工程材料科学与设计(原书第2版)课后习题答案(4—8)

- 格式:doc

- 大小:2.15 MB

- 文档页数:228

武汉理工大学材料科学基础(第2版)课后习题和答案第一章绪论1、仔细观察一下白炽灯泡,会发现有多少种不同的材料?每种材料需要何种热学、电学性质?2、为什么金属具有良好的导电性和导热性?3、为什么陶瓷、聚合物通常是绝缘体?4、铝原子的质量是多少?若铝的密度为2.7g/cm3,计算1mm3中有多少原子?5、为了防止碰撞造成纽折,汽车的挡板可有装甲制造,但实际应用中为何不如此设计?说出至少三种理由。

6、描述不同材料常用的加工方法。

7、叙述金属材料的类型及其分类依据。

8、试将下列材料按金属、陶瓷、聚合物或复合材料进行分类:黄铜钢筋混凝土橡胶氯化钠铅-锡焊料沥青环氧树脂镁合金碳化硅混凝土石墨玻璃钢9、Al2O3陶瓷既牢固又坚硬且耐磨,为什么不用Al2O3制造铁锤?第二章晶体结构1、解释下列概念晶系、晶胞、晶胞参数、空间点阵、米勒指数(晶面指数)、离子晶体的晶格能、原子半径与离子半径、配位数、离子极化、同质多晶与类质同晶、正尖晶石与反正尖晶石、反萤石结构、铁电效应、压电效应.2、(1)一晶面在x、y、z轴上的截距分别为2a、3b、6c,求出该晶面的米勒指数;(2)一晶面在x、y、z 轴上的截距分别为a/3、b/2、c,求出该晶面的米勒指数。

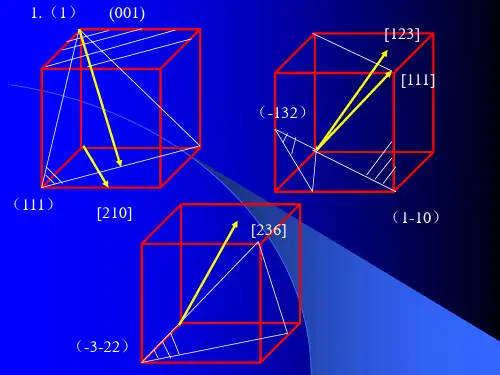

3、在立方晶系的晶胞中画出下列米勒指数的晶面和晶向:(001)与[210],(111)与[112],(110)与[111],(322)与[236],(257)与[111],(123)与[121],(102),(112),(213),[110],[111],[120],[321]4、写出面心立方格子的单位平行六面体上所有结点的坐标。

5、已知Mg2+半径为0.072nm,O2-半径为0.140nm,计算MgO晶体结构的堆积系数与密度。

6、计算体心立方、面心立方、密排六方晶胞中的原子数、配位数、堆积系数。

7、从理论计算公式计算NaC1与MgO的晶格能。

MgO的熔点为2800℃,NaC1为80l℃, 请说明这种差别的原因。

第一章材料的结构与性能一、材料的性能(一)名词解释弹性变形:去掉外力后,变形立即恢复的变形为弹性变形。

塑性变形:当外力去除后不能够恢复的变形称为塑性变形。

冲击韧性:材料抵抗冲击载荷而不变形的能力称为冲击韧性。

疲劳强度:当应力低于一定值时,式样可经受无限次周期循环而不破坏,此应力值称为材料的疲劳强度。

σ为抗拉强度,材料发生应变后,应力应变曲线中应力达到的最大值。

bσ为屈服强度,材料发生塑性变形时的应力值。

sδ为塑性变形的伸长率,是材料塑性变形的指标之一。

HB:布氏硬度HRC:洛氏硬度,压头为120°金刚石圆锥体。

(二)填空题1 屈服强度、抗拉强度、疲劳强度2 伸长率和断面收缩率,断面收缩率3 摆锤式一次冲击试验和小能量多次冲击试验, U型缺口试样和V型缺口试样4 洛氏硬度,布氏硬度,维氏硬度。

5 铸造、锻造、切削加工、焊接、热处理性能。

(三)选择题1 b2 c3 b4 d f a (四)是非题 1 对 2 对 3错 4错(五)综合题 1 最大载荷为2805.021038.5πσ⨯=F b断面收缩率%10010810010⨯-=-=A A A ϕ 2 此题缺条件,应给出弹性模量为20500MP,并且在弹性变形范围内。

利用虎克定律 320℃时的电阻率为13.0130℃时的电阻率为18.01二、材料的结合方式 (一)名词解释结合键:组成物质的质点(原子、分子或离子)间的相互作用力称为结合键,主要有共价键、离子键、金属键、分子键。

晶体:是指原子在其内部沿三维空间呈周期性重复排列的一类物质。

非晶体:是指原子在其内部沿三维空间呈紊乱、无序排列的一类物质。

近程有序:在很小的范围内(一般为几个原子间距)存在着有序性。

(二)填空题1 四,共价键、离子键、金属键、分子键。

2 共价键和分子键,共价键,分子键。

3 强。

4 强。

(三)选择题1 a2 b3 a(四)是非题1 错2 错3 对4 错(五)综合题1晶体的主要特点:○1结构有序;○2物理性质表现为各向异性;○3有固定的熔点;○4在一定条件下有规则的几何外形。

工程材料与机械制造基础第二版课后练习题含答案第一章金属材料选择题1.金属的基本结构单位是()。

A. 原子 B. 分子 C. 离子 D. 高分子2.金属的导电性好,是因为()。

A. 金属原子共用周围电子形成了一个电子云 B. 金属原子之间的原子序数很大 C. 金属原子之间的距离很远D. 金属原子的原子半径很大3.现代材料科学的研究表明,金属的显微结构主要包括()两种结构。

A. 晶体和非晶体B. 多晶和单晶C. 非晶体和薄层结构D. 单晶和二晶轴4.在常温下铁、钨属于()。

A. 非晶态材料 B. 晶态材料 C. 二相材料 D. 单晶体材料5.劈铅试验所测试的是材料()。

A. 塑性 B. 韧性 C. 硬度 D. 强度简答题1.什么是金属材料?金属材料具有哪些特点?2.金属的结晶状态有哪些?请简述它们的特点。

3.介绍一下金属断裂的过程。

4.解释一下热处理和强化的含义。

答案选择题:1. A 2. A 3. B 4. B 5. D简答题:1.金属材料是一类以金属元素为主要组成成分的工程材料,具有一系列特点,如:密度大,强度高,塑性良好,导电导热性好等。

同时,也具有一些不足之处,如:易受腐蚀,疲劳寿命相对较短等。

2.金属的结晶状态主要有三种,分别为单晶、多晶以及非晶态。

单晶指的是具有完整晶格结构的材料,其具有优异的物理性能,但制造成本较高。

而多晶则指晶粒较小、有多个晶粒构成的材料。

这类材料具有低成本、高韧性等特点。

非晶态指材料的内部没有固定的原子排列方式,呈无序状态。

这类材料具有高强度、低应力腐蚀等特点。

3.金属断裂的过程主要包括两个阶段,分别为起始裂纹形成阶段和扩展裂纹阶段。

在起始裂纹形成阶段,由于外力作用,材料内部会出现微小的损伤,如缺陷、气孔等,这些损伤会在外力作用下产生应力集中。

当应力集中超过材料强度极限时,就会出现一条裂纹。

在扩展裂纹阶段,裂纹会不断扩大,细微损伤逐渐聚集,最终导致材料破裂。

工程材料第一章金属的晶体结构与结晶1.解释下列名词点缺陷:原子排列不规则的区域在空间三个方向尺寸都很小,主要指空位间隙原子、置换原子等。

线缺陷:原子排列的不规则区域在空间一个方向上的尺寸很大,而在其余两个方向上的尺寸很小。

如位错。

面缺陷:原子排列不规则的区域在空间两个方向上的尺寸很大,而另一方向上的尺寸很小。

如晶界和亚晶界。

亚晶粒:在多晶体的每一个晶粒内,晶格位向也并非完全一致,而是存在着许多尺寸很小、位向差很小的小晶块,它们相互镶嵌而成晶粒,称亚晶粒。

亚晶界:两相邻亚晶粒间的边界称为亚晶界。

刃型位错:位错可认为是晶格中一部分晶体相对于另一部分晶体的局部滑移而造成。

滑移部分与未滑移部分的交界线即为位错线。

如果相对滑移的结果上半部分多出一半原子面,多余半原子面的边缘好像插入晶体中的一把刀的刃口,故称“刃型位错”。

单晶体:如果一块晶体,其内部的晶格位向完全一致,则称这块晶体为单晶体。

多晶体:由多种晶粒组成的晶体结构称为“多晶体”。

过冷度:实际结晶温度与理论结晶温度之差称为过冷度。

自发形核:在一定条件下,从液态金属中直接产生,原子呈规则排列的结晶核心。

非自发形核:是液态金属依附在一些未溶颗粒表面所形成的晶核。

变质处理:在液态金属结晶前,特意加入某些难熔固态颗粒,造成大量可以成为非自发晶核的固态质点,使结晶时的晶核数目大大增加,从而提高了形核率,细化晶粒,这种处理方法即为变质处理。

变质剂:在浇注前所加入的难熔杂质称为变质剂。

2.常见的金属晶体结构有哪几种?α-Fe 、γ- Fe 、Al 、Cu 、Ni 、Pb 、Cr 、V 、Mg、Zn 各属何种晶体结构?答:常见金属晶体结构:体心立方晶格、面心立方晶格、密排六方晶格;α-Fe、Cr、V属于体心立方晶格;γ-Fe 、Al、Cu、Ni、Pb属于面心立方晶格;Mg、Zn属于密排六方晶格;3.配位数和致密度可以用来说明哪些问题?答:用来说明晶体中原子排列的紧密程度。

工程材料徐自立主编课后习题答案第一章材料的性能1-1什么是金属材料的力学性能?金属材料的力学性能包含哪些方面?所谓力学性能,是指材料抵抗外力作用所显示的性能。

力学性能包括强度刚度硬度塑性韧性和疲劳强度等1-2什么是强度?在拉伸试验中衡量金属强度的主要指标有哪些?他们在工程应用上有什么意义?强度是指材料在外力作用下,抵抗变形或断裂的能力。

在拉伸试验中衡量金属强度的主要指标有屈服强度和抗拉强度。

屈服强度的意义在于:在一般机械零件在发生少量塑性变形后,零件精度降低或其它零件的相对配合受到影响而造成失效,所以屈服强度就成为零件设计时的主要依据之一。

抗拉强度的意义在于:抗拉强度是表示材料抵抗大量均匀塑性变形的能力。

脆性材料在拉伸过程中,一般不产生颈缩现象,因此,抗拉强度就是材料的断裂强度,它表示材料抵抗断裂的能力。

抗拉强度是零件设计时的重要依据之一。

1-3什么是塑性?在拉伸试验中衡量塑性的指标有哪些?塑性是指材料在载荷作用下发生永久变形而又不破坏其完整性的能力。

拉伸试验中衡量塑性的指标有延伸率和断面收缩率。

1-4什么是硬度?指出测定金属硬度的常用方法和各自的优缺点。

硬度是指材料局部抵抗硬物压入其表面的能力。

生产中测定硬度最常用的方法有是压入法,应用较多的布氏硬度洛氏硬度和维氏硬度等试验方法。

布氏硬度试验法的优点:因压痕面积较大,能反映出较大范围内被测试材料的平均硬度,股实验结果较精确,特别适用于测定灰铸铁轴承合金等具有粗大经理或组成相得金属材料的硬度;压痕较大的另一个优点是试验数据稳定,重复性强。

其缺点是对不同材料需要换不同直径的压头和改变试验力,压痕直径的测量也比较麻烦;因压痕大,不宜测试成品和薄片金属的硬度。

洛氏硬度试验法的优点是:操作循序简便,硬度值可直接读出;压痕较小,可在工件上进行试验;采用不同标尺可测定各种软硬不同的金属厚薄不一的式样的硬度,因而广泛用于热处理质量检验。

其缺点是:因压痕较小,对组织比较粗大且不均匀的材料,测得的结果不够准确;此外,用不同标尺测得的硬度值彼此没有联系,不能直接进行比较。

张联盟《材料科学基础》(第2版)笔记和课后习题(含考研真题)详解完整版>精研学习网>免费在线试用20%资料全国547所院校视频及题库资料考研全套>视频资料>课后答案>往年真题>职称考试目录隐藏第1章材料引言1.1复习笔记1.2课后习题详解1.3名校考研真题详解第2章晶体结构2.1复习笔记2.2课后习题详解2.3名校考研真题详解第3章晶体结构缺陷3.1复习笔记3.2课后习题详解3.3名校考研真题详解第4章非晶态结构与性质4.1复习笔记4.2课后习题详解4.3名校考研真题详解第5章表面结构与性质5.1复习笔记5.2课后习题详解5.3名校考研真题详解第6章相平衡和相图6.1复习笔记6.2课后习题详解6.3名校考研真题详解第7章基本动力学过程—扩散7.1复习笔记7.2课后习题详解7.3名校考研真题详解第8章材料中的相变8.1复习笔记8.2课后习题详解8.3名校考研真题详解第9章材料制备中的固态反应9.1复习笔记9.2课后习题详解9.3名校考研真题详解第10章烧结10.1复习笔记10.2课后习题详解10.3名校考研真题详解第11章腐蚀与氧化11.1复习笔记11.2课后习题详解11.3名校考研真题详解第12章疲劳与断裂12.1复习笔记12.2课后习题详解12.3名校考研真题详解内容简介隐藏本书是张联盟主编的《材料科学基础》(第2版)的学习辅导书,主要包括以下内容:(1)梳理知识脉络,浓缩学科精华。

本书每章的复习笔记均对该章的重难点进行了整理,并参考了国内名校名师讲授该教材的课堂笔记。

因此,本书的内容几乎浓缩了该教材的知识精华。

(2)详解课后习题,巩固重点难点。

本书参考大量相关辅导资料,对张联盟主编的《材料科学基础》(第2版)的课后习题进行了详细的分析和解答,并对相关重要知识点进行了延伸和归纳。

(3)精选考研真题,培养解题思路。

本书从历年考研真题中挑选具有代表性的部分,并对之做了详尽的解析。

《工程材料力学性能》课后答案机械工业 2008第2版第一章 单向静拉伸力学性能1、 解释下列名词。

1弹性比功:金属材料吸收弹性变形功的能力,一般用金属开始塑性变形前单位体积吸收的最大弹性变形功表示。

2.滞弹性:金属材料在弹性围快速加载或卸载后,随时间延长产生附加弹性应变的现象称为滞弹性,也就是应变落后于应力的现象。

3.循环韧性:金属材料在交变载荷下吸收不可逆变形功的能力称为循环韧性。

4.包申格效应:金属材料经过预先加载产生少量塑性变形,卸载后再同向加载,规定残余伸长应力增加;反向加载,规定残余伸长应力降低的现象。

5.解理刻面:这种大致以晶粒大小为单位的解理面称为解理刻面。

6.塑性:金属材料断裂前发生不可逆永久(塑性)变形的能力。

韧性:指金属材料断裂前吸收塑性变形功和断裂功的能力。

7.解理台阶:当解理裂纹与螺型位错相遇时,便形成一个高度为b 的台阶。

8.河流花样:解理台阶沿裂纹前端滑动而相互汇合,同号台阶相互汇合长大,当汇合台阶高度足够大时,便成为河流花样。

是解理台阶的一种标志。

9.解理面:是金属材料在一定条件下,当外加正应力达到一定数值后,以极快速率沿一定晶体学平面产生的穿晶断裂,因与石断裂类似,故称此种晶体学平面为解理面。

10.穿晶断裂:穿晶断裂的裂纹穿过晶,可以是韧性断裂,也可以是脆性断裂。

沿晶断裂:裂纹沿晶界扩展,多数是脆性断裂。

11.韧脆转变:具有一定韧性的金属材料当低于某一温度点时,冲击吸收功明显下降,断裂方式由原来的韧性断裂变为脆性断裂,这种现象称为韧脆转变2、 说明下列力学性能指标的意义。

答:E 弹性模量 G 切变模量 r σ规定残余伸长应力 2.0σ屈服强度 gt δ金属材料拉伸时最大应力下的总伸长率 n 应变硬化指数 【P15】3、 金属的弹性模量主要取决于什么因素?为什么说它是一个对组织不敏感的力学性能指标?答:主要决定于原子本性和晶格类型。

合金化、热处理、冷塑性变形等能够改变金属材料的组织形态和晶粒大小,但是不改变金属原子的本性和晶格类型。

《工程材料力学性能》(第二版)课后答案第一章材料单向静拉伸载荷下的力学性能一、解释下列名词滞弹性:在外加载荷作用下,应变落后于应力现象。

静力韧度:材料在静拉伸时单位体积材科从变形到断裂所消耗的功。

弹性极限:试样加载后再卸裁,以不出现残留的永久变形为标准,材料能够完全弹性恢复的最高应力。

比例极限:应力—应变曲线上符合线性关系的最高应力。

包申格效应:指原先经过少量塑性变形,卸载后同向加载,弹性极限(ζP)或屈服强度(ζS)增加;反向加载时弹性极限(ζP)或屈服强度(ζS)降低的现象。

解理断裂:沿一定的晶体学平面产生的快速穿晶断裂。

晶体学平面--解理面,一般是低指数,表面能低的晶面。

解理面:在解理断裂中具有低指数,表面能低的晶体学平面。

韧脆转变:材料力学性能从韧性状态转变到脆性状态的现象(冲击吸收功明显下降,断裂机理由微孔聚集型转变微穿晶断裂,断口特征由纤维状转变为结晶状)。

静力韧度:材料在静拉伸时单位体积材料从变形到断裂所消耗的功叫做静力韧度。

是一个强度与塑性的综合指标,是表示静载下材料强度与塑性的最佳配合。

二、金属的弹性模量主要取决于什么?为什么说它是一个对结构不敏感的力学姓能?答案:金属的弹性模量主要取决于金属键的本性和原子间的结合力,而材料的成分和组织对它的影响不大,所以说它是一个对组织不敏感的性能指标,这是弹性模量在性能上的主要特点。

改变材料的成分和组织会对材料的强度(如屈服强度、抗拉强度)有显著影响,但对材料的刚度影响不大。

三、什么是包辛格效应,如何解释,它有什么实际意义?答案:包辛格效应就是指原先经过变形,然后在反向加载时弹性极限或屈服强度降低的现象。

特别是弹性极限在反向加载时几乎下降到零,这说明在反向加载时塑性变形立即开始了。

包辛格效应可以用位错理论解释。

第一,在原先加载变形时,位错源在滑移面上产生的位错遇到障碍,塞积后便产生了背应力,这背应力反作用于位错源,当背应力(取决于塞积时产生的应力集中)足够大时,可使位错源停止开动。

Problems - Chapter 5 1. FIND: Calculate the stress on a tensioned fiber.GIVEN: The fiber diameter is 25 micrometers. The elongational load is 25 g. ASSUMPTIONS: The engineering stress is requested.DATA: Acceleration due to gravity is 9.8 m/sec 2. A Newton is a kg-m/sec 2. A Pascal is a N/m 2. A MPa is 106 Pa.SOLUTION: Stress is force per unit area. The cross-sectional area is πR 2 = 1963.5 square micrometers. The force is 25 g (kg/1000g)(9.8 m/sec 2) = 0.245 N. Thus, the stress isσ = F/A =02451960100125262..N umum m MPa⨯☞☟☝✋ ☺=COMMENTS: You must learn to do these sorts of problems, including the conversions. 2. GIVEN: FCC Cu with a o = 0.362nmREQUIRED: A) Lowest energy Burgers vector, B) Length in terms of radius of Cu atom, C) Family of planesSOLUTION: We note that the Burgers vector is the shortest vector that connects crystallographically equivalent positions. A diagram of the structure is shown below:FCC structure with (111) shownWe note that atoms lying along face diagonals touch and are crystallographically equivalent. Therefore, the shortest vector connecting equivalent positions is ½ face diagonal. For example,one such vector is10]1[ 2a o as shown in (111).A. The length of this vector is0.256nm = 20.362= 2a= 4a+ 4a o 2o 2oB. By inspection, the size of the vector is 2 Cu atom radii.C. Slip occurs in the most densely packed plane which is of the type {111}. These are thesmoothest planes and contain the smallest Burgers vector. This means that the dislocations move easily and the energy is low.3. GIVEN:∣b∣ = 0.288nm in AgREQUIRED: Find lattice parameterSOLUTION: Recall the Ag is FCC. For FCC structures the Burgers vector is ½ a facediagonal as shown. We see that4. A. FCC structureThe (111) plane is shown in a unit cell with all atoms shown. Atoms touch along face diagonals. The (111) plane is the most closely packed, and the vectors shown connect equivalent atomic position. Thus 10]1[ 21= b etc. Then in general >110< 2a= bB. For NaC1We see that the shortest vector connecting equivalent positions is 10]1[ 2aas shown. Thisdirection lies in both the {100} and {110} planes and both are possible slip planes. However {110} are the planes most frequently observed as the slip planes. This is because repulsive interionic forces are minimized on these planes during dislocation motion. Thus we expect 1/2<110> Burgers vectors and {110} slip planes.5.GIVEN:Mo crystal0.272nm = ba o = 0.314nmREQUIRED: Determine the crystal structure.If Mo were FCC, then 0.222nm = 20.314= b __but |b| = 0.272 ⇒ Mo is not FCC.Assuming Mo is BCC, then 0.272nm.= 0.314 X 23 = b __Thus the Burgers vector isconsistent with Mo being BCC.6.FIND: Is the fracture surface in ionic solids rough or smooth?SOLUTION: Cleavages surfaces of ionic materials are generally smooth. Once a crack is started, it easily propagates in a straight line in a specific crystallographic direction on a specificcrystallographic plane. Ceramic fracture surfaces are rough when failure proceeds through the noncrystalline boundaries between small crystals.7. GIVEN: BCC Cr with |b| = 0.25nmREQUIRED: Find lattice parameter aASSUME: >111< 2a= b for BCC structureSOLUTION:2a 3= 4a+ 4a+ 4a= b 222__from the formula for the magnitude of a vector:8. GIVEN: Normal stress of 123 MPa applied to BCC Fe in [110] directionREQUIRED: Resolved shear in [101] on (010)SOLUTION: Recall that the resolved shear stress is given by:τ = σ cos θ cos φ (1)where θ = angle between slip direction and tensile axis; φ = angle between normal to slip plane and tensile axisThus MPa 43.5 = 2121 123 = ⎪⎭⎫⎝⎛⎪⎭⎫ ⎝⎛τ9. GIVEN: Stress in [123] direction of BCC crystalREQUIRED: Find the stress needed to promote slip if τcR = 800 psi. The slip plane is (11_0) and slip direction is [111]. SOLUTION: Recall τ = σ cos θ cos φ (1)θ = [123] [111][123] ⋅ [111] = ∣[123]∣ ∣[111]∣cos θφ = [123] [11_0][123] ⋅ [11_0] = ∣[123]∣ ∣[11_0]∣cos φ10.Burgers vectors lie in the closest packed directions since the distance between equivalentcrystallographic positions is shortest in the close-packed directions. This means that the energy associated with the dislocation will be minimum for such dislocations since the energy is proportional to the square of the Burgers vector.11. Close packed planes are slip planes since these are the smoothest planes (on an atomic level) and would then be expected to have the lowest critical resolved shear stress.12.GIVEN: Dislocation lies on (11_1) parallel to intersection of (11_1) and (111) with Burgers vector parallel to [1_1_0]. Structure is FCC.REQUIRED: A) Burgers vector of dislocation and, B) Character of dislocation.SOLUTION: A) Since the structure is FCC, the Burgers vector is parallel to <110> and has magnitude. 2a For a Burgers vector parallel to [1_1_0] the scalar multiplier must be a/2. Thus b _ = a/2 [1_1_0]. B) We must determine the line direction of the dislocation. From the diagramwe see that the BV and line direction are at 60o which means the dislocation is mixed.13. GIVEN: Dislocation reaction below:REQUIRED: Show it is vectorially correct and energetically proper. SOLUTION: [100] a =] 111[ 2a+[111] 2aThe sum of the x, y & z components on the LHS must be equal to the corresponding component on the right hand side.x component (LHS) = x component (RHS)y component (LHS) = y component (RHS)z component (LHS) = z component (RHS)Energy: The reaction is energetically favorable if | b 1 | 2 + | b 2 | 2 > | b 3| 3Thus the reaction is favorable since a > a 43+ a 4322214. GIVEN: Dislocation in FCCParallel to [1_01] i.e. t_ = [1_01]REQUIRED: Character and slip planeSOLUTION: Character is found by angle between b_ and t_. Note b_ t_∙ = -1 + 0 + 1 = 0. Thus b__t_. Since b__t_the dislocation is pure edge.To find the slip plane we note that the cross produce of t_ & b_gives a vector that is normal to the plane in which t_ & b_lie. This vector so formed has the same indices as the plane since we have a fundamentally cubic structure.We see from the diagram that these vectors lie on (010).Thus, we have the plane (01_0) which is the same as the (010) plane. This does not move by glide since planes of the kind {100} are not slip planes for the FCC structure.15.FCC metals are more ductile than BCC or HCP because: 1) there is no easy mechanism for nucleation of microcracks in FCC as there is for BCC and HCP; 2) the stresses for plastic deformation are lower in FCC due to the (generally) smoother planes. This means that the microcracks that form in BCC & HCP will have high stresses tending to make them propagate. 16.For a simple cubic system, the lowest energy Burgers vectors are of the type <001> since this is the shortest distance connecting equivalent atomic positions. This means that the energy is lowest since the strain energy is proportional to the square of the Burgers vector. 17.GIVEN:At. wt. 0 = 16At. wt. Mg = 24.32 Same structure as NaCl ρ = 3.65 g/cm 3REQUIRED: Find length of Burgers Vector in MgOSOLUTION: The structure of MgO is shown schematically below along with the shortestBurgers vector. To solve the problem we first note that we require the lattice parameter a o . We can take a sub-section of the unit cell (cross-hatched cube) whose edge is 2a o unitslong.We can calculate the total mass of this cube and the volume and calculate the density. Since the mass is known and the density is known, the volume may be calculated from which a o may beextracted.and ½ Mg ++ ions in our cube. Thus a10 x 3.35 x 8= 8/ a 10 x 2.02) + (1.33= 3.653o-233o-2318.GIVEN: Critical resolved shear stress (0.34MPa), slip system (111)[1_10], and tensile axis [101]REQUIRED: Applied stress at which crystal begins to deform and crystal structure. SOLUTION: (A)The situation is shown belowτcrss = σ cos θ ⋅ cos φθ = angle between tensile axis and slip directionθ = angle between tensile axis and normal to slip planeφ = [111] [101] θ = [101] [1_01][111] ⋅ [101] = ∣[111]∣ ∣[101]∣cos φ [101] ⋅ [110] = ∣[101]∣ ∣[110]∣cos θ(B): To have a {111}<110> slip system, the material must have an FCC structure.19. GIVEN:τcrss = 55.2 MPa, (111)[1_01] slip system, [112] tensile axisREQUIRED: Find the highest normal stress that can be applied before dislocation motion in the [10 1_] direction.SOLUTION: The situation is shown below. Essentially the problem reduces to finding the value of the tensile stress when the critical resolved shear is reached.τcrss = σ cosθ⋅ cosφθ = [112] [1_01] φ = [112] {111}B. Would have exactly the same stress for a BCC metal (φ & θ would be interchanged).20. GIVEN:σ at yield = 3.5 MPa; (111) [11_0] slip system [11_1] tensile axisREQUIRED: Compute τcrssSOLUTION:τcrss = σcosθcosφθ = [11_1] [11_0] φ = [11_1] [111]21. Item Edge ScrewLinear defect? Yes YesElastic Distortion? Yes YesGlide? Yes YesClimb? Yes NoCross-slip? No YesBurgers Vector (BV) ⊥ to line // to lineUnique slip plane? Yes NoOffset // to BV // to BVMotion // to BV ⊥ to BV22. GIVEN: BCC metal with τcrss = 7MPa [001] tensile axis.REQUIRED: (a) Slip system that will be activated and (b) normal stress for plasticdeformation.SOLUTION: Recall that for BCC metals the usual slip system is <111> {110}. Deformation occurs on the plane and direction for which cos θ⋅cos φ is a maximum since this will have the maximum resolved shear stress. The situation is shown below.(Note that the slip directions are shown shortened in this view)Possible slip systems are listed below:sketch (also [11_1] on (011)) (also [1_11] on (01_1)) (also [1_1_1] on (101)) similar to planes shown in sketch. Also [111] on (1_01)We see by inspection that the resolved shear due to a tensile force in [001] will all be the same. The resolved shear on all other {110}<111> systems is zero.B. To compute the normal stress at the onset of plastic deformation we will consider (011) [1_1_1]τcrss = σcos θcos φ = 7θ = [001] [1_1_1]; cos φ = [001] [011]Note if we considered (101) [1_1_1] we would haveand we would obtain exactly the same answer.23. GIVEN: Yielding occurs at normal stress of σ = 170 MPa in [100] direction. Dislocationmoves on (101) in [111_] direction.REQUIRED:τcrss and crystal structuresSOLUTION: Assume an edge dislocation. τcrss = σcos⋅cosφθ = [100] [111_] φ = [100] [101]The - sign means that the slip direction is opposite to the motion of the dislocation. Essentially, we have a negative edge dislocation on (101) as shown below:The edge dislocation moves in [111_] direction but the offset is in [1_1_1] direction.The slip plane and slip direction are representative of BCC structures.24. GIVEN: (1_10)[111] slip system. [123] tensile axisτcrss = 800 psi for BCC crystal τcrss = 80 psi for FCC crystal withσFCC = 457 psi [123] tensile axis and (111)[11_0] system.REQUIRED: Normal stress at yield for BCC metalSOLUTION: The simplest way to solve this problem is to note cos θ⋅cos φ is the same for the BCC and FCC crystal with the meaning of φ and θ interchanged. Let M = cos θ⋅cos φ. (1) (2)(3)25.Here crystallographically equivalent positions join ions at cube corners (b v = a o ), face diagonals )a 2 = b (o v , cube diagonals )a 3 = b (o vThe most densely packed plane is the (110) in which we haveThe shortest vector that will reproduce all elements of the structure is a o . Thus b = a<100> COMMENT: We note that this is not sufficient for general deformation (e.g. a tensile axis ofthe type <100> produces zero shear on the 1<100> Burgers vectors. We expect then a<110> Burgers vectors as well.26. GIVEN:σ = 1.7 MPa [100] tensile axis (111)[101] slip systemsREQUIRED:τcrss, and crystal structure. Also find flaw in problem statement.SOLUTION: Since the slip system is of the type {111}<110> the structure is FCC. Theproblem is misstated since the Burgers vector must lie on the slip plane and [101] does not lieon (111). The slip direction would more appropriately be [101_]. Thus the slip system is(111)[101_] as shown below.27.⊥ = edge dislocation x = start of Burgers circuitb = Burgers vector y = end of Burgers circuit28. FIND: Show energy/area = force/length, that is, surface energy is surface tension in liquids.DATA: The units of energy are J = W/s or N-m. The units of force are N.SOLUTION: Energy/area = J/m2 =N-m/m2 = N/m = force/length29. GIVEN: Two grain sizes, 10μm and 40μmREQUIRED: A) ASTM GS# for both processes, B) Grain boundary area.SOLUTION: Assume that the grains are in the form of cubes for ease of calculation. TheASTM GS# is defined through the equation: n = 2N-1 where n = # grains/in2 at 100X.N=ASTM GS#To solve the problem we first convert the grain size to in. where D = length of cube edge in μm.At 100X linear magnification, the sides of the smaller grains will be:The area of each grain at 100X will beSimilarly the area of the 40μm grains at 100X isFor the 10μm dia grain, the # of grains per in 2 (at box) is645.16 = 10x 1.5501= n3-100X10μgrains/in 2at 100X Similarly 40.31 = 10x 24.811= n 3-100X 40μgrains/in 2at 100X For the 10μm grain size:B. In computing the total g.s. area we will assume 1 in 3 of materials. Since there are 6 facescube and the area of each face is shared by 2 cubes, each cube has an area of 3x Area of face. G.B. Area =d / 3 = d 3 x d 123⎥⎦⎤⎢⎣⎡GB Area (10μ gs) = 3/3.937 x 10-4 = 7620in 2/in 3 GB Area (40μ gs) = 3/15.75 x 10-4 = 1905in 2/in 330.GIVEN:σys = 200MPa at GS#4 = 300MPa at GS#6REQUIRED: σys at GS#9SOLUTION: Recall σys = σo + kd -1/2(1)for low carbon steel.If d = grain size (assume cubes) load = grain diameter at 100X(2)(3)16.82 = d11/24For ASTM GS# 4:For ASTM GS#6:23.78 = d11/24(5) Substituting (4) and (5) into (1) we have200 - σo + k(16.82) (6) 300 = σo + k(23.78) (7)Subtracting (6) from (7):100 = k(23.78 - 16.82)∴k = 14.37Substituting this value of κ into (6) yields 200 = σo + 14.37 x 16.82σo = -41.70 (this is not physically realistic since σo relates to the lattice friction stress which should not be negative)For ASTM GS#9Thus σys = σo + 14.37 x 40 = 41.70 + 574 = 533MPa31.GIVEN: ∣b ∣ = 0.25μm for BCC metal tilt boundary has angular difference of 2.5o REQUIRED: Dislocation density in tilt boundary wall SOLUTION: The physical situation is shown below:If b = Burgers vector, D = spacing between edge dislocation# of dislocations in boundary for a 1cm high boundary isD1(where D is in cm)32.33.FIND: Show D = b / θ.GIVEN: b is the magnitude of the Burger's vector; D is the spacing between dislocations, and θ is the tilt angle.SKETCH: See Fig. 5.3-4.SOLUTION: We can see the geometry more clearly using the following sketch:bFrom the Figure we can immediately write that tan/θ22=b D . Since the tan of a small angle is the angle itself:θ22=b D /, so that D = b / θ, as is written in the margin.34. FIND: How can you detect a cluster of voids or a cluster of precipitates in a material?SOLUTION: This can be a difficult challenge indeed. If the total void volume is large, then the density of the sample will be lower than that of dense material. The same is true for clusters ofprecipitate; however, usually the density difference between host and precipitate is not as greatas between host and air, so the technique does not work as well. Another possible technique is microscopy. Samples can be prepared for microscopy, perhaps by polishing and etching andthe defects observed using optical or electron microscopy. X-ray diffraction can also be used. With a random spacing of void or precipitate there is then an average spacing. SometimesBragg's law can be used to calculate the spacing if an intensity maximum is observed. Note that the angle of the maximum will be very small.COMMENTS: There are many other potential techniques that can potentially be used. Theyall rely on some property difference - magnetic, electrical, optical, or whatever.35. FIND: How can you ascertain whether a material contains both crystalline and noncrystallineregions?GIVEN: Recall that the density (and other properties) of crystalline material is greater than that of noncrystalline material of the same compositionSOLUTION: There are three methods in common usage to establish crystallinity polymers.These methods apply to all materials.1. Density. Measure the density of your sample and compare it to the density of noncrystallineand crystalline samples of the same composition.2. Differential Scanning Calorimetry. Heat your sample in a calorimeter. Samples that arecrystalline will absorb heat at the melting temperature and show a "melting endotherm". Somenoncrystalline samples (such as amorphous metals) will crystallize in the calorimeter and show a huge release of heat prior to melting. This is a "crystallization exotherm".3. X-ray diffraction. Crystalline materials show well-defined peaks.COMMENTS: Knowing whether a material is crystalline or noncrystalline is a commonchallenge to polymers scientists. We often need to quantify the fraction or percent crystallinity.Can you suggest a method for each of the 3 techniques outlined?36. FIND: State examples of materials' applications that require the material to behave in a purelyelastic manner.SOLUTION: There are many such possible examples. Since plastic deformation isnonrecoverable deformation, any application that requires repeated stressing and dimensional stability is a good example. Here are some examples:1. Springs in automobiles - leaf and coil springs2. A diving board3. Trusses in a bridge4. The walls in a building5. A bicycle frame6. Piano wire7. Airplane wings37. As the dislocation density ↑, there are more dislocation/dislocation interactions and the strengthgoes up. At the same time, the degree of “damage” also increases and the ductility decreases.38. If the point defect concentration ↑, the strength will go up as well. This is because the defectsmay migrate to edge dislocations where they cause jogs on the dislocations. A joggeddislocation is much harder to move and may itself require the generation of point defects tomove. In addition the point defects may collapse to form dislocation loops which also impede the motion of other dislocations making the materials stronger. If the defects are interstitials,they may migrate to areas around the dislocations in which the system energy is reduced. For the dislocation to move away from the interstitial an increase in the system energy is requiredwhich means the stress to move the dislocation must increase. If the point defect is asubstitutional atom, similar considerations apply. However, the magnitude of the energyreduction is less because of the less severe distortion. Thus the strength increase is not as high as for intersitital.39. As d↓σys↑ since this means the path over which a dislocation moves ↓. This means that thestress will have to increase to either nucleate or unlock dislocations in adjacent grains. Therelationship quantifying this behavior is the Hall-Petch equation: σys = σo + kd-1/240. The strength may increase as a result of:1. decreasing grain size - should not be too (see previous questions) temperature dependent.2. Adding impurities (e.g. C in Fe). The impurities “lock” the dislocation by associating withthe dislocation to lower the system energy. This will be very temperature dependent for dilute concentrations of impurities as the impurities will diffuse away at high temperatures.3. Adding precipitates - blocks the motion of dislocations through either having a differentcrystal structure or a large strain field. Since the precipitates are usually large compared to the atomistic dimension, strong temperature dependence is not expected.4. Cold work - increase quantity of dislocations.41. GIVEN: = 1012/cm 2 for low C steelREQUIRED: concentration of C atoms (at %) to lock all dislocationsSOLUTION: Recalling the At. weight of Fe is 55.85 and the density is about 7.8 gm/cm 3 we may write10 x 6.02 55.857.8 = N 23Fc(assume 1C atom for every Fe atom along dislocations)42. FIND: Why can you not bend the bar of tin?GIVEN: The bar has been well annealed, so the initial dislocation density is low. You are required to re-bend the bar after cold working.SOLUTION: The deformation has increased the dislocation density and the bar now requires much more stress, or force, to deform it. You are not necessarily a weakling, but you have been taken. Re-anneal the bar and bend it back or use brute force.COMMENTS: It is often difficult to bend a metal back to its original shape and this is just one of many possible reasons that depend on the metal and its thermo-mechanical。

工程材料科学与设计原书第2版课后习题答案4—8章Solutions to Chapter 41. FIND: What material has a property that is hugely affected by a small impurity level?SOLUTION: Electrical conductivity spans a wide range. Incorporation of a few parts per million impurities can change electrical conductivity orders of magnitude. Small cracks in brittle materials decrease their tensile strength by orders of magnitude. Small additions of impurity can change the color of gems. COMMENTS: These are but a few examples. 2. COMPUTE: The temperature at which the vacancy concentration is one half thatof 25o C.GIVEN: C 2 = C C 25v C 35vo oEQUATION:⎪⎪⎭⎫⎝⎛RT Q - = C fv v expwhere C v = vacancy concentrationQ fv = activation energy for vacancy information R = gas constant 8.314 J/mole-KT = absolute temperatureIn the present problem C)25(C = C C);35(C = C o v 2v o v 1vand T 1 = 35 + 273 = 308KT 2 = 25 + 273 = 298K⎪⎪⎭⎫ ⎝⎛⎪⎪⎭⎫ ⎝⎛⎪⎪⎭⎫ ⎝⎛⎪⎪⎭⎫⎝⎛⎪⎪⎭⎫ ⎝⎛RT Q + RT Q - = C CRT Q - RT Q -= C CRT Q = CRT Q = C 2fv 1fv 2v 1v2fv 1fv 2v1v 2fv 2v1fv 1vexp exp exp exp expalso C v(35o C) = 2C v(25o C)Thus, Solving for Q fv we get Q fv = 52893.5 J/mole.Using this value of Q fv , the C v (25o C) can be calculatedThe problem requires us to calculate the temperature at which the vacancy concentration is ½ C v (25o C).½ C v (25o C) = 2.675 x 10-10Thusfor solving T, we get: T = 288.63K or 15.63o C.3. COMPUTE:C)80( C 3 = (T) C ov vGIVEN: C) 80( C 41 = C) 25( C o v ov EQUATION:⎪⎭⎫⎝⎛298.R Q - C) 25( C Sv o v expDividing (1) by (2) we get:⎥⎥⎦⎤⎢⎢⎣⎡⎪⎪⎭⎫ ⎝⎛⎥⎦⎤⎢⎣⎡91784Q 308 + Q 298- R 1 = 2R(298)Q + R(308)Q - = C)25( C C)25( C 2fv fv fv fv ov o v exp exp10 x 5.35 = C)25(C 298 x 8.3152893.5- = C)25(C 10-o v ov ⎪⎭⎫ ⎝⎛exp ⎪⎭⎫⎝⎛T x 8.3152893.5- = 10 x 2.67510-ex p⎪⎭⎫ ⎝⎛353.R Q - = C) 80( C ov ex pSolving for Q, we get:Q = 22033.56 J/mole= exp(-7.511)= 5.46 x 10-4The problem requires computing a temperature at which C v = 3C v (80o C).3C v (80o C) = 3 x 5.46 x 10-4= 1.63 x 10-3⎪⎭⎫⎝⎛T x 8.3122033.56- = 10 x 1.633-ex psolving for T, we get:T = 413.05K or 140.05o C4.5. FIND: Are Al and Zn completely soluble in solid solution?If Al-Zn system obeys all the Hume-Rothery rules. Then it is expected to show complete solubility.(i) The atomic radii of Al and Zn are 0.143nm and 0.133 nm respectively. Thedifference in their radii is 7.5% which is less than 15%.(ii) The electronegativities of Al and Zn are 1.61 an 1.65 respectively which arealso very similar.(iii) The most common valence of Al is +3 and +2 for Zn.(iv) Al has an FCC structure where Zn has a HCP structure.It appears that Al-Zn system obeys 3 out of 4 Hume-Rothery rules. In this case they are not expected to be completely soluble.⎥⎦⎤⎢⎣⎡⎪⎭⎫ ⎝⎛3531 - 2981 R Q - = 41= C) 80( C C) 25( C ov ov exp ⎪⎭⎫ ⎝⎛353 x 8.3122033.56- = C) 80(C ov ex p6. SHOW: The extent of solid solution formation in the following systems usingHume-Rothery Rules.(a) Al in NiSize: r(Ni) = 0.125nm; r(Al) = 0.143nm difference = 14.4%Electronegativity: Al = 1.61; Ni = 1.91Most Common Valence: Al3+; Ni2+Crystal Structure: Al: FCC; Ni:FCCThe crystal structure of Al and Ni are the same and the most common valencies are also comparable. However, the size difference is close to 15% and the difference is electronegativities is rather significant.Based on this, it appears that Ni and Al would not form a solid solution over theentire compositional range.(b) Ti in NiSize: r(Ti) = 0.147 nm, r(Ni) = 0.125nm difference = 17.6%Electronegativity: Ti: 1.54; Ni: 1.91Valence: Ti4+; Ni2+Crystal Structure: Ti:HCP; Ni FCCTi in Ni would not exhibit extensive solid solubility(c) Zn in FeSize r(Zn) = 0.133nm; r(Fe) - 0.124nm difference = 7.25%Electronegativity: Zn = 1.65; Fe = 1.83Most Common Valence: Zn2+; Fe2+Crystal Structure: An: HCP; Fe: BCCSince electronegativities and crystal structures are very different, Zn - Fe will notexhibit extensive solid solubility.(d) Si in AlSize r(Si) = 0.117 nm; r(Al) = 0.143nm; difference = 22.2%Electronegativity: (Si) = 1.90; Al = 1.61Valence: Si4+; A;3+Crystal Structure: Si: Diamond Cubic; Al: FCCSince the size difference is greater than 15%, and the crystal structures are different, Si-Al would not exhibit extensive solid solubility.(e) Li in AlSize r(li): 0.152, r(Al): 0.143; difference - 6.29%Electronegativity: Li: 0.98; Al: 1.61Most Common Valence: Li1+; Al3+Crystal Structure: Li:BCC; Al: FCCSince electronegativity and crystal structures are very different, Li-Al will not exhibit extensive solid solubility.(f) Cu in AuSize r(Cu) = 0.125nm; r(au) = 0.144nm; difference = 12.5% Electronegativity: Cu = 1.90; Au = 1.93Most Common Valence: Cu+; Au+Crystal Structure: Cu:FCC; Au:FCCCu-Au will exhibit extensive solid solubility.(g) Mn in FeSize r(Mn) = 0.112, r(Fe) = 0.124 difference = 10.71%Electronegativity: Mn 1.55; Fe 1.83Most Common Valence: Mn2+; Fe2+Crystal Structure: Mn:BCC; Fe BCCThe difference in electronegativity is high but Mn-Fe does obey the other 3Hume-Rothery rules. Therefore, it will form solid solutions but not over the entire compositional range.(h) Cr in FeSize r(Cr) = 0.125nm, Fe = 0.144nm difference = 12.5%Electronegativity: Cr = 1.66; Fe = 1.83Most Common Valence: Cr3+; Fe2+Crystal Structure: Cr:BCC; Fe:BCCCr in Fe will exhibit extensive solid solubility but not over the entire compositional range since it obeys only 3 of 4 Hume-Rothery rules.(i) Ni in FeSize r(Ni) = 0.125nm, r(Fe) = 0.124nm difference = 0.8%Electronegativity: Ni: 1.91; Fe 1.83Most Common Valence: Ni3+; Fe3+Crystal Structure: Ni:FCC; Fe: BCCNi and Fe obeys 3 of the 4 Hume-Rothery rules therefore, extensive solid solutionwill be exhibited but not over the entire compositional range.7. (a) When one attempts to add a small amount of Ni to Cu, Ni is the solute and Cuis the solvent.(b) Based on the relative sizes of Ni and Cu, radius of Ni = 0.128nm, radius of Cu =0.125nm, these two are expected to form substitutional solid solutions.(c) Ni and Cu will be completely soluble in each other because they obey all fourHume-Rothery rules.8. FIND: Predict how Cu dissolves in Al.DATA: Cu Alatomic radius (A) 1.28 1.43electronegativity 1.90 1.61valence 1+,2+ 3+crystal structure FCC FCCSOLUTION: All of Hume-Rothery's rules must be followed for a substitutionalsolution. In this case, the valences do not match. Cu will not go into substitutional positions in Al to a large extent.COMMENTS: This principle is often used to precipitation harden Al using Cu.9. What type of solid solution is expected to form when C is added to Fe?The radius of carbon atom is 0.077nm and that of an Fe atom is 0.124nm. The size difference between these two is ~61% which is much grater than ~15%. Thus,these two are not expected to form substitutional solid solution.If we compare the size ratio of C to Fe atoms with the size of tetrahedral andoctahedral interstitial sites in BCC iron, we find that C does not easily fit into either type of interstitial position. C, however, forms an interstitial solid solution with Fe but the solubility is limited.10. FIND: Calculate the activation for vacancy formation in Fe.GIVEN: The vacancy concentration at 727 C = 1000K is 0.00022.SOLUTION: We use equation 4.2-2 to solve this problem:C v = exp (-Q fv/RT)Solving for Q fv:Q fv = -RT ln C v = -(8.31 J/mole-K)(1000K) ln 0.00022 = 7.0 x 104 J/mole11. SHOW: A Schottky and Frenkel defect in MgF2 structuresA 2-D representation of the MgF2 structure containing a Schottky defect and aFrenkel defect is shown below.12. Explain why the following statement is incorrect: In ionic solids the number ofcation vacancies is equal to the number of anion vacancies.In ionic crystals, even in the presence of vacancies, the charge neutrality must bemaintained. Therefore, single vacancies do not occur in ionic crystals sinceremoval of a single ion would lead to charge imbalance. Instead the vacanciesoccur in a manner such that the anion: cation vacancy ratio render the solidelectrically neutral. This, however, does not mean that the anion vacancies areequal to cation vacancies. For example, a Schottky defect in MgCl2 or MgF2involves two Cl- or F- cation vacancies for every Mg2+ anion vacancy to maintainelectrical neutrality.The number of cation vacancies equals the number of anion vacancies only for thelimiting case where the chemical formula of the compound is MX.13. Calculate the number of defects created when 2 moles of NiO are added to 98 molesof SiO2. Also, determine the type of defect created.GIVEN: Neglect interstial vacanciesWe have 2 moles of NiO and 98 moles of SiO2. Since NiO is a 1:1 compound there are 2 moles of Ni2+ ions and 2 moles of O2- ions present. SiO2 on the other hand is a 1:2 compound; therefore, there are 98 moles of Si4+ and 196 moles of O2-. Thetotal number of each type of ion isN Ni = 2 molesN Si = 98 molesN O2 = 196 molesThe total number of moles of ions in the system isN T = N Ni + N Si + N O = 2 + 98 + 196 = 196 molesEach substitution of an Ni2+ for Si4+ results in a loss of 2 positive charges. If nointerstitials are created, this loss of positive charge is balanced by the creation ofanion vacancies. Charge neutrality requires one oxygen vacancy created for every Ni 2+ ion. Therefore, the number of oxygen vacancies isN Ov = N Ni = 2 molesThere are 2 moles of oxygen ion vacancies created with the addition of 2 moles of NiO to 98 moles of SiO 2. 14. Calculate the number of defects created when 1 mole of MgO is added to 99 moles ofAl 2O 3.MgO is a 1:1 compound, therefore there is 1 mole of Mg 2+ ions and 1 mole of O 2- ions in the system.From Al 2O 3, there are 198 moles of Al 3+ ions and 297 moles of O 2- ions in the system.Each substitution of an Mg 2+ ion for Al 3+ ion results in a loss of one positive charge. This loss of positive charge is balanced by oxygen vacancy. Charge neutrality requires one oxygen vacancy to be created for every two Mg 2+ ion 3. Therefore thenumber of oxygen ion vacancies created is0.5 moles of oxygen ion vacancies are created by the addition of 1 mole of MgO to 99 moles of Al 2O 3. 15.COMPUTE: Relative concentration of cation vacancies, anion vacancies and cation interstitials.GIVEN: Q Cv = 20kJ/moleQ Av = 40kJ/mole Q CI = 30kJ/moleASSUMPTION: assume room temperatureT = 298KConcentration of cation vacancies, C Cv is given by0.5moles = 21= 2N= N Mg O vSimilarly for anion vacancies and for cation interstitials16. (a) Describe a Schottky defect in U 2(b) Would you expect to find more cation or anion Frenkel defects in this compound? Why?UO 2 has a fluorite structure with U 4+ ions occupying FCC lattice sites and O 2- occupying tetrahedral interstitial sites.(a) A Schottky defect in UO 2 will involve one U 4+ cation vacancy and 2 O 2- anion vacancies.(b) In general cation Frenkel defects are more common than anion Frenkel defects because cations are usually smaller. In this case, the radii of U 4+ is 0.106nm and that of O 2- is 0.132nm. The U 4+ cation is smaller than the O 2- anion. However, the size difference is not very high. Still, cation Frenkel defects are expected to be more.17. Ionic compound Li 2O(a) Describe a Schottky defect (b) Describe a Frenkel defectLi 2O has an antifluorite structure. O 2- ions occupy FCC lattice sites and Li + occupies tetrahedral interstitial sites.10 x 3.108 = (-8.0763) = C 298 x 8.3120,000- = RT Q - = C 4-Cv cv Cv exp exp exp ⎪⎭⎫⎝⎛⎪⎭⎫⎝⎛10 x 9.6 = (-16.152) = 298 x 8.3140,000- = C 8-AV ex p ex p ⎪⎭⎫⎝⎛ 10 x 5.48 = (-12.114) = 298 x 8.3130,000- = C 6-CIex p ex p ⎪⎭⎫⎝⎛(a) A Schottky defect in Li2O involves 2 Li2+ cation vacancies and one O2- anion vacancy(b) The ionic radii of Li+ and O2- are 0.078nm and 0.132nm respectively. Thismaterial is most likely to exhibit cation Frenkel defect since the size of the cation is much smaller than the anion.18. DETERMINE:(a) Interstitial Na+ ions(b) Interstitial O2- ions(c) Vacant Na+ sites(d) Vacant O2- sites in Na2OGIVEN: r(Na+) = 0.098nmr(O2-) = 0.132nmNa2O structure is similar to antifluorite structure. Na+ ions occupy tetrahedralinterstitial sites and O2- ions occupy FCC lattice sites.Since the ratio of Na:0 is 2:1 for this materials, a Schottky defect results in 2 cation vacancies for every one anion vacancy.no. of vacant Na+ sites = 2 x no. of vacant O2- sitesA cation Frenkel defect is more likely to occur in this material(a) Interstitial Na+ ions = 1(b) Interstitial O2- ions = 0(c) Vacant Na+ sites = 2(d) Vacant O2- sites = 119. SOLVENT: AuSOLUTE: N, Ag or CsDETERMINE: (a) which element is most likely to form an interstitial solidsolution.(b) which element is most likely to form a substitutional solid solution.r(Au) = 0.144nmr(N) = 0.071nmr(Ag) = 0.144nmr(Cs) = 0.265nm(a) Based on atomic radii N is most likely to form are interstitial solid solutionwith Au as solvent.(b) Ag is most likely to form a substitutional solid solution because the size difference between Au & N and Au & Cs is more than 15%.In addition, Au and Ag have similar valence, and crystal structure. Theelectronegativities are not quite similar, but since Ag-Au system obeys 3 out of 4 of the Hume-Rothery rules, Ag is the most likely element with which Au forms a substitutional solid solution.Section 4.4 Diffusion20. Under what condition can Fick’s first law be used to solve diffusion problems.The Fick’s first law can be used to solve diffusion problems provided the concentration gradient does not change with time.21. GIVEN: 1 wt% B is added to Fe.FIND: (a) if B would be present as an interstitial impurity or substitutionalimpurity, (b) fraction of sites occupied by B atoms, (c) if Fe containing B were to be gas carburized, would the process be faster or slower than for Fe which has no B? Explain.r(B) = 0.097nm r(Fe) = 0.124nm(a) Based on the atomic radii B would be present as an interstitial impurity(b) amount of B present = 1 wt%As a basis of calculation assume 100gms of material.Determine the no. of moles of Fe and B present.Total no. of moles of Fe and B = 1.773 + 0.092 = 1.865 moles.Fraction of sites occupied by B atoms = 1.8650.092= mole fraction of B = 0.049Thus, B roughly occupies 5% of the sites.mole 0.092 = 10.8111= B of molesmoles 1.773 = 55.8599=Fe of wt mol.Feof gms= Fe of moles(c) If Fe containing B were to be gas carburized the process would be slower than for Fe which has no B simply because the presence of B atoms already in interstitial sites leave fewer sites for interstitial C to diffuse through. 22.Determine which type of diffusion would be easier (a) C in HCP Ti (b) N in BCC Ti (c) Ti in BCC Tir(C) << r(Ti) so we can predict that diffusion occurs via an interstitial mechanism r(N)<<r(Ti). In this case the diffusion also occurs via interstitial mechanism.Ti in BCC Ti is a case of self-diffusion and self-diffusion occurs via a vacancy mechanism. In general the activation energy for self diffusion is higher than interstitial mechanism because vacancy mechanism involves two steps. One is to create a vacancy and second is to promote a vacancy/atom exchange. Thus Ti in BCC Ti will be the slowest.The activation energy for diffusion via interstitial mechanism is just the energy necessary to move an atom into a neighboring interstitial site. An open crystal structure, as opposed to a dense structure, should have a lower activation energy. Between BCC Ti and HCP Ti, BCC Ti has a more open structure (lower APF) than HCP Ti.Thus, N in BCC Ti diffusion would be the easiest by virtue of its lowest activation energy.23. GIVEN:C 1 = 0.19 at % at surfaceC 2 = 0.18 at % at 1.2mm below the surfaceD = 4 x 10-14 m 2/sec a o = 4.049 A oCOMPUTE: Flux of copper atoms from surface to interior.We must first calculate the concentration gradient in terms of [copperatoms/cm 3/cm]. It can be calculated as follows:The concentration gradient is thencm / atoms 10 x 4.60 = 10 x 6.02 x 63.54] / 2.70) x [(0.0018= C cm / atoms 10 x 4.86 = 10 x 6.02 x 63.54] / 2.70) x [(.0019= CN x Cu] wt at / FCCAl) of density x [(a/oCu = C 319232319231AV24.FIND: Predict whether diffusion is faster in vitreous or crystalline silica.GIVEN: Diffusion is the movement of atoms through the material one step at a time. The ease of movement is in part determined by the amount of space that surrounds each atom. In more open or less dense structures, atoms have an increased chance of being able to squeeze past a neighbor into a new position. SOLUTION: Diffusion can be thought of as an Arrhenius process. The activation energy is that required to move an atom from one position to another, as shown in Fig. 2.3-2. In a crystal the activation energy will be greater than in a glass, since the density is higher and there is less free, or unoccupied, volume. Thus, we expect diffusion to be slower in crystal than in glasses at the same temperature.COMMENTS: When a noncrystalline material is raised to a temperature above the glass transition temperature, diffusion increases enormously. In metals this brings about rapid crystallization. In some ceramic and polymer systems, crystallization may be slow or absent.25.FIND: Do textile dyes more readily penetrate crystalline or noncrystalline regions? GIVEN: Most textile fibers are semicrystalline, containing both crystalline andnoncrystalline regions. The density of the noncrystalline regions is less than that of the crystalline regions. Often dyeing is conducted at a temperature at which the noncrystalline regions are above their glass transition temperature.SOLUTION: Dye penetration through the glass will be greater than that through the crystal; however, the rate of dyeing is not sufficiently high to be commercially feasible. The temperature must be raised so that the noncrystalline polymer is in the rubber state. Diffusion becomes rapid (radially inward) into the small fibers.secsec cm atoms10 x 8.5 = Jcm atoms 10 x 2.125-m cm 10 x m 10 x 4- =dx dc D - = Jcm / atoms 10 x 2.125- = 0.1210 x 2.55- =0.1210 x 4.86) - (4.60 = dx dc 29419224214-4191819⎪⎭⎫ ⎝⎛⎪⎪⎭⎫ ⎝⎛⎪⎭⎫ ⎝⎛COMMENTS: One of the key lessons that dye houses learn is that a sufficient amount of noncrystalline poorly oriented polymer must be present in the fiber. The temperature of the dye bath needs to be above the glass transition temperature. Sometimes water and carriers are used to swell the noncrystalline regions to get yet a greater diffusion rate. The dyes may attach to the polymer using ionic bonds or covalent bonds. Unattached dye may wash out later. 26.CALCULATE: The factor by which the diffusion coefficient of Al in Al 2O 3 change when temperature is increased from 1800o C to 2000o C GIVEN: T 1 = 1800o C = 2073KT 2 = 2000o C = 2273KEQUATION: ⎪⎭⎫⎝⎛RT Q - D = D o ex pdividing (1) by (2), we getfrom table 4.4-1 of the text Q = 477kJ/mole and R = 8.31 J/mole-K⎪⎭⎫⎝⎛RT Q - D = D 1o 1exp ⎪⎭⎫⎝⎛RT Q - D = D 2o 2exp ⎥⎦⎤⎢⎣⎡⎪⎭⎫ ⎝⎛⎪⎭⎫ ⎝⎛ T 1 - T 1 R Q - = RT Q + RT Q - = D D 212121exp expThus, the diffusion coefficient of Al in Al 2O 3 changes by a factor of 11.43 when thetemperature is increased from 1800o C to 2000o C.27. FIND: Temperature at which a specimen of Fe must becarburized for two hours to achieve the same diffusion result asat 900o C for 15 hrs.GIVEN: T 1 = 900o C = 1173K; Q = 84000 J/molet 1 = 15 hrs; D o = 2.00 x 10-6 m 2/sec. t 2 = 2 hrs; R = 8.31 J/mole-KThe value of flux J is in units of cm 2 per sec.Flux per cm 2 J f = Jx time 3600 x 15 x dxdcD - = J 11f(1)We need the same result in 2 hours.D 11.43 = D 0.0871= D 0.087 = D D0.087= [-2.436]=22731 - 20731 8.31477000- = D D 1122121exp exp ⎥⎦⎤⎢⎣⎡⎪⎭⎫ ⎝⎛dxdcD - = J./ m 10 x 3.62 =1173 x 8.3184000- 10 x 2.00 = RT Q - D = D 1210-6-o1sec exp exp ⎪⎭⎫ ⎝⎛⎪⎭⎫⎝⎛ 3600 x 2 x dx dc D - = J 22f,J = J 2f 1f dividing (1) by (2).28. GIVEN:D = 4 x 10-4 m 2/s @ 20o CC 1 = 2.2 x 10-3 k mol/m 3wall thickness = 3mm, diameter = 50cm height = 10cmCOMPUTE: Initial rate of mass loss through cylinder.Initially the concentration of He outside the cylinder, C 2, is zero. First, we need to convert the concentration of He from kmol/m 3 into (atoms/cm 3)/cm.C 1 = 2.2 x 10-3 kmol/m 3 = 2.2mol/m 3 = 2.2 x 10-6 mol/cm 3 = 2.2 x 10-6 mole/cm 3In terms of (atoms/cm 3)/cm0.00135 = T 10108.3-T 8.3184000- 10 x 2.00 = 10 x 2.7RT Q - D = D / m 10 x 72. = D x 7.5 = D 7.5 = D D7.5 x D D = 1226-9-2o229-2121221⎪⎭⎫⎝⎛⎪⎭⎫⎝⎛⎪⎭⎫⎝⎛exp exp exp sec C.1258 =1531K = T 6.60310108.3 = T6.603- = )1n(0.00135 = T 10108.3-o 222The concentration gradient isThe flux of atoms per second per cm 2 is obtained by using Fick’s first law ofdiffusionThe rate of mass loss is 1.766 x 1019atoms/cm 2 sec. The total surface area of the cylinder is 2πr(r+h) where r = radius and h = height.Total surface area = 2π x 25 (25 + 10) = 5497.79 cm 2The rate of mass loss per secondNote:(i ) The steady state mass loss is calculated because the initial rate of mass loss (i.e., rate of mass loss at time t = 0) is 0. (ii ) It is assumed that the curvature of the cylinder is large enough to calculate J using the expression for plate geometry. 29. Diffusion across a polymer membrane depends not only on size of the diffusing species but also the polarity of the diffusing species. A polar membrane may pass nonpolar species but serve as a barrier to polar species.Saran wrap contains highly polar atoms making it a polar membrane which serves as a barrier to water which is a polar compound. thus, there is no diffusion of water through the package unlike polyethylene, which is a nonpolar membrane and allows diffusion of water molecules which form ice. 30.COMPUTE: Temperature required to yield a carbon content of 0.5% at a depthcmatoms 10 x 1.324 = mole atoms 10 x 6.02 x cm mole102.2x = C 3182336-1 cm atoms/ 10 x 4.415- = 0.310 x 1.324 - 0 = dx dcxC - C = dx dc 4181812 .cm atoms/ 10 x 1.766 )10 x (-4.415 )10 x 10 x (4- = dxdcD - = J 2191844-sec secsec secmoles0.16 = .atoms 10 x 9.709 =cm 5497.79 x - cm atoms10 x 1.766 =222219of 0.4mn below the surface of the rod in 48 hours. GIVEN: Carbon concentration the interior = 0.2w/oCarbon concentration in the furnace = 1.0w/oBase material: HCP TiEQUATION: In this problem c(x, t) = 0.5wt%c o = 0.2 wt%c s = 1.0 wt%From figure 4.4-11, when⎥⎦⎤⎢⎣⎡⎪⎭⎫ ⎝⎛Dt 2x erf - 1 = ]c - c []c - t) (x, [cRT Q- D = D o s o o ex p0.625=0.375 - 1 = Dt .04 erf Dt .04 erf - 1 = 0.375Dt 2.04cm erf - 1 = 0.2 - 1.00.2 - 0.5⎥⎦⎤⎢⎣⎡⎥⎦⎤⎢⎣⎡⎥⎦⎤⎢⎣⎡From Metals Handbook, Desk Edition, Pg. 28.66 for C diffusion in Ti, D o = 3.02 x 10-3 cm 2/sec, Q = 20,000 cal/mole = 83682 J/mole. 31.The diffusion process through vacancy-interchange mechanism depends on creation of vacancies and vacancy/atom interchange.At comparable homologous temperatures, for Ge and Cu the diffusion coefficientfor that material which has a higher vacancy concentration would be higher.A covalent bond as opposed to a metallic bond is stronger and directional. It isalso difficult to create vacancies in a covalently bonded material due to its strongbonding. Therefore, the activation energy for vacancy creation in a covalentlybonded material such as Ge is larger than Cu which has a weak metallic bond.The directional nature of a covalent bond places geometrical restrictions on thevacancy atom interchange which again results in an increase in the activationenergy.sec /cm 10 x 2.33 = DDt = 0.630.040.630 = Dt0.040.630 = Z0.625 = (Z) erf 28-2⎪⎭⎫ ⎝⎛ C 582 = T855K = T11.18-10065.2 = T11.18- = T10065.2-10 x 7.72 = T 10065.2- T x 8.31483682- 10 x 3.02 = 10 x 2.33 = D e 83682J/mol = mole 20,000cal/ = Q /cm 10 x 3.02 = D o 6-3-8-2-3o ⎪⎭⎫ ⎝⎛⎪⎭⎫ ⎝⎛exp exp secTherefore, at comparable temperatures the diffusion coefficient for Ge will belarger.32. FIND: Describe the energy and entropy in Fig. 4.4-5a, b, and c.SOLUTION: The order in part a is high. The materials is perfect. There is only one way to arrange the atoms in such a system. The entropy is low. In part b there is less order, more disorder, and the entropy has increased. Part c is nearly random. It has low order and high entropy. Energy contains a contribution from entropy: E = H -TS, where E is energy, T is absolute temperature, and S is entropy. Assuming all other contributions to energy change negligibly (T and H), the energy of part c is the low, part a is high and part b is intermediate.COMMENTS: What is shown in going from a to c is the entropy of mixing.33. GIVEN: After 10 hrs at 550o C an oxide layer of thickness 8 μm is formed.COMPUTE: Thickness after 100 hrs. Using the definition of effective penetration distance and equation 4.4-11 of text,with γ = 2 we have Dt 2 x eff ≈.In this case34. GIVEN: D w = 1.0 x 10-12 m 2/s (water)D dc = 1.0 x 10 (dye carrier)D d = 1.0 x 10-14 m 2/s (dye)COMPUTE:(a) Times required for the water, dye and carrier to penetrate to the center of the fiber. m25.3 = x 100hr 10hr = x m8t t = t D t D = x x100hr = t 10hr = t? = x m 8 = x 2eff 2eff2122111eff 1eff 212eff 1eff μμμ(b) Same as (a) but fiber diameter doubles(c) If thermal diffusivity of PET is secm 10 x 828-how long will it take for the heat to penetrate to the center of a 50μm diameter fiber.(a) using equation 4.4-11 of text with γ = 2.for water,for dye carriersimilarly for dye t = 6.25secs.(b) If the diameter fiber is doubled x eff = 50 x 10-6 mfor water, Dt 2 = x eff minutes2.60 or secs 156 = tt x 10 x 1.0 = 10 x 625.00t x 10 x 1.0 = 2)10 x (25.0m 10 x 25 = x/s m 10 x 1.0 = D 12-12-12-6-26-eff 2-12w ⎪⎪⎭⎫⎝⎛ minutes26.04 = secs 15.63 = tm 10 x 25 = x/s m 10 x 1.0 = D 6-eff 2-13dcsimilarly for dye carriert = 6250 secsand for dyet = 6.25 x 104 secs(c) Substituting D with D th , we can use the same equation to calculate the timerequired for heat to penetrate the center of fiber diameter = 50μm.Note: The units of thermal diffusivity is m 2/sec and notK - m Watt as printed in text35. FIND: How long will it take to case carburize a steel chain to a depth of 1/16 inch?GIVEN: It requires 4 hours to carburize a plate of similar composition to a depthof 1/16 inch.ASSUMPTIONS: All carburization conditions are the same in both treatments.SOLUTION: Equation 4.4-11 is used to solve the problem:secs.625 = 10 x 1.0)10 x 50 ( = tt x D = 2)10 x (5010 x 50 = x/s m 19 x 1.0 = D 12-26-26-6-eff 2-12wsecs0.00195 = t10x 81 x 210 x 25 = _tt x 10 x 8 = 210 x 25t x D 2 = x 8-6-28-6-2th eff ⎪⎪⎭⎫ ⎝⎛⎪⎪⎭⎫ ⎝⎛。

土木工程材料第二版课后习题答案土木工程材料的基本性第一章(1)当某一建筑材料的孔隙率增大时,材料的密度、表观密度、强度、吸水率、搞冻性及导热性是下降、上生还是不变?(2)材料的密度、近似密度、表观密度、零积密度有何差别?答:(3)材料的孔隙率和空隙率的含义如何?如何测定?了解它们有何意义?答:P指材料体积内,孔隙体积所占的百分比:P′指材料在散粒堆积体积中,颗粒之间的空隙体积所占的百分比:了解它们的意义为:在土木工程设计、施工中,正确地使用材料,掌握工程质量。

(4)亲水性材料与憎水性材料是怎样区分的?举例说明怎样改变材料的变水性与憎水性?答:材料与水接触时能被水润湿的性质称为亲水性材料;材料与水接触时不能被水润湿的性质称为憎水性材料。

例如:塑料可制成有许多小而连通的孔隙,使其具有亲水性。

例如:钢筋混凝土屋面可涂抹、覆盖、粘贴憎水性材料,使其具有憎水性。

(5)普通粘土砖进行搞压实验,浸水饱和后的破坏荷载为183KN,干燥状态的破坏荷载为207KN(受压面积为115mmX120mm),问此砖是否宜用于建筑物中常与水接触的部位?答:(6)塑性材料和塑性材料在外国作用下,其变形性能有何改变?答:塑性材料在外力作用下,能产生变形,并保持变形后的尺寸且不产生裂缝;脆性材料在外力作用下,当外力达到一定限度后,突然破坏,无明显的塑性变形。

(7)材料的耐久性应包括哪些内容?答:材料在满足力学性能的基础上,还包括具有抵抗物理、化学、生物和老化的作用,以保证建筑物经久耐用和减少维修费用。

(8)建筑物的屋面、外墙、甚而所使用的材料各应具备哪些性质?答:建筑物的屋面材料应具有良好的防水性及隔热性能;外墙材料应具有良好的耐外性、抗风化性及一定的装饰性;而基础所用材料应具有足够的强度及良好的耐水性。

第1章天然石材(1)岩石按成因可分为哪几类?举例说明。

答:可分为三大类:1)岩浆岩,也称火成岩,是由地壳内的岩浆冷凝而成,具有结晶构造而没有层理。

材料力学第二版课后答案1. 弹性力学。

1.1. 什么是材料的弹性?材料的弹性是指材料在受力后能够恢复原状的性质。

当外力作用于材料上时,材料会发生形变,但在去除外力后,材料会恢复到原来的形状和尺寸。

1.2. 什么是胡克定律?胡克定律是描述弹性体在弹性变形时,应力和应变之间的关系。

它可以用数学公式表示为,σ = Eε,其中σ表示应力,E表示弹性模量,ε表示应变。

1.3. 什么是杨氏模量?杨氏模量是描述材料抗拉伸性能的指标,它表示单位面积内的拉应力增加一个单位的长度时,材料的伸长量。

杨氏模量的计算公式为,E = σ/ε。

2. 塑性力学。

2.1. 什么是材料的塑性?材料的塑性是指材料在受力后会发生永久性变形的性质。

当外力作用于材料上时,材料会发生塑性变形,去除外力后,材料无法完全恢复原状。

2.2. 什么是屈服点?屈服点是材料在受力过程中,应力-应变曲线上的一个特殊点,表示材料从弹性变形进入塑性变形的临界点。

在屈服点之后,材料会发生永久性变形。

2.3. 什么是材料的硬度?材料的硬度是指材料抵抗外力压入的能力。

硬度测试可以用来评价材料的耐磨性、耐压性等性能,常用的硬度测试方法包括洛氏硬度、巴氏硬度等。

3. 断裂力学。

3.1. 什么是断裂韧性?断裂韧性是材料抵抗断裂的能力。

它是指材料在受到外力作用时,能够吸收大量的能量而不发生断裂的能力。

3.2. 什么是脆性断裂?脆性断裂是材料在受力过程中,发生迅速、不可逆的断裂现象。

脆性断裂的特点是断裂前往往不伴随明显的塑性变形。

3.3. 什么是韧性断裂?韧性断裂是材料在受力过程中,发生缓慢、可逆的断裂现象。

韧性断裂的特点是断裂前伴随明显的塑性变形,能够吸收大量的能量。

4. 疲劳力学。

4.1. 什么是疲劳寿命?疲劳寿命是指材料在受到交变应力作用下,经过一定次数的循环载荷后发生疲劳断裂的次数。

4.2. 什么是疲劳强度?疲劳强度是指材料在受到交变应力作用下,能够承受的最大应力水平,也可以理解为材料的抗疲劳能力。

材料科学与工程习题答案【篇一:材料科学与工程导论课后习题答案杨瑞城蒋成禹】1.为什么说材料的发展是人类文明的里程碑?材料是一切文明和科学的基础,材料无处不在,无处不有,它使人类及其赖以生存的社会、环境存在着紧密而有机的联系。

纵观人类利用材料的历史,可以清楚地看到,每一种重要材料的发现和利用,都会把人类支配和改造自然的能力提高到一个新的水平,给社会生产和人类生活带来巨大的变化。

2.什么是材料的单向循环?什么是材料的双向循环?两者的差别是什么?物质单向运动模式:“资源开采-生产加工-消费使用-废物丢弃”双向循环模式:以仿效自然生态过程物质循环的模式,建立起废物能在不同生产过程中循环,多产品共生的工业模式,即所谓的双向循环模式(或理论意义上的闭合循环模式)。

差别:单向循环必然带来地球有限资源的紧缺和破坏,同时带来能源浪费,造成人类生存环境的污染。

无害循环:流程性材料生产中,如果一个过程的输出变为另一个过程的输入,即一个过程的废物变成另一个过程的原料,并且经过研究真正达到多种过程相互依存、相互利用的闭合的产业“网”、“链”,达到了清洁生产。

3.什么是生态环境材料?生态环境材料是指同时具有优良的使用性能和最佳环境协调性能的一大类材料。

这类材料对资源和能源消耗少,对生态和环境污染小,再生利用率高或可降解化和可循环利用,而且要求在制造、使用、废弃直到再生利用的整个寿命周期中,都必须具有与环境的协调共存性。

因此,所谓环境材料,实质是赋予传统结构材料、功能材料以特别优异的环境协调性的材料,它是材料工作者在环境意识指导下,或开发新型材料,或改进、改造传统材料,任何一种材料只要经过改造达到节约资源并与环境协调共存的要求,它就应被视为环境材料。

4.为什么说材料科学和材料工程是密不可分的系统工程?材料科学与工程的材料科学部分主要研究材料的结构与性能之间所存在的关系,即集中了解材料的本质,提出有关的理论和描述,说明材料结构是如何与其成分、性能以及行为相联系的。