再发防止对策书(五原则报告)

- 格式:xls

- 大小:43.50 KB

- 文档页数:1

防止不良再发生对策报告书(二)引言概述:不良事件的再发生对于任何组织和企业都是一种风险。

为了确保正常运营并保护利益相关者,必须采取适当的对策来防止不良事件再次发生。

本报告将讨论针对不良再发生的对策,从组织结构、流程管理、培训教育、监督与评估以及持续改进等五个大点展开,以确保组织能够做到预防、控制和应对不良事件。

正文内容:1. 组织结构a. 设立不良事件防范部门:建立专门的部门负责不良事件的防控、预警和处理。

b. 职责明晰化:明确各部门和岗位的职责,建立责任体系,确保不良事件可以得到及时、有效地处理。

c. 内外部协调机制:建立内外部协调机制,整合外部资源,提高对不良事件的应对能力。

d. 激励机制:建立奖惩机制,激励员工参与到不良事件防控中,提高员工的责任心和主动性。

2. 流程管理a. 风险评估与管理:进行全面的风险评估,确定关键风险点,并针对性地建立管理措施。

b. 制定标准作业程序(SOP):为每个业务流程制定明确的SOP,确保每个环节都符合规范。

c. 强化审批程序:加强对重大决策的审批和监督,确保决策的合理性和科学性。

d. 加强内部控制:加强内部控制机制,包括制定审计制度、加强内部审计和风险管理,确保业务运作的合规性和规范性。

3. 培训教育a. 培训计划制定:根据不良事件的具体情况,制定具体的培训计划,包括员工岗位培训和管理人员培训等。

b. 培训方式多样化:采用多种培训方式,包括集中培训、在线培训、内部实训等,提高培训的效果。

c. 定期知识测试:定期组织知识测试,评估培训效果,并针对测试结果进行补充培训。

d. 激励机制建设:设立激励措施,鼓励员工积极参与培训,提高自身的专业素质和技能。

4. 监督与评估a. 内部监督:建立健全的内部监督机制,包括内部审计、风险评估等,及时发现问题并采取措施解决。

b. 外部监督:建立与外部监管机构的密切合作机制,接受监管部门的监督和指导,提高不良事件防控的透明度和合规性。

防止不良再发生对策报告书

一、不良对策报告书填写注意事项:

1、不要填写加强员工质量意识,要求员工认真自检。

(注:对策要有

实施性和可测量性)

2、加强培训(注:培训人,培训对象,培训内容,如何确认培训有效)

3、改进工装及工艺(注:如何改进,何时改进,要具体写明)

4、更新设备(注:更新成什么样的设备,何时更新)

5、如要写对产品进行全检(注:每次发货时都要附带检测报告)

6、加强检查力度(注:一定要把此次不良现象添加到检查表中,发

货时附带更新检查表确认)

二、如何填写不良对策报告书

1、不良原因分析:要通过5Why进行分析,分析不良要坚持不良原

因未调查清楚不放过原则,责任人未调查清楚不放过原则,不

落实改进措施不放过的原则。

2、防止再发生对策:填写时应该能够落实,有具体实施的责任人,

对策实施时间。

3、不良再发生对策报告书应严格按照5W1H分析法来填写:是对选

定的问题、工序或操作,都要从原因(何因why)、对象(何事

what)、地点(何地where)、时间(何时when)、人员(何人

who)、方法(何法how)等六个方面提出问题进行对策思考。

地址:山东省威海市工业新区苘山镇苘兴路8-10号ADD:No.8-10,Manxing road,Manshan Town,Weihai,Shandong province 采购中心电话(TEL):0631-8575915传真(FAX):0631-8575915网址:。

制定事故防止再次发生对策的流程规定Developing a Process for Preventing Recurrence of AccidentsCreating an effective process to prevent the recurrence of accidents is crucial for ensuring a safe and secure environment. This process requires careful planning, implementation, and evaluation. In this response, I will outline the steps involved in developing a comprehensive procedure for preventing accidents from happening again.Identifying the Root Causes of Accidents(事故的根本原因分析)The first step in the process is to identify the root causes of accidents. This involves conducting thorough investigations and analyzing all available data to determine why the accident occurred in the first place. By identifying these underlying factors, we can develop targeted strategies to prevent similar incidents from happening again.Analyzing Data and Identifying Patterns(数据分析与模式识别)Once we have identified the root causes, it is important to analyze relevant data and look for patterns or trends that could help us understand why certain types of accidents occur frequently. This analysis could involve examining incident reports, accident statistics, and any other pertinent information related to past incidents. By identifying recurring patterns, we can develop more focused preventive measures.Developing Solutions based on Previous Experiences(基于经验开发解决方案)Based on our analysis, we can develop appropriate solutions that address the root causes identified earlier. These solutions should be practical, feasible, and tailored tosuit our specific context. It is essential to involve key stakeholders such as management, employees, safety experts, and relevant authorities during this stage to ensure that multiple perspectives are taken into account.Implementing Preventive Measures(实施预防措施)After developing the preventive measures, it is imperative to implement them effectively throughout the organization. This involves clearly communicating the new procedures or guidelines to all personnel involved. Training programs may also be necessary to educate employees about their roles and responsibilities in maintaining a safe working environment.Evaluating the Effectiveness of Preventive Measures(评估预防措施有效性)Regular evaluation is crucial to determine whether the implemented preventive measures are effective in preventing accidents. This evaluation process could involve monitoring accident reports, conducting audits, seeking feedback from employees, and using performance indicators to measure progress. If any shortcomings or gaps are identified, appropriate adjustments should be made accordingly.Continual Improvement(持续改进)A process for preventing the recurrence of accidents cannot be static; it requires continuous improvement. It is essential to review and update the preventive measures regularly based on changing circumstances, new research findings, or evolving industry standards. Furthermore, learning from past incidents and sharing lessons learned across the organization can help foster a safety culture and reduce the likelihood of future accidents.制定事故防止再次发生对策的流程规定建立一个有效的防止事故再次发生的流程对于确保安全和稳定的环境至关重要。

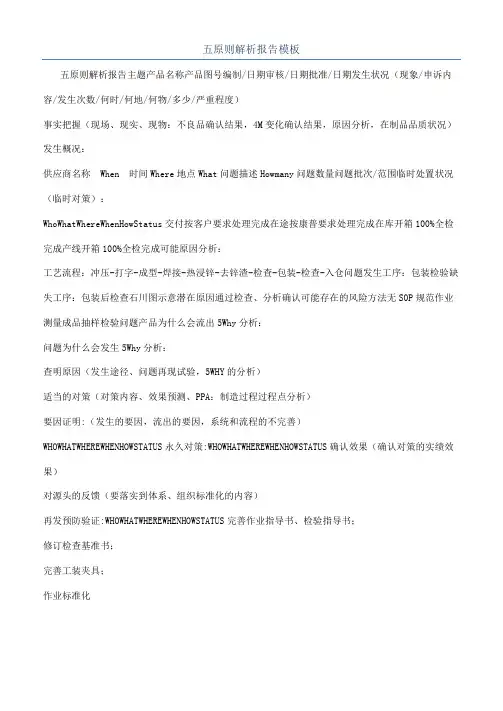

五原则解析报告模板

五原则解析报告主题产品名称产品图号编制/日期审核/日期批准/日期发生状况(现象/申诉内容/发生次数/何时/何地/何物/多少/严重程度)

事实把握(现场、现实、现物:不良品确认结果,4M变化确认结果,原因分析,在制品品质状况)发生概况:

供应商名称When 时间Where地点What问题描述Howmany问题数量问题批次/范围临时处置状况(临时对策):

WhoWhatWhereWhenHowStatus交付按客户要求处理完成在途按康普要求处理完成在库开箱100%全检完成产线开箱100%全检完成可能原因分析:

工艺流程:冲压-打字-成型-焊接-热浸锌-去锌渣-检查-包装-检查-入仓问题发生工序:包装检验缺失工序:包装后检查石川图示意潜在原因通过检查、分析确认可能存在的风险方法无S0P规范作业测量成品抽样检验问题产品为什么会流出5Why分析:

问题为什么会发生5Why分析:

查明原因(发生途径、问题再现试验,5WHY的分析)

适当的对策(对策内容、效果预测、PPA:制造过程过程点分析)

要因证明:(发生的要因,流出的要因,系统和流程的不完善)WHOWHATWHEREWHENHOWSTATUS永久对策:WHOWHATWHEREWHENHOWSTATUS确认效果(确认对策的实绩效果)

对源头的反馈(要落实到体系、组织标准化的内容)

再发预防验证:WHOWHATWHEREWHENHOWSTATUS完善作业指导书、检验指导书;

修订检查基准书;

完善工装夹具;

作业标准化。

制定再发防止对策报告的基本内容和流程下载提示:该文档是本店铺精心编制而成的,希望大家下载后,能够帮助大家解决实际问题。

文档下载后可定制修改,请根据实际需要进行调整和使用,谢谢!本店铺为大家提供各种类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by this editor. I hope that after you download it, it can help you solve practical problems. The document can be customized and modified after downloading, please adjust and use it according to actual needs, thank you! In addition, this shop provides you with various types of practical materials, such as educational essays, diary appreciation, sentence excerpts, ancient poems, classic articles, topic composition, work summary, word parsing, copy excerpts, other materials and so on, want to know different data formats and writing methods, please pay attention!第一部分:报告概述。

1.1 现状分析:对目前再发防止情况进行分析,包括再发事件的频率、影响范围等。