台湾winner插装阀

- 格式:pdf

- 大小:11.11 MB

- 文档页数:93

Vickers™带位置反馈的三通插装阀11-05-0002C1000带位置反馈的三通插装阀目录页码概述和功能符号 3用于流量控制型的系统元件 4用于 p/Q型的系统元件 4型号编法:CVU-**-EPQ插装阀和 KBSD G4V-3...EN83 先导阀 5 CVU-**-EPQ插装阀:工作数据 6性能数据:压力增益和流量增益 7频率响应 8安装尺寸 9腔孔加工细节用于 CVU-32-EPQ110 和11腔孔加工细节用于 CVU-50-EPQ212 和13 KBSDG4V-3...EN83 先导阀:安装尺寸 14内置放大器: 方框图 15内置放大器: 接线 16应用数据 17本样本介绍型号 CVU - -EPQ 的三油口插装阀,它们在两类系统中作为基本功能元件:1. 流量控制和2. p /Q ,压力和流量控制。

液控的 CVU -**-EPQ 阀,必须由一个单独的比例电磁铁控制的先导阀控制。

这种推荐的先导阀包括在样本中。

规格 3 先导阀带有内置放大器,阀的型号是 KBSDG4V-3,允许与用户的控制三通功能通过闭式过渡特性提供在工作油口 “A” 和进油口 “P” 或出油口 “T”之间(根据阀芯位置)完全可控的节流作用。

在正常工况(即无液压先导压力)阀芯在弹簧作用下给出流道 “A ” 至 “T” ,这可用来作为 “故障保险” 工况。

这些阀供开环和闭环控制系统使用,这里给出的性能数据是当这些阀用于这类系统并采用合适的威格士先导阀和电控器时才具有的。

闭环压力控制主阀芯的零正遮盖工况使 EPQ 阀用于压力控制模式,通过检测压力传感器出油口 “A ” 处的压力使控制回路闭环。

单/双先导控制型式 EPQ 1来自远程先导阀 “A” 口的控制压力是通过安装接口中的 “X” 口,作用在阀芯顶部的整个面积上,阀芯位置则是由输入(指令)信号和 LVD T 位置反馈信号之间的关系来确定。

型式 EPQ 2先导压力除了通过油口 “X”, 还由先导阀的 “B” 口通过三通插装阀中的第二个先导控制口 “B” 连接到阀芯的环状面积,这样阀芯在两个方向的移动都受到先导压力的控制。

阀岛CPV10-EX-VI,紧凑性Subject to change –2019/112 Internet:/catalogue/...主要特性创新功能多样可靠性佳易于安装•立方体结构,性能出色,重量轻•坚固耐用•优化用于控制柜内安装•适用于过程阀的先导控制•流量大,结构十分紧凑•得益于每个阀片可有两个阀功能,每个阀岛最多可配备16片两位两通或两位三通阀•灵活而经济地连接2…8片阀•极佳的灵活性得益于:–多种气动功能(阀派生型)–不同的压力范围•隔离板,用于创建压力分区•盲板,用于未来扩展•阀有手控装置•安装在控制柜内时防护等级可达IP65•本安型阀岛,符合ATEX 类别2(区域1)•金属阀结构,十分坚固•使用寿命长•即可安装、已经过测试的单元•降低选型、订货、安装和调试成本•牢固地安装在墙面或H 型导轨上•复合接头板–快速替换阀模块,无需替换现有气管接口•阀装配为控制柜内安装而优化主要特性主要特性标签坚固的金属螺纹或预装配快插接头QS 丰富的阀功能、压力分区创建、盲板电接口简单:–单独接口快速安装:–用螺丝直接安装–安装在H型导轨上–通过复合接头板可靠操作:手控装置,按钮式、锁定式或封盖式阀宽–10mm配备选项阀功能•两位五通阀,单电控•两位五通阀,双电控•2x两位三通阀,常开•2x两位三通阀,常闭•2x两位三通阀,1x常开,1x常闭•2x两位三通阀,常闭,带集成背压保护•三位五通阀1)•2x两位两通阀,常闭•2x两位两通阀,1x常开,1x常闭特性单独连接•2…8个阀位,最多16个电磁线圈本安阀岛CPV10-EX-VI为本安设计,用于爆危场所,符合ATEX类别2(区域1)复合接头板复合接头板用于柜壁开口,便于在控制柜内安装,密封后,防护等级达IP65工作仅通过单独的阀连接本安电路驱动。

1)通过功能模块,不能组合复合接头板2019/11–Subject to change3Internet:/catalogue/...Subject to change –2019/114 Internet:/catalogue/...主要特性电接口单独连接,防爆CPV10-EX-VI 是一款本安型阀岛,用于区域1爆危场所(ATEX 类别2G)。

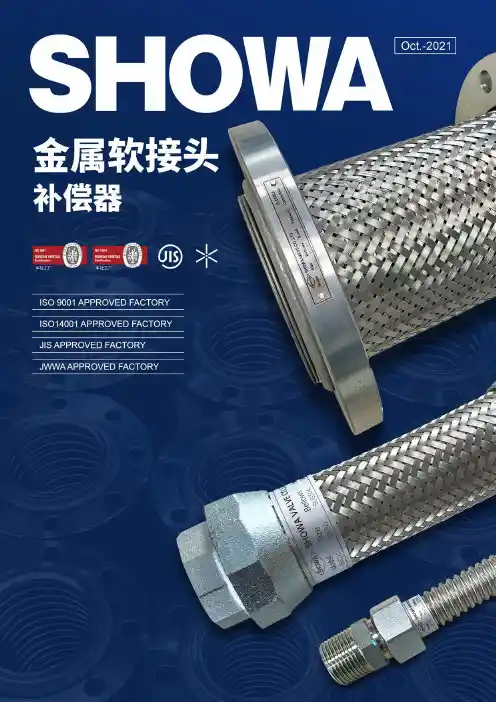

SHOWA 补偿器金属软接头目 录科目目录 ................................................................................................ 金属软接头..................................................................................EXF 110 .......................................................................................... EXF 115 .......................................................................................... EXF 122 .......................................................................................... EXS 210 .......................................................................................... EXS 255 .......................................................................................... 补偿器.........................................................................................EXDZ .............................................................................................. EXFZ .............................................................................................. EXWZ ............................................................................................. 软管和软网的尺寸及性能................................................................... 有变位时软管长度计算...................................................................... 正确的安装方式................................................................................ 法兰连接尺寸................................................................................... 单位换算表...................................................................................... 资料 不锈钢耐腐蚀表........................................................................ 软管产品选型、安装及实用注意事项.................................................... 0102-06020304050607-1207091113151819222328页码具有优异耐弯曲性能的焊接组装法兰连接形式。

氢气集装格阀门规格

- 美国rego高压总阀HP9560:这是一款低温气体充装阀,适用于氢气、氧气、氮气等气体的集装格。

其连接形式为螺纹,材质为黄铜,公称通径为DN15,压力环境为高压,标准为美标,外形为微型,流动方向为单向,驱动方式为气动。

- 衬胶隔膜阀SEG41W-16P:此型号的阀门使用介质为氢气,阀门材质要求304不锈钢,阀门内部有阀座、阀芯杆组件、四氟隔膜垫片(PTEF+EPDM)组成,所有内部件均可以拆卸方便与更换,零泄漏标准。

其尺寸要求为:阀门长度127mm,法兰孔距85mm。

- 衬胶隔膜阀G41J-10/DN25:该型号的阀门使用介质同样为氢气,其阀门长度为145mm,法兰孔距为85mm。

- 衬胶隔膜阀G41J-10/DN50:这款型号的阀门使用介质也是氢气,其阀门长度为210mm,法兰孔距为125mm。

需要注意的是,以上规格仅供参考,实际应用中可能会有所不同。

在选择氢气集装格阀门时,建议咨询专业人士或参考相关标准和规范,以确保选择合适的阀门规格。

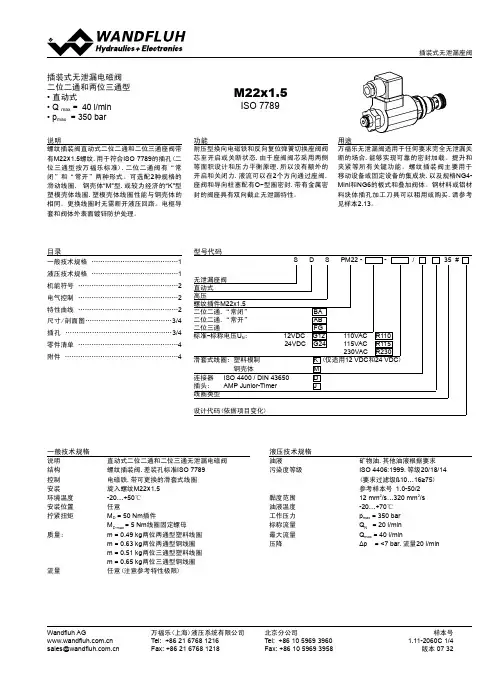

样本号1.11-2060C 1/4版本 07 32北京分公司Tel: +86 10 5969 3960Fax: +86 10 5969 3958万福乐(上海)液压系统有限公司Tel: +86 21 6768 1216Fax: +86 21 6768 1218Wandfluh AG 插装式无泄漏电磁阀二位二通和两位三通型• 直动式• Q max = 40 l/min • p max = 350 barM22x1.5用途万福乐无泄漏阀适用于任何要求完全无泄漏关断的场合,能够实现可靠的密封加载、提升和夹紧等所有关键功能。

螺纹插装阀主要用于移动设备或固定设备的集成块,以及规格NG4-Mini 和NG6的板式和叠加阀体。

钢材料或铝材料块体插孔加工刀具可以租用或购买,请参考见样本2.13。

说明螺纹插装阀直动式二位二通和二位三通座阀带有M22×1.5螺纹,用于符合ISO 7789的插孔(二位三通型按万福乐标准),二位二通阀有“常闭”和“常开”两种形式。

可选配2种规格的滑动线圈, 钢壳体“M”型,或较为经济的“K”型塑模壳体线圈,塑模壳体线圈性能与钢壳体的相同。

更换线圈时无需断开液压回路。

电枢导套和阀体外表面镀锌防护处理。

功能耐压型换向电磁铁和反向复位弹簧切换座阀阀芯至开启或关断状态,由于座阀阀芯采用两侧等面积设计和压力平衡原理,所以没有额外的开启和关闭力,液流可以在2个方向通过座阀,座阀和导向柱塞配有O -型圈密封,带有金属密封的阀座具有双向截止无泄漏特性。

一般技术规格说明 直动式二位二通和二位三通无泄漏电磁阀结构 螺纹插装阀,差装孔标准ISO 7789控制 电磁铁,带可更换的滑套式线圈安装 旋入螺纹M22×1.5环境温度 -20…+50℃安装位置 任意拧紧扭矩 M D = 50 Nm 插件M D max = 5 Nm 线圈固定螺母质量: m = 0.49 kg 两位两通型塑料线圈 m = 0.63 kg 两位两通型钢线圈 m = 0.51 kg 两位三通型塑料线圈 m = 0.65 kg 两位三通型钢线圈流量任意(注意参考特性极限)液压技术规格油液矿物油,其他油液根据要求污染度等级 ISO 4406:1999,等级20/18/14 (要求过滤级ß10…16≥75) 参考样本号 1.0-50/2黏度范围 12 mm 2/s…320 mm 2/s 油液温度 -20…+70℃工作压力 p max = 350 bar 标称流量 Q N = 20 l/min 最大流量 Q max = 40 l/min压降Δp = <7 bar ,流量20 l/minISO 7789目录一般技术规格 .......................................1液压技术规格 .......................................1机能符号 .............................................2电气控制 .............................................2特性曲线 .............................................2尺寸/剖面图.......................................3/4插孔 ................................................3/4零件清单 .............................................4附件 (4)型号代码S D S PM22 - - / 35 #无泄漏座阀直动式高压螺纹插件M22x1.5二位二通,“常闭” BA 二位二通,“常开” AB 二位三通 FG标准-标称电压U N :12VDC G12 110VAC R110 24VDC G24 115VAC R115 230VAC R230滑套式线圈: 塑料模制K (仅适用12 VDC 和24 VDC ) 钢壳体M 连接器 ISO 4400 / DIN 43650D 插头: AMP Junior-TimerJ 线圈类型设计代码(依据项目变化)样本号1.11-2060C 2/4版本 07 32北京分公司Tel: +86 10 5969 3960Fax: +86 10 5969 3958万福乐(上海)液压系统有限公司Tel: +86 21 6768 1216Fax: +86 21 6768 1218Wandfluh AG ******************.cn 机能符号SDSPM22-BA... SDSPM22-AB...SDSPM22-FG... 过渡机能“FG"电气控制结构湿式推力型耐压电磁铁带可更换的滑套式线圈标准标称电压 U N = 12 VDC, 24 VDCU N = 110 VAC*, 115 VAC*, 230 VAC* AC = 50至60 Hz*整流器集成在插头内可提供其他标称电压和性能的产品电压允差 ±10%,标称电压防护等级 IP 65,按EN 60 529(如果安装正确)相对暂载率 100%DF (见样本1.1-430)切换循环 15'000/h工作寿命 107(理论切换次数)连接/电源 具体见型号代码电磁铁类型: -钢线圈(M.35/16) (样本1.1-170)-塑料线圈(K.35/16)(样本1.1-172)p=f (Q ) 低于标称电压10%和在最高环境温度时的特性极限 二位二通型,“常闭”[BA]p=f (Q ) 低于标称电压10%和在最高环境温度时的特性极限 二位二通型,“常开”[AB]p=f (Q ) 低于标称电压10%和在最高环境温度时的特性极限 二位三通型[FG]Δp =f (Q )压力损失/流量特性流动方向品种1→2 2→1SDSPM22-BA-…/ “M” 1 2SDSPM22-BA-…/ “K”34流动方向品种1→2 2→1SDSPM22-AB-…/ “M” 1 2SDSPM22-AB-…/ “K”12流动方向品种1→22→1 2→3 3→2SDSPM22-FG-…/ “M” 4 1 2 3SDSPM22-FG-…/ “K”4156特性曲线 油液黏度 υ=30 mm 2/s备注!在不同的应用回路中,实际通流量允许大于额定流量,但是在换向期间,总流量(3→2和2→1)必须不大于Q=30 l/min 。

NORGREN电磁阀连接和安装方法详解一、焊接方式NORGREN电磁阀这种连接适用于各种压力和温度,在较荷刻的条件下使用时,比法兰连接更为牢靠。

但是焊接连接的阀门拆卸和重新安装都比较困难,所以它的使用限于通常能长期牢靠地运行,或使用条件荷刻、温度较高的场合。

如火力发电站、核能工程、乙烯工程的管道上。

公称通径在50mm以下的焊接阀门通常具有焊接插口来承接荷平面端的管道。

由于承插焊接在插口与管道间形成缝隙,因而有可能使缝隙受到某些介质的腐蚀,同时管道的振动会使连接部位疲乏,因此承插焊接的使用受到肯定的限制。

在公称直径较大,使用条件荷刻,温度较高的场合,阀体常采纳坡口对焊接,同时,对焊接缝有原格要求,必须选用技术过硬的焊工完成此项工作。

二、NORGREN电磁阀,其安装和拆卸都比较便利。

但是比螺纹连接的阀门沉重,相应价格也价高。

故它适用于各种通径和压力的管道连接。

但是,当温度超出350度时,由于螺栓、垫片和法兰一变松弛,也明显地降低螺栓的负荷,对受力很大的法兰连接可能产生泄漏。

三、NORGREN电磁阀这种连接通常是将阀门进出端部加工成锥管或直管螺纹,可使其连接到锥管螺纹接头或管路上。

由于这种连接可能显现较大的泄漏沟道,故可用密封剂、密封胶带或填料来堵塞这些沟道。

假如阀体的料子是可以焊接的,但膨胀系数差异很大,或者工作温度的变更幅度范围较大,螺纹连接部必须进行蜜封焊。

螺纹连接的阀门重要是公称通经在50mm以下的阀门。

假如通径尺寸过大,连接部的安装和密封非常困难。

NORGREN电磁阀安装前的准备工作1、保证NORGREN电磁阀安装位置管线在同轴位置上,管线上两片法兰应保持平行,确认管线能够经受球阀自身重量,假如发觉管线不能经受球阀重量,则在安装前为管线配备相应的支撑。

2、确认管线内是否有杂质、焊渣等,必须要把管线内吹扫干净。

核对电动偏心半球阀铭牌,并对球阀进行全开全闭数次操作,确认阀门能够正常工作,再全面检查一次阀门的各个细节,保证阀门完好无损。

进口阀门十大品牌一、品牌概述进口阀门是指生产和销售国外知名品牌阀门的企业。

进口阀门具有优质的材料、先进的制造工艺和可靠的性能,广泛应用于石油、化工、电力、冶金、水处理等行业。

本文将介绍进口阀门领域的十大品牌,以供参考。

二、品牌排名1. ABC阀门ABC阀门成立于20世纪80年代,总部位于美国。

该品牌专注于研发和生产高品质的进口阀门,广泛应用于石油和化工行业。

ABC阀门以其可靠性和性能而闻名,产品畅销全球。

2. XYZ阀门XYZ阀门是德国一家知名阀门制造商,成立于19世纪末。

该品牌拥有先进的技术和制造设备,产品涵盖各类阀门。

XYZ阀门以其精准的控制和耐久性而备受赞誉,是许多工程项目的首选品牌。

3. DEF阀门DEF阀门源自日本,创立于20世纪60年代。

该品牌以其高质量和创新性而闻名,产品广泛应用于能源、化工和制药等行业。

DEF阀门在国际市场上享有很高的声誉,是许多大型工程项目的合作伙伴。

4. GHI阀门GHI阀门是法国一家著名的阀门制造商,成立于19世纪。

该品牌注重产品的可靠性和安全性,产品通过了多项国际认证。

GHI阀门在石油和天然气行业中应用广泛,被公认为高品质阀门的代表品牌之一。

5. JKL阀门JKL阀门是英国一家历史悠久的阀门制造商,成立于19世纪中叶。

该品牌致力于创新和技术领先,产品涵盖各类阀门和控制系统。

JKL阀门以其卓越的性能和长寿命而受到客户的青睐。

6. MNO阀门MNO阀门源自意大利,创立于20世纪70年代。

该品牌专注于高端阀门的研发和制造,产品广泛应用于化工和石油行业。

MNO阀门以其精湛的工艺和可靠性而享有很高的声誉。

7. PQR阀门PQR阀门是瑞典一家知名阀门制造商,成立于20世纪90年代。

该品牌注重产品的可持续性和环保性能,产品通过了多项国际认证。

PQR阀门在水处理和环保领域中具有重要地位,是可靠的合作伙伴。

8. STU阀门STU阀门源自瑞士,创立于20世纪50年代。

该品牌以其精密的制造工艺和卓越的性能而著名,产品广泛应用于石油、天然气和化工行业。

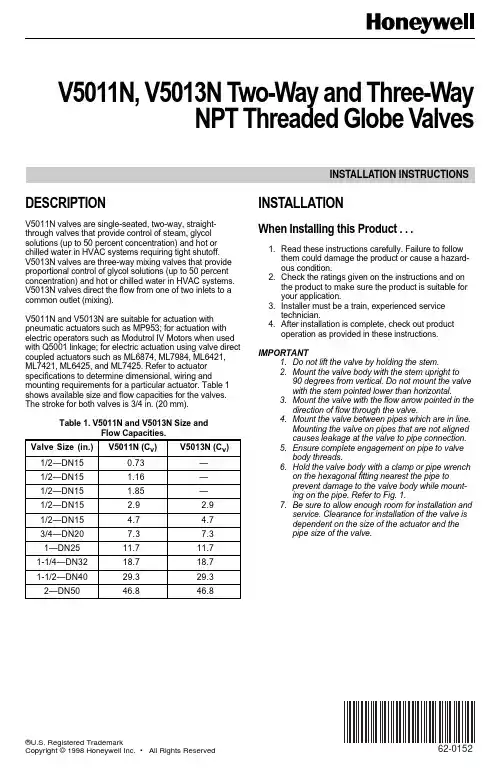

X-XX ULINSTALLATION INSTRUCTIONS®U.S. Registered TrademarkCopyright © 1998 Honeywell Inc. • All Rights Reserved62-0152V5011N, V5013N Two-Way and Three-WayNPT Threaded Globe ValvesDESCRIPTIONV5011N valves are single-seated, two-way, straight-through valves that provide control of steam, glycol solutions (up to 50 percent concentration) and hot or chilled water in HVAC systems requiring tight shutoff.V5013N valves are three-way mixing valves that provide proportional control of glycol solutions (up to 50 percent concentration) and hot or chilled water in HVAC systems.V5013N valves direct the flow from one of two inlets to a common outlet (mixing).V5011N and V5013N are suitable for actuation with pneumatic actuators such as MP953; for actuation with electric operators such as Modutrol IV Motors when used with Q5001 linkage; for electric actuation using valve direct coupled actuators such as ML6874, ML7984, ML6421,ML7421, ML6425, and ML7425. Refer to actuator specifications to determine dimensional, wiring andmounting requirements for a particular actuator. Table 1shows available size and flow capacities for the valves.The stroke for both valves is 3/4 in. (20 mm).INSTALLATIONWhen Installing this Product . . .1.Read these instructions carefully. Failure to follow them could damage the product or cause a hazard-ous condition.2.Check the ratings given on the instructions and on the product to make sure the product is suitable for your application.3.Installer must be a train, experienced service technician.4.After installation is complete, check out product operation as provided in these instructions.IMPORTANT1.Do not lift the valve by holding the stem.2.Mount the valve body with the stem upright to 90 degrees from vertical. Do not mount the valve with the stem pointed lower than horizontal.3.Mount the valve with the flow arrow pointed in the direction of flow through the valve.4.Mount the valve between pipes which are in line.Mounting the valve on pipes that are not aligned causes leakage at the valve to pipe connection.5.Ensure complete engagement on pipe to valve body threads.6.Hold the valve body with a clamp or pipe wrench on the hexagonal fitting nearest the pipe toprevent damage to the valve body while mount-ing on the pipe. Refer to Fig. 1.7.Be sure to allow enough room for installation and service. Clearance for installation of the valve is dependent on the size of the actuator and the pipe size of the valve.V5011N, V5013N TWO-WA Y AND THREE-WA Y NPT THREADED GLOBE VAL VESLocationSelect a location where the valve, linkage (if used), andactuator to be used are within the appropriate ambientpressure and temperature ratings.Leave sufficient clearance above the valve to accommo-date installation of the actuator and allow room forservicing the valve body. (The valve body should becompletely installed in the pipe line before the actuator andlinkage are installed.)When selecting a location for the valve, consider actuatormounting restrictions. Most Modutrol IV Motors require thatshafts be mounted horizontally.MountingThe preferred mounting position of the valve is with thestem vertical. For steam applications, mount with the stemat a 45 degree angle. Do not mount the valve with thestem more than 90 degrees from the vertical (pointinglower than horizontal). Scale and foreign material cancollect and can score the stem and cause packingleakage. Protect the stem from damage due to bending orscratching.V5011N, V5013N screwed body threads conform to American Standard Taper Pipe Threads (NPT).Align the pipes squarely with the valve at each end connection. If the pipes are forced into the valve, the body can become twisted and improper seating can result. Apply pipe dope sparingly. Be careful to prevent pipe debris such as pipe chips, scale, etc., from entering the piping because this material can lodge in the seat and prevent proper closing.Refer to Fig. 1 for valve pipe sizes and thread lengths. Fig. 1 also shows two effective methods of holding the valve and pipe when attaching it. The valve will not function properly if twisted or squeezed during installation.Fig. 1. Installing valve with threaded connections.CHECKOUTBefore installing linkage (if used) and actuator, make sure that valve stem operates freely. Impaired stem operation can indicate that the body was twisted or that the stem was bent. Either of these conditions may require valve replacement.Check valve body and connections for leaks. After installing linkage and actuator, check the operation according to installation information provided with these controls. Operate the system through one complete cycle to be sure the valve controls properly.USE VISE GRIPS WITH THE HEX END NEXT TO THE PIPE(DO NOT TWIST OR SQUEEZE VALVE BODY).USE VISE TO HOLD PIPE SECURELY TO PREVENT TURNING. USEPARALLEL-JAW WRENCH TO GRIP VALVE HEX FLATS NEXT TO PIPE.M11763A USE PROPERLY REAMED AND CLEANED PIPE AND MODERATEAMOUNT OF DOPE (LEAVE TWO THREADS BARE).PIPE SIZE(IN.)1/23/411-1/41-1/22EFFECTIVE LENGTH OF THREADSIN IN. (MM)1/29/1611/1611/1611/163/4(12.7)(14.3)(17.5)(17.5)(17.5)(19.1)112233。

TopWorx ™ D-Series Valve ControllersMaster Installation, Operation & Maintenance Manual35 Series GO™ Switches35-13319M Option L2/L4 - SPDT35-83358M Option Z2/Z4 - DPDT Stainless SteelSwitch / Module Replacement KitsAV-FFD2-1Foundation Fieldbus module replacement ( with piezo pilots) AV-FFD2-2Foundation Fieldbus module replacement ( without piezo pilots) AV-AS1-1AS-Interface moduleAV-DN1-1DeviceNet moduleAV-PB1-1Profibus ModuleAV-MSW1 (M) SPDT mechanical switch replacementAV-E1 (E) P+F NJ2-V3-N sensor replacementAV-TSW1 (T) DPDT mechanical switch replacementAV-420TBD4-20mA transmitter replacement assemblyAV-420HBD Hart Board ReplacementIndicator / Dome Replacement KitsAV-GB00290º, Green/Open, Red/Closed, Buna O-RingAV-YB00290º, Yellow/Open, Black/Closed, Buna O-RingAV-BB00290º, Black/Open, Yellow/Closed, Buna O-RingAV-4B00245º, Green/Open, Red/Closed, Buna O-RingShaft Replacement KitsMechanical Switches (M2 or T2)AV-SSB201 Standard shaftBuna-N O-Rings & (2) cam Assembly w/ HardwareAV-NSB201 NAMUR ShaftBuna-N O-Rings & (2) cam Assembly w/ HardwareShaft Replacement KitsGO™ Switches (L2 - Manufactured after July 1, 2007)AV-SSB205 Standard shaftBuna-N O-Rings & (2) Target Assembly w/ HardwareAV-SNB205 NAMUR shaftBuna-N O-Rings & (2) Target Assembly w/ HardwareShaft Replacement Kits SCMs with Reed Switches (R2)AV-NSB202NAMUR ShaftBuna-N O-Rings & (2) cam Assembly w/ HardwareAV-SSB202Standard ShaftBuna-N O-Rings & (2) cam Assembly w/ HardwareConsult FactoryTo order replacement parts or for information concerning parts or spool valve options not listed callTopWorx™ at 502-969-800052Pilot Replacement KitsAV -S24VPMRK 24vdc pilot/manifold replacement kitAV-S110VPMRK 110vac pilot/manifold replacement kitAV-A220PMRK220 VAC pilot/manifold replacement kitAV-SP20PMRK Piezo pilot/manifold replacement kitSpool Valve Replacement AssembliesAV-AB1A20ASCO 8551 Spool Valve, Fail Open/Closed, Aluminum AV-AB1620ASCO 8551 Spool Valve, Fail Open/Closed, SSTAV-AV2A20ASCO 8551 Spool Valve, Fail Last, AluminumAV-AB2620ASCO 8551 Spool Valve, Fail Last, SSTAV-AB1A30ASCO 8553 Spool Valve, Fail Open/Closed, Aluminum AV-AB1630ASCO 8553 Spool Valve, Fail Open/Closed, SSTAV-AB2A30ASCO 8553 Spool Valve, Fail Last, AluminumAV-AB2630ASCO 8533 Spool Valve, Fail Last, SST53。

螺纹插装阀生产商1.HYDRAFORCE(海德福斯)1983年,当时世界上规模最大的螺纹插装阀专业生产厂Modular公司被Vickers公司并购。

两年后,3个当年Modular的员工建立了HYDRAFORCE公司。

至今,HF在美国的厂房达13,000m²,在英国的厂房也有4,650m²。

2003年销售额已达90MUS$,螺纹插装阀的生产规模是世界第一。

以前产品基本以中压为主,无平衡阀。

现在也已开发了很多高压的阀。

孔型以ICC 系列为主。

2.SUNSUN公司建立于1970年。

目前在美、英、德、法、韩、印多处有子公司。

1998年与台湾橡达公司合作,在上海松江建立了一个合资子公司。

2011年初退出了合资,建立了自己在中国的销售公司。

橡达公司仍然是SUN产品的代理商。

2004年螺纹插装阀的产能就达到5.8 万件/周。

2010年销售额达到了150MUS$,税后纯利润达12%。

公司销售收入约75%来自螺纹插装阀,25%则来自阀块和集成块。

产品约70%供应移动液压,30%固定液压。

孔型自成一格,公制英制螺纹兼有。

3.Sterling(斯特林)母公司在英国的Crewkerne。

以前生产汽车零件,60年代后期开始生产螺纹插装阀。

90年代初,美国Waterman公司的主任设计师Kolchinski先生到了Sterling公司美国分部,开始研发电磁阀。

95年形成全系列。

他设计的电磁线圈后被Parker公司称为Super-Coil超级线圈。

插装阀生产能力达到1.5百万件/年。

30%供应建筑机械公司Caterpillar。

2004年的销售额约为35M€。

2005年6月被Parker Hannifin公司兼并了,成为Parker Hannifin公司插装阀系统欧洲总部,管辖处于瑞典和捷克的分部。

孔型以SAE 和ICC 为主。

4.Parker Hannifin(派克汉尼汾)派克汉尼汾的液压插装阀部门通过兼并拥有了众多受人尊敬的品牌。

进口阀门十大品牌一、品牌概述进口阀门是指生产制造商位于国外,产品进口到国内销售的阀门品牌。

进口阀门通常具有优质的材料、先进的制造工艺和严格的质量控制,因此备受消费者的青睐。

在国内市场上,有许多知名的进口阀门品牌,下面将介绍十大品牌。

二、进口阀门十大品牌介绍1. ABC Valve(ABC阀门)ABC阀门是一家国际知名的阀门制造商,总部位于欧洲。

该品牌的阀门产品涵盖了各个领域,包括石油、天然气、化工、能源等行业。

ABC阀门以其卓越的质量和可靠性而闻名,产品广泛销售到全球各地。

2. XYZ Valve(XYZ阀门)XYZ阀门是一家亚洲领先的进口阀门品牌,总部位于日本。

该品牌的阀门产品在全球范围内广受认可,其独特的设计和高品质的制造使其成为许多行业的首选。

XYZ阀门在石油、化工、电力等领域中有着广泛的应用。

3. DEF Valve(DEF阀门)DEF阀门是一家美国知名的进口阀门制造商,其产品以其高度可靠性和卓越的性能而著称。

该品牌的阀门广泛应用于石油、天然气、化工等行业,满足了客户对高质量阀门的需求。

4. GHI Valve(GHI阀门)GHI阀门是一家欧洲领先的进口阀门品牌,其产品质量一直以来都备受认可。

GHI阀门的产品涵盖了多个行业,包括石油、化工、制药等。

该品牌的阀门以其先进的技术和卓越的性能而闻名。

5. JKL Valve(JKL阀门)JKL阀门是一家亚洲知名的进口阀门制造商,其产品在国际市场上享有盛誉。

JKL阀门的产品广泛应用于石油、天然气、化工等行业,以其高质量和可靠性而受到客户的青睐。

6. MNO Valve(MNO阀门)MNO阀门是一家澳大利亚著名的进口阀门品牌,其产品在全球范围内销售。

MNO阀门的产品质量一直以来都备受认可,其广泛应用于石油、天然气、化工等行业。

7. PQR Valve(PQR阀门)PQR阀门是一家欧洲知名的进口阀门制造商,其产品以其卓越的质量和可靠性而受到客户的赞誉。

万福乐的电磁阀的使用原理

万福乐电磁阀是一种利用电磁力控制液流的装置。

它主要由电磁铁、阀体、阀芯、弹簧等组成。

当电磁铁通电时,产生的磁场将会使得阀芯受到电磁力的作用而被吸引,从而改变阀门的开启状态,控制液体的流通。

电磁阀的使用原理可以分为两个阶段:通电阶段和断电阶段。

在通电阶段,当电磁阀接收到电流信号时,电磁铁中的线圈产生磁场,使得阀体上的阀芯受到吸引力,将阀芯向电磁铁方向移动。

当阀芯移动到一定位置时,阀芯上的密封垫与阀座之间的密封面离开,液体便可顺利通过阀体进入管道,在阀门开启的状态下,液体可以流通。

在断电阶段,当电磁铁停止通电时,电磁铁中的线圈产生的磁场消失,此时弹簧的作用力大于阀芯上的吸引力,将阀芯向弹簧的方向移动。

当阀芯移动到一定位置时,阀芯上的密封垫与阀座之间的密封面重新贴合在一起,阀门关闭。

在阀门关闭的状态下,液体无法通过阀体进入管道,流通被阻断。

总结来说,万福乐电磁阀的使用原理是通过控制电磁铁的通电和断电,利用电磁力使阀芯发生位移,从而改变阀门的开启状态。

当通电时,阀门开启,液体可以流通;断电时,阀门关闭,液体不能通过。

这种使用原理使得电磁阀可以广泛应用于管道系统中,实现对液体、气体等流体的控制和调节。

例如,在自动化设备、

工业生产和家用设备中都可以见到万福乐电磁阀的身影,发挥着重要的作用。

上海蕴匠贸易有限公司专业经销美国topworx阀门、topworx 开关阀、topworx旋转阀、topworx、topworx线性阀、topworx 限位开关、topworx阀门控制器。

欢迎有需求的客户前来咨询、洽谈!

美国topworx是美国著名的阀门生产厂家,公司被艾默生收购后成为艾默生过程管理的一部分,扩充艾默生现有的阀门产品线,同时将艾默生plantweb数字工厂产品范围延伸到开关阀及其它仪表。

美国topworx的主产品之一:阀门控制和定位感应解决方案能使工厂、平台和管道在极端苛刻的环境中实现更为智能化和有效的管理及控制。

TOPWORX 位置反馈器 DXP-T21GNEB

TOPWORX 开关TV A-E20GNAM

TOPWORX 位置开关DXP-M21GNEB

TOPWORX 回讯开关TXP-M2CFNEM

TOPWORX 回讯开关TXP-M21GNEM

TOPWORX 开关DXP-M21BS4B 4569

TOPWORX 开关73-1352T-B2。

安装NORGREN电磁阀阀芯出现问题有哪些原因安装NORGREN电磁阀阀芯消失问题有哪些缘由NORGREN电磁阀的主要特点是响应快、微小型、耐压高,它在原有微型低压电磁阀设计的基础上,进行了一些必要的修改,如通过增大电磁吸力来实现电磁阀快速响应; 通过简化结构达到小型化等。

为了使NORGREN电磁阀达到的性能并满意尺寸、重量、性能等要求,设计中主要从材料和参数的优化选取、结构尺寸的细心设计、加工工艺的合理制定等方面对电磁阀的各个部件进行了结构及性能的优化设计。

由于微型高压电磁阀的高性能指标与微小型化的结构是相互冲突的,因此,在整个设计中,必需通过严密的设计以及反复的性能测试,掌握电磁阀的设计余量,电磁阀的小型化和高性能。

微型高压电磁阀是在微型低压电磁阀的基础上改进而成的。

高压电磁阀的工作介质一般是氮气、氦气、氙气、液化气(如NH3)等。

其工作原理是:当线圈通电时,线圈产生足够的电磁力克服弹簧和介质压力,从而驱动衔铁运动,阀门打开,工作介质由阀门的入口经过衔铁上的流道,从下游流出,当线圈断电时,电磁力消逝,衔铁在弹簧力及介质压力作用下复位,回到关闭位置,形成密封,将介质流淌截断。

微型高压电磁阀是传统的螺管式常闭电磁阀,采纳了紧凑的单线圈、单阀座、螺旋弹簧、全焊接结构形式,该阀门充分继承成熟产品的技术,从微小型化的角度进行了优化,并且在微型低压电磁阀的基础上大大提高了阀门的工作压力,其结构简洁、重量轻、体积小、功耗低、响应快,且工作压力范围广。

NORGREN电磁阀阀芯是整个电磁阀结构中的部件之一,一旦阀芯发生故障问题,例如堵塞和损坏等,则整个电磁阀无法正常使用和工作。

详细导致电磁阀阀芯故障的缘由有以下几个:缘由1、安装错误问题安装错误,例如安装方向错误,接线错误等,都会导致电磁阀无法正常工作,严峻的就会导致电磁阀部件损坏,例如电磁阀的阀芯或者其他接口的损坏。

缘由2、工作环境发生变化例如工作环境的温度、压力等,或者介质的属性发生变化,而使用用户仍旧牵强使用,或者在不知道的状况下连续使用,则同样简单造成电磁阀阀芯故障问题。

TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 30 Cavity-Tooling: 08W-2Installation torque: 25-35Weight: 0.13Z2A2 Ports 、20 Watt. CoilNon-adjustableNkgNm l/min bar01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-ClosedNo Reverse Flow Energized1210864240302010P r e s s u r e - P (b a r )Flow-Q(l/min)14②t o ①TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 25-35 Weight: 0.13 Z2A2 Ports 、20 Watt. CoilNon-adjustable N kg Nm l/min bar642503020100P r e s s u r e - P (b a r )Flow-Q(l/min)01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 210 bar 90 % of nominal8②t o ①Normally-ClosedNo Reverse Flow Energized40TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 10W-2Installation torque: 35-45 Weight: 0.16Z2A2 Ports 、20 Watt. CoilNon-adjustable NkgNml/minbar01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-ClosedNo Reverse Flow EnergizedFlow-Q(l/min)P r e s s u r e - P (b a r )102060802468101230405070②t o ①TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 12W-2Installation torque: 45-55 Weight: 0.23Z2A2 Ports 、20 Watt. CoilNon-adjustable NkgNm l/minbar12108642150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominal②t o ①Normally-ClosedNo Reverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 16W-2Installation torque: 60-70 Weight: 0.35 Z2A 2 Ports 、20 Watt. CoilNon-adjustable Nkg Nm l/minbar12108642150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominal②t o ①Normally-ClosedNo Reverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 17E-2Installation torque: 45-55 Weight: 0.22Z2A2 Ports 、20 Watt. CoilNon-adjustableNkgNm l/min bar01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalFlow-Q(l/min)P r e s s u r e - P (b a r )102060802468101230405070②t o ①Normally-ClosedNo Reverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 21E-2Installation torque: 70-90 Weight: 0.35Z2A2 Ports 、20 Watt. CoilNon-adjustableNkgNm l/min bar01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalFlow-Q(l/min)P r e s s u r e - P (b a r )3060901201502468101214②t o ①Normally-ClosedNo Reverse Flow EnergizedSOLENOID OPERATED VALVES(Pilot Operated)TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 13A-2Installation torque: 25-35 Weight: 0.13 Z2A2 Ports 、20 Watt. CoilNon-adjustable N kgNm l/minbar642503020100P r e s s u r e - P (b a r )Flow-Q(l/min)01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute (3 drops/minute) max.at 210 bar 90 % of nominal8②t o ①Normally-ClosedNo Reverse Flow Energized40GENERAL INDEXSOLENOID OPERATED VALVESTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 250Rated flow: 20 Cavity-Tooling: 08W-2Installation torque: 25-35 Weight: 0.13Z2A2 Ports 、20 Watt. CoilLkgNm l/min bar01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute (3 drops/minute) max.at 250 bar 90 % of nominalFlow-Q(l/min)P r e s s u r e - P (b a r )51015202524681012142 t o1Normally-ClosedNo Reverse Flow EnergizedPULL STYPE(CABLE OPERATED)TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 25-35Weight: 0.132A2 Ports 、20 Watt. CoilkgNm l/min bar 01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalWhen de-energized, the valve acts as a check vlave,allowing flow from ①to ②,while blocking flow from ②to ①.When energized,the cartridge's poppet lifts to Normally-ClosedNo Reverse Flow EnergizedN Non-adjustable ZOPTIONSFlow-Q(l/min)14106240②t o ①16P r e s s u r e - P (b a r )1020304812TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 10W-2Installation torque: 35-45 Weight: 0.162A2 Ports 、20 Watt. CoilkgNm l/min bar01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalWhen de-energized, the valve acts as a check vlave,allowing flow from ①to ②,while blocking flow from ②to ①.When energized,the cartridge's poppet lifts to Normally-ClosedNo Reverse Flow Energized1210864280604020P r e s s u r e - P (b a r )Flow-Q(l/min)14②t o①N Non-adjustable ZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 12W-2Installation torque: 45-55 Weight: 0.232A2 Ports 、20 Watt. CoilkgNm l/minbar30252015105150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalWhen de-energized, the valve acts as a check vlave,allowing flow from ①to ②,while blocking flow from ②to ①.When energized,the cartridge's poppet lifts to ②to ①Normally-ClosedNo Reverse Flow EnergizedN Non-adjustable ZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 16W-2Installation torque: 60-70 Weight: 0.352A2 Ports 、20 Watt. CoilkgNm l/minbar30252015105150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalWhen de-energized, the valve acts as a check vlave,allowing flow from ①to ②,while blocking flow from ②to ①.When energized,the cartridge's poppet lifts to ②to ①Normally-ClosedNo Reverse Flow EnergizedNNon-adjustableZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 17E-2Installation torque: 45-55 Weight: 0.222A2 Ports 、20 Watt. CoilkgNm l/minbar 01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalWhen de-energized, the valve acts as a check vlave,allowing flow from ①to ②,while blocking flow from ②to ①.When energized,the cartridge's poppet lifts to Normally-ClosedNo Reverse Flow EnergizedNNon-adjustableZOPTIONS②t o①14Flow-Q(l/min)P r e s s u r e - P (b a r )2040608024681012TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 21E-2Installation torque: 70-90 Weight: 0.35Z2A2 Ports 、20 Watt. CoilNon-adjustableNkgNm l/minbar30252015105150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)01Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalWhen de-energized, the valve acts as a check vlave,allowing flow from ①to ②,while blocking flow from ②to ①.When energized,the cartridge's poppet lifts to ②to ①Normally-ClosedNo Reverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 30 Cavity-Tooling: 08W-2Installation torque: 25-35 Weight: 0.112A2 Ports 、20 Watt. CoilkgNm l/min bar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 210 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energized40②t o ①8Flow-Q(l/min)P r e s s u r e - P (b a r )102030246Push StyleN Non-adjustable ZOPTIONS101214TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 25-35 Weight: 0.132A2 Ports 、20 Watt. CoilkgNm l/min bar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 210 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energized40②t o ①8Flow-Q(l/min)P r e s s u r e - P (b a r )010203050246Push StyleN Non-adjustable ZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 10W-2Installation torque: 35-45 Weight: 0.162A2 Ports 、20 Watt. CoilkgNml/minbar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energized②t o ①705040301210864280602010P r e s s u r e - P (b a r )Flow-Q(l/min)OPTIONSZNon-adjustable N Push StyleTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 12W-2Installation torque: 45-55 Weight: 0.232A2 Ports 、20 Watt. CoilkgNm l/min bar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energized②t o ①Flow-Q(l/min)P r e s s u r e - P (b a r )30609012015024681012Push StyleN Non-adjustable ZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 16W-2Installation torque: 60-70 Weight: 0.352A2 Ports 、20 Watt. Coilkg Nm l/minbar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energized12108642150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)②t o ①N Non-adjustable ZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 17E-2Installation torque: 45-55 Weight: 0.222A2 Ports 、20 Watt. Coilkg Nm l/minbar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energizedFlow-Q(l/min)P r e s s u r e - P (b a r )102060802468101230405070②t o ①Push StyleN Non-adjustable ZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 21E-2Installation torque: 70-90 Weight: 0.352A2 Ports 、20 Watt. CoilkgNml/minbar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energized②t o ①Flow-Q(l/min)P r e s s u r e - P (b a r )30609012015024681012OPTIONSZNon-adjustable N Push StylePTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 13A-2Installation torque: 25-35 Weight: 0.142A2 Ports 、20 Watt. CoilkgNm l/minbar02Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute (3 drops/minute) max.at 210 bar 90 % of nominalNormally-OpenNo Reverse Flow De-energized40②t o ①8Flow-Q(l/min)P r e s s u r e - P (b a r )010203050246Push StyleN Non-adjustable ZOPTIONS(Pilot Operated)SOLENOID OPERATED VALVESGENERAL INDEXTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 45-55 Weight: 0.132A2 Ports 、20 Watt. CoilkgNm l/min bar03Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-Closed,Reverse FlowEnergized,Nose-in,Side-out OperationNNon-adjustableZOPTIONSFlow-Q(l/min)P r e s s u r e - P (b a r )102030405101520①t o②TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 17E-2Installation torque: 45-55 Weight: 0.222A2 Ports 、20 Watt. CoilkgNml/min bar03Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-Closed,Reverse FlowEnergized,Nose-in,Side-out OperationNNon-adjustableZOPTIONSFlow-Q(l/min)①t o ②7060P r e s s u r e - P (b a r )102030405051015TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 21E-2Installation torque: 70-90 Weight: 0.352A2 Ports 、20 Watt. CoilkgNm l/minbar 03Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute (3 drops/minute) max.at 350 bar 90 % of nominalNormally-Closed,Reverse FlowEnergized,Nose-in,Side-out OperationNNon-adjustableZOPTIONSFlow-Q(l/min)20①t o②P r e s s u r e - P (b a r )30609012015051015TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 260 Cavity-Tooling: 04E-2Installation torque: 110-130 Weight: 1.132A2 Ports 、20 Watt. Coilkg Nm l/minbar03Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute (3 drops/minute) max.at 350 bar 90 % of nominalNormally-Closed,Reverse FlowEnergized,Nose-in,Side-out OperationNNon-adjustableZOPTIONS12①to ②Flow-Q(l/min)P r e s s u r e - P (b a r )060120180240300369TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 25-35 Weight: 0.132A2 Ports 、20 Watt. CoilkgNm l/min bar151055040302010P r e s s u r e - P (b a r )Flow-Q(l/min)04Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separatelyMounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-Open,Reverse FlowDe-energized ,Nose-in,Side-out Operation20OPTIONSZNon-adjustable N Push Style①t o ②TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 260 Cavity-Tooling: 04E-2Installation torque: 110-130 Weight: 1.132A2 Ports 、20 Watt. Coilkg Nm l/minbar963300240180120600P r e s s u r e - P (b a r )Flow-Q(l/min)04Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute (3 drops/minute) max.at 350 bar 90 % of nominal①t o ②Normally-Open,Reverse FlowDe-energized ,Nose-in,Side-out Operation12OPTIONSZNon-adjustable N Push StyleTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 30 Cavity-Tooling: 08W-2Installation torque: 25-35Weight: 0.13Z2A2 Ports 、20 Watt. CoilNon-adjustableNkgNm l/min bar05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-ClosedReverse Flow Energized1210864240302010P r e s s u r e - P (b a r )Flow-Q(l/min)14②t o ①TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 25-35 Weight: 0.13 Z2A2 Ports 、20 Watt. CoilNon-adjustable N kg Nm l/min bar05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 210 bar 90 % of nominalNormally-ClosedReverse Flow Energized②to ①Flow-Q(l/min)P r e s s u r e - P (b a r )102030405024681012TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 10W-2Installation torque: 35-45 Weight: 0.16Z2A2 Ports 、20 Watt. CoilNon-adjustable NkgNml/minbar05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-ClosedReverse Flow EnergizedFlow-Q(l/min)P r e s s u r e - P (b a r )102060802468101230405070②t o ①TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 12W-2Installation torque: 45-55 Weight: 0.23 Z2A2 Ports 、20 Watt. CoilNon-adjustable N kg Nml/minbar12108642150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominal②t o ①Normally-ClosedReverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 16W-2Installation torque: 60-70 Weight: 0.35 Z2A 2 Ports 、20 Watt. CoilNon-adjustable N kg Nm l/minbar12108642150120906030P r e s s u r e - P (b a r )Flow-Q(l/min)05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominal②t o ①Normally-ClosedReverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 17E-2Installation torque: 45-55 Weight: 0.22Z2A2 Ports 、20 Watt. CoilNon-adjustableNkgNm l/min bar05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalFlow-Q(l/min)P r e s s u r e - P (b a r )102060802468101230405070②t o ①Normally-ClosedReverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 21E-2Installation torque: 70-90 Weight: 0.35Z2A2 Ports 、20 Watt. CoilNon-adjustableNkgNml/minbar05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalFlow-Q(l/min)P r e s s u r e - P (b a r )3060901201502468101214②t o ①Normally-ClosedReverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 25-35Weight: 0.132A2 Ports 、20 Watt. CoilkgNm l/min bar 05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-ClosedReverse Flow EnergizedN Non-adjustable ZOPTIONSFlow-Q(l/min)14106240②t o ①16P r e s s u r e - P (b a r )1020304812TECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 70 Cavity-Tooling: 17E-2Installation torque: 45-55 Weight: 0.222A2 Ports 、20 Watt. CoilkgNm l/minbar 05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or betterMinimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-ClosedReverse Flow EnergizedNNon-adjustableZOPTIONS②t o①14Flow-Q(l/min)P r e s s u r e - P (b a r )2040608024681012TECHNICAL DATASTRUCTUREXOPERATIONOPTIONSYMax.Operating pressure: 350 Rated flow: 150 Cavity-Tooling: 21E-2Installation torque: 70-90 Weight: 0.35Z2A2 Ports 、20 Watt. CoilNon-adjustableNkg Nm l/minbar05Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalFlow-Q(l/min)P r e s s u r e - P (b a r )3060901201505101520253035Normally-ClosedReverse Flow EnergizedTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 30 Cavity-Tooling: 08W-2Installation torque: 25-35Weight: 0.132A2 Ports 、20 Watt. CoilkgNm l/min bar06Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-OpenReverse Flow De-Energized1210864240302010P r e s s u r e - P (b a r )Flow-Q(l/min)14②t o ①Push StyleN Non-adjustable ZOPTIONSTECHNICAL DATASTRUCTUREXOPERATIONYMax.Operating pressure: 350 Rated flow: 40 Cavity-Tooling: 08W-2Installation torque: 25-35Weight: 0.132A2 Ports 、20 Watt. CoilkgNm l/min bar06Fluids-Temperatures: -40~120Internal Leakage:Filtration: 25 μm nominal or better Minimun Voltage Required:Coils must be ordered separately Mounting Position:℃unrestricted0.15cc/minute(3 drops/minute) max.at 350 bar 90 % of nominalNormally-OpenReverse Flow De-Energized2 t o114121086425040302010P r e s s u r e - P (b a r )Flow-Q(l/min)Push StyleN Non-adjustable ZOPTIONS。