Goulds pumps安装、操作和维护手册

- 格式:pdf

- 大小:327.74 KB

- 文档页数:21

This repair stack instruction sheet MUST be used in conjunction with Goulds Water Technology Installation, Operation and Maintenance manual for the Model e-SV. Contact your local Goulds Water Technology distributor or the factory for a replacement manual if needed. Before placing repaired pump back on line, CAREFULLY examine removed components andentire pump system for indications of the cause ofthe component failure and possible corrective action. Massive component failure may indicate that the pumping system is not adequately protected from deadheading, running beyond maximum flow, water hammer, abrasive particulate, etc.REPAIR STACKIM2352SAFETY INSTRUCTIONSFAILURE TO DISCONNECT ANDLOCKOUT ELECTRICAL POWER BE-FORE ATTEMPTING MAINTENANCE CAN CAUSE SEVERE PERSONAL IN-JURY .IF PUMPING HAZARDOUS OR TOXIC FLUIDS, SYSTEM MUST BE FLUSHED PRIOR TO PERFORMING SERVICE.PUMP STACK REMOVAL1. Close all necessary suction and discharge valves.2. Drain the liquid from the pump by removing the lower drain plug and the upper vent plug.3. Remove the coupling guards, the 4 coupling hex cap screws, the coupling and coupling drive pin.4. Remove the 4 motor hex cap screws. *On 33-125SV units with motor frames 213TC and larger and 1-22SV units with motor frames 280TC and larger, remove the 4 motor adapter flange hex cap screws.5. With an adequately sized crane, carefully remove the motor. DO NOT rest the motor on the motor shaft.6. Remove Seal Gland or Cartridge Seal• For 1-22SV units, remove the 4 socket head cap screws to lift and remove the seal gland.• For 33-125SV units without cartridge seal; 1. Remove the 4 socket head cap screws.2. Lift and remove the seal gland. If seal gland does not lift by hand, use the two tapped holes provided to loosen and lift the gland for removal.• For 33-125SV units with cartridge seal;1. Loosen the 4 set-screws located around the ID of the pump shaft.2. Remove the 4 socket head cap screws.3. Remove the cartridge seal using the two tapped holes provided on the gland of the cartridge seal by threading two of the hex cap screws into these holes and evenly tightening these screws..4. Once loosened, lift and remove the cartridge seal.7. Remove the 4 tie rod nuts and washers.8. Remove Motor Adapter / Motor adapter assembly and upper seal plate• For 1-22SV units lift the motor adapter to remove. *Note that the upper seal plate may remove with the motor adapter when lifting. If the upper seal plate remains on the pump casing, lift to remove.• For 33-125SV units, lift the motor adapter assembly (motor adapter and top seal plate). A crane may be required to safely lift the motor adapter assembly.9. Remove the pump stack, grasp the pump shaft, rock side to side to free the stack, then lift vertically. If the first stage bowl remained in the pump body, CARE-FULLY pry up the bowl and remove.REPAIR STACK INSTALLATION1. Inspect and clean the inside of the pump body, re-moving any debris.2. Remove repair stack from packaging, inspect fordamage and clean, removing any tape used to holdcomponents together.3. Grasp shaft of repair stack and lower into the pumpbody. Center the stack within the pump body untilthe first stage seats in the bottom. Push down onstack to lock in place.4. Replace O-ring in top groove in casing.5. Re-install the upper seal plate and motor adapter• For 1-22SV units place the upper seal plate squarely on top of the pump casing and press down firmly.The seal plate should seat firmly and the o-ringshould remain in the casing groove. Once upperseal plate is installed the motor adapter can beplaced on top of the assembly and aligned as origi-nally installed.• For 33-125SV units, lift the motor adapter as-sembly (motor adapter and top seal plate) andplace squarely on top of the pump casing, alignedas originally installed. A crane may be required tosafely lift the motor adapter assembly.6. Reinstall Tie Rods, Nuts, and W ashers (see “T orqueValues” for appropriate tightening torque). The tie-rod nuts should be tightened in small increments in a diagonal pattern to ensure it seats properly. Pay close attention to ensure that the casing o-ring remains inthe casing groove.7. Reinstall Seal Gland or Cartridge Seal• For 1-22SV units, remove the used stationary sealface from the seal gland.1. Remove the used stationary seal seat from theseal gland.2. With a clean cloth wipe the seal bore and inspectfor damage; replace seal gland if damaged.3. Insert the new stationary seal seat into the sealbore of the seal gland with the seal face out. DONOT scratch or damage the seal face. Ensurethat the seal is seated firmly and squarely insidethe seal bore. With a clean lint-free cloth or alco-hol swab wipe the seal face clean of all lubricantor debris. DO NOT use grease or heavy lubri-cants to install seal, as these materials can causethe seal to leak.4. Replace o-ring on seal gland.5. Install the rotating portion of the seal onto thepump shaft, seating the plate fully and squarely.6. Re-install the 4 socket head cap screws (see“T orque Values” for appropriate tighteningtorque). The screws should be tightened in smallincrements in a diagonal pattern to ensure theseal gland seats properly.• For 33-125SV units without cartridge seal;1. Remove the used stationary seal seat from theseal gland.2. With a clean cloth wipe the seal bore and inspectfor damage; replace seal gland if damaged.3. Insert the new stationary seal seat into the sealbore of the seal gland with the seal face out. DONOT scratch or damage the seal face. Ensurethat the seal is seated firmly and squarely insidethe seal bore. With a clean lint-free cloth or alco-hol swab wipe the seal face clean of all lubricantor debris. DO NOT use grease or heavy lubri-cants to install seal, as these materials can causethe seal to leak.4. Rotate the rotary portion of the mechanical sealon the pump shaft until it “locks” and you areunable to turn freely. If you are unable to turninitially, the seal is seated properly.5. Replace o-ring on seal gland.6. Install the seal gland onto the pump shaft, seat-ing the plate fully and squarely.7. Re-install the 4 socket head cap screws (see“T orque Values” for appropriate tighteningtorque). The screws should be tightened in smallincrements in a diagonal pattern to ensure theseal gland seats properly.• For 33-125SV units with cartridge seal;1. Replace the o-ring on the cartridge seal.2. Slide the cartridge seal assembly along the pumpshaft into position and alignment with boltholes. Seat the cartridge seal squarely and firmly.3. Re-install the 4 socket head cap screws (see“T orque Values” for appropriate tighteningtorque). The screws should be tightened in smallincrements in a diagonal pattern to ensure theseal gland seats properly.8. Reinstall the coupling pin and locate the spacer shimon the shaft, resting on the seal gland or cartridgeseal. If the shim is not available, a 5mm shim can be used.9. Lower the motor slowly onto the motor adapter andalign the motor shaft with the coupling and motormounting holes. Reinstall the 4 motor hex cap screws (see "T orque Values" for appropriate tighteningtorque) to secure motor to motor adapter.10. Reinstall the coupling halves evenly to maintain aconsistent gap on either side of the coupling halves.The coupling halves should not touch. T orque thecoupling bolts to the appropriate values defined in“T orque Values”.11. Remove the spacer shim and save for future use.12. FOR 33-125SV PUMPS WITH CARTRIDGE SEALONLY; tighten the 4 set screws on the shaft collar.3GOULDS WATER TECHNOLOGY LIMITED WARRANTYThis warranty applies to all water systems pumps manufactured by Goulds W ater T echnology.Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.A dealer who believes that a warranty claim exists must contact the authorized Goulds W ater T echnology distributor from whom the pump was purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds W ater T echnology Customer Service Department.The warranty excludes:(a) Labor, transportation and related costs incurred by the dealer;(b) Reinstallation costs of repaired equipment;(c) Reinstallation costs of replacement equipment;(d) Consequential damages of any kind; and,(e) Reimbursement for loss caused by interruption of service.For purposes of this warranty, the following terms have these definitions:(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds W ater T echnology and the dealer inpurchases, consignments or contracts for sale of the subject pumps.(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liabilitycompany, association or other legal entity which may engage in any type of business.THIS WARRANTY EXTENDS TO THE DEALER ONLY .TORQUE VALUESHP Motor BoltAdapter FlangeCoupling1-5SV 10-22SV 33-125SV0.5-7.5 HP 20 lbs ft (27 N m) —15 lbs ft (20 N m) 40 lbs ft (54 N m) 37 lbs ft (50 N m) 10-75 HP45 lbs ft (61 N m)48 lbs ft (65 N m)*15 lbs ft (20 N m)40 lbs ft (54 N m)48 lbs ft (65 N m)*213TC and 215TC Adapter Flange use 30 lbs ft (40 N m)Pump Size Tie Rod Nuts Vent / Drain Plug 1-5SV 22 lbs ft (30 N m) 15 lbs ft (20 N m) 10-22SV37 lbs ft (50 N m)15 lbs ft (20 N m) 33-125SV 44 lbs ft (60 N m)29 lbs ft (40 N m)Seal Gland [lbs ft (N m)]1-22SV 33-125SV18 lbs ft (25 N m)37lbs ft (50 N m)Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.© 2012 Xylem Inc. IM235 Revision Number 1 July 2012Xylem, Inc.2881 East Bayard Street Ext., Suite A Seneca Falls, NY 13148Phone: (800) 453-6777 Fax: (888) 322-5877/brands/gouldswatertechnology。

IMPORTANT SAFETY NOTICETo: Our Valued CustomersUser safety is a major focus in the design of our products. Following the precautions outlined in this manual will minimize your risk of injury.ITT Goulds pumps will provide safe, trouble-free service when properly installed, maintained, and operated.Safe installation, operation, and maintenance of ITT Goulds Pumps equipment are an essential end user responsibility. This Pump Safety Manual identifies specific safety risks that must be considered at all times during product life. Understanding and adhering to these safety warnings is mandatory to ensure personnel, property, and/or the environment will not be harmed. Adherence to these warnings alone, however, is not sufficient — it is anticipated that the end user will also comply with industry and corporate safety standards. Identifying and eliminating unsafe installation, operating and maintenance practices is the responsibility of all individuals involved in the installation, operation, and maintenance of industrial equipment.Please take the time to review and understand the safe installation, operation, and maintenance guidelines outlined in this Pump Safety Manual and the Instruction, Operation, and Maintenance (IOM) manual. Current manuals are available at /literature_ioms.html or by contacting your nearest Goulds Pumps sales representative.These manuals must be read and understood before installation and start-up.For additional information, contact your nearest Goulds Pumps sales representative or visit our Web site at .SAFETY WARNINGSSpecific to pumping equipment, significant risks bear reinforcement above and beyond normal safety precautions.WARNINGA pump is a pressure vessel with rotating parts that can be hazardous. Any pressure vessel can explode,rupture, or discharge its contents if sufficiently over pressurized causing death, personal injury, property damage, and/or damage to the environment. All necessary measures must be taken to ensure overpressurization does not occur.WARNINGOperation of any pumping system with a blocked suction and discharge must be avoided in all cases.Operation, even for a brief period under these conditions, can cause superheating of enclosed pumpage and result in a violent explosion. All necessary measures must be taken by the end user to ensure this condition is avoided.WARNINGThe pump may handle hazardous and/or toxic fluids. Care must be taken to identify the contents of the pump and eliminate the possibility of exposure, particularly if hazardous and/or toxic. Potential hazards include, but are not limited to, high temperature, flammable, acidic, caustic, explosive, and other risks.WARNINGPumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers and/or impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly expand and result in a violent explosion and injury.ITT Goulds Pumps will not accept responsibility for physical injury, damage, or delays caused by a failure to observe the instructions for installation, operation, and maintenance contained in this Pump Safety Manual or the current IOM available at /literature.SAFETYDEFINITIONSThroughout this manual the words WARNING, CAUTION, ELECTRICAL, and ATEX are used to indicate where special operator attention is required.Observe all Cautions and Warnings highlighted in this Pump Safety Manual and the IOM provided with your equipment.WARNINGIndicates a hazardous situation which, if not avoided, could result in death or serious injury.Example:Pump shall never be operated without coupling guard installed correctly.CAUTIONIndicates a hazardous situation which, if not avoided, could result in minor or moderate injury.Example: Throttling flow from the suction side may cause cavitation and pump damage.ELECTRICAL HAZARDIndicates the possibility of electrical risks if directions are not followed.Example:Lock out driver power to prevent electric shock, accidental start-up, and physical injury.When installed in potentially explosive atmospheres, the instructions that follow the Ex symbol must be followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If there is any question regarding these requirements or if the equipment is to be modified, please contact an ITT Goulds Pumps representative before proceeding.Example: Improper impeller adjustment could cause contact between the rotating and stationaryparts, resulting in a spark and heat generation.GENERAL PRECAUTIONSWARNINGA pump is a pressure vessel with rotating parts that can be hazardous. Hazardous fluids may be contained by the pump including high temperature, flammable, acidic, caustic, explosive, and other risks. Operators andmaintenance personnel must realize this and follow safety measures. Personal injuries will result if procedures outlined in this manual are not followed. ITT Goulds Pumps will not accept responsibility for physical injury, damage or delays caused by a failure to observe the instructions in this manual and the IOM provided with your equipment.General PrecautionsWARNINGNEVER APPLY HEAT TO REMOVE IMPELLER. It may explode due to trapped liquid. WARNINGNEVER use heat to disassemble pump due to risk of explosion from tapped liquid. WARNINGNEVER operate pump without coupling guard correctly installed. WARNING NEVER run pump below recommended minimum flow when dry, or withoutprime.WARNING ALWAYS lock out power to the driver before performing pump maintenance.WARNING NEVER operate pump without safety devices installed.WARNING NEVER operate pump with discharge valve closed.WARNING NEVER operate pump with suction valve closed.WARNING DO NOT change service application without approval of an authorized ITTGoulds Pumps representative.WARNING Safety Apparel:Insulated work gloves when handling hot bearings or using bearing heaterHeavy work gloves when handling parts with sharp edges, especiallyimpellersSafety glasses (with side shields) for eye protectionSteel-toed shoes for foot protection when handling parts, heavy tools, etc.Other personal protective equipment to protect against hazardous/toxic fluidsWARNING Receiving:Assembled pumping units and their components are heavy. Failure to properly liftand support equipment can result in serious physical injury and/or equipmentdamage. Lift equipment only at specifically identified lifting points or asinstructed in the current IOM. Current manuals are available at/literature_ioms.html or from your local ITT GouldsPumps sales representative. Note: Lifting devices (eyebolts, slings, spreaders, etc.)must be rated, selected, and used for the entire load being lifted.WARNINGAlignment:Shaft alignment procedures must be followed to prevent catastrophic failure ofdrive components or unintended contact of rotating parts. Follow couplingmanufacturer’s coupling installation and operation procedures.General PrecautionsWARNING Before beginning any alignment procedure, make sure driver power is locked out.Failure to lock out driver power will result in serious physical injury.CAUTION Piping:Never draw piping into place by forcing at the flanged connections of the pump.This may impose dangerous strains on the unit and cause misalignment betweenpump and driver. Pipe strain will adversely effect the operation of the pumpresulting in physical injury and damage to the equipment.WARNING Flanged Connections:Use only fasteners of the proper size and material.WARNING Replace all corroded fasteners.WARNING Ensure all fasteners are properly tightened and there are no missing fasteners.WARNING Startup and Operation:When installing in a potentially explosive environment, please ensure that themotor is properly certified.WARNING Operating pump in reverse rotation may result in contact of metal parts, heatgeneration, and breach of containment.WARNING Lock out driver power to prevent accidental start-up and physical injury.WARNING The impeller clearance setting procedure must be followed. Improperly settingthe clearance or not following any of the proper procedures can result in sparks,unexpected heat generation and equipment damage.WARNING If using a cartridge mechanical seal, the centering clips must be installed and setscrews loosened prior to setting impeller clearance. Failure to do so could resultin sparks, heat generation, and mechanical seal damage.WARNING The coupling used in an ATEX classified environment must be properly certifiedand must be constructed from a non-sparking material.WARNING Never operate a pump without coupling guard properly installed. Personal injurywill occur if pump is run without coupling guard.WARNING Make sure to properly lubricate the bearings. Failure to do so may result in excessheat generation, sparks, and / or premature failure.CAUTION The mechanical seal used in an ATEX classified environment must be properlycertified. Prior to start up, ensure all points of potential leakage of process fluid tothe work environment are closed.CAUTION Never operate the pump without liquid supplied to mechanical seal. Running amechanical seal dry, even for a few seconds, can cause seal damage and must beavoided. Physical injury can occur if mechanical seal fails.WARNING Never attempt to replace packing until the driver is properly locked out and thecoupling spacer is removed.WARNING Dynamic seals are not allowed in an ATEX classified environment.WARNINGDO NOT operate pump below minimum rated flows or with suction and/ordischarge valve closed. These conditions may create an explosive hazard due tovaporization of pumpage and can quickly lead to pump failure and physical injury.General PrecautionsWARNINGEnsure pump is isolated from system and pressure is relieved beforedisassembling pump, removing plugs, opening vent or drain valves, ordisconnecting piping.WARNINGShutdown, Disassembly, and Reassembly:Pump components can be heavy. Proper methods of lifting must be employed toavoid physical injury and/or equipment damage. Steel toed shoes must be worn atall times.WARNINGThe pump may handle hazardous and/or toxic fluids. Observe properdecontamination procedures. Proper personal protective equipment should beworn. Precautions must be taken to prevent physical injury. Pumpage must behandled and disposed of in conformance with applicable environmentalregulations.WARNINGOperator must be aware of pumpage and safety precautions to prevent physicalinjury.WARNING Lock out driver power to prevent accidental startup and physical injury. CAUTIONAllow all system and pump components to cool before handling them to preventphysical injury.CAUTIONIf pump is a Model NM3171, NM3196, 3198, 3298, V3298, SP3298, 4150, 4550,or 3107, there may be a risk of static electric discharge from plastic parts that arenot properly grounded. If pumped fluid is non-conductive, pump should bedrained and flushed with a conductive fluid under conditions that will not allowfor a spark to be released to the atmosphere.WARNINGNever apply heat to remove an impeller. The use of heat may cause an explosiondue to trapped fluid, resulting in severe physical injury and property damage. CAUTIONWear heavy work gloves when handling impellers as sharp edges may causephysical injury.CAUTIONWear insulated gloves when using a bearing heater. Bearings will get hot and cancause physical injury.ATEX CONSIDERATIONS and INTENDED USESpecial care must be taken in potentially explosive environments to ensure that the equipment is properly maintained. This includes but is not limited to:1. Monitoring the pump frame and liquid end temperature.2. Maintaining proper bearing lubrication.3. Ensuring that the pump is operated in the intended hydraulic range.The ATEX conformance is only applicable when the pump unit is operated within its intended use. Operating, installing or maintaining the pump unit in any way that is not covered in the Instruction, Operation, and Maintenance manual (IOM) can cause serious personal injury or damage to the equipment. This includes any modification to the equipment or use of parts not provided by ITT Goulds Pumps. If there is any question regarding the intended use of the equipment, please contact an ITT Goulds representative before proceeding. Current IOMs are available at /literature_ioms.html or from your local ITT Goulds Pumps Sales representative.All pumping unit (pump, seal, coupling, motor and pump accessories) certified for use in an ATEX classified environment, are identified by an ATEX tag secured to the pump or the baseplate on which it is mounted. Atypical tag would look like this:The CE and the Ex designate the ATEX compliance. The code directly below these symbols reads as follows:II = Group 22 =Category2G/D = Gas and Dust presentT4 = Temperature class, can be T1 to T6 (see Table 1)Table 1CodeMax permissiblesurface temperatureo F (o C)Max permissibleliquid temperatureo F (o C)T1 842 (450) 700 (372)T2 572 (300) 530 (277)T3 392 (200) 350 (177)T4 275 (135) 235 (113)T5 212 (100) Option not availableT6 185 (85) Option not availableThe code classification marked on the equipment must be in accordance with the specified area where the equipment will be installed. If it is not, do not operate the equipment and contact your ITT Goulds Pumps sales representative before proceeding.PARTSThe use of genuine Goulds parts will provide the safest andmost reliable operation of your pump. ITT Goulds Pumps ISOcertification and quality control procedures ensure the parts aremanufactured to the highest quality and safety levels.Please contact your local Goulds representative for details ongenuine Goulds parts.S-8©2007 Goulds Pumps, Incorporated Form ITRASHHOGIIa subsidiary of ITT Corporation。

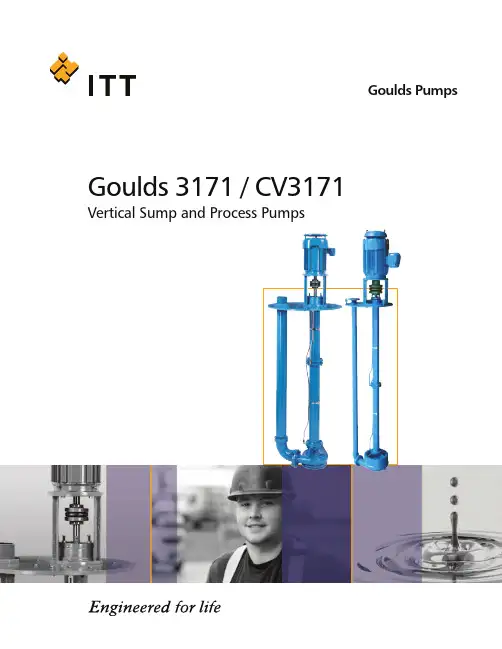

Goulds Pumps Goulds 3171 / CV3171Vertical Sump and Process PumpsModel 3171 Vertical Sump and Process PumpsHeavy Duty Design Features for a Wide Range of ServicesGoulds 31713LABYRINTH BEARING SEALPrevents premature bearing failure due to lubricant contamination.HEAVY COLUMN PIPEProvides rigid support for pump and bearings.LINESHAFT STEADY BEARING Self-lubricating carbon/graphite bearing furnished as standard—best for handling water,corrosives, solvents and high temperature liquids.RESTRICTOR BUSHINGClose running bushing to prevent pressure loss from casing.FULL Y OPEN IMPELLERWITH BACK PUMP-OUT VANES Acknowledged best design for process services—solids handling,stringy material, corrosives,abrasives.C-FACE MOTOR MOUNTING Accommodates readily available C-face motors. Also available forP-base and IEC motors.CONTINUOUS HIGH PERFORMANCE Original high efficiency maintained by simple external adjustment resultingin long-term energy savings.DOUBLE ROW THRUST BEARINGGrease lubricated—carries pump thrust load; sealed for outdoorinstallation.DISCHARGE LOCKED TO PUMP SUPPORT PLATEFOR STRENGTHANY MOUNTING REQUIREMENTS Met by support plate and optional pit cover. Float switches, alternators and other control devices can beeasily mounted.STEADY BEARING HOUSING Precision machined register fit of column, bearing housing and casing assures positive bearing andshaft alignment. Completely interchangeable with all lineshaftbearing options.HEAVY DUTY ONE-PIECE SHAFTWith closely spaced steady bearingsassures long life and lowmaintenance.HEAVY DUTY CASINGProvides rigid support for shaft–closer to impeller load–resulting in longersteady bearing life.REMOVABLE SUCTION COVER Replaceable wear part for lowoperational costs.OPTIONAL UPPER STUFFING BOXGoulds sealed bearing recommended for applications where are in the pumpage for sealing the bearing housing. Spring loaded grease cup is provided.Optional Features for Application FlexibilityGoulds offers a variety of options to meet users’ specific plant and application requirements. Your Gouldsrepresentative will be glad to recommend the featuresbest suited to your particular service conditions to assure safe, efficient and reliable operation.SEALED BEARING ARRANGEMENTJACKETED COLUMNJACKETED DISCHARGEGoulds offers the best choice of steady bearings to meet service requirements...optional fluted rubber with rigid shell, bronze,and (standard) carbon.56Maximum Sealing FlexibilityVapor-Proof ConstructionOptional upper stuffing box allows use of wide rangeof sealing arrangements to meet specific user requirements for sealing toxic, hazardous, noxious or corrosive fumes.With this option, the discharge pipe and all fittings are sealed at the support plate.Your Goulds representative will gladly recommend the best sealing solution for your service, some of which are illustrated here.PACKED BOX Standard vapor-proof sealing option. Includes packing, lantern ring and grease lubricator (not illustrated).DRY RUNNING SEALDry running, non-contacting cartridge gas seal.Pressurized air barrier between seal facesprevents vapor leakage.SINGLE OUTSIDE SEALMechanical seal with oil lubricator and sight glass.Outside mount has no metal parts in contact with vapors.DOUBLECARTRIDGE SEAL Available in wet or dry versions to control emissions.Dimensions Model 3171All dimensions in inches and (mm). Not to be used for construction.*Add 3 in. (76) for float mounted option.78240134242189122195192123190197178182315187332A136213155199100198101351Designed to Meet (or Exceed) T oday’s T ough Environmental Requirements Installed in 1988 on hydrocarbon waste sump service, this 3171 was easilyretrofitted with vapor-proof construction including a ferrofluidic seal (see page 7)to meet tougher EPA emissionrequirements. Readings were less than 30 ppm—exceeding EPA requirementsOptional Upper Stuffing BoxSectional View Model 31719Goulds CV 3171LABYRINTH BEARING SEALPrevents premature bearing failure due to lubricant contamination.HEAVY COLUMN PIPEProvides rigid support for pump and bearings.LINESHAFT STEADY BEARINGGrease lubricating sealed bearings furnished as standard—best for handling fluids with solids.RESTRICTOR BUSHINGClose running bushing to prevent pressure loss from casing.RECESSED IMPELLERSince impeller is recessed in the casing, velocities are low and solids contact with the casing are reduced.Wear rate, solids degradation, and shearing of liquids are minimized.OPTIONAL STRAINERRecommended for services where solids larger than the discharge of the pump can potentially enter the casing.C-FACE MOTOR MOUNTING Accommodates readily available C-face motors. Also available forP-base and IEC motors.CONTINUOUS HIGH PERFORMANCE Original high efficiency maintained by simple external adjustment resultingin long-term energy savings.DOUBLE ROW THRUST BEARINGGrease lubricated—carries pump thrust load; sealed for outdoorinstallation.DISCHARGE LOCKED TO PUMP SUPPORT PLATEFOR STRENGTHANY MOUNTING REQUIREMENTS Met by support plate and optional pit cover. Float switches, alternators and other control devices can beeasily mounted.STEADY BEARING HOUSING Precision machined register fit of column, bearing housing and casing assures positive bearing andshaft alignment. Completely interchangeable with all lineshaftbearing options.HEAVY DUTY ONE-PIECE SHAFTWith closely spaced steady bearingsassures long life and lowmaintenance.NON-CLOG CIRCULAR CASING Large open passageways prevent clogging when handling bulky,fibrous, or stringy liquids. Circular Volute reduces radial loads during lowflow operation, extending steadybearing life.OPTIONAL UPPER STUFFING BOX11Model CV 3171 Vertical Sump and Process PumpsHeavy Duty Design Features for a Wide Range of ServicesCV 3171 Parts List and Materials of Construction1213Sectional View Model CV 3171221107105106240136242189122195333H 190197315351A332A134112333369A 192123213369306155108A 351412A 101100187Upper Stuffing Box14Dimensions Model CV 3171All dimensions in inches and (mm). Not to be used for construction.*Add 3 in. (76) for float mounted option.15PumpSmart ®is the latest advancement in pump control and protection to reduce energy consumption, increase uptime and decrease maintenance cost. It allows the pump to be right-sized to the application by dialing in the speed and torque whichincreases flow economy, reduces heat and vibration, and improves overall system reliability. •Simplified Pump Control — PumpSmart was designed specifically to optimize pumping applications and can be used to control a single pump or coordinate between multiple pumps without the need for an external controller.•Pump Protection — PumpSmart guarantees to protect the pump from upset conditions with patented sensorless pump protection algorithms.•Smart Flow — PumpSmart features a sensorless flow function for centrifugalpumps that can calculate the flow of the pump within ±5% of the pump rated flow. •Drive for the DCS — While most VFDs can only provide basic information,PumpSmart offers unparalleled insight to the pump operation which allows for smoother process control and efficiency.•Pump Experts — PumpSmart is a variable speed drive with pump-specific algorithms imbedded into the drive. With over 150 years of pump knowledge,let the pump experts take responsibility of your pump system.PUMP SMARTVisit our Web site at in the world. By identifying and alerting you to changes in operating conditions, ProSmart increases your time to respond to either correcting Form B3171/CV3171 10/08© 2008 Goulds Pumps, Incorporated A subsidiary of ITT Corporation, Inc.。

Goulds Pumps4XDSubmersible Explosion Proof Sewage Pumps4" Non-Clog X-Proof Sewage PumpFEATURESn Impeller: Cast iron, two vane closed design for high ef-ficiency and maximum wear life. Balanced for smooth operation. Optional bronze impeller available.n Bronze Wear Ring: Replaceable to renew the running clearances and efficiencies to original conditions.n Casing: Heavy duty cast iron, volute type for maximum efficiency . 4" 125# ANSI cast iron flanged. Adaptable to guide rail mounting system.n T andem Seals: T wo independently mounted mechanical face type seals are separated by an oil filled chamber . The oil chamber acts as a barrier to trap moisture and provide time for a planned shutdown and maintenance. The oil provides lubrication to the internal (upper) seal. Carbon rotating and ceramic sta-tionary faces are standard on both internal (upper) and external (lower) seals. Optional materials are available for the lower seals. See the Nomenclature Page for order number changes to order either silicon carbide/silicon carbide faces with Viton or silicon carbide/tung-sten carbide faces with Viton elastomers. These are recommended for applications containing fine solids or abrasives as found in parking lot/garage drainage and construction dewatering jobs.n Moisture Protection System: T wo-wire, dual mois-ture sensing probes are located in the oil filled chamber between the inner and outer seals. When connected to a control panel with an optional Moisture Detection System and an alarm it will detect the presence of moisture should the outer seal fail. It will also detect moisture in the motor chamber and provide a warning prior to water levels reaching the bearing or stator .n Designed for Continuous Operation: Motor is rated continuous duty submerged condition in water that is 40ºC or below . Maximum runtime with pump unsub-merged for 7½–40 HP is 15 minutes. Motor is suitable for 10 starts per hour .n Bearings: Ball, single-row , angular contact, Conrad type bearings with a Class 3 internal fit conforming to AFBMA Standard 20 are used. The bearings are greased for life with a premium moisture resistant polyurea thickened grease containing rust inhibitors and suitable for operation over a range of – 25º C to + 120º C.n Impeller Mounting Screw: 300 series stainless steel with anti-rotational locking patch.n Castings: All iron castings are ASTM A48 class 30 gray cast iron. Optional bronze impeller is ASTM B584 C87600 silicon bronze.Goulds Pumps is a brand of ITT Engineered for life2U L UnderwritersLaboratories MOTOR LISTED EXPLOSION PROOFCLaSS I, DIvISION I, GROuPS C & DAPPLICATIONS• Sewage systems• Flood and pollution control• Industrial dewatering• Wastewater treatment plants• Municipal and subdivision lift stations SPECIFICATIONSPump:• Solids handling capabilities: 3" maximum.• Discharge size: 4" 125# ANSI flanged.• Capacities: up to 1160 GPM.• Total heads: up to 140 feet.• Minimum flow: 100 GPM.• Maximum flow: end of published curve.• Mechanical seals: 304 stainless steel metal parts, BUNA- N elastomers with carbon/rotary and ceramic/stationary faces standard for upper and lower seals. Optional lower seals are available with Viton elastomers and either silicon carbide/ silicon carbide or silicon carbide/tungsten carbide faces.• Fasteners: 300 series stainless steel.Motor:•Explosion Proof Motor: Motors up to and including 40 HP are rated as Class F, 1.15 service factor and are certified explosion proof for Class I, Division I, Groups C and D locations.•CSA certified motors (Canadian Standards Association).•UL (Underwriters Laboratories) Listed Motors.•Three phase motors only.•Available voltages: 200, 230, 400, 460 and 575 volt, 60 Hz.•HP Range: 7.5 - 40.•Motor shaft is a one-piece design of high strength 416 stainless steel.•All motors are air-filled and designed for continuous duty when fully submerged or for up to 15 minutes operation in air.•NEMA design “B” with copper windings.•Class “F” stator winding designed for inverter duty.•Moisture System: Two wire dual probe monitoring system constantly monitors seal oil chamber and stator housing for moisture. Note: control panel must contain an alarm circuit and alarm device.•Two (2) normally-closed, automatic reset thermostats connected in series and embedded in adjoining phases.•Power and sensor cords are 25’ standard length, 50’ available as an option.•Motors conform to the latest applicable requirements of NEMA, IEEE, ANSI and NEC standards.NOTICE: Class 10 quick trip overload protection must be provided in control panel.1st Character – Discharge Size4 = 4” 125 # ANSI Discharge Flange2nd and 3rd Character – Pump Type / DesignXD = Explosion Proof, Dual Seal Pump with On-Winding Thermal Sensors and Moisture Detection Sensors 4th Character – Mechanical Seals1 = Standard Seal – the upper seal is carbon/ceramic,the lower seal is carbon/ceramic, BUNA and 304stainless steel metal parts.3 = Optional Lower Seal – silicon carbide/siliconcarbide, Viton elastomers and 304 SS metal parts.5 = Optional Lower Seal – silicon carbide/tungstencarbide, Viton elastomers and 304 SS metal parts. 5th Character – Motor RPM / Hertz2 = 1750 RPM / 60 Hz 6 = 1450 RPM / 50 Hz3 = 1150 RPM / 60 Hz6th Character – HorsepowerK = 7.5 M= 15 P = 25 R = 40L = 10 N = 20 Q = 307th Character – Voltage / Phase2 = 200 /34 = 460 / 3 6 = 380/400 / 33 = 230 / 3 5 = 575 / 38th Character – Impeller CodeA = 11.0” 10 HP 1150 RPM 40 HP 1750 RPM20 HP 1450 RPMB = 10.75” 30 HP 1750 RPMC = 10.38” 25 HP 1750 RPMD = 10.12” 7.5 HP 1150 RPM 15 HP 1450 RPME = 9.75” 20 HP 1750 RPMG = 9.00” 15 HP 1750 RPM 10 HP 1450 RPM K = 8.00” 10 HP 1750 RPM 7.5 HP 1450 RPM M = 7.50” 7.5 HP 1750 RPMT = SPECIAL TRIM9th Character – Cord Length - Power and Sensor Cords C = 25’ standard F = 50’ Optional10th Character – OptionsB = Silicon Bronze Impeller E = Epoxy PaintF = Both Bronze Impeller and Epoxy PaintNOMENCLATURE DESCRIPTIONSERIES 4XD(all ratings at 3 phase, 60 Hz. Consult factory for 3 phase, 50 Hz applications.)3Goulds Pumps and the ITT Engineered Blocks Symbol are registered trademarks and tradenames of ITT Corporation.SPECIFICaTIONS aRE SuBJECT TO CHaNGE WITHOuT NOTICE.B4XD August, 2008© 2008 ITT CorporationEngineered for lifeMaximum Solid Size3"Minimum Casing Thickness 5⁄16"Casing Corrosion Allowance 1⁄8"Maximum Working Pressure 100 PSI Maximum Submergence 200 feetMaximum Environmental Temperature40º C or 104º F ambient conditions.Maximum Starts Per Hour Maximum of 10 evenly spaced starts per hour.APPLICATION DATAPower Cable Type 1/0 / 4, 2/4, 4/4, 6/4, 8/4, 10/4, 12/4 SOW or SOOW(see Model Info).Control / Sensor Cable / Type 18/5 SOW.Power Cable and Leads have a BUNA N grommet in addition to being Cap Assembly epoxy encapsulated.Power and Control 25’ standard, 50’ optional.Cable Lengths Motor Enclosure Cast iron ASTM A-48 Class 30.Motor Shaft Series 416 Stainless steel.NEMA design “B” with copper windings and designed to Motor Designwithstand 200 psi water pressure at all seal locations. Air- filled NEMA 210TY frame on 7.5, 10, 15 and 20 HP models.Air-filled NEMA 250TYS frame on 25 - 40 HP models.Motor Insulation Rating Class "F" insulation.Motor Thermal Protection Two (2) normally closed on-winding thermostats open at320º F (160º C), automatic reset closes at 221º F (105º C).Motor Overload Protection Class 10, ambient compensated, quick-trip overloadprotection must be provided in control panel.Motor Moisture Protection Two (2) moisture sensing probes in the oil-filled sealchamber must be connected to a relay in control panel.CasingCast iron ASTM A-48 Class 30.Impeller Cast iron ASTM A-48 Class 30 or optional cast bronzeASTM B584 UNS C87600.Impeller TypeTwo vane enclosed design for maximum efficiency.Casing/Impeller/Wear Ring Replaceable bronze wear ring.External HardwareStainless steel.CONSTRUCTION DETAILSSTANDARD PARTSBall BearingsLubricated for life bearings are designed for aminimum L10 life of 30,000 hours .210 and 250 FrameSingle row Radial (upper). Single row Thrust (lower).Mechanical Seals – Upper Carbon/rotary and ceramic/stationary.Standard Lower Carbon/rotary and ceramic/stationary.Mechanical Seals – Lower Silicon carbide/rotary and tungsten carbide/stationary.Optional Lower Silicon carbide/rotary and silicon carbide/stationary.Standard Motor O-rings BUNA-N (nitrile)Premium moisture resistant polyurea thickened grease Seal Chamber Oil containing rust inhibitors is suitable for operation over a temperature range of - 25º C to +120º C.DIMENSIONS(All dimensions are in inches.Do not use for construction purposes.)。

Effective: 07-28-2023 Replaces: 02-26-2021 P/N 241295 Rev. 7SUPPLEMENTAL INSTALLATION AND OPERATING INSTRUCTIONSFor Hi Delta Models H 302CD-2342CD WH 302CD-2342CD P 992CD-2342CDIMPORTANT SAFETY INSTRUCTIONS. READ AND FOLLOW ALL INSTRUCTION. SAVE THESE INSTRUCTIONS.Patent No. 6,904,873FlexGas®Revision 7 reflects the following changes:Added two warnings regarding carbon monoxide to "Warnings" section per ANSI Z21.13_22 Chapters 4.33.1 b and 4.34 i. 2CONTENTSWarnings (4)Model Identification (5)Ratings and Certifications (5)Component Locations (6)Installation Codes (6)Gas Supply..............................................................6Bleed Vents . (7)Start up (8)FlexGas System Start Up (9)FlexGas Operation (10)Wiring Diagram (11)Illustrated Parts List (12)THIS INSTALLATION MANUAL MAY NOT BE THE LATEST REVISION PRINTED AT THE TIME OF PRODUCT SHIPMENT. VISIT THE RAYPAK WEBSITE TO VERIFY THE MANUAL DELIVERED WITH YOUR RAYPAK UNIT IS THE MOST UP-TO-DATE VERSION.34WARNINGSPay Attention to These Terms.56Figure 2. Gas Supply Connection - Top ViewGas Supply PressureA minimum of 5.6 in. WC and a maximum of 10.5 in. WC upstream gas pressure is required under load and no-load conditions for natural gas. A minimum of 11.0 in. WC and a maximum of 13.0 in. WC is required for propane gas. The gas pressure regulator(s) supplied on the heater is for low-pressure service. If upstream gas pressures exceed 14.0 in. WC, intermediate gas pressure regulators, of the lockup type, must be installed.When connecting additional gas utilization equipment to the gas piping system, the existing piping must be checked to determine if it has adequate capacity for the combined load.The gas valve pressure regulator(s) on the Hi Delta heater are nominally preset at 3.5 in. WC. The pressure regulator on the FlexGas propane system is nominally set at 2.2 ± 0.1 in. WC. This can be verified by measuring the propane gas pressure at the upper manifold pressure tap shown in Figure 4. The pressure at the gas valve(s) outlet tap, measured with a manometer, while in operation should be 3.5 ± 0.1 in. WC for natural gas. A nominal pressure of 1.3 in. WC will be observed at the individual heater gas valve outlet taps on propane gas. See Figure 4 for gas pressure measurement locations.Bleeds/VentsThis FlexGas gas train is equipped with a propane gas regulator which may need to be vented to the outdoors as required by state and local codes. If the regulator is required to be vented, the cover must be removed and vent lines installed and ran to a suitable location outside the building in compliance with the NFGC. See Figure 3. Figure 3. FlexGas Cover Removal & Vent Locations78MODELS: 302CD - 902CD MODELS: 992CD - 2342CDGAS VALVE OUTLET TAPGAS VALVE OUTLET TAPStart-UpFor Your SafetyThis appliance has a hot surface igniter(s). It is equipped with an ignition device(s) which automatically lights the burners. Do not try to light the burners by hand.BEFORE OPERATING, smell all around the appliance area for gas. Be sure to smell near the floor because some gas is heavier than air and will settle on the floor.WHAT TO DO IF YOU SMELL GAS:• Do not try to light any appliance.• Do not touch any electrical switch; do not use any telephone in your building.• Immediately call your gas supplier from a neighbor’s telephone. Follow the gas supplier’s instructions.• If you cannot reach your gas supplier, call the fire department.•Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not turn by hand, do not try to repair it, call a qualified service technician. Forced or attempted repair may result in a fire or explosion.•Do not use this appliance if any part has been under water, immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water.•Check around unit for debris and remove combustible products, i.e. gasoline, etc.Pre Start-up Check1. Verify heater is filled with water.2. Check system piping for leaks. If found, repairimmediately.3. Vent air from system. Air in system can interfere withwater circulation.4.Purge air from gas lines up to FlexGas gas train.Initial Start-up Tools Needed:• (1) 12-0-12, 24" scale U-tube manometer • (4) 6-0-6, 12" scale U-tube manometers (min.)• (1) Screwdriver • (1) Multi-meter •(1) 3/16" Allen wrench9PreparationCheck Power Supply With multi-meter at incoming power in Hi Delta heater, check voltage between:Hot - Common (≈120 VAC)Hot - Ground (≈120 VAC)Common - Ground (< 1 VAC)Attach Manometers to Measure Pressures1. Turn off main gas valves.2. Attach 24" scale manometer to the first main gasshutoff valve pressure tapping.3. Attach (1) 12" scale manometer to the outlet side ofthe second main gas shutoff valve pressure tapping.4. Attach (1) 12" scale manometer near the fan-provingswitch. Pull black cap from air pressure switch tee and connect the manometer. NOTE : Retain caps for reinstallation later.Check Gas Supply Pressure1. Slowly turn on main gas shutoff valve.2. Read the gas supply pressure from the manometer;minimum supply pressure for natural gas is 5.6 in. WC, recommended supply is 7.0 in. WC, minimum supply pressure for propane gasis 11.0 in. WC(dynamic readings, all stages firing).3. If the pressure is > 14.0 in. WC, turn off the valve.4. Check if the service regulator is installed and/or adjust the service regulator.FlexGas System Start-up1. Turn off unit. Ensure that the switch on the FlexGascontrol is in the position marked “NAT”. See Figure 5 for FlexGas control operation. Ensure the manualvalve on the natural gas supply is open and the manual valve on the propane supply is closed.2. Turn on the unit, wait 15 seconds, and the igniter should glow. Look into sight glass located at eachend of the heater to check igniter operation. Gas valves should open in 45-60 seconds.3. If burner does not light on first trial. It will retry, up tothree times.4. Main burner ignition: Check manifold gas pressure atgas valve outlet pressure tap. This should read 3.5 ± 0.1 in. WC for natural gas. If the natural gas manifold pressure is not within 3.5 ± 0.1 in. WC, follow theinstructionsin the Hi Delta manual for adjustingmanifold pressure. If a flue gas analyzer is used,the CO2 on natural gas should be 7.5-8.5% and CO should be less than 150 ppm.5. When acceptable operation on Natural Gas is confirmed, turn the gas selector key on the FlexGas control to “OFF”.6. Close the manual valve on the natural gas supplythen open the manual valve on the propane supply. When the heater shuts off, turn the FlexGas control key counter-clockwise to the “PRO” position.7. Wait 15-seconds, and the igniter should glow. Lookinto sight glass located at each end of the heater tocheck igniter operation. Gas valves should open in45-60 seconds.8. If burner does not light on first trial. It will retry, up to three times.9. Main burner ignition: Check upper manifold gaspressure.10. If the pressure readings differ by more than ± 0.1in. WC, remove screw cover from the gas pressureregulator on the FlexGas fuel train and adjust untilupper manifold pressure is nominally 2.2 ± 0.1 in. WC (manifold pressure 1.3 ± 0.1 in. WC). If a flue gas analyzer is used, the CO2 on propane should be 9.0-10.0% and CO should be less than 150 ppm.1011. Replace the screw cover.12. Turn the gas selector key on the FlexGas controlpanel to “OFF”.13. Close the manual valve on the propane gas supplyand open the manual valve on the natural gas supply. Turn the gas selector key on the FlexGascontrol clockwise to “NAT”. The heater is now readyfor operation.FlexGas Operation - Changing FuelsFrom NAT to PRO:1. Turn the boiler off (power switch on front control panel).2. Turn FlexGas key to “OFF”.3. Close NAT manual valve.4. Open PRO manual valve.5. Turn FlexGas key to “PRO”.6. Turn the boiler on.From PRO to NAT:1. Turn the boiler off (power switch on front control panel).2. Turn FlexGas key to “OFF”.3. Close PRO manual valve.4. Open NAT manual valve.5. Turn FlexGas key to “NAT”.6. Turn the boiler on.Safety Inspection1. Check all thermostats and high limit settings.2. During the following safety checks leave manometers hooked up, check and record.3. If other gas-fired appliances in the room are on thesame gas main, check all pressures on the Hi Delta with all other equipment running.4. Check thermostats for ON-OFF operation.5. Check high limits for ON-OFF operation.6. While in operation, check flow switch operation.7. Check the low gas pressure switch (if so equipped). (For proper adjustment, use the attached manometers,if available, to set pressure. The scales on the switchare approximate only.) Low gas pressure switch must be set at 5.0 in. WC for natural gas.Follow-UpSafety checks must be recorded as performed.Turn heater on. After main burner ignition:1. Check manometer for proper reading.2. Cycle heater several times and re-check readings.3. Turn unit off.4. Remove all manometers and replace caps andscrews. 5. Replace all gas pressure caps.6. Check for gas leaks one more time.7. Restart unit.11Figure 5.FlexGas Control PanelFigure 6.Wiring Diagram1213Raypak, Inc. 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 。

IM080R06TABLE OF CONTENTSSUBJECT PAGE Operating and Safety Instrutions (3)Maintenance Instructions (3)Recommended Precautions (3)Operating Instructions (4)Operating (4)General (4)Proper Location (4)Connections (4)Strainer Advisable (4)Starting (4)Lubrication (4)High Discharge (4)Maintenance (4)Troubleshooting Guide (5)Repair Parts (6)Limited Warranty (8)Please fill in data from your pump nameplate.Warranty information is on page 8.Pump Model:Serial Number:Dealer:Dealer’s Phone Number:Date of Purchase:Installation Date:2CongratulationsY ou are now the owner of a Goulds pump. This pump was carefully inspected and subjected to final tests before releas-ing for shipment. In order to assure maximum performance please follow the simple instructions in this manual.PUMPING OF VOLATILE PETROLEUMPRODUCTS CAN BE HAZARDOUS. FOR THIS REASON, EXTREME CARE MUST BE EXERCISED AND ALL OPERATING AND SAFETY INSTRUCTIONS STRICTLY ADHERED TO. FAILURE TO DO THIS CAN RESUL T IN A FIRE OR EXPLOSION. APPLICATION: This pump is designed to pump petro-leum products such as diesel fuel, jet fuel or gasolinein well-ventilated areas that do not contain potentially explosive fumes.This equipment should be operated only by personnel who have been thoroughly instructed as to the hazards involved and who are familiar with the following operat-ing and safety instructions.OPERATING AND SAFETY INSTRUCTIONS1. Use non-sparking tools when making pump connec-tions.2. Always securely connect the ground wire to a goodground on the tank being filled, before operating the pump.3. Do not operate the engine while filling the pump tankwith its initial priming liquid.4. Do not refill engine if running or hot.5. Do not pump liquids other than water or petroleumproducts.6. Do not operate with leaky seal or piping, closed suc-tion or discharge valve or with a fill plug removed. 7. Operate pump only with guard in place. MAINTENANCE INSTRUCTIONS1. If engine is hard to start, or runs rough, move unit to asafe area and check out on water.2. This engine must be maintained in original conditionthroughout its use. Prior to each use, inspect the aircleaner, spark arresting muffler, shielded spark plug, shielded spark plug wire, and the enclosed run-stop switch, to make certain that these are not worn ordamaged in any way.3. Use only original replacement parts - this is criticalsince each part was selected for its safety and highquality.RECOMMENDED PRECAUTIONS1. APPLICATION: This pump is designed to pumppetroleum products such as diesel fuel, jet fuel orgasoline in well-ventilated areas that do not containpotentially explosive fumes. Primarily intended forfuel transfer or refueling construction equipment atremote open air sites where the lack of electricitymakes it impossible to use pumps driven by explo-sion-proof electric motors.Pumping of volatile petroleum products can be haz-ardous. For this reason, extreme care must be exer-cised and all operating and safety instructions strictly adhered to.2. As with all self-priming centrifugal pumps, the pumptank must be initially filled with the liquid beingpumped. DO NOT run the engine while filling thepump tank. Failure to follow this precaution couldresult in a fire or explosion.3. This pump is designed primarily for water and petro-leum products use. Before pumping other liquids,carefully read the special note below.4. Do not subject the pump to a pressure in excess of75 psi.5. Should the fluid temperature rise more than 50ºF.ambient, expansion joints must be installed on both the suction and discharge ports to relieve any stress on the pump casing.6. No modifications, additions or deletions should bemade to the pump.7. Prime movers powering the pumps may operateat high temperatures. Keep hands off mufflers andmanifolds to avoid burns.8. In systems where shock wave pressures may begenerated, protective devices (check valve/gatevalve, etc.) must be installed on discharge line toprevent shock wave pressures from entering casing.A discharge check valve is required when operatingagainst high static heads.9. Do not refill engine fuel tank while power unit is run-ning or while hot. Prevent splashing of gasoline orother fuel while filling supply tank.10. Do not use in a combustible atmosphere.11. Make daily checks of the tightness of suction anddischarge pipe, drain, filler plug and pump gaskets.Check tightness of gasoline tank filler cap each time tank is filled. Operation should not proceed until allof the above items have been checked and are tight.The performance of Goulds WaterT echnology is based upon clear, cold, fresh water with suction conditions as shown on the performance curve. If used to pump other liquids, pump performance may differ from rated performance based on the different specific gravity, temperature, viscosity, etc. of the liquid being pumped. However, a standard pump may not be safe for pumping all types of liquids, such as toxic, volatile or chemical liquids, or liquids under extreme temperatures or pressures. Please consult your Goulds Water T echnology catalog as well as local codes and general references to determine the appropriate pumps for your particular application. Since it is impos-sible for us to anticipate every application of a Goulds pump, if you plan to use the pump for other than a water or petroleum product application, consult Goulds Water T echnology beforehand to determine whether such ap-plication may be proper or safe under the circumstances. Failure to do so could result in property damage or personal harm.THE INSTALLATION OF THE PUMPSHALL INCLUDE ADEQUATE DRAINAGE OR LOCATED SUCH THAT OTHER EQUIP-MENT OR PROPERTY WOULD NOT BE DAMAGED IN THE EVENT OF ANY LEAKAGE. THE PUMP SHOULD NOT BE INSTALLED ABOVE EQUIPMENT OR PROP-ERTY UNLESS ADEQUATE DRAINAGE IS PROVIDED. FAILURE TO COMPLY WITH THIS WARNING COULD RESULT IN PROPERTY DAMAGE.OVERTIGHTENING OF THE CASINGFASTENERS COULD DAMAGE THE FASTENER, RESULTING IN LEAKAGE ANDPROPERTY DAMAGE.3OPERATING INSTRUCTIONSGENERAL• Our shipping container has been specifically designed to prevent transit damage. However, any indications of damage or shortage should be carefully noted on the delivery ticket and a claim filed promptly with the car-rier.PROPER LOCATION• By placing your Goulds pump on a firm, level founda-tion, you reduce the chance of its falling into the liquid and damaging the engine. You also insure proper oil lubrication of the engine and obtain optimum engine performance. Best pump operation is obtained by locating the pump so as to minimize the suction lift as much as practical, keeping in mind that a pump can push liquid more effectively than it can pull or draw liquid.CONNECTIONS• Connections at the easily accessible suction and dis-charge ports can be made with either oil-resistant hose or pipe. The use of strongly reinforced suction hosewill prevent collapsing of the hose during operation. New hose washers should be used at the couplings to prevent trouble-causing leaks. Pipe joint compound that will not dissolve in the liquid being pumped should be used on all pipe joints. All hose or pipe should be inde-pendently supported to eliminate excessive strain on the pump. For best results your hose should discharge higher than the pump to prevent siphoning action when the unit is shut down.• We strongly recommend the use of extra-heavy close faced nipples on the suction and discharge ports ofthe 2AM32-P petroleum pump. Also, be sure to apply pipe compound on the nipples before installing. When pumping petroleum products, it is particularly important to use suitable hose, gaskets and fittings to minimize the chance of a leak occurring.• Also, be certain that the splash guard special air cleaner and spark arresting muffler are used on every applica-tion.STRAINER ADVISABLE• Protect your investment, use a strainer. Strainers are at-tached to the suction line to prevent stones and foreign debris from damaging the impeller or diffuser, result-ing in reduced performance. Stones lodged insidethe pump can cause premature wear and poor perfor-mance. T o keep the strainer from working into the sedi-ment, suspend the hose from the end of a rope. If you do not have a strainer, your Goulds Water T echnology dealer can supply one in the correct size. STARTING• Follow the engine manufacturer’s instructions carefully. Fill the pump tank with liquid before starting.• Your pump has been designed to prime itself in a few minutes with the engine running fast. High suction lifts require additional time and reduce the performanceof the pump. Should you have difficulty, refer to the Troubleshooting Guide section.• Goulds Water T echnology prime and reprime them-selves providing the tank is filled with liquid. Should you lose this liquid from the tank accidentally or by draining purposely, it will be necessary to refill it with liquid be-fore starting. DO NOT operate the engine while filling the pump tank with its initial priming liquid.LUBRICATION• The latest engineering advancements have been incor-porated into our self-lubrication shaft seal. The liquid being pumped cools and lubricates the seal. Running the pump dry will damage the seal. Always keep liquid in the tank, and no further lubrication of the pump end is necessary. Refer to engine manual for proper engine lubrication.• It is particularly important when pumping petroleum products to regularly check the condition of the seal. At the first sign of a leak in the seal, the unit should be shut down immediately and the seal replaced with a new one of the same design.HIGH DISCHARGE• If you have a vertical discharge line rising 30 feet or more, your pump is subject to severe back pressures when it is shut down. This back pressure can cause damage to the pump. T o prevent the possibility of this damage, install a check valve on the discharge line as near to the pump as possible, and the shock will be stopped at the valve.MAINTENANCE1. The pump is fitted with a mechanical shaft seal whichrequires no other lubrication than the liquid in which it operates.2. On occasion, the mechanical shaft seal may becomeworn and must be replaced. Follow the replacementinstructions enclosed with each seal assembly. Do not operate with a leaky seal.3. When pump is not in use for several days, or for winterstorage, drain all the liquid from the tank.4. Follow the engine manufacturer’s manual for periodicmaintenance and adjustment. Also follow their pro-cedure for winterizing the engine as set forth in themanual.5. Storage of engine requires rotation of engine shaftto the compression stroke, thus inhibiting rust on theengine valves.6. Maintenance and functional problems relating to theengine should be referred directly to the manufac-turer’s service station.7. This engine is modified by:a. An Air Maze air cleaner, with oil-wetted metallicelement. A small amount of engine oil should beadded per instruction label on the outside of theair cleaner.b. A spark arresting muffler, centrifugal type. It mustbe mounted with the clean-out plug at the bot-tom. Carbon particles should be removed throughthe clean-out hole on a regular basis. Do this onlywhen engine is cold and in a well-ventilated areafree from petroleum vapors.c. A shielded spark plug and shielded spark plugwire.d. An enclosed run-stop switch on the side of theengine shroud.4TROUBLESHOOTING GUIDEThe following are some common causes of problems that may arise.SYMPTOMS PROBABLE CAUSE RECOMMENDED ACTIONWill Not Prime No liquid Fill tank with liquid.Air leak in suction line Tighten all joints or remake using newcompound.Blocked suction line Clean strainer or suction line.Worn seal Install new seal.Stops Pumping Until Collapsing suction hose lining Replace hose.Engine is Stoppedand RestartedSuddenly Stops Clogged strainer or hose Clean hose and strainer.PumpingSlowly Stops Clogged impeller, diffuser or lines Clean out debris and use strainer.PumpingLeakage Around Worn seal Replace seal.Pump Shaft WhileOperatingPerformance Poor Worn impeller or seal Replace with new impeller or seal.Engine not up to speed Refer to engine manual.Suction lift too high Relocate pump closer to supply.Suction hose too small Use larger size hose.56IMPORTANT:How to use the drawing to order parts:The table above indicates the repair part number for parts indicated in the drawing. Refer to the drawing - locate the part that matches your pump part. Contact your local Goulds Water Technology dealer and supply him with the number of the part required or place your order directly in eCOM. For units manufactured prior to May 2018, contact customer service with your model number and serial number, which are located on the pump nameplate to determine appropriate repair parts.REPAIR PARTS LISTKey Description Part Number 1Pipe plug 16K1422Casing 16K1433Gasket, o-ring 16K1444Impeller, open 16K1455Seal assembly 16K1466Bracket 16K1477Slinger16K1488Splash deflector 16K1499Muffler guard 16K15010Handle 16K15111Ground cable 16K15212Base 16K15313Locknut 16K15414Air cleaner16K15515Spark arresting muffler16K156Key DescriptionPart Number 16Shielded spark plug wire assembly with Magneto16K15716a Shield, spark plug wire 16K15816b Magneto B&S Engine - N/A 16K15917Spark plug16K16018Rotary ignition switch16K16119Engine assembly (includes engine plus items 14 through 18)16K16220Gasket, o-ring 16K16321Capscrew 16K16422Lockwasher 23Nut 24Capscrew 25Capscrew 26Capscrew 27Capscrew 28Lockwasher 29Nut1156723228102418171614232220282926254322711912211915137LIMITED CONSUMER WARRANTYFor goods sold for personal, family or household purposes, Seller warrants the goods purchased hereunder (with the exception of membranes, seals, gaskets, elastomer materials, coatings and other “wear parts” or consumables all of which are not warranted except as otherwise providedin the quotation or sales form) will be free from defects in material and workmanship for a period of one (1) year from the date of installation or eighteen (18) months from the product date code, whichever shall occur first, unless a longer period is provided by law or is specified in the product documentation (the “Warranty”).Except as otherwise required by law, Seller shall, at its option and at no cost to Buyer, either repair or replace any product which fails to conform with the Warranty provided Buyer gives written notice to Seller of any defects in material or workmanship within ten (10) days of the date when any defects or non-conformance are first manifest. Under either repair or replacement option, Seller shall not be obligated to remove or pay for the removal of the defective product or install or pay for the installation of the replaced or repaired product and Buyer shall be responsible for all other costs, including, but not limited to, service costs, shipping fees and expenses. Seller shall have sole discretion as to the method or means of repairor replacement. Buyer’s failure to comply with Seller’s repair or replacement directions shall terminate Seller’s obligations under this Warranty and render this Warranty void. Any parts repaired or replaced under the Warranty are warranted only for the balance of the warranty period on the parts that were repaired or replaced. The Warranty is conditioned on Buyer giving written notice to Seller of any defects in material or workmanship of warranted goods within ten (10) days of the date when any defects are first manifest.Seller shall have no warranty obligations to Buyer with respect to any product or parts of a product that have been: (a) repaired by third parties other than Seller or without Seller’s written approval; (b) subject to misuse, misapplication, neglect, alteration, accident, or physical damage; (c) used in a manner contrary to Seller’s instructions for installation, operation and maintenance; (d) damaged from ordinary wear and tear, corrosion, or chemical attack; (e) damaged due to abnormal conditions, vibration, failure to properly prime, or operation without flow; (f) damaged due to a defective power supply or improper electrical protection; or (g) damaged resulting from the use of accessory equipment not sold or approved by Seller. In any case of products not manufactured by Seller, there is no warranty from Seller; however, Seller will extend to Buyer any warranty received from Seller’s supplier of such products.Goulds Water Technology Policy Concerning Online Sales to Consumers. Homeowners using the Internet to locate information regarding residential water systems, residential wastewater systems, controls and tanks may discover several sites offering a direct-to-consumer purchasing opportunity. Residential water and wastewater systems are mission critical applications and are designed to be installed by qualified professionals. Goulds Water Technology has an extensive nationwide network of distributors and dealers, including authorized resellers. For a complete view of Goulds Water Technology recognized distributors, dealers and authorized resellers, please refer to our locator at: /sales-service/ No warranty is offered on Goulds Water Technology equipment purchased over the Internet, including web-based options from unauthorized retailers. This policy is necessary to ensure that Goulds Water Technology equipment is installed properly, in compliance with applicable laws, rules and codes, in a manner that addresses safety concerns and the proper performance of Goulds Water Technology equipment.THE FOREGOING WARRANTY IS PROVIDED IN PLACE OF ALL OTHER EXPRESS WARRANTIES. ALL IMPLIED WARRANTIES, INCLUDING BUTNOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE (1) YEAR FROM THE DATE OF INSTALLATION OR EIGHTEEN (18) MONTHS FROM THE PRODUCT DATE CODE , WHICHEVER SHALL OCCUR FIRST. EXCEPT AS OTHERWISE REQUIRED BY LAW, BUYER’S EXCLUSIVE REMEDY AND SELLER’S AGGREGATE LIABILITY FOR BREACH OF ANY OF THE FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT AND SHALL IN ALL CASES BE LIMITED TO THE AMOUNT PAID BY THE BUYER FOR THE DEFECTIVE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY OTHER FORM OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL, CONSEQUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE, LOSS OF INCOME, LOSS OF BUSINESS, LOSS OF PRODUCTION, LOSS OF OPPORTUNITY OR LOSS OF REPUTATION.Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.To make a warranty claim, check first with the dealer from whom you purchased the product or visit for the name and location of the nearest dealer providing warranty service.Xylem Inc.2881 East Bayard Street Ext., Suite A,Seneca Falls, NY 13148Phone: (800) 453-6777 Fax: (888) 322-5877/gouldsXylem is a trademark of Xylem Inc.Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.© 2022 Xylem Inc. IM080 Revision Number 6 May 2022。