上海海灼化工 产品手册 Version2015(1)

- 格式:pdf

- 大小:453.38 KB

- 文档页数:8

Test Standard, Specs DB-WAX (Capillary), Part Number 200-0370*************(24小时)化学品安全技术说明书GHS product identifier 应急咨询电话(带值班时间)::供应商/ 制造商:安捷伦科技贸易(上海)有限公司中国(上海)外高桥自由贸易试验区英伦路412号(邮编:200131)电话号码: 800-820-3278传真号码: 0086 (21) 5048 2818Test Standard, Specs DB-WAX (Capillary), Part Number 200-0370化学品的推荐用途和限制用途200-0370部件号:物质用途:供分析化学实验室使用的试剂和标准一个1毫升安瓶安全技术说明书根据 GB/ T 16483-2008 和 GB/ T 17519-2013GHS化学品标识:测试标样,DB-WAX 规格(毛细管),部件号 200-0370有关环境保护措施,请参阅第 12 节。

物质或混合物的分类根据 GB13690-2009 和 GB30000-2013紧急情况概述液体。

透明。

氯仿。

[轻微]如仍觉眼刺激: 求医要么就诊。

H225 - 高度易燃液体和蒸气。

H302 - 吞咽有害。

H304 - 吞咽及进入呼吸道可能致命。

H313 - 皮肤接触可能有害。

H315 - 造成皮肤刺激。

H319 - 造成严重眼刺激。

H331 - 吸入会中毒。

H335 - 可能造成呼吸道刺激。

H351 - 怀疑致癌。

H402 - 对水生生物有害。

物理状态:颜色:气味:GHS危险性类别标签要素易燃液体 - 类别 2急性毒性 (口服) - 类别 4H313急性毒性 (皮肤) - 类别 5H331急性毒性 (吸入) - 类别 3H315皮肤腐蚀/刺激 - 类别 2H319严重眼损伤/眼刺激 - 类别 2A H351致癌性 - 类别 2H335特异性靶器官毒性 一次接触 (呼吸道刺激) - 类别 3H304吸入危害 - 类别 1H402危害水生环境一急性危险 - 类别 3警示词:危险危险性说明:H225 - 高度易燃液体和蒸气。

FRONT COVER Flow Control: Thermoplastic Valves | Actuation & Controls | Strainers | Filters | Instrumentation | Pumps | Bulkhead Fittings & Tank AccessoriesBuyTruly engineered to perform in sensitive Life Support Systems, when you see our LifeStar® emblem, know that we are passionate in supporting your vital aquatic systems.With hundreds of years of combined in-house experience, our Engineering, Technical Support and Customer Service teams are well versed in what it takes to support delicate aquatic processes.Here at Hayward Flow Control, we are committed to tackling any problem, standing shoulder to shoulder with our customers.Our products are engineered, manufactured and assembled under the same roof, proudly offering an industry-leading true 3-year warranty.Our World-class ISO 9001:2015 certified facility embodies the American Engineering approach:We Build for Potential.True Grit. We have it.Lifestar® A Series Single Speed up to 5 HPKEY FEATURES• Corrosion Resistant Housing• Self-Priming• Suitable for High Volume Pumping • Perforated HDPE Basket• Clear High Capacity Basket Strainer Lid for Visual Inspection• Elevated Base Ensures Ventilation and Protection from Flooding•ODP and TEFC Motors Available Lifestar® A Series VS Variable Speed 2 HPKEY FEATURES VARIABLE SPEED• Multi-Position or Detachable RemoteMount Digital Control Interface• Fully Programmable with up to 8 UserPreset Functions• Corrosion Resistant Housing• Self-Priming• Suitable for High Volume Pumping • Perforated HDPE Basket• Clear High Capacity Basket Strainer Lidfor Visual Inspection• Elevated Base Ensures Ventilation andProtection from Flooding• TEFC MotorWhen Life Matters.A TRUE L.S.S. PUMP. We understand the complexity of life support systems and the reliability they demand. Our LifeStar® Series Aquatic Pumps are a true Life Support System Pump, ideal for sensitive aquatic environments, both fresh and salt water.Minute amounts of incompatible component materials leaching in delicate aquatic systems can be devastating to life sustainability. Knowing these dangers, the LifeStar® Series employs all wetted hardware made from 316 Stainless Steel and Silicon Carbide Shaft Seals. Models available in single or variable speed as well as multiple horsepower and voltage configurations. The LifeStar® Series Aquatic Pumps stand ready to defend your vital Life Support Systems.W W W.H AY W A R D F L O W C O N T R O L.C O M • 1.888.429.4635Lifestar ® MV Series Single Speed up to 7 HP KEY FEATURES • VFD Compatible • Modular Strainer Basket Design - Can Be Mounted Remotely • 3” Flanged Connection - Basket to Pump• Corrosion Resistant Housing • Self-Priming• Suitable for High Volume Pumping • Perforated HDPE Basket • Clear High Capacity Basket Strainer Lid for Visual Inspection • Elevated Base Ensures Ventilation and Protection from Flooding• Industrial Grade TEFC Motor •2.5” x 3” End Connections Lifestar ® MV Series VSVariable Speed 3 HP KEY FEATURESVARIABLE SPEED• Modular Strainer Basket Design - Can Be Mounted Remotely • Multi-Position or Detachable RemoteMount Digital Control Interface • Fully Programmable with up to 8 UserPreset Functions• Corrosion Resistant Housing• Self-Priming• Suitable for High Volume Pumping• Perforated HDPE Basket • Clear High Capacity Basket Strainer Lidfor Visual Inspection • Elevated Base Ensures Ventilation andProtection from Flooding •Industrial Grade TEFC Motorpatible.The need to reduce energy consumption and lower the carbonfootprint of facilities across the Globe is real. Our LifeStar ® SeriesAquatic Pump line is the most hydraulically efficient in its classwith a wide range of horsepower options, variable speed, VFD compatibility and an industry best 3-Year Warranty.®SUPERPUMP®We understand the need to reduceenergy consumption and lower thecarbon footprint of facilities acrossthe Globe. SUPERPUMP ® VS variablespeed pumps are drop-in upgradesthat deliver up to 80% energy costsavings over single-speed models.80%SUPERPUMP ® VSThe World’s Best Selling Freshwater Pump. An industry icon. Trusted to perform day-in and day-out. The SUPERPUMP® line offers rock-solid reliability, variable speed models affording up to 80% energy cost savings, multiple voltage and horsepower configurations.SUPERPUMP®Single or 2-Speed.5 to 2.5 HP SUPERPUMP® VSVariable Speed115V or 230VSUPERPUMP®700Single Speed up to 1.5 HPKEY FEATURES• ODP Motor• Corrosion Resistant Housing • Self-Priming• Suitable for High Volume Pumping• Perforated HDPE Basket • Clear High Capacity Basket Strainer Lid for Visual Inspection • Elevated Base Ensures Ventilation and Protection from Flooding• Freshwater applications onlyKEY FEATURES VARIABLE SPEED• Multi-Position or DetachableRemote Mount Digital ControlInterface• Fully Programmable with up to8 User Preset Functions• TEFC Motor• Corrosion Resistant Housing• Self-Priming• Suitable for High VolumePumping• Perforated HDPE Basket• Clear High Capacity BasketStrainer Lid for Visual Inspection• Elevated Base EnsuresVentilation and Protection fromFlooding• Freshwater applications onlyKEY FEATURES• TEFC Motor• Corrosion Resistant Housing• Chemical Resistant Viton Seal• Top-mount Wiring forHassle-free Install• Self-Priming• Suitable for High VolumePumping• Perforated HDPE Basket• Clear High Capacity BasketStrainer Lid for Visual Inspection• Elevated Base EnsuresVentilation and Protection fromFlooding• Freshwater applications onlySUPERPUMP®Freshwater PumpsW W W.H AY W A R D F L O W C O N T R O L.C O M• 1.888.429.4635BYV SeriesTBH Series TBH Series Butterfly Valves2” to 12” DN50-DN300 PVC, CPVC, GFPP True Union Ball Valves 1/2” to 2” DN8-DN50 PVC, CPVCLarge Diameter True Union Ball Valves2 1/2” to 6” DN65-DN150 PVC, CPVC CPVCVITON ®EPDMNITRILEPVCB O D Y L I N E R GFPPMATERIALS *Platinum *Disc only “Patented & Other Patents Pending” Pat. No.:9,695,947“Patent Pending” CPVCFPMEPDMPTFEPVCB O D Y S E A L S MATERIALS S E A T S CPVCFPMEPDMPTFE PVCB O D Y S E A L SMATERIALSS E A T S KEY FEATURES • S ystem2™ Sealing Technology Provides Longer Cycle Life • 250 PSI / 16 Bar, Non-shock at 70°F / 23°C Full Pressure Rating • C onsistent Operating Torque with Adjustment-free Design • L ockout/Tagout Mechanism Secures Directly to Valve Body for Enhanced Safety • E rgonomic Handle for Improved Grip and Comfort • I SO Mounting Flange Simplifies Actuation • P ermanent Markings, Eliminates Labels • I ntegral Footpad for Skid or Panel Mount • D ouble O-Ring Stem Seals OPTIONS • Pneumatic or Electric Actuators • Stem Extensions • Manual Limit Switch KEY FEATURES • 235 PSI / 16 Bar, Non-shock at 70°F / 23°C Full Pressure Rating • C onsistent Operating Torque withAdjustment-free Design • L ockout/Tagout Mechanism Secures Directly to Valve Body for Enhanced Safety • E rgonomic Handle for Improved Grip and Comfort • I SO Mounting Flange Simplifies Actuation • P ermanent Markings, Eliminates Labels • I ntegral Footpad for Skid or Panel Mount• D ouble O-Ring Stem SealsOPTIONS • Pneumatic or Electric Actuators • Stem Extensions • Manual Limit Switch KEY FEATURES • One Piece Injection Molded Body • Hand Lever with 19 Lockable Stop Positions & 360° Interlocking Splines • External Disc Position and Flow Indication • Hydro-dynamic Centric Disc for Increased Flow Performance • Over-Sized Liner Face Maximizes Surface Contact with Flanges • 1-Piece 316 Stainless Steel Stem with Threaded Retaining Gland • Stem Bearing and Seal Retainer for Absolute Stem Position and Seal • ISO 5211 Top Flange and Stem Drive • All Sizes Meet ANSI B16.10 / ISO 5752• Pressure Rated at 150 PSI/10 Bar in All Sizes @ 70°F Non-Shock OPTIONS • Over-Molded 316 Stainless Steel Lugs • Titanium or Hastelloy ™ Stem Materials • Gear Operators • Complete Range of Pneumatic or Electric Actuators • Lock Out Caps • Stem Extensions • 2" Square Operating Nut • Chain Operator for Gear Box BYB Series Large Diameter Butterfly Valves 14” to 24” available in PVC, CPVC, PP and PVDFW W W.H AY W A R D F L O W C O N T R O L.C O M • 1.888.429.4635KEY FEATURES • Available in PVC, CPVC, and PVDF • PVDF 1-pc Construction • Horizontal or Vertical Installation • Threaded, Socket or True Union Connection • Full Flow Design • Minimal Back Pressure Required to Seat Piston • PVC, CPVC or PVDF Coil to Guide Piston to a Positive Seat OPTIONS • Drilled Cap for Easy Drainage • True Union End Connections KEY FEATURES • Robust Full Pattern Body • PVC and CPVC • N o Special Spacers or Flanges Required • High Cv Rating Equal to Metal Check Valves, Saves on Energy and Pump Wear • FPM or EPDM Gasket and Face Seal • One-Piece Disc and Shaft Design • Designed for ANSI150 and PN10 Flanges • Patent No. 8,887,757OPTIONS • 316 S tainless Steel or Hastelloy ® Disc Spring KEY FEATURES • A vailable in PVC, CPVC, PP and PVDF • For Horizontal or Vertical Installation • 1/2” to 6” are Sure Block Design • Square Cut Seat for Positive Sealing • Seats with Minimum Back Pressure • 1/4” and 3/8” are Trim Check DesignOPTIONS • Foot Valve ScreensTC Series True Union Ball Check Valves 1/4” to 3/8” DN8-DN10 PVC1/2” to 2” DN15-DN50 PVC, CPVC, PP 2-1/2” to 6” DN63-DN150 PVC, CPVC 1/4” to 1” DN8-DN28 PVDFCPVCPVCB OD Y MATERIALS FPMEPDM S E A L S WCV Series Full Pattern Wafer Check Valves 2” to 8” DN50-DN200 PVC, CPVCYC Series Y-Strainers1/2” to 4” DN15 - DN100 PVC, CPVC 1/2” to 1” DN15 - DN28 PVDF CPVCPVDFFPMEPDMPVCB O D Y S E A L S MATERIALS PP PVDFFPMEPDM CPVC PVCS E A L S MATERIALS B O D Y HAYWARD CHECK VALVES For more check valve solutions from Hayward Flow Control,visit our website to learn more about our full line of ball and Y-pattern checks as well as Swing Check, Wafer and Full Pattern Wafer check valves.SW Series Swing CheckCPVC PVC B O D Y FPM EPDM S E A L S GFPPMATERIALS FLV/CFLV Series SB Series Simplex & Duplex Bag/Cartridge Filters Single Length 1-1/4” - 2” DN32-DN50 GFPP , PVC, CPVC Double Length 2-1/2” - 4” DN65 - DN100 GFPP , PVC, CPVC Simplex & Duplex Basket Strainers 1/2” to 4” DN15-DN100 PVC, CPVC, GFPP , GFPP Platinum and Eastar ®6” to 8” DN150-DN200 PVC, CPVC 1/2” to 2” DN15-DN 50 PVDF“Patented” Pat. No.:9,630,127SYSTEM PROTECTION Hayward offers a full line of Pressure Differential Gauge kits to help better protect your vital systems fromdamage. Pressure Differential Gauges indicate when to clean, change or replace yourbag filter or strainer.YS Series Y-Strainers 1/2” to 2” PVC, CPVC, CLEAR PVC 2-1/2” to 4” PVC, CPVC1/4” to 1” PVDFincluding DN15-DN100.Eastar ®FPM EPDM B O D Y S E A L S MATERIALS GFPP Platinum PVDF CPVC PVC YS Series True Union KEY FEATURES • Available in PVC, CPVC, Clear PVC and PVDF • PVDF 1-pc Construction • Horizontal or Vertical Installation • Threaded, Socket or True Union Connection • FPM O-Ring Seals • 2:1 Open Area Ration • Hex Cap for Easy Access to Screen • Standard Screen Has 1/32” Perforation****Standard PVDF Screen Has 3/32” Perforation OPTIONS • Stainless Steel Perf or Mesh Strainer Screens Available in Various Sizes KEY FEATURES • PVC, CPVC, GFPP , PVDF and Eastar ®• Ergonomic Hand Removable Cover • In-Line or Loop Connections • External Cover Threads • Integral Flat Mounting Bases • PVC or CPVC Baskets Standard • Ideal for protecting pumps and other critical system equipment OPTIONS • Stainless Steel, Monel ®, Hastelloy ® and Titanium Strainer Baskets • Pressure Differential Gauge and Switch • Baskets Available with Perforated or • Mesh Liners KEY FEATURES GFPP • Platinum GFPP Material • Heavy Duty One-Piece Injection Molded Construction • Standard Solid Heavy-Duty Basket • Hand Removable Ergonomic Cover with Liquid Displacing Dome • Vent Valve on Cover • In-Line or Loop Configuration • Drain Port at Bottom • Integral Mounting Base OPTIONS • Vent Gauge with Gauge Guard • Pressure Differential Gauge and Switch • EPDM Seals • Cartridge Adapters - CFLV only KEY FEATURES PVC & CPVC • True Union End Connections - Socket, Threaded or Flanged • Hand Removable, Ergonomic Cover with Liquid Displacing Dome • Vent Valve Included On Cover • Rated up to 100 GPM • In-Line or Loop Flow Configurations • Solid 1-Piece Basket • Drain Port at Bottom • Integral Mounting Base OPTIONS • Pressure Gauge with Gauge Guard • Pressure Differential Gauge and Switch • EPDM Seals • Duplex Configurations PVDF FPM EPDM CPVC PVC S E A L S MATERIALS CLEAR PVC B O D YW W W.H AY W A R D F L O W C O N T R O L.C O M • 1.888.429.4635HCF SeriesCommercial Cartridge FiltersLS SeriesAquatic Sand FiltersHCF SeriesCommercial Sand FiltersKEY FEATURES • Ideal for Saltwater and Freshwater Systems • UV-Resistant External Surface Coating for Easier Cleaning, Longer LifeOutdoors and Increased UV Protection • Durable Heavy Duty Fiberglass Filter Body• Transparent Manway Design Simplifies Operation and Improves Durability • Commercial-grade PVC and ABS Injection Molded Internals with 360° Slotted Laterals• Industrial Valve and Pressure Gauge • Available in 30”, 34” and 36” Sizes • Flow Rates up to 143GPM • 2” Inlet/Outlet ConnectionsOPTIONS• HFC Commercial 6-Way Multiport Valve (Fresh Water Only)KEY FEATURES• Ideal for Sensitive AquaticEnvironments both Fresh and Salt Water Systems• All Wetted Hardware Manufactured from 316 Stainless Steel• Corrosion Resistant Thermoplastic Housing and Base• Durable Flanged Inspection Cover • Integral Top Diffuser• Available in 31” and 32” Sizes • Efficient, Multilateral Underdrain Assembly• Integral Molded Drain Plug • 2” Inlet/Outlet Connections OPTIONS• LS Aquatic 6-Way Multi-port Valve (Fresh Water Only)KEY FEATURES • Ideal for Freshwater Systems • 700ft 2of High Performance Polyester Filter Media• Commercial-grade Glass Reinforced Co-polymer Housing• Combination Pressure and Filter Cleaning Cycle Indicator Gauge• Heavy-Duty, Tamper-proof One-Piece Tank Clamp• Commercial Capacity DualQuad-Cluster Cartridge Elements • Full Size Integral Molded Drain Plug • Flow Rates up to 150GPM• 2” by 2.5” Inlet/Outlet Connections • Covered by Hayward Industries, Inc. Pool division Warranty.OPTIONS •HFC Commercial 6-Way Multi-portValve (Fresh Water Only)IN A TIGHT SPOT?Hayward offers our ProSeries TM top-mount and side-mount sand filters for those unique installs. Available in 22” to 30” sizes.ProSeries TM Sand FiltersSwimClear TMSwimClear TMSingle Element Cartridge FilterMulti-Element Cartridge FilterStarClear TM & StarClear TM PlusSingle-Element Cartridge FilterKEY FEATURES• For Saltwater and Freshwater Applications• Ideal for Small Systems and Systems with Limited Backwash Water• Available in 100ft 2, 150ft 2 and 200ft 2 Sizes• Corrosion Resistant Thermoplastic Construction• Easy-off Ring Lock Lid• Nominal 30 Micron Polyester Cartridge • Includes Pressure Gauge, Relief Valve and Drain Fitting• 2” by 2.5” Union Connection Inlet/Outlets• Up to 75 GPM• Covered by Hayward Industries, Inc. Pool division Warranty.KEY FEATURES• For Saltwater and Freshwater Applications• Ideal for Small Systems and Systems with Limited Backwash Water • 225ft 2 up to 700ft 2 Sizes• Corrosion Resistant Thermoplastic Construction• Center Based Ring Clamp for Lid Removal• Nominal 30 Micron Polyester Cartridge • Includes Pressure Gauge, Relief Valve and Drain Fitting• 2” by 2.5” Union Connection Inlet/Outlets• Up to 150 GPM• Covered by Hayward Industries, Inc. Pool division Warranty.KEY FEATURES• For Freshwater Applications Only • Ideal for Small Systems and Systems with Limited Backwash Water • 25ft 2 up to 175ft 2 Sizes• Corrosion Resistant Thermoplastic Construction• Single Locking Knob for Lid Removal • Nominal 30 Micron Polyester Cartridge • Includes Pressure Gauge, Relief Valve and 1/2” Drain Fitting• 1” or 2” Connection Inlet/Outlets • Up to 66 GPM• Covered by Hayward Industries, Inc. Pool division Warranty.W W W.H AY W A R D F L O W C O N T R O L.C O M • 1.888.429.4635KEY FEATURES • Units are equipped with two (2) volt-free Form A Auxiliary switches • ISO5211 compliant mounting with a double square female drive socket • Raised visual position indicator*• NEMA 4X/IP67 compliant • EMT entry ports with sealed cable glands • Internal Heater Standard • Manual OverrideOPTIONS• Power Supply Flexibility • On / Off Proportional Control • Local Control Stations • IP68 Submersion • Battery Backup • Supercap Backup• Interchangeable ISO5211 Flange &Drives EAU1 Series Commercial Electric ActuatorsBall Valves up to 2” DN50HRS Series Industrial Electric Actuators266 - 177,000 Torque in/lbsECP Series Industrial Electric ActuatorsBall & Butterfly Valves up to 6” DN150KEY FEATURES • ISO5211 Compliant F05 Base • UL/CSA Listed Motor • Thermoplastic NEMA 4 / 4X Enclosure • 2.5 Second, 90° Cycle Time• Permanently Lubricated Gear Train • Motor Brake • 90° Operation• Unidirectional, Not Reversing • Terminal Block Connections • Standard 120 VAC• End of Travel Dry Contact Limit Switch • Thermal Overload Protection• Lightweight, Compact and InexpensiveOPTIONS • Voltage Options of 12, 24 or 230 VAC and 12, 24 VDC KEY FEATURES• Ideal for Corrosive Atmosphere and Environments• Corrosion-Resistant GFPP Housing • LED Status Light• Anti-Condensation Heater • Manual Override • Position Indicator• 4 SPDT Micro Limit Switches • Lightweight - Easy for Installation • Namur-Style Solenoid Mounting • ISO 5211 Mounting Base• Stainless Steel Fasteners 303 SS • 100% Factory Tested • CE MarkOPTIONS • D igital Positioner 0-20mA, 4-20mA or 0-10V• Single Phase 120/230V & 12/24V •Battery BackupWhen Life Matters.HAYWARD AQUATIC ACTUATION. Hayward offers a comprehensive actuation line of electric, pneumatic and gear automation. Control is critical in vital Life Support Systems. With features like Corrosion Resistant Housings, Fail-Safe Battery Backups, Manual Overrides, Local Control Stations and an industry leading3-year warranty, we have you covered.HLS Series Level SensorsLiquid Level, Flow and Analytical measure and control wide ranging Aquatic, Municipal, Commercial and Industrial processes.HLST SeriesIndicating Level TransmitterHEX800 Series FlowmeterHMC200 SERIESGOT HEAT?Hayward Industries offers both gas and electric heat pump options up to 500,000 BTU’s. Please consult Hayward Flow Control Aquatics team for sizing, applications and Aquatic Life Support Systems for more information.Universal H-Series High Performance Gas HeaterPropane or Natural GasUniversal H-Series ASME High Performance Commercial Gas HeaterPropane or Natural GasHeatPro Series High Performance Heat PumpKEY FEATURES • Up to 500,000 BTU’s • For Freshwater Use Only• Standard Cupro Nickel Heat Exchanger • Exclusive “Totally Managed” Curpo Nickel Heat Exchanger Water Flow • Patented Header By-pass Design • Uniform Water Velocity Through All Piping for Faster Heating• Up to 18% Savings by Reducing Pump Run-Time• 2” by 2.5” Union Connection Inlet/Outlets• Low NOx Emissions Meets Clean Air Quality Standards• Covered by Hayward Industries, Inc. Pool division Warranty.OPTIONS • Propane or Natural Gas KEY FEATURES•Up to 500,000 BTU’s • For Freshwater Use Only• Patented Cupro Nickle Finn Plate TM Heat Exchanger• Electronic Lock-out PreventsUnauthorized Access to Control Panel • Patented Header By-pass Design • ASME Pressure Relief Valve Standard • Dual Voltage Conversion with Fuse-protected Circuit Boards • 2” by 2.5” Union Connection Inlet/Outlets• Low NOx Emissions Meets Clean Air Quality Standards• Covered by Hayward Industries, Inc. Pool division Warranty.OPTIONS • Propane or Natural Gas KEY FEATURES• Up to 140,000 BTU’s (heat only)• For Freshwater Use Only• Exclusive ‘Ultra Gold’ Evaporator Coil Corrosion Resistant•Extremely Quiet Operation • AHRI Certified Performance• 2” by 2.5” Union Connection Inlet/Outlets• 240V Single Phase• Lightweight for Ease of Installation • Covered by Hayward Industries, Inc. Pool division Warranty.W W W.H AY WA R D F L O W C O N T R O L.C O M • 1.888.429.4635BACK COVERUSA: 1.888.429.4635•Fax:1.888.778.8410•OneHaywardIndustrialDrive•Clemmons,NC27012•Email:********************Canada: 1.888.238.7665•Fax:1.905.829.3636•2880PlymouthDrive•Oakville,ONL6H5R4•Email:***********************Visit us at: Hayward is a registered trademark of Hayward Industries, Inc. © 2020 Hayward Industries, Inc.Hayward Flow Control is passionate about solving our customer’s problems. Our products serve vital roles in numerous unforgiving processes that impact all walks of life. With an industrial mindset and a passion for excellence, Hayward Flow Control continues to drive forward with purpose, forward thinking and American ingenuity. We mean it when we say:True Grit. We have it.BuyAmericanAQG1120。

生效日期19.03.2008化學品安全技術說明書根據EC 2001/58/EC指令1. 化學品及企業標識化學產品中文名稱: SHELL JET A-1使用: 用於飛機上所安裝的航空渦輪發動機的燃油。

產品代碼: 002C0364製造商/供應商: Shell Hong Kong Ltd36th floor, Shell TowerTimes Square, Causeway BayHong KongHong Kong電話: +852 ********傳真: +852 ********緊急電話號碼:2432 87042. 成分/組成信息配方說明: 烴複雜混合物由石蠟、環烷、芳香劑及烯烴構成,碳原l數主要介於 C9 至 C16 之間。

可能亦含若干添加劑,每種添加劑的含量為 <0.1% v/v 。

危險組份化學名稱CAS(化學文摘社)EINECS符號危險警語濃度Kerosine (petroleum), hydrodesulphuris ed 64742-81-0265-184-9Xi, Xn, N R10; R38;R65; R51/530.00 - 100.00%Kerosine8008-20-6232-366-4Xn, N R10; R38;R65; R51/530.00 - 100.00%額外資訊:芳香烴總的含量通常為 10-20%v/v。

有關歐盟物質危害風險分類R-phrases的全文,請參閱第 16章。

3. 危險性概述EC分類: 易燃。

有害。

刺激物。

對環境危險。

健康危害: 對呼吸系統有輕微刺激作用。

吸入高濃度的蒸汽可能導致中樞神經系統 (CNS)生效日期19.03.2008化學品安全技術說明書根據EC 2001/58/EC指令衰竭,導致頭暈、頭輕、頭痛及噁心。

刺激皮膚。

有害:誤吞對肺有嚴重損害。

症狀及徵兆: 若材料進入肺部,會出現一些徵候與症狀,如咳嗽、憋悶、哮喘、呼吸困難、胸部充血、呼吸短促、及/或發燒。

化学品安全技术说明书警告吸入可能有害灭火注意事项及防护措施消防措施通知消防队,并告知事故位置与危害特性。

仅在火灾时,佩戴呼吸设备及防护手套。

采取一切可能的措施防止溢出物进入下水道或水道。

采用适合于周围环境的灭火程序。

不要靠近可能灼热的容器。

从有防护的位置喷水以便冷却暴露于火灾中的容器。

如果这么做安全的话,将容器从火场中移走。

使用后彻底清洗设备。

火灾/爆炸危害固体呈现难燃或不易点燃的特性。

都可能会引起火灾和爆炸。

微米将会导致爆炸蔓延扩散。

粉尘爆炸可能会释放大量的气态产物,进而使压力上升,其爆炸力能够破坏厂房和建筑并使人员受伤。

通常,爆炸起初发生在诸如工厂或机械装置等受限空间里,具有足以破坏或炸破整座厂房的力量。

如果初始爆炸产生的冲击波进入周围区域,它将破坏任何一层固定的粉尘,并形成第二层粉尘云,这常常会引发更剧烈的二次爆炸。

所有的大爆炸都是由这种连锁反应所引发的。

在排气管或运输过程中,由于涡流、气动输送、灌流,干燥的粉尘能够产生静电。

可用跨接和接地的方法来防止静电积累。

粉末处理设备如粉尘收集器、烘干器、磨粉机可能需要额外的防护措施,如防爆通风设施。

秒。

一氧化碳(CO),可能释放有毒烟雾。

部分 6: 泄漏应急处理作业人员防护措施,防护装备和应急处置程序请参见阅第8部分防止发生次生灾害的预防措施请参阅以上部分环境保护措施请参阅第12部分泄漏化学品的收容,清除方法及所使用的处置材料小量泄漏清除所有点火源。

立即清理所有泄漏物。

避免接触皮肤和眼睛。

使用采用防护装设备以控制人员接触。

采用干燥清理程序,并避免产生粉尘。

放入合适的、贴有标签的容器里,以便进行废弃处置。

大量泄漏中等程度危害。

通知该区域内全体人员。

报告应急部门,并告知事故地点和危害特性。

穿防护服控制人员接触。

采取一切可能的措施防止溢出物进入下水道或水体。

如果可能,尽量回收产品。

采用干燥清理程序,避免产生粉尘。

将收集的残留物放入密封的塑料袋或其它容器,以便废弃处置。

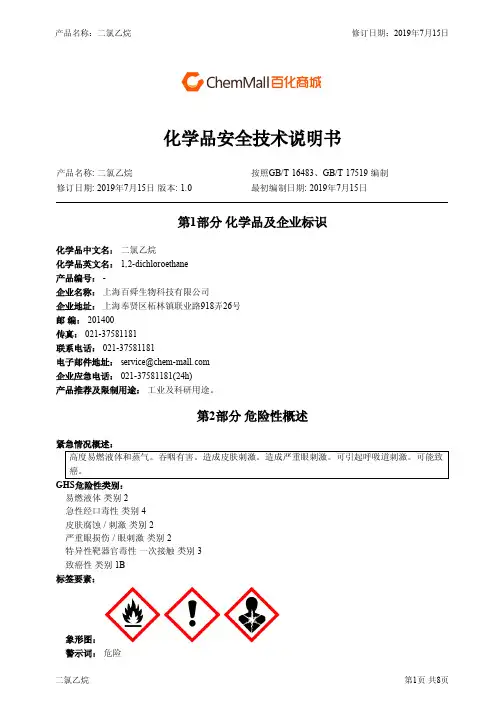

化学品安全技术说明书产品名称: 二氯乙烷按照GB/T 16483、GB/T 17519 编制修订日期: 2019年7月15日版本: 1.0最初编制日期: 2019年7月15日第1部分化学品及企业标识化学品中文名:二氯乙烷化学品英文名: 1,2-dichloroethane产品编号: -企业名称:上海百舜生物科技有限公司企业地址:上海奉贤区柘林镇联业路918弄26号邮编: 201400传真:联系电话:电子邮件地址:企业应急电话:产品推荐及限制用途:工业及科研用途。

第2部分危险性概述紧急情况概述:高度易燃液体和蒸气。

吞咽有害。

造成皮肤刺激。

造成严重眼刺激。

可引起呼吸道刺激。

可能致癌。

GHS危险性类别:易燃液体类别 2急性经口毒性类别 4皮肤腐蚀 / 刺激类别 2严重眼损伤 / 眼刺激类别 2特异性靶器官毒性一次接触类别 3致癌性类别 1B标签要素:象形图:警示词:危险危险性说明:H225 高度易燃液体和蒸气H302 吞咽有害H315 造成皮肤刺激H319 造成严重眼刺激H335 可引起呼吸道刺激H350 可能致癌防范说明:预防措施:—— P210 远离热源/火花/明火/热表面。

禁止吸烟。

—— P233 保持容器密闭。

—— P240 容器和装载设备接地/等势联接。

—— P241 使用防爆的电气/通风/照明/设备。

—— P242 只能使用不产生火花的工具。

—— P243 采取防止静电放电的措施。

—— P280 戴防护手套/穿防护服/戴防护眼罩/戴防护面具。

—— P264 作业后彻底清洗。

—— P270 使用本产品时不要进食、饮水或吸烟。

—— P261 避免吸入粉尘/烟/气体/烟雾/蒸气/喷雾。

—— P271 只能在室外或通风良好处使用。

—— P201 使用前取得专用说明。

—— P202 在阅读并明了所有安全措施前切勿搬动。

事故响应:—— P303+P361+P353 如皮肤(或头发)沾染:立即脱掉所有沾染的衣服。

Chemlok® 607 Technical Data SheetChemlok® 607 is a clear, one-coat surface treatment used to affix unvulcanized silicone rubber to various substrates such as metals, glass, plastics and textiles.Chemlok 607 also works on specialty elastomers such as fluoroelastomers, polyacrylates, epichlorohydrin and some peroxide-cured elastomers.Features and Benefits:Versatile – used on a wide variety of commercially available elastomer stocks and many diverse metallic and nonmetallic substrates.Environmentally Resistant – creates high strength systems capable of withstanding salt spray, harsh chemical exposure, corrosive atmospheres and temperature extremes.Durable – provides high strength performance at both high and low temperatures.Easy to Apply – applies easily by brush, spray or dip methods.High Temperature Resistant – withstands temperatures up to 204°C (400°F), and below -51°C (-60°F) for fluoroelastomers or silicone. Elastomers:• Polyacrylate (ACM) • Ethylene Acrylic (AEM)• Fluoroelastomer (FKM) • Epichlorohydrin (ECH)• S ilicone (VMQ, PMQ, PVMQ) - peroxide cure• Nitrile (NBR) - peroxide cure• Hydrogenated Nitrile (HNBR) - peroxide cure Application:Surface Preparation – Thoroughly clean metal surfaces prior to application. Remove protective oils, cutting oils and greases by solvent degreasing or alkaline cleaning. Remove rust, scale or oxide coatings by suitable chemical or mechanical cleaning methods.Carefully prepare nonmetallic surfaces. Fabric is usually desized by a scouring operation. Glass can be cleaned in an alkaline bath. Clean plastic surfaces with a solvent.For further detailed information on surface preparation of specific substrates, refer to Chemlok application guide. Mixing – Pour Chemlok 607 into a receptacle and dilute with methanol or ethanol as required. Average dilution ratio of 1:1 to 3:1 solvent to Chemlok 607 will providethe optimum performance and maximum coverage with minimum product use.Pour out only enough Chemlok 607 to use for a short period of time, as rapid evaporation occurs in open containers. Porous substrates, such as heavy fabrics, may require more extensive dilution in order to prevent excessive pick-up.Applying – Apply Chemlok 607 in a uniformly thin coatby brush, spray or dip methods. Performance can be compromised by repeated brushing or improper dipping drainage.When coating fabrics, use a dry pick-up level of 0.05-1.0%, based on the dry weight of the fabric. Spray applications ensure that Chemlok 607 is effectively applied to the fabric surface. For fabrics that are dippedor brushed, diluting Chemlok 607 will help preventfabric stiffness caused by excessive pick-up levels. For information on using dyes and fluorescing additives with Chemlok 607, contact your Parker LORD Technical ServiceRepresentative.Chemlok 607 — Technical Data SheetParker LORDEngineered Materials Group 111 LORD DriveCary, NC 27511-7923USAValues stated in this document represent typical values as not all tests are run on each lot of material produced. For formalized product specifications for specific product end uses, contact the Customer Support Center.Information provided herein is based upon tests believed to be reliable. In as much as Parker LORD has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, Parker LORD does not guarantee the performance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user. Nor does the company make any express or implied warranty of merchantability or fitness for a particular purpose concerning the effects or results of such use.WARNING — USER RESPONSIBILITY . FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise.The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.©2021 Parker Hannifin - All Rights ReservedInformation and specifications subject to change without notice and without liability therefor. Trademarks used herein are the property of their respective owners.OD DS6008CE 03/21 Rev.1Drying/Curing – Allow Chemlok 607 to air-dry forapproximately 10-30 minutes at room temperature. Porous substrates may require a longer time for the solvent to completely evaporate. Allow for longer drying times during humid conditions. The parts can be dried at elevated temperatures; excellent results have been achieved by drying at 104°C (220°F) for 15 minutes.Parts coated with Chemlok 607 may be vulcanized immediately after air-drying.Open steam, autoclave and other curing methods are also amenable to creating strong performing systems with Chemlok 607. Maintain intimate contact between the compound and the substrate.Oven or post-cures can be used to enhance the cohesive strength of the system because the parts are exposed to higher temperatures for longer periods of time than during press-cure.Exposing the system to high temperatures without proper conditioning at lower temperatures is detrimental toperformance. This conditioning is especially important for end-use temperatures that exceed 204°C (400°F). Systems created using Chemlok 607 are resistant to many destructive environments. Electroplating or anodizingmetal parts after fabrication will not harm the quality of the system.Shelf Life/Storage:Shelf life is two years from date of shipment when stored by the recipient at 21-27°C (70-80°F) in original, unopened container. Do not store or use near heat, sparks or open flame.Cautionary Information:Before using this or any Parker LORD product, refer to the Safety Data Sheet (SDS) and label for safe use and handling instructions.For industrial/commercial use only. Required to use under organized emissions. Must be applied by trained personnel only. Not to be used in household applications. Not for consumer use.Chemlok® 607技术说明书Chemlok® 607是一种透明的单涂表面处理剂,可以帮助和促进未固化的硅橡胶附着至各种基材,如金属、玻璃、塑料和织物等。

STW601水性丙烯酸改性环氧树脂产品说明书类 型水稀释型丙烯酸改性环氧分散体用 途可与氨基树脂配套使用,如Cymel303、Resimene717,制备水性单组分工业烘烤涂料,如水性环氧浸渍漆、玻璃涂料。

性能特点乳液粒径小,贮存稳定性良好。

具有良好的颜料润湿性和高度的剪切稳定性。

具有优异的附着力和高硬度。

具有良好的耐水性和耐化学品性。

具有优异的耐盐雾性。

使用方法本产品是含羟基官能团的丙烯酸改性环氧水分散体,可用水稀释到施工粘度,能与醇醚类溶剂混溶。

用水稀释时,粘度会快速下降,但适量加入低极性溶剂,如苯甲醇,可迅速增加体系粘度,并保持稳定。

本产品可直接与颜填料一起研磨。

但由于可使用的颜填料种类繁多,酸碱性各不相同,使用时应进行混溶性的测试。

必要时,在加入颜填料前,需加入适量的二甲基乙醇胺。

本产品可与氨基树脂类混合制备烘烤涂料。

该体系在120-220℃温度范围内,对应的固化时间为10Min -30s 。

根据用户实际使用要求,本产品与氨基树脂的混合比可为10:1-3:1(均以固体计)之间不等。

氨基树脂使用时应和本产品进行混溶性测试。

为确保单组分烘烤涂料体系的储存稳定性,在制备过程中要将PH 值调整到8.0-8.5。

施工和配漆设备可以用水、碱性洗涤剂或丙酮清洗。

上海市涂料研究所Shanghai Research Institute of Paint & CoatingsSTW601水性丙烯酸改性环氧树脂产品说明书储 存在5-23℃的原装密封容器中储存,本产品储存稳定性至少6个月。

不得与容易腐蚀的金属或合金接触,最好贮存在塑胶桶中。

在0℃以下结冰,而且也不排除被损坏的可能性。

所以应防冻储存。

安 全对水生物有害,可能对水生环境产生长期不良影响。

应该仔细阅读安全数据表(MSDS )。

该安全数据表包括标签、运输、储存、产品使用、产品安全和生态信息。

包 装50KG 或200KG 塑料桶。

上海市涂料研究所Shanghai Research Institute of Paint & Coatings。

安全技术说明书页: 1/10 巴斯夫安全技术说明书按照GB/T 16483编制日期 / 本次修订: 09.05.2023版本: 1.0日期/上次修订: 不适用上次版本: 无日期 / 首次编制: 09.05.2023产品: 海卓帕特 WE 3323 ECProduct: Hydropalat® WE 3323 EC(30797308/SDS_GEN_CN/ZH)印刷日期 04.11.20231. 化学品及企业标识海卓帕特 WE 3323 ECHydropalat® WE 3323 EC推荐用途和限制用途: 表面活性剂, 润湿剂, 墨水,清漆或涂料用添加剂公司:巴斯夫(中国)有限公司中国上海浦东江心沙路300号邮政编码 200137电话: +86 21 20391000传真号: +86 21 20394800E-mail地址: **********************紧急联络信息:巴斯夫紧急热线中心(中国)+86 21 5861-1199巴斯夫紧急热线中心(国际):电话: +49 180 2273-112Company:BASF (China) Co., Ltd.300 Jiang Xin Sha RoadPu Dong Shanghai 200137, CHINA Telephone: +86 21 20391000Telefax number: +86 21 20394800E-mail address: ********************** Emergency information:Emergency Call Center (China):+86 21 5861-1199International emergency number: Telephone: +49 180 2273-1122. 危险性概述纯物质和混合物的分类:对水环境的急性危害: 分类3对水环境的慢性危害: 分类3巴斯夫安全技术说明书日期 / 本次修订: 09.05.2023版本: 1.0产品: 海卓帕特 WE 3323 ECProduct: Hydropalat® WE 3323 EC(30797308/SDS_GEN_CN/ZH)印刷日期 04.11.2023标签要素和警示性说明:危险性说明:H402对水生生物有害。

编写日期 :2008.09.30修订日期 :2012.11.051.化学品及企业标识产品名称:ADK STAB FP-2200化学品英文名称:ADK STAB FP-2200分子式/结构式:无(混合物)。

推荐用途:塑料用阻燃剂。

限制用途:无。

企业名称:艾迪科精细化工(上海)有限公司企业地址:上海市金山区山阳镇板桥东路228号电话:021-5724-5988::传真:企业应急电话:021-5724-59882.危险性概述危险性类别:象形图:警示词:警告物理化学危险性:人体健康危害性:环境危害性:特殊危险有害性:人体接触后的主要症状:人体接触后的应急综述:立即脱去被污染的衣物,用大量干净水冲洗皮肤、眼睛。

送医院就医。

化学品安全技术说明书根据GB/T16483-2008编写CSDS 编号:眼睛损伤/刺激;吸入有害ADK STAB 邮政编码FP-2200CN-G05201508021-5724-5829电子信箱不可燃。

能造成皮肤/眼睛刺激,吸入有害。

眼睛、皮肤、呼吸道感觉刺痛;长期反复接触可造成肺损害。

对水生生物有害。

无。

3.成分/组成信息混合物:4.急救措施皮肤接触:眼睛接触:吸入:食入:5.消防措施灭火剂::灭火方法:特别危险性:无。

消防员保护:6.泄漏应急处理人员防护措施:泄露处理方法:环境保护措施:次生危害预防措施:雾状水、泡沫灭火剂、二氧化碳灭火剂、干粉灭火剂、干燥砂2勿摄入任何东西以确保呼吸道畅通,将头低于身体平躺下,勿催吐,立即送医院就医。

立即用大量的干净水冲洗被接触的眼睛至少15分钟,送医院就医。

立即撤离污染区到空气清新场所,深呼吸新鲜空气。

送医院就医。

OSHA 危险物质ppmppm立即脱去被污染的衣物和鞋,用肥皂和大量的水充分清洗沾污的皮肤处。

mg/m3氧化锌mg/m3若皮肤外表发生变化、持续感觉刺痛或刺激,立即送医院就医。

10PELppmmg/m 3STEL TWA 严禁直接排入公共下水道和河流湖泊。

彤程新材料集团股份有限公司地址: 中国上海市浦东新区银城中路501号上海中心大厦25层Add: 25/F,Shanghai Tower,No. 501,Middle Yincheng Rd., Pudong New Area,Shanghai 200120,China.电话Tel : +86-21-6210 9966 传真Fax : +86-21-52371633邮件E-mail : ******************RedAvenue New Materials Group Co.,Ltd.材料让地球更美好Materials make the world betterREDAVENUE彤程电子材料(镇江)有限公司是一家高性能酚醛树脂精益制造工厂,坐落于江苏省镇江市镇江新区化工园区,总占地83亩,年产能4万吨。

彤程电子镇江工厂集研发和生产为一体,业务涵盖:环氧塑封料、覆铜板等电子行业用特种树脂,还涉及航天航空材料、罐听树脂、耐火材料、岩棉等行业。

彤程电子材料(镇江)有限公司前身是瀚森树脂(镇江)有限公司,成立于2015年。

2021年彤程新材料集团股份有限公司(股票代码:603650)战略全资收购瀚森树脂,更名为彤程电子材料(镇江)有限公司。

RedAvenue Electronic Materials (Zhenjiang) Co., Ltd. is amanufacture plant which produces high-performance phenolicresin. It is located in Chemical Industry Park, Zhenjiang NewDistrict, Zhenjiang City, Jiangsu Province, with a total area of 83acre and annual production capacity of 40000 tons.Zhenjiang Factory of RedAvenue Electronics Co., Ltd. integratesR & D and production, and covers the business of (EMC)EpoxyMolding Compound, (CCL)copper Clad Laminate and otherspecial resins for electronic industry, as well as aerospacematerials, tin resin, refractory materials, rock wool and otherindustries.RedAvenue Electronic Materials (Zhenjiang) Co., Ltd., formerlyknown as Hexion Resin (Zhenjiang) Co., Ltd., was established in2015. RedAvenue New Materials Group Co., Ltd. (Stock ID:603650) strategically acquired Hexion Resin Company as awholly-owned subsidiary and renamed it to RedAvenueElectronic Materials (Zhenjiang) Co., Ltd. in 2021.上海彤程电子材料有限公司是彤程集团一体两翼布局的电子领域的全资子公司,彤程电子旗下包含北京北旭电子材料有限公司(液晶面板光刻胶)、北京科华微电子材料(半导体光刻胶)和彤程电子材料(镇江)有限公司,依托彤程集团在轮胎橡胶用高性能酚醛树脂的全球领导者地位,以及在高分子材料领域20多年的研发、生产的经验积累,加快在电子化学品领域的深耕。

修订日期: 15 六月 2021SDS 编号:7049077XCN 最初编制日期: 17 May 2005版本:1.02______________________________________________________________________________________________________________________化学品安全技术说明书产品产品名称: MOBILUBE 1 SHC 75W-90产品简介: 合成基础油及添加剂产品代码: 201520501010, 511261推荐用途: 齿轮油公司资料供应商: 埃克森美孚( 中国 )投资有限公司美罗大厦17楼天钥桥路30号上海市 200030 中国二十四小时应急电话(+86**************供应商联系电话(+86*************电子邮件*************************.cn传真(+86*************供应商: 埃克森美孚化工商务(上海)有限公司紫星路1099号闵行区上海市, 中国中国二十四小时应急电话供应商联系电话电子邮件传真(+86**************(+86**************************************.cn(+86*************紧急情况概述:物理状态: 液体颜色: 琥珀色气味: 特有的根据法规指引(参阅第十五部分),本产品不属于危险品。

修订日期: 15 六月 2021SDS 编号:7049077XCN 最初编制日期: 17 May 2005版本:1.02______________________________________________________________________________________________________________________高压射向皮肤可能会造成严重的损伤过度接触会造成眼部、皮肤或呼吸刺激。

化学品安全技术说明书公司地址:上海化学工业区奉贤分区银工路28号E栋楼客服热线:400-133-2688 1 化学品及企业标识1.1 产品标识符化学品俗名或商品名:5-溴吲哚CAS No.:10075-50-0别名:5-溴代吲哚;1.2 鉴别的其他方法无数据资料1.3 有关的确定了的物质或混合物的用途和建议不适合的用途无数据资料2 危险性概述2.1 GHS分类健康危害严重损伤/刺激眼睛:EyeIrrit.2皮肤腐蚀/刺激:SkinIrrit.2特异性靶器官毒性(单一接触):STOTSE32.2 GHS 标记要素,包括预防性的陈述危害类型GHS07:感叹号;信号词 【警告】危险申明H315 引起皮肤过敏。

H319 造成了严重的眼睛发炎。

H335 可能引起呼吸道发炎。

警告申明P261 避免吸入粉尘/烟/气体/烟雾/蒸汽/喷雾。

P261 避免吸入粉尘/烟/气体/烟雾/蒸汽/喷雾。

P271 只能在室外或通风良好的环境下使用。

P280 戴防护手套/防护服/护眼/防护面具。

P302+P352 如沾染皮肤:用大量肥皂和水清洗。

P304+P340 如果吸入:将受害人移到空气新鲜处,在呼吸舒适的地方休息。

P305+P351+P338 如进入眼睛:用水小心清洗几分钟。

如果可以做到,摘掉隐形眼镜,继续冲洗。

P312 如果你感到不适,呼叫解毒中心/医生。

P321 特殊明确的治疗见本标签上的...。

P332+P313 如发生皮肤刺激:求医/就诊。

P337+P313 如果发生眼刺激:求医/就诊。

?P362 脱掉受污染的衣服,清洗后方可重新使用。

P362 脱掉受污染的衣服,清洗后方可重新使用。

P405 存放处须加锁。

P501 根据…来处理容量/容器。

RSHazard symbol(s) XiR-phrase(s) R38S-phrase(s) S26;S362.3 其它危害物-无3 成分/组成信息3.1 物质分子式 - C8H6BrN分子量 - 196.054 急救措施4.1 必要的急救措施描述一般的建议请教医生。

化学药品使用综合手册(doc 69页)化学药品使用安全手册无机部分01 硫化氢10 过氧化氢19 液溴28 硫酸亚铁02 氨11 碘20 氯化铜29 硫氰酸铵03 二氧化硫12 氯化钙21 三氯化铁33 氯化铵04 二氧化氮13 氢氧化钠22 氯酸钾31 硝酸钾05 硫酸14 重铬酸钾23 磷酸32 硝酸铜06 氯15 氯化汞24 铝粉33 硝酸银07 硝酸16 三氯化铝25 过氧化钠34 氧化钙08 盐酸17 白磷26 铬酸钾09 高锰酸钾18 硫27 硫化钠有机部分01 甲醛05 苦味酸09 四氯甲烷13 甲酸02 冰醋酸06 乙醚10 苯酚(酚)14 甲苯03 丙酮07 苯11 乙醇15 煤油04 二甲苯08 三氯甲烷12 对苯二酚16 汽油17 放射性同位素无机部分【返回第一页】硫化氢(一)理化性状和用途无色有臭蛋气味的可燃气体。

易溶于水。

自然点:246℃,爆炸极限;4.3-46%。

硫化氢很少用于生产,一般作为化学反应或蛋白质自然分解产物而存在于多种生产过程中以及自然界中。

凡含硫的有机物发酵腐败均产生硫化氢。

含硫石油开采和提炼、人造丝、鞣革等生产过程都有硫化氢产出。

(二)毒性硫化氢是强烈的刺激神经的毒物,可引起窒息。

对粘膜也有明显的刺激作用。

最高容许浓度10mg/m3(三)短期过量暴露的影响吸入:鼻烟部灼热感,咳、胸闷、头晕、头痛、乏力、恶心、呕吐、意识模糊或出现昏迷。

暴露于1000mg/m3以上时,可发生“电击样”中毒,瞬间内呼吸停止但心脏可仍搏动数分钟。

眼睛接触:出现畏光、流泪、眼刺疼(浓度为16-32mg/m3以上时)。

暴露于200-300mg/m3时,还可有眼睑痉挛、视力模糊等症状。

(四)长期暴露的影响长期接触低浓度硫化氢,可致嗅觉减退。

暴露于100mg/m3以上浓度时可能引起肺部损害。

(五)火灾和爆炸本品极易燃,严禁明火、火花和吸烟。

其蒸汽与空气混合物具有爆炸性。

燃烧时会产生二氧化硫有毒气体。

*This SDS for user in China - Not correspond to the regulation of other regions.梯希爱(上海)化成工业发展有限公司修订日期修订日期:: 08/07/2021化学品安全技术说明书修改号码修改号码:: 2修订日期修订日期:: 08/07/2021Page 1 of 42. 危险性概述G H S 分类物理性危害未分类 健康危害急性毒性(经口)第4级 皮肤腐蚀/刺激1C 类 严重损伤/刺激眼睛第1级 环境危害未分类 G H S 标签元素图标或危害标志信号词危险 危险描述吞咽有害造成严重的皮肤灼伤和眼损伤 防范说明[预防]请勿吸入粉尘或雾。

使用本产品时不要进食、饮水或吸烟。

作业后彻底洗手和洗脸。

戴防护手套、防护服、面部防护。

[急救措施]如果吞咽:漱口。

请勿催吐。

立刻呼叫中毒控制中心或者医生。

如果皮肤(或头发)沾染:立刻脱掉所有受沾染的衣物。

用水冲洗皮肤或者淋浴。

立刻呼叫中毒控制中心或者医生。

受沾染的衣物清洗后方能再次使用。

如果吸入:将受害者移到新鲜空气处,保持呼吸通畅。

立刻呼叫中毒控制中心或者医生。

如果进入眼睛:用水小心冲洗几分钟。

如果戴有隐形眼镜且可方便取出,取出隐形眼镜。

继续冲洗。

立刻呼叫中毒控制中心或者医生。

[储存]存放处须加锁。

[废弃处置]内容物和容器的废弃处置,请遵守当地、地区和国家的法律法规。

1. 化学品及企业标识产品名称产品名称::二苯基(甲基)锍四氟硼酸盐T C I 产品编码产品编码::D2685公司:梯希爱(上海)化成工业发展有限公司地址:上海化学工业区普工路96号部门:营业部电话号码:************传真号码:************e-mail:*************************应急电话应急电话::*************修改号码修改号码::2梯希爱(上海)化成工业发展有限公司修改号码修改号码::2修订日期修订日期::08/07/2021Page 2 of 4 3.成分/组成信息单一物质/混合物单一物质化学名(中文名):二苯基(甲基)锍四氟硼酸盐百分比百分比::>97.0%(T)CAS RN:10504-60-6俗名俗名::Methyldiphenylsulfonium Tetrafluoroborate分子式分子式::C13H13S・BF44.急救措施吸入吸入::将受害者移到新鲜空气处,保持呼吸通畅,休息。

SAFETY DATA SHEET1. IdentificationProduct identifier IOTHALAMIC ACID CAS #2276-90-6Other means of identificationSDS numberLACADSynonyms5-Acetamido-2,4,6-triiodo-N-methylisophthalamic acid * Benzoic acid,3-(acetylamino)-2,4,6-triiodo-5-[(methylamino)carbony l]-Recommended use Diagnostic imaging agent.Recommended restrictionsNone known.Manufacturer/Importer/Supplier/Distributor information Manufacturer MallinckrodtAddress 675 McDonnell pany name Telephone Not available.Emergency phone numberCustomer Service 888-744-141424 Hour Emergency 314-654-1600Chemtrec 800-424-9300E-mailNot available.Hazelwood, MO 63042Item code10832. Hazard(s) identificationNot classified.Physical hazards Not classified.Health hazards Not classified.Environmental hazards Not classified.OSHA defined hazards *Hazards not stated here are "Not classified", "Not applicable" or "Classification not possible".LabelingContains IOTHALAMIC ACID Label elementsNone.Hazard symbolSignal word None.Hazard statement The substance does not meet the criteria for classification.Precautionary statementPreventionObserve good industrial hygiene practices.Response Wash hands after handling.Storage Store away from incompatible materials.DisposalDispose of waste and residues in accordance with local authority requirements.Hazard(s) not otherwise classified (HNOC)None known.Supplemental informationNone.3. Composition/information on ingredientsSubstancesCAS number% Chemical name Common name and synonyms5-Acetamido-2,4,6-triiodo-N-methylisophthal amic acidBenzoic acid,3-(acetylamino)-2,4,6-triiodo-5-[(methylamin o)carbonyl]-2276-90-6IOTHALAMIC ACID100 Composition comments All concentrations are in percent by weight unless ingredient is a gas. Gas concentrations are inpercent by volume.4. First-aid measuresInhalation If dust from the material is inhaled, remove the affected person immediately to fresh air. Oxygen orartificial respiration if needed. Do not use mouth-to-mouth method if victim inhaled the substance.Induce artificial respiration with the aid of a pocket mask equipped with a one-way valve or otherproper respiratory medical device. Call a physician if symptoms develop or persist.Skin contact Rinse skin with water/shower. Get medical attention if irritation develops and persists.Eye contact Immediately flush eyes with plenty of water for at least 15 minutes. Get medical attention ifirritation develops and persists.Ingestion IF SWALLOWED: Call a POISON CENTER or doctor/physician if you feel unwell. If ingestion of alarge amount does occur, call a poison control center immediately. Never give anything by mouthto a victim who is unconscious or is having convulsions. Do not induce vomiting without advicefrom poison control center. Do not use mouth-to-mouth method if victim ingested the substance.Induce artificial respiration with the aid of a pocket mask equipped with a one-way valve or otherproper respiratory medical device. Rinse mouth. If vomiting occurs, keep head low so that stomachcontent doesn't get into the lungs. Get medical attention if symptoms occur.Most importantsymptoms/effects, acute and delayed Dust or powder may irritate eye tissue. Inhalation of dusts may cause respiratory irritation. Coughing. Ingestion may cause gastrointestinal irritation, nausea, vomiting and diarrhea.Indication of immediate medicalattention and special treatmentneededOxygen, if needed. Keep victim warm. Keep victim under observation.General information Call a POISON CENTER or doctor/physician if you feel unwell.5. Fire-fighting measuresFlammable properties The product is not flammable.Suitable extinguishing media Use any media suitable for the surrounding fires.Unsuitable extinguishing media None known.Specific hazards arising fromthe chemicalDuring fire, gases hazardous to health may be formed.Special protective equipment and precautions for firefighters Wear full protective clothing, including helmet, self-contained positive pressure or pressure demand breathing apparatus, protective clothing and face mask.Fire-fighting equipment/instructions In the event of fire, cool tanks with water spray. Move containers from fire area if you can do so without risk.Specific methods Cool containers exposed to flames with water until well after the fire is out. General fire hazards No unusual fire or explosion hazards noted.6. Accidental release measuresPersonal precautions, protective equipment and emergency procedures Ensure adequate ventilation. Keep unnecessary personnel away. Avoid inhalation of dust from the spilled material. Wear appropriate protective equipment and clothing during clean-up.Methods and materials for containment and cleaning up If sweeping of a contaminated area is necessary use a dust suppressant agent which does not react with the product. Sweep up or vacuum up spillage and collect in suitable container for disposal. Avoid dust formation. Collect dust using a vacuum cleaner equipped with HEPA filter. Following product recovery, flush area with water. For waste disposal, see section 13 of the SDS.Environmental precautions Prevent further leakage or spillage if safe to do so.7. Handling and storagePrecautions for safe handling Avoid breathing dust. Avoid contact with eyes. Keep formation of airborne dusts to a minimum.Provide appropriate exhaust ventilation at places where dust is formed. In case of insufficientventilation, wear suitable respiratory equipment. Handle and open container with care. Washthoroughly after handling.Conditions for safe storage, including any incompatibilities Store in a well-ventilated place. Keep container tightly closed. Guard against dust accumulation of this material. Use care in handling/storage.8. Exposure controls/personal protectionOccupational exposure limits No exposure limits noted for ingredient(s).Biological limit values No biological exposure limits noted for the ingredient(s).Exposure guidelines No exposure standards allocated.Appropriate engineering controls Good general ventilation (typically 10 air changes per hour) should be used. Ventilation ratesshould be matched to conditions. If applicable, use process enclosures, local exhaust ventilation,or other engineering controls to maintain airborne levels below recommended exposure limits. Ifexposure limits have not been established, maintain airborne levels to an acceptable level.Ventilation should be sufficient to effectively remove and prevent buildup of any dusts or fumesthat may be generated during handling or thermal processing. Ensure adequate ventilation,especially in confined areas.Individual protection measures, such as personal protective equipmentEye/face protection Safety glasses with side-shields. Provide eyewash station and safety shower.Skin protectionHand protection Wear protective gloves.Other Wear appropriate chemical resistant clothing.Respiratory protection Particulate air-purifying respirator approved for dust or oil mist is recommended.Thermal hazards Wear appropriate thermal protective clothing, when necessary.General hygiene considerations Avoid breathing dust. Avoid contact with eyes. Handle in accordance with good industrial hygieneand safety practice.9. Physical and chemical propertiesAppearance Powder.Physical state Solid.Form Powder.Color WhiteOdor Odorless.Odor threshold Not available.pH Not available.Melting point/freezing point545 °F (285 °C)Initial boiling point and boilingrangeNot available.Flash point Not available.Evaporation rate Not available.Flammability (solid, gas)Not available.Upper/lower flammability or explosive limitsFlammability limit - lower(%)Not available.Flammability limit - upper(%)Not available.Explosive limit - lower (%)Not available.Explosive limit - upper (%)Not available.Vapor pressure Not available.Vapor density Not available.Relative density Not available.Solubility(ies)Solubility (water)InsolublePartition coefficient(n-octanol/water)Not available.Auto-ignition temperature Not available.Decomposition temperature Not available.Viscosity Not available.Other informationDensity 1.00 estimatedMolecular formula C11H9I3N2O4Molecular weight613.9210. Stability and reactivityReactivity The product is stable and non-reactive under normal conditions of use, storage and transport. Chemical stability Material is stable under normal conditions.Possibility of hazardousreactionsHazardous polymerization does not occur.Conditions to avoid Contact with incompatible materials. Heat, flames and sparks. Avoid spread of dust. Incompatible materials Strong oxidizing agents.Hazardous decompositionproductsNitrogen oxides (NOx). Carbon oxides. Halogens.11. Toxicological informationInformation on likely routes of exposureIngestion Ingestion of large amounts may produce gastrointestinal disturbances including irritation, nausea,and diarrhea.Inhalation Inhalation of dusts may cause respiratory irritation. Coughing.Skin contact May cause skin irritation.Eye contact Dust or powder may irritate eye tissue.Symptoms related to the physical, chemical and toxicological characteristics Dust or powder may irritate eye tissue. Inhalation of dusts may cause respiratory irritation. Coughing. Ingestion may cause gastrointestinal irritation, nausea, vomiting and diarrhea.Information on toxicological effectsAcute toxicity Dusts may irritate the respiratory tract, skin and eyes.Chronic effects Prolonged inhalation may be harmful.Skin corrosion/irritation May cause skin irritation.Serious eye damage/eyeirritationDust or powder may irritate eye tissue.Respiratory or skin sensitizationRespiratory sensitization Due to lack of data the classification is not possible.Skin sensitization Due to lack of data the classification is not possible.Germ cell mutagenicity No data available to indicate product or any components present at greater than 0.1% aremutagenic or genotoxic.Carcinogenicity This product is not considered to be a carcinogen by IARC, ACGIH, NTP, or OSHA. Reproductive toxicity Due to lack of data the classification is not possible.Specific target organ toxicity -single exposureDue to lack of data the classification is not possible.Specific target organ toxicity -Due to lack of data the classification is not possible.repeated exposureAspiration hazard Due to lack of data the classification is not possible.Further information Health injuries are not known or expected under normal use. Handle in accordance with goodindustrial hygiene and safety practice.12. Ecological informationEcotoxicity This product has no known eco-toxicological effects.Persistence and degradability No data is available on the degradability of this product.Bioaccumulative potential No data available.Mobility in soil No data available.Other adverse effects An environmental hazard cannot be excluded in the event of unprofessional handling or disposal.13. Disposal considerationsDisposal instructions Collect and reclaim or dispose in sealed containers at licensed waste disposal site. Dispose ofcontents/container in accordance with local/regional/national/international regulations. Hazardous waste code Waste codes should be assigned by the user based on the application for which the product wasused. The waste code should be assigned in discussion between the user, the producer and thewaste disposal company.Waste from residues / unusedDispose of in accordance with local regulations.productsContaminated packaging Empty containers should be taken to an approved waste handling site for recycling or disposal.14. Transport informationDOTNot regulated as dangerous goods.IATANot regulated as dangerous goods.IMDGNot regulated as dangerous goods.Transport in bulk according toThis substance/mixture is not intended to be transported in bulk.Annex II of MARPOL 73/78 andthe IBC Code15. Regulatory informationUS federal regulations This product is not known to be a "Hazardous Chemical" as defined by the OSHA HazardCommunication Standard, 29 CFR 1910.1200.TSCA exempt status.TSCA Section 12(b) Export Notification (40 CFR 707, Subpt. D)Not regulated.CERCLA Hazardous Substance List (40 CFR 302.4)Not listed.SARA 304 Emergency release notificationNot regulated.OSHA Specifically Regulated Substances (29 CFR 1910.1001-1050)Not listed.CERCLA (Superfund) reportable quantityNoneSuperfund Amendments and Reauthorization Act of 1986 (SARA)Hazard categories Immediate Hazard - NoDelayed Hazard - NoFire Hazard - NoPressure Hazard - NoReactivity Hazard - NoSARA 302 Extremely hazardous substanceNot listed.SARA 311/312 HazardousNochemicalOther federal regulationsClean Air Act (CAA) Section 112 Hazardous Air Pollutants (HAPs) ListNot regulated.Clean Air Act (CAA) Section 112(r) Accidental Release Prevention (40 CFR 68.130)Not regulated.Safe Drinking Water ActNot regulated.(SDWA)US state regulations California Safe Drinking Water and Toxic Enforcement Act of 1986 (Proposition 65): This materialis not known to contain any chemicals currently listed as carcinogens or reproductive toxins.US. Massachusetts RTK - Substance ListNot regulated.US. New Jersey Worker and Community Right-to-Know ActNot listed.US. Pennsylvania Worker and Community Right-to-Know LawNot listed.US. Rhode Island RTKNot regulated.US. California Proposition 65Not Listed.International InventoriesCountry(s) or region Inventory name On inventory (yes/no)* Australia Australian Inventory of Chemical Substances (AICS)Yes Canada Domestic Substances List (DSL)Yes Canada Non-Domestic Substances List (NDSL)No China Inventory of Existing Chemical Substances in China (IECSC)No Europe European Inventory of Existing Commercial ChemicalYesSubstances (EINECS)Europe European List of Notified Chemical Substances (ELINCS)No Japan Inventory of Existing and New Chemical Substances (ENCS)Yes Korea Existing Chemicals List (ECL)No New Zealand New Zealand InventoryNo Philippines Philippine Inventory of Chemicals and Chemical SubstancesNo(PICCS)No United States & Puerto Rico Toxic Substances Control Act (TSCA) Inventory*A "Yes" indicates that all components of this product comply with the inventory requirements administered by the governing country(s)A "No" indicates that one or more components of the product are not listed or exempt from listing on the inventory administered by the governingcountry(s).16. Other information, including date of preparation or last revisionIssue date04-08-2015Version #01Further information New US GHS SDS.Disclaimer Mallinckrodt provides the information contained herein in good faith but makes no representationas to its comprehensiveness or accuracy. This document is intended only as a guide to theappropriate precautionary handling of the material by a properly trained person using this product.Individuals receiving the information must exercise their independent judgment in determining itsappropriateness for a particular purpose. MALLINCKRODT MAKES NO REPRESENTATIONS ORWARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANYWARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE WITHRESPECT TO THE INFORMATION SET FORTH HEREIN OR THE PRODUCT TO WHICH THEINFORMATION REFERS. ACCORDINGLY, MALLINCKRODT WILL NOT BE RESPONSIBLE FORDAMAGES RESULTING FROM USE OF OR RELIANCE UPON THIS INFORMATION.Revision Information Product and Company Identification: Product CodesHazards Identification: US HazardousComposition / Information on Ingredients: Disclosure OverridesPhysical & Chemical Properties: Multiple PropertiesRegulatory Information: United StatesHazReg Data: North America。

目录一、企业背景 (5)1.1 工商信息 (5)1.2 分支机构 (5)1.3 变更记录 (5)1.4 主要人员 (8)1.5 联系方式 (8)二、股东信息 (9)三、对外投资信息 (9)四、企业年报 (9)五、重点关注 (10)5.1 被执行人 (10)5.2 失信信息 (11)5.3 裁判文书 (11)5.4 法院公告 (11)5.5 行政处罚 (11)5.6 严重违法 (11)5.7 股权出质 (11)5.8 动产抵押 (11)5.9 开庭公告 (12)5.11 股权冻结 (12)5.12 清算信息 (12)5.13 公示催告 (12)六、知识产权 (12)6.1 商标信息 (12)6.2 专利信息 (12)6.3 软件著作权 (13)6.4 作品著作权 (13)6.5 网站备案 (13)七、企业发展 (13)7.1 融资信息 (13)7.2 核心成员 (13)7.3 竞品信息 (13)7.4 企业品牌项目 (14)八、经营状况 (14)8.1 招投标 (14)8.2 税务评级 (14)8.3 资质证书 (14)8.4 抽查检查 (14)8.5 进出口信用 (14)8.6 行政许可 (15)一、企业背景1.1 工商信息企业名称:上海海灼化工有限公司工商注册号:310117003300416统一信用代码:91310117351124478X法定代表人:周钢组织机构代码:35112447-8企业类型:有限责任公司(自然人投资或控股)所属行业:批发业经营状态:开业注册资本:200万(元)注册时间:2015-08-18注册地址:上海市松江区泖港镇中民路599弄1号3幢3层D302-17营业期限:2015-08-18 至 2035-08-17经营范围:危险化学品(具体项目详见许可证)经营(不带储存设施),化工原料及产品(除危险化学品、监控化学品、烟花爆竹、民用爆炸物品、易制毒化学品)、橡塑制品、金属制品、电线电缆、水性涂料、皮革制品、鞋材制品、热塑性弹性体、高分子材料、实验室设备及耗材、机械设备、一类医疗器械、日用百货、建筑材料、化妆品、聚氨酯制品批发零售;从事货物及技术的进出口业务,从事化工、环保、生物科技领域内的技术开发、技术咨询、技术服务、技术转让,润滑油研发,危险化学品(具体项目详见许可证)批发(不带储存设施)。

SAFETY DATA SHEETSECTION 1 - CHEMICAL IDENTIFICATIONPRODUCT NAME: L-ASPARTIC ACIDCATALOG #: DSA50060SUPPLIER’S NAME: DOT SCIENTIFIC INC.SUPPLIERS ADDRESS: 4165 Lippincott, Burton, MI 48519EMERGENCY CONTACT: 1-800-424-9300(Reference Customer Number: 18739)OTHER INFORMATION: 1-800-878-1785OTHER INFORMATION: 800-878-1785SECTION 2 - HAZARDS IDENTIFICATION2.1 Classification of the substance or mixtureGHS Classification in accordance with 29 CFR 1910 (OSHA HCS)Not hazardousSignal word: NoneHazard statement(s): Not hazardousSECTION 3- COMPOSITION/INFORMATION ON INGREDIENTSCAS Number: 56-84-8EINECS Number: 200-291-6Molecular Weight: 133.1 g/molFormula: C4H7NO4SECTION 4 - FIRST-AID MEASURES4.1 Description of first aid measuresGeneral advice: Consult a doctor and show this safety data sheet.i.If inhaled: Remove to fresh air and monitor breathing. If breathing becomes difficult, give oxygen. If breathingstops, give artificial respiration. Consult a doctor.ii.In case of skin contact: Immediately wash skin with copious amounts of soap and water for at least 15 minutes.Remove contaminated clothing and shoes and wash before reuse. Consult a doctor.iii.In case of eye contact: Flush with copious amounts of water for at least 15 minutes. Consult a doctor.iv.If swallowed: Rinse mouth with water. Do not induce vomiting unless directed to do so by medical personnel.Never give anything by mouth to an unconscious person. Consult a doctor.4.2 Most important symptoms and effects, both acute and delayed: To the best of our knowledge, the chemical, physical and toxicological properties have not been thoroughly investigated.4.3 Indication of immediate medical attention and special treatment needed: Show this safety data sheet to the doctor in attendance. Immediate medical attention is required.SECTION 5 - FIRE FIGHTING MEASURES5.1 Extinguishing mediaSuitable extinguishing media: Use water spray, alcohol-resistant foam, dry chemical or carbon dioxide5.2 Special hazards arising from the substance or mixture: Carbon oxides.5.3 Precautions for fire-fighters: Wear suitable protective clothing to prevent contact with skin and eyes and self-contained breathing apparatus.5.4 Further information: No data availableSECTION 6 - ACCIDENTAL RELEASE MEASURES6.1 Personal precautions, protective equipment and emergency procedures: Do not take action without suitableprotective clothing - see section 8 of SDS. Evacuate personnel to safe areas. Ensure adequate ventilation. Avoid breathing vapors, mist, dust or gas.6.2 Environmental precautions: Do not let product enter drains.6.3 Methods and materials for containment and cleaning up: Cover spillage with suitable absorbent material. Using non-spark tools, sweep up material and place in an appropriate container. Decontaminate spill site with 10% caustic solution and ventilate area until after disposal is complete. Hold all material for appropriate disposal as described under section 13 of SDS.6.4 Reference to other sections: For required PPE see section 8. For disposal see section 13.SECTION 7 - HANDLING AND STORAGE7.1 Precautions for safe handling: Use in a chemical fume hood, with air supplied by an independent system. Avoid inhalation, contact with eyes, skin and clothing. Avoid the formation of dust and aerosols. Use in a well-ventilated area. Keep away from sources of ignition. Avoid prolonged or repeated exposure.7.2Conditions for safe storage, including any incompatibilities: Store in cool, well-ventilated area. Keep away from direct sunlight. Keep container tightly sealed until ready for use. Keep in a dry place.7.3 Specific end use(s): Use in a laboratory fume hood where possible. Refer to employer's COSHH risk assessment.SECTION 8 - EXPOSURE CONTROLS/PERSONAL PROTECTION8.1 Control parametersComponents with workplace control parameters: Contains no substances with occupational exposure limit values.8.2 Exposure Controlsi.Appropriate engineering controls: Use in a fume hood where applicable. Ensure all engineering measuresdescribed under section 7 of SDS are in place. Ensure laboratory is equipped with a safety shower and eye wash station.8.3 Personal protective equipmenti.Eye/face protection: Face shield and safety glasses Use equipment for eye protection tested and approved underappropriate government standards such as NIOSH (US) or EN 166(EU).ii.Skin protection: Wear appropriate protective eyeglasses or chemical safety goggles as described by OSHA's eye and face protection regulations in 29 CFR 1910.133 or European Standard EN166iii.Body Protection: Wear appropriate protective clothing. Complete suit protecting against chemicals, The type of protective equipment must be selected according to the concentration and amount of the dangerous substance at the specific workplace.iv.Respiratory Protection: Follow the OSHA respirator regulations found in 29 CFR 1910.134 or European Standard EN 149. Use a NIOSH/MSHA or European Standard EN149 approved respirator if exposure limits are exceeded or if irritation or other symptoms are experienced.v.Control of environmental exposure: Do not let product enter drainsSECTION 9 - PHYSICAL AND CHEMICAL PROPERTIESInformation on basic physical and chemical propertiesAppearance White Solid Vapor Pressure No Data Available Odor Odorless Vapor Density No Data Available Odor Threshold No Data Available Relative Density No Data AvailablepH No Data Available Water Solubility No Data Available Melting / Freezing Point> 300 °C Partition Coefficient No Data Available Initial Boiling Point Range No Data Available Auto-Ignition Temperature No Data Available Flash Point No Data Available Decomposition Temperature No Data Available Evaporation Rate No Data Available Viscosity No Data Available Flammability (Solid, Gas)No Data Available Explosive Properties No Data Available Upper / Lower FlammabilityNo Data Available Oxidizing Properties No Data AvailableOr Explosive LimitsSECTION 10 - STABILITY AND REACTIVITYStability: Stable under recommended storage conditions.Hazardous Decomposition Products: Nitrogen oxides (NOx), Carbon monoxide (CO), Carbon dioxide (CO2). Incompatibilities: strong oxidizing agent.SECTION 11 - TOXICOLOGICAL INFORMATIONAcute ToxicityLD50 Oral LD50 Dermal LD50 Inhalation LD50 Intraperitonea 9000 mg/kg ( Rat )Not Listed Not Listed Not Listed SECTION 12 - ECOLOGICAL INFORMATIONEcotoxicity: No data availablePersistence and degradability/ Bioaccumlative potential: No data availableMobility in soil: No data availableResults of PBT and vPvB assessment: No data availableOther adverse effects: No data availableChronic Toxicity: There are no known carcinogenic chemicals in this productSECTION 13 - DISPOSAL CONSIDERATIONSWhatever cannot be saved for recovery or recycling should be managed in an appropriate and approved waste disposal facility. Processing, use or contamination of this product may change the waste management options. State and local disposal regulations may differ from federal disposal regulations. Dispose of container and unused contents in accordance with federal, state and local requirements.SECTION 14 - TRANSPORT INFORMATIONDOT TDG IATA IMDG/IMONot regulated Not regulated Not regulated Not regulatedSECTION 15 - REGULATORY INFORMATIONINTERNATIONAL INVENTORIESTSCA DSL NDSL ELINCS NLP PICCS ENCS AICS CHINA KECL Listed Listed---Listed Listed Listed Listed ListedUSA FEDERAL REGULATIONTSCA 12(b): Not ApplicableSARA 313: Not ApplicableClean Water Act/ Clean Air Act: Not ApplicableOSHA: N ot ApplicableCalifornia Proposition 65: This product does not contain any Proposition 65 chemicals.CERCLA: Not ApplicableSTATE RIGHT TO KNOWMassachusetts New Jersey Pennsylvania Illinois Rhode Island -Listed Listed--HMIS RatingHealth Hazard Flammability Physical Hazard000NFPA RatingHealth Hazard Flammability Reactivity Hazard000US DEPARTMENT OF TRANSPORTATIONREPORTABLE QUANTITY (RQ)DOT MARINE POLLUTANT DOT SEVER MARINE POLLUTANT No No NoU.S. DEPARTMENT OF HOMELAND SECURITY: This product does not contain any DHS chemicals.Canada: This product has been classified in accordance with the hazard criteria of the Controlled Products Regulations (CPR) and the SDS contains all the information required by the CPR.This SDS complies with the requirements of Regulation (EC)SECTION 16 - OTHER INFORMATIONThe above information is believed to be correct but does not purport to be all inclusive and shall be used only as a guide. DOT SCIENTIFIC INC. shall not be held liable for any damage resulting from handling or from contact with the above product. See reverse side of invoice or packing slip for additional terms and conditions of sale. This product is sold for laboratory research and development purposes use only. REV October 2015。