车载逆变电源系统的研究外文翻译

- 格式:doc

- 大小:135.50 KB

- 文档页数:7

外文原文Principle, Modeling and Control of DC-DCConvertors for EVZHAN G Cheng-ning , SUN Feng-chun , ZHAN G Wang (School of Vehic le and Transportation Engineering , Beijing Institute of Technology , Beijing 100081)Abstract :DC-DC convertors can convert the EV’s high-voltage DC power supply into the lowvoltage DC power supply. In order to design an excellent convertor one must be guided by theory of automatic control. The principle and the method of design, modeling and control for DC-DC convertors of EV are introduced. The method of the system-response to a unit step-function input and the frequency-response method are applied to researching the convertor’s mat- hematics model and control characteristic. Experiments show that the designed DC-DC convertor’s output voltage precision is high , the antijamming ability is strong and the adjustable performance is fast and smooth.Key words: EV ; DC-DC convertors ; automatic control ; mathematics model ; Bode drawingCLC number : U 469-72 Document code : A Generally there are two power supplies in EV. One is the DC high-voltage power supply that is used by high power devices such as traction motors and air conditioners etc. The other is the DClow-voltage power supply that is usually used in some control circuitand low-voltage electrical devices such as the inst- rument and lighting. It s rating voltage is 24 V or 12 V. The low-voltage power supply can be gained from the high-voltage power supply by aDC-DC conver-tor.In this paper, the main performance of the designed convertor is that the input voltage range is from DC 250 V to DC 450 V , the output voltage is DC 24 V , the maximum output current is DC 20 A , and the output precision is 1 %.1 Principle of the Convertor1.1 The Block Diagram of the DC-DC ConvertorThe block diagram of the DC-DC convertor is showed in Fig. 1. The battery series provide the DC high-voltage input U s. Thelow-voltage output of the con-vertor is U o. The setting value U i of the convertor is equal to or is in proportion to the demanded output voltage U o. The convertor is a closed-loop negative feedback-system with voltage feedback.1.2 Power Switch CircuitThe power switch circuit with semi-bridge mode is showed in Fig. 2. L1 and C1 constitute an input filter to avoid high-frequencyimpulses flowing bac- kwards. Capacitors C2and C3 constitute the partial-voltage circuit while resist-ances R1 and R2do so. IGBT1 and IGBT2 are semiconductor switch devices. C6 is a separation DC capacitor. T1 is a transformer that reduces the voltage. L2 and C7 constitute an output filter. RL is the load resistance. When the PWM signalsin the reverse semi-waves are inputted onto IGBT1 and IGBT2’s control poles , the corresponding DC voltage can be yielded from the convertor.Fig. 2 Principle circuit of power switch with semi-bridge mode 1.3 Control CircuitThe chip SG3525 is used in the PWM control circuit showed in Fig. 3. V cc is the power voltage applied to the chip, it is 12.0 V. A base-voltage of 5.1 V is yielded on pin16 of the chip that is partially used as parameter voltage input U i. The chip includes asawtooth-wave generator. R t and C t are the external resis-tance and capacity that determine the sawtooth-wave’s frequency.Pin2 of the chip is a positive-phase input port. Voltage input U i is putted to the port, here U i =2. 5 V. Pin1 of the chip is the negative-phase input port where the feedback voltage is inputted.Pin9 of the chip is the output end of the inside amplifier of the chip. The proper resistance and capacitor are connected between the pin1 andpin9 to realize compensation of the DC-DC convertor.C8 is the integral capacitor. The integral compensator is adopted as the system-compensation of the system. The PWM impulses are yielded from pin11 and pin14 of the chip. When the PWM control circuit operates normally, U i on the pin2 and U b on the pin1 should be balanced. When U b is not equal to U i , the PWM width can be automatically adjusted by the PWM control circuit to make U b equal to U i. By this way we can control the output voltage of the convertor.Fig. 3 The connection circuit for the PWM control chip SG3525 1.4 Drive CircuitThe drive circuit of IGBT usually adopts a pulse-transformer or an opto-coupler to isolate the power circuit from the control circuit. An individual power supply is needed if an opto-coupler is used, which increases the complexity of the system. So the isolation-circuit adopt s a pulse-transformer showed in Fig. 4. Transistors BG1 and BG2 in Fig. 4 compose a complementation power amplification circuit. T2 is the pulse-transformer that isolates the power circuit from the control circuit. R5 and C8 compose the acceleration circuit. The diode D6eliminates negative impulses. The diode D7 and transistor BG3 compose the rapid discharge circuit of the distributing capacitor at the control pole of IGBT.Fig. 4 Principle circuit for IGBT drive2Modeling and Control2.1 ModelingThe DC-DC convertor is a voltage negative feedback-system. Aiming to obtain the better dynamic and static characteristic we must model and analyse it in theory. According to Ref. [ 1 ] ,DC-DC convertors are the approximate second-order systems. In order to obtain accurate parameters , the method of the system-response to a unit step-function input is adopted in this paper.2.1.1 Measuring the Open-Loop System’s Response to a Unit Step-Function InputThe block diagram for measuring is shown in Fig. 5. The concrete method is described as follows : ①The voltage feedback signal is cut off ; ②The setting value of the chip SG3525 adopts themiddling value U i0 to make the width of an impulse be about 0.5 T ;③U i0 is superimposed with d U i that is composed by positive and negative rectangle wave impulses. The amplitude of d U i is taken to be equal to 0.2U i0. It should make d U o be easy to be observed to select the rectangle wave frequency , adopting f 1 = 400 Hz ; ④The output waveform of U o ( = U o 0 + d U o ) is shown in Fig. 6. As shown in Fig. 6 when f 1 = 400 Hz , period T = 2.5 ms (5 grills) , the time for the maximum voltage value is about 0.2 grills. d U o’s stable voltage amplitude is - grills. Peak overshoot is 1 grill. Every grill in the vertical direction represents 5 V. By this way the data of system-response to a unit step-function input can be obtained as follows :peak time t p = 0.1 ms ; peak overshoot σp = 1/ 2 = 50 %;output and input’s incremental ratio K0 = d U o/ d U i = 10/ 1 = 10.Fig.5 The measuring block diagram of the open-loop systemFig. 6 The system-response to a unit step-function inpu t2.1.2Determining the Open-Loop Transfer FunctionAccording to Ref s. [2,3 ] , we have the damping ratio ξ, undamped natural frequency ωn and transfer function of controlled object G p ( s) as follows :In order to ensure that when the output voltage U o =24 V the feedback voltage to pin1 of the SG3525 is 2.5 V to balance the input voltage U i = 2.5 V, we take the feedback and measuring factor asK b = U b/ U o = -15/ -4 = 01104.( 4 )2.2Design of the PID Regulator2.2.1The Principle Scheme and Transfer Function of the PID RegulatorTo resist the disturbance of the power supply voltage and load current to the DC-DC convertor so as to improve control precision , an integral compensator is adopted. The principle scheme of the integral compensator is shown in Fig. 7.Fig. 7 The principle scheme of the integral compensatorIt s transfer function isG c ( s) = K i/ s = 1/ ( RCs).( 5 )In Fig. 7 and Eq. (5), R = 10 kΩ, C = 0.1μF , K i = 1/ ( RC) = 1/ (10 ×103 ×011 ×10 - 6)= 1 000.2.2.2The Bode Drawing of the System Open-Loop Transfer FunctionThe system open-loop transfer function is the product of the controlled object’s , feedback and measuring circuit’s and integral compensator’s transfer functions. We haveG( s) = G c ( s) G p ( s) G b ( s) =The system Bode drawing is shown in Fig. 8 from Eq. (6). The curves ①and ④are respectively the logarithmic gain-frequency characteristic ,logarithmic phase-frequency characteristic of controlled object G p ( s). The curves ②and ⑤are respectively the logarithmic gain-frequency characteristic , logarithmicphase-frequency characteristic of the feedback and measuring circuit joint the integral compensator. The curves ③and ⑥are respectively the logarithmic gain-frequency characteristic and logarithmic phase-frequency characteristic of the compensatedopen-loop system. By Fig. 8 we know that the system is I-model system. When the input doesn’t change , there isn’t steady-state error. It s original phase-margin frequency ωc = 1 016 rad/ s , phase margin γ= 89.21°, so the adjustable performance of the system is fast and smooth.Fig. 8 The Bode drawing of the system open2loop transfer function 3 The Result and Conclusion of ExperimentWhen the load resistance R L = 1.2Ω, the experiment data of U s , I s , U o , I o , η(ηis efficiency of the convertor) are shown in Tab. 1. When the load resistance R L = 2.4Ω, the experiment data ofU s , I s , U o , I o , ηare shown in Tab.2.4 Conclusions①Because the integral compensator is adopted , the output voltage U o of the convertor has quite high precision even if the input power voltage and the load changes.②The width of the impulses is adjusted automatically in the convertor to realize constant output voltage value. With the increase of the input voltage the width of the impulses turn narrow , the convertor’s efficiency drops. In the process of designing a DC-DC convertor, we must diminish the adjustable range of the impulse width and make the impulse width wider when the convertor operates.③The reasonable value of the resistance and capacitor in the feedback circuit must be selected so that the feedback-system has enough gain margin and phase margin that can guarantee thecontrol-system to be adjusted smoothly.References:[1 ] Cai Xuansan , Gong Shaowen. High-frequency electronics (in Chinese) [ M].Beijing : Science Press , 1994. 232 - 246.[2] Zhang Wang , Wang Shiliu. Automatic control principle (in Chinese)[M]. Beijing: Beijing Institute of Technology Publishing House , 1994. 71 - 72.[3 ] D’Azzo J J. Linear control system analysis and design [M]. San Francisco: McGraw-Hill Book Company,1981. 83 - 92.电动汽车DC-DC电源转换器的原理、建模和控制张承宁, 孙逢春, 张旺(北京理工大学车辆与交通工程学院, 北京100081)摘要:为了设计出在电动汽车上把高压直流电源变换成低压直流电源的高品质DC-DC 变换器,采用自动控制理论进行指导. 介绍电动汽车DC-DC 变换器原理和设计,建模与控制方法. 应用阶跃响应法、频率法研究其数学模型和控制特性,并且进行分析和计算. 实验结果表明,用这种方法所研制的电动汽车DC-DC 变换器输出电压精度高,抗干扰能力强,调节特性快速、平稳.关键词:电动汽车; DC-DC 变换器; 自动控制; 数学模型; Bode 图中图分类号U 469172 文献标识码A通常有两种电源电动汽车。

宝骚与Hl奔基于单片机的车载逆变电源设计Design of intelligeaquarium monitoring system郭志成任晓芳朱东山(兰州工业学院电气工程学院,甘肃兰州730070)摘要:设计了一种车载逆变电源,系统采用两级变换结构,先使用PWM芯片SG3525控制双变压器结构的推挽电路将蓄电池电压升高,在通过单片机PIC16F877A输出SPWM信号控制全桥逆变电路,得到220V/50Hz正弦交流电为车载电器供电系统设计简单、容易实现,克服了传统车载逆变电源存在的问题,提高了电源的适用性关键词:逆变电源;SG3525;推挽电路;PIC16F877AAbstract:A vehicle-mounted inverter power supply is designed.The system adopts a two-stage conversion structure.The PWM chip SG3525is used to control the push-pull circuit of the dual-transformer structure to taise the battery voltage.The SPWM signal is output through the single-chip PIC16F877A to control the full-bridge inverter circuit.220v/50Hz sinusoidal AC power supply for vehical electrical appliances.The system design is simple and easy to implement,overcomes the problems existing in the traditional vehicle inverter power supply,and improves the applicability of the power supply.Key words:Inverter power supply;SG3525;Push-pull circuit;PIC16F877A中图分类号:TM76文献标识码:B文章编号:1003-8965(2019)02-0086-020引言随着私家汽车的普及和现代科技的进步,大量电子产品,例如车载音响、电视、冰箱、平板电脑、医疗急救电器等的投入使用,使人们出行更加舒适和方便。

文献出处:Pollet G. The research of electric car charging system and controller [J]. Electrochimica Acta, 2015, 5(3): 235-249.原文The research of electric car charging system and controllerPollet GAbstractThis paper puts forward the whole bridge main circuit topology and PWM control method effectively improves the reliability of the charging system and efficiency. Put forward and realized based on digital signal processing chip controller circuit intelligent PI control algorithm and variable parameters, significantly improve the control precision of the charging system voltage, current and response characteristics. Double proposes a CAN bus and RS - 485 bus communication network, realized the distributed control of the process of charging, the charging operation is flexible and reliable. Due to be able to provide a communication interface to battery management system and algorithm, charging system according to the state change of battery charging mode, optimizing the charging mode. The success of the charging system has important theoretical significance and engineering value. Keywords: Electric cars; Charging system, PWM, Intelligent PI, Distributed control 1 IntroductionElectric car, it is all or part of the electric drive system of power car, compared with conventional cars powered by gasoline as, electric cars in such aspects as environmental protection, clean, energy-saving occupy obvious advantages. Now each big international automobile manufacturer have invested a lot of money and manpower to electric car research and development, a variety of the electric car prototype appeared frequently, some have reached high industrialization scale. Now the development of the electric car industry has formed a hybrid vehicles, pure battery-powered electric vehicles (electric cars) and three main direction of fuel cell electric vehicles. Pure electric vehicle itself is not harmful gas emissions, can make full use of surplus power in the evening, improve the efficiency of energy utilization, and improve the economic benefit. Pure electric vehicles completely eliminateemissions of the vehicle running, fully use of secondary energy electricity, in line with the energy sustainable utilization strategy, along with the progress of the technical level, the pure electric vehicles has a broad development prospects. But at present, the development of the battery and charging system can't satisfy the requirement of electric cars, there are some theoretical and technical problems have yet to be research, serious lack of relevant standards and norms, has become the bottleneck of affecting the development of electric vehicles.2 The current situation of the electric vehicle charging systemAt the beginning of last century, as the secondary battery research is successful, and matching charging system arises at the historic moment. The charging system using the conventional charging method, which is USES small current for a long time to recharge battery. This way of charge due to the charging time is too long, can not meet the requirement of the electric cars and so on, the demand of the quick charge. Widely at home and abroad to carry out the study of fast charging system. Fast charging system produce roughly experienced three stages of development:(l) Groping stageIs the earliest in the 50 s of the last century, the United States as a result of the need of military, began to study fast charging technology, made the metal rectifying shape fast charging system, for 6 to 24 v lead-acid battery quick charging, the weight of 40 kg, have fast, medium and slow three charging modes.(2) The theory research stage1967 U.S. troops (Mas) have bubbles in the process of charging is studied, find the reason and law of gas, on the premise of minimum gas rate and find out the maximum charging current of battery can accept and acceptable charging current curve, discusses the theory of quick charge battery, and on the basis of practice, put forward the basic rules of quick charge battery.(3) The practical application stageMcCulloch electronic companies in the United States in 1970 made the lead-acid battery quick charging system, for 500A to 190AH battery charging current, and in 1200A discharge to deal with the polarization current for short periods of time, theresults 30 minutes to put the battery is good. In addition to the United States, such as Japan, other countries such as Britain, France, Germany, the former Soviet Union also has different degree of development in rapid charging technology. Britain's associated company invented "TEC total energy intelligent charging control technology" and its control system, effectively control the powder charging when the amount of energy needed, overcome existing corona charging system and friction type charging system caused various problems, to solve the "Faraday shielding effect" and "reverse ionization effect" and so on.At present the batteries of electric cars in use process, because of the limitation of the voltage of the power battery energy and need to adopt more battery in series combination, and power battery characteristics of highly nonlinear, individual difference is very big, therefore become the electric car battery management system, a necessary device. The most basic function of BMS is to monitor the working state of the battery (voltage, current and temperature of the battery), prediction of power battery (SOC) of battery capacity, battery management to avoid over discharge, overcharge, overheating and serious imbalance between monomer battery voltages, maximize battery storage capacity and cycle life.Current of the electric vehicle charging system is not very good with a serious defect currently has been relatively mature and supporting the use of on-board BMS system, charging system is either not provide communication interface with BMS, or communication interface is not compatible with popular now BMS interface. BMS system has the most comprehensive, full of battery state of real-time data, if you can provide the charging system and its communication interface, can fundamentally solve the current charging system in the process of charging the battery status change resulting in without understanding the state of the battery charged blindly charging, thus reduce battery life.In addition, as the core of the electric vehicle charging system, the existing charging controller, the control process are mostly based on analog signal processing, and its control structure is a centralized control structure. The traditional charging system boundary is not clear, complex structure and each subsystem is unitized degreeis very low. Its applied electromagnetic environment, all kinds of high frequency signals could easily lead to serious interference of microcomputer control charging system failure. In the past, often using analog signal for each signal transmission is between the control systems. Various kinds of interference signal into analog signals, it is easy to lead to failure of the control system, its structure and the process may not apply to the requirement of the distributed control and the whole process of the digital processing requirements.3 The function of the electric vehicle charging system requirementsThe charging system in addition to providing communication interface with BMS, received by the BMS battery status parameters of transfer function, extract energy from power supply and charging system is passed to the battery in the right way, so as to set up between power supply and battery power conversion interface. Charging system is usually performed by the power conversion unit and process control of controller. The basic properties of the charging system requirements include the following:Security: electric vehicle charging, how to ensure that personnel's personal safety and the safety of the battery is very important. Easy to use: charging system should have high intelligence, operators don't need too much intervention in the charging process. Cost economy: economic and cheap charging system helps to reduce the cost of the whole electric cars, improve operation efficiency, and promote the commercialization of electric vehicles. High efficiency: efficiency is one of the most important requirements for modern charging system; the efficiency of the energy efficiency of high and low for the electric car has a huge impact. Low pollution to the power supply: the power electronic technology of the charging system is a kind of highly nonlinear devices, will produce harmful to the supply network and other electrical equipment of the harmonic pollution, moreover, because of the charging system power factor is low, the charging system load increases, its effect on the supply network also not allow to ignore.4 EV charging method4.1 Constant current chargingIn the whole process of charging and is always with constant current for rechargeable battery. In this way, to ensure that in the later stages of charging without a lot of gas, therefore can only use small current charging, so need a long time, the charging method has the advantage of simple operation, the current is too small, but in the beginning in the late charge and charging current is too large, charging time is long.4.2 Constant voltage chargingEarly charging current is quite large, as the charge and current decreases. For more battery discharge, the initial charging current is too large in order to protect cells from damage, at the beginning of the charging to limited flow measures to avoid the charging current is too large. Compared with constant current charging, the battery is not easy to calculate.4.3 Constant voltage charging current limitingTo remedy constant-voltage charging shortcomings, is widely used in constant voltage current limiting method. Set the maximum charging current, at the beginning of the charge, when the current exceeds the limit of flow value, with the current limiting value, when the current less than the current limit value, constant voltage charging. Thus automatically adjust the charging current, does not exceed a certain limit, the charging current is controlled in the early.4.4 Constant voltage charge after constant currentThis method is a combination of constant current charging and constant voltage charge, the previous constant current charging and accounting period of constant voltage charging way, on the one hand to avoid the constant voltage charging current is too large, in the early late again on the other hand to avoid the constant current charging phenomenon.4.5 Charge attenuationIn the process of charging, with the increase of voltage of the battery, charging current attenuation of charging method gradually. This is a kind of ideal charging method; charge saves time and prevents the sulfuric acid stratification and the plate vulcanizing. But this charging method implementation requires more complex control,compared with the constant current charging; the charging amount is not easy to estimate. Due to the battery and nonlinear dispersion, complexity, the problems in the process of charging, the battery charging has become a more complex issue. The traditional charging method is used to charging very troublesome, because often be charging for 10 hours, and in the process of charging must be manned. Quick charge is the problem to be solved in the process of charging current control, in the process of charging, if the charging current is not enough, to reach the purpose of quick charge. If the charging current is too large and will cause a large number of precipitation of gas, electrolyte temperature will rise quickly, easy to cause the battery plate is damaged, shorten the battery life. Also in the process of charging battery monomer battery consistency of difference, this factor must be fully considered.译文电动汽车充电系统及控制器研究Pollet G摘要本文提出了全桥的主电路拓扑结构和PWM的控制手段,有效的提高了充电系统的可靠性和效率。

山东科技大学学士学位论文摘要摘要车载逆变器就是一种能把汽车上12V直流电转化为220V/50Hz交流电的电子装置,是常用的车用电子用品。

在日常生活中逆变器的应用也很广泛,比如笔记本电脑、录像机和一些电动工具等。

本设计主要基于开关电源电路技术等基础知识,采用二次逆变实现逆变器的设计。

主要思路是:运用TL494以及SG3525A等芯片,先将12V直流电源升压为320V/50Hz的高频交流电,再经过整流滤波将高频交流电整流为高压直流电,然后采用正弦波脉冲调制法,通过输出脉冲控制开关管的导通。

最后经过LC工频滤波及相应的输入输出保护电路后,输出稳定的准正弦波,供负载使用。

本设计具有灵活方便、适用范围广的特点,基本能够满足实践需求。

而且本设计采用高频逆变方式,具有噪声降低、反应速度提高以及电路调整灵活的优点。

设计符合逆变电源小型化、轻量化、高频化以及高可靠性、低噪声的发展趋势。

关键词:车载逆变器;脉冲调宽;保护电路;TL494 ;SG3525A;山东科技大学学士学位论文ABSTRACTABSTRACTCar inverter is a kind of vehicle that can be converted to 220V/50Hz 12V DC AC electronic device which is commonly used in automotive electronic products. The inverter applications are very broad in the daily life , such as notebook computer, video recorder and electric tools etc.This design is mainly based on switch power supply circuit technology basic knowledge, using two inverter realize inverter design. The main idea uses the TL494 and SG3525A etc chip, the first 12 V dc power boost for 320 V/frequency 50 Hz high frequency alternating current, and rectification of high frequency ac filter will rectifier for high voltage dc and then using sine pulse regulation law, through the output pulse control switch tube conduction. Finally after LC industrial frequency filter and the corresponding input/output protection circuits, stable output prospective sine wave, used for load.The design is flexible and convenient, apply a wide range of features, can basically meet the demand of practice. Besides the design uses the high frequency inverter, with noise reduction, response speed and adjust the advantages of flexible circuit. Finally the design conforms to the power supply miniaturization, lightweight, high frequency and high reliability, low noise trend.Key words: car invert ;pulse width modulation;circuit protection;TL494; SG3525A ;山东科技大学学士学位论文目录目录1 绪论 (1)1.1 车载逆变器及其发展 (1)1.2 逆变电源技术的发展 (2)1.3 逆变电源的发展趋势 (5)2 设计总体目标 (7)2.1 设计要求及系统指标 (7)2.2 总体方案的选取 (8)3 整体电路设计 (11)3.1 逆变电源整体框图 (11)3.2 脉宽调制技术及其原理 (13)3.3 正弦波脉宽调制技术 (18)4 逆变电源主要集成芯片外围电路及其功能简介 (21)4.1 TL494外围电路及其应用 (21)4.2 SG3525A外围电路及其应用 (23)4.3 ICL8038外围电路及其应用 (28)4.4 IR2110外围电路及其应用.................................315 逆变电源单元电路设计 (35)5.1 DC/DC变换电路 (35)5.2 DC/AC变换电路 (36)5.3 输入过压保护电路.......................................38 5.4 输入欠压保护电路.......................................38 5.5 过热保护电路...........................................39山东科技大学学士学位论文目录5.6 输出过压保护电路......................................40 5.7 输出过流保护电路.....................................41 致谢词.............................................43 参考文献...........................................44 附录...............................................46 附录一外文翻译..........................................46 附录二逆变电源原理图....................................631 绪论1.1 车载逆变器及其发展车载逆变电源是将汽车发动机或汽车电瓶上的直流电转换为交流电,供一般电器产品使用,是一种较方便的车用电源转换设备。

基于PIC单片机的数字式车载逆变电源的研究与设计的开题报告一、研究背景和意义随着汽车电子设备的不断普及和迅速发展,车载逆变器作为一种可将车辆直流电源转换为交流电源的重要设备,受到了广泛的关注和应用。

目前市面上的车载逆变器大多数属于模拟式逆变器,存在体积大、效率低、噪音大等缺点。

数字式车载逆变器以其小巧、高效、低噪音等优点逐渐成为研究热点。

本次设计旨在基于PIC单片机,设计一款功能齐全、性能优良、价格实惠的数字式车载逆变器,为汽车电子设备提供更加优质的电源支撑,具有重要的应用意义和实用价值。

二、设计内容和研究方法本设计主要分为硬件设计和软件设计两个部分:1.硬件设计硬件设计包括功率电路设计、控制电路设计和保护电路设计。

其中功率电路要能够满足车载设备的电源需求,控制电路需要适配所选单片机,保护电路则需要在出现异常情况时对逆变器进行保护。

2.软件设计软件部分主要包括单片机程序设计和上位机软件开发。

单片机程序需要实现逆变器的控制功能和数据采集功能,上位机软件需要实现对逆变器数据实时显示和操作控制。

研究方法主要采用仿真和实验相结合的方式,先通过仿真软件进行模拟实验,验证设计的可行性,然后基于实验结果优化设计,最终通过实验验证出设计的正确性和有效性。

三、预期成果本研究的预期成果是设计出一款稳定性好、噪音小、效率高的数字式车载逆变器,并成功实现单片机控制。

同时,将开发一个友好的上位机软件,实现对逆变器的实时监控和控制,最终实现一个可靠的数字式车载逆变器系统,为汽车电子设备提供更加优质的电源支撑。

四、研究进度安排本论文的研究进度安排如下:1.文献调研和理论研究(2周);2.硬件设计和电路仿真(4周);3.单片机程序设计和调试(3周);4.上位机软件开发和测试(3周);5.系统集成和性能测试(2周);6.论文写作(2周)。

五、参考文献1.李正东.数字式车载逆变器研究[D].河南科技大学,2019.2.李晓明,周荣年.PIC单片机逆变控制系统的设计与研究[J].自动化应用,2017,2(2):135-137.3.汪琴.数字式车载逆变器设计[D].青岛理工大学,2018.4.宋华.基于DSP的数字式车载逆变器研究[D].长春工程学院,2018.。

Inverter1 IntroductionAn inverter is an electrical device that converts direct current (DC) to alternating current (AC); the converted AC can be at any required voltage and frequency with the use of appropriate transformers, switching, and control circuits.Solid-state inverters have no moving parts and are used in a wide range of applications, from small switching power supplies in computers, to large electric utility high-voltage direct current applications that transport bulk power. Inverters are commonly used to supply AC power from DC sources such as solar panels or batteries.There are two main types of inverter. The output of a modified sine wave inverter is similar to a square wave output except that the output goes to zero volts for a time before switching positive or negative. It is simple and low cost and is compatible with most electronic devices, except for sensitive or specialized equipment, for example certain laser printers. A pure sine wave inverter produces a nearly perfect sine wave output (<3% total harmonic distortion) that is essentially the same as utility-supplied grid power. Thus it is compatible with all AC electronic devices. This is the type used in grid-tie inverters. Its design is more complex, and costs 5 or 10 times more per unit power The electrical inverter is a high-power electronic oscillator. It is so named because early mechanical AC to DC converters were made to work in reverse, and thus were "inverted", to convert DC to AC.The inverter performs the opposite function of a rectifier.2 Applications2.1 DC power source utilizationAn inverter converts the DC electricity from sources such as batteries, solar panels, or fuel cells to AC electricity. The electricity can be at any required voltage; in particular it can operate AC equipment designed for mains operation, or rectified to produce DC at any desired voltageGrid tie inverters can feed energy back into the distribution network because they produce alternating current with the same wave shape and frequency as supplied by the distribution system. They can also switch off automatically in the event of a blackout.Micro-inverters convert direct current from individual solar panels into alternating current for the electric grid. They are grid tie designs by default.2.2 Uninterruptible power suppliesAn uninterruptible power supply (UPS) uses batteries and an inverter to supply AC power when main power is not available. When main power is restored, a rectifier supplies DC power to recharge the batteries.2.3 Induction heatingInverters convert low frequency main AC power to a higher frequency for use in induction heating. To do this, AC power is first rectified to provide DC power. The inverter then changes the DC power to high frequency AC power.2.4 HVDC power transmissionWith HVDC power transmission, AC power is rectified and high voltage DC power is transmitted to another location. At the receiving location, an inverter in a static inverter plant converts the power back to AC.2.5 Variable-frequency drivesA variable-frequency drive controls the operating speed of an AC motor by controlling the frequency and voltage of the power supplied to the motor. An inverter provides the controlled power. In most cases, the variable-frequency drive includes a rectifier so that DC power for the inverter can be provided from main AC power. Since an inverter is the key component, variable-frequency drives are sometimes called inverter drives or just inverters.2.6 Electric vehicle drivesAdjustable speed motor control inverters are currently used to power the traction motors in some electric and diesel-electric rail vehicles as well as some battery electric vehicles and hybrid electric highway vehicles such as the Toyota Prius and Fisker Karma. Various improvements in inverter technology are being developed specifically for electric vehicle applications.[2] In vehicles with regenerative braking, the inverter also takes power from the motor (now acting as a generator) and stores it in the batteries.2.7 The general caseA transformer allows AC power to be converted to any desired voltage, but at the same frequency. Inverters, plus rectifiers for DC, can be designed to convert from any voltage, AC or DC, to any other voltage, also AC or DC, at any desired frequency. The output power can never exceed the input power, but efficiencies can be high, with a small proportion of the power dissipated as waste heat.3 Circuit description3.1 Basic designsIn one simple inverter circuit, DC power is connected to a transformer through the centre tap of the primary winding. A switch is rapidly switched back and forth to allowcurrent to flow back to the DC source following two alternate paths through one end of the primary winding and then the other. The alternation of the direction of current in the primary winding of the transformer produces alternating current (AC) in the secondary circuit.The electromechanical version of the switching device includes two stationary contacts and a spring supported moving contact. The spring holds the movable contact against one of the stationary contacts and an electromagnet pulls the movable contact to the opposite stationary contact. The current in the electromagnet is interrupted by the action of the switch so that the switch continually switches rapidly back and forth. This type of electromechanical inverter switch, called a vibrator or buzzer, was once used in vacuum tube automobile radios. A similar mechanism has been used in door bells, buzzers and tattoo guns.As they became available with adequate power ratings, transistors and various other types of semiconductor switches have been incorporated into inverter circuit designs 3.2 Output waveformsThe switch in the simple inverter described above, when not coupled to an output transformer, produces a square voltage waveform due to its simple off and on nature as opposed to the sinusoidal waveform that is the usual waveform of an AC power supply. Using Fourier analysis, periodic waveforms are represented as the sum of an infinite series of sine waves. The sine wave that has the same frequency as the original waveform is called the fundamental component. The other sine waves, called harmonics, that are included in the series have frequencies that are integral multiples of the fundamental frequency.The quality of output waveform that is needed from an inverter depends on thecharacteristics of the connected load. Some loads need a nearly perfect sine wave voltage supply in order to work properly. Other loads may work quite well with a square wave voltage.3.3 Three phase invertersThree-phase inverters are used for variable-frequency drive applications and for high power applications such as HVDC power transmission. A basic three-phase inverter consists of three single-phase inverter switches each connected to one of the three load terminals. For the most basic control scheme, the operation of the three switches is coordinated so that one switch operates at each 60 degree point of the fundamental output waveform. This creates a line-to-line output waveform that has six steps. The six-step waveform has a zero-voltage step between the positive and negative sections of the square-wave such that the harmonics that are multiples of three are eliminated as described above. When carrier-based PWM techniques are applied to six-step waveforms, the basic overall shape, or envelope, of the waveform is retained so that the 3rd harmonic and its multiples are cancelled4 History4.1 Early invertersFrom the late nineteenth century through the middle of the twentieth century, DC-to-AC power conversion was accomplished using rotary converters or motor-generator sets (M-G sets). In the early twentieth century, vacuum tubes and gas filled tubes began to be used as switches in inverter circuits. The most widely used type of tube was the thyratron.The origins of electromechanical inverters explain the source of the term inverter. Early AC-to-DC converters used an induction or synchronous AC motor direct-connected to a generator (dynamo) so that the generator's commutator reversed its connections atexactly the right moments to produce DC. A later development is the synchronous converter, in which the motor and generator windings are combined into one armature, with slip rings at one end and a commutator at the other and only one field frame. The result with either is AC-in, DC-out. With an M-G set, the DC can be considered to be separately generated from the AC; with a synchronous converter, in a certain sense it can be considered to be "mechanically rectified AC". Given the right auxiliary and control equipment, an M-G set or rotary converter can be "run backwards", converting DC to AC. Hence an inverter is an inverted converter.4.2 Controlled rectifier invertersSince early transistors were not available with sufficient voltage and current ratings for most inverter applications, it was the 1957 introduction of the thyristor or silicon-controlled rectifier (SCR) that initiated the transition to solid state inverter circuits.The commutation requirements of SCRs are a key consideration in SCR circuit designs. SCRs do not turn off or commutate automatically when the gate control signal is shut off. They only turn off when the forward current is reduced to below the minimum holding current, which varies with each kind of SCR, through some external process. For SCRs connected to an AC power source, commutation occurs naturally every time the polarity of the source voltage reverses. SCRs connected to a DC power source usually require a means of forced commutation that forces the current to zero when commutation is required. The least complicated SCR circuits employ natural commutation rather than forced commutation. With the addition of forced commutation circuits, SCRs have been used in the types of inverter circuits describedIn applications where inverters transfer power from a DC power source to an AC above.power source, it is possible to use AC-to-DC controlled rectifier circuits operating in the inversion mode. In the inversion mode, a controlled rectifier circuit operates as a line commutated inverter. This type of operation can be used in HVDC power transmission systems and in regenerative braking operation of motor control systems.Another type of SCR inverter circuit is the current source input (CSI) inverter. A CSI inverter is the dual of a six-step voltage source inverter. With a current source inverter, the DC power supply is configured as a current source rather than a voltage source. The inverter SCRs are switched in a six-step sequence to direct the current to a three-phase AC load as a stepped current waveform. CSI inverter commutation methods include load commutation and parallel capacitor commutation. With both methods, the input current regulation assists the commutation. With load commutation, the load is a synchronous motor operated at a leading power factor. As they have become available in higher voltage and current ratings, semiconductors such as transistors or IGBTs that can be turned off by means of control signals have become the preferred switching components for use in inverter circuits.4.3 Rectifier and inverter pulse numbersRectifier circuits are often classified by the number of current pulses that flow to the DC side of the rectifier per cycle of AC input voltage. A single-phase half-wave rectifier is a one-pulse circuit and a single-phase full-wave rectifier is a two-pulse circuit. A three-phase half-wave rectifier is a three-pulse circuit and a three-phase full-wave rectifier is a six-pulse circuit。

基于单片机单相车载逆变电源设计Abstract:The design of a single-phase car-mounted inverter power supply based on a single-chip microcomputer is presented in this paper. The article analyzes the system requirements and design principle of the inverter power supply in detail. The system adopts a single-chip microcomputer as the core controller, and a power MOS tube as the switching device. By adjusting the pulse width modulation signal of the single-chip microcomputer, the DC voltage output by the car battery is converted into a stable AC voltage.Keywords:Single-phase inverter power supply; single-chip microcomputer; pulse width modulation; car-mounted applicationIntroduction:With the rapid development of automobile technology, more and more car electronics have been developed, which need AC power supply. However, the power supply of the onboard equipment is mainly provided by the car battery, which only provides DC voltage output. In order to meet the AC power supply needs of onboard equipment, an inverter power supply is required. Moreover, with the miniaturization of the car body, it is increasingly difficult to add a large-capacity generator to provide the required AC power supply. Therefore, it is necessary to design a small and efficient inverter power supply that can be easily installed in a car.The principle of an inverter power supply is to convert DC voltage into AC voltage. The conversion process needs touse a switching device to switch the DC voltage, and then use a filter circuit to filter the switching signal to obtain the stable output voltage. The conversion process requiresprecise control, and the single-chip microcomputer is anideal control device in the process of converting DC voltage into AC voltage. The pulse width modulation (PWM) technology of the single-chip microcomputer can effectively control the output voltage.Design and Implementation:The system block diagram of the inverter power supply based on the single-chip microcomputer is shown in Figure 1, including four parts: power supply unit, control unit, drive unit and switching unit.Power supply unit: This unit converts the input DC voltage (car battery) into a stable DC voltage for thecontrol unit and the drive unit. The DC voltage is filteredby a filter capacitor to remove the AC component and obtain a DC voltage.Control unit: This unit consists of a single-chip microcomputer, which is used to control the switching unit by generating a PWM signal. The single-chip microcomputer also provides feedback control of the inverter output voltage, which ensures the stable operation of the inverter power supply.Drive unit: This unit is composed of a driver circuit and an isolation transformer. The driver circuit is used to provide PWM signals to the switching unit. The isolation transformer is used to isolate the drive circuit and the switching circuit to ensure the safety of the system.Switching unit: This unit is composed of power MOS tubes,which is used to switch the DC voltage to obtain a stable AC voltage.The switching unit of the system is shown in Figure 2.It uses two power MOS tubes as switching devices, which convert the DC voltage input into a square wave signal. The square wave signal is filtered by the output transformer and then output as an AC voltage.Conclusions:In this paper, a single-phase car-mounted inverter power supply based on a single-chip microcomputer is designed. Through the analysis of the system requirements and design principle, the system adopts a single-chip microcomputer as the core controller, and uses power MOS tubes as the switching device to convert the DC voltage output by the car battery into a stable AC voltage. The control of the inverter power supply is realized by adjusting the PWM signal using the single-chip microcomputer. The experimental results show that the designed system has stable output performance and is suitable for car-mounted applications.。

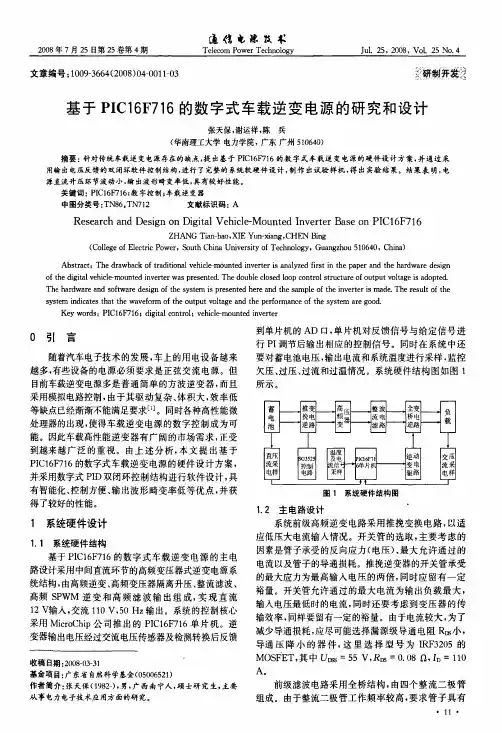

基于PIC16F716的数字式车载逆变电源的研究和设计作者:张天保, 谢运祥, 陈兵作者单位:华南理工大学,电力学院,广东,广州,510640刊名:通信电源技术英文刊名:TELECOM POWER TECHNOLOGIES年,卷(期):2008,25(4)被引用次数:1次1.李强,周席德.车载单相正弦脉宽调制IGBT逆变器的研制[J].电力电子技术.1997,(2):13-15.2.李学海.PIC单片机实用教程[M].北京:航空航天大学出版社.2002.3.Xuejun Pei,Xinehun Lin,etal.Analysis and design of the DSP-based fully digital ControlledUPS.IEEE,Power Electronics.2001,296-300.4.Cha H J.Real-Time digital control of PWM inverter with PI compensator for uninterruptible power supply[C].IEEE IECON Conf.Rec.1990,(2):1125-1128.5.Low K S.A Digital Control Technique for a Single-Phase PWM inverter[M].IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS.1998,(8):1335-1340.1.学位论文张天保基于PIC单片机的数字式车载逆变电源的研究与设计2008随着汽车的发展,车上的用电设备越来越多,对车载逆变电源的需求也日益增强,而且有些设备的电源还要求必须是正弦交流电。

但目前国内市场上的车载逆变电源多是普通简单的方波逆变电源,而且采用模拟电路控制,由于其驱动复杂、体积大,效率低等缺点已经渐渐不能满足要求。

同时各种高性能微处理器的出现,使得车载逆变电源的数字控制成为可能。

逆变器中英文对照外文翻译文献中英文对照外文翻译文献(文档含英文原文和中文翻译)逆变器1引言逆变器是一种电动装置,转换成直流电(DC),交流电流转换的AC(交流)可以在任何所需的电压和频率使用适当的变压器,开关,控制circuits.Solid状态逆变器有没有移动部件,用于广泛的应用范围从小型计算机开关电源,高压大型电力公司电力,运输散装直接电流应用。

逆变器通常用于提供交流电源,直流电源,如太阳能电池板或电池。

逆变器的主要有两种类型。

修改后的正弦波逆变器的输出是类似方波输出,输出变为零伏前一段时间切换积极或消极的除外。

它是简单,成本低,是大多数电子设备兼容,除敏感或专用设备,例如某些激光打印机。

一个纯正弦波逆变器产生一个近乎完美的正弦波输出(<3%的总谐波失真),本质上是相同的公用事业提供电网。

因此,它是与所有的交流电的电子设备兼容。

这是在电网领带逆变器使用的类型。

它的设计更复杂,成本5或10倍以上每单位功率电逆变器是一个高功率的电子振荡器。

它这样命名,因为早期的机械AC到DC转换器工作在反向,因而被“倒”,将直流电转换AC.The变频器执行的整流器对面功能。

2应用2.1直流电源利用率逆变器从交流电力来源,如电池,太阳能电池板,燃料电池的直流电转换成。

电力,可以在任何所需的电压,特别是它可以操作交流电源操作而设计的设备,或纠正,以产生任何所需的voltage Grid领带逆变器的直流送入分销网络的能量,因为它们产生电流交替使用相同的波形和频率分配制度提供。

他们还可以关掉一个blackout.Micro 逆变器的情况下自动转换成交流电电网的电流直接从当前个别太阳能电池板。

默认情况下,他们是格领带设计。

2.2不间断电源不间断电源(UPS),电池和逆变器,交流电源,主电源不可用时使用。

当主电源恢复正常时,整流提供直流电源给电池充电。

2.3感应加热逆变器的低频交流主电源转换到更高频率的感应加热使用。

汽车电子系统中英文对照外文翻译文献汽车电子系统中英文对照外文翻译文献1汽车电子系统中英文对照外文翻译文献(文档含英文原文和中文翻译)The Changing Automotive Environment: High-Temperature ElectronicsR. Wayne Johnson, Fellow, IEEE, John L. Evans, Peter Jacobsen, James R. (Rick) Thompson, and Mark ChristopherAbstract —The underhood automotive environment is harsh and current trends in the automotive electronics industry will be pushing the temperatureenvelope for electronic components. The desire to place engine control unitson the engine and transmission control units either on or in the transmissionwill push the ambient temperature above 125125℃℃.However, extreme cost pressures,increasing reliability demands (10 year/241 350 km) and the cost of field failures (recalls, liability, customer loyalty) will make the shift to higher temperatures occur incrementally. The coolest spots on engine and in the transmission will be used. These large bodies do provide considerableheat sinking to reduce temperature rise due to power dissipation in the controlunit. The majority of near term applications will be at 150 ℃ or less andthese will be worst case temperatures, not nominal. The transition toX-by-wire technology, replacing mechanical and hydraulic systems with electromechanical systems will require more power electronics. Integrationof power transistors and smart power devices into the electromechanical℃ to 200℃ . Hybridactuator will require power devices to operate at 175electric vehicles and fuel cell vehicles will also drive the demand for higher temperature power electronics. In the case of hybrid electric and fuel cell vehicles, the high temperature will be due to power dissipation. Thealternates to high-temperature devices are thermal management systems which add weight and cost. Finally, the number of sensors in vehicles is increasingas more electrically controlled systems are added. Many of these sensors mustwork in high-temperature environments. The harshest applications are exhaustgas sensors and cylinder pressure or combustion sensors. High-temperature electronics use in automotive systems will continue to grow, but it will be gradual as cost and reliability issues are addressed. This paper examines themotivation for higher temperature operation,the packaging limitations evenat 125 C with newer package styles and concludes with a review of challenge at both the semiconductor device and packaging level as temperatures push beyond 125 ℃.Index Terms—Automotive, extreme-environment electronics.I. INTRODUCTIONI N 1977, the average automobile contained $110 worth of electronics [1]. By 2003 the electronics content was $1510 per vehicle and is expected to reach$2285 in 2013 [2].The turning point in automotive electronics was governmentTABLE IMAJOR AUTOMOTIVE ELECTRONIC SYSTEMSTABLE IIAUTOMOTIVETEMPERATUREEXTREMES(DELPHIDELCOELECTRONIC SYSTEMS) [3]regulation in the 1970s mandating emissions control and fuel economy. The complex fuel control required could not be accomplished using traditional mechanical systems. These government regulations coupled with increasing semiconductor computing power at decreasing cost have led to an ever increasing array of automotive electronics. Automotive electronics can be divided into five major categories as shown in Table I.The operating temperature of the electronics is a function of location, power dissipation by the electronics, and the thermal design. The automotive electronics industry defines high-temperature electronics as electronics operating above 125 ℃. However, the actual temperature for various electronics mounting locations varies considerably. Delphi Delco Electronic Systems recently published the typical continuous maximum temperatures as reproduced in Table II [3]. The corresponding underhood temperatures are shown in Fig. 1. The authors note that typical junction temperatures for integrated circuits are 10 ℃to15℃ higher than ambient or baseplate temperature, while power devices can reach 25 ℃ higher. At-engine temperatures of 125℃ peak can be maintained by placing the electronics on theintake manifold.Fig. 1. Engine compartment thermal profile (Delphi Delco Electronic Systems) [3].TABLE III THEAUTOMOTIVEENVIRONMENT(GENERALMOTORS ANDDELPHIDELCO ELECTRONICSYSTEMS) [4]TABLE IV REQUIREDOPERATIONTEMPERATURE FORAUTOMOTIVEELECTRONIC SYSTEMS(TOYOTAMOTORCORP. [5]TABLE VMECHA TRONICMAXIMUMTEMPERA TURERANGES(DAIMLERCHRYSLER,EA TONCORPORA TION, ANDAUBURNUNIVERSITY) [6]Fig. 2. Automotive temperatures and related systems (DaimlerChrysler) [8].automotive electronic systems [8]. Fig. 3 shows an actual measured transmission transmission temperature temperature temperature profile profile profile during during during normal normal normal and and excessive excessive driving drivingconditions [8]. Power braking is a commonly used test condition where the brakes are applied and the engine is revved with the transmission in gear.A similar real-world situation would be applying throttle with the emergencybrake applied. Note that when the temperature reached 135135℃℃,the over temperature light came on and at the peak temperature of 145145℃℃,the transmission was beginning to smell of burnt transmission fluid.TABLE VI2002I NTERNA TIONAL T ECHNOLOGY R OADMAPFOR S EMICONDUCTORS A MBI ENTOPERA TINGTEMPERA TURES FORHARSHENVIRONMENTS (AUTOMOTIVE) [9]The 2002 update to the International Technology Roadmap for Semiconductors (ITRS) did not reflect the need for higher operating temperatures for complex integrated circuits, but did recognize increasing temperature requirements for power and linear devices as shown in Table VI [9]. Higher temperature power devices (diodes and transistors) will be used for the power section of power converters and motor drives for electromechanical actuators. Higher temperature linear devices will be used for analog control of power converters and for amplification and some signal processing of sensor outputs prior to transmission to the control units. It should be noted that at the maximum rated temperature for a power device, the power handling capability is derated to zero. Thus, a 200℃ rated power transistor in a 200℃ environment would have zero current carrying capability. Thus, the actual operating environments must be lower than the maximum rating.In the 2003 edition of the ITRS, the maximum junction temperatures identified forharsh-environment complex integrated circuits was raised to 150℃through 2018 [9]. Theambient operating temperature extreme for harsh-environment complex integrated circuits was defined as 40℃to 125℃ through 2009, increasing to 40℃to 150℃for 2010 and beyond. Power/linear devices were not separately listed in 2003.The ITRS is consistent with the current automotive high-temperature limitations. Delphi Delco Electronic Systems offers two production engine controllers (one on ceramic and one on thin laminate) for direct mounting on the engine. These controllers are rated for operation over the temperature range of 40℃to 125℃. The ECU must be mounted on the coolest spot on the engine. The packaging technology is consistent with 140℃ operation, but the ECU is limited by semiconductor and capacitor technologies to 125℃.The future projections in the ITRS are not consistent with the desire to place controllers on-engine or in-transmission. It will not always be possible to use the coolest location for mounting control units. Delphi Delco Electronics Systems has developed an in-transmission controller for use in an ambient temperature of 140℃[10] using ceramic substrate technology. DaimlerChrysler is also designing an in-transmission controller for usewith a maximum ambient temperature of 150℃ (Figs. 4 and 5) [11].II. MECHATRONICSMechatronics, or the integration of electrical and mechanical systems offers a number ofadvantages in automotive assembly. Integration of the engine controller with the engine allows pretest of the engine as a complete system prior to vehicle assembly. Likewise with the integration of the transmission controller and the transmission, pretesting and tuning to account for machining variations can be performed at the transmission factory prior to shipment to the automobile assembly site. In addition, most of the wires connecting to a transmission controller run to the solenoid pack inside the transmission. Integration of the controller into the transmission reduces the wiring harness requirements at the automobile assembly level.Fig. 4. Prototype DaimlerChrysler ceramic transmission controller [11]Fig. 5. DaimlerChrysler in-transmission module [11].The trend in automotive design is to distribute control with network communications. As the industry moves to more X-by-wire systems, this trend will continue. Automotivefinalassembly plants assemble subsystems and components supplied by numerous vendors to build the vehicle. Complete mechatronic subsystems simplify the design, integration, management, inventory control, and assembly of vehicles. As discussed in the previous section, higher temperature electronics will be required to meet future mechatronic designs.III. PACKAGINGCHALLENGES AT125℃Trends in electronics packaging, driven by computer and portable products are resulting in packages which will not meet underhood automotive requirements at 125℃. Most notable are leadless and area array packages such as small ball grid arrays (BGAs) and quadflatpacks no-lead (QFNs). Fig. 6 shows the thermal cycle test 40 ℃to 125℃ results for two sizes of QFN from two suppliers [12]. A typical requirement is for the product to survive 2000–2500 thermal cycles with<1% failure for underhood applications. Smaller I/O QFNs have been found to meet the requirements.Fig. 7 presents the thermal cycle results for BGAs of various body sizes [13]. The die size in the BGA remained constant (8.6 *8.6 mm). As the body size decreases so does the reliability. Only the 23-mm BGA meets the requirements. The 15-mm BGA with the 0.56-mm-thick BT substrate nearly meets the minimum requirements. However, the industry trend is to use thinner BT substrates (0.38 mm) for BGA packages.One solution to increasing the thermal cycle performance of smaller BGAs is to use underfill. Capillary underfill was dispensed and cured after reflow assembly of the BGA. Fig. 8 shows a Weibull plot of the thermal cycle data for the 15-mm BGAs with four different underfills. Underfill UF1 had no failures after 5500 cycles and is, therefore, not plotted. Underfill, therefore, provides a viable approach to meeting underhood automotive requirements with smaller BGAs, but adds process steps, time, and cost to the electronics assembly process.Since portable and computer products dominate the electronics market, the packages developed for these applications are replacing traditional packages such as QFPs for new devices. The automotive electronics industry will have to continuedeveloping assembly approaches such as underfill just to use these new packages in current underhood applications.IV. TECHNOLOGY CHALLENGES ABOVE125 ℃The technical challenges for high-temperature automotive applications are interrelated, but can be divided into semiconductors, passives, substrates,interconnections, and housings/connectors. Industries such as oil well logging have successfully fielded high-temperature electronics operating at 200℃ and above. However, automotive electronics are further constrained by high-volume production, low cost, and long-term reliability requirements. The typical operating life for oil well logging electronics may only be 1000 h, production volumes are in the range of 10s or 100s and, while cost is a concern, it is not a dominant issue. In the following paragraphs, the technical challenges for high-temperature automotive electronics are discussed.Semiconductors: The maximum rated ambient temperature for most silicon basedintegrated circuits is 85℃, which is sufficient for consumer, portable, and computing product applications. Devices for military and automotive applications are typically rated to 125℃. A few integrated circuits are rated to 150℃, particularly for power supply controllers and a few automotive applications. Finally, many power semiconductor devices are derated to zero power handling capability at 200℃.Nelmset al.and Johnsonet al.have shown that power insulated-gate bipolar transistors (IGBTs) and metal–oxide–semiconductorfield-effect transistors (MOSFETs) can be used at 200℃[14], [15]. The primary limitations of these power transistors at the higher temperatures are the packaging (the glass transition temperature of common molding compounds is in the 180℃ to 200℃range) and the electrical stress on the transistor during hard switching.A number of factors limit the use of silicon at high temperatures. First, with a bandgap of 1.12 eV, the silicon p-n junction becomes intrinsic at high temperature (225℃ to 400℃depending on doping levels). The intrinsic carrier concentration is given by (1)As the temperature increases, the intrinsic carrier concentration increases. When the intrinsic carrier concentration nears the doping concentration level, p-n junctions behave as resistors, not diodes, and transistors lose their switching characteristics. One approach used in high-temperature integrated circuit design is to increase the doping levels, which increases the temperature at which the device becomes intrinsic. However, increasing the doping levels decreases the depletion widths, resulting in higher electricfields within the device that can lead to breakdown.A second problem is the increase in leakage current through a reverse-biased p-n junction with increasing temperature. Reverse-biased p-n junctions are commonly used in IC design to provide isolation between devices. The saturation current (I,the ideal reverse-bias current of the junction) is proportional to the square of the intrinsic carrier concentrationwhere Ego=bandgap energy atT= 0KThe leakage current approximately doubles for each 10℃rise in junction temperature. Increased junction leakage currents increase power dissipation within the device and can lead to latch-up of the parasitic p-n-p-n structure in complimentary metal–oxide–semiconductor (CMOS) devices. Epitaxial-CMOS (epi-CMOS) has been developed to improve latch-up resistance as the device dimensions are decreased due to scaling and provides improved high-temperature performance compared to bulk CMOS.Silicon-on-insulator (SOI) technology replaces reverse-biased p-n junctions with insulators, typically SiO2 , reducing the leakage currents and extending the operating range of silicon above 200℃. At present, SOI devices are more expensive than conventional p-njunction isolated devices. This is in part due to the limited use of SOI technology. With the continued scaling of device dimensions, SOI is being used in some high-performance applications and the increasing volume may help to eventually lower the cost.Other device performance issues at higher temperatures include gate threshold voltage shifts, decreased noise margin, decreased switching speed, decreased mobility, decreased gain-bandwidth product, and increased amplifier input–offset voltage [16]. Leakage currents also increase for insulators with increasing temperature. This results in increased gate leakage currents, and increased leakage of charge stored in memory cells (data loss). For dynamic memory, the increased leakage currents require faster refresh rates. For nonvolatile memory, the leakage limits the life of the stored data, a particular issue for FLASH memory used in microcontrollers and automotive electronics modules.Beyond the electrical performance of the device, the device reliability must also be considered. Electromigration of the aluminum metallization is a major concern. Electromigration is the movement of the metal atoms due to their bombardment by electrons (current flow). Electromigration results in the formation of hillocks and voids in the conductor traces. The mean time to failure (MTTF) for electromigration is related to the current density (J)and temperature(T) as shown in (3)The exact rate of electromigration and resulting time to failure is a function of the aluminum microstructure. Addition of copper to the aluminum increases electromigration resistance. The trend in the industry to replace aluminum with copper will improve the electromigration resistance by up to three orders of magnitude [17].Time dependent dielectric breakdown (TDDB) is a second reliability concern. Time to failure due to TDDB decreases with increasing temperature. Oxide defects, including pinholes, asperities at the Si–SiO2 interface and localized changes in chemical structure that reduce the barrier height or increase the charge trapping are common sources of early failure [18]. Breakdown can also occur due to hole trapping (Fowler–Nordheim tunneling). The holes can collect at weak spots in the Si–SiO2 interface, increasing the electricfield locally and leading to breakdown [18]. The temperature dependence of time-to-breakdown(tBD) can be expressed as [18]Values reported for Etbd vary in the literature due to its dependence on the oxidefield and the oxide quality. Furthermore, the activation energy increases with breakdown time [18].With proper high-temperature design, junction isolated silicon integrated circuits can be used to junction temperatures of 150℃ to 165℃, epi-CMOS can extend the range to 225℃to 250℃ and SOI can be used to 250℃ to 280℃ [16, pp. 224]. High-temperature, nonvolatile memory remains an issue.For temperatures beyond the limits of silicon, silicon carbidebased semiconductors are being developed. The bandgap of SiC ranges from 2.75–3.1 depending on the polytype. SiC has lower leakage currents and higher electric field strength than Si. Due to its wider bandgap, SiC can be used as a semiconductor device at temperatures over 600℃. Theprimary focus of SiC device research is currently for power devices. SiC power devices may eventuallyfind application as power devices in braking systems and direct fuel injection. High-temperature sensors have also been fabricated with SiC. Berget al.have demonstrated a SiCbased sensor for cylinder pressure in combustion engines [19] at up to 350℃ and Casadyet al.[20] have shown a SiC-based temperature sensor for use to 500℃. At present, the wafer size, cost, and device yield have made SiC devices too expensive for general automotive use. Most SiC devices are discrete, as the level of integration achieved in SiC to date is low.Passives: Thick and thin-film chip resistors are typically rated to 125 ℃. Naefeet al.[21] and Salmonet al.[22] have shown that thick-film resistors can be used at temperatures above 200℃ if the allowable absolute tolerance is 5% or greater. The resistors studied were specifically formulated with a higher softening point glass. The minimum resistance as afunction of temperature was shifted from 25℃to 150℃to minimize the temperature coefficient of resistance (TCR) over the temperature range to 300℃. TaN and NiCr thin-film resistors have been shown to have less than 1% drift after 1000 h at 200℃ [23]. Thus, for tighter tolerance applications, thin-film chip resistors are preferred. Wire wound resistors provide a high-temperature option for higher power dissipation levels [21].High-temperature capacitors present more of a challenge. For low-value capacitors, negative-positive-zero (NPO) ceramic and MOS capacitors provide low-temperature coefficient of capacitance (TCC) to 200℃. NPO ceramic capacitorshave been demonstrated to 500℃ [24]. Higher dielectric constant ceramics (X7R, X8R, X9U), used to achieve the high volumetric efficiency necessary for larger capacitor values, exhibit a significant capacitance decrease above the Curie temperature, which is typically between 125℃ to 150℃. As the temperature increases, the leakage current increases, the dissipation factor increases, and the breakdown strength decreases. Increasing the dielectric tape thickness to increase breakdown strength reduces the capacitance and is a tradeoff. X7R ceramic capacitors have been shown to be stable when stored at 200℃ [23]. X9U chip capacitors are commercially available for use to 200 C, but there is a significant decrease in capacitance above 150℃.Consideration must also be given to the capacitor electrodes and terminations. Ni is now being substituted for Ag and PdAg to lower capacitor cost. The impact of this change on hightemperature reliability must be evaluated. The surface finish for ceramic capacitor terminations is typically Sn. The melting point of the Sn (232℃) and its interaction with potential solders/brazes must also be considered. Alternate surfacefinishes may be required.For higher value, low-voltage requirements, wet tantalum capacitors show reasonable behavior at 200℃ if the hermetic seal does not lose integrity [23]. Aluminum electrolytics are also available for use to 150℃. Mica paper (260℃) and Teflonfilm (200℃) capacitors can provide higher voltage capability, but are large and bulky [25]. High-temperature capacitors are relatively expensive. V capacitors are relatively expensive. Volumetrically efficient, high-voltage, highcapacitance, olumetrically efficient, high-voltage, highcapacitance, high-temperature and low-cost capacitors are still needed.Standard transformers and inductor cores with copper wire and teflon insulation are suitable for operation to 200℃. For higher temperature operation, the magnetic core, the conductor metal (Ni instead of Cu) and insulator must be selected to be compatible with the higher temperatures [16, pp. 651–652] Specially designed transformers can be used to 450℃ to 500℃, however, they are limited in operating frequency.Crystals are required for clock frequency generation for microcontrollers. Crystals with acceptable frequency shift over the temperature range from 55℃to 200℃ have been demonstrated [22]. However, the selection of packaging materials and assembly process for the crystal are key to high-temperature performance and reliability. For example, epoxies used in assembly must be compatible with 200℃ operation.Substrates: Thick-film substrates with gold metallization have been used in circuits to 500℃ [21], [23]. Palladium silver, platinum silver, and silver conductors are morecommonly used in automotive hybrids for reduced cost. Silver migration has been observed with an unpassivated PdAg thick-film conductor under bias at 300℃ [21]. The time-to-failure needs to be examined as a function of temperature and bias voltage with and without passivation. Low-temperature cofired ceramic (LTCC) and high-temperature cofired ceramic (HTCC) are also suitable for high-temperature automotive applications. Embedded resistors are standard to thick-film hybrids, LTCC, and some HTCC technologies. As previously mentioned, thick-film resistors have been demonstrated at temperatures 200℃. Dielectric tapes for embedded capacitors have also been developed for LTCC and HTCC. However, these embedded capacitors have not been characterized for high-temperature use.High-Tg laminates are also available for fabrication of hightemperature printed wiring boards. Cyanate esters [Tg=250℃by differential scanning calorimetry (DSC)], polyimide (260℃by DSC), and liquid crystal polymers(Tm>280℃)provide options for use to 200℃. Cyanate ester boards have been used successfully in test vehicles at 175℃, but failed when exposed to 250℃ [26]. The higher coefficient of thermal expansion (CTE) of the laminate substrates compared to the ceramics must be considered in the selection of component attachment materials. The temperature limits of the laminates with respect to assembly temperatures must also be carefully considered. Work is ongoing to develop and implement embedded resistor and capacitor technology for laminate substrates for conventional temperature ranges. This technology has not been extended to high-temperature applications.One method many manufacturers are using to address the higher temperatures whilemaintaining lower cost is the use of laminate substrates attached to metal. The typical design involves the use of higher Tg( +140℃ and above) laminate substrates attached to an aluminum plate (approximately 2.54-mm thick) using a sheet or liquid adhesive. To assist in thermal performance, the laminate substrate is often thinner (0.76 mm) than traditional automotive substrates for under-the-hood applications. While this design provides improved thermal performance, the attachment of the laminate to aluminum increases the CTE for the overall substrates. The resultant CTE is very dependent on the ability of the attachment material to decouple the CTE between the laminate substrate and the metal backing. However, regardless of the attachment material used, the combination of the laminate and metal will increase the CTE of the overall substrate above that of a stand-alone laminate substrate. This impact can be quite significant in the reliability performance for components with low CTE values (such as ceramic chip resistors). Fig. 9 illustrates the impact of two laminate-to-metal attachment options compared to standard laminate substrates [27], [28]. The reliability data presented is for 2512 ceramic chip resistors attached to a 0.79-mm-thick laminate substrate attached to aluminum using two attachment materials. Notice that while one material significantly outperforms the other, both are less reliable than the same chip resistor attached to laminate without metal backing.This decrease in reliability is also exhibited on small ball grid array (BGA) packages. Fig. 10 shows the reliability of a 15-mm BGA package attached to laminate compared to the same package attached to a laminate substrate with metal backing [27], [28]. The attachment material used for the metal-backed substrate was the best material selected from previous testing. Notice again that the metal-backed substrate deteriorates the reliability. This reliability deterioration is of particular concern since many IC packages used for automotive applications are ball grid array packages and the packaging trend is for reduced packaging size. These packaging trends make the use of metal-backed substrates difficult for next generation products.One potential solution to the above reliability concern is the use of encapsulants and underfills. Fig. 11 illustrates how conformal coating can improve component reliability for surface mount chip resistors [27], [28]. Notice that the reliability varies greatly depending on material composition. However, for components which meet a marginal level of reliability, conformal coatings may assist the design in meeting the target reliability requirements. The same scenario can be found for BGA underfills. Typical underfill materials may extend the component life by a factor of two or more. For marginal IC packages, this enhancement may provide enough reliability improvement toall the designs to meet under-the-hood requirements. Unfortunately, the improvements provided byencapsulants and underfills increase the material cost and adds one or more manufacturing processes for material dispense and cure.Interconnections: Methods of mechanical and electrical interconnection of the active and passive components to the board include chip and wire,flip-chip, and soldering of packaged parts. In chip and wire assembly, epoxy die-attach materials can beused to 165℃ [29]. Polyimide and silicone die-attach materials can be used to 200℃. For higher temperatures, SnPb ( >90Pb), AuGe, AuSi, AuSn, and AuIn have been used. However,with the exception of SnPb, these are hard brazes and with increasing die size, CTE mismatches between the die and the substrate will lead to cracking with thermal。

500W车载逆变电源的研究与设计的开题报告一、选题背景随着汽车功能的不断升级,人们对于车载电器的需求也越来越大。

车载逆变电源是一种将汽车直流电源转换为交流电源的设备,能够为车上的电器设备提供足够的电力支持。

然而目前市场上的车载逆变电源大多功率较小,不能满足人们对于高功率汽车电器的需求。

因此,本研究将以设计一款功率为500W的车载逆变电源为目标。

二、研究意义随着科技的进步,人们对于汽车舒适、便利性的需求越来越高。

车载逆变电源作为现代汽车电器的重要组成部分,其性能直接关系到用户的使用感受。

本研究旨在开发一种功率更高、性能更稳定的车载逆变电源,可为汽车主人提供更为便利舒适的驾车体验。

三、研究内容1. 建立逆变电路模型,分析逆变电路的理论工作过程。

2. 选取合适的电源变压器,根据理论计算,确定电路的相关参数。

3. 设计并制作相关电路板。

4. 对设计的逆变电源进行实验验证,测试不同负载情况下的输出电压和电流,分析实验结果。

四、进度安排第一阶段(1周):查阅相关文献,了解车载逆变电源的研究现状和发展趋势。

第二阶段(2周):建立逆变电路模型,进行逆变电路的理论计算。

第三阶段(3周):选取合适的电源变压器,根据理论计算确定电路的相关参数。

第四阶段(3周):设计并制作相关电路板。

第五阶段(2周):对车载逆变电源进行实验验证,测试不同负载情况下的输出电压和电流,分析实验结果。

第六阶段(1周):撰写论文,总结研究成果。

五、预期成果本研究的主要成果是成功设计并制作出一款功率为500W的车载逆变电源,实现对汽车电器设备的高效供电。

同时,基于对逆变电路的理论研究和实验验证,对于车载逆变电源的设计和制作提供了一定的参考依据,有利于推广和应用车载逆变电源技术。

车载电源逆变器行业市场现状分析及未来三到五年发展趋势报告Analysis of the Current Situation and Future Development Trends of the Car Power Inverter IndustryIntroduction:Car power inverters are devices that convert direct current (DC) from a car's battery into alternating current (AC) that can power various electronic devices. With the increasing popularity of car travel and the increasing demand for electronic devices, the car power inverter industry has developed rapidly in recent years. This article will analyze the current situation of the car power inverter industry and predict its future development trends in the next three to five years.Current Situation:1. Market Size:According to market research, the global car power inverter market size was valued at 2.5 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 6.5 from 2021 to 2028. The Asia-Pacific region is the largest market for car power inverters, accounting for over 50 of the global market share, followed by North America and Europe.2. Product Types:There are mainly two types of car power inverters, pure sine wave and modified sine wave. Pure sine wave inverters are more expensive but provide high-quality power that is suitable for sensitive electronic devices, while modified sine wave inverters are cheaper but may produce lower-quality power that can damage some electronic devices.3. Applications:Car power inverters are widely used in various fields, such as car travel, outdoor activities, emergency backup power supply, and commercial vehicles. The increasing demand for electronic devices, such as smartphones, laptops, and tablets,has driven the growth of the car power inverter market.Future Development Trends:1. Technological Innovation:Technological innovation is the driving force behind the development of the car power inverter industry. In the future, the industry will focus on improving the efficiency, reliability, and safety of car power inverters. For example, the development of wireless charging technology will enable car power inverters to charge electronic devices without cables.2. Market Segmentation:As the car power inverter market becomes more mature, market segmentation will become more important. Companies will focus on developing products for specific applications, such as RVs, commercial vehicles, and emergency backup power supply.3. Environmental Protection:Environmental protection is becoming a hot topic in the car power inverter industry. In the future, companies will develop more environmentally friendly products, such as solar-powered car power inverters.Conclusion:The car power inverter industry has great potential for development in the next three to five years. With the increasing demand for electronic devices and the continuous innovation of technology, the industry will continue to grow and evolve. Companies that can keep up with the latest trends and provide high-quality products will have a competitive advantage in the market.中文版:车载电源逆变器行业市场现状分析及未来三到五年发展趋势报告导言:车载电源逆变器是将汽车电池的直流电转换为可用于各种电子设备的交流电的设备。

英文原文The auto electric power steering system researchAlong with automobile electronic technology swift and violent development, the people also day by day enhance to the motor turning handling quality request. The motor turning system hanged, the hydraulic pressure boost from the traditional machinery changes (Hydraulic Power Steering, is called HPS), the electrically controlled hydraulic pressure boost changes (Electronic Hydraulic Power Steering, is called EHPS), develops the electrically operated boost steering system (Electronic Power Steering, is called EPS), finally also will transit to the line controls the steering system (Steer By Wire, will be called SBW).The machinery steering system is refers by pilot's physical strength achievement changes the energy, in which all power transmission all is mechanical, the automobile changes the movement is operates the steering wheel by the pilot, transmits through the diverter and a series of members changes the wheel to realize. The mechanical steering system by changes the control mechanism, the diverter and major part changes the gearing 3 to be composed.Usually may divide into according to the mechanical diverter form: The gear rack type, follows round the world -like, the worm bearing adjuster hoop type, the worm bearing adjuster refers sells the type. Is the gear rack type and follows using the broadest two kinds round the world -like (uses in needing time big steering force).In follows round the world -like in the diverter, the input changes the circle and the output steering arm pivot angle is proportional; In the gear rack type diverter, the input changes the turn and the output rack displacement is proportional. Follows round the world -like the diverter because is the rolling friction form, thus the transmission efficiency is very high, the ease of operation also the service life are long, moreover bearing capacity, therefore widely applies on the truck. The gear rack type diverter with follows round the world -like compares, the most major characteristic is the rigidity is big, the structure compact weight is light, also the cost is low. Because this way passes on easily by the wheel the reacting force to the steering wheel, therefore has to the pavement behavior response keen merit, but simultaneously also easy to have phenomena and so on goon and oscillation, also its load bearing efficiency relative weak, therefore mainly applies on the compact car and。

车载逆变驱动标准Car inverters are an essential component for driving standard vehicles, as they convert DC power from the vehicle's battery to AC power for powering various devices. 车载逆变器是驱动标准车辆的重要组件,它将车辆电池的直流电源转换为交流电源,用于为各种设备供电。

One of the key requirements for car inverters is their ability to provide reliable and stable power output to ensure the proper functioning of electronic devices in the vehicle. 车载逆变器的一个关键要求是能够提供可靠稳定的电源输出,以确保车辆内的电子设备正常工作。

Another important aspect to consider when designing car inverters is their efficiency in converting DC power to AC power, as this can have a significant impact on the vehicle's overall energy consumption. 另一个设计车载逆变器时需要考虑的重要方面是它们在将直流电源转换为交流电源时的效率,因为这可能会对车辆的整体能耗产生显著影响。

In addition, car inverters should be durable and able to withstand the harsh conditions of automotive environments, such as temperaturevariations, vibrations, and moisture. 此外,车载逆变器应该具有耐用性,能够经受住汽车环境的严苛条件,如温度变化、振动和潮湿。