随机预测控制经典参考文献2

- 格式:doc

- 大小:68.00 KB

- 文档页数:7

g11=poly2tfd(12.8,[16.7,1],0,1);%POL Y2TFD Create transfer functions in 3 row representation将通用的传递函数模型转换为MPC传递函数模型% g = poly2tfd(num,den,delt,delay)% POL Y2TFD creates a MPC toolbox transfer function in following format:%g为对象MPC传递函数模型% g = [ b0 b1 b2 ... ] (numerator coefficients)% | a0 a1 a2 ... | (denominator coefficients)% [ delt delay 0 ... ] (only first 2 elements used in this row)%% Inputs:% num : Coefficients of the transfer function numerator.% den : Coefficients of the transfer function denominator.% delt : Sampling time. Can be 0 (for continuous-time system)% or > 0 (for discrete-time system). Default is 0.% delay : Pure time delay (dead time). Can be >= 0.% If omitted or empty, set to zero.% For discrete-time systems, enter as PERIODS of pure% delay (an integer). Otherwise enter in time units.g21=poly2tfd(6.6,[10.9,1],0,7);g12=poly2tfd(-18.9,[21.0,1],0,3);g22=poly2tfd(-19.4,[14.4,1],0,3);delt=3;ny=2;tfinal=90;model=tfd2step(tfinal,delt,ny,g11,g21,g12,g22)%对于这个例子,N=90/3=30figure(3)plot(model)%TFD2STEP Determines the step response model of a transfer function model.传递函数模型转换成阶跃响应模型% plant = tfd2step(tfinal, delt2, nout, g1)% plant = tfd2step(tfinal, delt2, nout, g1, ..., g25)% The transfer function model can be continuous or discrete.%% Inputs:% tfinal: truncation time for step response model.% delt2: desired sampling interval for step response model.% nout: output stability indicator. For stable systems, this% argument is set equal to number of outputs, ny.% For systems with one or more integrating outputs,% this argument is a column vector of length ny with% nout(i)=0 indicating an integrating output and% nout(i)=1 indicating a stable output.% g1, g2,...: SISO transfer function described above ordered% to be read in columnwise (by input). The number of % transfer functions required is ny*nu. (nu=number of % inputs). Limited to ny*nu <= 25.%% Output:% plant: step response coefficient matrix in MPC step format. plant=model;P=6;M=2;ywt=[];uwt=[1 1];Kmpc=mpccon(model,ywt,uwt,M,P)%ywt,uwt : 相当于Q,R%MPCCON Calculate MPC controller gains for unconstrained case.% Kmpc = mpccon(model,ywt,uwt,M,P)% MPCCON uses a step-response model of the process.% Inputs:% model : Step response coefficient matrix of model.% ywt,uwt : matrices of constant or time-varying weights.相当于Q,R% If the trajectory is too short, they are kept constant% for the remaining time steps.% M : number of input moves and blocking specification. If% M contains only one element it is the input horizon% length. If M contains more than one element% then each element specifies blocking intervals.% P : output (prediction) horizon length. P = Inf indicates the% infinite horizon.%% Output:% Kmpc : Controller gain matrixtend=30;r=[0 1];[y,u]=mpcsim(plant,model,Kmpc,tend,r);%plan为开环对象的实际阶跃响应模型%model为辨识得到的开环阶跃响应模型%Kmpc相当于D阵%Tend仿真的结束时间.%R输出设定值和参考轨迹%r=[r1(1) r2(1)...rny(1);r1(2) r2(2)....rny(2);... r1(N) r2(N) ...rny(N)]%y:控制输出%u:控制变量%ym:模型预测输出%MPCSIM Simulation of the unconstrained Model Predictive Controller.% [y,u,ym] = mpcsim(plant, model, Kmpc, tend, r,usat, tfilter,% dplant, dmodel, dstep)% REQUIRED INPUTS:% plant(model): the step response coefficient matrix of the plant (model)% generated by the function tfd2step% Kmpc: the constant control law matrix computed by the function mpccon% (closed-loop simulations).For open-loop simulation, controller=[].% tend: final time of simulation.% r: for the closed-loop simulation, it is a constant or time-varying% reference trajectory. For the open-loop simulation, it is the% trajectory of the manipulated variable u.% OPTIONAL INPUTS:% usat: the matrix of manipulated variable constraints.It is a constant% or time-varying trajectory of the lower limits (Ulow), upper limits% (Uhigh) and rate of change limits (DelU) on the manipulated % variables. Default=[].% tfilter: time constants for noise filter and unmeasured disturbance lags.% Default is no filtering and step disturbance.% dplant: step response coefficient matrix for the disturbance effect on the% plant output generated by the function tfd2step. If distplant is% provided, dstep is also required. Default = [].% dmodel: step response coefficient matrix for the measured disturbance% effect on the model output generated by the function tfd2step.% If distmodel is provided, dstep is also required. Default=[].% dstep: matrix of disturbances to the plant. For output step disturbances% it is a constant or time-varying trajectory of disturbance values% For disturbances through step response models,it is a constant or% time-varying trajectory of disturbance model inputs.Default=[].% OUTPUT ARGUMENTS: y (system response), u (manipulated variable) and% ym (model response)plotall(y,u,delt)figure(2)plot(y,'*')南通大学毕业设计(论文)任务书题目锅炉液位系统的DMC-PID控制学生姓名朱养兵学院电气工程学院专业自动化班级自051学号0512012010起讫日期2009.2 -2009.6指导教师李俊红职称讲师发任务书日期2009 年2 月18 日●MATLAB 软件●JX-300X组态监控软件●浙大中控DCS●上海齐鑫公司过程控制对象●PC机。

模型预测控制作为可持续发展政策的综合评定摘要:基于静态开环最优化随机和多目标制定方法是形成定量可持续发展政策的综合评定方法的基础。

这里,人们探索出了模型预测控制和这种方法间的联系,重新提出了介绍动力学和地址转化闭环性能与稳定方法。

此方法具有适用性,但是希望这将提供给可持续发展规划从业人员选出新视野。

索引词:MPC-(随机模型预测控制),可持续发展。

1:介绍这里注重探讨预测控制与政策评价可持续发展的问题之间的联系。

最近的工作提出了一种综合应用滚动时域静态优化和定量研究的方法政策评估来分配科学研究和能源替代开发技术之间的预算。

然而,静态优化只允许一个政策的调整(例如:随机模型预测控制将输入预测的基准线当做1),并且两者兼有约束(关于预算和测量指标的成本),放置的目标函数(根据指标测量收益)这些都要强调在预测的基准线的终点的效应积累。

更为重要的是,以上没有考虑到滚动时域的开环优化应用到闭环时的效应。

折扣(一个程序一般占通货膨胀比例的大小通过i-steps-ahead,ρ i 0<ρ<1进行预测)以及因为发生直接限制条件引起的常见问题的避免不稳定的情况,但闭环性质却可以远离最优的情况。

尽管如此,这种方法是向前迈进的一步,因为它提出的问题,是一个强有力随机规划以及一个多目标背景的设定。

其中后者是可以透过概率的手段做出目标函数和约束,这种手段允许目标函数和任何一个被交换的约束。

这种方法的目的是维持约束等这些性质,却也做到引入动态性质并且保持了闭环稳定性。

这是既实现MPC(模型预测控制)配置的想法又同时保留随机和多目标本质问题的方法。

论文中第二部分回顾之前的研究,而第3部进行讨论重新提出了一种允许引进动态方法。

文中在第四部分研究模式选择,第五部分讨论MPC(模型预测控制)分解算法的战略目标相优化。

两部分中都是随机的并且能在众多问题中得到应用,并不仅限于可持续发展问题。

第VI部分给出了插图和第VII部分得出结论。

随机控制理论的一个主要组成部分是随机最优控制,这类随机控制问题的求解有赖于动态规划的概念和方法。

简介随机控制理论随机控制理论的目标是解决随机控制系统的分析和综合问题。

维纳滤波理论和卡尔曼-布什滤波理论是随机控制理论的基础之一。

内容控制理论中把随机过程理论与最优控制理论结合起来研究随机系统的分支。

随机系统指含有内部随机参数、外部随机干扰和观测噪声等随机变量的系统。

随机变量不能用已知的时间函数描述,而只能了解它的某些统计特性。

自动控制系统分为确定性系统和不确定性系统两类,前者可以通过观测来确定系统的状态,后者则不能。

随机系统是不确定性系统的一种,其不确定性是由随机性引起的。

严格地说,任何实际的系统都含有随机因素,但在很多情况下可以忽略这些因素。

当这些因素不能忽略时,按确定性控制理论设计的控制系统的行为就会偏离预定的设计要求,而产生随机偏差量。

涉及领域飞机或导弹在飞行中遇到的阵风,在空间环境中卫星姿态和轨道测量系统中的测量噪声,各种电子装置中的噪声,生产过程中的种种随机波动等,都是随机干扰和随机变量的典型例子。

随机控制系统的应用很广,涉及航天、航空、航海、军事上的火力控制系统,工业过程控制,经济模型的控制,乃至生物医学等。

研究课题随机控制理论研究的课题包括随机系统的结构特性和运动特性(如动态特性、能控性、能观测性、稳定性)的分析,随机系统状态的估计,以及随机控制系统的综合(即根据期望性能指标设计控制器)。

随机系统中含有随机变量,所以在研究中需要使用随机过程的基本概念和概率统计方法。

严格实现随机最优控制是很困难的。

对于线性二次型高斯(LQG)随机过程控制问题,包括它的特例最小方差控制问题,可以应用分离原理把随机最优控制问题分解成状态估计问题和确定性最优控制问题,最终能得到全局最优的结果。

但对于一般的随机控制问题应用分离原理只能得到次优的结果。

随机状态模型随机系统在连续时间情形下的动态过程,常可用随机微分方程随机微分方程描述,式中x(t)为状态向量,d x(t)为由时刻t至t+d t状态的增量,u(t)为控制输入,θ为随机参数,w(t)为独立增量随机过程,其微分d w(t)可理解为白噪声。

全过程控制研究参考文献全过程控制(APC)是一种在工业生产过程中实现自动化控制的方法,它涉及到多个学科领域,因此在研究中会涉及到大量的参考文献。

在全过程控制的研究中,参考文献可以涉及到控制理论、化工工程、计算机科学、数学建模等多个领域。

以下我将从不同角度列举一些可能涉及到的参考文献:1. 控制理论方面的参考文献,经典的控制理论著作如《现代控制工程》(Modern Control Engineering) by Ogata、《控制系统工程》(Control Systems Engineering) by Nise等都是全过程控制研究中常见的参考书目。

此外,针对特定的控制方法和算法,如模型预测控制(MPC)、PID控制、最优控制等,也有大量相关的期刊论文和专著可供参考。

2. 化工工程方面的参考文献,在全过程控制的研究中,化工工程领域的文献也是必不可少的。

例如,关于化工过程建模与仿真的经典著作《化工过程模拟与优化》(Chemical Process Simulation and Optimization) by George Stephanopoulos等,以及涉及到具体化工过程控制的期刊论文和专业杂志。

3. 计算机科学方面的参考文献,随着信息技术的发展,计算机科学在全过程控制研究中也扮演着越来越重要的角色。

例如,关于实时控制系统、数据采集与处理、人机交互等方面的文献都是非常重要的参考资料。

4. 数学建模方面的参考文献,全过程控制研究通常需要进行系统的数学建模与分析,因此数学方面的参考文献也是必不可少的。

例如,关于微分方程、优化理论、统计学等方面的文献都可能对全过程控制研究有所帮助。

需要注意的是,以上只是一些可能涉及到的参考文献领域和范围,并不是具体的文献清单。

在实际的研究过程中,需要根据具体的研究课题和方向,结合文献检索工具如Google Scholar、IEEE Xplore、ScienceDirect等进行详细的文献调研和查找,以获取最新、权威的参考文献。

mse,mae评价指标的参考文献均方误差(MSE)和平均绝对误差(MAE)是常用的评价指标,用于衡量预测模型的准确度。

关于这两个评价指标的参考文献有很多,以下是一些常见的参考文献:1. James, G., Witten, D., Hastie, T., & Tibshirani, R. (2013). An Introduction to Statistical Learning. Springer. 这本书介绍了统计学习的基本概念和方法,其中包括对MSE和MAE 等评价指标的讨论。

2. Hastie, T., Tibshirani, R., & Friedman, J. (2009). The Elements of Statistical Learning. Springer. 这本书是统计学习领域的经典教材,对于回归模型评价指标有详细的介绍。

3. Hyndman, R. J., & Athanasopoulos, G. (2018). Forecasting: Principles and Practice. OTexts. 这本书主要介绍了预测建模的原理和实践,其中包括对于MSE和MAE等评价指标的应用。

4. Montgomery, D. C., Peck, E. A., & Vining, G. G.(2012). Introduction to Linear Regression Analysis. Wiley. 这本书是关于线性回归分析的经典教材,对于回归模型评价指标有详细的讨论。

5. Shmueli, G. (2010). To Explain or to Predict? Statistical Science, 25(3), 289-310. 这篇论文讨论了统计建模的目的,其中包括对于预测模型评价指标的选择和应用。

以上文献都是在统计学、机器学习或预测建模领域具有权威性和影响力的著作,对于MSE和MAE等评价指标的原理、应用和比较都有较为详尽的讨论,可以作为参考文献来深入了解这些评价指标的相关知识。

本科毕业设计(论文)题目:二号,黑体,加粗,居中学院专业学生姓名学生学号指导教师提交日期年月日封面纸推荐用210g/m2的橙色色书编辑完后需将全文绿色说明文字删除,格式不变(另起页;摘要范例)摘要(小三号,宋体,加粗,居中,上下空一行)(摘要正文共400—600个字;小四号,宋体,行距为固定值20磅,段首行空两个汉字)本文详细介绍了多变量预测控制算法及其在环境试验设备控制中的应用。

由于环境试验设备的温度和湿度控制系统具有较大的时间滞后,而且系统间存在比较严重的耦合现象,用常规的PID控制不能取得满意的控制效果。

针对这种系统,本文采用了多变量预测控制算法对其进行了控制仿真。

预测控制算法是一种基于系统输入输出描述的控制算法,其三项基本原理是预测模型、滚动优化、反馈校正。

它选择单位阶跃响应作为它的“预测模型”。

这种算法除了能简化建模过程外,还可以通过选择合适的设计参数,获得较好的控制效果和解耦效果。

本文先对环境试验设备作了简介,对控制中存在的问题进行了说明;而后对多变量预测控制算法进行了详细的推导,包括多变量自衡系统预测制算法和多变量非自衡系统预测控制算法;然后给出了系统的建模过程及相应的系统模型,在此基础上采用多变量预测控制算法对环境试验设备进行了控制仿真,并对仿真效果进行了比较。

仿真结果表明,对于和环境试验设备的温度湿度控制系统具有类似特性的多变量系统,应用多变量预测控制算法进行控制能够取得比常规PID控制更加令人满意的效果。

关键词(小三号,宋体,加粗,居左):多变量系统;预测控制;环境试验设备(关键词3—5个;小四号,宋体;关键词之间用分号隔开;最后一个关键词不打标点符号)(另起页:外文摘要范例;英文摘要和关键词应该是中文摘要和关键词的翻译)Abstract(小三号,Times New Roman字体,加粗,居中,上下空一行)。

(正文:Times New Roman字体,小四号,行距为固定值20磅)In this paper, multivariable predictive control algorithm and its application to the control of the environmental test device are introduced particularly. The temperature and humidity control system of the environmental test device is characterized as long time delay and severe coupling. Therefore, the routine PID control effect is unsatisfactory. In this case, the simulation of the temperature and humidity control of the environmental test device based on multivariable predictive control algorithm is made.Predictive control algorithm is one of control algorithm based on description of system’s input-output. Its three basic principles are predictive model, rolling optimization and feedback correction. It chooses unit step response as its predictive model, so that the modeling process is simplified. In addition, good control and decoupling effects could be possessed by means of selection suitable parameters.In this paper, the environmental test device is introduced briefly and the existing problems are showed. Then multivariable predictive control algorithm is presented particularly, including multivariable auto-balance system predictive control algorithm and multivariable auto-unbalance system predictive control algorithm. Next, system modeling process and corresponding system model are proposed. Further, the multivariable predictive control algorithm is applied to the temperature and humidity control system of the environmental test device. Finally, the simulation results are compared.Results of the simulation show that multivariable predictive control algorithm could be used in those multivariable system like the temperature and humidity control system of the environmental test device and the control result would be more satisfactory than that of the routine PID control.Keyword(Times New Roman字体,小三号,加粗,居左): Multivariable system, Predictive control, Environmental test device(Times New Roman字体,小四号)(另起页:目录范例)目录(小三号,宋体,加粗,居中,上下空一行,目录由电脑自动生成)(各章题序及标题:小四号,宋体,加粗,居左;其余用小四号,宋体)摘要ⅠABSTRACT Ⅱ第一章引言1 1.1 预测控制概述 11.2 环境试验设备简介 2 1.3 主要研究工作 21.4 本文安排 3第二章基础知识介绍 42.1预测控制的基本原理 42.1.1 预测控制的三项基本原理 42.1.2 预测控制的几种算法 52.2 动态矩阵控制算法 52.2.1 概述 52.2.2 动态矩阵控制算法 62.3 本章小结 10第三章环境试验设备介绍及建模研究113.1 环境试验设备介绍 113.1.1 简介 113.1.2 环境试验设备的结构及硬件 113.1.3 环境试验设备控制的难点 123.2 环境试验设备的建模研究 123.2.1环境实验设备的模型概述123.2.2飞升曲线法辨识环境试验设备的数学模型143.3 本章小结 19第四章多变量预测控制算法的研究与推导 204.1 多变量预测控制算法的推导 204.2 仿真研究 244.3 本章小节 25第五章多变量非自衡系统预测控制算法的研究与推导26 5.1 多变量非自衡系统预测控制算法 265.1.1 单变量非自衡系统预测控制算法 265.1.2 多变量非自衡系统预测控制算法 295.2 仿真研究 335.3 本章小结 34第六章环境试验设备的预测控制研究 356.1 脉冲响应系数模型的获得及对象特性分析 356.1.1 脉冲响应系数模型的获得356.1.2 对象特性分析 36 6.2仿真控制实验376.2.1 参数选择376.2.2 仿真控制结果 43 6.3本章小结45结束语 46 参考文献47 附录48 致谢49第一章绪论(三号,宋体,加粗,居中,上下空一行)(1)正文层次正文所有章节按“第一章、第二章、第三章……(换章时必须换页);1.1、1.2、1.3……;1.2.1、1.2.2、1.2.3……”编排。

文献综述模糊PID控制器的研究与应用学院自动化与电子信息学院二O一四年四月四川理工学院毕业(设计)论文文献综述0 前言PID控制作为一种典型的传统反馈控制器,以其结构简单,易于实现和鲁棒性好等特点在工业过程控制中广泛应用。

但是传统PID控制器的参数需要被控对象的数学模型来进行调整,而控制过程中的滞后性、控制参数的非线性和高阶性增加了对Kp、Ki、Kd三个参数的调整难度。

所以对确定的控制系统通过复杂的计算后,其三个参数的值在控制运行中一般是固定的,不易进行在线的调整。

而在实际的工业生产过程中,许多被控对象受到负荷变化和干扰因素的作用,其对象参数的特征和结构易发生改变,这就需要对参数进行动态的调整。

同样因为被控系统的复杂性和不确定性,其精确的数学模型难以建立,甚至无法建立模型,所以需要利用模糊控制技术等方法来解决。

模糊PID无需考虑被控系统的模型,而只根据其误差e 和误差变化ec等检测数据来自适应调整Kp、Ki、Kd的值,最终使被控系统处于稳定工作态。

1 国外研究现状ŞabanÇetin,AliVolkanAkkaya[1](2010)表示准确度和精密度液压系统的位置控制是为了设置更经济和高质量系统的关键参数。

在此背景下,他们提出了由一个非对称液压缸由一个四通、三位比例阀驱动的液压驱动系统的建模与位置控制。

在此系统模型中,体积弹性模量被认为是一个变量。

此外,基于规则的混合型模糊 PID控制器(H F P I DC R)提出了液压系统的位置控制,并对其性能进行了仿真研究测试。

这种控制器的新颖方面是模糊逻辑和PID 控制器结合在一个开关条件。

该HFPIDCR 基于控制器的模拟结果与经典PID、模糊逻辑控制器(FLC)和混合模糊PID 控制器(HFPID)的结果进行了比较。

因此,它被证明了混合型模糊PID控制器加上规则比其他的控制器更有效。

IndranilPana[ 2] 等(2011)通过减少积分时间降低最优PID 和最优模糊PID的绝对误差(ITAE)和平方控制器输出的网络控制系统(NCS)的响应速度。

预测控制之探究摘要预测控制是近年来发展起来的一类新型的计算机控制算法。

由于它采用多步测试、滚动优化和反馈校正等控制策略,因而控制效果好,适用于控制不易建立精确数字模型且比较复杂的工业生产过程,所以它一出现就受到国内外工程界的重视,并已在石油、化工、电力、冶金、机械等工业部门的控制系统得到了成功的应用。

关键词:预测控制滚动优化反馈校正AbstractPredictive control is developed in recent years to a new type of computer control algorithm.Because it USES multi-step testing, roll optimization and feedback correction, the control strategies and control effect is good, suitable for control is not easy to build accurate digital model and more complex industrial production process, so it appeared at home and abroad by the attention of engineering, and has set up a file in the petroleum, chemical, electric power, metallurgy, machinery, and other departments of industry control systems have been successful application. Keywords: Predictive control rolling optimization feedback correction预测控制的起源预测控制是自动控制理论的一个分支。

预测控制经典书籍预测控制是一种控制理论和方法,它在许多工程和科学领域中都有广泛的应用。

关于预测控制的经典书籍有很多,以下是一些被广泛认可的经典著作:1. "Predictive Control for Linear and Hybrid Systems",作者,Alberto Bemporad 和 Manfred Morari。

这本书详细介绍了线性和混合系统的预测控制理论和方法,包括基本概念、算法和应用。

2. "Predictive Control with Constraints",作者,Jan Maciejowski。

这本书深入探讨了带有约束条件的预测控制问题,涵盖了理论、算法和实际应用,对于控制工程师和研究人员来说是一本非常有价值的参考书。

3. "Predictive Control: An Introduction",作者,Finn Haugen。

这本书是一本介绍性的著作,适合初学者阅读,它详细解释了预测控制的基本概念、原理和应用,是学习预测控制的良好起点。

4. "Predictive Control in Process Engineering: From the Basics to the Applications",作者,Andrey P. Naumenko 和Leonid M. Fridman。

这本书着重介绍了预测控制在过程工程中的应用,涵盖了从基础知识到实际应用的内容,对于从事过程控制工程的专业人士来说是一本不可多得的参考书。

这些经典书籍涵盖了预测控制的基本理论、算法和实际应用,对于想深入了解预测控制的人士来说都是非常有价值的参考资料。

阅读这些书籍可以帮助读者建立扎实的预测控制理论基础,掌握预测控制的关键概念和技术,从而在工程实践中取得更好的应用效果。

先进控制技术的几种控制策略综述明权(湖南大学电气与信息工程学院,湖南长沙410004)(E-mai: 87269709@)摘要:近十几年来,世界各国在加强建模理论、辨识技术、最优控制、高级过程控制等方面进行了研究,涌现出很多针对模型要求不高、在线计算方便、对过程及环境的不确定性有一定适应能力的先进控制策略和方法,主要有自适应控制、鲁棒控制、预测调制、H∞控制、模糊控制、人工智能控制等,本文综合分析了这些先进控制策略发展动态。

关键词:先进控制;控制策略;自适应控制;鲁棒控制;H∞控制;预测调制;模糊控制;人工智能控制。

1、引言众所周知,控制策略是控制的核心。

从模拟控制系统开始,到数字控制系统及模数混合系统的长期发展过程中,形成了许多有效的控制策略(方法),一般分为两类:传统控制策略和现代控制策略。

传统控制策略主要有PID控制、Smith控制和解耦控制。

然而随着现代工业的大型化、复杂化发展,为了保证系统的稳定性、生产的安全性以及控制的精确性,采用单一基于定量的数学模型的传统控制理论与控制策略已经远远不能胜任。

于是,开发高级的过程控制系统,研究高级的控制策略,越来越成为控制界的关注对象。

近些年来,针对复杂控制过程的不确定性(环境结构和参数的未知性、时变性、随机性、突变性)、非线性、变量间的关联性以及信息的不完全性和大纯滞后性等,一批对模型要求不高、在线计算方便,对过程和环境的不确定性有一定适应能力的控制策略和方法得到了引用、改进和发展。

下文将先简单介绍几种传统控制策略,然后在其基础上比较性地引出自适应控制、鲁棒控制、H∞控制、预测控制、模糊控制、智能控制等控制策略。

2、传统控制策略简介2.1 PID控制PID控制策略是应用的最广泛的一种算法,它无论在模拟调节或数字控制中,都得到了广泛的应用。

这种控制方法具有一系列特性:(1)PID算法蕴涵了动态控制过程中过去、现在和将来的主要信息,而且其配置几乎最优。

自动控制理论发展摘要:本文主要回顾了“自动控制理论”的产生与发展过程,通过对不同时期,不同阶段的理论研究成果的简要介绍,掌握经典控制理论、现代控制理论、大系统理论和智能控制系统理论知识理论框架,进而加深对“自动化控制理论”认知。

关键词:自动控制理论产生与发展过程理论框架结构控制论一词Cybernetics,来自希腊语,原意为掌舵术,包含了调节、操纵、管理、指挥、监督等多方面的涵义。

[1]因此”控制”这一概念本身即反映了人们对征服自然与外在的渴望,控制理论与技术也自然而然地在人们认识自然与改造自然的历史中发展起来。

一、经典控制论阶段(20世纪50年代末期以前)经典控制理论,是以传递函数为基础,在频率域对单输入---单输入控制系统进行分析与设计的理论[4]1、控制系统的特点单输入---单输出系统的,线性定常或非线性系统中的相平面法也只含两个变量的系统。

2、控制思路基于频率域内传递函数的“反馈”和“前馈”控制思想,运用频率特性分析法、根轨迹分析法、描述函数法、相平面法、波波夫法,解决稳定性问题。

3、发展事件回顾[4][5]1)我国古人发明的指南车就应用了反馈的原理2)1788年J.Watt在发明蒸汽机的同时应用了反馈思想设计了离心式飞摆控速器,这是第一个反馈系统的方案。

3)1868年J.C.Maxwell为解决离心式飞摆控速器控制精度和稳定性之间的矛盾,发表《论调速器》,提出了用基本系统的微分方正模型分析反馈系统的数学方法。

4)1868年,韦士乃格瑞斯克阐述了调节器的数学理论。

5)1875年E.J.Routh和A.Hurwitz提出了根据代数方程的系数判断线性系统稳定性方法6)1876年俄国学者N.A.维什涅格拉诺基发表著作《论调速器的一般理论》,对调速器系统进行了全面的理论阐述。

7)1895年劳斯与古尔维茨分别提出了基于特征特征根和行列式的稳定性代数判别方法。

8)1927年H.S.Black发现了采用负反馈线路的放大器,引入负反馈后,放大器系统对扰动和放大器增益变化的敏感性大为降低。

浅谈控制理论演化及其发展趋势发布时间:2022-06-22T06:30:48.395Z 来源:《科技新时代》2022年6期作者:陈安杰[导读] 根据控制理论的理论基础及所能解决的问题的难易程度,我们把控制理论大体的分为了三个不同的阶段,经典控制论阶段,现代控制论阶段以及大系统理论与智能控制理论阶段。

本文在每个阶段都指出了其控制思路、主要成果以及不足,并在现代控制论部分给出了单输入单输出系统的R-L-C电路状态空间表达式。

最后结合当前的云计算阐述了控制理论的发展趋势及应用前景。

陈安杰(杭州万向职业技术学院,浙江杭州 310023)摘要:根据控制理论的理论基础及所能解决的问题的难易程度,我们把控制理论大体的分为了三个不同的阶段,经典控制论阶段,现代控制论阶段以及大系统理论与智能控制理论阶段。

本文在每个阶段都指出了其控制思路、主要成果以及不足,并在现代控制论部分给出了单输入单输出系统的R-L-C电路状态空间表达式。

最后结合当前的云计算阐述了控制理论的发展趋势及应用前景。

关键词:控制理论;现代控制;状态空间表达式;大系统理论;智能控制Talk about the evolution and development trend of control theoryChen An-jieHangzhou Wanxiang polytechnic College, Hangzhou 310023,ChinaAbstract: According to the theoretical basis of control theory and the difficulty degree of the problem it can solve, we divide control theory into three different stages, classical control stage, modern control stage and large system theory and intelligent control theory stage. In this paper, the control ideas, main achievements and shortcomings are pointed out in each stage, and the expression of R-L-C circuit state space of SISO system is given in the section of modern control stage. Finally, the development trend and application prospect of control theory are described in combination with current cloud computing.Key words:Control theory; Modern control; State space expression; Large systems theory; Intelligent control1 控制理论的演化发展史控制理论是关于各种系统的一般性控制规律的科学,它研究如何通过信号反馈来修正动态系统的行为和性能,以达到预期的控制目的[1]。

基于RBF网络的广义预测控制在单元机组中的应用X王景学1,杨学敏2(1.内蒙古机电职业技术学院,2.呼和浩特供电局,内蒙古呼和浩特 010010) 摘 要:大型火电机组具有控制对象复杂、非线性、大滞后、模型难以建立等特点,用传统的控制方法很难得到最佳的运行效果。

本文在RBF 神经网络建模的基础上,采用多变量广义预测控制策略,可有效弥补上述不足。

仿真结果表明了其有效性。

关键词:RBF 神经网络;广义预测控制;非线性;多变量;单元机组 中图分类号:T P183∶T M76 文献标识码:A 文章编号:1006—7981(2012)04—0020—02 火电厂大型单元机组控制对象具有非线性,多变量、强耦合、时变、大滞后的特性,当各种扰动作用时导致控制对象的参数不确定,模型难以准确建立,属于复杂难控的大型生产过程。

在常规局部控制系统基础上发展起来的协调控制系统是解决这个问题的有效途径。

协调控制系统的控制策略的设计直接决定了系统的调试和控制品质。

本文利用RBF 神经网络对非线性、大时滞和时变的大型单元机组协调控制系统进行建模和用广义预测控制方法进行控制,为大型单元机组协调控制问题的解决提供了一条很好的途径。

1 理论研究基于RBF 网络的广义预测控制算法由两部分组成:一是利用RBF 神经网络学习简单的受控对象非线性模型和以此为预测模型的滚动优化计算。

1.1 基于RBF 神经网络的预测模型火电厂锅炉、汽机协调控制系统是一个多变量非线性的复杂控制对象,数学上已经证明RBF 神经网络可以实现任何非线性映射,可以逼近任何复杂的函数。

因此本文首先建立一个RBF 神经网络来逼近此被控对象。

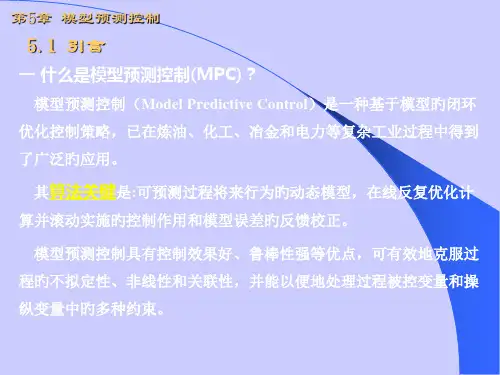

它是具有单隐层的三层前馈网络,结构如图1所示:图1 RBF 网络结构第一层为输入层,输入层节点数等效于系统的独立变量数目;第二层为隐含层,隐含层节点数目的选择通常根据经验确定;第三层为输出层,输出层节点数为被控对象输出的个数。

隐单元的变换函数是RBF,它是一种局部分布的对中心点径向对称衰减的非负非线性函数。

1971[5] Kushner,H.J. Introduction to stochastic control. Holt, Rinehartand Winston, 1971.1983[24] T. Morozan, “Stabilization of some stochastic discrete-time control-systems,”Stochast. Anal. Applicat. , vol. 1, no. 1, pp. 89–116, 1983.1986[12] Robert FS.1986.Stochastic optimal control:theory and application[M].Wiley.[] Kumar,P.R.,&Varaiya,P. Stochastic systems : estimation, identification, and adaptive control. Prentice Hall.19861987[16] D.W. Clarke, C. Mothadi, and P.S. Tuffs. Generalized predictive control. Auto-matica , 23:137–160, 1987.1997[10] J. Birge and F. Louveaux, Introduction to Stochastic Programming[M]. Springer, New York, 1997.[9] McLachlan GJ, Thriyambakam Krishnan. The EM algorithm and extensions[M]. Wiley.1997.[6]Meadows ES.Dynamic Programming and Model Predictive Control[C].Proceedings of the American Control Conference,1635-1639.1997.[2] Lee J,Yu Z. Worst-case formulation of model predictive control for systems with bounded parameters[J].Automatica 33,763–781. 1997.1998[6] Schwarm A,Nikolaou M.1998.Chance constrained model predictive control[J].AIChE Journal,45,1743–1752.[21] J.H. Lee and B.L. Cooley. Optimal feedback control strategies for state-space systems with stochastic parameters. IEEE Trans. Autom. Control, 43(10):1469–1475, 1998.[14] P.O.M. Scokaert and D.Q. Mayne. Min-max feedback model predictive control for constrained linear systems. IEEE Trans. Autom. Control , 43:1136–1142, 1998.[25] Koroleva N. Robust stability of uncertain stochastic differential delay equations [J]. Systems & Control Letters,1998,35(9):325-336.[] Kamen, E. W., & Su, J. K. Introduction to optimal estimation. London, UK:Springer.1999. 1999[4] Bemporad A, Morari M. Robust model predictive control: A survey[J]. Robustness in Identification and Control, 1999, 245: 207-226.[5] Blanchini F. Set invariance in control[J]. Automaica, 1999,35(11): 1747-1767.2000[3] Mayne D Q, Rawlings J B, Rao C V. Constrained model predictive control: Stability and optimality[J]. Automatica, 2000,36(6): 789-814.2001[10] 杜晓宁,席裕庚,李少远.约束预测控制的一种快速算法[J].上海交通大学学报,2001,35(11):1624-1627.Du X N, Xi Y G, Li S Y. Fast algorithm of constrained model predictive control[J]. Journal of Shanghai Jiaotong University, 2001, 35(11): 1624-1627.[11] Chisci L, Rossiter J A, Zappa G. Systems with persistent disturbance: Predictive control with restricted constraints[J]. Automatica, 2001, 37(7): 1019-1028.[23] Gershon R,Shaked U. H ∞control and filtering of discrete-time stochastic systems with multiplicative noise[J].Automatica,2001,37(3):409-417.[] I. Batina, A. A. Stoorvogel, and S. Weiland. Stochastic disturbance rejection in model predictive control by randomized algorithms. In proceedings of American Control Conference, pages 732–737, 2001.[1] I. Batina, A. A. Stoorvogel, and S. Weiland. Feed-back model predictive control by randomized algorithms. In proceedings of European Control Conference, pages 3185–3189, 2001.[2] I. Batina, A. A. Stoorvogel, and S. Weiland. Model predictive control by randomized algorithms for systems with constrained inputs and stochastic disturbances. IEEE Transactions on Automatic Control, December 2001.[11] D. H. van Hessem, C. W. Scherer, and O. H. Bosgra, “LMI-based closed-loop economic optimization of stochastic process operation under state and input constraints,”in Proc. 40th IEEE Conf. Decision Control, Orlando, FL, 2001, pp. 4228–4233.2002[17] P. Li, M. Wendt, and G. Wozny. A probabilistically constrained model predictive controller. Automatica, 38(7):1171–1176, 2002.[3] Kouvaritakis B,Cannon M,Tsachouridis V. Recent developments in stochastic MPC and sustainable development[J].Annual Reviews in Control,2002,volume 28,23–35. 2002.[4] I. Batina, A. A. Stoorvogel, and S. Weiland. Optimal control of linear, stochastic systems with state and input constraints. In proceedings of European Control Conference, pages 1564–1569, 2002.[7] vanHessem,D.H.,&Bosgra,O.H. A conic reformulation of model predictive control including boundedand stochastic disturbances understate and input constraints. In Proc.41st IEEE conf.Decision control (pp.4643 4648), 2002.2003[9] Liu B, Xi Y G. An aggregation based robust model predictive controller[J]. Acta Automatic Sinica, 2003, 29(6): 801-808.[19] A.J. Felt. Stochastic linear model predictive control using nested decomposition.In Proc. American Control Conf., pages 3602–3607, 2003.[15] A. Bemporad, F. Borrelli, and M. Morari. Min-max control of constrained uncertain discrete-time linear systems. IEEE Trans. Automatic Control , 48(9):1600–1606, 2003.[] vanHessem,D.H.,&Bosgra,O.H. A full solution to the constrained stochastic closed-loop MPC problem via state and innovations feedback and its receding horizon implementation, In Proceedings of the 42nd IEEE conference on decision and control,vol.1,(pp.929–934).2003.2004[12] Foss S, Konstantopoulos T. An overview of some stochastic stability methods[J]. Journal of Operations Research of Japan, 2004, 47(4): 275-303.[18] I. Batina. Model predictive control for stochastic systems by randomized algorithms . PhD thesis, Technische Universiteit Eindhoven, 2004.[24] Zhang WeiHai. On stabilizability and exact observability of stochastic systems with their applications [J], Automatic,2004,40(7):87-94.[7] Munoz D de la Pena, Alamo T, Bemporad A, Camacho EF. 2004. A Dynamic Programming Approach for Determining the explicit solution of linear MPC controllers[C]. Proceedings of 43rd IEEE Conference on Decision and Control, 2479-2484.[1] Batina,I. Model predictive control for stochastic systems by randomized algorithms. Ph.D.thesis, Technische Universiteit Eindhoven,2004.[4] Kouvaritakis B., Cannon M., Tsachouridis V. Recent developments in stochastic MPC and sustainable development. Annual Reviewsin Control, 28(1),23 35. 2004.[15] J. Dupaˇcova, G. Consigli, and S. W. Wallace, “Scenarios for multistage stochastic programs,”Ann. Operat. Res., vol. 100, pp. 25–53, 2004.[24] Zhang WeiHai.On stabilizability and exact observability of stochastic systems with their applications[J],Automatic,40(7):87-94, 2004.2005[13] 方洋旺.随机系统最优控制[M].北京:清华大学出版社,2005.Fang Y W. Optimal control for stochastic system[M]. Beijing: Tsinghua University Press, 2005.[4]Munoz D de la Pena,Bemporad A,Alamo T. Stochastic Programming Applied to Model Predictive Control[C].Proceeding of the 44th IEEE CDC,1361-1366.2005.[] Yan, J., & Bitmead, R. R. Incorporating state estimation into model predictive control and its application to network traffic control.Automatica, 595–604. 2005.2006[31] Couchman P, Kouvaritakis B, Cannon M. MPC on state space models with stochastic input map [C]. Decision and Control, 2006 45th IEEE Conference on. IEEE, 2006: 3216-3221.[20] B. Kouvaritakis, M. Cannon, and P. Couchman. MPC as a tool for sustain-able development integrated policy assessment. IEEE Trans. Autom. Control ,51(1):145–149, 2006.[47] Couchman PD,Cannon M,Kouvaritakis B. Stochastic MPC with inequality stability constraints [J]. Automatica, 2006, 42(6):2169-2174.Couchman, P., Cannon, M., & Kouvaritakis, B. (2006). Stochastic model predictive control with nonlinear models. Automatica , submitted for Publication.[3] Couchman P, Kouvaritakis B, Cannon, M. MPC on state space models with stochastic input map. InProc. 45th IEEE Conf. Decision and Control (pp.3216 3221).20062007[28] Cannon M, Couchman P, Kouvaritakis B. MPC for stochastic systems [J]. Assessment and Future Directions of Nonlinear Model Predictive Control, 2007: 255-268.[5] Cannon M,Couchman P,Kouvaritakis B. MPC for stochastic systems.Assessment and Future Directions of Nonlinear Model Predictive Control[J].Springer LNCIS,vol 358,255-268.2007.[11]Maciejowski JM,Visintini AL,Lygeros J. NMPC for Complex Stochastic Systems Using a Markov Chain Monte Carlo Approach [J]. Springer-Verlag, Assessment and Future Directions, LNCIS 358,pp.269-281. 2007.[3] Bertsimas, D., & Brown, D. B. (2007). Constrained stochastic LQC: a tractable approach. IEEE Transactions on Automatic Control, 52(10),1826–1841.[5]Primbs, J.A. A soft constraint approach to stochastic receding horizon control . InProc . 46th IEEE Conf.Decision Control. 2007.2008[26] Cannon M, Kouvaritakis B, Couchman P. [C]. Proceedings of 17th IFAC World Congress. 2008: 15321-15326.[9] Wang C, Ong C J, Sim M. Constrained linear system with disturbance: convergence under disturbance feedback.Au-tomatica, 2008, 44(10): 2583--2587[16] G. C. Goodwin, J.stergaard, D. E. Quevedo, and A. Feuer, “A vector quantization approach to scenario generation for stochastic NMPC,”in Int. Workshop Assess. Future Direct. Nonlinear Model Predict. Con-trol , Pavia, Italy, 2008.2009[11] Mark Cannon, Basil Kouvaritakis, Xingjian Wu, Model predictive control for systems with stochastic multiplicative uncertainty and probabilistic constraints, Automatica, V olume 45, Issue 1, January 2009, Pages 167-172[13] Cannon M, Kouvaritakis B, Ng D. Probabilistic tubes in linear stochastic model predictive control [J]. Systems & Control Letters, 2009, 58(10): 747-753.[4] Cannon M, Kouvaritakis B, Wu X J. Probabilistic constrained MPC for multiplicative and additive stochastic uncertainty.IEEE Transactions on Automatic Control,54(7),1626–1632. 2009[4] Cannon M. Ng, D,Kouvaritakis, B. Successive linearization NMPC for a class of stochastic nonlinear systems. InLNCIS: V ol. 384. Nonlinear model predictive control :towards new challenging applications (pp.249 262).2009.[6] Primbs J, Sung C H. Stochastic receding horizon control of constrained linear systems with state and control multiplicative noise[J]. IEEE Transactions on Automatic Control, 2009, 54(2):221-230.[8] Hokayem P, Chatterjee D, Lygeros J. On stochastic model predictive control with bounded control inputs[C]//Proceedings of the Combined 48th IEEE Conference on Decision & Control and 28th Chinese Control Conference. Piscataway, NJ, USA: IEEE, 2009: 6359-6364.[8]Wang C, Ong C J, Sim M. Convergence properties of con-strained linear system under MPC control law using a±nedisturbance feedback.Automatica, 2009, 45(7): 1715-1720.[] Wang, Y., & Boyd, S. (2009). Performance bounds for linear stochastic control. SystemsandControlLetters, 58(3),178–182.[] Magni.L.,Pala.D,Scattolini,R.Stochastic model predictive control of constrained linear systems with additive uncertainty. In European control conference (pp.2235–2240).Budapest, Hungary, 2009.[] Eugenio.E,Agarwal.M,Chatterjee,D.Lygeros,J. Convexity and convex approximations of discete-time stochastic control problems with constraints. Automatica, 47(9), 2082–2087.2011.[8] Chatterjee, D., Hokayem, P., & Lygeros, J. Stochastic receding horizon control with bounded control inputs: a vector space approach. IEEE Transactions on AutomaticControl,2009.[2] Bernardini D,Bemporad A. Scenario-based model predictive control of stochastic constrained linear systems. In IEEE conference on decision and control (pp.6333–6338).Shanghai,China.2009[4] Oldewurter,F.,Jones,C.N.,Morari,M..A tractable approximation of chance constrained stochastic MPC based on affine disturbance feedback . InProc.48th IEEE Conf. Decision Control.Cancun .2009.2010[27] Kouvaritakis B, Cannon M, RakovićS V, et al. Explicit use of probabilistic distributions in linear predictive control [J]. Automatica, 2010, 46(10): 1719-1724.[10]Wang C, Ong C J, Sim M. Model predictive control using segregated disturbance feedback. IEEE Transactions on Automatic Control, 2010, 55(4): 831--840[48] Minyong Shin.Primbs constrained stochastic MPC under multiplicative noise for financial applications[C].49th IEEE Conference on Decision and Control,Atlanta,2010,6101-6106.[] Ramponi, F., Chatterjee, D., Milias-Argeitis, A., Hokayem, P., & Lygeros, J. Attaining mean square boundedness of a marginally stable stochastic linear system with a bounded control input.IEEE Transactions on Automatic Control,55(10),2414–2418. 2010.[] Hokayem,P.,Chatterjee,D.,Ramponi,F.,Chaloulos,G.,Lygeros,J. Stable stochastic receding horizon control of linear systems with bounded control inputs. InInt. Symposium on mathematical theory of networks and systems (MTNS) (pp.31–36, Budapest).Hungary, July 2010.[] Hokayem, P., Cinquemani, E., Chatterjee. D,Lygeros, J. Stochastic MPC with imperfect state information and bounded controls .In Proceedings of the UKACC int. Conference on control. Coventry, UK, Sept.2010.[20] A. Bemporad, T. Gabbriellini, L. Puglia, and L. Bellucci, “Scenario-based stochastic model predictive control for dynamic option hedging,”in Proc. 49th IEEE Conf. Decision Control , Atlanta, GA, 2010, pp. 6089–6094[19] D. Bernardini, M. C. F. Donkers, A. Bemporad, and W. P. M. H.Heemels, “A model predictive control approach for stochastic networked control systems,”inProc. 2nd IFAC Workshop Estimation and Control Netw. Syst. , Annecy, France, 2010, pp. 7–12.[18] M. Bichi, G. Ripaccioli, S. Di Cairano, D. Bernardini, A. Bemporad, and I. Kolmanovsky, “Stochastic model predictive control with driver behavior learning for improved powertrain control,”in Proc. 49th IEEE Conf. Decision Control, Atlanta, GA, 2010, pp. 607–6082.[17] G. Ripaccioli, D. Bernardini, S. Di Cairano, A. Bemporad, and I. V. Kolmanovsky, “A stochastic model predictive control approach for series hybrid electric vehicle power management,”in Proc. Amer. Contr.Conf., Baltimore, MD, 2010, pp. 5844–5849.2011[7] Chatterjee D, Hokayem P, Lygeros J. Stochastic receding horizon control with boundedcontrol inputs –A vector space approach[J]. IEEE Transactions on Automatic Control, 2011,56(11): 2704-2710.[5]Cannon M, Kouvaritakis B, Rakovic S V, Cheng Q F. Stochastic tubes in model predictive control with probabilistic constraints. IEEE Transactions on Automatic Control,56(1),194-200, 2011[7]Wen J W, Liu F. Receding horizon control for constrained Markovian jump linear systems with bounded disturbance.ournal of Dynamic Systems, Measurement, and Control,2011[2]Su Y, Tan K K, Lee T H. Comments on \ Model predictive control for systems with stochastic multiplicative uncertainty and probabilistic constraints. Automatica, 2011[9] Eugenio.E,Agarwal.M,Chatterjee,D.Lygeros,J. Convexity and convex approximations of discete-time stochastic control problems with constraints. Automatica, 47(9), 2082–2087.2011. 2012[11] Hokayem P, Cinquemani E, Chatterjee D, Ramponi F, Lygeros J. Stochastic receding horizon control with output feedback and bounded controls. Automatica, 2012, 48(1):77--88[6] Bernardini D, Bemporad A. Stabilizing model predic tive control of stochastic constrained linear systems. IEEE Transactions on Automatic Control, 2012[50] Mark Cannon, Cheng QiFeng.Stochastic tube MPC with state estimation[J].Automatica, 2012,48 (7):536-5412013[5]Oldewurtel.F,Sturzenegger.D,Esfahani.P.M,Andersson.G,Morari.M,Lygeros.J. A daptively Constrained Stochastic Model Predictive Control for Closed-Loop Constraint Satisfaction . American Control Conference (ACC), pages 4674 - 4681,2013冯德兴.1995.凸分析基础[M].北京:科学出版社.方洋旺.2005.随机系统最优控制[M].北京:清华大学出版社.郭尚来.1999.随机控制[M].北京:清华大学出版社.钱积新,赵均,徐祖华.2007.预测控制[M].北京:化学工业出版社.王金德.1990.随机规划[M].南京:南京大学出版社.席裕庚.1993.预测控制[M].北京:国防工业出版社.。