树脂传递模塑成型工艺及设备

- 格式:ppt

- 大小:6.38 MB

- 文档页数:105

树脂传递模塑 (R TM 工艺的发展及应用北京振兴科技文献服务中心曹运红文摘树脂传递模塑 (R TM 工艺是介于手铺法、喷射法和机械成形法之间的一种对模成形法。

文中叙述了 R TM 的发展过程和基本原理以及工艺装备、 , 并介绍了 R TM 的应用范围。

主题词 1引言 , 在美国已被广泛地用于汽车制造业的原始模型制造 , 并正在考虑生产复合材料结构零件。

船舶工业和小型导弹生产也采用了 R TM 工艺。

该工艺与传统的湿法铺层工艺相比 , 具有生产周期短、费用低及结构整体性好的优点。

飞机工业采用 R TM 工艺 , 可以生产出低费用和轻质量的飞机零件。

如小而复杂的控制面通常是用铝合金铸造而成。

这很可能用单一的 R TM 工艺所取代。

转枢、加强件等可以与连续纤维蒙皮一起模塑 , 大零部件 (如全翼也可以采用 R TM 工艺。

R TM 工艺的起源 , 可以追溯到四十年代末期 , 最初是为适用飞机雷达天线罩成形而发展起来的。

经过 30年的发展 , 英国航空航天公司在采用 R TM 工艺生产高整体性和高价结构如雷达天线罩方面拥有相当的经验。

手铺成型和喷射成型具有投资少等优点 , 但对环境污染 (苯乙烯较严重。

近年来 ,欧美等国家限制大气中苯乙烯含量 , 人们的兴趣也转移到 R TM 工艺上来。

因 R TM 工艺的掘起已使欧美发达国家产生了很大的变。

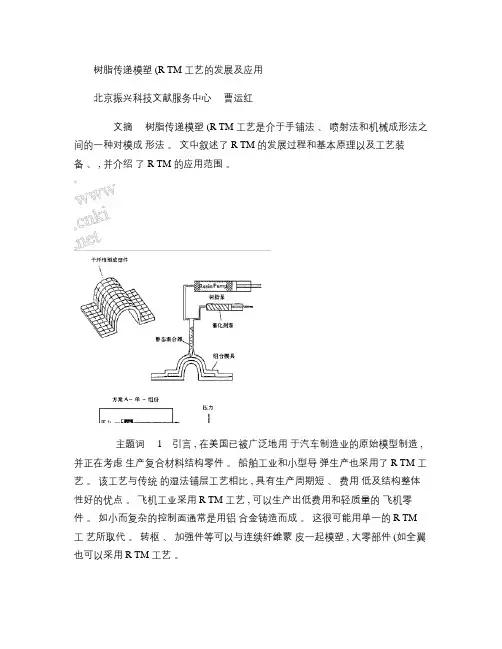

2基本原理及工艺装备 2. 1基本原理图 1 R TM 工艺原理图R TM 工艺的基本原理是 :在一个闭式的模具内预置纤维增强预型件 , 再用低压 (小于 0. 69M Pa 将树脂系统注入模具内 , 使之浸透纤维增强预型件 , 然后固化成两面光洁的零件 , 如图 1、 2所示。

图 2 R TM 工艺简图2. 2 R TM 工艺装备美国壳牌发展公司用作 R TM 工艺的装备包括注射系统、电热式加热器加热的 P -20钢模具、液压机、温度控制系统、真空泵、压力容器。

真空辅助树脂传递模塑工艺真空辅助树脂传递模塑工艺(VARTM/SCRIMP)适用于质量要求高、小批量和尺寸较大的制品。

它和传统的热压罐成型工艺相比,具有模具低成本,树脂室温固化以及几乎不受限制的制品尺寸等突出的特点。

在国外VAR TM已成功地用于舰船、军事设施、国防工程、航空和民用工业等领域。

目前,真空辅助树脂传递注塑中应用最广泛的工艺之一,SCRIMP TM成型工艺,是在19世纪80年代后期在RTM 工艺基础上发展起来的以低成本、适合制作大型复合材料制品的成型工艺。

该加工工艺的成品有较好的品质,如:孔隙率低、纤维含量高,和良好的机械性能,并且可以将挥发性有毒气体的排放量控制在最小的程度。

SCRIMP真空辅助树脂传递注塑是利用薄膜将增强材料密封于单边模具上,完全借助于真空将低黏度树脂吸入,利用高渗透率介质沿增强材料的表面快速浸渍,并同时向增强材料厚度方向进行浸润的加工工艺。

用这种方法加工的复合材料,纤维含量高,制品力学性能优良,而且产品尺寸不受限制,尤其适合制作大型制品。

最近,由于树脂体系和纺织增强材料成型技术的不断发展,航空制造者们也对VAR TM表现出了浓厚的兴趣,主要表现为采用碳纤维-环氧树脂、碳纤维-双马来酰亚胺树脂的复合材料。

几种常用的纺织复合材料增强体和传统的开模成型工艺相比,SCRIMP成型工艺具有许多的优点。

SCRIMP工艺比手工铺放节约成本约50%,树脂浪费率低于5%,特别是加工过程的环保性,是SCRIM P工艺最突出的优点。

在同样原材料的情况下,与手糊构件相比,复合材料的强度、刚度或硬度及其它的物理特性可提高30%-50%以上。

产品质量不受操作人员影响,产品性能的均匀性和重复性比开模产品好得多,缺陷也少得多。

轻型树脂传递模塑工艺(L1.L-RTM工艺介绍传统的RTM工艺,由于是闭模工艺,具有减少挥发性有机物(VOC)排放(可达SPPm以下)、扩大可用原材料范围、降低用工、环境友善以及可得到两面光洁的产品等优点。

但是在RTM工艺中,树脂的注入是在较高的压力和流速下进行的,因此我们要使模具的结构强度和刚度大到足够在注射压力下不破坏、不变形。

通常采用带钢管支撑的夹芯复合材料,或用数控机床加工的铝模或钢模,这使制造费用增大,只有对产量足够大的产品,才能抵消模具费用。

此外为了闭合模具,要使周边有足够的箝紧能力或使用闭合模具的压力系统。

上述因素都限制了RTM工艺在大产品上的应用,否则模具会变得很重.而且投资也会很大。

轻型树脂传递模塑工艺(RTM一Light)又称为LRTM,ECO,Vacuum Molding或VARTM。

是近年来发展迅速的低成本制造工艺,目前在船舰、汽车、工业和医用复合材料领域中应用已有超过RTM工艺的趋势。

RTM一Light工艺保留了RTM工艺的对模工艺,从而几乎保留了RTM工艺的所有的优点。

但其上模为半刚性的玻璃钢模,厚度一般为6一8mm,通常不需要用钢管加固,模具有一个宽约100mm的刚性周边,由双道密封带构成一个独立的密封区,只要一抽真空模具即闭合,非常方便、快捷。

然后对模腔内抽真空,利用模内的负压和较低的注射压力将树脂注入模具,使树脂渗入预先铺设的增强纤维或预制件中。

RTM—Light的模具费用低,而且由于模内的受压降低,其模具已和开模相近,很容易从开模工艺的模具改造过来。

RTM一Light的主要设备包括树脂注入装置、模具、抽真空装置和其它辅助工具等。

2 轻型RTM和常规RTM比较(1)模具模具是这两种工艺的最大差别,在RTM投资中,由于注射压力大,相当部分的成本花在模具和夹紧装置上。

这样对于产量少的产品在价格上是不适合的。

RTM工艺模具使用寿命可达5000件以上,生产效率高,适合年产2000件以上的产品。

高压树脂传递模塑成型工艺高压树脂传递模塑成型工艺是一种常用的塑料加工工艺,它利用高压将树脂材料传递到模具中进行模塑成型。

这种工艺具有成型速度快、精度高、表面光滑等优点,在塑料制品生产中得到广泛应用。

高压树脂传递模塑成型工艺的原理是利用高压将树脂材料从供料系统中传递到模具中。

在传递过程中,树脂材料被加热熔化,并通过进料系统进入模具腔体。

在模具腔体中,树脂材料受到高压的作用,充分填充模具腔体,并快速冷却固化。

最后,打开模具,取出成型件,完成整个成型过程。

高压树脂传递模塑成型工艺的特点之一是成型速度快。

由于树脂材料在高压下能够迅速填充模具腔体,并且在快速冷却固化后即可取出成型件,因此整个成型周期较短。

这一特点使得高压树脂传递模塑成型工艺在大批量生产中非常适用。

高压树脂传递模塑成型工艺具有较高的成型精度。

在成型过程中,树脂材料受到高压的作用,能够充分填充模具腔体,使得成型件的尺寸精度较高。

同时,模具腔体的设计也能够保证成型件的形状精度。

因此,高压树脂传递模塑成型工艺适用于对尺寸和形状要求较高的产品制造。

高压树脂传递模塑成型工艺还具有表面光滑的优点。

在成型过程中,树脂材料充分填充模具腔体,并在快速冷却固化后即可取出成型件。

这一过程使得成型件的表面光滑,不需要额外的表面处理。

因此,高压树脂传递模塑成型工艺适用于对表面质量要求较高的产品制造。

在实际应用中,高压树脂传递模塑成型工艺可以应用于各种塑料制品的生产。

例如,汽车零部件、家电外壳、日用品等都可以使用这种工艺进行生产。

在生产过程中,可以根据不同产品的要求选择不同的树脂材料和模具设计,以满足产品的性能和质量要求。

高压树脂传递模塑成型工艺是一种常用的塑料加工工艺,它具有成型速度快、精度高、表面光滑等优点。

在塑料制品生产中,可以根据不同产品的要求选择这种工艺进行生产,以满足产品的性能和质量要求。

复合材料树脂渗透成型工艺随着行业发展对生产速度提出更高的需求,单依靠传统的手糊成型工艺已经难以满足日益增长的市场需求,因此,加工工艺的自动化是顺应这一潮流的必然趋势。

最常见的自动化成型工艺是树脂传递模塑工艺(-ResinTransferMolding),有时也被称为液体成型工艺(LiquidMolding)。

树脂传递模塑工艺是一种十分简单的成型工艺:其原理是首先在金属或复合材料制成的闭合模具中铺放干增强材料预成型体(preform),然后将树脂和催化剂按照一定比例计量并充分混合,再采用注射设备通过注射口(injectionports)利用压力注入到模具中,使树脂按照预先设计的路径浸润到增强材料上的过程。

树脂传递模塑工艺要求极低粘度的树脂,特别是当预成型体较厚时,较好的树脂的流动性能够确保更及时和更充分的浸润效果。

如有需要,模具和树脂可以进行加热,但是成型工艺的固化无需使用热压釜。

但是,一部分应用于高温的制品通常在脱模后还要进行后固化(postcure)。

大多数的应用程序都采用双组分环氧树脂配方(two-partepoxyformulation):双马来酰亚胺(Bismaleimideresin)和聚酰亚胺树脂(polyimideresin)。

组分的配方过程不会提前太早,通常在注射前进行。

轻型树脂传递模塑工艺(Light)是近年来发展较快的低成本成型工艺,是树脂传递模塑工的变体工艺。

轻型树脂传递模塑工艺不仅具备工艺的所有特点,还降低了成型工艺对一系列指标的要求,例如,注射压力,真空耦合(coupledwithvacuum),和模具的造价和刚性指标。

树脂传递模塑工艺具有许多显著的优点。

一般来说,在树脂传递模塑工艺过程中所使用的干预成型体和树脂材料的价格都比预浸料便宜,而且还可以在室温下存放。

利用这种工艺可以生产较厚的净成形零件,同时免去许多后续加工程序。

该工艺还能帮助生产尺寸精确,表面工艺精湛的复杂零件。

树脂传递模塑成型工艺RTM工艺的主要原理是在模腔中铺放按性能和结构要求设计的增强材料预成形体,采用注射设备将专用树脂体系注入闭合模腔,模具具有周边密封和紧固以及注射及排气系统,以保证树脂流动流畅并排出模腔中的全部气体和彻底浸润纤维,还具有加热系统,可加热固化成形复合材料构件。

它是一种不采用预浸料,也不采用热压罐的成形方法。

因此,具有效率高、投资、绿色等优点,是未来新一代飞机机体有发展潜力的制造技术。

该方法的优点是环保、形成的层合板性能好且双面质量好,在航空中应用不仅能够减少本身劳动量,而且由于能够成形大型整体件,使装配工作量减少。

但是树脂通过压力注射进入模腔形成的零件存在着孔隙含量较大、纤维含量较低、树脂在纤维中分布不匀、树脂对纤维浸渍不充分等缺陷,因此该技术还有改进潜力。

该工艺还能帮助生产尺寸精确,表面工艺精湛的复杂零件。

树脂传递模塑工艺还有一个特点是,能够允许闭模前在预成型体中放入芯模填充材料,避免预成型体在合模过程中被挤压。

芯模在整个预成型体中所占的比重较低,大约在0-2%之间。

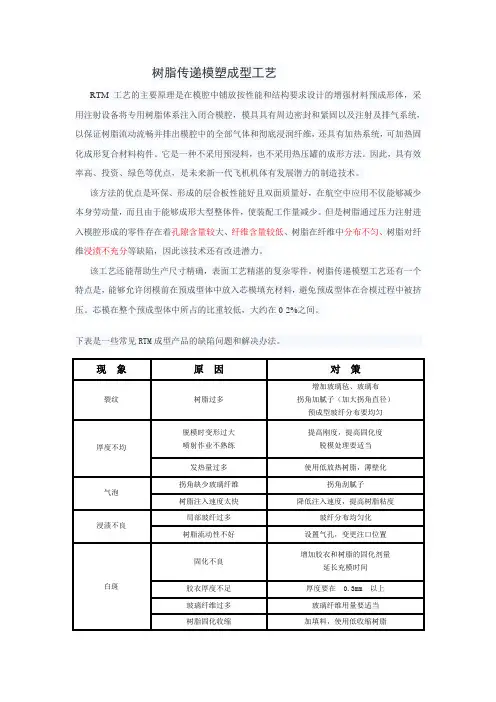

下表是一些常见RTM成型产品的缺陷问题和解决办法。

粗纱、硬度大再选牌号邹折玻璃纤维流动错位用对预成型坯粘结剂有效的粘结剂,减慢注入速度玻璃纤维类型质量不好选择质量好的玻纤挠曲变形脱模时固化不完全促进树脂固化,用补强材料提高刚度使用矫正夹具树脂固化收缩使用低收缩剂,使用填料RTM工艺成功事例:图:ASC – II桨叶通过美国联邦航空局的认证,成功运用于派珀飞机上(Piper Matrixaircraft),ASC – II桨叶同样适用于Cirrus的SR - 22和其他通用航空飞机。

来源:派珀飞机公司Hartzell公司使用自有设计软件--PROP Code和ANSYS公司开发的有限元分析(FEA)软件对桨叶上应力的分配进行分析和设计,然后用另一个内部开发程序来生成ASC - II复合层压结构。

汉克将这种泡沫夹芯三明治结构设计描述为单体横造结构。

真空辅助树脂传递模塑工艺真空辅助树脂传递模塑工艺(VARTM/SCRIMP)适用于质量要求高、小批量和尺寸较大的制品。

它和传统的热压罐成型工艺相比,具有模具低成本,树脂室温固化以及几乎不受限制的制品尺寸等突出的特点。

在国外VARTM已成功地用于舰船、军事设施、国防工程、航空和民用工业等领域。

目前,真空辅助树脂传递注塑中应用最广泛的工艺之一,SCRIMPTM成型工艺,是在19世纪80年代后期在RTM 工艺基础上发展起来的以低成本、适合制作大型复合材料制品的成型工艺。

该加工工艺的成品有较好的品质,如:孔隙率低、纤维含量高,和良好的机械性能,并且可以将挥发性有毒气体的排放量控制在最小的程度。

SCRIMP真空辅助树脂传递注塑是利用薄膜将增强材料密封于单边模具上,完全借助于真空将低黏度树脂吸入,利用高渗透率介质沿增强材料的表面快速浸渍,并同时向增强材料厚度方向进行浸润的加工工艺。

用这种方法加工的复合材料,纤维含量高,制品力学性能优良,而且产品尺寸不受限制,尤其适合制作大型制品。

最近,由于树脂体系和纺织增强材料成型技术的不断发展,航空制造者们也对VARTM表现出了浓厚的兴趣,主要表现为采用碳纤维-环氧树脂、碳纤维-双马来酰亚胺树脂的复合材料。

几种常用的纺织复合材料增强体和传统的开模成型工艺相比,SCRIMP成型工艺具有许多的优点。

SCRIMP工艺比手工铺放节约成本约50%,树脂浪费率低于5%,特别是加工过程的环保性,是SCRIMP工艺最突出的优点。

在同样原材料的情况下,与手糊构件相比,复合材料的强度、刚度或硬度及其它的物理特性可提高30%-50%以上。

产品质量不受操作人员影响,产品性能的均匀性和重复性比开模产品好得多,缺陷也少得多。

SCRIMP由于是采用闭模成型工艺,挥发性有机物和有毒空气污染物均受到很大程度的控制,VOC排放不超过5PPm的标准,而开模成型的苯乙烯的挥发量超过500PPm。

SCRIMP工艺特别适合制造较大的制品,并且可以进行芯材、加筋结构件的一次成型以及厚的、大型复杂几何形状的制造,提高了产品的整体性,而且材料和人工的节省实为可观。

树脂传递模塑工艺树脂传递模塑工艺是一种高效率的成型工艺,广泛应用于各种行业,包括航空航天、汽车、电子、医疗等。

该工艺主要是通过将树脂材料注入模具中,然后通过加热、加压等方式进行固化,最终得到所需形状和尺寸的制品。

一、树脂传递模塑工艺流程1. 准备模具:根据制品的形状和尺寸要求,准备相应的模具。

2. 准备树脂材料:选择适合制品要求的树脂材料,并进行相应的处理,以保证其流动性和固化性能。

3. 注入树脂:将处理好的树脂材料注入模具中。

4. 固化:通过加热、加压等方式,使树脂材料在模具中固化。

5. 脱模:待树脂材料完全固化后,将制品从模具中脱出。

6. 后处理:对制品进行修整、打磨、喷漆等后处理,以满足制品的质量和外观要求。

二、树脂传递模塑工艺特点1. 效率高:树脂传递模塑工艺可以实现自动化生产,生产效率高。

2. 成本低:由于该工艺使用的模具可以根据制品的形状和尺寸进行定制,因此可以大大降低生产成本。

3. 适用范围广:树脂传递模塑工艺可以用于各种形状和尺寸的制品生产,适用范围广。

4. 环保:该工艺使用的树脂材料可以循环使用,对环境友好。

三、树脂传递模塑工艺的应用1. 航空航天领域:在航空航天领域,树脂传递模塑工艺被广泛应用于制造各种形状和尺寸的轻量化制品,如飞机零部件、卫星零部件等。

2. 汽车领域:在汽车领域,树脂传递模塑工艺被广泛应用于制造各种零部件,如汽车车门、汽车发动机罩等。

3. 电子领域:在电子领域,树脂传递模塑工艺被广泛应用于制造各种电子元器件,如电路板、电池等。

4. 医疗领域:在医疗领域,树脂传递模塑工艺被广泛应用于制造各种医疗器材,如医疗器械外壳、医疗容器等。

树脂传递模塑工艺是一种高效、环保、低成本的成型工艺,具有广泛的应用前景。

随着科技的不断发展,该工艺将会不断创新和完善,为各行各业的发展提供更加优质的技术支持。

轻型树脂传递模塑工艺(l-rtm)(Lightweight resin transfermolding process (l-rtm))Lightweight resin transfer molding (L-RTM) - a rapidly developing low cost manufacturing technologyIntroduction of 1.L-RTM processThe traditional RTM technique, because it is a closed mold, with reduced volatile organic compounds (VOC) emissions (up to SPPm), the advantages of expanding available range of raw materials, reduce labor, environment friendly and can get two clean products etc.. But in RTM process, the injection of resin is carried out under higher pressure and velocity, so we must make the structure strength and stiffness of the mold sufficiently large enough to break and deform under the injection pressure. Usually, the sandwich composite material with steel tube support or aluminum die or steel mould processed by numerical control machine tool can make the manufacture cost increase, and the mould cost can be offset only when the product is big enough. In addition, in order to close the mold, it is necessary to make the peripheral sufficient clamping capacity or to use a closed die pressure system. All these factors limit the application of RTM technology to large products, otherwise the mold will become very heavy and the investment will be great.Lightweight resin transfer molding process (RTM, Light), also known as LRTM, ECO, VacuumMolding or VARTM. It is a low-cost manufacturing process developed in recent years. It has been used in the field of ship,automobile, industry and medical composite material more than RTM technology.The RTM Light process retains the die processing process of the RTM process, thus retaining almost all of the advantages of the RTM process. But the upper die for glass steel mould half rigid, thickness 6 8mm, usually do not need to use the steel reinforcement, the mold has a width of about 100mm by the rigid surrounding, double sealing belt constitutes an independent seal area, as long as a vacuum mold is closed and is very convenient and fast. Then the cavity is evacuated, and the resin is injected into the mold with the negative pressure in the mold and the lower injection pressure. The resin is infiltrated into the pre laid reinforcing fiber or preform. RTM - Light mold cost is low, and because the mold pressure reduction, its mold has close to the mold, it is easy to open mold from the process of transformation.The main equipment of RTM Light includes resin injection device, mold, vacuum pump and other auxiliary tools.2 light RTM compared with regular RTM(1) die;The mold is the biggest difference between the two processes. In the RTM investment, a considerable part of the cost is spent on the die and the clamping device because of the high injection pressure. This is not a good price for a product with little output. RTM process, mold life of up to 5000 or more, high production efficiency, suitable for an annual output of morethan 2000 products.The biggest advantage of RTM Light is the low cost of its mold production. The cost is only about half of the regular RTM mold, but the service life of the die is lower than that of the RTM mold. It is suitable for the products with an annual output of about 1000 pieces.The RTM Light process produces products that are larger in size than the traditional RTM, which is usually as small as a basketball cap, a length of 8m long hull (about 25m2), but this is not the ultimate limit of size. The product size is smaller than the basketball cap, the difficulty is to add fiber, and the product is greater than 8m, how to deal with the mold on the difficult.The disadvantage of glass fiber reinforced plastic mould is short service life of mould surface. In order to get good die life and product repeatability and dimensional accuracy, RTM -Both the Light and RTM processes must be of high quality and have an accurate cross section. In the composite molding process, the cost of surface requirements of the final product can reach 60% of the final product price. The composite mold can achieve the use of 500 times the surface quality of the car, and then the surface treatment of the mold. One way to increase life expectancy is to use a replaceable die surface(ex-changeablemoldSkins), such as the patent of JHm Technologies company, ZIPRTM technology,It can be used in RTM and RTM Light processes. Through the use of replaceable die surface to replace the vulnerable mold surface, thereby prolonging the life of the die and improving the quality of the die, the service life of the die can reach 8000, 10000 times. When the simultaneous use of several replaceable mold surface, due to the outside in the mold can be replaced directly on the mold surface coating and heating, thereby greatly improving the production efficiency.(2) injection pressure, flow rate and equipment;The injection pressure of RTM process is usually 0.1 0.4MPa, while the injection pressure of RTM Light process is not more than.1MPa, usually at 0.03-0.07MPa.The rate of resin injection varies with various factors such as resin viscosity, component size, fiber type and ply structure. The usual injection rate is 1.3 to 2 litres per minute.In order to prevent mold deformation or burst mode (especially in the position of the injection port), which requires a strict control of pressure. Injection equipment for the RTM Light process is usually equipped with a pressure feedback device that controls the pressure as a closed loop. RTM is also available in the standard equipment of a simple line pressure control design (mold protection system and a VMPC) and VMPC with POD electronic closed-loop system, can not lead to molddeformation and failure under the condition of using the original production equipment to get the best productivity.Equipment research is also developing toward low cost and multi use. The SSB injection equipment of Plastech adopts patented piston reforming precision metering pump. The minimum ratio of catalyst is up to 0.5%, which matches the industrial MPG (MouldPressureguard) the pump speed can be controlled by the machine itself. In 12 seconds and 15 seconds, the 1m2 reinforced material can be impregnated, and the wetting speed can be accurately controlled. Configure other options, also for hand gluing and brushing.(3) production efficiency and costRTM one Light process is a low-cost production technology. Compared with the traditional RTM technology, the die cost is low, and the complicated pressing device or pressure system is not needed, the investment is small, the operation is simple, and the manpower capital is saved, etc.. Compared with the opening process, it has the high precision of the product size, low porosity, production of styrene volatilization, environmental friendly, less waste materials (resin utilization rate of up to 95%), low rejection rate, high production efficiency.The injection pressure is low, the resin flow rate can not be accelerated to the optimum flow, before the RTM Light process the production speed of less than half of the RTM process, with each class 8 hours, for the use of the gel coat and non heatingmould process, RTM process in each class can produce 10 A 12 die, RTM-The Light process produces only 4 and 6 dies. For a 34 square foot product that needs to be heated and cured, the RTM process produces 40 molds per shift with the use of a hydraulic press, a heating die, and 5 replaceable dies. RTM in the same situation- Light process, can produce 20 die. But no water press is needed, and the mold price is also half lower.In recent years, through the improvement of mold design and process control, both production speed is approaching. Such as Xiraplas company in the use of RTM Light process alternative mold opening process, the workshop has become orderly, the use of the original 50 workers, and 3000m2 workshop area, making production increased by 25%. According to the company, production efficiency has been increased by 90% compared to the original mold opening process.(4) runner designThe flow design of the general RTM process is injected from the center and discharged from the periphery. But the RTM-Light process usually flows in from the perimeter and out of the center. We know that when the resin enters the mold cavity from the resin pipe and meets the fabric, the fabric will produce a counter pressure (resistance) to the resin. The magnitude of the reverse pressure is related to the permeability of thefabric, the viscosity of the resin, and the flow velocity of the resin, when the fabric and resin are selected,It is proportional to the flow velocity of the resin. Take an area of 3M2, thickness of 3mm products as an example, the general injection pressure is 0.05MPa, the injection time is 6min, the injection flow is 1.33L/min. If the injection from the center and maintain the flow unchanged, the anti pressure can be increased to more than 0.1MPa, resulting in the mold opening or mold phenomenon, and lead to resin flow forward out of control and the formation of dry spots and other issues. For this reason, the flow rate must be reduced, but this prolongs the injection time, so the injection from the center usually takes more than 6 minutes. When the surrounding resin injection, first into a gap about the surrounding flow 1mm almost no resistance, and then enter the fiber resin into the fiber increase due to pathway (from a point into a surrounding), relative resin in fabric flow slows down, back pressure decreases, the injection rate increase the injection time can be shortened. Tests show that for a 0.2m2 product, the time of injection from the periphery is 2.1 minutes, and the injection from the center to 9 minutes, the speed difference of four times. Of course, RTM process can also be injected from the surrounding resin, the pressure gradient is unchanged, but the highest point of the pressure from the original center point is moved to the periphery, which is beneficial to the deformation control of die, because the surrounding rigid die is better than that of the central area, but also on the periphery of the sealing requirements increased.The flow path design varies with the product, such as the 18mlong lamp post of Spectrayte company and the long runner. Brands's 6m2 floor, due to its asymmetrical structure, uses two outlets, each with a resin collector (Catchpot) at the center of each structure, with an injection time of 15 minutes. The Holland Royal Navy 13m2 hull manufacturing, due to larger products, using two diagonal arrangement of resin imports.(5) product accuracy, structure and otherThe size, viscosity, and repeatability of RTM and RTM Light products are affected by molding, resin, process control, and product curing. The product cross sectional accuracy is also affected by resin flow rate and injection pressure in the process. For the RTM process, when the mold is made according to the standard, without bending, the appropriate clamping device or press clamping, the parts of the dimensional accuracy repeatability is very good, the thickness deviation is not greater than 0.OlOmm. The RTM Light process usually has a certain deformation of the upper die, but the product size accuracy can also reach 0.020mm. Individual places are 4 0.030mm.Both RTM and RTM a Light process can suppress the sandwich material. The core can be made of balsa wood and foam. But the RTM process has a high injection pressure, limiting the use of low-density foam materials, the minimum density of foam is not less than 80Kg/m3, while RTM, Light and ZIPThe RTM process has a lower pressure, and the foam density he uses can be as small as 37Kg/m3. However, it is important to point out that the dimensional accuracy of core material meetsthe requirements of the mold in order to ensure the repeatability of the molding process and the quality of the product.The RTM and RTM Light processes also use preforms and inserts, which allow for high fiber volume products when using preforms.RTM-Light process can not gel, as long as the general release of wax, can release products. But do not release products such as RTM gel, more difficult.Compared with the die opening process, the investment of RTM Light is still relatively high, so it is necessary to consider the rationality of the cost of producing the necessary molds. In addition, the process is very professional and the daily maintenance task is heavy. It also affects the use of RTM Light for some manufacturers of hand ply composites.Compared to RTM, RTM Light has a low energy consumption, not too high on the mold rigidity requirement, but the viscosity of resin, resin and enhance the compatibility of materials, and the resin forward speeds demanding.3 light RTM process should pay attention to the problemRTM Light process is a highly specialized process, operators must be properly trained. If there is no reasonable fiber coating, good gas tightness and accurate mold installation, there is no consistent resin flow control, the product will be messy dry spots, radial bubbles, and resin enrichment and other issues. The following is a brief explanation of the relevantissues.(1) tightnessThe RTM Ligh process requires a higher level of detail, especially the tightness of the mold. The lower the vacuum of the vacuum trough used for the peripheral clamping, the better. The degree of vacuum in the lumen is generally controlled at about 15mm Hg. The periphery is clamped with a vacuum sealing groove and a flexible neoprene wing sealing ring (WingSeal profile) its bottom width is 20mm, the sealing ring joint should be vertical cut, with flexible adhesive glue, in order to ensure its elasticity. Outer ring and then 6mm wide silicone rubber edge.In the molding process, in addition to pay attention to the sealing of mold vacuum sealant, but also note the assembly of the mold, sealing ring and pipe connection, as well as the mold leakage caused by leakage. In fact, any seal or the entrance of the resin entrance, including the outlet of the vacuum zone, shall be checked strictly. A more hidden leak is due to cracks in the surface of the die panel, which are usually not found. The solution to this problem is that it is a very effective way to coat the outer surface of a mold with a resin that has been modified by a catalyst before it reaches the vacuum.Also, keep the cover clean and try not to clean it with solvent. The best release agent is free semi permanent release agent.(2) precise matching between upper and lower dies.The precise matching between the upper and lower dies contributes to the pressure balance in the cavity of the mold, and enables the resin to permeate evenly and helps to improve the quality of the products. Since the upper die is a semi rigid die, each die must be carefully calibrated.If the white spot appears continuously at the same location, this may be because the mold is closed inaccurate, resulting in inaccurate internal cavity, which led directly to the uneven thickness of the inner cavity. In this case, if the glass fiber layer is uniform, resin injection process flow is selective, it will choose the thickness (GAP) where relatively large, so in the region will lead to a relatively thin cavity of leukoplakia.Poor die positioning is an important cause of poor matching of dies. When the edge pin of the die is installed, the X and Y axes of the mold are naturally defined. If the location of the pin is not correct, it will cause unpredictable errors and change the injection characteristics.(3) reasonable paving and selection of raw materials,Due to the low pressure molding process on a RTM Light layer paving fabric requirements more stringent, laying unreasonable, especially the processing of the lap joint, will seriously affect the consistency of the resin flow, resulting in the lack of glue or resin products (dry spots) phenomenon.But with the help of glue fixed fabric in the layer, the layeris more smooth. But the spray and the resin must be good intermiscibility, spray too much or have a certain impact on the final performance of the product.Different fabrics and felt have a great influence on the process. It is necessary to use the enhanced material as much as possible. The resin flow rate of the O.c. closed felt or Hi Flow composite felt is twice as fast as that of the ordinary chopped felt.The appropriate resin system should be chosen according to the product requirements. Use low viscosity, low shrinkage resin as much as possible. Its standards are comparable to those required for vacuum resin diffusion processes.(4) surface crackCracks on the surface of the product will often be observed in the corner area. This is a common problem in the resin enrichment zone.This can also be traced back to the manufacture of the mold. If the 2.5 dies do not fit well with each other, a margin exceeding the expected thickness is produced. To solve this problem, in addition to the correction of the semi mold, the thickness of the glass can also be increased by adding additional glass fibers in these thicker areas to prevent cracks in the product.In the large flat area, cracks in the mold due to excessive thickness are found. This is due to the arbitrary increase in the speed at which the resin is injected. Injection speed toofast, it will make the mould cavity expansion, if the injection process is completed in a very short period of time. So, the cavity is no time to recover, so will lead to excessive resin mold crack. In extreme cases, the cracks on the surface of the mold can not be repaired.(5) overflow of resinIn order to receive the resin that is discharged before molding, many manufacturers feel the need to use a larger resin collector. This is the result of their lack of accurate control of mold filling. If the resin filling process is too fast, it is difficult to determine when to stop the injection. Because if you see the resin go to the resin collector and then stop the injection, then you'll see that too much of the resin will flow to the resin collector because the excess expansion mold has returned to its original size. To overcome this possibility, you can only replace a larger resin collector to prevent the spillage of the resin.The easy way to solve this problem is to calculate how much resin to use. But it is difficult to know exactly how much resin to use when molding large articles. Another method is to provide the operator with accurate pneumatic control to avoid the operator's blind judgment. The air pressure readings in the chamber provide more accurate mold filling information for operations, avoiding the need for larger resin receivers. Such a system ensures that the allowance of 10 to 100 milliliters is sufficient after each injection, which allows the resin to minimize waste and ensure an increase in profits.If there is a resin overflow in the vacuum zone at the edge of the mold, there are several reasons:Sealing of sealant is not goodWhen the sealant path is not in a horizontal position, will result in leakage of resin, in the mold on the panel if there is a convex part, it is necessary to ensure sufficient pressure on the part of the sealant that is completely sealed. A better method is to install a dynamic strip, this dynamic strip, in the edge of complex adaptive path on the sealing surface when the mold is closed this strip can be slightly expanded to seal.Improper placement of fibers in mouldsPlaced in the mold when the fiber is not fully sunburner or pruning, that cannot be placed in the fiber in the mould, and some fibers in the sealant path, which will directly lead to the leakage of resin, to do so before molding each time to carefully check the fiber layer.The injection pressure is too largeAnother common cause is the cause of leakage of resin sealant in the injection process, injection pressure in the pipeline is too large RTM Light mold is closed only by the action of atmospheric pressure, resin injection molding machine can produce more than the actual needs of the pressure, if there is no more sensitive and accurate pressure control, resin will leak into the vacuum zone, which will lead to the loss and mould around vacuum production failure.Loss of vacuum sealWhether it is a long-term or temporary edge vacuum loss, will lead to leakage of resin. Therefore, do not access several molds in the same vacuum system, as this will result in a reduction in the vacuum in the main vacuum zone.In fact, a simple automatic vacuum lock valve helps reduce the possibility of this vacuum loss.4 light RTM applicationsThere are not many reports about RTM Light technology and products in China, but the application development in foreign countries is very fast, and there are more than RTM application trends. At present, the common application areas are aerospace, military, transportation, construction, ships and energy, etc.. For example: the field of aerospace doors, fan blades, radome, aircraft engine hood: military field, torpedo shell tank, tubes and other areas; traffic light rail bus door, side panels, chassis, bumper, truck at the top of the baffle; the building area of street lamp pole, tubular wind generator hood decoration, doors, tables and chairs and the helmet; the field of ship hull, deck and other small boats.。

树脂传递模塑工艺(树脂压铸成型)属于复合材料的液体成型工艺

(Liquid composite molding)。

它是在20世纪70年代发展起来的复合材料成型新工艺,也有资料认为它是由20世纪30年代的浇铸冷模工艺演变而来的,在西欧RTM工艺也称"树脂注射"工艺。

RTM 工艺的基本原理示意如图-1(a)所示,在一定的温度、压力下,低黏度的液体树脂被注人铺有预成型坯(增强材料)的模具中,注人树脂,固化成型,然后脱模。

工艺过程图解如图- 1 (10所示,包括预成型坯的加工与树脂的注入和固化两步。

由于这两步可分开进行,所以说RTM工艺具有髙度的灵活性和组合性,便于实现"材料设计",同时使操作工艺简单。

图-1RTM成型工艺

RTM工艺的注射操作一般要求在1/4 ~ 1/2树脂凝胶时间内完成,传递时间为2~15min,传递压力为0.3~0.7MPa。

为脱除模腔内的气泡,促进树脂的流动和改善浸渍性,还发展了一种在注入树脂的同时抽真空的新工艺——真空辅助RTM工艺。

万方数据第3期齐燕燕等:新型树脂传递模塑技术分对人体和环境的毒害;(5)RTM一般采用低压注射技术(注射压力<4kg/cm2),有利于制备大尺寸、外形复杂、两面光洁的整体结构,及不需后处理制品;(6)加工中仅需用树脂进行冷却;(7)模具可根据生产规模的要求选择不同的材料,以降低成本。

2RTM工艺的发展目前,RTM技术国内外普遍存在的难点和问题表现在以下三个方面[6’7]:(1)树脂对纤维的浸渍不够理想,导致成型时间加长,制品空隙率较高;(2)制品的纤维含量较低(一般约50%);(3)大面积、结构复杂的模具型腔内,树脂流动不均衡,而这个动态过程无法观察,更不能进行预测和控制。

产生上述难点和问题的主要原因有:物料里残存、截留着气泡,树脂的浸渍性差等。

近年来,为解决这些问题,RTM工艺广泛吸取其他成型工艺的特点,发展成为RTM系列,常用的有真空辅助RTM(VacuumAssistedRTM)、See—mann复合材料树脂浸渍模塑成型工艺SCRIMP(SeemannCompositesResinInfusionMoldingProcess)、树脂膜渗透成型工艺RFI(Resinfilmin-fusion)。

2.1真空辅助RTIVl工艺(VARTM)VARTM是在注射树脂的同时,在排出口接真空泵抽真空。

与RTM相比,VARTM的优点有:(1)模腔内抽真空使压力减小,增加了使用更轻型模具的可能性,从而使模具的使用寿命更长、可设计性更好;(2)真空袋材料取代了在RTM中的需相配对的金属模具[83;(3)真空也可提高玻璃纤维与树脂的比率,使玻璃纤维的含量更高,增加制品的强度;(4)无论增强材料是编织的还是非编织的,无论树脂类型及粘度如何,VARTM都能大大改善模塑过程中纤维的浸润性,使树脂和纤维的结合界面更完美,提高制品的质量;(5)用Ⅵ气R1M工艺可使直径38.11mm的致密预成型坯的纤维体积含量为16%~68%,累计孔隙率为1.7%,而普通的预浸料的孔隙率为5%~7%[9]。

树脂传递模塑成型工艺嘿,朋友们!今天咱来聊聊树脂传递模塑成型工艺,这可真是个有意思的玩意儿呢!你看啊,树脂传递模塑成型工艺就像是一个神奇的魔法,能把液态的树脂变成各种形状坚固的物件。

就好像你给面团塑形一样,只不过这个“面团”是树脂啦!想象一下,把树脂倒进模具里,然后看着它慢慢填满每一个角落,是不是感觉很奇妙?这可不是随随便便就能做到的哦!这需要精确的控制和高超的技巧。

在这个过程中,模具就像是一个宝贝盒子,它决定了最终成品的形状和尺寸。

要是模具做得不好,那可就糟糕啦,出来的东西可能就奇形怪状咯!所以说模具的制作可得精心再精心呀。

树脂呢,就像是个调皮的小精灵,你得好好“伺候”着它。

温度啦、压力啦,都得把握得恰到好处,不然它可就不听话啦,不是凝固得不好,就是出现气泡之类的问题。

这就好像你养宠物,得了解它的脾气习性,才能把它照顾好呀!然后啊,等树脂在模具里乖乖地凝固了,你就能得到一个崭新的物件啦!那感觉,就像是你亲手创造了一个小世界一样,特别有成就感。

树脂传递模塑成型工艺的好处可不少呢!它能做出很复杂的形状,那些传统工艺很难做到的,它都能轻松搞定。

而且啊,成品的质量还特别好,坚固又耐用。

咱再说说它在实际生活中的应用吧,汽车零件、飞机部件,好多地方都有它的身影呢!你想想,那些精致的零件,可都是通过这个工艺制造出来的呀,多厉害!咱普通人虽然不会直接去用这个工艺做东西,但了解了解也挺有意思的呀,说不定哪天就能派上用场呢!比如说你突然想自己动手做个小玩意,这时候知道树脂传递模塑成型工艺不就派上用场啦?总之呢,树脂传递模塑成型工艺真的是个很了不起的工艺,它让我们的生活变得更加丰富多彩。

它就像一个默默奉献的幕后英雄,为我们制造出各种好用又好看的东西。

咱可得好好感谢这个工艺呀,不是吗?。

RTM工艺

树脂传递模塑成型(RTM)是一种介于手糊工艺和SMC工艺之间的、适合中等批量生产的闭模成型技术。

RTM的基本原理是将玻璃纤维增强材料铺入到闭模的模腔内,用压力将液态树脂注入模腔,浸润玻璃纤维增强材料,然后经固化、脱模后形成产品。

RTM工艺的优点:

1.无需胶衣涂层即可为构件提供光滑表面,能制造出具有良好表面的高精度复杂制品

2.模具制造及选材灵活性大,设备及模具投资小,产品只需做小的修边

3.产品铺层过程中可加入嵌件及对局部进行加强

4.制品纤维含量高,孔隙率低(<0.2%)

5.可以生产高性能、尺寸较大、批量中等的产品

目前,RTM工艺已广泛应用于建筑、交通、电讯、航海航天航空等领域

RTM模具、制品(高铁VIP座椅模具、制品):

高铁VIP座椅(扶手)上模高铁VIP座椅(扶手)下模

高铁VIP座椅高铁VIP座椅

地铁高压接线盒模具、制品:

地铁高压接线盒(盖板)模具地铁高压接线盒(底座)模具

地铁高压接线盒(防弧罩)模具

地铁高压接线盒制品

地铁高压接线盒制品

地铁高压接线盒制品。