金石机器人样本201304s

- 格式:pdf

- 大小:8.85 MB

- 文档页数:20

张小只智能机械工业网

张小只机械知识库金石机器人助力渤海活塞全自动生产线

金石机器人常州有限公司与渤海活塞于2011年合作以来,为其配备多条活塞全自动柔性生产线,在用户现场已得到很好的验证效果,获得了客户好评。

2014年6月26日,金石机器人常州有限公司和山东滨州渤海活塞股份有限公司现场签约,合同总额1.7亿元。

如今,三期多套机械手已交付使用,第四期正在生产中。

金石助力渤海活塞全自动柔性生产线,产能大幅提高,全面展示了金石机器人的特点、优势,以及金石服务团队的专注与高效。

渤海活塞主导产品为高性能活塞,品种达1000多个、年产能力3000万件,是国内唯一一家能够全面生产各种汽车、船舶、工程等动力机械用活塞的专业化企业,为国内一汽集团、东风集团、潍柴动力、我国重汽、广西玉柴、上汽集团、长安集团、广汽集团、福田汽车、江淮汽车、奇瑞汽车、长城汽车、比亚迪汽车、华晨汽车、江铃汽车、吉利汽车等多家知名主机厂配套,活塞产品制造产能居世界单个工厂首位,国内综合市场占有率35%,国内欧III、欧IV等高端产品市场占有率达到60%;国外市场遍及北美、欧洲、东亚、中东等地区,拥有康明斯、卡特彼勒、大众、菲亚特、科勒等国际高端客户。

金石35KG重型桁架机械手助力自动化

渤海活塞现建有汽油机活塞销和柴油机活塞销自动化生产线各一条,汽油机活塞销产能为500万只,柴油机活塞销产能为300万只。

计划再增加柴油机、汽油机活塞销自动化生产线各一条,届时产能达到1600万只。

所有生产线设备配备工业机械手,实现自动上下料、自动料道连接。

为此,需要配置更多的活塞全自动柔性,完成活塞的毛坯粗孔加工、精孔、精外圆切口、珩磨、修口、去毛刺、检测的生产上下料。

针对渤。

温州金石机器人科技有限公司简介温州金石机器人科技有限公司,是专业从事工业机器人系统集成的开发与制造,拥有经验丰富的专业研发团队。

集品质,技术,服务,合作与一体。

金石科技以(瑞典)ABB机器人公司,德国KUKA(库卡)公司,日本FANUC(发那科)公司为战略合作伙伴,与中科院哈工大建立产学研合作平台,研发出一系列具自有知识产权的全新意义的异形产品表面抛磨系统。

其中“机器人自动表面抛磨机组及自动控制系统”被评为浙江省高新技术产品、省重大科技项目、省装备制造业重点领域首台(套)产品,2015年获行业最高金球奖。

是ABB抛磨系统集成研发战略合作伙伴,被ABB授予“抛磨系统集成合作实验基地”

机器人自动表面抛磨机组及自动控制系统,主要用于汽摩配、五金工具、厨卫、家俱、医疗器械、航天航空、船舶高铁等行业的表面抛磨的全自动抛磨系统,是一种人工智能操作、全自动控制、可重复编程、能在三维空间完成各种作业的机电一体化自动化生产设备。

特别适合于恶劣环境下、多品种、大批量的柔性生产,对稳定、提高产品质量,提高生产效率,改善劳动条件和产品的快速更新换代起着十分重要的作用。

拥有自动恒压系统、多功能自动夹具、复合材料抛光轮、成套软件系统等核心技术和自主知识产权。

产品填补国内空白,先进的技术使得该系统能够处理各种复杂形状工件,并且保证了工件的加工质量和产品的一致性。

提高了成品率,缩短了加工时间,并极大地降低企业的生产和管理成本。

EPSON机器人视觉培训讲座教学PPT课件REPORTING2023 WORK SUMMARY目录•EPSON机器人视觉概述•EPSON机器人视觉系统组成•EPSON机器人视觉图像处理技术•EPSON机器人视觉识别与定位技术•EPSON机器人视觉检测与测量技术•EPSON机器人视觉系统集成与应用案例PART01 EPSON机器人视觉概述EPSON机器人视觉定义与发展定义EPSON机器人视觉是EPSON公司研发的一种基于图像处理和计算机视觉技术的自动化检测系统,旨在通过模拟人类视觉功能,实现对物体形状、颜色、纹理等特征的识别、定位和测量。

发展历程自20世纪80年代起,EPSON开始致力于机器人视觉技术的研究与应用。

随着计算机技术和图像处理技术的不断发展,EPSON机器人视觉系统逐渐实现了从二维到三维、从静态到动态、从单一到多元的检测与识别能力。

智能家居在家庭环境中,EPSON 机器人视觉技术可实现家居设备的自动识别和控制、家庭安全的自动监控和报警等,提高家居生活的便捷性和安全性。

工业制造在自动化生产线中,EPSON 机器人视觉系统可用于零部件的自动识别和定位、产品质量的自动检测等,提高生产效率和产品质量。

物流仓储在智能仓储系统中,EPSON 机器人视觉技术可实现货物的自动识别和分类、库位的自动规划和优化等,提高物流效率和准确性。

医疗卫生EPSON 机器人视觉系统可用于医疗影像的自动分析和诊断、手术机器人的自动导航和定位等,提高医疗水平和效率。

高精度识别高速处理灵活配置易用性EPSON机器人视觉系统采用先进的图像处理和计算机视觉算法,可实现高精度的物体识别和定位。

EPSON机器人视觉系统支持多种硬件配置和软件定制,可根据用户需求进行灵活配置和扩展。

EPSON机器人视觉系统具备高性能的计算能力,可实现高速的图像处理和数据分析。

EPSON机器人视觉系统提供友好的用户界面和简单易用的操作方式,方便用户进行使用和维护。

273 Branchport AvenueLong Branch, N.J. 07740(800) 631-2148Thank you for using our products.INSTALLATION INSTRUCTIONSSERIES MPS-400X EXPLOSION-PROOF FIRE ALARM PULL STATIONUse this product according to this instruction manual. Please keep this instruction manual for future reference.The Series MPS-400X Explosion Proof Manual Pull Station is UL and FM Listed for use in hazardous environments and for NEMA Type 4X weatherproof applications. The unit also complies with ADA Standards when installed at less than 48 inches above the floor for front wheelchair access and less than 54 inches for side wheelchair access. All installations must comply with local codes and regulations.Ratings: Listed By: UL, FM, CSFM, MEAEnclosures: Class I, Groups B, C and D, Class II, Groups E, F and G. Class IIIContacts: D.P.D.T. 10 Amps at 250VAC 1/2 Amp at 125VDCINSTALLATION:Please also refer to assembly diagram and installation notes.The Series MPS-400X station includes a front housing, backbox, a switch plate and all the necessary hardware to assemble the station.1.Install the backbox onto its mounting surface using the holes provided on the mounting tabs. The tabs are designed to accept ascrew size of up to 1/4-inch.2.The backbox is supplied with two 3/4-inch 14 NPT conduit entries. Threaded joints between conduit and backbox must be madewith a minimum of 5 threads fully engaged. Seal unused conduit entry with a 3/4-inch NPT pipe plug. All joints must be sealed using pipe thread sealing compound or Teflon tape and in accordance with the requirements for the particular installation.3.Connect the field wiring to the terminal blocks on the adapter plate. Use the insulated terminal plug supplied to ground the boxproperly. Each wire or terminal lug must be placed under its corresponding clamping plate for proper connection.4.Install the switch plate onto the backbox using the 4-1/4 -20 X 7/8 pan head screws provided. Make sure that the O-Ring seals onthe screws and around the edge of the switch plate are properly seated.5.Open the front housing, align its mounting plate with the pins provided on the switch plate and attach it using the two 6-32 screwsprovided into the slot holes.Copyright 2009 Cooper Wheelock Inc., dba Cooper Notification. All rights reserved.INSTALLATION DIAGRAM:Before beginning, verify that the supply is turned off. Take care not to scratch or damage the surfaces of the flange joint.1.Check to make sure that the flange surfaces arecompletely clean and free of scratches, debris and dust.2.Verify that the O-Rings seals on the 4-/7/8 screws and thegasket around the inside surface of the switch plate areproperly seated.3.Seal unused conduit entry with a 3/4-inch NPT plug.4.Connect the ground wire to the grounding screw in thebackbox.5.After tightening the 4 switch plate bolts, verify that a0.00015-inch feeler gauge does not penetrate more than1/8-inch at any point around the flange joint.Terminal Block LayoutCNCNO NONCC SHOWN IN THE UPRIGHT POSITIONLIMITED WARRANTYCooper Wheelock, Inc. dba Cooper Notification and Cooper Notification, Inc. (each, a “Seller”) products must be used within their published specifications and must be PROPERLY specified, applied, installed, operated, maintained and operationally tested in accordance with these instructions at the time of installation and at least twice a year or more often and in accordance with local, state and federal codes, regulations and laws. Specification, application, installation, operation, maintenance and testing must be performed by qualified personnel for proper operation in accordance with all of the latest National Fire Protection Association (NFPA), Underwriter’s Laboratories (UL), National Electrical Code (NEC), Occupational Safety and Health Administration (OSHA), local, state, county, province, district, federal and other applicable building and fire standards, guidelines, regulations laws and codes including, but not limited to, all appendices and amendments and the requirements of the local authority having jurisdiction (AHJ). Seller products when properly specified, applied, installed, operated, maintained and operationally tested as provided above are warranted against mechanical and electrical defects for a period of (a) three (3) years from date of manufacture with respect to MEDC and Seller Industrial Signals and Seller Fire and Security Notification Appliances and Devices, or (b) one (1) year from date of manufacture with respect to Waves and SafePath Voice Evacuation and Mass Notification Systems (date of manufacture is determined by date code.) Correction of defects by repair or replacement shall be at Seller’s sole discretion and shall constitute fulfillment of all obligations under this warranty. THE FOREGOING LIMITED WARRANTY SHALL IMMEDIATELY TERMINATE IN THE EVENT ANY PART NOT FURNISHED BY SELLER IS INSTALLED IN THE PRODUCT. THE FOREGOING LIMITED WARRANTY SPECIFICALLY EXCLUDES ANY SOFTWARE REQUIRED FOR THE OPERATION OF OR INCLUDED IN A PRODUCT. SELLER MAKES NO REPRESENTATION OR WARRANTY OF ANY OTHER KIND, EXPRESS, IMPLIED OR STATUTORY WHETHER AS TO MECHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER MATTER.USERS ARE SOLELY RESPONSIBLE FOR DETERMINING WHETHER A PRODUCT IS SUITABLE FOR THE USER’S PURPOSES, OR WHETHER IT WILL ACHIEVE THE USER’S INTENDED RESULTS. THERE IS NO WARRANTY AGAINST DAMAGE RESULTING FROM MISAPPLIACATION, IMPROPER SPECIFICATION, ABUSE, ACCIDENT OR OTHER OPERATING CONDITIONS BEYOND SELLER’S CONTROL.SELLER DOES NOT WARRANT THAT THE OPERATION OF THE SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE OR THAT THE SOFTWARE WILL MEET ANY OTHER STANDARD OF PERFORMANCE, OR THAT THE FUNCTIONS OR PERFORMANCE OF THE SOFTWARE WILL MEET THE USER’S REQUIREMENTS. SELLER SHALL NOT BE LIABLE FOR ANY DELAYS, BREAKDOWNS, INTERRUPTIONS, LOSS, DESTRUCTION, ALTERATION, OR OTHER PROBLEMS IN THE USE OF A PRODUCT ARISING OUT OF OR CAUSED BY THE SOFTWARE.THE LIABILITY OF SELLER ARISING OUT OF THE SUPPLYING OF A PRODUCT, OR ITS USE, WHETHER ON WARRANTIES, NEGLIGENCE, OR OTHERWISE, SHALL NOT IN ANY CASE EXCEED THE COST OF CORRECTING DEFECTS AS STATED IN THE LIMITED WARRANTY AND UPON EXPIRATION OF THE WARRANTY PERIOD ALL SUCH LIABILITY SHALL TERMINATE. SELLER IS NOT LIABLE FOR LABOR COSTS INCURRED IN REMOVAL, REINSTALLATION OR REPAIR OF A PRODUCT BY ANYONE OTHER THAN SELLER OR FOR DAMAGE OF ANY TYPE WHATSOEVER, INCLUDING BUT NOT LIMITED TO, LOSS OF PROFIT OR INCIDENTAL, INDIRECT, CONSEQUENTIAL, SPECIAL, PUNTIVE OR EXEMPLARY DAMAGES. THE FOREGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER AND THE EXCLUSIVE LIABILITY OF SELLER.IN NO CASE WILL SELLER’S LIABILITY EXCEED THE PURCHASE PRICE PAID FOR A PRODUCT.LIMITATION OF LIABILITYSELLER’S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUDING NEGLIGENCE AND BREACH OF WARRNTY, FOR ANY LOSS OR DAMAGE RESULTING FROM, ARISING OUT OF, OR CONNECTED WITH THIS CONTRACT, OR FROM THE MANUFACTURE, SALE, DELIVERY, RESALE, REPAIR OR USE OF ANY PRODUCT COVERED BY THIS ORDER SHALL BE LIMITED TO THE PRICE APPLICABLE TO THE PRODUCT OR PART THEREOF WHICH GIVES RISE TO THE CLAIM. SELLER’S LIABILITY ON ANY CLAIM OF ANY KIND SHALL CEASE IMMEDIATELY UPON THE INSTALLATION IN THE PRODUCT OF ANY PART NOT FURNISHED BY SELLER. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY CLAIM OF ANY KIND UNLESS IT IS PROVEN THAT ITS PRODUCT WAS THE DIRECT CAUSE OF SUCH CLAIM. FURTHER, IN NO EVENT, INCLUDING IN THE CASE OF A CLAIM OF NEGLIGENCE, SHALL SELLER BE LIABLE FOR INCIDENTAL, INDIRECT, CONSEQUENTIAL, SPECIAL, PUNITIVE OR EXEMPLARY DAMAGES. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE PRECEDING LIMITATION MAY NOT APPLY TO ALL PURCHASERS.6/09。

TO WHOM IT MAY CONCERNBosch Security SystemsTorenallee 495617 BA EindhovenThe Netherlands Product Test Report ST-VS 2016-E-099 ProductF.01U.321.914 DDH-3532-200N00 DIVAR hybrid 3000 16AN/16IPF.01U.321.915 DDN-3532-200N00 DIVAR network 3000 32IPF.01U.321.916 DDN-3532-200N16 DIVAR network 3000 32IP 16PoEF.01U.321.917 DDN-2516-200N00 DIVAR network 2000 16IPF.01U.321.918 DDN-2516-200N08 DIVAR network 2000 16IP 8PoEF.01U.321.919 DDN-2516-200N16 DIVAR network 2000 16IP 16PoEF.01U.321.920 DRH-5532-400N00 DIVAR hybrid 5000 16AN/16IPF.01U.321.921 DRN-5532-400N00 DIVAR network 5000 32IPF.01U.321.922 DRN-5532-400N16 DIVAR network 5000 32IP 16PoEF.01U.329.367 DDH-3532-212N00 Recorder 16-ch IP/16-ch AN 1x2TBF.01U.329.368 DDH-3532-112D00 Recorder 16-ch IP/16-ch AN 1x2TB DVDF.01U.329.369 DRH-5532-414N00 Recorder 16ch IP/16ch AN 1.5U 1x4TBF.01U.329.370 DRH-5532-214D00 Recorder 16ch IP/16ch AN 1.5U 1x4TB DVDF.01U.343.101 DRH-5532-226D00 Recorder 16ch IP/16ch AN 1.5U 2x6TB DVDF.01U.329.371 DDN-3532-212N00 Recorder 32ch 1x2TBF.01U.329.372 DDN-3532-112D00 Recorder 32ch 1x2TB DVDF.01U.329.373 DDN-3532-212N16 Recorder 32ch 1x2TB 16PoEF.01U.329.382 DDN-3532-112D16 Recorder 32ch 1x2TB 16PoE DVDF.01U.329.383 DRN-5532-414N00 Recorder 32ch 1.5U 1x4TBF.01U.329.384 DRN-5532-214D00 Recorder 32ch 1.5U 1x4TB DVDF.01U.329.385 DRN-5532-414N16 Recorder 32ch 1.5U 1x4TB 16PoEF.01U.329.386 DRN-5532-214D16 Recorder 32ch 1.5U 1x4TB 16PoE DVDF.01U.329.387 DDN-2516-212N00 Recorder 16ch 1x2TBF.01U.329.388 DDN-2516-112D00 Recorder 16ch 1x2TB DVDF.01U.329.389 DDN-2516-212N08 Recorder 16ch 1x2TB 8PoEF.01U.329.390 DDN-2516-112D08 Recorder 16ch 1x2TB 8PoE DVDF.01U.329.391 DDN-2508-200N08 Recorder 8ch w/o HDD 8PoEF.01U.329.392 DDN-2508-212N08 Recorder 8ch 1x2TB 8PoEF.01U.329.393 DDN-2508-112D08 Recorder 8ch 1x2TB 8PoE DVDF.01U.329.394 DDN-2516-212N16 Recorder 16ch 1x2TB 16PoEF.01U.329.395 DDN-2516-112D16 Recorder 16ch 1x2TB 16PoE DVDThe above mentioned Bosch Security Systems products have been tested in accordance and were found to comply with the tests listed below which were conducted during the development phase of the product.EMC approvalsDirective or standard DescriptionEMC EU, 2014/30/EU (EMCD)EN 55032:2012 /AC:2013 Class B Electromagnetic compatibility of multimedia equipment - EmissionRequirementsEN 55024 : 2010 Information technology equipment - Immunity characteristics - Limits andmethods of measurementEN 50130-4:2011 Alarm systems - Part 4: Electromagnetic compatibility - Product familystandard: Immunity requirements for components of fire, intruder, hold up,CCTV, access control and social alarm systemsEN 61000-3-2:2014 Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for harmoniccurrent emissions (equipment input current ≤ 16 A per phase)EN 61000-3-3:2013 Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation of voltagechanges, voltage fluctuations and flicker in public low-voltage supply systems,for equipment with rated current <= 16 A per phase and not subject toconditional connectionEN 50121-4:2006 /AC:2008 Railway applications - Electromagnetic compatibility - Part 4: Emission andimmunity of the signalling and telecommunications apparatusEN 61000-4-5:2014 Electromagnetic compatibility (EMC) - Part 4-5: Testing and measurementtechniques - Surge immunity test.Installation class 3 applied to all input, output and supply wiring.± 0.5, 1, and 2 kV common mode (line-to-ground),± 0.5, and 1 kV differential mode (line-to-line).EMC USCFR 47 FCC part 15, Class B ANSI C63.4 (2014) Code of Federal Regulations, Radio Frequency Devices, Unintentional Radiators. Radiated Emission based on verification procedure.EMC AustraliaAS/NZS CISPR 32:2013 Electromagnetic compatibility of multimedia equipment - Emissionrequirements. Compliance via EN 55032:2012Safety approvalsDirective or standard DescriptionSafety EU, 2014/35/EU (LVD)EN 60950-1:2006 /A11:2009Information technology equipment - Safety - Part 1: General requirements. /A1:2010 /A12:2011 /A2:2013Safety USA + CanadaUL 60950-1, 2nd Ed., 2014-10-14Information technology equipment - Safety – Part 1: General requirements. CAN/CSA C22.2 No. 60950-1-07,2nd Edition, 2014-10Environmental approvalsDirective or standard DescriptionRoHS EU, 2011/65/EURestriction of the use of certain hazardous substances (RoHS)EN 50581:2012WEEE EU, 2012/19/EU Waste Electrical and Electronic Equipment (WEEE)Packaging EU, 94/62/ECPackaging and packaging waste(amended by 2004/12/EC)N2580-1 (Bosch standard) Central directive Bosch-Norm N 2580-1: “Prohibition and declaration ofsubstances“Bosch-Norm N 2580-1 regulates prohibited substances and those rateddeclarable in materials, and it is part of the requirements for materials.N33 6 (Bosch standard) Design for Environment (DfE): Design and manufacturing rules Management systemDirective or standard DescriptionISO 9001:2008 Quality management systems -- RequirementsScope: Development, production, installation and sales.ISO 14001:2004 /AC:2009 Environmental management systems -- Requirements with guidance for useScope: Development, Production, Sales and After Sales.Reliability testsAccording: EN 50130-5:2011 Alarm systems Part 5: Environmental test methods Class I, Indoor but restricted to residential/office environmentTest specification DescriptionDry heat (operational)(EN 60068-2-2:2007)Temperature +40ºC, Duration 16 hours.Cold (operational) (EN 60068-2-1:2007) Temperature 5℃, Duration 16 hours.Bosch tested more severe at temperature 0ºCDamp heat, steady state(operational)(EN 60068-2-78:2001)Temperature 40ºC, Relative Humidity 93%, Duration 4 days.Damp heat, steady state(endurance)(EN 60068-2-78:2001)Temperature 40ºC, Relative Humidity 93%, Duration 21 days.Shock (operational)(EN 60068-2-27:2009)Halve sine wave pulse, duration 6ms, 3 pulses per direction, 6 directions.Impact (operational)(EN 60068-2-75:1997 Test Ehb) Impact energy 0.5Joule, 3 impacts per point (Similar to EN 62262 IK04 rating)Vibration, sinusoidal (operational) (EN 60068-2-6:2008) Frequency range 10-150 Hz, 5 ms², 3 axes, sweep rate 1 octave x min-1, 1 sweep cycles per axis functional mode.Vibration, sinusoidal (endurance) (EN 60068-2-6:2008) Frequency range 10-150 Hz, 10 m/s², 3 axes, sweep rate 1 octave x min-1, 20 sweep cycles per axis.Dust tightness (endurance)(EN 60529:1991 A1:2000)Duration 8h (Similar to EN 60529 IP5X or IP6X)Additional reliability testsActivity DescriptionMTBF(Mean Time Between Failures) > 300.000 h MTBF calculation of used components(According Telcordia SR-332 i03 2011, Prediction Method Method I Case 3, EnvironmentTemperature 35 ℃ (95°F), Environment condition GF(Ground fixed,controlled, πE=1), Quality Factor Level II ( πQ = 1))Note: MTBF calculations are excluding Hard Disks and DVD-writer > 157.000 h Based on current field performance of predecessor productsincluding Hard Disks and DVD-writerAdditional surge tests according IEC 61000-4-5:2014Lightning / surge protection The test is applied to the next connections:Video input, Audio input, Video spot output, Video CVBS output, Bidirectional talk input, Audio output, RS232 port, Alarm input/alarm output/RS485 port, power input (12VDC or 230VAC) and network port using UTP cable.And with the test severity ‘ Installation class 3’:± 0.5, 1, and 2 kVcommon mode (line-to-ground)± 0.5, and 1 Kv differential mode (line-to-line)ALT Reliability test in which a moderate number of products are stressed at elevated,but non-destructive stress levels for a longer period of time.Temperature cycling -15ºC to +65ºC (15ºC /min)HALT Full HALT overstress test to fail according the Qualmark HALT guideline:Cold Step Stress Test, Hot Step Stress test, Rapid Thermal Stress Test,Random Vibration Stress Test, Combined Vibration/Rapid Thermal StressTest.Defined operating limits: -30°C to +70°C and vibration level 30 Grms. Decorative surface test 25 rubbings by hand on text + labels and Bosch logo / print with a piece of woolfelt soaked with liquids. The used liquids are boiling point spirit 100-140°C andEthanol 96 % with 5% methanolTemperature of hot spots on components Measured with an infrared scanner and thermocouples at room temperature (20 ±5 °C).Noise < 45 dBA at 1m from front in sound free environment.Ambient temperature 20±5°C and maximum system load.HDD release in the product application HDD release of functional compatibility and the mechanical construction. Special attention to HDD mounting construction and mechanical vibration and interference of mutual HDD’s and temperature. See Operation manual for list of release HDDs.Vibration test of product in packaging Product in packaging including all accessories and manuals.Test frequency: 7 HzDisplacement: 5.3 mm (= 1.05g)30 min each side, 3 directionsTransport drop test Product in packaging including all accessories and manuals.This test is executed after the vibration test on the same modelsTotal 7 dropsDrop height depending of the weight of the DVRDynamic compression test of package Product in packaging including all accessories and manuals. Package shall be in visible good condition and product shall be conform specification.Data subject to change without notice. Eindhoven, August 2017。

Enterprise Development专业品质权威Analysis Report企业发展分析报告金石机器人技术开发(东莞)有限公司免责声明:本报告通过对该企业公开数据进行分析生成,并不完全代表我方对该企业的意见,如有错误请及时联系;本报告出于对企业发展研究目的产生,仅供参考,在任何情况下,使用本报告所引起的一切后果,我方不承担任何责任:本报告不得用于一切商业用途,如需引用或合作,请与我方联系:金石机器人技术开发(东莞)有限公司1企业发展分析结果1.1 企业发展指数得分企业发展指数得分金石机器人技术开发(东莞)有限公司综合得分说明:企业发展指数根据企业规模、企业创新、企业风险、企业活力四个维度对企业发展情况进行评价。

该企业的综合评价得分需要您得到该公司授权后,我们将协助您分析给出。

1.2 企业画像类别内容行业计算机、通信和其他电子设备制造业资质空产品服务能机器人的研发;工业机器人制造;特殊作业1.3 发展历程2工商2.1工商信息2.2工商变更2.3股东结构2.4主要人员2.5分支机构2.6对外投资2.7企业年报2.8股权出质2.9动产抵押2.10司法协助2.11清算2.12注销3投融资3.1融资历史3.2投资事件3.3核心团队3.4企业业务4企业信用4.1企业信用4.2行政许可-工商局4.3行政处罚-信用中国4.4行政处罚-工商局4.5税务评级4.6税务处罚4.7经营异常4.8经营异常-工商局4.9采购不良行为4.10产品抽查4.11产品抽查-工商局4.12欠税公告4.13环保处罚4.14被执行人5司法文书5.1法律诉讼(当事人)5.2法律诉讼(相关人)5.3开庭公告5.4被执行人5.5法院公告5.6破产暂无破产数据6企业资质6.1资质许可6.2人员资质6.3产品许可6.4特殊许可7知识产权7.1商标7.2专利7.3软件著作权7.4作品著作权7.5网站备案7.6应用APP7.7微信公众号8招标中标8.1政府招标8.2政府中标8.3央企招标8.4央企中标9标准9.1国家标准9.2行业标准9.3团体标准9.4地方标准10成果奖励10.1国家奖励10.2省部奖励10.3社会奖励10.4科技成果11土地11.1大块土地出让11.2出让公告11.3土地抵押11.4地块公示11.5大企业购地11.6土地出租11.7土地结果11.8土地转让12基金12.1国家自然基金12.2国家自然基金成果12.3国家社科基金13招聘13.1招聘信息感谢阅读:感谢您耐心地阅读这份企业调查分析报告。

资料下载

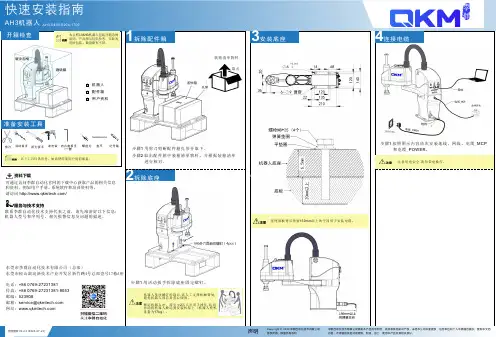

可通过访问李群自动化官网的下载中心获取产品的相关信息 服务与技术支持

联系李群自动化技术支持代表之前,请先准备好以下信息:剪刀活动扳手扭力扳手 冲击钻内六角扳手 (一套)螺丝刀记号笔Copyright © 2020 李群自动化技术有限公司

版权所有,保留所有权利李群自动化技术有限公司具有本产品的专利权、版权和其他知识产权,未经本公司书面授权,任何单位和个人不得擅自摘抄、复制本文档内容;不得直接或者间接复制、制造、加工、使用本产品及其相关部分。

2拆除底座用活动扳手拆除底座固定螺钉。

步骤1 根据基座尺寸设计并准备安装孔位。

步骤2 采用正装的安装方式对机器人进行底座安装。

以上工具仅供参考,如需使用需用户提前准备4安装基座

步骤1 2 用剪刀剪断配件箱扎带并取下。

步骤取出配件箱中装箱清单物料,并根据装箱清单

进行核对。

4连接电缆机器人基座螺钉拆除后,需人工支撑机械臂处,避免机器人因自身重心倾斜。

搬运机器人时,需至少2名人员用手撑住,共同

协助将机器人搬运到安装机架上(机器人整机

重量为17kg )。

步骤1 按照图示内容依次安装地线、网线、电缆_MCP

和电缆_POWER 。

注意用电安全,请勿带电操作。

基座面板背后预留150mm 以上的空间用于安装电缆。

取出准备安装工具

货时包装、数量略有不同。

缠绕膜

缓冲泡棉。

概述2手册修订情况文件编号: 修订日期修订次数 说 明 2018年 3月 1 A8 Plus 智能RTK 系统使用说明书V1.0A8 Plus 智能RTK 系统使用说明书3前言说明书用途欢迎使用华星A8 Plus 系列接收机,本说明书适用于华星A8 Plus 系列产品。

说明书简介华星A8 Plus 是一款新型GNSS 接收机,说明书对如何安装、设置和使用华星A8 Plus 系列产品进行描述。

经验要求为了您能更好的使用华星A8 Plus 产品,中海达建议您仔细阅读本说明书。

如果您对华星A8 Plus 产品尚不了解,请查阅中海达的官方网站: 安全技术提示注意:注意提示的内容一般是操作特殊的地方,需要引起您的特殊注意,请认真阅读。

警告:警告提示的内容一般为非常重要的提示,如果没有按照警告内容操作,将会造成仪器的损害,数据的丢失,以及系统的崩溃,甚至会危及到人身安全。

责任免除使用本产品之前,请您务必仔细阅读使用说明书,这会有助于您更好地使用本产品。

广州市中海达测绘仪器有限公司对您未按照使用说明书的要求而操作本产品,或未能正确理解使用说明书的要求而误操作本产品所造成的损失不承担责概述4任。

中海达致力于不断改进产品功能和性能、提高服务质量,并保留对使用说明书的内容进行更改而不另行通知的权利。

我们已对印刷品中所述内容与硬件和软件的一致性作过检查,然而不排除存在偏差的可能性,使用说明书中的图片仅供参考,若有与产品实物不符之处,请以产品实物为准。

技术与服务如果您有任何技术问题,可以电话联系各分支机构技术中心、总部技术部,我们会及时的解答您的问题。

相关信息您可以通过以下途径找到该说明书:1、购买华星A8 Plus 产品后,仪器箱里的光盘中会有一份《A8 Plus 智能RTK 系统使用说明书》,指导您操作仪器;2、登陆中海达官方网站,在“服务中心”→“资料下载”→“RTK 产品”里即可下载该电子版说明书。

您的建议如果您对华星A8 Plus 系列产品有什么建议和意见,请联系我们,或者拨打全国热线:400-678-6690。

The Evolution of theSensorless VectorTechnologyIndustrial Grade Induction MotorRibbed Base Casting Direct Drive Steppers Polymer Bonded SlidewaysPolyphase Steppers Series 3 is the next evolution of our best selling PCNC 770 mill.In this generation, we’ve updated the motion system with ultra-quiet polyphase axis motors and the latest driver technology fromLeadshine ®.The Leadshine and motors are not only quieter, impressive performance improvements include better positional resolution,improved linearity and repeatability, and significant gains in available torque at cutting speeds. New co-polymer oil-resistant paint, aredesigned operator console, and a host of other improvementsclearly demonstrate why Series 3 is Tormach’s best combination ofvalue and performance to date.OUR ENGINEERS ARE EXCITED ABOUT THEIMPROVEMENTS IN THE NEW DRIVE SYSTEM.Tormach PCNC Millsaccessories to expand its utility. Our commitment to modular design principles means the latest accessories can be fitto any mill – regardless of purchase date – so your mill can grow with your interests and expand with your business. We offer innovative and useful accessories to expand your PCNC mill’s capability, including a 4th Axis, Power Drawbar, Automatic Tool Changer andmuch more.Each PCNC mill undergoes acomprehensive 30 point factoryinspection prior to shipment,and our experienced technicalsupport staff is available toassist with your questions andkeep your mill making chips inthe months and years after that.ASK ANY TORMACH OWNER:OUR SUPPORT IS SECOND-TO-NONE, BOTH BEFOREAND AFTER DELIVERY.Our customers purchase withconfidence knowing they’vechosen the best value in CNC.Once you’ve taken a look at us,we’re sure that you’ll agree, too.SPINDLESensorless Vector TechnologyWe’ve partnered with Emerson Control Techniques ™to engineer a maintenance-free spindle drive with significant low-speed torque, quick acceleration, and real cutting power throughout its speed range. Unlike a Volts/Hz drive, sensorless vector technology uses sophisticated drive intelligence that reacts quickly to changing spindle motor loads. Improvements in reactor technology enables consistent cutter performance in rapidly changing cutting conditions in a typical CNC program.Industrial Grade Induction Motor Induction motors require zero maintenance and long life. Our 1.0 HP motor is robust and uses vacuum pressure impregnated resin for motor insulation to encase the entire stator and windings in resin for long life and trouble-free operation. VPI is the same technique used for demanding motor applications, including elevators and generators.Dual Pulley Belt Transmission A dual pulley belt system is the best of both worlds. Two pulley ratios allow you to achieve necessary spindle RPMs without abandoning low speed torque necessary for large diameter drilling and tapping operations. Significant ratio overlap means changes are rarely necessary, but conveniently available when needed. The transmission can be easily adjusted to compensate for wear and eliminate non-uniform bind points inherent to plate and screw gibs.MOTION Polyphase Steppers Ultra-quiet polyphase stepper motors provide superior torque at cutting speeds. We’ve partnered with Leadshine ® to incorporate the latest advances in microstepping driver technology. These drive systems not only provide superior torque at cutting speeds, they improve linearity, reduce vibration, and have quieter operation when compared to other stepper systems available today. Precision Ground Ballscrews Each PCNC uses ground ball screws that are ground for precision. Other manufacturers may use cheaper, rolled screws not capable of providing the same level of precision. Additionally, our anti-backlash ball nuts use a superior double-nut technique to apply preload instead of a less expensive over-sized ball technique that PRECISION GROUND BALLSCREWSEMERSON DRIVERTORMACH SPINDLEAUTOMA TIC OILER (OPTIONAL)Direct Drive SteppersOur motors are coupled directly to the ball screw. This improves positioning accuracy and reduces maintenance, as there is no beltor gearbox to wear or slip. 15 Point Lubrication Each PCNC has a 15 point single shot lubrication system that distributes oil to each set of ways, gibs, and ball nuts with a single stroke. Polymer Bonded Slideways The PCNC slideway surfaces are bonded with PTFE-filled Acetyl polymer. Similar in chemistry to brand name products like Turcite ® and Rulon ®, PTFE-filled Acetyl provides low friction and long life.Tapered Gibs PCNC mills use a tapered gib with dove-tail instead of inferior plate and screw design common on benchtop and other small mill machines. Tapered gibs can be easily adjusted to compensate for wear and eliminate non uniform bind points inherent to plate and screw gibs.IRON Cast Iron Construction At over 660 lbs of rigid cast iron construction, the PCNC 770 is built on a foundation engineered to do real work. Modern simulation techniques were used to create a reinforced design with superior rigidity in its class.Breakdown Design A unique feature of the PCNC 770 is the moving kit feature that allows transportation of the machine as subassemblies for increased portability. Tormach’s patent-pending design allows for assembly and disassembly of the mill – move it in your shop or take it with you to a new location. This is only CNC mill designed specifically for machinists with basement shops.Ribbed Base Casting The PCNC base casting is a sturdy platform for precision work. Ribbed reinforcements provide stiffness and resist deflection under load. Pinned and Fitted Surfaces All mating surfaces are hand scraped and pinned for precise trueness and alignment.POL YMER BONDED SLIDEWAYSA PA TENT -PENDING MOVING KIT MAKESDISASSEMBL Y OF THE PCNC 770 SAFERAND EASIER.MACH 3 CONTROL SOFTWARE TORMACH MACHINE CONTROLLER*CONTROLLER SOLD SEPARA TEL Y.SERIES 3 OPERATOR PANELRedesigned Operator Panel The panel has been reorganizedfor improved workflow and theaddition of an optional loadmeter display.ControlYour PCNC ships with Mach3-enabled control software*. Mach3 is a versatile program for PC-based motion control.Features include:•Storage of up to 256 work offsets •Storage of over 200 tool length offsets •Graphical tool path simulation •G-code editor •MDI manual data input line •Selectable and programmable jog and step control • Handy programming wizards to automate simpleprogramming tasks using parametric tool andfeature definitions.• Active modal list• Feed/speed control override• Specialized control for probing, tool setting,tapping, and more.Series 3 mills have been coated with a new paint that is based ona copolymer enamel system of cross-linked acrylic modified andamino resins. This new coating is resistant to most coolants andoils and engineered for adhesion and long life.Cast Iron Tool TrayEach PCNC includes a cast iron tool tray for convenient and handystorage.CAST IRON TOOL TRAYPOWER DRAWBAR4TH AXISPCNC 770 Options TORMACH TTS TOOLING SYSTEMCOOLANT KIT FOR PCNC 7704th Axis Tormach PCNC mills come prewired and preconfigured for continuous 4th axis rotary motion. Our 4th axis options are available in several sizes and designed and built for machining operations that involve large forces, cutting fluids, and frequent operation. They use high performance direct drive motors and can be outfitted with a variety of chucks and accessories.PN 30290: 4TH AXIS KIT 6 INCH Power Drawbar The Power Drawbar integrates with your PCNC 770 for lightning-fast manual tool changes with the push of a button, eliminating the need to hand-tighten your drawbar. To change tools, a pneumatic multi-stack air-over-air cylinder is actuated to depress the drawbar, releasing clamping pressure and opening the collet without putting harmful load on the spindle bearings. When the cylinder is released, the drawbar tightens and the tool is held firmly in place. This system provides over 2500 lbs of holding force to the tool.PN 32436: PCNC 770 POWER DRAWBAR Stand The Stand has been designed as a sturdy steel foundation for your PCNC 770. Chips and coolant stay contained with its generous tray depth, back, and side guarding. The table mounted guard shields in the forward direction, while the integrated coolant system keeps the mill running at maximum speeds.PN 31191: PCNC 770 STAND Coolant Kit The flood Coolant Kit is highly recommended for general metal cutting. The kit includes a coolant reservoir tank, pump, hose, and necessary fittings, and mounting brackets. It also includes a backsplash surround and chip guard.PN 31192: COOLANT KIT FOR PCNC 770Tormach Tooling System ®Genuine TTS is the most popular and most expansive line of tooling for small milling machines - an affordable toolholding system that works with any R8 or MT3 spindle. Upgrade your existing toolholders with the advantages of TTS: offline tool measurement, repeatable Z offsets, increased rigidity, and reduced stick out compared to traditional R8 toolholders.CNC SCANNER™KRESS 800 WATT HIGH SPEED SPINDLE KITAND 5” CNC VISE FOR WORKHOLDINGPCNC 770 AccessoriesCNC Scanner™The Tormach CNC Scanner turns your PCNC into a high resolution 2D optical scanner and reverse engineering system. This unique tool has hundreds of uses, including toolmaking, artistry, repair and restoration, precision measurement, and quality assurance, to name a few.PN 31738: CNC SCANNER™Kress 800 Watt High Speed Spindle Kit The Kress 800 FME is a premium quality German die grinder with and 800W motor with variable speed from 10000-29000 RPM. It includes 1/8” and 1/4” steel collets. Additional collet sizes are also available.PN 31890: KRESS 800 WATT HIGH SPEED SPINDLE KIT MORE Electronic Touch Probes and Tool Setter Your PCNC mill includes an accessory port that allows you to interface electronic accessories to expand function or streamline part setup. We offer turn-key electronic touch probes and tool setters suitable for probing, digitizing, or setting tool, and work offsets.Workholding Your PCNC mill also includes a complete line of vises, vacuum chucks, and clamps common to custom-workholding C Workshops Get the confidence you need to start making parts. Hands-on small group training workshops are available at our modern training center. All experience levels welcome and dates and class schedules are available on the Tormach website.SprutCAM for Tormach SprutCAM is serious CAM with exceptional value. With over 40 programming strategies and support for 3D machining, lathe, and 4th axis, SprutCAM is a perfect match for programming your PCNC Mill.SpecificationsKey Dimensions/Weight8”x28”TableSize:5/8”SlotsTable3Slots:13.25”(X,Y,Z)x14”7.5”Travel:xSpindle Nose to Table: 14.8” maximumSpindle Center to Column: 8 5/8”Spindle Nose Diameter: 3 3/8”Shipping Dimensions: 42” x 45” x 49”Weight: 662 lbs net / 800 lbs grossMax Workpiece : 400 lbs MaximumPowerPower Requirements: 115 VAC 50/60 Hz single phase (primary).recommendedbreaker20A(secondary)H zVAC11550/60SpindleTaper: R8SpindleSpindle Construction: Dynamically balanced cartridge with spindle lockTechniques™ Sensorless VectorControlSpindleDrive: EmersonTechnology750W1300Wpeakcontinuous,Spindle Power: 1.0 hp Brushless AC 3-phase Induction Motor,(VPI)WindingsPressureVacuumImpregnatedSpindle Speed: 175 to 10000 RPMPolyflex® V-Belt Drive, 2 ratiosGatesTransmission:SpecificationsIronFrame and Table: Cast iron frame and table, with hand scrapedtaperedgibsandadjustmentwaysslidehydrodynamicWay Surfaces: Low friction PTFE-filled Acetyl bonded slidingtoRulon® and Turcite®Similarsurface.MotionIPM(X,Y)Rate:135Feed(Z)IPM110StepperPerformancePolyphaseDrives: H ighAxiswithLeadshine® Microstepping DriversMotorsBallscrews: P4 (medical grade) with double-nutted anti-backlashnutball<.0006”/ftError:Incremental35”<.0008”atError:CumulativeControlOperator Console: Complete spindle control, plusKeySpindleLock-OutOn/Off/AutoCoolantController: PC – MachOS (recommended) or Ubuntu Linux;(Sold Separately) Windows XP, Vista, Windows 7 (compatible)includedPCNCwithMach3licenseAdditional Control Features: Integrated DIN accessory port–axis4thoptionalPrewiredfor(soldseparately)handwheelforelectronicPreconfiguredE-StopRemoteOptional11 ABOUT TORMACHThe people at Tormach are dedicatedto delivering tools, accessories, andcomponents of unprecedented valuein the world of CNC and motioncontrol. Whether you’re involved inR&D, education, short run production,or simply an entrepreneur with anidea, you need to make things.Tormach products allow you tomake what you need easier, quicker,and more affordably. We want tohelp make your goal a reality, toenable your ideas. Our missionis to empower people who makethings. Whether you’re cuttingparts with our machine tools orbuilding your own equipment usingour components, our focus is tomanifest your concepts and helpyou bring your ideas into reality.ORDERING, PAYMENT &SHIPPINGQuotations can be requested onlineusing our web based quotationsystem, or through FAX, email,or over the phone. Machines andaccessories can also be orderedusing our secure web shoppingcart. Payment can be madeby check, credit card, or wiretransfer. Machines and machinestands are shipped via truckfreight in North America, whileaccessories are normally shippedvia package service (UPS, USPS,FedEx). Tormach ships worldwidein cooperation with establishedinternational freightforwarding companies.WARRANTY AND SUPPORTMachines and accessories arewarranted for 12 months. Warrantyservice is limited to repair orreplacement of components withtelephone support, there isno on-site fi eld service staff.Replacement parts are stocked atour Wisconsin facility. Additionalinformation is available at www..ENABLING YOUR IDEAS204 Moravian Valley Road, Suite NWaunakee, WI 53597 USAPh 608.849.8381 • Fx 209.885.4534****************COPYRIGHT TORMACH LLC 2011SPECIFICATIONS ARE SUBJECT TO CHANGEWITHOUT NOTICEDS32084_PCNC770_SERIES3.PDFREV 1.0。

No. 3855No. 3853No. 3968No. 3851For pelletizing, destructive testing, fluid extraction, pressure forming, etc.No. 3850No. 3970Specifications12 TON PRESSES n No. 3850 (Mini C)• T welve ton, manual, two-column hydraulic press with 69 x 69 work area • C ompact and portable, requiring less bench space than our Model C • T his press is ideal for constricted bench space or glove box applications, as well as field work• I t features adjustable daylight, steel construction for rigid precision and includes safety shield for operator protection • E asy-to-read dual scale gauge, reading in pounds force and metric tons n No. 4350• Pellet press with 49 round platen • Available with and without pellet die (see page 10)n No. 3851 (Model C)• T welve ton, manual, two-column hydraulic lab press • S imilar to Mini C above, but larger, heavier construction with daylight to 189• E asy-to-read dual scale gauge, reading in pounds force and metric tons n No. 3968 (Model 12-10)• T welve ton, manual, two-column hydraulic press, with 109 x 79 work area• S imilar to No. 3851 press described above, but heavier construction with fully guided moving platen and daylight to 149• E asy-to-read dual scale gauge, reading in pounds force and metric tons n No. 3969 (Model 12-12)• T welve ton, manual, four-column hydraulic press • F ully guided moving platen assuresparallelism over 129 x 129 surface • E asy-to-read dual scale gauge, reading inpounds force and metric tons 25 TON PRESSES n No. 3853 (Model M)• T wenty-five ton, manual, two-column hydraulic press, with a 99 x 99 work area • D aylight opening is adjustable • R igid cast iron and steel construction for precision and durability• E asy-to-read dual scale gauge, reading in pounds force and metric tons n No. 3855 (Model 25-12)•T wenty-five ton, manual, four-column hydraulic press with a 129 x 129 work area •E asy-to-read dual scale gauge, reading in pounds force and metric tons 30 TON PRESSESn No. 3970 (Model 30-12)•Thirty ton, manual, four-column, hydraulic press with a 129x 129 work area• H as two-speed pump, first stage for rapid closing and second for pressing mode• E asy-to-read dual scale gauge, reading inpounds force and metric tons Note: Existing Carver presses can be automated with an optional AutoPak power package (see back cover).9Standard Unheated Manual Presses12, 25 and 30 ton capacityNOTE: Standard manual presses come with analog gauge (as shown in pictures). Digital gauges available upon request. Consult factory for details. Information on digital gauges may also be found on page 13.Carver reserves the right to change specifications without notice. Presses and accessories may differ from photos shown.Carver strongly recommends the use of a safety shield and personal protection equipment when operating Carver equipment.CarverInc1569MorrisStreet•WabashIndianaUSA•(P)260-563-7577•(F)260-563-7625•****************************available。

G780DS-250•••••Technical dataFunctional dataValve Size 3" [80]Fluidchilled or hot water, up to 60% glycol Fluid Temp Range (water)32...300°F [0...149°C]Body Pressure Rating ANSI Class 250, up to 280 psi below 350°F Flow characteristic linearServicing repack/rebuild kits available Rangeability Sv 50:1Flow Pattern 3-way Diverting Leakage rateANSI Class III Controllable flow range stem up - open AB – B Cv 85 ANSI Class250Body pressure rating noteup to 280 psi below 350°F MaterialsValve body Cast iron - ASTM A126 Class B Valve plug Stainless steelStem seal NLP EPDM (no lip packing)SeatStainless steel AISI 316Pipe connection250 lb flanged Suitable actuatorsNon-Spring EVB(X)Electronic fail-safeAVKB(X)Safety notesWARNING: This product can expose you to lead which is known to the State of California to cause cancer and reproductive harm. For more information go to The valve has been designed for use in stationary heating, ventilation and air-conditioning systems and must not be used outside the specified field of application, especially in aircraft or in any other airborne means of transport.Only authorised specialists may carry out installation. All applicable legal or institutional installation regulations must be complied during installation.The valve does not contain any parts that can be replaced or repaired by the user.When determining the flow rate characteristic of controlled devices, the recognised directives must be observed.Product featuresG780DS-250 Flow/Mounting detailsDimensionsDimensional drawingsEVB, EVX, RVB, RVXA B C D E F Number of Bolt Holes12.6" [320]10.7" [273]27.3" [693]19.0" [483] 4.1" [105] 4.1" [105]8AVKB, AVKXA B C D E F Number of Bolt Holes12.6" [320]10.7" [273]27.3" [693]19.0" [483] 4.1" [105] 4.1" [105]8AFB, AFXA B C D E F Number of Bolt Holes12.6" [320]10.7" [273]25.6" [650]17.2" [438] 4.1" [105] 5.3" [135]8AFB, AFXG780DS-250A B C D E F Number of Bolt Holes12.6" [320]10.7" [273]25.6" [650]17.2" [438] 4.1" [105] 5.3" [135]8AVKB120-3 On/Off, Floating Point, Electronic Fail-Safe, Linear,120 VTechnical dataElectrical data Nominal voltage AC 100...240 VNominal voltage frequency50/60 HzPower consumption in operation 3.5 WPower consumption in rest position 2 WTransformer sizing 6.5 VA (class 2 power source)Electrical Connection18 GA appliance cable with 1/2" conduit connector,3 ft [1 m], degree of protection NEMA 2 / IP54Overload Protection electronic throughout full strokeElectrical Protection actuators are double insulatedFunctional data Actuating force motor450 lbf [2000 N]Input Impedance100 kΩ (0.1 mA), 500 Ω, 1000 Ω (on/off)Position feedback U note No FeedbackBridging time 2 s delay before fail-safe activatesPre-charging time 5...20 sDirection of motion motor selectable with switchDirection of motion fail-safe reversible with switchManual override 5 mm hex crank (3/16" Allen), suppliedStroke 1.25" [32 mm]Running Time (Motor)90 s, constant, independent of loadRunning time motor note constant, independent of loadRunning time fail-safe<35 sNoise level, motor60 dB(A)Noise level, fail-safe60 dB(A)Position indication Mechanically, with pointerSafety data Degree of protection IEC/EN IP54Degree of protection NEMA/UL NEMA 2 UL Enclosure Type 2Agency Listing cULus acc. to UL60730-1A/-2-14, CAN/CSAE60730-1:02, CE acc. to 2014/30/EU and 2014/35/EUQuality Standard ISO 9001Ambient temperature-22...122°F [-30...50°C]Storage temperature-40...176°F [-40...80°C]Ambient humidity max. 95% r.H., non-condensingServicing maintenance-freeWeight Weight 6.39 lb [2.9 kg]Materials Housing material Die cast aluminium and plastic casingSafety notesAVKB120-3•••••PVC W'Shld for GV w/UGLK (GM)Battery Back Up System for SY(7~10)-110120 to 24 VAC, 40 VA transformer.50% voltage divider kit (resistors with wires).PC Tool computer programming interface, serial port.Electrical installationINSTALLATION NOTESActuators with appliance cables are numbered.Actuators may be connected in parallel. Power consumption and input impedance must be observed.Meets cULus requirements without the need of an electrical ground connection.Warning! Live Electrical Components!During installation, testing, servicing and troubleshooting of this product, it may be necessary to work with live electrical components. Have a qualified licensed electrician or other individual who has been properly trained in handling live electrical components perform these tasks. Failure to follow all electricalsafety precautions when exposed to live electrical components could result in death or serious injury. On/Off Floating Point。