HP) / 315~450kW (400~600HP) <400V/600V Class>15~18.5kW (20~25HP) <Built-in DC Reactor Type, 400V Class>22~30kW (30~40HP) <Built-in DC Reactor Type, 400V Class>37~90kW (50~125HP) / 110 ~280kW (150~350HP) <Built-in DC Reactor Type, 400V Class>Note) P1 (+) is not provided for wiring.Terminal Configurations (Power Circuit Terminal)Wires & Terminal lugs* Use copper wires only with 600V, 75℃ ratings. For 7.5~11kW 240V type drives, R(L1), S(L2), T(L3) and U, V, W terminals are only for use with insulated ring type connector.Industrial Drive for Fan and Pump Starvert ip5aTerminal Configurations (Control Circuit Terminal)0.75~30kW / 1~40HP (200V/400V Class)37~450 kW/50~600HP (400V Class)Terminal Configurations (Control Circuit Terminal)Note) NC terminal is unavailableIndustrial Drive for Fan and Pump Starvert ip5aSink mode (NPN mode)•Put J1 switch down to set to Sink mode (NPN mode). CM terminal (24V GND) is common terminal for contact signal input.•The factory default is Sink mode (NPN mode).Source mode (PNP mode) Internal Power Supply Used•Put J1 switch up to set to Source mode (PNP mode). Terminal 24 (24V Power Supply) is common terminal for contact input signal.Source mode (PNP mode) External Power Supply Used•Put J1 switch up to set to Source mode (PNP mode).•To use external 24V Power Supply,make a sequence between external Power Supply (-) terminal and CM (24V GND) terminal.iP5A provides Sink/Source (NPN/PNP) modes for sequence input terminal on the control circuit. The logic of the input terminal is settable to Sink mode (NPN mode)/Source mode (NPN mode) by using the J1 switch. Connection method is shown below.Programming KeypadIndustrial Drive for Fan and Pump Starvert ip5a Programming Keypad (Parameter Navigation)Parameter Descriptioneither [Speed] (Hz or Rpm), [Percent], [Bar], [mBar], [kPa] or [Pa]. Output Frequency (Hz or Rpm; Unit of outupt speed) is displayed in DRV-00 during the Drive is running. User Unit reference (Unit of PID controller selected) is displayed in DRV-00 during the Drive is not running.2) DRV-15, DRV-18 will appear when APP-02 [Process PI Mode] is set to メYesメ. Also User Unit is displayed when one of I/O-86~ I/O-88 is set to either [Speed](Hz or Rpm), [Percent], [Bar], [mBar], [kPa] or [Pa]. 3)DRV-20 will appear when APP-80 [ExtProcess PI Mode] is set to メYesメ. 4) DRV-91/92 will appear only when DRV-22 is set to [2nd Source].Industrial Drive for Fan and Pump Starvert ip5aParameter DescriptionFU1-41~48 only displayed when FU1-40 is set to ‘User V/F’.10) Only displayed when FU1-51 is set to ‘Manual’.11) Only displayed when FU1-66 is set to ‘Yes’.31) Only displayed when FU1-75 is set to ‘Yes’.Industrial Drive for Fan and PumpStarvert ip5a14) FU2-26 is displayed when FU2-25 [Retry number] is set to [1~10]. 15) FU2-64 is displayed when FU2-60 is set to [Sensorless].Parameter DescriptionFU2-64 is displayed when FU2-60 is set to [Sensorless].Table 1) Switching frequency and fatory default value for each drive capacityIndustrial Drive for Fan and Pump Starvert ip5aW hen DRV-04 is set to either V1, V1S, I or V1+I or Pulse, only selected item codes are displayed in I/O-1~I/O-19.18) I /O-3,5,8,10,14,16 is displayed 0~100.00 [**] when App-02 is set to [proc PI mode] or APP-80 is set to [Ext PImode] and APP-06 PID Feedback Signal Selection is set to one of I, VI, Pulse, after then, one of I/O-86 ~I/O-88 is set to percentage, Bar, mBar, kPa, Pa except for Speed. Unit will be changed to selected unit. Only user unit displayed when APP-02 or APP-80 is set to [Yes], after APP-06 is set to one of I, V, Pulse, after then one of I/O-86 ~I/O-88 is set to either speed, percentage, Bar, mBar, kPa, Pa..Parameter DescriptionIndustrial Drive for Fan and Pump Starvert ip5a21) I/O-74 ~ I/O-75 displayed only when one of I/O-76 ~ I/O-79 is set to either FDT-1~FDT5Parameter Description38400 bps can be set only when the external communication option card is installed.23) Only I/O-92 ~ I/O-93 displayed when DRV-03/04 is set to [int485].Industrial Drive for Fan and Pump Starvert ip5aOnly APP-03 ~ APP-17 displayed when APP-02 is set to [Yes]. Only APP-03 ~ APP-17 and APP-63 ~ APP-65 displayed when APP-2 is set to [Yes].26) If APP-04 Aux Ref Mode is no set, DRV-04 setting will be reference of process PID. And APP -05 setting will be ignored27) If APP-04 is set, APP-04 will appear. And APP -05 setting value will be reference of process PID, DRV-04 setting will be ignored.28) Only APP-20 ~ APP-29 displayed only when one of I/O-20 ~ I/O-27 is set to either 。。2nd Func 。。.O nly APP-40 ~ APP-71 displayed when APP-01 is set to [MMC].30) O nly APP-81 ~ APP-97 displayed when APP-80 Ext PI mode is set to [Yes].Parameter DescriptionIndustrial Drive for Fan and Pump Starvert ip5a* Only the above EXT group displayed when the corresponding option board is installed.* Refer to the SUB board option manual for details.Parameter Description* Only the above COM group displayed when the corresponding option board is installed.* COM-61~66 parameter is used to LonWorks and BACnet communication.Industrial Drive for Fan and Pump Starvert ip5a Trial RunOperation Example (1)V/F Control + Analog Voltage Input (V1)+ Operation via Terminal (FX/RX)Operation condition•Control mode: V/F control•Frequency command:50 [Hz] analog input via V1 terminal•Accel/Decel time: Accel -15 [sec],Decel -25 [sec]•Drive mode: Run/Stop via FX/RX terminal,Control terminal: NPN modeTrial RunOperation Example (2) Array V/F control + Analog input (V1S)+ Operation via terminal FX/RXOperation condition•Control mode: V/F control •Frequency command:Setting 50 [Hz] via Analog input (V1S)•Accel/Decel time: Accel time 15 [sec], Decel time 25 [sec]•Drive mode: Run/Stop via FX/RX,Control terminal: NPN modeIndustrial Drive for Fan and Pump Starvert ip5a DimensionsDimensionsIndustrial Drive for Fan and Pump Starvert ip5a41Drive Starvert iP5A SeriesDimensions42Industrial Drive for Fan and Pump Starvert ip5a43Drive Starvert iP5A Series44Industrial Drive for Fan and Pump Starvert ip5aDB (Dynamic Braking) UnitTerminal Configuration•Group 1 -•Group 2 -•Group 3 -CM G POH N NB2GG P/B1B1B2B2B1N P45Drive Starvert iP5A Series46Industrial Drive for Fan and Pump Starvert ip5a DB (Dynamic Braking) UnitGroup 147Drive Starvert iP5A Series48Industrial Drive for Fan and Pump Starvert ip5a DB (Dynamic Braking) Unit49Drive Starvert iP5A SeriesExternal DB ResistoriP5A do not have built-in DB resistor on power stack as factory installation. External DB Unit and Resistor (Optional) should be installed. See the following table for more details (ED: 5%, Continuous Braking Time: 15 sec). If Enable duty (%ED) is increased to 10%, use external DB resistor having twice Wattage rating.Peripheral DeviceMCCB (Molded Case Circuit Breaker) and MC (Magnetic Contactor)50。