螺纹底孔对应表

- 格式:doc

- 大小:68.50 KB

- 文档页数:1

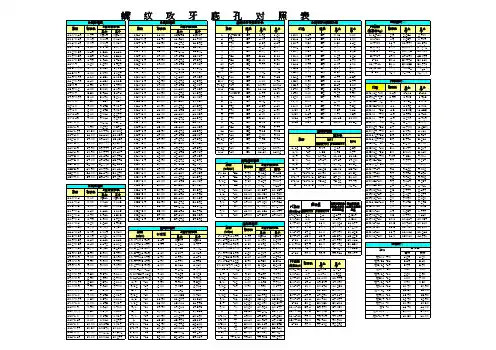

PS 规格最大最小最大最小(新规格Rp)M1.0*0.250.750.7850.72911.0011.15310.9171-64UNC G5 1.76 1.68M1.00.25G40.920.891/16-28 6.5 6.632 6.490M1.1*0.250.850.8850.82911.5011.52011.4002-56G4 2.04 1.96M1.20.25G4 1.11 1.091/8-288.58.6378.495M1.2*0.250.950.9850.92912.5012.67612.3763-48G4 2.35 2.25M1.40.30G4 1.30 1.261/4-1911.411.54911.341M1.4*0.3 1.10 1.142 1.07513.0013.15312.9174-40G5 2.64 2.54M1.60.35G4 1.47 1.433/8-1914.915.05414.846M1.6*0.35 1.25 1.321 1.22113.5013.67613.3765-40G5 2.97 2.87M1.70.35G4 1.57 1.521/2-1418.618.77318.489M1.7*0.35 1.35 1.421 1.32114.0014.15313.9176-32G5 3.22 3.11M1.80.35G4 1.67 1.623/4-1424.024.25923.975M1.8*0.35 1.45 1.521 1.42114.5014.67614.3768-32G6 3.89 3.78M2.00.40G4 1.84 1.791-1130.230.47230.110M2*0.4 1.60 1.679 1.56715.0015.15314.91710-24G6 4.44 4.30M2.20.45G5 2.04 1.9811/4-1138.839.13338.771M2.2*0.45 1.75 1.838 1.71315.5015.67615.37612-24G6 5.07 4.96M2.30.40G4 2.14 2.0911/2-1144.745.02644.664M2.3*0.4 1.90 1.979 1.86716.0016.15315.9171/4〞-20G7 5.86 5.73M2.50.45G5 2.34 2.272-1156.556.83756.475M2.5*0.45 2.10 2.138 2.01316.0016.21015.8355/16〞-18G77.387.23M2.60.45G5 2.44 2.37M2.6*0.45 2.20 2.238 2.11316.5016.67616.3763/8〞-16G78.898.72M3.00.50G5 2.82 2.75M3*0.5 2.50 2.599 2.45917.0017.15316.9177/16〞-14G810.4010.02M3.50.60G5 3.27 3.19M3.5*0.6 2.90 3.010 2.85018.0018.21017.8351/2〞-13G811.9211.70M4.00.70G6 3.72 3.65M4*0.7 3.30 3.422 3.24218.5018.67618.3760-80UNF G5 1.45 1.39M5.00.80G6 4.67 4.59SM1/16 -80 1.25 1.281 1.211M4.5*0.75 3.80 3.878 3.68819.0019.15318.9171-72G5 1.77 1.70M6.0 1.00G7 5.59 5.49SM5/64 -64 1.55 1.593 1.513M5*0.8 4.20 4.334 4.13420.0020.21019.8352-64G4 2.06 1.98M7.0 1.00G7 6.59 6.48SM3/32 -56 1.9 1.936 1.841M6*1.0 5.00 5.153 4.91720.5020.67620.3763-56G4 2.37 2.29M8.0 1.25G77.497.36SM3/32-100 2.1 2.156 2.081M7*1.0 6.00 6.153 5.91721.0021.15320.9174-48G5 2.68 2.59M10 1.5G79.349.22SM1/8 -32 2.3(2.393)(2.233)M8*1.25 6.80 6.912 6.64722.0022.21021.8355-44G5 2.99 2.90M10 1.25G79.499.35SM1/8 -40 2.5 2.551 2.421M9*1.257.807.9127.64722.5022.67622.3766-40G5 3.29 3.19M12 1.75G811.2311.09SM1/8 -44 2.5 2.605 2.485M10*1.58.508.6768.37623.0023.15322.9178-36G5 3.91 3.81M12 1.25G911.5011.36SM1/8 -48 2.6 2.657 2.547M11*1.59.509.6769.37623.0023.21022.83510-32G6 4.53 4.44SM9/64 -32 2.7(2.790)(2.630)M12*1.7510.3010.44110.10623.5023.67623.37612-28G6 5.13 5.03SM9/64 -40 2.9 2.948 2.818M14*2.012.0012.21011.83524.0024.15323.9171/4〞-28G7 6.00 5.91SM11/64-32 3.5 3.584 3.424M16*2.014.0014.21013.83524.5024.67624.3765/16〞-24G77.537.42SM11/64-40 3.7 3.742 3.612M18*2.515.5015.74415.29425.0025.21024.8353/8〞-24G79.108.99使用铰刀时不使用铰刀时SM3/16 -24 3.6 3.658 3.498M20*2.517.5017.74417.29425.5025.67625.3767/16〞-20G810.6210.481/16-27 5.94 6.15 6.35SM3/16 -28 3.8 3.844 3.684M22*2.519.5019.74419.29426.0026.15325.9171/2〞-20G812.2012.061/8-278.338.438.74SM3/16 -32 3.9 3.980 3.820M24*3.021.0021.25220.75226.0026.21025.8351/4-1810.7211.1311.13SM3/16 -40 4.05 4.138 4.008M27*3.024.0024.25223.75226.5026.67626.3763/8-1814.2714.2714.68SM7/32-32 4.7 4.774 4.614M30*3.526.5026.77126.21127.0027.15326.9171/2-1417.4817.8618.26SM15/64-28 5.0 5.055 4.875M33*3.529.5029.77129.21127.0027.25226.752最大最小3/4-1422.6323.0123.42SM1/4-24 5.2 5.266 5.086M36*4.032.0032.27031.67028.0028.21027.835No.12-32 4.70 4.826 4.8231-11-1/228.5828.9829.36SM1/4-28 5.4 5.452 5.272M39*4.035.0035.27034.67028.5028.67628.3761/4-32 5.60 5.689 5.4871-1/4-11-1/237.3137.6938.10SM1/4-40 5.6 5.726 5.59629.0029.15328.9175/16-327.107.2647.0871-1/2-11-1/243.2643.6644.45SM9/32-20 5.7 5.824 5.63430.0030.21029.8353/8-328.708.8648.6622-11-1/255.1755.5856.36SM9/32-28 6.2 6.256 6.06630.5030.67630.3767/16-2810.2010.33710.135SM5/16-18 6.3 6.444 6.254最大最小30.0030.25229.7521/2-2811.8011.93811.710SM5/16-24 6.8 6.864 6.674M1.0*0.20.800.8210.78331.0031.21030.8359/16-2413.2013.38511.132SM5/16-28 6.97.050 6.860M1.1*0.20.900.9210.88331.5031.67631.3765/8-2414.8014.96814.732SM11/32-287.77.8437.653M1.2*0.2 1.00 1.0210.98333.5033.67633.3763/4-2017.8017.95717.679SM3/8-187.98.0537.843M1.4*0.2 1.20 1.221 1.18333.0033.25232.7527/8-2021.0021.13220.854(新规格Rc)使用铰刀时不使用铰刀时SM3/8-288.58.6378.447M1.6*0.2 1.40 1.421 1.38334.0034.21033.8351-2024.0024.30724.0291-16-28 6.1 6.2 6.244 6.384SM7/16-169.39.4409.220M1.7*0.2 1.45 1.500 1.46034.5034.67634.3761/8-288.18.28.2498.388SM7/16-2810.110.22410.034M1.8*0.2 1.60 1.621 1.5831/4-1910.711.010.96211.174SM1/2-1210.310.42010.180M2.0*0.25 1.75 1.785 1.7293/8-1914.214.514.44814.658SM1/2-2011.311.41011.190M2.2*0.25 1.95 1.985 1.929最大最小1/2-1417.618.017.97918.263SM1/2-2811.711.81211.622M2.3*0.35 2.05 2.061 2.001最大最小1.55 1.582 1.4253/4-1423.023.523.37823.663SM9/16-2012.913.01812.778M2.5*0.35 2.20 2.221 2.121 1.25 1.305 1.1821.80 1.871 1.6951-1129.029.529.45929.822M2.6*0.35 2.20 2.246 2.186 1.55 1.612 1.4742.10 2.146 1.941 1 1/4-1137.538.037.97638.339M3.0*0.35 2.70 2.721 2.621 1.85 1.912 1.7562.30 2.385 2.157 1 1/2-1143.444.043.86944.232M3.5*0.35 3.50 3.599 3.459 2.10 2.197 2.0252.60 2.697 2.4872-1154.955.555.41255.844硬材软材M4.5*0.5 4.00 4.0993.959 2.40 2.458 2.2712.80 2.895 2.642W1/8-40 2.65 2.60M5.0*0.5 4.50 4.599 4.459 2.70 2.740 2.5513.40 3.530 3.302PF 规格W5/32-32 3.25 3.20M5.5*0.5 5.00 5.0994.959 2.90 3.022 2.8203.90 3.962 3.683(新规格G)W3/16-24 3.75 3.70M6.0*0.5 5.50 5.550 5.400 3.50 3.606 3.4044.50 4.597 4.3441/16-28 6.7 6.843 6.561W1/4-205.10 5.00M6.0*0.75 5.30 5.378 5.188 4.10 4.165 3.9631/4-20 5.10 5.257 4.9791/8-288.78.8488.566W5/16-18 6.60 6.50M7.0*0.5 6.50 6.550 6.400 4.60 4.724 4.4965/16-18 6.60 6.731 6.4011/4-1911.711.89011.445W3/8-168.007.90M7.0*0.75 6.30 6.378 6.1881/4-28 5.50 5.588 5.3603/8-168.008.1537.7983/8-1915.215.39514.950W7/16-149.409.30M8.0*0.57.507.5207.4005/16-24 6.907.035 6.7827/16-149.409.5509.1441/2-1419.019.17218.631W1/2-1210.7010.50M8.0*0.757.307.3787.1883/8-248.508.6368.3821/2-1310.9011.02310.5925/8-1421.021.12820.587W9/16-1212.3012.00M8.0*1.07.007.153 6.9177/16-209.9010.0339.7299/16-1212.2012.44611.9893/4-1424.524.65824.117W5/8-1113.7013.50M9.0*0.758.308.3788.1881/2-2011.5011.60711.3295/8-1113.6013.86813.3867/8-1428.228.41827.877W3/4-1016.7016.50M9.0*1.08.008.1537.9179/16-1812.9013.08112.7513/4-1016.6016.84016.3071-1130.630.93130.291W7/8-919.5019.30M10*0.59.509.5209.4005/8-1814.5014.68114.3517/8-919.6019.76119.17711/8-1135.235.57934.939W1-822.4022.00M10*0.759.309.3789.1883/4-1617.5017.67817.3231-822.3022.60621.97111/4-1139.239.59238.952W1-1/8-725.0024.80M10*1.09.009.1538.9177/8-1420.5020.67520.2701-1/8-725.0025.34924.63811/2-1145.045.48544.845W1-1/4-728.3028.00M10*1.258.808.9128.6471-1223.3023.57123.1141-1/4-728.2028.52427.81313/4-1151.051.42850.788M11*1.010.0010.1539.9171-1/8-1226.5026.74626.2891-3/8-630.8031.11530.3532-1157.057.29656.656M11*0.7510.3010.37810.1881-1/4-1229.6029.92129.4641-1/2-634.0034.29033.528M12*1.510.5010.67610.3761-3/8-1232.8033.09632.6391-3/4-539.5039.82738.964M12*1.2510.8010.91210.6471-1/2-1236.0036.27135.8142-4-1/245.2045.59344.679标准径最大最小No.10-24(4.826)No.12-24(5.486)No.10-32(4.826)No.12-28(5.486)英制螺纹规格钻孔径螺 纹 攻 牙 底 孔 对 照 表PT 规格標准徑有效牙部之長度(最小)中之母螺牙內徑標准長度(最小)中之母螺牙內徑公制粗螺纹2级牙钻孔径规格标准径No.8-32(4.166)(UNEF)美制细螺纹No.4-40(2.845)No.5-40(3.175)美制粗螺纹标准径2级牙钻孔径M30*3.0M33*3.0No.6-32(3.505)规格(UNF)M15*1.0M16*1.5M22*1.5M22*1.0M24*2.0公制细螺纹M17*1.5M17*1.0M18*2.0M18*1.5M20*2.0M20*1.5M20*1.0M18*1.0M22*2.0公制细螺纹标准径2级牙钻孔径M16*1.0规格M12*1.0M12*0.5M14*1.5M14*1.0M15*1.5M24*1.5M24*1.0M25*2.0M25*1.5M25*1.0M26*1.5M27*2.0M27*1.5M27*1.0M28*2.0M28*1.5M28*1.0M32*1.5M33*2.0M36*1.5M30*2.0M30*1.5M30*1.0M32*2.0M33*1.5M35*1.5M36*3.0M36*2.0规格规格(UNC)No.2-64(2.184)No.8-36(4.166)规格规格标准径2级牙钻孔径No.3-56(2.515)No.4-48(2.845)No.5-44(3.175)No.6-40(3.505)美制迫牙丝攻钻孔径No.1-64(1.854)No.2-56(2.184)2级牙钻孔径精度最大最小美制特细螺纹标准径No.3-48(2.515)标准径2级牙钻孔径No.1-72(1.854)No.0-80(1.524)英制管螺纹标准径最大最小NPT 公制迫牙丝攻钻孔径规格精度最大最小NPS 美制管螺纹规格钻孔径針車用螺纹规格标准径最大最小。

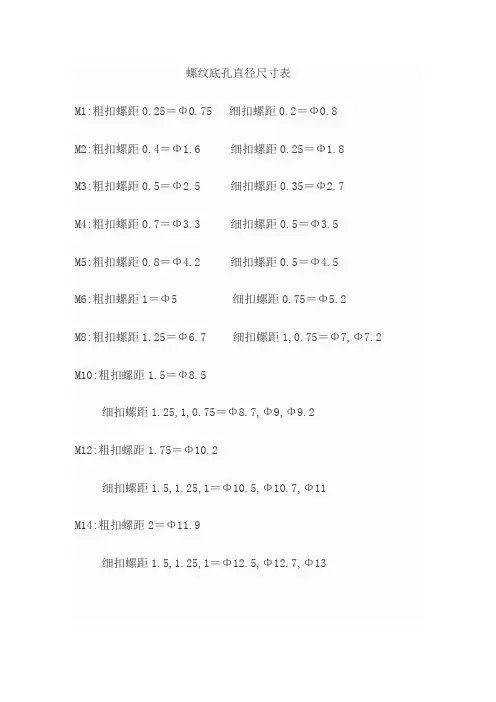

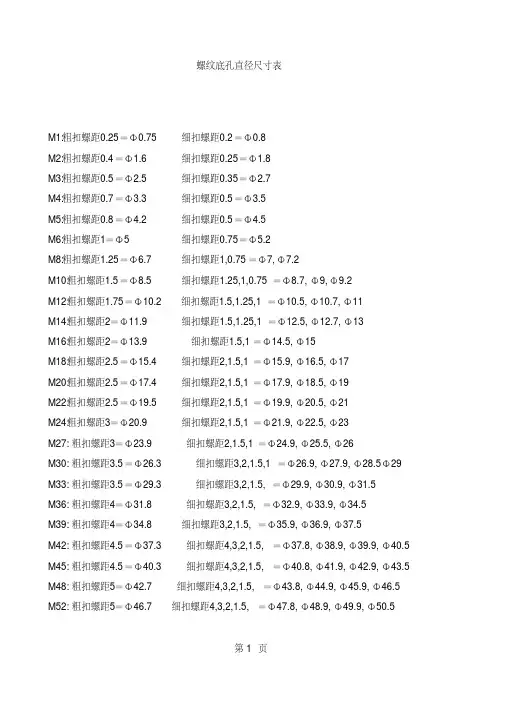

螺纹底孔直径尺寸表M1:粗扣螺距0.25=Φ0.75细扣螺距0.2=Φ0.8M2:粗扣螺距0.4=Φ1.6细扣螺距0.25=Φ1.8M3:粗扣螺距0.5=Φ2.5细扣螺距0.35=Φ2.7M4:粗扣螺距0.7=Φ3.3细扣螺距0.5=Φ3.5M5:粗扣螺距0.8=Φ4.2细扣螺距0.5=Φ4.5M6:粗扣螺距1=Φ5细扣螺距0.75=Φ5.2M8:粗扣螺距1.25=Φ6.7细扣螺距1,0.75=Φ7,Φ7.2 M10:粗扣螺距1.5=Φ8.5细扣螺距1.25,1,0.75=Φ8.7,Φ9,Φ9.2M12:粗扣螺距1.75=Φ10.2细扣螺距1.5,1.25,1=Φ10.5,Φ10.7,Φ11M14:粗扣螺距2=Φ11.9细扣螺距1.5,1.25,1=Φ12.5,Φ12.7,Φ13细扣螺距1.5,1=Φ14.5,Φ15M18:粗扣螺距2.5=Φ15.4细扣螺距2,1.5,1=Φ15.9,Φ16.5,Φ17M20:粗扣螺距2.5=Φ17.4细扣螺距2,1.5,1=Φ17.9,Φ18.5,Φ19M22:粗扣螺距2.5=Φ19.5细扣螺距2,1.5,1=Φ19.9,Φ20.5,Φ21M24:粗扣螺距3=Φ20.9细扣螺距2,1.5,1=Φ21.9,Φ22.5,Φ23M27:粗扣螺距3=Φ23.9细扣螺距2,1.5,1=Φ24.9,Φ25.5,Φ26M30:粗扣螺距3.5=Φ26.3细扣螺距3,2,1.5,1=Φ26.9,Φ27.9,Φ28.5Φ29细扣螺距3,2,1.5,=Φ29.9,Φ30.9,Φ31.5M36:粗扣螺距4=Φ31.8细扣螺距3,2,1.5,=Φ32.9,Φ33.9,Φ34.5M39:粗扣螺距4=Φ34.8细扣螺距3,2,1.5,=Φ35.9,Φ36.9,Φ37.5M42:粗扣螺距4.5=Φ37.3细扣螺距4,3,2,1.5,=Φ37.8,Φ38.9,Φ39.9,Φ40.5 M45:粗扣螺距4.5=Φ40.3细扣螺距4,3,2,1.5,=Φ40.8,Φ41.9,Φ42.9,Φ43.5 M48:粗扣螺距5=Φ42.7细扣螺距4,3,2,1.5,=Φ43.8,Φ44.9,Φ45.9,Φ46.5 M52:粗扣螺距5=Φ46.7细扣螺距4,3,2,1.5,=Φ47.8,Φ48.9,Φ49.9,Φ50.5螺纹底孔直径尺寸表.txt生产中钻螺纹底孔公式:t<1mm:Dz=d-tt>1mm:Dz=d-(1.04~1.06)t式中t螺距(毫米)Dz攻丝前钻头直径(毫米)d螺纹公称直径(毫米)生产中钢料可按数值选取,软料钻头直径可选大些,但不可太大。

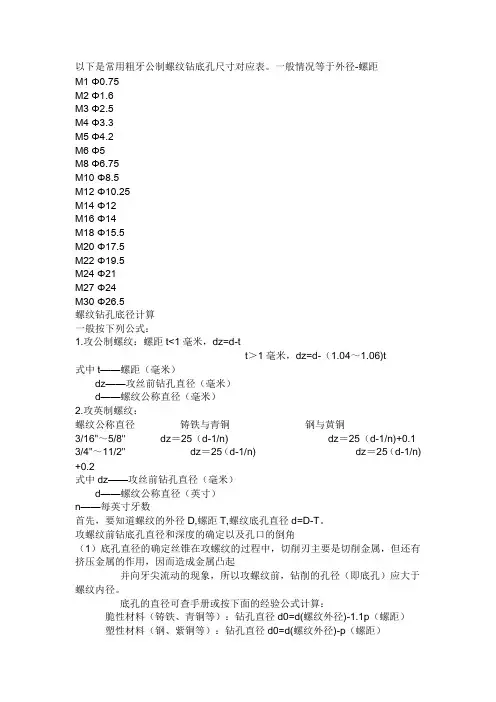

以下是常用粗牙公制螺纹钻底孔尺寸对应表。

一般情况等于外径-螺距M1 Φ0.75M2 Φ1.6M3 Φ2.5M4 Φ3.3M5 Φ4.2M6 Φ5M8 Φ6.75M10 Φ8.5M12 Φ10.25M14 Φ12M16 Φ14M18 Φ15.5M20 Φ17.5M22 Φ19.5M24 Φ21M27 Φ24M30 Φ26.5螺纹钻孔底径计算一般按下列公式:1.攻公制螺纹:螺距t<1毫米,dz=d-tt>1毫米,dz=d-(1.04~1.06)t式中t——螺距(毫米)dz——攻丝前钻孔直径(毫米)d——螺纹公称直径(毫米)2.攻英制螺纹:螺纹公称直径铸铁与青铜钢与黄铜3/16"~5/8" dz=25(d-1/n) dz=25(d-1/n)+0.1 3/4"~11/2" dz=25(d-1/n) dz=25(d-1/n) +0.2式中dz——攻丝前钻孔直径(毫米)d——螺纹公称直径(英寸)n——每英寸牙数首先,要知道螺纹的外径D,螺距T,螺纹底孔直径d=D-T。

攻螺纹前钻底孔直径和深度的确定以及孔口的倒角(1)底孔直径的确定丝锥在攻螺纹的过程中,切削刃主要是切削金属,但还有挤压金属的作用,因而造成金属凸起并向牙尖流动的现象,所以攻螺纹前,钻削的孔径(即底孔)应大于螺纹内径。

底孔的直径可查手册或按下面的经验公式计算:脆性材料(铸铁、青铜等):钻孔直径d0=d(螺纹外径)-1.1p(螺距)塑性材料(钢、紫铜等):钻孔直径d0=d(螺纹外径)-p(螺距)(2)钻孔深度的确定攻盲孔(不通孔)的螺纹时,因丝锥不能攻到底,所以孔的深度要大于螺纹的长度,盲孔的深度可按下面的公式计算:孔的深度=所需螺纹的深度+0.7d普通螺纹底孔直径简单计算可按下式要攻丝的尺寸乘上0.85如:M3--2.4mmM4--3.1mmM5--4.2mM6--5.1mmM8--6.8mm公制螺纹的计算方法:底径=大径-1.0825*螺距英制螺纹的计算方法:底径=大径-1.28*螺距脆性材料钻孔直径D=d(螺纹外径)-1.1p(螺距)塑性材料钻孔直径D=d(螺纹外径)-p(螺距)除了以上的经验公司外,还要考虑螺纹的公差等级.普通公制螺纹用外径-螺距。

螺纹底孔直径尺寸表M1:粗扣螺距0.25=Φ0.75 细扣螺距0.2=Φ0.8M2:粗扣螺距0.4=Φ1.6 细扣螺距0.25=Φ1.8M3:粗扣螺距0.5=Φ2.5 细扣螺距0.35=Φ2.7M4:粗扣螺距0.7=Φ3.3 细扣螺距0.5=Φ3.5M5:粗扣螺距0.8=Φ4.2 细扣螺距0.5=Φ4.5M6:粗扣螺距1=Φ5 细扣螺距0.75=Φ5.2M8:粗扣螺距1.25=Φ6.7 细扣螺距1,0.75=Φ7,Φ7.2M10:粗扣螺距1.5=Φ8.5 细扣螺距1.25,1,0.75=Φ8.7,Φ9,Φ9.2M12:粗扣螺距1.75=Φ10.2 细扣螺距1.5,1.25,1=Φ10.5,Φ10.7,Φ11M14:粗扣螺距2=Φ11.9 细扣螺距1.5,1.25,1=Φ12.5,Φ12.7,Φ13M16:粗扣螺距2=Φ13.9 细扣螺距1.5,1=Φ14.5,Φ15M18:粗扣螺距2.5=Φ15.4 细扣螺距2,1.5,1=Φ15.9,Φ16.5,Φ17M20:粗扣螺距2.5=Φ17.4 细扣螺距2,1.5,1=Φ17.9,Φ18.5,Φ19M22:粗扣螺距2.5=Φ19.5 细扣螺距2,1.5,1=Φ19.9,Φ20.5,Φ21M24:粗扣螺距3=Φ20.9 细扣螺距2,1.5,1=Φ21.9,Φ22.5,Φ23M27: 粗扣螺距3=Φ23.9 细扣螺距2,1.5,1=Φ24.9,Φ25.5,Φ26M30: 粗扣螺距3.5=Φ26.3 细扣螺距3,2,1.5,1=Φ26.9,Φ27.9,Φ28.5Φ29 M33: 粗扣螺距3.5=Φ29.3 细扣螺距3,2,1.5,=Φ29.9,Φ30.9,Φ31.5M36: 粗扣螺距4=Φ31.8 细扣螺距3,2,1.5,=Φ32.9,Φ33.9,Φ34.5M39: 粗扣螺距4=Φ34.8 细扣螺距3,2,1.5,=Φ35.9,Φ36.9,Φ37.5M42: 粗扣螺距4.5=Φ37.3 细扣螺距4,3,2,1.5,=Φ37.8,Φ38.9,Φ39.9,Φ40.5 M45: 粗扣螺距4.5=Φ40.3 细扣螺距4,3,2,1.5,=Φ40.8,Φ41.9,Φ42.9,Φ43.5 M48: 粗扣螺距5=Φ42.7 细扣螺距4,3,2,1.5,=Φ43.8,Φ44.9,Φ45.9,Φ46.5 M52: 粗扣螺距5=Φ46.7 细扣螺距4,3,2,1.5,=Φ47.8,Φ48.9,Φ49.9,Φ50.5螺纹底孔直径尺寸表.txt生产中钻螺纹底孔公式:t<1mm: Dz=d-tt>1mm: Dz=d-(1.04~1.06)t式中 t 螺距(毫米)Dz 攻丝前钻头直径(毫米)d 螺纹公称直径(毫米) 生产中钢料可按数值选取,软料钻头直径可选大些,但不可太大.。

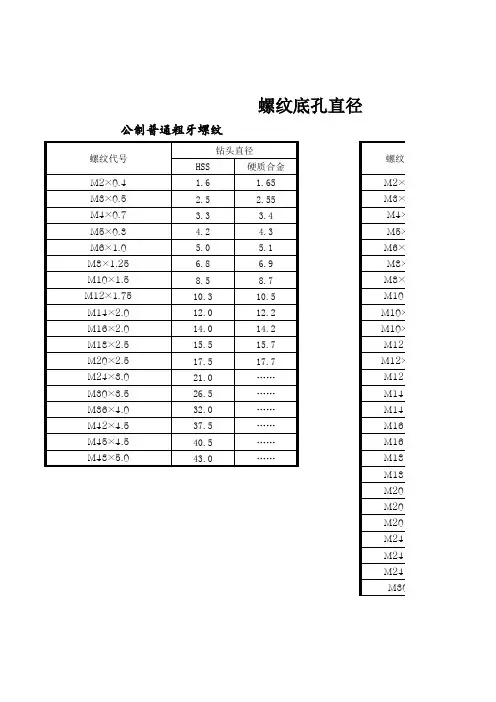

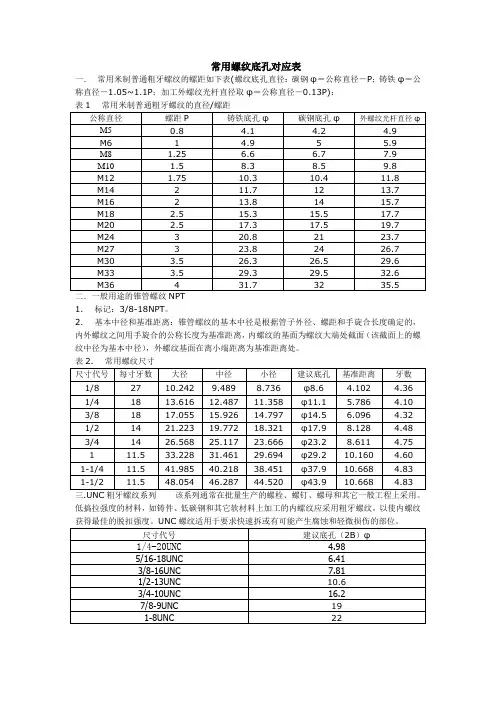

常用螺纹底孔对应表

一.常用米制普通粗牙螺纹的螺距如下表(螺纹底孔直径:碳钢φ=公称直径-P;铸铁φ=公称直径-1.05~1.1P;加工外螺纹光杆直径取φ=公称直径-0.13P):

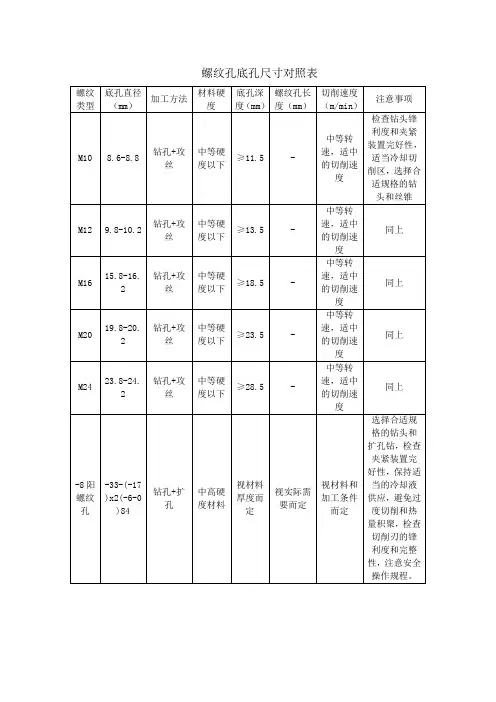

表1 常用米制普通粗牙螺纹的直径/螺距

二.一般用途的锥管螺纹NPT

1. 标记:3/8-18NPT。

2. 基本中径和基准距离:锥管螺纹的基本中径是根据管子外径、螺距和手旋合长度确定的,内外螺纹之间用手旋合的公称长度为基准距离,内螺纹的基面为螺纹大端处截面(该截面上的螺纹中径为基本中径),外螺纹基面在离小端距离为基准距离处。

表2. 常用螺纹尺寸

三.UNC粗牙螺纹系列该系列通常在批量生产的螺栓、螺钉、螺母和其它一般工程上采用。

低搞拉强度的材料,如铸件、低碳钢和其它软材料上加工的内螺纹应采用粗牙螺纹,以使内螺纹获得最佳的脱扣强度。

UNC螺纹适用于要求快速拆或有可能产生腐蚀和轻微损伤的部位。

常用螺纹底孔对应表

一.常用米制普通粗牙螺纹的螺距如下表(螺纹底孔直径:碳钢φ=公称直径-P;铸铁φ=公称直径-1.05~1.1P;加工外螺纹光杆直径取φ=公称直径-0.13P):

表1 常用米制普通粗牙螺纹的直径/螺距

二.一般用途的锥管螺纹NPT

1. 标记:3/8-18NPT。

2. 基本中径和基准距离:锥管螺纹的基本中径是根据管子外径、螺距和手旋合长度确定的,内外螺纹之间用手旋合的公称长度为基准距离,内螺纹的基面为螺纹大端处截面(该截面上的螺纹中径为基本中径),外螺纹基面在离小端距离为基准距离处。

表2. 常用螺纹尺寸

三.UNC粗牙螺纹系列该系列通常在批量生产的螺栓、螺钉、螺母和其它一般工程上采用。

低搞拉强度的材料,如铸件、低碳钢和其它软材料上加工的内螺纹应采用粗牙螺纹,以使内螺纹获得最佳的脱扣强度。

UNC螺纹适用于要求快速拆或有可能产生腐蚀和轻微损伤的部位。