模具标准件数据手册

- 格式:pdf

- 大小:490.84 KB

- 文档页数:25

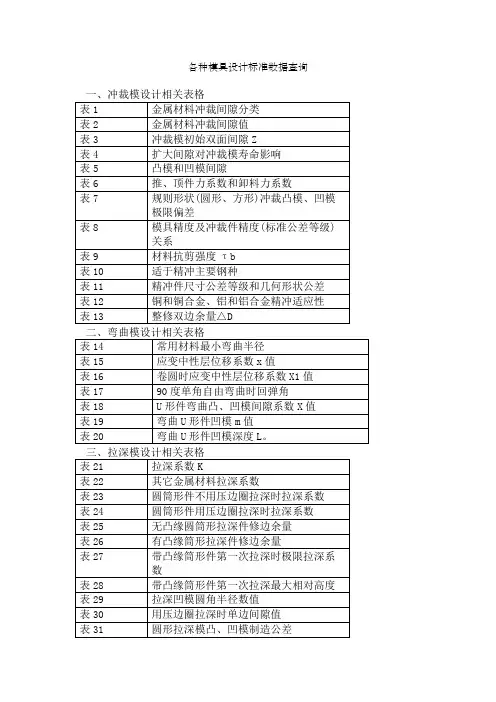

各种模具设计标准数据查询

表1 金属材料冲裁间隙分类

表2 金属材料冲裁间隙值

表3 冲裁模初始双面间隙Z

表4 扩大间隙对冲裁模寿命影响

表5 凸模和凹模间隙

表6 推、顶件力系数和卸料力系数

表7 规则形状(圆形、方形)冲裁凸模、凹模极限偏差

表8 模具精度及冲裁件精度(标准公差等级)关系

表9 材料抗剪强度τb

表10 适于精冲主要钢种

表11 精冲件尺寸公差等级和几何形状公差

表12 铜和铜合金、铝和铝合金精冲适应性

表13 整修双边余量△D

表14 常用材料最小弯曲半径

表15 应变中性层位移系数x值

表16 卷圆时应变中性层位移系数X1值

表17 90度单角自由弯曲时回弹角

表18 U形件弯曲凸、凹模间隙系数X值

表19 弯曲U形件凹模m值

表20 弯曲U形件凹模深度L。

表21 拉深系数K

表22 其它金属材料拉深系数

表23 圆筒形件不用压边圈拉深时拉深系数

表24 圆筒形件用压边圈拉深时拉深系数

表25 无凸缘圆筒形拉深件修边余量

表26 有凸缘筒形拉深件修边余量

表27 带凸缘筒形件第一次拉深时极限拉深系数

表28 带凸缘筒形件第一次拉深最大相对高度

表29 拉深凹模圆角半径数值

表30 用压边圈拉深时单边间隙值

表31 圆形拉深模凸、凹模制造公差

表32 低碳钢极限圆孔翻边系数K1

表33 其它金属材料极限翻边系数K1

表34 外缘翻边允许极限变形程度

表35 平均缩口系数Ksp

表36 材料厚度及缩口系数关系

表37 极限胀形系数和切向许用伸长率。

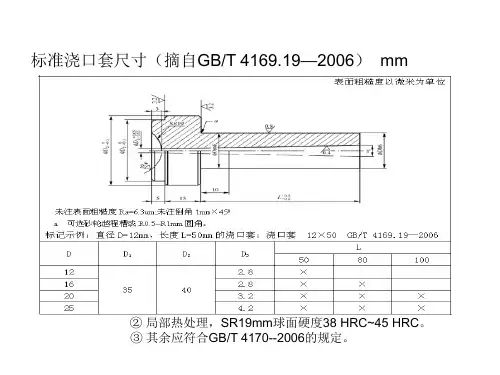

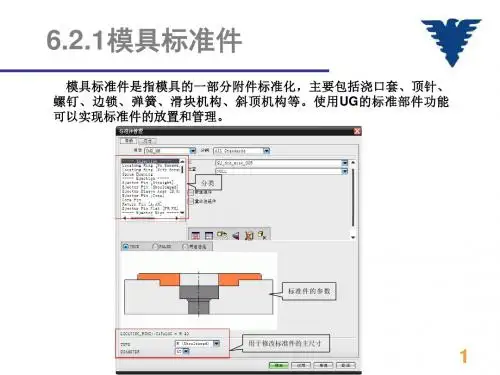

注塑模具标准手册版本编号: 2006-V1.1编辑: 编辑日期:送呈:审核: 批准: 批准日期:目录检索一、总则 (5)二、文件控制规范2.1设计文件控制规范 (6)2.2编程文件控制规范 (7)2.3E D M、线切割文件控制规范 (9)三、设计基础相关参数3.1常见塑料原料性质一览表 (10)3.3常见模具钢料性质一览表 (20)3.6桑菲模具零件标准中英文命名 (24)四、详细的设计规范4.1模胚组件设计规范4.1.1模胚材料及整体规范 (37)4.1.2拉模扣及水口勾针设计规范 (38)4.1.3拉圾钉及哥林柱设计规范 (39)4.1.4水口拉杆与山打螺丝配合设计规范 (40)4.1.5边司(导边)长度规范 (41)4.2 模肉及镶件设计规范4.2.1模肉基准角及加工基准设计规范 (43)4.2.2模肉方位及定位设计规范 (44)4.2.3P L面设计规范 (45)4.2.4镶件设计规范 (48)4.2.5模肉及镶件字麦规范 (50)4.2.6排气系统设计规范 (51)4.3 行位及斜顶设计规范4.3.1行位设计要点 (53)4.3.2行位导滑结构设计规范 (55)4.3.3硬片设计规范 (56)4.3.4行位镶件设计规范 (57)4.3.5行位压条及油槽设计规范设计规范 (58)4.3.6斜顶结构设计规范 (59)4.3.7斜顶滑块及斜顶设计规范 (60)4.4浇注系统设计规范4.4.1法兰设计规范 (61)4.4.2唧嘴设计规范 (62)4.4.3小水口唧嘴设计规范 (63)4.4.4浇注系统设计规范 (64)4.4.5主流道设计规范 (65)4.4.6入水点设计规范 (66)4.5顶出系统设计规范4.5.1顶出系统注意事项 (68)4.5.2顶针避空及顶针托止转 (69)4.5.3顶针位置排布 (70)4.5.4水口勾针设计 (72)4.5.5司筒针设计规范 (73)4.5.5先复位结构设计 (74)4.6冷却系统设计规范 (75)五、加工中心控制规范5.1电极设计作业规范 (76)5.2C N C编程作业规范 (78)5.3C N C操作标准规范 (79)5.4C N C加工组现场工件管理 (80)5.5铜公开料标准规范 (81)5.6C N C刀具管理规范 (82)5.7C N C工装夹具标准化 (84)六、线割、电火花加工作业规范6.1慢走丝机操作规范<A Q360L> (85)6.2慢走丝机操作规范<D K7632> (87)6.3火花机操作规范<E A8、M P-50、X-300> (89)6.4火花机操作规范<A Q360L> (90)6.5火花机加工参数标准化 (92)6.6火花机留纹加工标准 (94)6.7火花机加工方法规范 (95)6.8线割加工参数标准化<沙迪克> (97)6.9线割加工参数标准化<苏三光> (98)6.10线切割加工方法规范 (99)6.11打孔机操作规范 (101)6.12快走丝机操作规范 (103)七、组立加工作业规范7.1机床操作规范标准7.1.1铣床操作规范标准 (105)7.1.2车床操作规范标准 (106)7.1.3磨床操作规范标准 (107)7.1.4手摇平面磨床操作规范标准 (108)7.1.5锯床操作规范标准 (109)7.2 机床保养规范7.1.1铣床保养规范标准 (110)7.1.2车床保养规范标准 (111)7.1.3磨床保养规范标准 (112)7.1.4锯床保养规范标准 (113)7.3F i t模操作规范 (114)7.4省模作业规范及标准 (115)7.5模具保养管理规范 (116)7.6模具组立管理规范 (117)7.7模具零件管理规范 (118)7.8工/量具使用管理规范 (119)7.9 安全操作、安全生产规范7.9.1车床安全规范 (120)7.9.2模床安全规范及保养 (121)7.9.3天车使用安全规范 (122)七、检测相关附录表格8.1 产品评审检查报告8.2 模图初稿评审报告8.3 EDM加工检查报告8.48.5导引:<<模具标准手册>>是桑达百利电器有限公司在长期的模具制造实践中, 积累起来的经验与技术的结晶. 并且随着公司的发展而不断完善此规范, 以此来保持和不断提高公司的模具设计水平.<<模具标准手册>>分为两部份主要内容: 一部份是设计制造规范; 一部份是检查规范附录表. 设计规范是桑菲模塑中心模具设计科在进行模具设计时所参照的主要依据及基本要求; 检查规范附录表是进行模具设计检讨, 以及在模具制造过程中针对关键步骤进行检查的依据.<<模具设计标准图册>>是根据我司的严格按照标准化设计模具部件产生的附录文件,它对于我司在模具零件上的可换性以及零件的批量生产、提高工作速度减短模具周期起到决定性的作用。

五金模具标准件目录 (2)1、内导柱、导套 (3)2、外导柱、导套 (4)3、内六角螺丝 (8)4、固定销 (10)5、弹簧 (11)6、等高套筒 (14)7、顶料销 (15)8、止符螺丝 (18)9、两用销 (19)10、导正销 (21)11、圆冲子 (23)12、优力胶 (25)13、检测销 (25)第一节:内导柱、导套一、主要功能:内导柱主要用于模板间和上、下模间的导正。

内导套主要与内导柱相配合导正作用。

二、相关代号、规格及参数:1、代号:内导柱为“GP”,如GP20-80=>4 表示内导柱直径为∮20mm,长度为80mm,共4支。

内导套为肩型“GA”和直杆型“GB”,如GA20-25=>4 表示内导套内径为∮20mm,长度为25mm,共4支。

2、规格及参数:(见下图)三、选用原则:1、通常以直径较大的来优先设计,最主要还是根据模具的大小来选择直径的大小。

2、冲孔(或连续)模上模内导柱长度选取原则:一般情况下,开模时内导柱伸出打板面15~20MM,例图(a);当下模定位块(或导料块)等伸出模板面很高时,导柱伸出打板面的长度L=定位块(或导料块)伸出模板面的长度H+(5-7)MM(保证模具闭模过程中,内导柱先导正,定位块后进入打板)例图(b)(图a) (图b)四、排配原则:1、导柱一般排在模板的四个角落上,其孔边距板边最小处不低于12mm。

2、如果选用两柱,可排在斜对角,也可根据实际情况排。

3、在排配过程中要注意防呆,其防呆一般采用以左下角一孔向料带的平行方向偏移10MM以上来防呆。

4、内导套一般适用于精密模具上,产品形状或位置要求准确的情况下使用。

第二节:外导柱、导套一、主要功能:外导柱的功能主要是用于上、下模的导正,保证上、下模的相对位置。

外导套主要与外导柱相配合导正作用。

二、相关代号、规格及参数:1、代号:无附钢珠的外导柱、导套为“SGP组件”,如:SGP组件32-120=>4 表示外导柱直径为∮32mm,长度为120mm,无附钢珠的外导柱、导套共4支。

模具标准件数据手册第一篇范文:模具标准件申购表的填写规范制表:刘东林2004-5-29审核:批准:制表:刘东林2004-5-29审核:批准:第二篇范文:标准件手册标准件速查手册(第一版)紧固件的常用规格目录一螺纹紧固件综合1.GB/T2-2001紧固件外螺纹零件未端------------------------------------12.GB/T152.2-1988紧固件沉头用沉孔-----------------------------------23.GB/T152.3-1988紧固件圆柱头用沉孔--------------------------------4.GB/T152.4-1988紧固件六角头螺栓和六角螺母用沉孔-----------5.GB/T5277-1985紧固件螺栓和螺钉通孔---------------------------二螺栓6.GB/T8-1988方头螺栓C级--------------------------------------7.GB/T37-1988T形槽用螺栓----------------------------------------------8.GB/T799-1988地脚螺栓--------------------------------------------------9.GB/T5780-2000六角头螺栓C级------------------10.GB/T5781-2000六角头螺栓全螺纹C级--------11.GB/T5782-2000六角头螺栓-----------------------------------------------12.GB/T5783-2000六角头螺栓全螺纹-------------------------------三螺柱13.GB/T897-1988双头螺柱bm1d------------------14.GB/T898-1988双头螺柱bm1.25d----------------------------------------15.GB/T899-1988双头螺柱bm15d------------------------------------------16.GB/T900-1988双头螺柱bm2d-------------------------------------------17.GB/T901-1988等长双头螺柱正B级----------------------------------18.GB/T9953-1988等长双头螺柱C级----------------------------------------四螺母19.GB/T41-2000六角螺母C级---------------------------------------------20.GB/T56-1988六角厚螺母-----------------------------------------------21.GB/T810-1988小圆螺母-------------------------------------------------22.GB/T812-1988圆螺母---------------------------------------------------23.GB/T6170-2000Ⅰ型六角螺母---------------------------------------------24.GB/T6172.1-2000六角薄螺母---------------------------------------25.JB/T7382-1994吊环螺母-------------------------------------------------五螺钉1标准件速查手册26.GB/T70.1-2000内六角圆柱头螺钉-----------------------------------------27.GB/T71-1985开槽锥端紧定螺钉-----------------------------------------28.GB/T72-1985开槽锥端定位螺钉-----------------------------------------29.GB/T73-1988开槽平端紧定螺钉-----------------------------------------30.GB/T74-1985开槽凹端紧定螺钉-----------------------------------------31.GB/T75-1985开槽长圆柱端紧定螺钉-----------------------------------32.GB/T77-1985内六角平端紧定螺钉---------------------------------------33.GB/T78-2000内六角锥端紧定螺钉---------------------------------------34.GB/T79-2000内六角圆柱端紧定螺钉------------------------------------35.GB/T80-2000内六角凹端紧定螺钉--------------------------36.GB/T825-1988吊环螺钉-------------------------------------------------六组合件连接副37.GB/T9074.1-2002螺栓或螺钉和平垫圈组合件---------------------38.GB/T9074.15-1988六角头螺栓和平垫圈组合件----------------------39.GB/T9074.17-1988六角头螺栓和弹簧垫圈及平垫圈组合件----40.GB/T9074.26-1988组合件用弹簧垫圈-----------------------------41.GB/T9074.27-1988组合件用外锯齿锁紧垫圈----------------------七木螺钉及自攻螺钉(略)八销42.GB/T91-2000开口销---------------------------------------------43.GB/T117-2000圆锥销----------------------------------------44.GB/T119.1-2000圆柱销不淬硬钢和奥氏体不锈钢-----------------45.GB/T119.2-2000圆柱销淬硬钢和马氏体不锈钢-----------------46.GB/T120.1-2000内螺纹圆柱销不淬硬钢和奥氏体不锈钢----------47.GB/T120.2-2000内螺纹圆柱销淬硬钢和马氏体不锈钢----------48.GB/T879.1-2000弹性圆柱销直槽重型-------------------------49.GB/T879.2-2000弹性圆柱销直槽轻型--------------------------50.GB/T879.3-2000弹性圆柱销卷制重型-------------------------2标准件速查手册51.GB/T879.4-2000弹性圆柱销卷制标准型-----------52.GB/T879.5-2000弹性圆柱销卷制轻型-------------------------------53.GB/T881-2000螺尾锥销---------------------------------------------------九铆钉54.GB/T827-1986标牌用铆钉-------------------------------------------------十垫圈及档圈55.GB/T93-1987标准型弹簧垫圈---------------------------------------------56.GB/T95-2002平垫圈C级-------------------------------------------------57.GB/T97.1-2002平垫圈A级-------------------------------------------------58.GB/T97.4-2002平垫圈用于螺钉和垫圈组合----------------------59.GB/T848-2002小垫圈A级-------------------------------------------------60.GB/T856-1988外舌止动垫圈-----------------------------------------------61.GB/T857-1988圆螺母用止动垫圈---------------------------------62.GB/T886-1986轴肩挡圈---------------------------------------------------63.GB/T893.1-1986孔用弹性挡圈A型---------------------------------64.GB/T893.2-1986孔用弹性挡圈B型-------------------------------65.GB/T894.1-1986轴用弹性挡圈A型-----------------------------------66.GB/T894.2-1986轴用弹性挡圈B型--------------------------------67.GB/T895.1-1986孔用钢丝挡圈-----------------------------------68.GB/T895.2-1986轴用钢丝挡圈---------------------------------------69.GB/T921-1986钢丝锁圈---------------------------------------------------十一焊钉3标准件速查手册一螺纹紧固件综合1.GB/T2-2001紧固件外螺纹零件未端(返回文档顶端)1标准件速查手册5.56.69.011.013.517.522.0------4.GB/T152.4-1988紧固件六角头螺栓和六角螺母用沉孔d2d3td1螺纹规格M5M6M8M10M12M16M20M24M27--d2H13111318222633404853--d3--------1620242833--d1(H13)5.56.691113.517.5222630--螺纹规格M30M36M39M42M45M48M52M56M60M64d2H13617176828998107112118125d336 424548515660687276d1(H13)33394245485256626670(返回文档顶端)-2-标准件速查手册5.GB/T5277-1985紧固件螺栓和螺钉通孔(一般选用中等装配精度)螺纹规格M5M6M8M10M12M16M20M24M27M30精装配精5.36.48.410.5131721252831第三篇范文:五金模具标准件五金模具标准件目录 (2)1、内导柱、导套 (3)2、外导柱、导套 (4)3、内六角螺丝 (8)4、固定销 (10)5、弹簧 (11)6、等高套筒 (14)7、顶料销 (15)8、止符螺丝 (18)9、两用销 (19)10、导正销 (21)11、圆冲子 (23)12、优力胶 (25)13、检测销 (25)第一节:内导柱、导套一、主要功能:内导柱主要用于模板间和上、下模间的导正。

注塑模具标准手册版本编号: 2006-V1.1编辑: 编辑日期:送呈:审核: 批准: 批准日期:目录检索一、总则 (5)二、文件控制规范2.1 设计文件控制规范 (6)2.2 编程文件控制规范 (7)2.3 EDM、线切割文件控制规范 (9)三、设计基础相关参数3.1 常见塑料原料性质一览表 (10)3.3 常见模具钢料性质一览表 (20)3.6 桑菲模具零件标准中英文命名 (24)四、详细的设计规范4.1模胚组件设计规范4.1.1 模胚材料及整体规范 (37)4.1.2 拉模扣及水口勾针设计规范 (38)4.1.3 拉圾钉及哥林柱设计规范 (39)4.1.4 水口拉杆与山打螺丝配合设计规范 (40)4.1.5 边司(导边)长度规范 (41)4.2 模肉及镶件设计规范4.2.1模肉基准角及加工基准设计规范 (43)4.2.2模肉方位及定位设计规范 (44)4.2.3 PL面设计规范 (45)4.2.4 镶件设计规范 (48)4.2.5 模肉及镶件字麦规范 (50)4.2.6 排气系统设计规范 (51)4.3行位及斜顶设计规范4.3.1 行位设计要点 (53)4.3.2 行位导滑结构设计规范 (55)4.3.3硬片设计规范 (56)4.3.4 行位镶件设计规范 (57)4.3.5 行位压条及油槽设计规范设计规范 (58)4.3.6斜顶结构设计规范 (59)4.3.7斜顶滑块及斜顶设计规范 (60)4.4浇注系统设计规范4.4.1 法兰设计规范 (61)4.4.2 唧嘴设计规范 (62)4.4.3 小水口唧嘴设计规范 (63)4.4.4 浇注系统设计规范 (64)4.4.5 主流道设计规范 (65)4.4.6 入水点设计规范 (66)4.5顶出系统设计规范4.5.1 顶出系统注意事项 (68)4.5.2 顶针避空及顶针托止转 (69)4.5.3 顶针位置排布 (70)4.5.4 水口勾针设计 (72)4.5.5司筒针设计规范 (73)4.5.5先复位结构设计 (74)4.6 冷却系统设计规范 (75)五、加工中心控制规范5.1 电极设计作业规范 (76)5.2 CNC编程作业规范 (78)5.3 CNC操作标准规范 (79)5.4 CNC加工组现场工件管理 (80)5.5 铜公开料标准规范 (81)5.6 CNC刀具管理规范 (82)5.7 CNC工装夹具标准化 (84)六、线割、电火花加工作业规范6.1 慢走丝机操作规范<AQ360L> (85)6.2慢走丝机操作规范<DK7632> (87)6.3火花机操作规范<EA8、MP-50、X-300> (89)6.4火花机操作规范<AQ360L> (90)6.5 火花机加工参数标准化 (92)6.6 火花机留纹加工标准 (94)6.7 火花机加工方法规范 (95)6.8 线割加工参数标准化<沙迪克> (97)6.9 线割加工参数标准化<苏三光> (98)6.10 线切割加工方法规范 (99)6.11打孔机操作规范 (101)6.12快走丝机操作规范 (103)七、组立加工作业规范7.1机床操作规范标准7.1.1铣床操作规范标准 (105)7.1.2车床操作规范标准 (106)7.1.3磨床操作规范标准 (107)7.1.4手摇平面磨床操作规范标准 (108)7.1.5锯床操作规范标准 (109)7.2 机床保养规范7.1.1铣床保养规范标准 (110)7.1.2车床保养规范标准 (111)7.1.3磨床保养规范标准 (112)7.1.4锯床保养规范标准 (113)7.3 Fit模操作规范 (114)7.4 省模作业规范及标准 (115)7.5 模具保养管理规范 (116)7.6 模具组立管理规范 (117)7.7 模具零件管理规范 (118)7.8 工/量具使用管理规范 (119)7.9 安全操作、安全生产规范7.9.1 车床安全规范 (120)7.9.2 模床安全规范及保养 (121)7.9.3 天车使用安全规范 (122)七、检测相关附录表格8.1 产品评审检查报告8.2 模图初稿评审报告8.3 EDM加工检查报告8.48.5导引:<<模具标准手册>>是桑达百利电器有限公司在长期的模具制造实践中, 积累起来的经验与技术的结晶. 并且随着公司的发展而不断完善此规范, 以此来保持和不断提高公司的模具设计水平.<<模具标准手册>>分为两部份主要内容: 一部份是设计制造规范; 一部份是检查规范附录表. 设计规范是桑菲模塑中心模具设计科在进行模具设计时所参照的主要依据及基本要求; 检查规范附录表是进行模具设计检讨, 以及在模具制造过程中针对关键步骤进行检查的依据.<<模具设计标准图册>>是根据我司的严格按照标准化设计模具部件产生的附录文件,它对于我司在模具零件上的可换性以及零件的批量生产、提高工作速度减短模具周期起到决定性的作用。

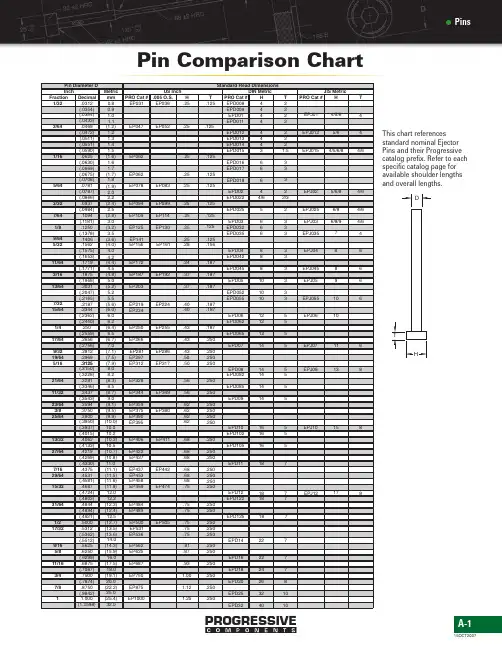

A-1PROGRESSIVE15OCT2007Pin Comparison ChartThis chart references standard nominal Ejector Pins and their Progressive catalog prefix.Refer to each specific catalog page for available shoulder lengths and overall lengths.A-2PROGRESSIVE15OCT2007MH-13HCore:40-44HRC,Surface:66-70HRC Ejector PinsStraight Pins •Inch StandardD Tolerances3/64ø-7/16ø-.0004-.000715/32øand Up-.0004-.0009CAD insertion pointH=25"For keyed pins,see page A-10.PROGRESSIVE15OCT2007A-3=14"CAD insertion pointMH-13HCore:40-44HRC,Surface:66-70HRCEjector PinsShoulder Pins •Inch StandardFor keyed pins,see page A-10.Ejector PinsStraight Pins•DINStandardM1.2344H Core:40-44HRC,Surface:68-70HRCD T CAD insertion pointContact Customer Service for the availability of through-hardened ejector pins.For keyed pins,see page A-10.A-4PROGRESSIVE15OCT2007A-5PROGRESSIVE15OCT2007Ejector PinsShoulder Pins •DINStandardM1.2344HCore:40-44HRC,Surface:68-70HRCBL=200mmg635±2CAD insertion pointContact Customer Service for the availability of through-hardened ejector pins.For keyed pins,see page A-10.A-6PROGRESSIVEEjector PinsStraight Pins •JISStandard15OCT2007MSKD61HCore:40-44HRC,Surface:66-70HRCDL=-0.01-0.02CAD insertion pointFor keyed pins,see page A-10.A-7PROGRESSIVE15OCT2007MSKD61HCore:40-44HRC,Surface:66-70HRCEjector PinsShoulder Pins •JISStandardD -0.01-0.0235±2STANDARD B L=200mmCAD insertion pointFor keyed pins,see page A-10.A-8PROGRESSIVEMH-13HCore:40-44HRC,Surface:66-70HRCSChrome Plated .00005-.00007”ThickUltraPins®Treated StraightPinsDApplication Information:•Maximum operating temperature:1600˚F (870˚C)•Not recommended for use with PVC or similarly corrosive materials.•Contact Customer Service for availability on other diameters and lengths not shown.US Patent No.5,644,833and 6,752,616Other patents pendingCAD insertion point15OCT2007A-9PROGRESSIVE15OCT2007MH-13HCore:40-44HRC,Surface:66-70HRCSChrome Plated .00005-.00007”Thick US Patent No.5,644,833and 6,752,616Other patentspending36CAD insertion pointUltraPins®Treated Shoulder PinsA-10PROGRESSIVE15OCT2007Keyed Ejector PinsStraight Style •Inch Standard+.002-.000D (Pin tangent)+.002-.000D Tolerances1/8ø-7/16ø-.0004-.00071/2øand Up-.0004-.0009MH-13CAD insertion pointAll Progressive standard Ejector Pins (Inch,DIN,and JIS)can be supplied with keyed heads.To order items with the flat ground tangent to the pin diameter,specify -K after the catalog number.Ex.EP437L10-K or EPD10L200-KTo order pins with the flat machined a specific distance from the center of the pin,specify that distance after the “K”designation for the flat as shown below.HCore:40-44HRC,Surface:66-70HRCExamples:EP437L10-K250for a 7/16øpin with a flat 1/4”from centerEPD10L200-K6for a 10mm diameter DIN pin with a flat 6mm from center EPJ055L250-K4for a 5.5mm diameter JIS pin with a flat 4mm from centerDHA-11PROGRESSIVE15OCT2007D R X L=+0.000-0.015Y CAD insertion pointContact Customer Service for the availability of JIS Blade Ejectors by specifying the information shown below:MO-1H58-60HRCJIS SpecificationMaterial:SKS-21Blade EjectorsDIN StandardA-12PROGRESSIVE15OCT2007MH-13H30-35HRCNote:Heads are annealed on 6",10"and 14"lengthsCorePinsHDHCAD insertion pointMH-13H50-55HRCA-13PROGRESSIVE15OCT2007MM-2H60-64HRCTI TMPinsThousandth IncrementPinsDTo order:Specify the prefix TI-and the three place decimal of the pin required,followed by a "0"if not nominal:Ex:.090ø=TI-0900or.252ø=TI-2520If a nominal size,carry to a four place decimal as listed in the chart at left:Ex.5/32ønominal =TI-1562or3/32ø=TI-0937Contact Customer Service for availability of additional diameters or lengths.CAD insertion pointA-14PROGRESSIVE15OCT2007MH-13HCore:40-44HRC,Surface:65-75HRCEjector SleevesInch StandardJIS &DINSpecification32±2General DimensionsN=1-3/4”for ES094&ES125N=2-1/4”for ES156and largerT=.187”for ES094thru ES156T=.250”for ES187and largerDBCAD insertion pointJIS Material:SKD61,40HRC Core,70HRC Surface DIN Material:1.2067,60HRC Thru-hardenedContact Customer Service for the availability of metric sleeves,either in the JIS or DIN standard,by specifying the information shown below.Contact Customer Service for the availability of sleeves with the outer diameter (B).005"oversize (10”lengths or less)To achieve longer lengths,use Sleeve Extensions shown on page A-16.A-15PROGRESSIVE15OCT2007MA-2H58-60HRCSElectroless Nickel Coated .00003”-.00007”ThickMaterial:A-2Contact Customer Service for the availability of metric Thin Wall Sleeves by specifying the information shown below.MetricSpecificationCAD insertion pointDGH To achieve longer lengths,use Sleeve Extensions shown on page A-16.US Patent No.6,872,069Ejector SleevesThin Wall SleevesA-16PROGRESSIVEMAISI 1215H170BrinellSBlack OxideCatalog DHCAD insertion pointUS Patent No.6,872,06915OCT2007A-17PROGRESSIVE5DEC2007Core PinRetainersCAD insertion pointUS Patent No.6,872,069ABHexBM AISI 12L14H 165Brinell SBlack OxideCatalogAM AISI 12L14H 165BrinellSBlack OxideCatalogAInch StandardMetric Standard15OCT2007CAD insertion point =1/2"DM AISI52100H Core:30HRC max,Surface:58-62HRCReturn PinsA-18PROGRESSIVEInjection Mold ComponentsPin ProductsCatalog Pages are provided in Adobe Acrobat?.PDF) format. Comparison ChartThe full range of Progressive Pins are engineered and manufactured to meet the demands of today's plastic injection molders. Most pins are etched with Progressive's logo and catalog number for easy identification. A comprehensive listing of US Inch, DIN and JIS may be downloaded for your reference.Pin ChartEjector PinsProgressive Ejector Pins are precision ground and hardened for maximum wear resistance and are available in JIS, DIN and Inch standards.Inch StandardStraight Style Catalog Page Download 2D Download 3DShoulder Style Catalog Page Download 2D Download 3DDIN StandardStraight Style Catalog Page Download 2D Download 3DShoulder Style Catalog Page Download 2D Download 3DJIS StandardStraight Style Catalog Page Download 2D Download 3DShoulder Style Catalog Page Download 2D Download 3DKeyed Ejector PinsNew from Progressive Components: KeyedEjector Pins with ground heads tangent to thepin diameter.Inch: Straight Style Catalog Page Download 2D Download 3DUltra Pins?/font>Progressive UltraPins?/font> are through-hardened to minimize dishing, nicking, andbending. The surface is treated with chrome toassist in applications where grease is notallowed.Straight Style Catalog Page Download 2D Download 3DShoulder Style Catalog Page Download 2D Download 3DBlade EjectorsProgressive Blade Ejectors are hardenedthroughout to eliminate chipping and allowflexing.Catalog Page Download 2D Download 3DEjector SleevesProgressive Ejector Sleeves are nitrided onthe inner diameter and the outer diameter forsmooth performance with standard EjectorPins or UltraPins.Standard Sleeves Catalog Page Download 2D Download 3DProgressive Thin-Wall Sleeves aredesigned for today's thinner plastic wallsections and are engineered with wearresistance against both the pin and moldinsert. Patent Pending.Thin-Wall Sleeves Catalog Page Download 2D Download 3DSleeve ExtensionsSleeve Extensions eliminate the need forspecial sleeves when utilized in largermolding applications where long sleeves arerequired. Compatible with all Progressiveand industry-standard sleeves. PatentPending.Catalog Page Download 2D Download 3DCore Pin RetainersProgressive Core Pin Retainers provide aspace-efficient method of retaining the centercore pin in ejector sleeve applications. Unlikea set screw, the retainer allows the pin tofloat slightly for optimum pin/sleeve performance while eliminating the need tomachine plates. Patent Pending.Catalog Page Download 2DDownload 3D Core PinsProgressive Core Pins are precision ground and through-hardened available as 'hard' and'soft'.Catalog Page Download 2DDownload 3DThousandth Increment Pins?/b>Progressive TI Pins?are available in .001"increments from .060 diameter to .320diameter. These thousandth-increment pinsallow mold builders to eliminate timeconsuming finishing work of fractionalincrement core pins, and unlike stamping punches, TI Pins feature finish ground headthicknesses. Catalog Page Download 2DDownload 3DReturn PinsProgressive Return Pins are precisionground and nitrided.Catalog Page Download 2DDownload 3D页码,3/3Progressive Components - PINS2008-12-25/content/products/pins/pins_new.htm。

模具部件名称代号与规格说明导柱Z00/A/B*C A管位+有托的长度;B导柱直径;C导柱长度导套Z11/A/B A内径;B长度;用在没有面板的模具管钉Z20/A*B A直径;B高度顶针Z40;Z41/A*B A直径;B长度,Z40的规格较贵,Z41便宜常用波仔螺丝Z36;Z37/A*B A直径;B长度杯头螺丝Z30;Z31;Z32/A*B A螺纹直径;B除去杯头的长度平头螺丝Z33/A*B A螺纹直径;B总长密封圈Z98/A*B A内径;B高度弹簧Z60/A*B A内径;B自由状态下长度有托顶针Z44/A/B A小头直径;B总高度司筒Z45/A*B A内径大小(司筒针直径);B总长锁模片Z73/A/B/C A高度;B宽度;C厚度定位环K100/A*B A直径;B高度定位环K500/A*B A大头直径;B高度;未加工喉咀Z81/A/B A与模具外接水接头的直径;B与内模接水接头的直径;B是英制A直径英制单位 如R3/8, A内模与运水相接的喉塞Z94/A(英制) Z94/A*导套Z10/A*B A内径;B长度;用在有面板的模具,导套上有管位管住面板中托斯Z12/A*B A内径;B总长中托边Z012/A*B A直径;B长度(中托斯)石墨导套Z13W/A*B内径,B管位加长方向长度扣机Z170扣机Z171扣机Z174这种扣机的功能是实现两次顶出加长喉咀Z90/A*B A直径;B总长感应器Z140/1感应器连接线Z1401/8*1/5000对锁Z07/A/B*C A杯头螺丝沉头高度;B对锁小端得宽度;C对锁小端的长度对锁Z17/A/B A宽度;B缺口宽度;与Z07对插的宽度一样垃圾钉Z55/A*B A直径;B宽度行位固定器Z189/10销钉Z25/A*B A直径;B长度塞打螺丝Z38/A*B A中间直径;B中间长度塞打螺丝Z381/A*B A中间直径;B中间长度日期码Z4861/A/B*C A类型;B直径;C高度;类型4记月,类型5记年材料标示Z487/A/B/C A类型;B直径;C材料导柱Z03/A/B*C A拖长度;B小头直径;C小头长度连接线Z853隔水片Z965/A*B*C A厚度;B宽度;C总长;有托隔水片Z967/A*B A厚度;B长度;无托计数器A5710/51*34*21只有一种类型版本标示STD直径4*1.25铜管(类似隔水片)Z95/A*B外径*外径扁顶针Z46/A*B*C A扁长;B扁宽;C总长无头螺丝Z35;Z36/A*B A直径;B长度螺旋运水Z961/A*B A直径;B总长唧咀Z51/A*B/C/D A小端直径;B小端长度;C唧咀对炮嘴口直径;D对炮嘴口德弧唧咀Z511/A*B A唧咀大头直径;B总长柱长度,Z41便宜常用与内模接水接头的直径;B是英制单位 如R3/8模与运水相接的地方直径,B螺牙的深度模具,导套上有管位管住面板端得宽度;C对锁小端的长度插的宽度一样记月,类型5记年咀对炮嘴口直径;D对炮嘴口德弧度。

模具设计参数表表3-1 搭边值与侧边值的数值材料厚度t(mm)圆件及r>2t圆角矩形边长l≤50 矩形边长>50或圆角≤2t 工件间a1侧边a 工件间a 侧边a1工件间a1侧边a0.25以下 1.8 2.0 2.2 2.5 2.8 3.0 0.25~0.5 1.2 1.5 1.8 2.0 2.2 2.5 0.5~0.8 1.0 1.2 1.5 1.8 1.8 2.00.8~1.2 0.8 1.0 1.2 1.5 1.5 1.81.2~1.5 1.0 1.2 1.5 1.8 1.92.01.6~2.0 1.2 1.5 1.8 2.0 2.0 2.22.0~2.5 1.5 1.8 2.0 2.2 2.2 2.52.5~3.0 1.8 2.2 2.2 2.5 2.5 2.83.0~3.6 2.2 2.5 2.5 2.8 2.8 3.23.5~4.0 2.5 2.8 2.8 3.2 3.2 3.54.5~5.0 3.0 3.5 3.5 4.0 4.0 4.5表4-3 规则形状冲裁凸、凹模制造极限偏差材料厚度t/mm基本尺寸/mm-10 >10~50 >50~100 >100~150 +δd﹣δp+δd﹣δp+δd﹣δp+δd﹣δp0.4 +0.006 -0.004 +0.006 -0.004 ————0.5 +0.006 -0.004 +0.006 -0.004 +0.008 -0.005 ——0.6 +0.006 -0.004 +0.008 -0.005 +0.008 -0.005 +0.010 -0.0070.8 +0.007 -0.005 +0.008 -0.006 +0.010 -0.007 +0.012 -0.0081.0 +0.008 -0.006 +0.010 -0.007 +0.012 -0.008 +0.015 -0.010 1.2 +0.010 -0.007 +0.012 -0.008 +0.017 -0.010 +0.017 -0.012 1.5 +0.012 -0.008 +0.015 -0.010 +0.020 -0.012 +0.020 -0.0141.8 +0.015 -0.010 +0.017 -0.012 +0.025 -0.014 +0.025 -0.0172.0 +0.017 -0.012 +0.020 -0.014 +0.030 -0.017 +0.029 -0.0202.5 +0.023 -0.014 +0.027 -0.017 +0.035 -0.020 +0.035 -0.0233.0 +0.027 -0.017 +0.030 -0.020 +0.040 -0.023 +0.040 -0.027表4-1 落料、冲孔模具刃口初始间隙材料名称45T8、T7(退火)磷青铜(硬)铍青铜(硬)10、15、20冷轧带钢30钢板H62、H68(硬)LY12、硅钢片Q215、Q235 08、10、15H62、H68(半硬)纯铜磷青铜铍青铜(软)H62、H68(软)纯铜(软)3A21、5A02 1060、1050A 1035、12008A06、2A12力学性能HBS≥190σb≥600MPa HBS=140~190σb≥400~600MPa HBS=70~140σb≥300~400MPa HBS≤70σb≤300MPa厚度初始间隙Z min ZmaxZminZmaxZminZmaxZminZmax0.1 0.015 0.035 0.01 0.03 ————0.2 0.025 0.045 0.015 0.035 0.01 0.03 ——0.3 0.04 0.06 0.03 0.05 0.02 0.04 0.01 0.03 0.5 0.08 0.10 0.06 0.08 0.04 0.06 0.025 0.0450.8 0.13 0.16 0.10 0.13 0.07 0.10 0.045 0.0751.0 0.17 0.20 0.13 0.16 0.10 0.13 0.065 0.095 1.2 0.21 0.24 0.16 0.19 0.13 0.16 0.075 0.105 1.5 0.27 0.31 0.21 0.25 0.15 0.19 0.100.141.8 0.34 0.38 0.27 0.30 0.20 0.24 0.13 0.172.0 0.38 0.42 0.30 0.34 0.22 0.26 0.14 0.18表4-2 磨损系数材料厚度t/mm非圆形工件x值圆形工件x值1 0.75 0.5 0.75 0.5工件公差Δ/mm1 <0.16 0.17~0.35 ≥0.36 <0.16 ≥0.16 1~2 <0.20 0.21~0.41 ≥0.42 <0.20 ≥0.20 2~4 <0.24 0.25~0.49≥0.50 <0.24 ≥0.24>4 <0.30 0.31~0.59 ≥0.60 <0.30 ≥0.30。

模具标准件数据手册篇一:模具标准件申购表的填写规范制表:刘东林2019-5-29审核:批准:制表:刘东林2019-5-29审核:批准:篇二:标准件手册标准件速查手册(第一版)紧固件的常用规格目录一螺纹紧固件综合12-2001紧固件外螺纹零件未端------------------------------------12152.2-1988紧固件沉头用沉孔-----------------------------------23152.3-1988紧固件圆柱头用沉孔--------------------------------4152.4-1988紧固件六角头螺栓和六角螺母用沉孔-----------55277-1985紧固件螺栓和螺钉通孔---------------------------二螺栓68-1988方头螺栓级--------------------------------------737-1988形槽用螺栓----------------------------------------------8799-1988地脚螺栓--------------------------------------------------95780-2000六角头螺栓级------------------105781-2000六角头螺栓全螺纹级--------115782-2000六角头螺栓-----------------------------------------------125783-2000六角头螺栓全螺纹-------------------------------三螺柱13897-1988双头螺柱1------------------14898-1988双头螺柱125----------------------------------------15899-1988双头螺柱15------------------------------------------16900-1988双头螺柱2-------------------------------------------17901-1988等长双头螺柱正级----------------------------------189953-1988等长双头螺柱级----------------------------------------四螺母1941-2000六角螺母级---------------------------------------------2056-1988六角厚螺母-----------------------------------------------21810-1988小圆螺母-------------------------------------------------22812-1988圆螺母---------------------------------------------------236170-2000Ⅰ型六角螺母---------------------------------------------246172.1-2000六角薄螺母---------------------------------------257382-1994吊环螺母-------------------------------------------------五螺钉1标准件速查手册2670.1-2000内六角圆柱头螺钉-----------------------------------------2771-1985开槽锥端紧定螺钉-----------------------------------------2872-1985开槽锥端定位螺钉-----------------------------------------2973-1988开槽平端紧定螺钉-----------------------------------------3074-1985开槽凹端紧定螺钉-----------------------------------------3175-1985开槽长圆柱端紧定螺钉-----------------------------------3277-1985内六角平端紧定螺钉---------------------------------------3378-2000内六角锥端紧定螺钉---------------------------------------3479-2000内六角圆柱端紧定螺钉------------------------------------3580-2000内六角凹端紧定螺钉--------------------------36825-1988吊环螺钉-------------------------------------------------六组合件连接副379074.1-2019螺栓或螺钉和平垫圈组合件---------------------389074.15-1988六角头螺栓和平垫圈组合件----------------------399074.17-1988六角头螺栓和弹簧垫圈及平垫圈组合件----409074.26-1988组合件用弹簧垫圈-----------------------------419074.27-1988组合件用外锯齿锁紧垫圈----------------------七木螺钉及自攻螺钉(略)八销4291-2000开口销---------------------------------------------43117-2000圆锥销----------------------------------------44119.1-2000圆柱销不淬硬钢和奥氏体不锈钢-----------------45119.2-2000圆柱销淬硬钢和马氏体不锈钢-----------------46120.1-2000内螺纹圆柱销不淬硬钢和奥氏体不锈钢----------47120.2-2000内螺纹圆柱销淬硬钢和马氏体不锈钢----------48879.1-2000弹性圆柱销直槽重型-------------------------49879.2-2000弹性圆柱销直槽轻型--------------------------50879.3-2000弹性圆柱销卷制重型-------------------------2标准件速查手册51879.4-2000弹性圆柱销卷制标准型-----------52879.5-2000弹性圆柱销卷制轻型-------------------------------53881-2000螺尾锥销---------------------------------------------------九铆钉54827-1986标牌用铆钉-------------------------------------------------十垫圈及档圈5593-1987标准型弹簧垫圈---------------------------------------------5695-2019平垫圈级-------------------------------------------------5797.1-2019平垫圈级-------------------------------------------------5897.4-2019平垫圈用于螺钉和垫圈组合----------------------59848-2019小垫圈级-------------------------------------------------60856-1988外舌止动垫圈-----------------------------------------------61857-1988圆螺母用止动垫圈---------------------------------62886-1986轴肩挡圈---------------------------------------------------63893.1-1986孔用弹性挡圈型---------------------------------64893.2-1986孔用弹性挡圈型-------------------------------65894.1-1986轴用弹性挡圈型-----------------------------------66894.2-1986轴用弹性挡圈型--------------------------------67895.1-1986孔用钢丝挡圈-----------------------------------68895.2-1986轴用钢丝挡圈---------------------------------------69921-1986钢丝锁圈---------------------------------------------------十一焊钉3标准件速查手册一螺纹紧固件综合1.2-2001紧固件外螺纹零件未端(返回文档顶端)1标准件速查手册2.152.2-1988紧固件沉头用沉孔螺纹规适用于沉头螺钉及半沉头螺钉格568101262021310.612.817.620.324.432.440.42.73.34.6568101135.56.691113.517.5223.152.3-1988紧固件圆柱头用沉孔231适用于70螺纹规格5681012162024303621310.011.015.018.020.026.033.040.048.057.0135.76.89.011.013.017.521.525.532.038.03--------16.020.0 24.028.026.042.01135.56.69.011.013.517.522.026.033.039.0适用于65,6190,6191螺纹规格56810121620------21310.011.015.018.020.026.033.0------134.04.76.07.08.010.512.5------3--------16.018.024.0------1135.56.69.011.013.517.522.0------4.152.4-1988紧固件六角头螺栓和六角螺母用沉孔231螺纹规格568101216202427--213111318222633404853--3--------1620242833--1(13)5.56.691113.517.5222630--螺纹规格303639424548525660642136171768289981071121181253364245485156606872761(13)33394245485256626670(返回文档顶端)-2-标准件速查手册5.5277-1985紧固件螺栓和螺钉通孔(一般选用中等装配精度)螺纹规格56810121620242730精装配精5.36.48.410.5131721252831篇三:五金模具标准件五金模具标准件目录……………………………………………………………………21、内导柱、导套………………………………………………………32、外导柱、导套………………………………………………………43、内六角螺丝…………………………………………………………84、固定销………………………………………………………………105、弹簧…………………………………………………………………116、等高套筒……………………………………………………………147、顶料销………………………………………………………………158、止符螺丝……………………………………………………………189、两用销………………………………………………………………1910、导正销……………………………………………………………2111、圆冲子……………………………………………………………2312、优力胶……………………………………………………………2513、检测销……………………………………………………………25第一节:内导柱、导套一、主要功能:内导柱主要用于模板间和上、下模间的导正。

progressive模具标准件-1预览说明:预览图片所展示的格式为文档的源格式展示,下载源文件没有水印,内容可编辑和复制A-1PROGRESSIVE15OCT2007Pin Comparison ChartThis chart references standard nominal Ejector Pins and their Progressive catalog prefix.Refer to each specific catalog page for available shoulder lengths and overall lengths.A-2PROGRESSIVE15OCT2007MH-13HCore:40-44HRC,Surface:66-70HRC Ejector PinsStraightPins ?Inch StandardD Tolerances3/64?-7/16?-.0004-.000715/32?and Up-.0004-.0009CAD insertion pointH=25"For keyed pins,see page A-10.PROGRESSIVE15OCT2007A-3=14"CAD insertion pointMH-13HCore:40-44HRC,Surface:66-70HRCEjector PinsShoulder Pins ?Inch StandardFor keyed pins,see page A-10.Ejector PinsStraight Pins?DINStandardM1.2344H Core:40-44HRC,Surface:68-70HRCD T CAD insertion pointContact Customer Service for the availability of through-hardened ejector pins.For keyed pins,see page A-10.A-4PROGRESSIVE15OCT2007A-5PROGRESSIVE15OCT2007Ejector PinsShoulder Pins ?DINStandardM1.2344HCore:40-44HRC,Surface:68-70HRCBL=200mmg635±2CAD insertion pointContact Customer Service for the availability of through-hardened ejector pins.For keyed pins,see page A-10.A-6PROGRESSIVEEjector PinsStraight Pins ?JISStandard15OCT2007MSKD61HCore:40-44HRC,Surface:66-70HRCDL=-0.01-0.02CAD insertion pointFor keyed pins,see page A-10.A-7PROGRESSIVE15OCT2007MSKD61HCore:40-44HRC,Surface:66-70HRCEjector PinsShoulder Pins ?JISStandardD -0.01-0.0235±2STANDARD B L=200mmCAD insertion pointFor keyed pins,see page A-10.A-8PROGRESSIVEMH-13HCore:40-44HRC,Surface:66-70HRCSChrome Plated .00005-.00007”ThickUltraPinsTreated StraightPinsDApplication Information:Maximum operating temperature:1600?F (870?C)Not recommended for use with PVC or similarly corrosive materials.Contact Customer Service for availability on other diameters and lengths not shown.US Patent No.5,644,833and 6,752,616Other patents pendingCAD insertion point15OCT2007A-9PROGRESSIVE15OCT2007MH-13HCore:40-44HRC,Surface:66-70HRCSChrome Plated .00005-.00007”Thick US Patent No.5,644,833and 6,752,616Other patentspending36CAD insertion pointUltraPinsTreated Shoulder PinsA-10PROGRESSIVE15OCT2007Keyed Ejector PinsStraight Style ?Inch Standard+.002-.000D (Pin tangent)+.002-.000D Tolerances1/8?-7/16?-.0004-.00071/2?and Up-.0004-.0009MH-13CAD insertion pointAll Progressive standard Ejector Pins (Inch,DIN,and JIS)can be supplied with keyed heads.To order items with the flat ground tangent to the pin diameter,specify -K after the catalog number.Ex.EP437L10-K or EPD10L200-KTo order pins with the flat machined a specific distance from the center of the pin,specify that distance after the “K”designation for the flat as shown below.HCore:40-44HRC,Surface:66-70HRCExamples:EP437L10-K250for a 7/16?pin with a flat 1/4”from centerEPD10L200-K6for a 10mm diameter DIN pin with a flat 6mm from center EPJ055L250-K4for a 5.5mm diameter JIS pin with a flat 4mm from centerDHA-11PROGRESSIVE15OCT2007D R X L=+0.000-0.015Y CAD insertion pointContact Customer Service for the availability of JIS Blade Ejectors by specifying the information shown below:MO-1H58-60HRCJIS SpecificationMaterial:SKS-21Blade EjectorsDIN StandardA-12PROGRESSIVE15OCT2007MH-13H30-35HRCNote:Heads are annealed on 6",10"and 14"lengthsCorePinsHDHCAD insertion pointMH-13H50-55HRCA-13PROGRESSIVE15OCT2007MM-2H60-64HRCTI TMPinsThousandth IncrementPinsDTo order:Specify the prefix TI-and the three place decimal of the pin required,followed by a "0"if not nominal:Ex:.090?=TI-0900or.252?=TI-2520If a nominal size,carry to a four place decimal as listed in the chart at left:Ex.5/32?nominal =TI-1562or3/32?=TI-0937Contact Customer Service for availability of additional diameters or lengths.CAD insertion pointA-14PROGRESSIVE15OCT2007MH-13HCore:40-44HRC,Surface:65-75HRCEjector SleevesInch StandardJIS &DINSpecification32±2General DimensionsN=1-3/4”for ES094&ES125N=2-1/4”for ES156and largerT=.187”for ES094thru ES156T=.250”for ES187and largerDBCAD insertion pointJIS Material:SKD61,40HRC Core,70HRC Surface DIN Material:1.2067,60HRC Thru-hardenedContact Customer Service for the availability of metric sleeves,either in the JIS or DIN standard,by specifying the information shown below.Contact Customer Service for the availability of sleeves with the outer diameter (B).005"oversize (10”lengths or less)To achieve longer lengths,use Sleeve Extensions shown on page A-16.A-15PROGRESSIVE15OCT2007MA-2H58-60HRCSElectroless Nickel Coated .00003”-.00007”ThickMaterial:A-2Contact Customer Service for the availability of metric Thin Wall Sleeves by specifying the information shown below.MetricSpecificationCAD insertion pointDGH To achieve longer lengths,use Sleeve Extensions shown on page A-16.US Patent No.6,872,069Ejector SleevesThin Wall SleevesA-16PROGRESSIVEMAISI 1215H170BrinellSBlack OxideCatalog DHCAD insertion pointUS Patent No.6,872,06915OCT2007A-17PROGRESSIVE5DEC2007Core PinRetainersCAD insertion pointUS Patent No.6,872,069ABHexBM AISI 12L14H 165Brinell SBlack OxideCatalogAM AISI 12L14H 165BrinellSBlack OxideCatalogAInch StandardMetric Standard15OCT2007CAD insertion point =1/2"DM AISI52100H Core:30HRC max,Surface:58-62HRCReturn PinsA-18PROGRESSIVEInjection Mold ComponentsPin ProductsCatalog Pages are provided in Adobe Acrobat?.PDF) format. Comparison ChartThe full range of Progressive Pins are engineered and manufactured to meet the demands of today's plastic injection molders. Most pins are etched with Progressive's logo and catalog number for easy identification. A comprehensive listing of US Inch, DIN and JIS may be downloaded for your reference.Pin ChartEjector PinsProgressive Ejector Pins are precision ground and hardened for maximum wear resistance and are available in JIS, DIN and Inch standards.Inch StandardStraight Style Catalog Page Download 2D Download 3DShoulder Style Catalog Page Download 2D Download 3DDIN StandardStraight Style Catalog Page Download 2D Download 3DShoulder Style Catalog Page Download 2D Download 3DJIS StandardStraight Style Catalog Page Download 2D Download 3DShoulder Style Catalog Page Download 2D Download 3DKeyed Ejector PinsNew from Progressive Components: KeyedEjector Pins with ground heads tangent to thepin diameter.。