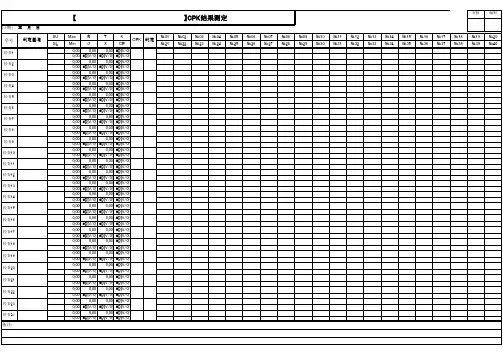

CPK机台稳定性尺寸调查表)

- 格式:xls

- 大小:27.50 KB

- 文档页数:1

cpk规格上限与下限的计算摘要:1.引言2.CPK 规格上限与下限的定义3.CPK 规格上限的计算方法4.CPK 规格下限的计算方法5.计算实例6.总结正文:1.引言在制造业中,过程能力指数(CPK)是用于衡量一个过程生产稳定性和加工精度的重要指标。

CPK 指标包括规格上限和下限,它们可以判断过程是否处于受控状态,以及产品的质量是否达到要求。

本文将介绍如何计算CPK 规格上限与下限。

2.CPK 规格上限与下限的定义CPK 规格上限是指过程能够生产的最大值,即过程的最大容忍值;CPK 规格下限是指过程能够生产的最小值,即过程的最小容忍值。

3.CPK 规格上限的计算方法CPK 规格上限的计算公式为:上限= 公差上限- 过程标准差其中,公差上限是指产品尺寸允许的最大偏差,过程标准差是指过程的波动程度。

通过这个公式,我们可以计算出CPK 规格上限,从而判断过程是否能够满足产品的尺寸要求。

4.CPK 规格下限的计算方法CPK 规格下限的计算公式为:下限= 公差下限- 过程标准差其中,公差下限是指产品尺寸允许的最小偏差,过程标准差同样是指过程的波动程度。

通过这个公式,我们可以计算出CPK 规格下限,从而判断过程是否能够满足产品的尺寸要求。

5.计算实例假设某个产品的尺寸公差为±0.05mm,过程标准差为0.03mm,那么:CPK 规格上限= 0.05 - 0.03 = 0.02mmCPK 规格下限= -0.05 - 0.03 = -0.08mm可见,该过程的规格上限为0.02mm,规格下限为-0.08mm。

这意味着该过程的尺寸稳定性较好,产品尺寸基本能满足要求。

6.总结通过计算CPK 规格上限与下限,我们可以了解过程的尺寸稳定性和加工精度,从而判断产品是否达到质量要求。

文件属性:系统文件版本号: A / 0 页次: 1 / 6编制部门:第三事业部品质部QP科适用范围:第三事业部华为业务拟稿人:乐来兵发行:第三事业部文控中心受控状态:☐非受控☑受控受控号:密级设定:□一级(绝密)□二级(机密)☑三级(秘密)□四级(一般)文件发行/修订履历版本号发行日期修改内容拟稿审核批准A/0 首次发行乐来兵刘波王江文件属性:系统文件版本号: A / 0 页次: 2 / 6章节号内容页次1 目的 22 适用范围 23 参考文件 24 定义 25 职责2-36 程序3-67 附件 61 目的本规范规定了终端结构件产品在试制、爬坡和量产阶段Cpk 的要求,包括抽样方法、报告的产生及Cpk异常时处理方法、及爬坡、量产时的 SPC 管理方法,以推动 Cpk、SPC 在生产过程的合理应用,有效监控品质趋势,确保量产的制程稳定性。

2 适用范围华为产品结构件的冲压、注塑成型及部分机加工物料。

3 参考文件3.1 《SPC应用及管理程序》(MSP-18-D03-0-18)4 术语与定义Cpk 制程能力指数,用一个数值来表达制程的水准, Cpk = (1-|Ca|)*Cp,。

;SPC 统计制程控制,用于确认产品生产的制程是否达到统计制程状态的质量应用工具;Ca 表示制程特性中心位置的偏移程度,代表制程准确度,Ca=(实际平均值-规格中心值)/ (规格公差/2);Cp 表征工艺或设备的相对于允许规格的能力,代表制程精密度,体现为数据的离散程序,CP=∣规格公差(规格上限-规格下限)/ (6*Sigma );δ(Sigma) 标准差,体现机台设备精密度最重要的指标,数值越小说明距均值越集中。

CL:控制中心线,非规格中心值,而制程稳定后的数据求均值u计算得出,CL=u 。

UCL: 上控制界限,UCL= CL+3Sigma;LCL: 下控制界限,LCL= CL-3Sigma;5 职责5.1 NPI :文件属性:系统文件版本号: A / 0 页次: 3 / 65.1.1 跟进项目总体进度,对工程图上Cpk/SPC尺寸合理性评估并向华为研发提出改进建议;5.1.2 协调SPC / Cpk管控过程中的问题,与客户进行沟通。

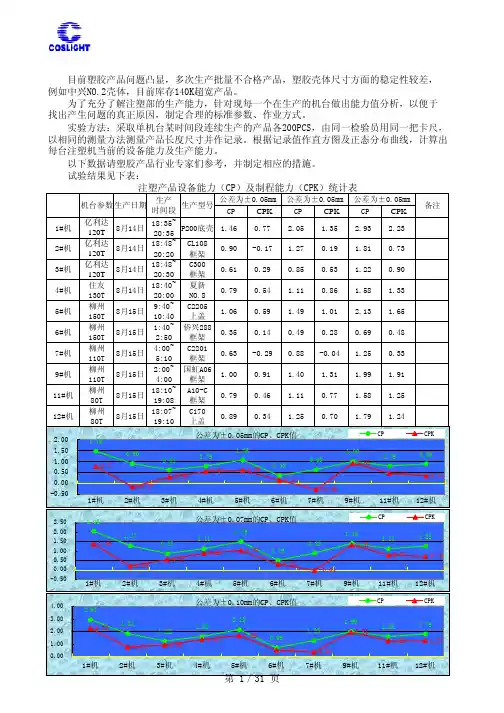

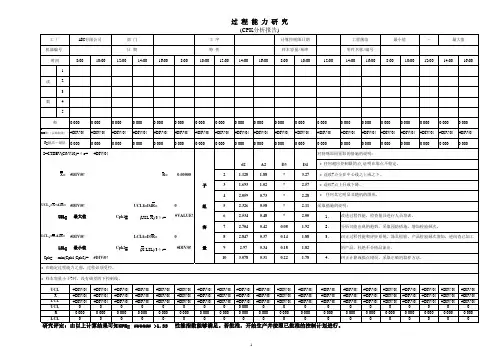

珠海光宇电子科技有限公司品质部 林奉斌目前塑胶产品问题凸显,多次生产批量不合格产品,塑胶壳体尺寸方面的稳定性较差,例如中兴NO.2壳体,目前库存140K超宽产品。

为了充分了解注塑部的生产能力,针对现每一个在生产的机台做出能力值分析,以便于找出产生问题的真正原因,制定合理的标准参数、作业方式。

实验方法:采取单机台某时间段连续生产的产品各200PCS,由同一检验员用同一把卡尺,以相同的测量方法测量产品长度尺寸并作记录。

根据记录值作直方图及正态分布曲线,计算出每台注塑机当前的设备能力及生产能力。

以下数据请塑胶产品行业专家们参考,并制定相应的措施。

试验结果见下表:CP CPK CP CPK CP CPK 1#机亿利达120T 8月14日18:35~20:35P200底壳 1.460.772.05 1.35 2.93 2.232#机亿利达120T 8月14日18:48~20:20CL108框架0.90-0.171.270.19 1.810.733#机亿利达120T 8月14日18:48~20:30C300框架0.610.290.850.53 1.220.904#机住友130T 8月14日18:40~20:00夏新NO.80.790.541.110.86 1.58 1.335#机柳州150T 8月15日9:40~10:40C2205上盖 1.060.591.49 1.012.13 1.656#机柳州150T 8月15日1:40~2:50侨兴288框架0.350.140.490.280.690.487#机柳州110T 8月15日4:00~5:10C2201框架0.63-0.290.88-0.04 1.250.339#机柳州110T 8月15日2:00~4:00国虹A06框架 1.000.911.40 1.31 1.99 1.9111#机柳州80T 8月15日18:10~19:08A10-C框架0.790.461.110.77 1.58 1.2512#机柳州80T8月15日18:07~19:10C170上盖0.890.341.250.701.791.24机台参数生产型号生产时间段塑胶产品生产能力CPK分析报告公差为±0.05mm 公差为±0.05mm公差为±0.05mm备注注塑产品设备能力(CP)及制程能力(CPK)统计表生产日期公差为±0.05mm的CP、CPK值1.460.900.610.791.060.350.631.000.790.890.77-0.170.290.540.590.14-0.290.910.460.34-0.500.000.501.001.502.001#机2#机3#机4#机5#机6#机7#机9#机11#机12#机CPCPK 公差为±0.07mm的CP、CPK值2.051.270.851.111.490.490.881.401.111.251.350.190.530.861.010.28-0.04 1.310.770.70-0.500.000.501.001.502.002.501#机2#机3#机4#机5#机6#机7#机9#机11#机12#机CPCPK 公差为±0.10mm的CP、CPK值2.931.811.221.582.130.691.251.991.581.792.230.730.901.331.650.480.33 1.911.251.240.001.002.003.004.001#机2#机3#机4#机5#机6#机7#机9#机11#机12#机CPCPK日 期:2006.08.14生产时间段:18:35-20:35品 名:中兴P200底壳 机台号:1#机台参数:亿利达120T 样本数:200不良数:1不良率:0.50%尺寸上限:58.90尺寸下限:58.80最大值:58.92最小值:58.85平均值:58.874标准差:Cp : 1.46U_Cpk :0.77L_Cpk :2.16Cpk :0.77——————————————————————————————————————————12345678910158.8658.8758.8858.8758.8858.8758.8858.8658.8858.87258.8758.8958.8958.8758.8858.8858.8858.8658.8758.87358.8658.8858.8858.8658.8858.8858.8658.8958.8858.88458.8658.8858.8758.8658.8958.8858.8758.8758.8858.86558.8858.8958.8858.8658.8758.8758.8758.8858.8858.87658.8958.8558.8758.8658.8758.8758.8958.8758.8658.87758.9258.8858.8658.8858.8858.8858.9058.8658.8658.86858.8758.9058.8658.8858.8858.8758.8758.8858.8758.86958.8758.8858.8758.8858.8858.8758.8658.8858.8758.861058.8658.8758.8758.8858.8758.8858.8758.8758.8758.851158.8558.8658.8758.8958.8858.8758.8758.8758.8658.881258.8758.8958.9058.9058.8958.8758.8758.8758.8858.881358.8758.8858.8858.9058.9058.8758.8858.8858.8658.861458.8858.8758.8758.8958.8658.8858.8658.8758.8958.871558.8858.8758.8658.8958.8858.8858.8658.8858.8958.881658.8758.8858.8758.9058.8858.8658.8558.8658.8858.861758.8758.8858.8858.8758.8958.8758.8658.8958.8658.891858.8858.8658.8758.8958.8858.8958.8858.8758.8658.881958.8758.8658.8658.8858.8858.8858.8658.8858.8558.882058.8858.8758.8758.8758.8658.8658.8858.8758.8758.870.011458.9458.9258.9058.8858.8658.8458.8258.80USLLSLProcess Capability Analysis for 中兴P200底壳长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPLCPU CpStDev (LT)StDev (ST)Sample N Mean LSL Target USL 11076.5411076.54 0.0011357.7511357.75 0.00 5000.005000.00 0.000.762.150.761.46 *0.772.160.771.460.01143050.011478420058.873858.8000 *58.9000Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:35-20:35品 名:中兴P200底壳 机台号:1#机台参数:亿利达120T 样本数:200不良数:0不良率:0.00%尺寸上限:58.92尺寸下限:58.78最大值:58.92最小值:58.85平均值:58.874标准差:Cp : 2.05U_Cpk : 1.35L_Cpk :2.75Cpk : 1.35——————————————————————————————————————————12345678910158.8658.8758.8858.8758.8858.8758.8858.8658.8858.87258.8758.8958.8958.8758.8858.8858.8858.8658.8758.87358.8658.8858.8858.8658.8858.8858.8658.8958.8858.88458.8658.8858.8758.8658.8958.8858.8758.8758.8858.86558.8858.8958.8858.8658.8758.8758.8758.8858.8858.87658.8958.8558.8758.8658.8758.8758.8958.8758.8658.87758.9258.8858.8658.8858.8858.8858.9058.8658.8658.86858.8758.9058.8658.8858.8858.8758.8758.8858.8758.86958.8758.8858.8758.8858.8858.8758.8658.8858.8758.861058.8658.8758.8758.8858.8758.8858.8758.8758.8758.851158.8558.8658.8758.8958.8858.8758.8758.8758.8658.881258.8758.8958.9058.9058.8958.8758.8758.8758.8858.881358.8758.8858.8858.9058.9058.8758.8858.8858.8658.861458.8858.8758.8758.8958.8658.8858.8658.8758.8958.871558.8858.8758.8658.8958.8858.8858.8658.8858.8958.881658.8758.8858.8758.9058.8858.8658.8558.8658.8858.861758.8758.8858.8858.8758.8958.8758.8658.8958.8658.891858.8858.8658.8758.8958.8858.8958.8858.8758.8658.881958.8758.8658.8658.8858.8858.8858.8658.8858.8558.882058.8858.8758.8758.8758.8658.8658.8858.8758.8758.870.011458.9458.9258.9058.8858.8658.8458.8258.8058.78USLLSLProcess Capability Analysis for 中兴P200底壳长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPLCPU CpStDev (LT)StDev (ST)Sample N Mean LSL Target USL 27.0227.02 0.0029.0329.03 0.00 0.000.00 0.001.352.741.352.04 *1.352.751.352.050.01143050.011478420058.873858.7800 *58.9200Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:35-20:35品 名:中兴P200底壳 机台号:1#机台参数:亿利达120T 样本数:200不良数:0不良率:0.00%尺寸上限:58.95尺寸下限:58.75最大值:58.92最小值:58.85平均值:58.874标准差:Cp :2.93U_Cpk :2.23L_Cpk :3.63Cpk :2.23——————————————————————————————————————————12345678910158.8658.8758.8858.8758.8858.8758.8858.8658.8858.87258.8758.8958.8958.8758.8858.8858.8858.8658.8758.87358.8658.8858.8858.8658.8858.8858.8658.8958.8858.88458.8658.8858.8758.8658.8958.8858.8758.8758.8858.86558.8858.8958.8858.8658.8758.8758.8758.8858.8858.87658.8958.8558.8758.8658.8758.8758.8958.8758.8658.87758.9258.8858.8658.8858.8858.8858.9058.8658.8658.86858.8758.9058.8658.8858.8858.8758.8758.8858.8758.86958.8758.8858.8758.8858.8858.8758.8658.8858.8758.861058.8658.8758.8758.8858.8758.8858.8758.8758.8758.851158.8558.8658.8758.8958.8858.8758.8758.8758.8658.881258.8758.8958.9058.9058.8958.8758.8758.8758.8858.881358.8758.8858.8858.9058.9058.8758.8858.8858.8658.861458.8858.8758.8758.8958.8658.8858.8658.8758.8958.871558.8858.8758.8658.8958.8858.8858.8658.8858.8958.881658.8758.8858.8758.9058.8858.8658.8558.8658.8858.861758.8758.8858.8858.8758.8958.8758.8658.8958.8658.891858.8858.8658.8758.8958.8858.8958.8858.8758.8658.881958.8758.8658.8658.8858.8858.8858.8658.8858.8558.882058.8858.8758.8758.8758.8658.8658.8858.8758.8758.870.011458.9558.9058.8558.8058.75USLLSLProcess Capability Analysis for 中兴P200底壳长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPL CPU Cp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 0.000.000.000.000.000.000.000.000.002.223.612.222.92 *2.233.632.232.930.01143050.011478420058.873858.7500 *58.9500Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:48-20:20品 名:CL108 机台号:2#机台参数:亿利达120T 样本数:200不良数:118不良率:59.00%尺寸上限:53.90尺寸下限:53.80最大值:53.98最小值:53.80平均值:53.909标准差:Cp :0.90U_Cpk :-0.17L_Cpk :1.98Cpk :-0.17——————————————————————————————————————————12345678910153.9053.8953.9153.9153.8853.9253.8853.9053.9153.90253.9253.8853.9153.9553.9053.9053.9253.9353.9053.89353.8953.8953.8953.9453.9153.9253.9253.9053.9253.91453.8853.9053.9353.9053.9153.9153.9153.9053.9453.89553.9153.8953.9153.8953.9153.9253.9253.9053.9053.93653.9153.9153.8953.9053.9053.9353.9153.9153.9253.91753.9253.9353.9053.9153.9353.8953.9253.9053.9053.91853.9153.9153.9153.8953.9253.9453.9153.9053.9353.91953.9053.9053.9053.8853.9353.9053.9253.9153.9253.891053.9253.9253.9153.9353.9253.9253.9153.9153.8953.921153.9053.8953.9053.9153.9353.9153.9253.9153.9153.911253.9053.9053.9253.9153.9253.9253.9053.9253.9053.901353.9253.8953.9053.9053.9453.9053.8953.9453.9253.901453.9353.9253.9153.9153.9353.9453.9253.9053.9253.921553.8953.9053.8953.9153.9253.9053.9153.9353.8953.801653.9553.9353.8853.9253.9153.8953.8853.9053.9153.901753.8953.9053.9453.9353.9353.9253.9353.9053.9453.891853.9353.8953.9253.9253.9253.9153.9353.9353.9353.901953.9153.9053.9853.9053.9053.8453.9053.9353.9253.93200.0184深爱CL108框架长度尺寸CPK分析(公差0.1)54.0053.9553.9053.8553.80USLLSLProcess Capability Analysis for 深爱CL108框架长度PPM Total PPM > USL PPM < LSL PPM Total PPM > USL PPM < LSL PPM Total PPM > USL PPM < LSL Ppk PPL PPU Pp CpmCpk CPL CPU Cp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 694322.83694322.83 0.00694535.08694535.08 0.00590000.00590000.00 0.00-0.171.97-0.17 0.90 *-0.17 1.97-0.17 0.900.01849880.018476820053.909453.8000 *53.9000Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) Capability Process DataST LT日 期:2006.08.14生产时间段:18:48-20:20品 名:CL108 机台号:2#机台参数:亿利达120T 样本数:200不良数:35不良率:17.50%尺寸上限:53.92尺寸下限:53.78最大值:53.98最小值:53.80平均值:53.909标准差:Cp : 1.27U_Cpk :0.19L_Cpk :2.34Cpk :0.19——————————————————————————————————————————12345678910153.9053.8953.9153.9153.8853.9253.8853.9053.9153.90253.9253.8853.9153.9553.9053.9053.9253.9353.9053.89353.8953.8953.8953.9453.9153.9253.9253.9053.9253.91453.8853.9053.9353.9053.9153.9153.9153.9053.9453.89553.9153.8953.9153.8953.9153.9253.9253.9053.9053.93653.9153.9153.8953.9053.9053.9353.9153.9153.9253.91753.9253.9353.9053.9153.9353.8953.9253.9053.9053.91853.9153.9153.9153.8953.9253.9453.9153.9053.9353.91953.9053.9053.9053.8853.9353.9053.9253.9153.9253.891053.9253.9253.9153.9353.9253.9253.9153.9153.8953.921153.9053.8953.9053.9153.9353.9153.9253.9153.9153.911253.9053.9053.9253.9153.9253.9253.9053.9253.9053.901353.9253.8953.9053.9053.9453.9053.8953.9453.9253.901453.9353.9253.9153.9153.9353.9453.9253.9053.9253.921553.8953.9053.8953.9153.9253.9053.9153.9353.8953.801653.9553.9353.8853.9253.9153.8953.8853.9053.9153.901753.8953.9053.9453.9353.9353.9253.9353.9053.9453.891853.9353.8953.9253.9253.9253.9153.9353.9353.9353.901953.9153.9053.9853.9053.9053.8453.9053.9353.9253.932053.9353.9253.9153.8853.9053.9053.9053.9253.8853.920.0184深爱CL108框架长度尺寸CPK分析(公差0.14)54.0053.9553.9053.8553.80USLLSLProcess Capability Analysis for 深爱CL108框架长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPL CPU Cp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 283318.87283318.87 0.00283087.79283087.79 0.00175000.00175000.00 0.000.192.330.191.26 *0.192.340.191.270.01849880.018476820053.909453.7800 *53.9200Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:48-20:20品 名:CL108 机台号:2#机台参数:亿利达120T 样本数:200不良数:1不良率:0.50%尺寸上限:53.95尺寸下限:53.75最大值:53.98最小值:53.80平均值:53.909标准差:Cp : 1.81U_Cpk :0.73L_Cpk :2.88Cpk :0.73——————————————————————————————————————————12345678910153.9053.8953.9153.9153.8853.9253.8853.9053.9153.90253.9253.8853.9153.9553.9053.9053.9253.9353.9053.89353.8953.8953.8953.9453.9153.9253.9253.9053.9253.91453.8853.9053.9353.9053.9153.9153.9153.9053.9453.89553.9153.8953.9153.8953.9153.9253.9253.9053.9053.93653.9153.9153.8953.9053.9053.9353.9153.9153.9253.91753.9253.9353.9053.9153.9353.8953.9253.9053.9053.91853.9153.9153.9153.8953.9253.9453.9153.9053.9353.91953.9053.9053.9053.8853.9353.9053.9253.9153.9253.891053.9253.9253.9153.9353.9253.9253.9153.9153.8953.921153.9053.8953.9053.9153.9353.9153.9253.9153.9153.911253.9053.9053.9253.9153.9253.9253.9053.9253.9053.901353.9253.8953.9053.9053.9453.9053.8953.9453.9253.901453.9353.9253.9153.9153.9353.9453.9253.9053.9253.921553.8953.9053.8953.9153.9253.9053.9153.9353.8953.801653.9553.9353.8853.9253.9153.8953.8853.9053.9153.901753.8953.9053.9453.9353.9353.9253.9353.9053.9453.891853.9353.8953.9253.9253.9253.9153.9353.9353.9353.901953.9153.9053.9853.9053.9053.8453.9053.9353.9253.932053.9353.9253.9153.8853.9053.9053.9053.9253.8853.920.018454.0053.9553.9053.8553.8053.75USLLSLProcess Capability Analysis for 深爱CL108框架长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPL CPUCp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 14091.2214091.22 0.0013997.6413997.64 0.00 5000.005000.00 0.000.732.870.731.80 *0.732.880.731.810.01849880.018476820053.909453.7500 *53.9500Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:48-20:30品 名:华为C330框架 机台号:3#机台参数:亿利达120T 样本数:200不良数:19不良率:9.50%尺寸上限:57.24尺寸下限:57.14最大值:57.28最小值:57.14平均值:57.216标准差:Cp :0.61U_Cpk :0.29L_Cpk :0.93Cpk :0.29——————————————————————————————————————————12345678910157.2557.1957.1757.1957.2057.1657.2557.2257.2457.18257.2757.2257.2157.2457.2357.1857.1857.2357.2457.23357.2857.2357.1957.2357.2457.1457.2557.2457.2157.19457.2057.2457.1957.2357.2257.2357.2457.2357.2557.18557.2357.2557.2457.2257.2357.2457.2057.2157.2357.24657.2257.2457.2457.1857.1557.2157.1557.2257.2157.25757.2157.2257.2457.2457.2157.2457.2557.2557.2057.24857.1657.2257.2457.1957.2257.2457.2057.2057.2157.25957.2557.2157.2057.2457.2357.2257.2257.2157.1857.161057.2357.2357.2257.1857.2357.2357.2457.2457.2457.241157.2257.2357.1957.2357.2357.2157.2557.2157.2357.191257.1857.2157.2457.2457.2357.2357.2057.2357.2057.161357.2457.2357.1657.2457.1457.2057.2457.2157.2557.251457.2357.2157.2057.2257.1857.2357.2057.2057.2457.211557.2257.2457.2357.1557.2457.2057.2357.1857.2557.231657.2257.2257.2557.2457.2257.2457.2457.2057.2357.191757.1857.2457.1857.1857.2457.2157.2357.2057.2157.141857.2357.2457.2357.2057.2257.1957.2557.1457.2357.231957.1957.2057.2057.2157.2257.1957.2557.2257.2357.232057.1557.2157.1557.2357.2357.2357.2257.2057.2257.230.027457.3257.2757.2257.1757.12USLLSLProcess Capability Analysis for 华为C330框架长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPL CPUCp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 197399.40194672.75 2726.64199097.40196215.49 2881.91 95000.0095000.00 0.000.290.930.290.61 *0.290.930.290.610.02747430.027*********.216357.1400 *57.2400Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:48-20:30品 名:华为C330框架 机台号:3#机台参数:亿利达120T 样本数:200不良数:2不良率: 1.00%尺寸上限:57.26尺寸下限:57.12最大值:57.28最小值:57.14平均值:57.216标准差:Cp :0.85U_Cpk :0.53L_Cpk :1.17Cpk :0.53——————————————————————————————————————————12345678910157.2557.1957.1757.1957.2057.1657.2557.2257.2457.18257.2757.2257.2157.2457.2357.1857.1857.2357.2457.23357.2857.2357.1957.2357.2457.1457.2557.2457.2157.19457.2057.2457.1957.2357.2257.2357.2457.2357.2557.18557.2357.2557.2457.2257.2357.2457.2057.2157.2357.24657.2257.2457.2457.1857.1557.2157.1557.2257.2157.25757.2157.2257.2457.2457.2157.2457.2557.2557.2057.24857.1657.2257.2457.1957.2257.2457.2057.2057.2157.25957.2557.2157.2057.2457.2357.2257.2257.2157.1857.161057.2357.2357.2257.1857.2357.2357.2457.2457.2457.241157.2257.2357.1957.2357.2357.2157.2557.2157.2357.191257.1857.2157.2457.2457.2357.2357.2057.2357.2057.161357.2457.2357.1657.2457.1457.2057.2457.2157.2557.251457.2357.2157.2057.2257.1857.2357.2057.2057.2457.211557.2257.2457.2357.1557.2457.2057.2357.1857.2557.231657.2257.2257.2557.2457.2257.2457.2457.2057.2357.191757.1857.2457.1857.1857.2457.2157.2357.2057.2157.141857.2357.2457.2357.2057.2257.1957.2557.1457.2357.231957.1957.2057.2057.2157.2257.1957.2557.2257.2357.232057.1557.2157.1557.2357.2357.2357.2257.2057.2257.230.027457.3057.2557.2057.1557.10USLLSLProcess Capability Analysis for 华为C330框架长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPL CPUCp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 56284.1556057.48 226.6757478.5457231.69 246.8510000.0010000.00 0.000.531.170.530.85 *0.531.170.530.850.02747430.027*********.216357.1200 *57.2600Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:48-20:30品 名:华为C330框架 机台号:3#机台参数:亿利达120T 样本数:200不良数:0不良率:0.00%尺寸上限:57.29尺寸下限:57.09最大值:57.28最小值:57.14平均值:57.216标准差:Cp : 1.22U_Cpk :0.90L_Cpk :1.54Cpk :0.90——————————————————————————————————————————12345678910157.2557.1957.1757.1957.2057.1657.2557.2257.2457.18257.2757.2257.2157.2457.2357.1857.1857.2357.2457.23357.2857.2357.1957.2357.2457.1457.2557.2457.2157.19457.2057.2457.1957.2357.2257.2357.2457.2357.2557.18557.2357.2557.2457.2257.2357.2457.2057.2157.2357.24657.2257.2457.2457.1857.1557.2157.1557.2257.2157.25757.2157.2257.2457.2457.2157.2457.2557.2557.2057.24857.1657.2257.2457.1957.2257.2457.2057.2057.2157.25957.2557.2157.2057.2457.2357.2257.2257.2157.1857.161057.2357.2357.2257.1857.2357.2357.2457.2457.2457.241157.2257.2357.1957.2357.2357.2157.2557.2157.2357.191257.1857.2157.2457.2457.2357.2357.2057.2357.2057.161357.2457.2357.1657.2457.1457.2057.2457.2157.2557.251457.2357.2157.2057.2257.1857.2357.2057.2057.2457.211557.2257.2457.2357.1557.2457.2057.2357.1857.2557.231657.2257.2257.2557.2457.2257.2457.2457.2057.2357.191757.1857.2457.1857.1857.2457.2157.2357.2057.2157.141857.2357.2457.2357.2057.2257.1957.2557.1457.2357.231957.1957.2057.2057.2157.2257.1957.2557.2257.2357.232057.1557.2157.1557.2357.2357.2357.2257.2057.2257.230.027457.3057.2557.2057.1557.10USLLSLProcess Capability Analysis for 华为C330框架长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPLCPU CpStDev (LT)StDev (ST)Sample N Mean LSL Target USL 3675.673673.54 2.123871.523869.07 2.45 0.000.00 0.000.891.530.891.21 *0.901.540.901.220.02747430.027*********.216357.0900 *57.2900Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT珠海光宇电子科技有限公司品质部 林奉斌日 期:2006.08.14生产时间段:18:40-20:00品 名:夏新NO.8 机台号:4#机台参数:住友130T 样本数:200不良数:3不良率: 1.50%尺寸上限:38.45尺寸下限:38.35最大值:38.45最小值:38.33平均值:38.384标准差:Cp :0.79U_Cpk : 1.03L_Cpk :0.54Cpk :0.54——————————————————————————————————————————12345678910138.3638.3638.4138.3738.3938.3938.4138.3838.4138.42238.3338.3738.3638.3538.3638.3938.4138.3938.3938.41338.3538.3838.3738.3738.3938.3938.3738.3738.4138.37438.3638.4138.3738.3838.4138.4038.3738.4038.3938.38538.3738.4038.3638.3938.4238.3638.4138.4038.4138.41638.3538.4238.3538.3738.3638.3738.4138.3838.4138.41738.3638.4138.3538.4038.3538.3938.3838.4038.4138.38838.3638.3938.3838.3938.3738.3738.3738.4138.3938.41938.3638.3838.3438.3838.3938.3738.4038.4138.4138.411038.3538.3938.3738.4138.3838.3838.3938.4138.3838.411138.3838.3738.3738.4138.3838.4138.3738.3638.4138.381238.3638.3738.3738.4138.3638.3738.4138.4238.3838.421338.3738.3938.3738.3738.3538.3838.3838.3838.3938.411438.3838.3738.3838.3538.3538.3838.3838.4138.4238.381538.3938.3638.4038.3738.3638.4138.3838.3938.3938.391638.4138.4138.4138.3638.3638.4138.4138.4138.4138.401738.4038.3938.3538.3638.4138.3838.4138.3738.4138.371838.4038.4138.3738.3738.3738.3938.4138.3738.4238.371938.3638.3938.3638.3838.3638.3838.3838.4138.3438.382038.4538.3838.3738.3838.3738.4138.3838.3638.3738.370.0211夏新NO.8框架长度尺寸CPK分析(公差0.1)38.4638.4438.4238.4038.3838.3638.3438.3238.30USLLSLProcess Capability Analysis for 夏新NO.8框架长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPL CPU Cp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 52998.67989.8052008.8655435.491132.9654302.5315000.000.0015000.000.540.541.030.79 *0.540.541.030.790.02119110.021*********.384438.3500 *38.4500Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:40-20:00品 名:夏新NO.8 机台号:4#机台参数:住友130T 样本数:200不良数:0不良率:0.00%尺寸上限:38.47尺寸下限:38.33最大值:38.45最小值:38.33平均值:38.384标准差:Cp : 1.11U_Cpk :1.35L_Cpk :0.86Cpk :0.86——————————————————————————————————————————12345678910138.3638.3638.4138.3738.3938.3938.4138.3838.4138.42238.3338.3738.3638.3538.3638.3938.4138.3938.3938.41338.3538.3838.3738.3738.3938.3938.3738.3738.4138.37438.3638.4138.3738.3838.4138.4038.3738.4038.3938.38538.3738.4038.3638.3938.4238.3638.4138.4038.4138.41638.3538.4238.3538.3738.3638.3738.4138.3838.4138.41738.3638.4138.3538.4038.3538.3938.3838.4038.4138.38838.3638.3938.3838.3938.3738.3738.3738.4138.3938.41938.3638.3838.3438.3838.3938.3738.4038.4138.4138.411038.3538.3938.3738.4138.3838.3838.3938.4138.3838.411138.3838.3738.3738.4138.3838.4138.3738.3638.4138.381238.3638.3738.3738.4138.3638.3738.4138.4238.3838.421338.3738.3938.3738.3738.3538.3838.3838.3838.3938.411438.3838.3738.3838.3538.3538.3838.3838.4138.4238.381538.3938.3638.4038.3738.3638.4138.3838.3938.3938.391638.4138.4138.4138.3638.3638.4138.4138.4138.4138.401738.4038.3938.3538.3638.4138.3838.4138.3738.4138.371838.4038.4138.3738.3738.3738.3938.4138.3738.4238.371938.3638.3938.3638.3838.3638.3838.3838.4138.3438.3838.4538.3838.3738.3838.3738.4138.3838.3638.3738.370.021138.47538.45038.42538.40038.37538.35038.32538.300USLLSL Process Capability Analysis for 夏新NO.8框架长度尺寸PPM TotalPPM > USL PPM < LSL PPM TotalPPM > USL PPM < LSL PPM TotalPPM > USL PPM < LSL PpkPPL PPU Pp CpmCpk CPL CPU Cp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 5119.7627.065092.695640.3733.825606.55 0.000.00 0.000.860.861.351.10 *0.860.861.351.110.02119110.021*********.384438.3300 *38.4700Ex pected LT Performance Ex pected ST Performance Observ ed Performance Ov erall (LT) Capability Potential (ST) CapabilityProcess DataST LT日 期:2006.08.14生产时间段:18:40-20:00品 名:夏新NO.8 机台号:4#机台参数:住友130T 样本数:200不良数:0不良率:0.00%尺寸上限:38.47尺寸下限:38.33最大值:38.45最小值:38.33平均值:38.384标准差:Cp : 1.11U_Cpk :1.35L_Cpk :0.86Cpk :0.86——————————————————————————————————————————12345678910138.3638.3638.4138.3738.3938.3938.4138.3838.4138.42238.3338.3738.3638.3538.3638.3938.4138.3938.3938.41338.3538.3838.3738.3738.3938.3938.3738.3738.4138.37438.3638.4138.3738.3838.4138.4038.3738.4038.3938.38538.3738.4038.3638.3938.4238.3638.4138.4038.4138.41638.3538.4238.3538.3738.3638.3738.4138.3838.4138.41738.3638.4138.3538.4038.3538.3938.3838.4038.4138.38838.3638.3938.3838.3938.3738.3738.3738.4138.3938.41938.3638.3838.3438.3838.3938.3738.4038.4138.4138.411038.3538.3938.3738.4138.3838.3838.3938.4138.3838.411138.3838.3738.3738.4138.3838.4138.3738.3638.4138.381238.3638.3738.3738.4138.3638.3738.4138.4238.3838.421338.3738.3938.3738.3738.3538.3838.3838.3838.3938.411438.3838.3738.3838.3538.3538.3838.3838.4138.4238.381538.3938.3638.4038.3738.3638.4138.3838.3938.3938.391638.4138.4138.4138.3638.3638.4138.4138.4138.4138.401738.4038.3938.3538.3638.4138.3838.4138.3738.4138.371838.4038.4138.3738.3738.3738.3938.4138.3738.4238.371938.3638.3938.3638.3838.3638.3838.3838.4138.3438.3838.4538.3838.3738.3838.3738.4138.3838.3638.3738.370.021138.47538.45038.42538.40038.37538.35038.32538.300USLLSL Process Capability Analysis for 夏新NO.8框架长度尺寸PPM TotalPPM > USL PPM < LSL PPM TotalPPM > USL PPM < LSL PPM TotalPPM > USL PPM < LSL PpkPPL PPU Pp CpmCpk CPL CPU Cp StDev (LT)StDev (ST)Sample N Mean LSL Target USL 5119.7627.065092.695640.3733.825606.55 0.000.00 0.000.860.861.351.10 *0.860.861.351.110.02119110.021*********.384438.3300 *38.4700Ex pected LT Performance Ex pected ST Performance Observ ed Performance Ov erall (LT) Capability Potential (ST) CapabilityProcess DataST LT日 期:2006.08.15生产时间段:09:40-10:40品 名:华为C2205上盖 机台号:5#机台参数:柳州150T 样本数:200不良数:1不良率:0.50%尺寸上限:34.35尺寸下限:34.25最大值:34.36最小值:34.30平均值:34.322标准差:Cp : 1.06U_Cpk :0.59L_Cpk :1.54Cpk :0.59——————————————————————————————————————————12345678910134.3234.3234.3334.3134.3234.3334.3334.3434.3234.31234.3134.3034.3034.3234.3434.3034.3134.3034.3034.33334.3434.3334.3234.3534.3234.3134.3234.3134.3134.33434.3334.3134.3234.3234.3134.3134.3334.3334.3134.33534.3534.3234.3434.3234.3234.3234.3434.3134.3434.30634.3334.3134.3234.3334.3034.3034.3434.3334.3134.34734.3034.3534.3034.3134.3034.3334.3234.3134.3534.35834.3334.3134.3034.3034.3534.3234.3534.3234.3334.33934.3434.3234.3234.3334.3234.3134.3534.3134.3534.351034.3234.3134.3434.3334.3134.3234.3034.3134.3134.341134.3134.3134.3334.3034.3234.3434.3334.3034.3234.321234.3234.3034.3434.3434.3534.3534.3434.3234.3134.301334.3034.3134.3234.3434.3534.3134.3134.3134.3234.341434.3234.3334.3334.3034.3234.3134.3534.3334.3434.331534.3034.3134.3034.3134.3334.3534.3134.3334.3434.311634.3234.3134.3034.3534.3534.3234.3234.3434.3534.331734.3034.3534.3534.3034.3234.3134.3134.3134.3034.351834.3134.3334.3134.3234.3034.3234.3234.3234.3134.331934.3334.3134.3034.3234.3034.3334.3134.3334.3634.352034.3134.3334.3334.3434.3234.3434.3334.3134.3134.330.015734.3734.3534.3334.3134.2934.2734.25USLLSLProcess Capability Analysis for 华为C2205上盖长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPLCPU CpStDev (LT)StDev (ST)Sample N Mean LSL Target USL 39164.2939162.12 2.1640678.3840675.68 2.69 5000.005000.00 0.000.591.530.591.06 *0.591.540.591.060.01573420.015893120034.322334.2500 *34.3500Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT日 期:2006.08.15生产时间段:09:40-10:40品 名:华为C2205上盖 机台号:5#机台参数:柳州150T 样本数:200不良数:0不良率:0.00%尺寸上限:34.37尺寸下限:34.23最大值:34.36最小值:34.30平均值:34.322标准差:Cp : 1.49U_Cpk : 1.01L_Cpk :1.96Cpk : 1.01——————————————————————————————————————————12345678910134.3234.3234.3334.3134.3234.3334.3334.3434.3234.31234.3134.3034.3034.3234.3434.3034.3134.3034.3034.33334.3434.3334.3234.3534.3234.3134.3234.3134.3134.33434.3334.3134.3234.3234.3134.3134.3334.3334.3134.33534.3534.3234.3434.3234.3234.3234.3434.3134.3434.30634.3334.3134.3234.3334.3034.3034.3434.3334.3134.34734.3034.3534.3034.3134.3034.3334.3234.3134.3534.35834.3334.3134.3034.3034.3534.3234.3534.3234.3334.33934.3434.3234.3234.3334.3234.3134.3534.3134.3534.351034.3234.3134.3434.3334.3134.3234.3034.3134.3134.341134.3134.3134.3334.3034.3234.3434.3334.3034.3234.321234.3234.3034.3434.3434.3534.3534.3434.3234.3134.301334.3034.3134.3234.3434.3534.3134.3134.3134.3234.341434.3234.3334.3334.3034.3234.3134.3534.3334.3434.331534.3034.3134.3034.3134.3334.3534.3134.3334.3434.311634.3234.3134.3034.3534.3534.3234.3234.3434.3534.331734.3034.3534.3534.3034.3234.3134.3134.3134.3034.351834.3134.3334.3134.3234.3034.3234.3234.3234.3134.331934.3334.3134.3034.3234.3034.3334.3134.3334.3634.352034.3134.3334.3334.3434.3234.3434.3334.3134.3134.330.015734.3834.3634.3434.3234.3034.2834.2634.2434.22USLLSLProcess Capability Analysis for 华为C2205上盖长度尺寸PPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPPM TotalPPM > USL PPM < LSLPpkPPLPPU PpCpmCpk CPLCPU CpStDev (LT)StDev (ST)Sample N Mean LSL Target USL 1216.281216.28 0.001344.111344.11 0.00 0.000.00 0.001.011.961.011.48 *1.011.961.01.490.01573420.015893120034.322334.2300 *34.3700Ex pected LT PerformanceEx pected ST PerformanceObserv ed PerformanceOv erall (LT) CapabilityPotential (ST) CapabilityProcess DataST LT。

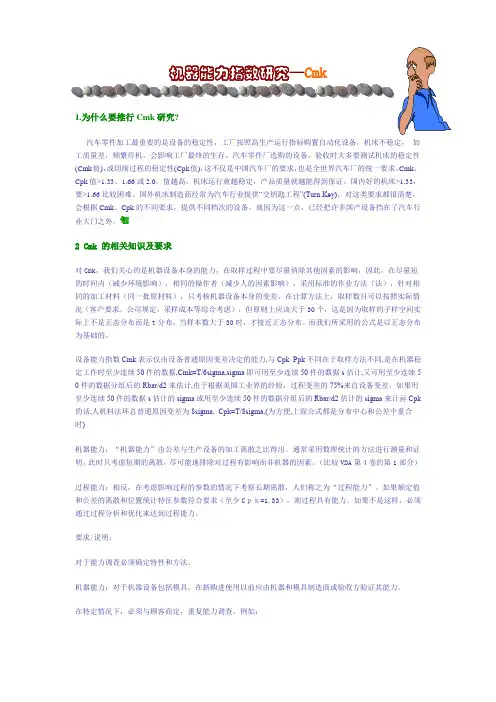

机器能力指数研究—Cmk1.为什么要推行Cmk研究?汽车零件加工最重要的是设备的稳定性,工厂按照高生产运行指标购置自动化设备,机床不稳定,加工质量差,频繁停机,会影响工厂最终的生存。

汽车零件厂选购的设备,验收时大多要测试机床的稳定性(Cmk 值),或切削过程的稳定性(Cpk值),这不仅是中国汽车厂的要求,也是全世界汽车厂的统一要求。

Cmk、Cpk值>1.33、1.66或2.0,值越高,机床运行就越稳定,产品质量就越能得到保证。

国内好的机床>1.33,要>1.66比较困难。

国外机床制造商经常为汽车行业提供“交钥匙工程”(Turn Key),对这类要求都很清楚,会根据Cmk、Cpk的不同要求,提供不同档次的设备。

就因为这一点,已经把许多国产设备挡在了汽车行业大门之外。

2 Cmk 的相关知识及要求对Cmk,我们关心的是机器设备本身的能力,在取样过程中要尽量消除其他因素的影响,因此,在尽量短的时间内(减少环境影响),相同的操作者(减少人的因素影响),采用标准的作业方法(法),针对相同的加工材料(同一批原材料),只考核机器设备本身的变差。

在计算方法上,取样数目可以按照实际情况(客户要求,公司规定,采样成本等综合考虑),但原则上应该大于30个,这是因为取样的子样空间实际上不是正态分布而是t分布,当样本数大于30时,才接近正态分布。

而我们所采用的公式是以正态分布为基础的。

设备能力指数Cmk表示仅由设备普通原因变差决定的能力,与CpkPpk不同在于取样方法不同,是在机器稳定工作时至少连续50件的数据,Cmk=T/6sigma,sigma即可用至少连续50件的数据s估计,又可用至少连续5 0件的数据分组后的Rbar/d2来估计,由于根据美国工业界的经验,过程变差的75%来自设备变差,如果用至少连续50件的数据s估计的sigma或用至少连续50件的数据分组后的Rbar/d2估计的sigma来计祘Cpk 的话,人机料法环总普通原因变差为8sigma, Cpk=T/8sigma,(为方便,上面公式都是分布中心和公差中重合时)机器能力:“机器能力”由公差与生产设备的加工离散之比得出。

Cmk、Cpk、Ppk的区别及应用场景,别在傻傻的分不清!术语解释Cmk 针对对象是--设备对产品质量的能力指数Cmk 是德国汽车行业常采用的参数,称为临界机器能力指数, 是衡量设备运行稳定性的一个指标。

1.CMK仅考虑设备本身对产品结果的影响,因此,在采样时对除设备因素外的其他因素要严加控制;2.CMK考虑的是短期离散,因此取样必须是短时间内取样;3.CMK同时考虑样本分布的平均值与规范中心值的偏移;CMK使用时机1、新机器验收时2、机器大修后3、新产品试制时4、产品不合格追查原因时5、在机械厂应和模具结合在一起考虑CMK使用流程序号工作事项要求备注1人员准备选择技能水平和操作熟练程度高的生产线操作工和质检员消除人员、物料、工艺、环境和生产环境带来的波动2物料准备确保原料稳定性,应做到:1、使用同一批原料,评估期间不换批2、若有条件,评估原料的稳定性,如计算其过程性能指数3环境准备确保生产环境符合工艺要求4工艺准备确保工艺操作标准化,人员操作时严格按照工艺要求执行。

若开工后需要一定时间的稳定,应等工艺稳定后方可实施抽样和测量。

5测量工具准备使用前校准,已确认测量工具带来的误差6抽样方案计算设备能力指数的数据,快速的从生产线上随机抽取。

应做到:1、每分钟抽取一根玻管;2、连续抽取20根消除由于时间延续而带来的不可控异常因素的影响7测量方案确定测量方案,包括:1、确定测量指标,如外径、壁厚2、确定单个产品上的测量点数。

如测量任意值、最大值和最小值。

3、确定测量标准化操作程序4、确定数据修约标准消除测量带来的波动7Cmk计算利用公式计算设备能力指数,可从mintab中实现8评估1、设备能力指数评估分级2、设备能力指数与工序性能指数比较评估设备能力指数通常应高于1.339行动计划根据评估结果确定提升生产工序能力的行动计划。

设备能力不足时,首先应对生产线设备进行全面检修或改造。

行动计划应包含5W2H七要素Cpk 针对对象是--生产系统对产品质量的能力指数CPK是指过程能力指数,是指工序在一定时间里,处于控制状态(稳定状态)下的稳定过程的实际加工能力。

计算CPK的数据取样原则探讨计算Cpk收集数据:子组容量n:最好是在4~5,子组个数k:20~25,子组抽样间隔一般看产品的产量考虑,1hr少于10件8hr 1组1hr10~19pics 4hr 1组1hr20~49pics 2hr 1组1hr大于50pics 1hr 1组抽样一般都是在尽量短的时间完成计算CmK 数据取样原则探讨取样条件:必须是连续加工零件组成,且为单一批量设备必须先进行预热至正常/最佳状态,预热时间视不同设备而具体规定;设备附件:设备之工装、夹具必须为正常/最佳状态(新工装、夹具需使用至寿命5-10%为正常),且在加工过程中不允许改变和损坏,否则需重新开始;生产过程:设备在生产过程内要保持其性能稳定性,(如避免受机械故障;停电;损耗;腐蚀等),否则需重新开始;操作员:只允许指定一名操作人员(为熟练者);检验员:只允许指定一名检验人员(为熟练者);量具:只允许使用一个量具(为合格者);检验过程:保持同一检验方法和检验环境条件不变(如温度、湿度、场地等);零件测量规定在具体确定位置,并保持每次测量均相同。

.在什么情况下要对机器能力进行测试?回答是,在很多情况下都要进行机器能力系数测试,但是,最重要的情况有两种:(1)在最终认可以前,证明新设备是合格的;或者(2)确定工序中新发现的造成工序异常波动的原因。

前提条件:1.在机器能力测试中使用的零件毛坯应从同一供货厂商处购买,并要求其材料相同,由同一浇铸模铸成或由同一套模具配套件制成。

2.前一道工序(前一台机床)所加工出的零件应符合设计和加工要求,其尺寸须符合公差要求。

3.对于所选取的零件数目有如下规定:连续地测量每个产品规格中的50个零件以某种特定的方式记录下来。

(如连续的序数)4.如果一台机床可以加工两种以上的零件,或者是零件编号不同的同种零件,则对其加工的每一种规格的零件都要求做机器能力的测试。

5.在机器能力测试前,如果刀具是未曾使用过的刀具,则要求先用去刀具总寿命的5~10%(因为新的刀具磨损剧烈,故而加工出的产品尺寸极不稳定,当用去刀具总寿命的5~10%以后刀具磨损程度平缓,零件的加工尺寸稳定)。

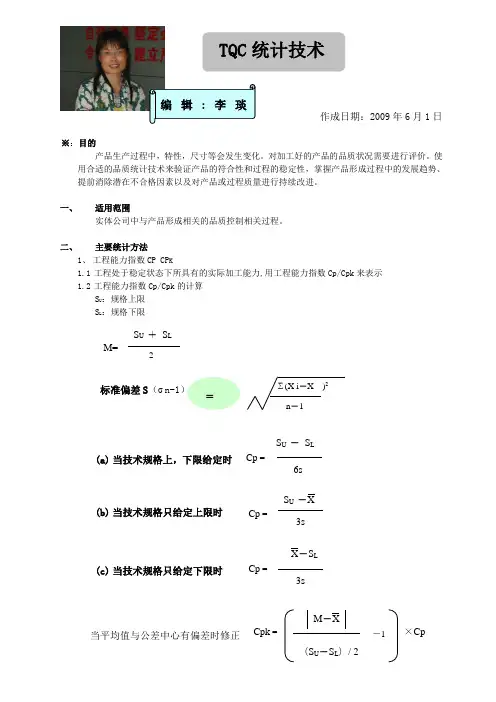

作成日期:2009年6月1日※:目的产品生产过程中,特性,尺寸等会发生变化。

对加工好的产品的品质状况需要进行评价。

使用合适的品质统计技术来验证产品的符合性和过程的稳定性,掌握产品形成过程中的发展趋势、提前消除潜在不合格因素以及对产品或过程质量进行持续改进。

一、 适用范围实体公司中与产品形成相关的品质控制相关过程。

二、 主要统计方法1、 工程能力指数CP CP K1.1 工程处于稳定状态下所具有的实际加工能力,用工程能力指数Cp/Cpk 来表示 1.2 工程能力指数Cp/Cpk 的计算S U :规格上限 S L :规格下限标准偏差S (σ n-1)(a) 当技术规格上,下限给定时(b) 当技术规格只给定上限时(c) 当技术规格只给定下限时当平均值与公差中心有偏差时修正∑(X i -X )2 n -1S U + S L 6s Cp = 2 M= S U - S L3s Cp =S U -X3sCp =X -S LCpk =×Cp(S U -S L )/ 2-1M -X=TQC 统计技术1.3利用Cp/Cpk 值计算结果进行工程能力判定即可实施的事项或过程2、控制图法2.1 控制图的产要用途在于判别生产过程是否处于稳定状态。

主要应用于工序质量诊断、工序质量控制、工序调查、正确指定工序质量标准、工序成本和质量成本的预测2.2控制图通常用点子来反映生产过程的稳定程度。

如果生产过程处于稳定或稳定状态,图中的点子就随机地分散在中心线地两侧附近,越接近上、下控制点,点子就越少。

也就是说,生产过程满足下列条件时,可以认为生产过程处于稳定或控制状态:点子没有超出控制界限;点子地排列没有缺陷(或异常)。

反之,可以判断生产过程受到了系统性地干扰,发生了异常变化,此时,需要查明原因,找出系统性因素并设法消除。

2.4控制图可分为计量控制图和计数值控制图两种。

现行主要采用X-R 图(平均值一极差控制图)来表示。

2.4.1控制图的一般形式2.4.2 X-R 图(平均值-极差控制图)的作成要点2.4.2.1 收集数据:在工序生产条件一定,工序能力充足的条件下,随机收集近期数据.样品个数一般不少于100个。

在Excel表格中,CPK(即过程能力指数)是用来评估一个过程的稳定性和一致性的指标。

CPK值越高,表明该过程的成品质量越稳定,生产的产品质量也越高。

在实际工作中,我们经常需要使用Excel来计算CPK值,下面将介绍在Excel中计算CPK值时所使用的公式和注解。

一、CPK值的计算公式1. 标准CPK值的计算公式如下:CPK = min((USL - μ) / (3σ), (μ - LSL) / (3σ))其中,USL代表过程的上限规格,LSL代表过程的下限规格,μ代表过程的均值,σ代表过程的标准差。

2. CPK值的计算步骤:a. 我们需要计算出数据的均值μ和标准差σ。

b. 根据公式进行计算并得出CPK值。

二、在Excel中的CPK值计算方法在Excel中,我们可以通过使用一些函数来轻松地计算出CPK值。

下面是在Excel表格中计算CPK值的具体步骤和函数使用注解:1. 计算数据的均值和标准差在Excel中,我们可以使用AVERAGE函数来计算数据的均值,使用STDEV.S函数来计算数据的样本标准差。

具体的函数如下:- 均值的计算: =AVERAGE(A1:A100)- 标准差的计算: =STDEV.S(A1:A100)2. 使用函数计算CPK值在Excel中,我们可以使用MIN函数和IF函数来计算出CPK值。

具体的函数如下:=MIN((B1-C1)/(3*D1),(C1-A1)/(3*D1))其中,B1代表上限规格,C1代表均值,D1代表标准差,A1代表下限规格。

三、CPK值的解读和应用1. CPK值的范围一般来说,CPK值越大,说明该过程的稳定性和一致性越好。

根据一般标准,CPK值大于1.33表示过程能力良好,大于1.0表示过程能力可以接受,小于1.0则表示过程能力不足。

2. CPK值的应用在实际工作中,CPK值的计算可以帮助我们评估生产过程的稳定性和一致性,及时发现并解决生产中的质量问题,以提高产品的质量和生产效率。

CPK(过程能力)研究报告1. 引言1.1 研究背景及意义在当今激烈的市场竞争环境下,企业对产品质量的要求越来越高,过程控制能力成为衡量企业质量管理水平的重要指标。

CPK(过程能力指数)作为衡量过程稳定性和控制能力的重要参数,得到了广泛的应用。

然而,在实际应用中,许多企业对CPK的理解和应用仍存在一定的误区。

本研究旨在深入剖析CPK的基本理论,通过实际案例分析,为企业提供有效的过程改进方法,从而提高产品质量和市场竞争力。

1.2 研究方法与内容概述本研究采用文献分析、实证分析和案例研究等方法,系统地梳理了CPK的相关理论、计算方法和应用领域。

首先,对CPK的定义、计算方法和过程控制关系进行阐述;其次,通过实际案例进行分析,探讨CPK在制造业和服务业中的应用价值;接着,分析CPK在过程改进中的作用,并结合成功案例进行解读;最后,探讨CPK与其他质量管理工具的关联,为企业的质量管理提供更为全面的理论支持。

1.3 研究目标与预期成果本研究旨在实现以下目标:1.深入剖析CPK的基本理论,为企业提供理论指导;2.通过案例分析,总结CPK在实际应用中的经验和教训;3.探讨CPK在过程改进中的应用,为企业提供有效改进方法;4.分析CPK与其他质量管理工具的关联,促进企业质量管理水平的提升。

预期成果包括:1.形成一套系统的CPK理论知识体系;2.提供具有实践指导意义的CPK应用案例;3.提出针对性的过程改进策略;4.促进企业质量管理水平的提升。

2. CPK基本理论2.1 CPK定义与计算方法CPK(过程能力指数)是衡量过程稳定性和过程能力的指标,是统计过程控制(SPC)中一个重要的参数。

它反映了在一定的生产过程中,产品质量特性值在规格限内的波动情况。

CPK值越高,表明过程能力越强,生产出的产品越能满足规格要求。

CPK的计算公式如下: [ CPK = ] 其中,USL为上限规格限,LSL为下限规格限,()为过程标准差。

什么是CP和CPK(工序能力指数)CP(或Cpk)是工序能力指数,也有译作工艺能力指数过程能力指数。

工序能力指数,是指工序在一定时间里,处于控制状态(稳定状态)下的实际加工能力。

它是工序固有的能力,或者说它是工序保证质量的能力。

这里所指的工序,是指操作者、机器、原材料、工艺方法和生产环境等五个基本质量因素综合作用的过程,也就是产品质量的生产过程。

产品质量就是工序中的各个质量因素所起作用的综合表现。

对于任何生产过程,产品质量总是分散地存在着。

若工序能力越高,则产品质量特性值的分散就会越小;若工序能力越低,则产品质量特性值的分散就会越大。

那么,应当用一个什么样的量,来描述生产过程所造成的总分散呢?通常,都用6σ(即μ+3σ)来表示工序能力:工序能力=6σ若用符号P来表示工序能力,则:P=6σ式中:σ是处于稳定状态下的工序的标准偏差工序能力是表示生产过程客观存在着分散的一个参数。

但是这个参数能否满足产品的技术要求,仅从它本身还难以看出。

因此,还需要另一个参数来反映工序能力满足产品技术要求(公差、规格等质量标准)的程度。

这个参数就叫做工序能力指数。

它是技术要求和工序能力的比值,即工序能力指数=技术要求/工序能力当分布中心与公差中心重合时,工序能力指数记为Cp。

当分布中心与公差中心有偏离时,工序能力指数记为Cpk。

运用工序能力指数,可以帮助我们掌握生产过程的质量水平。

工序能力指数的判断工序的质量水平按Cp值可划分为五个等级。

按其等级的高低,在管理上可以作出相应的判断和处置(见表1)。

该表中的分级、判断和处置对于Cpk也同样适用。

表1 工序能力指数的分级判断和处置参考表Cp值级别判断双侧公差范(T) 处置Cp>1.67 特级能力过高 T>10σ(1)可将公差缩小到约土46的范围(2)允许较大的外来波动,以提高效率(3)改用精度差些的设备,以降低成本(4)简略检验1.67≥Cp1.33 一级能力充分 T=8σ—10σ (1)若加工件不是关键零件,允许一定程度的外来波动(2)简化检验(3)用控制图进行控制1.33≥Cp>1.0 二级能力尚可 T=6σ—8σ (1)用控制图控制,防止外来波动(2)对产品抽样检验,注意抽样方式和间隔(3)Cp—1.0时,应检查设备等方面的情示器1.0≥Cp>0.67 三级能力不足 T=4σ—6σ (1)分析极差R过大的原因,并采取措施(2)若不影响产品最终质量和装配工作,可考虑放大公差范围(3)对产品全数检查,或进行分级筛选0.67>Cp 四级能力严重不足 T<4σ (1)必须追查各方面原因,对工艺进行改革(2)对产品进行全数检查1.定义理解cpk:表示所研究的制程能力可以达到的程度,是潜在的能力(potential capabilityppk:表示所研究的制程能力当前达到了什么程度,是实际的能力(actual capability2.解释比如一个跳远运动员的一次的跳远(如图1),他跳出是跳出了边界.那么那跳的有效距离为ppk,在边界内他跳的距离为pp;但是如果没有边界的话,那他跳的有效距离为cpk,可是他若没有跳斜的话,他能跳的实际距离为cp.3.关于算cpk,ppk是用什么sigma在求ppk时应用StDev(LT),即为overall sigma.其公式如(图2)在求cpk时所用的sigma我还时有些搞不清,到底时用within sigma还是between sigma?在Minitab中有这一选项,供分析者自己选.2.PPK用途是在check組間變異,CPK是在check過程能力,所以在做CPK前建議先做PPK,確保組間變異是沒問題的,亦即不存在非機遇性問題。

供应商cpk报告的内容1. 简介供应商CPK报告是一种关于供应商质量控制的统计分析报告,通常用于评估供应商的生产过程是否稳定,并确定其生产的产品是否符合规定的质量标准。

CPK指数是常见的统计指标之一,用于衡量制造过程的稳定性和能力。

2. 报告内容供应商CPK报告一般包括以下内容:2.1 供应商信息- 供应商名称:报告中列出所评估的供应商名称。

- 供应商联系人:提供与供应商联系的信息,以便进一步沟通和合作。

2.2 测量数据- 抽样数据:报告中应包含供应商提供的抽样数据,以便进行统计分析。

- 数据指标:包括产品尺寸、重量、功能等关键指标,用于衡量产品的质量水平。

- 数据样本量:报告中应注明每个指标的样本量,以确保统计结果的准确性。

2.3 统计分析供应商CPK报告的核心就是基于测量数据进行的统计分析,其中包括以下内容:2.3.1 均值、标准差和极差通过计算各指标的均值、标准差和极差,评估供应商生产过程的稳定性和变异程度。

如果均值稳定、标准差较小,说明生产过程相对稳定,产品具有较好的一致性。

2.3.2 过程能力指数CPK计算CPK指数是判断供应商生产过程能力的常用指标。

通过统计分析,计算出每个指标的CPK值,以评估供应商生产过程的能力是否符合要求。

CPK值大于1.33表示生产过程能力良好,小于1.33可能需要进一步改进。

2.3.3 直方图和正态性检验通过绘制直方图和进行正态性检验,验证测量数据是否符合正态分布。

正态分布的数据有助于判断生产过程的可控程度和产品质量的一致性。

2.4 结论与建议供应商CPK报告最后总结出供应商生产过程的能力和稳定性,并给出相应的建议。

3. 报告价值供应商CPK报告作为供应链管理的重要工具,具有以下价值:3.1 提供供应商质量评估的数据支持通过统计分析供应商提供的测量数据,CPK报告能够客观地评估供应商生产过程的稳定性和能力,为采购决策提供数据支持。

3.2 促进供应商合作与改进CPK报告可向供应商提供清晰的数据和图表,帮助他们了解自身生产过程的表现,并指导他们进行改进措施,以提高产品质量。

规格平均极差(R)能力指数(CPU)能力指过程比标准偏标准偏方差(n-方差(n)性能指性能比2.52.55性能指n A 2d 3d 42 1.880 3.2673 1.0230 2.57440.7290 2.28250.5770 2.11460.4830 2.00470.4190.076 1.92480.3730.136 1.86490.3370.184 1.816100.3080.2231.777n123456789101112131415161718192021222324251 2.521 2.523 2.526 2.524 2.529 2.525 2.522 2.524 2.526 2.527 2.526 2.520 2.530 2.520 2.529 2.526 2.513 2.529 2.525 2.521 2.530 2.530 2.529 2.521 2.5322 2.521 2.530 2.531 2.524 2.523 2.521 2.522 2.528 2.535 2.519 2.522 2.527 2.519 2.531 2.523 2.522 2.536 2.524 2.530 2.520 2.526 2.520 2.524 2.521 2.5163 2.517 2.529 2.522 2.527 2.521 2.529 2.519 2.528 2.517 2.524 2.528 2.520 2.525 2.533 2.518 2.527 2.534 2.530 2.523 2.523 2.528 2.526 2.530 2.528 2.5234 2.522 2.517 2.522 2.519 2.531 2.538 2.513 2.522 2.528 2.535 2.523 2.522 2.528 2.526 2.527 2.523 2.531 2.522 2.520 2.525 2.526 2.529 2.531 2.526 2.52552.5312.5342.5202.5232.5312.5312.5222.5342.5222.5192.5292.5202.5262.5212.5212.5282.5292.5262.5182.5182.5162.5222.5222.5222.528设备编号公称尺寸2017.10.4下限尺寸2.52.5 2.55数据终止日期2017.10.31数据总数尺寸上限 2.52.55315.62数据数n最小值Min 2.5382.5132.5250.00001.6591.649D2 ,n=5低于下限数0.5960.6050.004940.00001.6740.004961.679平均值( X )最大值Max 上公差名义尺寸上限尺寸2.5工装编号数显千分尺部 门零件名称量具精度1.649最终结论0.001高度零件图号2002/3/3工序名称 2.5过程能力满足要求组内容量5公称值00尺寸下限0.01172125组数25数据起始日期高于上限数 2.3261.654量具名称下公差CpCpk0.00.05 2.53172.52492.51822.4902.5002.5102.5202.5302.5402.55012345678910111213141516171819202122232425均值(Xbar 表)0.02480.01170.0000.0200.04012345678910111213141516171819202122232425极差(R 表)281333112516105251015202530352.5122.5172.5222.5272.5322.53700238517204060801001201402.4852.4952.5052.5152.5252.5352.5452.5552.565双侧公差下限公差上限公差规格设备编号公称尺寸2017.10.4下限尺寸2.52.52.55数据终止日期2017.10.31数据数n上公差名义尺寸上限尺寸2.5工装编号数显千分尺部 门零件名称量具精度1.649最终结论0.001高度零件图号2002/3/3工序名称 2.5过程能力满足要求组内容量5尺寸下限125组数25数据起始日期1.654量具名称下公差CpCpk0.00.053335双侧公差下限公差上限公差Xbar 2.522 2.527 2.524 2.523 2.527 2.529 2.520 2.527 2.526 2.525 2.526 2.522 2.526 2.526 2.524 2.525 2.529 2.526 2.523 2.521 2.525 2.525 2.527 2.524 2.525。

cpk 与cmk区别一、CPK1、计算公式:cpk=(1-K)*CP或MIN(cpu,cpl)K=CA=T/2T=规格上限-规格下限cpk值越大,代表综合制程能力越强.2.等级判定:cpk值大约可分为五级:A+ CPK>=1.67 制程无缺点,考虑降低成本.A 1.33<=cpk<=1.67 维持现状;B 1.0<=CPK<=1.33 有缺点发生,引起注意;C 0.67<=CPK<=1.0 立即进行检讨,提出改善措施;D CPK<=0.67 采取紧急措施,甚至停线,检讨规格设定.二、CMKCMK对设备能力的评估,称为设备能力指数,计算公式和CPK大体一致,只是CMK是连续取样,取样方法有所不同!!CPK:在过程稳定受控情况下适当频率抽25组至少100个样本CMK:一般在机器生产稳定后约一小时内抽样10组50样本三、区别:CPK:强调的是过程固有变差和实际固有的能力;CMK:考虑短期离散,强调设备本身因素对质量的影响;CPK:分析前提是数据服从正态分布,且过程受控;(基于该前提,CPK一定>0)CMK:用于新机验收时、新产品试制时、设备大修后等情况CPK:至少1.33CMK:至少1.67转载请注明出自六西格玛品质论坛 /,本贴地址:/viewthread.php?tid=108152CMK是指设备能力指数,CPK指的是综合过程能力指数.CMK评价的设备;CPK评价的是5M1E的综合影响因素转载请注明出自六西格玛品质论坛 /,本贴地址:/viewthread.php?tid=108152Cmk是德国汽车行业常采用的参数,称为临界机器能力指数,它仅考虑设备本身的影响,同时考虑分布的平均值与规范中心值的偏移;由于仅考虑设备本身的影响,因此在采样时对其他因素要严加控制,尽量避免其他因素的干扰,计算公式与Ppk相同,只是取样不同SPC ,CP(或Cpk)工序能力指数,是指工序在一定时间里,处于控制状态(稳定状态)下的实际加工能力。