卫星导航增强系统:SBAS

- 格式:pptx

- 大小:4.57 MB

- 文档页数:58

SBAS

一、

SBAS 即Satellite Based Augmentation Systems (DGNSS/DGPS/WAAS/EGNOS) 是利用地球静止轨道卫星建立的地区性广域差分增强系统。

目前全球发展的SBAS系统有:

欧空局接收卫星导航系统(EGNOS),覆盖欧洲大陆;

美国的DGPS(Differential GPS),美国雷声公司的广域增强系统(WAAS),覆盖美洲大陆;

日本的多功能卫星增强系统(MSAS),覆盖亚洲大陆;

印度的GPS辅助型静地轨道增强导航(GAGAN)。

三者具有完全兼容的互操作性。

其特点是:

1、通过地球静止卫星(GEO)发布包括GPS卫星星历误差改正、卫星钟差改正和电离层改的信息;

2、通过GEO卫星发播GPS和GEO卫星完整的数据;

3、GEO卫星的导航载荷发射GPS L1测距信号。

二、

SBAS即门店听觉系统,是Store Brand Auditory System的缩写。

SBAS主要包括:

1、品牌主题曲

这是品牌的精神内核以及门店听觉的灵魂。

2、品牌LOGO

品牌听觉标识,让陌生人认识品牌接近品牌的最好名片。

3、广告音乐

功用在于在发布门店信息的第一时间传到消费者的耳朵里,吸引火爆人气。

4、氛围音乐

营造购物氛围,强化消费者的购物欲。

SBAS的功能:

1、吸引门店人气。

2、完善品牌识别系统。

3、强化品牌特色。

4、发布促销信息。

5、提高消费者购物欲望。

6、营造购物氛围。

一、卫星导航系统性能的基本要素精度、完好性、连续性、可用性是评价一个卫星导航系统性能的基本要素,其中:1、精度是在给定时间内,接收机给出位置和速度的测量值与真值之间的一致性的度量。

当前卫星导航系统民用定位精度为10m (95%),授时精度为100ns(95%),10m 的定位精度可以满足大部分用户的使用要求。

例如,对于开阔海域的水面舰艇以及商用货轮的导航,以及从航线、航路到非精密进近阶段的飞机导航,数十米的水平精度就已经足够了。

但是在船舶进港、船舶靠岸、狭窄航道航行等特殊场景,定位精度要求到米级;飞机精密进近、大地测量、国土测绘等应用领域,10m的定位精度也远远不能满足应用要求;实时监测水库、高速公路、铁路等附近山体的三维形变,监测精度要求为毫米级;水库或水电站的大坝由于水负荷的重压而产生变形,危及坝体的安全,需要对大坝外观形变进行连续而精密的监测,监测精度则要求为亚毫米级。

如此高的定位精度要求,仅仅单独靠卫星导航系统的能力是无法实现的。

2、完好性是当系统出现异常、故障或精度不能满足设计指标要求时,系统向用户发出实时“不可用”告警的能力,一般用系统不能提供完好性服务的风险概率表示。

没有完好性保证的定位、授时和授时服务,就无法成为用户可以依靠的系统,尤其是那些涉及生命安全相关的应用领域,对卫星导航系统的完好性提出了较高要求,这些要求超出了卫星导航系统自身的服务能力。

涉及生命安全的交通运输领域利用卫星导航系统开展导航应用时,用户更加关注的是当系统处于95%服务可用性之外时,系统的完好性相关服务。

虽然卫星导航系统自身具有一定的完好性监测能力,地面运行控制系统通过接收导航信号和卫星自身健康状态来监测卫星的状态,然后将监测的告警信息上注给卫星并再由卫星以导航电文方式广播给用户,这个周期一般是一个小时,最短也需要15分钟。

卫星导航差分系统和增强系统(一)+刘天雄——什么是卫星导航系统的性能增强?——什么是卫星导航差分系统?——什么是卫星导航增强系统?——卫星导航增强系统分类及技术特点几何?不同应用领域对卫星导航系统完好性要求不同,例如:①船舶在远洋航路上航行时,对完好性要求相对较低,依靠卫星导航系统提供的完好性保障能力,以及用户接收机内部提供的自主完好性监视,就可满足使用要求;而对于船舶进港与靠岸来说,这个告警时间是不能满足用户需求的,需要建设专门系统在提高定位精度的同时增强卫星导航系统的完好性,保证船舶进港和靠岸的安全。

SBAS 即Space Based Augmentation System,是利用地球静止轨道卫星建立的地区性广域差分增强系统。

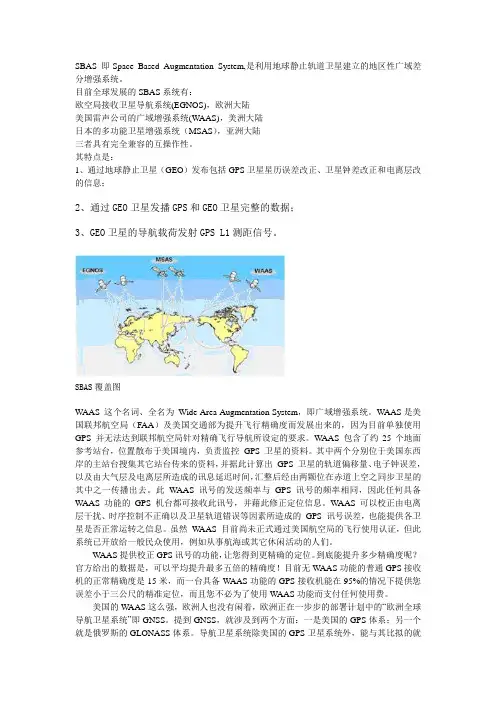

目前全球发展的SBAS系统有:欧空局接收卫星导航系统(EGNOS),欧洲大陆美国雷声公司的广域增强系统(W AAS),美洲大陆日本的多功能卫星增强系统(MSAS),亚洲大陆三者具有完全兼容的互操作性。

其特点是:1、通过地球静止卫星(GEO)发布包括GPS卫星星历误差改正、卫星钟差改正和电离层改的信息;2、通过GEO卫星发播GPS和GEO卫星完整的数据;3、GEO卫星的导航载荷发射GPS L1测距信号。

SBAS覆盖图WAAS 这个名词、全名为Wide Area Augmentation System,即广域增强系统。

WAAS是美国联邦航空局(FAA)及美国交通部为提升飞行精确度而发展出来的,因为目前单独使用GPS 并无法达到联邦航空局针对精确飞行导航所设定的要求。

WAAS 包含了约25个地面参考站台,位置散布于美国境内,负责监控GPS 卫星的资料。

其中两个分别位于美国东西岸的主站台搜集其它站台传来的资料,并据此计算出GPS 卫星的轨道偏移量、电子钟误差,以及由大气层及电离层所造成的讯息延迟时间,汇整后经由两颗位在赤道上空之同步卫星的其中之一传播出去。

此W AAS 讯号的发送频率与GPS 讯号的频率相同,因此任何具备WAAS 功能的GPS 机台都可接收此讯号,并藉此修正定位信息。

WAAS 可以校正由电离层干扰、时序控制不正确以及卫星轨道错误等因素所造成的GPS 讯号误差,也能提供各卫星是否正常运转之信息。

虽然W AAS 目前尚未正式通过美国航空局的飞行使用认证,但此系统已开放给一般民众使用,例如从事航海或其它休闲活动的人们。

W AAS提供校正GPS讯号的功能,让您得到更精确的定位。

到底能提升多少精确度呢?官方给出的数据是,可以平均提升最多五倍的精确度!目前无W AAS功能的普通GPS接收机的正常精确度是15米,而一台具备W AAS功能的GPS接收机能在95%的情况下提供您误差小于三公尺的精准定位,而且您不必为了使用WAAS功能而支付任何使用费。

SBAS(卫星增强系统)SBAS (Satellite-Based Augmentation System),即基于卫星的增强系统。

SBAS 系统主要由四部分组成:地面参考基站,主控站,上传站和地球同步卫星等。

下面以WAAS为例,介绍该卫星系统的工作原理:WAAS 是为民用飞行开发的极精确的导航系统。

在WAAS以前,美国的国家飞行系统(NAS)并没有足够的能力为所有区域的所有用户提供水平与垂直导航,有了WAAS后就有了给所有用户提供导航的能力。

WAAS为各种类型的飞行器各飞行阶段提供服务,确保飞行过程、升空、着陆时的安全。

WAAS 不像传统的地面导航辅助系统,它包含了所有的国家飞行系统(NAS),WAAS 给GPS 接收机提供增强信息,提高接收机的定位精度。

WAAS 系统主要由四部分组成:地面广域参考基站,WAAS主控站,WAAS上传站和地球同步卫星等,其工作可以分为四个过程:一、基站接收GPS信号在美国境内,广泛地分布着广域参考基站(Wide Area Reference Station(WRS)),每个基站都已知其准确的地理位置,通过接收GPS信号,探测出GPS信号中的误差。

二、基站向主控站传输GPS误差数据广域参考基站(WRS)收集的GPS信息,通过地面的通讯网络传输到WAAS主控站(WMS),主控站生成WAAS 增强信息,这些信息包含了GPS接收机中消除GPS信号误差的信息,使GPS接收机大大改善了定位精度和可靠性。

三、WAAS增强信息上传增强信息由WASS主控站(WMS)传输到WAAS上传站,上传站调制成导航数据,并上传到地球同步通讯卫星。

四、增强信息的传播地球同步通讯卫星以GPS信号频率向地面广播有增强信息的导航数据,地面接收机接收WASS增强信号,得到GPS误差数据补偿定位,得到更加精确的定位。

WAAS也能给GPS接收机提供GPS系统误差或其他不良影响的信息,其也有严格的安全标准,当存在危险的误导信息时,WAAS能在六秒内发布给用户。

satellite based augmentation system -回复什么是卫星增强系统(satellite-based augmentation system)?卫星增强系统(SBAS)是一种通过卫星信号来提供精确的位置和导航信息的技术。

它是全球卫星导航系统(如GPS、GLONASS、北斗导航系统)的一种增强系统,旨在提高位置和导航服务的准确性、可靠性和可用性。

SBAS系统通常由地面控制站和一组地球轨道上的卫星组成。

地面控制站负责监测全球导航系统卫星的轨道和时间偏差,并计算位置和时间修正数据。

这些修正数据通过卫星传输到用户的接收设备,从而实现对全球导航系统信号的增强。

SBAS系统是通过提供信号纠正来提高定位和导航准确性的。

全球导航系统信号在传输过程中可能会受到大气层和其他因素的影响,从而导致位置和时间的偏差。

SBAS系统通过纠正这些误差来提供更精确的位置和导航信息。

SBAS系统的工作原理如下:地面控制站监测全球导航系统卫星信号,计算出卫星的轨道和时间修正数据。

这些数据被发送到地球轨道上的一组地球轨道上的卫星,然后由这些卫星发送回地球,传输给用户接收设备。

用户接收设备接收到这些数据后,使用它们来纠正全球导航系统信号并提供更准确的位置和导航信息。

SBAS系统的优势在于提供了高精度的位置和导航信息。

它可以在各种应用领域中发挥作用,包括航空、航海、车辆导航和物流等。

在航空领域,SBAS系统可以提供更准确的飞行引导和自动驾驶功能,提高航班安全性和效率。

在航海领域,SBAS系统可以帮助船舶精确定位,避免与其他船只和障碍物的碰撞。

在车辆导航和物流领域,SBAS系统可以提供准确的行驶路径和交通信息,提高物流运输的效率。

SBAS系统的发展和应用是一个持续的过程。

目前,美国的广域增强系统(WAAS)和欧洲的欧洲地区增强系统(EGNOS)是两个较成熟和广泛应用的SBAS系统。

其他国家和地区也在开发和部署自己的SBAS系统。

卫星导航增强系统及发展现状卫星导航增强系统是卫星导航系统建设中的一项重要内容,堪称卫星导航系统的“能力倍增器”。

目前的卫星导航系统尽管已经在各个民商用领域应用广泛,并且成为各大强国发展所不可或缺的一环,但由于技术和系统的局限性,在某些领域如航空精密进近等仍无法满足需求,需要增强系统将其能力加以提升。

从目前全球卫星导航系统发展的大趋势看,从前的美国 GPS 系统“一家独大”,已经由于俄罗斯 GLONASS、中国北斗、欧洲伽利略的崛起,向着“四分天下”发展。

甚至未来可能还会有印度、日本等国家的区域系统出现,那时全球 GNSS 将是“群雄逐鹿”的局面,系统间的竞争将愈加激烈。

如何能够突破重围,在竞争中立于不败之地?本文认为系统服务性能将是制胜关键,而作为系统能力倍增器的增强系统将是实现这一能力的重中之重。

目前,国外卫星导航增强系统主要分为星基增强系统(SBAS)和地基增强系统(GBAS)两大类。

星基增强系统如美国的广域增强系统(WAAS)、俄罗斯的差分校正和监测系统(SDCM)等,地基增强系统如美国的局域增强系统(LAAS)等。

这些系统综合使用了各种不同增强效果的导航增强技术,最终实现了其增强卫星导航服务性能的目的。

从增强效果上看,这些增强系统所使用的卫星导航增强技术主要包括精度增强技术、完好性增强技术、连续性和可用性增强技术。

其中,精度增强技术主要运用差分原理,进一步可分为广域差分技术、局域差分技术、广域精密定位技术和局域精密定位技术;完好性增强技术主要运用完好性监测原理,进一步可分为系统完好性监测技术、广域差分完好性监测技术等等。

连续性和可用性增强技术主要是增加导航信号源,进一步可分为天基卫星增强技术、地基伪卫星增强技术等。

当前卫星导航增强系统所采用的各种增强技术分类见下表。

以下主要从星基增强系统和地基增强系统这一分类角度,对于目前国外卫星导航增强系统的发展情况进行简要介绍。

表 1 当前卫星导航增强系统所采用的增强技术分类一、星基增强系统及应用发展星基增强系统(SBAS)通过地球静止轨道(GEO)卫星搭载卫星导航增强信号转发器,可以向用户播发星历误差、卫星钟差、电离层延迟等多种修正信息,实现对于原有卫星导航系统定位精度的改进,从而成为各航天大国竞相发展的手段。

sbas电文格式

SBAS(Satellite-Based Augmentation System)电文格式是用于卫星导航增强系统的数据传输格式。

它通常用于向地面用户提供关于卫星导航信号质量、完好性和校正信息的数据。

SBAS电文格式的具体细节可能因不同的卫星导航系统和增强系统而有所差异。

以下是一般情况下SBAS电文格式的一些常见元素:

1. 电文头(Header):包含电文的标识和同步信息,用于接收设备正确解析电文。

2. 发射站标识(Transmitter Identification):指示发送SBAS电文的地面站或卫星的标识信息。

3. 卫星状态(Satellite Status):提供关于可见卫星的状态信息,如卫星的健康状况、信号质量等。

4. 完好性信息(Integrity Information):包含有关卫星导航信号的完好性参数,如保护级别、完好性风险值等,用于评估导航解的可靠性。

5. 校正信息(Correction Information):提供对卫星导航信号的校正数据,如伪距校正、相位校正等,以改善导航解的精度。

6. 其他辅助信息:可能包含其他辅助数据,如电离层模型参数、对流层模型参数等,用于进一步提高导航解的精度和可靠性。

Number:CTSO-C145eApproved by:Xu ChaoqunChina Civil Aviation Technical Standard OrderAirborne Navigation Sensors Using The Global Positioning SystemAugmented By The Satellite Based Augmentation System (SBAS)1. Purpose.This China Civil Aviation Technical Standard Order (CTSO) is for manufacturers applying for airborne navigation sensors using the global positioning system (GPS) augmented by the satellite based augmentation system (SBAS) CTSO authorization (CTSOA). This CTSO prescribes the minimum performance standards(MPS) that airborne navigation sensors using the GPS augmented by the SBAS must first meet for approval and identification with the applicable CTSO marking.2. Applicability.This CTSO affects new application submitted after its effective date.Major design changes to article approved under this CTSO will require a new authorization in accordance with section 21.353 of CCAR-21R4.3. RequirementsNew models of airborne navigation sensors using the GPS augmented by the SBAS identified and manufactured on or after the effective date of this CTSO must meet the MPS qualification and documentation requirements for functional equipment Class Beta in RTCA, Inc. document RTCA/DO-229E, Minimum Operational Performance Standards for Global Positioning System/Satellite-Based Augmentation System Airborne Equipment dated December 15, 2016, Section 2.1. Class Beta equipment is defined in RTCA/DO-229E, Section 1.4 and Appendix 2 adds a new section 1.8.3.Note: Manufacturers have the option to use the RTCA/DO-229E change described in Appendix 3. The change is based on a past commonly granted deviation.a. An alternate method for applicants is to apply for CTSO-C145e using their existing approved design data plus additional substantiation data showing compliance with the changes in RTCA/DO-229E. The three areas where requirements changed are: 1) expanding the SBAS pseudorandom noise (PRN) codes (i.e., PRN range of 120 thru 158); 2) ensuring a graceful degradation to GPS-only operations; and, 3) prohibiting use of the broadcast Navigation Message Correction Table.Note 1: It is not necessary for applicants to re-submit previously approved deviations. Previously approved deviations, and any limitations,will apply to the CTSO-C145e CTSOA.Note 2: Applicants with Class 1 and 2, revision ‘b’ equipment must not have claimed the 3db broadband intrasystem noise credit.b. CTSO-C145e applicants have the option to use a CTSO-C204a SBAS CCA functional sensor. Applicants choosing to use a CTSO-C204a SBAS CCA can take certification compliance credit by virtue of the CTSO-C204a CTSOA for:z Meeting the MPS section 2.1 requirements;z The hardware/software qualification;z The failure condition classification; and,z MPS section 2.5 performance testing (functional qualification) except those specified in Appendix 1 of this CTSO.c. The CTSO-C145e applicant using a CTSO-C204a SBAS CCA functional sensor shall perform the testing described in Appendix 1 and satisfy the remaining paragraphs in this CTSO not covered by the bullets above to receive a CTSO-C145e CTSOA.Note: The end-use manufacturer using a CTSO-C204a SBAS CCA functional sensor as part of their CTSO-C145e application assumes full responsibility for the design and function under their CTSO-C145e authorization.d. Functionality.This CTSO’s standards apply to equipment intended to provideposition, velocity, time information for a navigation management unit application that outputs deviation commands keyed to a desired flight path, or a non-navigation application such as automatic dependent surveillance-broadcast (ADS-B) or terrain awareness and warning system (TAWS). In navigation applications, pilots or autopilots will use the deviations output by the navigation management unit to guide the aircraft. In non-navigation applications, the position, velocity, time outputs will provide the necessary input for the end-use equipment. These TSO standards do not address integration issues with other avionics.e. Failure Condition Classifications.(1) Failure of the function defined in paragraph 3.d resulting in misleading information for en route, terminal, approach lateral navigation (LNA V), and approach LNA V/vertical navigation (VNA V) position data is a Major failure condition.(2) Failure of the function defined in paragraph 3.d resulting in misleading information for approach localizer performance without vertical guidance (LP), and approach localizer performance with vertical guidance (LPV) position data is a Hazardous failure condition.(3) Loss of the function defined in paragraph 3.d for enroute through approach LP/LPV position data is a Major failure condition.(4) Design the system to at least these failure condition classifications.f. Functional Qualification.(1) Demonstrate the required functional performance under the test conditions specified in RTCA/DO-229E, Section 2.5, or(2) When using a CTSO-C204a SBAS CCA functional sensor, demonstrate the required performance under the test conditions in appendix 1 of this CTSO.g. Environmental Qualification.Demonstrate the required performance under the test conditions specified in RTCA/DO-229E, Section 2.4 using standard environmental conditions and test procedures appropriate for airborne equipment. RTCA/DO-229E requires the use of RTCA/DO-160E, Environmental Conditions and Test Procedures for Airborne Equipment, dated December 9, 2004, Sections 4.0 through 8.0 and 10.0 through 25.0. You may use a different standard environmental condition and test procedure than RTCA/DO-160E, provided the standard is appropriate for the SBAS sensor.Note1: The use of RTCA/DO-160D (with Changes 1 and 2 only, incorporated) or earlier versions is generally not considered appropriate and will require substantiation via the deviation process as discussed in paragraph 3.k of this CTSO.Note 2: Applicants using a CTSO-C204a SBAS CCA sensor must perform the environmental qualification with the SBAS CCA in theend-use equipment.h. Software Qualification.If the article includes software, develop the software according to RTCA/DO-178C, Software Considerations in Airborne Systems and Equipment Certification, dated December 13, 2011, including referenced supplements as applicable, to at least the software level consistent with the failure condition classification defined in paragraph 3.e of this CTSO. The applicant may also develop the software according to RTCA/DO-178B, dated December 1, 1992.(2) Applicants using a CTSO-C204a SBAS CCA sensor may use CTSO-C204a as substantiation for the software qualification.i. Electronic Hardware Qualification.If the article includes complex custom airborne electronic hardware, develop the component according to RTCA/DO-254, dated April 19, 2000, Design Assurance Guidance for Airborne Electronic Hardware, to at least the design assurance level consistent with the failure condition classification defined in paragraph 3.e of this CTSO. For custom airborne electronic hardware determined to be simple, RTCA/DO-254, paragraph1.6 applies.(2) Applicants using a CTSO-C204a SBAS CCA sensor may use CTSO-C204a as substantiation for the hardware qualification.j. Barometric-aided Fault Detection and Exclusion (FDE).If the equipment uses barometric-aiding to enhance FDE availability, then the equipment must meet the requirements in RTCA/DO-229E, appendix G.k. Deviations.For using alternative or equivalent means of compliance to the criteria in this CTSO, the applicant must show that the equipment maintains an equivalent level of safety. Apply for a deviation under the provision of 21.368(a) in CCAR-21R4.4. Marking.a. Mark at least one major component permanently and legibly with all the information in 21.423(b) of CCAR-21R4. The marking must include the serial number.b. Also, mark the following permanently and legibly, with at least the manufacturer’s name, subassembly part number, and the CTSO number:(1) Each component that is easily removable (without hand tools); and,(2) Each subassembly of the article that manufacturer determined may be interchangeable.c. If the article includes software and/or airborne electronic hardware, then the article part numbering scheme must identify the software andairborne electronic hardware configuration. The part numbering scheme can use separate, unique part numbers for software, hardware, and airborne electronic hardware.d. The applicant may use electronic part marking to identify software or airborne electronic hardware components by embedding the identification within the hardware component itself (using software) rather than marking it on the equipment nameplate. If electronic marking is used, it must be readily accessible without the use of special tools or equipment.e. At least one major component must be permanently and legibly marked with the operational equipment class (for example, Class 2) as defined in RTCA/DO-229E, Section 1.4.2.5. Application Data Requirements.The applicant must furnish the responsible certification personnel with the related data to support design and production approval. The application data include a statement of conformance as specified in section 21.353(a)(1) in CCAR-21R4 and one copy each of the following technical data:a. A Manual(s) containing the following:(1) Operating instructions and equipment limitations sufficient to describe the equipment’s operational capability.(2) Describe in detail any deviations.(3) Installation procedures and limitations sufficient to ensure that the SBAS sensor, when installed according to the installation or operational procedures, still meets this CTSO’s requirements. Limitations must identify any unique aspects of the installation. The limitations must include a note with the following statement:“This article meets the minimum performance and quality control standards required by a CTSO. Installation of this article requires separate approval.”(4) For each unique configuration of software and airborne electronic hardware, reference the following:(a) Software part number including revision and design assurance level;(b) Airborne electronic hardware part number including revision and design assurance level;(c) Functional description.(5) A summary of the test conditions used for environmental qualifications for each component of the article. For example, a form as described in RTCA/DO-160G, Environmental Conditions and Test Procedures for Airborne Equipment, Appendix A.(6) Schematic drawings, wiring diagrams, and any other documentation necessary for installation of the SBAS sensor.(7) List of replaceable components, by part number, that makes up the SBAS sensor. Include vendor part number cross-references, when applicable.(a) If the equipment can satisfy the requirements of RTCA/DO-229E only when used with a particular antenna, make the use of that antenna (by part number) a requirement on the installation. Include this requirement in the installation manual (IM) as a limitation.(b) If the equipment is installed with a standard antenna, include maximum tolerable currents and voltages into the antenna port. See CTSO-C144a, Passive Airborne Global Navigation Satellite System (GNSS) Antenna, applicable only to operational Class 1 equipment, or CTSO-C190, Active Airborne Global Navigation Satellite System (GNSS) Antenna, applicable to all equipment operational classes.b. Instructions covering periodic maintenance, calibration, and repair, for the continued airworthiness of the SBAS sensor. Include recommended inspection intervals and service life, as appropriate.c. If not using a CTSO-C204a SBAS functional sensor and the article includes software: a plan for software aspects of certification (PSAC), software configuration index, and software accomplishment summary.d. If not using a CTSO-C204a SBAS functional sensor and the article includes simple or complex custom airborne electronic hardware: aplan for hardware aspects of certification (PHAC), hardware verification plan, top-level drawing, and hardware accomplishment summary (or similar document, as applicable).e. A drawing depicting how the article will be marked with the information required by paragraph 4 of this CTSO.f. Adequate specifics on the interface between the SBAS sensor and other systems to ensure proper functioning of the integrated system. If the equipment depends on any external inputs (like baro-aided FDE) to satisfy the requirements of RTCA/DO-229E, make those inputs a requirement in the installation. Include this requirement in the IM as a limitation.g. If the software qualification limits eligibility of the equipment to certain aircraft types, identify the qualification level, and that the equipment is not eligible for all aircraft types. For example, RTCA/DO-178B (or RTCA/DO-178C) Level C software may be associated with a hazardous failure condition for certain aircraft types. Identify other limitations applicable to the failure condition classification, for example, that two installed units are necessary.h. If the equipment has not been demonstrated as compatible with satellite communications (SatCom) record in the limitations section that the equipment should not be installed in SatCom equipped aircraft.i. Identify functionality or performance contained in the article notevaluated under paragraph 3 of this CTSO (that is, non-CTSO functions). Non-CTSO functions are accepted in parallel with the CTSO authorization. For those non-CTSO functions to be accepted, you must declare these functions and include the following information with your CTSO application:(1) Description of the non-CTSO function(s), such as performance specifications, failure condition classifications, software, hardware, and environmental qualification levels. Include a statement confirming that the non-CTSO function(s) do not interfere with the article’s compliance with the requirements of paragraph 3.(2) Installation procedures and limitations sufficient to ensure that the non-CTSO function(s) meets the declared functions and performance specification(s) described in paragraph 5.i.(1).(3) Instructions for continued performance applicable to the non-CTSO function(s) described in paragraph 5.i.(1).(4) Interface requirements and applicable installation test procedures to ensure compliance with the performance data defined in paragraph 5.i.(1).(5) Test plans, analysis and results, as appropriate, to verify that performance of the hosting CTSO article is not affected by the non-CTSO function(s).(6) Test plans, analysis and results, as appropriate, to verify thefunction and performance of the non-CTSO function(s) as described in paragraph 5.i.(1).(7) Alternatively, identify non-CTSO functionality or performance contained in the article not evaluated under paragraph 3 and submit previously accepted data for the non-CTSO function for acceptance in parallel with this CTSO application.j. The quality system description required by section 21.358 of CCAR-21R4, including functional test specifications. The quality system should ensure that it will detect any change to the approved design that could adversely affect compliance with the CTSO MPS, and reject the article accordingly.k. Material and process specifications list.l. List of all drawings and processes (including revision level) that define the article’s design.m. Manufacturer’s CTSO qualification report showing results of testing accomplished according to paragraph 3.f of this CTSO.6. Manufacturer Data Requirements.Besides the data given directly to the authorities, have the following technical data available for review by the authorities:a. Functional qualification specifications for qualifying each production article to ensure compliance with this CTSO.b. Equipment calibration procedures.c. Schematic drawings.d. Wiring diagrams.e. Material and process specifications.f. The results of the environmental qualification tests conducted according to paragraph 3.g of this CTSO.g. If the article includes software, the appropriate documentation defined in the version of RTCA/DO-178 or RTCA/DO-178C specified by paragraph 3.h of this CTSO, including all data supporting the applicable objectives in Annex A, Process Objectives and Outputs by Software Level.h. If the article includes complex custom airborne electronic hardware, the appropriate hardware life cycle data in combination with design assurance level, as defined in RTCA/DO-254, Appendix A, Table A-l. For simple custom airborne electronic hardware, the following data: test cases or procedures, test results, test coverage analysis, tool assessment and qualification data, and configuration management records, including problem reports.i. If not using CTSO-C204a, all the data necessary to evaluate the geo stationary (GEO) satellite bias as defined in RTCA/DO-229E, Section 2.1.4.1.5.j. If the article contains non-CTSO function(s), the applicant mustalso make available items 6.a through 6.h as they pertain to the non-CTSO function(s).7. Furnished Data Requirements.a. If furnishing one or more articles manufactured under this CTSO to one entity (such as an operator or repair station), provide one copy or technical data and information specified in paragraphs 5.a and 5.b of this CTSO. Add any data needed for the proper installation, certification, use, or for continued compliance with the CTSO, of the SBAS sensor.b. If the article contains declared non-CTSO function(s), include one copy of the data in paragraphs 5.i.(1) through 5.i.(4).8. Availability of Referenced Documents.Order RTCA documents from:Radio Technical Commission for Aeronautics, Inc.1150 18th Street NW, Suite 910, Washington D.C. 20036You may also order them online from the RTCA Internet website at: .APPENDIX 1. END-USE EQUIPMENT MANUFACTURER TESTS FOR SBAS CCA FUNCTIONAL POSITION, VELOCITY, TIME (PVT) SENSORS USED FOR NA VIGATION AND NON-NA VIGATION APPLICATIONS1. Scope.This appendix describes the required supplementary equipment level testing, in addition to the environmental testing of RTCA/DO-229E, section 2.4, required by the end-use equipment manufacturer to receive a CTSO-C145e Class Beta authorization when using a CTSO-C204a SBAS CCA functional sensor. These test procedures are intended to streamline and simplify the CTSO-C145e authorization process for the end-use equipment manufacturer by allowing credit for the design and selected testing done at the SBAS CCA functional sensor level. However, the end-use equipment manufacturer retains full responsibility for the design and control of the article per their CTSO-C145e CTSOA.2. General Principles.(a) Testing methods for GPS/SBAS equipment have been standardized by RTCA/DO-229E and serve as the basis for CTSO-C145e. RTCA/DO-229E was written with the perspective of equipment that canbe installed on aircraft. Section 2.4 specifically addresses the issues of the environment in which the equipment operates and provides approved test methods to validate performance in this environment. Section 2.4represents RTCA consensus in identifying which RTCA/DO-229E requirements are sensitive to environmental effects. These requirements are listed in the environmental tables referenced in section 2.4.1.(b) The determination that a MOPS requirement is susceptible to the environment does not depend on whether or not the implementation is a CCA within some host equipment. This is the same concept as an equipment enclosure designed to protect against a benign environment compared to one designed for a severe environment; the identification of susceptible requirements is the same.(c) Therefore this appendix uses the tables of RTCA/DO-229E, section 2.4.1 to identify the MOPS requirements susceptible to environmental affects for an SBAS CCA functional sensor in the end-use equipment. The focus is on the change in environment seen by the SBAS CCA functional sensor as a result of its installation in the end-use equipment. For example, other components inside the end-use equipment may radiate RF energy that could interfere with the GPS functions; therefore the ambient testing done at CCA level is not equivalent to tests done in the end-use equipment. This is the basis for defining the RTCA/DO-229E, section 2.5 performance tests that need to be repeated by the end-use equipment manufacturer.(d) The Class Beta environmental table referenced in RTCA/DO-229E, section 2.4.1 are the prime source to determine theMOPS performance requirements susceptible to environmental conditions. Based on the table, the susceptible requirements can be grouped in two categories: those susceptible to most types of environmental conditions (described in section 3) and those susceptible to just a few (described in section 4).Note: The Tables for Class Beta-1, -2, and -3 equipment identify similar requirements susceptible to the installed environment. The only difference is the applicable MOPS requirements consistent with the operational class (i.e., class -1, - 2, or -3).3. Performance Requirements Susceptible to Most Environmental Conditions.The RTCA/DO-229E requirements for Accuracy (2.1.3.1, 2.1.4.1, and 2.1.5.1) and Sensitivity and Dynamic Range (2.1.1.10) are sensitive to most environmental conditions. However, these requirements are linked to the message loss rate requirement in 2.1.1.3.2. Section 3.1 and 3.2 below identifies the testing end-use equipment manufacturers are required to repeat to demonstrate the SBAS CCA functional sensor continues to meet the Accuracy, Dynamic Range, and Message Loss Rate performance requirements after installation in the end-use equipment. All tests will be run under conditions where the end-use equipment functions are fully enabled to create the worst-case environment.3.1 RTCA/DO-229E, 2.5.8 Accuracy Test.(a) The accuracy test described in section 2.5.8 is actually a joint test covering both accuracy, and sensitivity and dynamic range. This joint testing also applies under environment as stated in section 2.4.1.1.5 with environmental adaptation as described in section 2.4.1.1.1.(b) The demonstration of accuracy is done in accordance with section 2.5.8.1 only for the test case with a broadband external interference noise. This test must be repeated when the CCA is installed in the end-use equipment and it is sufficient to perform it using broadband interference.(1) The environmental testing is limited to broadband interference as it represents the worst case signal to noise condition which is the most sensitive to environmental effects. This applies equally to the environment for the CCA created by the end-use equipment.(2) Section 2.5.8 contains a measurement accuracy test in 2.5.8.1 with the detailed test procedure in 2.5.8.2. The 2.5.8.1 test must be run under the worst case environment identified in the “Additional considerations for internal interference sources” section below. The measurement accuracy testing can be combined with the message loss rate testing in 2.5.2.1.(3) Section 2.5.8.3 is a 24-Hour actual satellite accuracy test. The section 2.5.8.3 test exposes the equipment to a variety of signal conditions and data processing conditions over varying satellite geometrythat will increase confidence that no unforeseen interactions between components within the end-use equipment and the SBAS CCA functional sensor goes undetected. The 24 hr testing in 2.5.8.3 can be combined with the 24 hr message loss rate testing in 2.5.2.4 (see Additional Considerations for Internal Interference Sources section).(4) Section 2.5.8.4 (SBAS Tracking Bias) is an analysis of the GPS hardware and is therefore not necessary to repeat at the end-use equipment level as long as no extra RF components that affect the RF filtering response are inserted in the RF path. Otherwise the end-use equipment manufacturer must repeat the SBAS Tracking Bias test as well.(c) The test threshold is relaxed from 110% to 125% as specified in table 2-25 of the 2.5.8.2.1 test procedure to shorten test time. However, Section 2.5.8 testing (excluding the SBAS Tracking Bias test in 2.5.8.4) for the CCA in the end-use equipment shall be under ambient conditions per section 2.5 with the 110% test pass threshold for maximum test sensitivity.(d) The Section 2.5.8 testing (excluding the SBAS Tracking Bias test in 2.5.8.4) will be repeated against the accuracy requirement consistent with the desired operational class (i.e., 2.1.3.1, 2.1.4.1, and 2.1.5.1 accuracy requirements as appropriate).(e) Only the broadband external interference noise test case usingminimum satellite power will be executed in most cases to shorten test time. Section 2.5.8.1 testing will be repeated for both minimum and maximum satellite power for the worst case environment only.3.2 RTCA/DO-229E, 2.5.2 Message Loss Rate Test.(a) Section 2.5.2 specifies the message loss rate test for the 2.1.1.3.2 message loss rate requirement. This test is conducted in conjunction with the 2.5.8 accuracy testing. Section 2.5.2.2 defines the test procedure to collect data verifying the SBAS message loss rate in the presence of interference using the test cases where the SBAS satellite is at minimum power. Section 2.5.2.3 defines the pass/fail criteria.(b) The test in section 2.5.2.2 will be performed during the measurement accuracy broadband interference test case described in paragraph 3.1.(c) The test procedure in section 2.5.2.4.1 is run in conjunction with the 2.5.8.3 24-hour accuracy test. Section 2.5.2.4.2 defines the pass/fail criteria for the test case described in paragraph 3.1(b)(3).4. Performance Requirements Partially Susceptible to Environmental Conditions.(a) The class Beta tables (tables 2-14, 2-16, and 2-18) in section2.4.1 of RTCA/DO-229E indicates the requirements for Initial Acquisition Time (2.1.1.7) and Satellite Reacquisition Time (2.1.1.9) are sensitive to four environmental conditions: Icing, Lightning InducedTransient Susceptibility, Lightning Direct Effects, and Normal/Abnormal Operating Conditions. The requirements for Loss of Navigation (2.1.1.13.2, 2.1.4.12.2, and 2.1.5.12.2) and Loss of Integrity (2.1.1.13.1, 2.1.4.12.1, and 2.1.5.12.1) are sensitive to low and high operating temperature.(b) The Lightning Induced Transient Susceptibility, Lightning Direct Effects, or Icing environmental conditions are not pertinent to the environment created by the end-use equipment relative to the SBAS CCA functional sensor. However, the end-use equipment manufacturer remains responsible for meeting the overall environmental qualification at the end-use equipment level.(c) Loss of navigation and loss of integrity indications are limited to temperature testing and the information in RTCA/DO-229E, sections 2.4.1.1.2 and 2.4.1.1.3 is appropriate. The purpose is to ensure that the interface used to indicate the loss of navigation is functional under environmental conditions after the SBAS CCA functional sensor is installed in the end-use equipment. Sections 2.4.1.1.2 and 2.4.1.1.3 indicate that any source that generates the indication can be used since it is the interface and not the detection mechanism that is verified. The temperature testing done at the end-use equipment level is the worst-case scenario. It is not necessary to repeat the CCA level test at room temperature in the end-use equipment since the environmentalqualification adequately addresses testing for these requirements.(d) RTCA/DO-160E section 16 relates to aircraft power supply (refer to TSO paragraph 3.g for environmental qualification requirements). Sections 16.5.1.2 and 16.6.1.2 are for supply voltage modulation (ac) /ripple (dc). Given the potential susceptibility of the SBAS CCA functional sensor to power supply noise, it is prudent to repeat tests at the end-use equipment level on this basis.(e) Sections 4.1 and 4.2 identify the testing end-use equipment manufacturers are required to repeat to demonstrate the SBAS CCA functional sensor continues to meet the Acquisition Time and Reacquisition Time performance requirements relative to Normal/Abnormal Operating Conditions after installation in the end-use equipment. All tests will be run under conditions where the end-use equipment functions are fully enabled to create the worst-case environment.4.1 2.5.4 Initial Acquisition Test Procedures.The information in RTCA/DO-229E, section 2.4.1.1.4 on the initial acquisition test in section 2.5.4 applies. The end-use equipment manufacturer shall repeat the initial acquisition testing described in RTCA/DO-229E, section 2.5.4.4.2 2.5.6 Satellite Reacquisition Time Test.The end-use equipment manufacturer is required to repeat the。

sbas数据处理代码SBAS(Satellite-Based Augmentation System)是一种卫星导航增强系统,它通过在全球范围内部署多个地面监测站和地面控制中心,并与卫星通信来提供更可靠和准确的定位信息。

在SBAS数据处理方面涉及一系列步骤和代码,下面将一步一步回答关于SBAS数据处理代码的主题。

第一步:数据获取和预处理SBAS数据处理的第一步是获取原始卫星导航数据。

这些数据通常以RINEX格式(Receiver Independent Exchange Format)提供,其中包含了卫星导航信号的观测量信息。

预处理过程包括数据的解压缩和格式转换,以便进一步的处理。

pythonimport rinex_parser# 解压缩和文件格式转换rinex_parser.decompress('data.zip', 'data.obs')# 使用RINEX解析库读取数据observations = rinex_parser.parse('data.obs')第二步:导航数据处理接下来的步骤涉及对获取的卫星导航数据进行处理。

这包括对不同导航卫星的轨道参数进行估计和更新,并计算卫星钟差等校准参数。

这些校准参数对后续的定位计算至关重要。

pythonimport navigation_processing# 估计卫星轨道和钟差参数orbit_params =navigation_processing.estimate_orbit_params(observations) clock_params =navigation_processing.estimate_clock_params(observations)# 更新导航数据orbit_params =navigation_processing.update_orbit_params(orbit_params)clock_params =navigation_processing.update_clock_params(clock_params)第三步:伪距测量处理接下来的处理步骤涉及将伪距观测值与校准的导航数据进行匹配和处理。