防爆投光灯说明书

- 格式:doc

- 大小:27.50 KB

- 文档页数:3

FeaturesFour flash rates: 1Hz, 1.3Hz, 1.5Hz & double flashAutomatic synchronisation on multi-beacon systemA4 316 Stainless Steel guard included as standardUV stable polycarbonate lens colour filter – field replaceable4 x side, 1 x pendant cable entries – stopping plugs includedCorrosion proof marine grade aluminium enclosureUL 1638 & CAN/ULC S526 signaling device for Fire Alarm Appro valsUL/cUL/ULC – File ref: E245313IECEx Certificate: IECEx ULD 19.0006XATEX Certificate: DEMKO 19 ATEX 2009XUKCA certificate: UL21UKEX2130XCCCEx certificate: 2022122309114969TR CU Ex EAC certificate: EAC RU C-GB.AA.71.B.00273/20PESO CCOE certified: P493433-1CSFM listing: 7300-2279:0508SIL1 & SIL2 compliant to IEC61508 (2010)Co dingNEC Class / ZoneClass I Zone 1 AEx db IIC T3 Ta -55°C to +80°C (AC: +65°C)Class I Zone 1 AEx db IIC T4 Ta -55°C to +65°CZone 21 AEx tb IIIC T132°C Ta -55°C to +80°C (AC: T153°C +70°C) CEC Class / ZoneEx db IIC T3 Ta -55°C to +80°C (AC: +70°C)Ex db IIC T4 Ta -55°C to +65°CEx tb IIIC T132°C Ta -55°C to +80°C (AC: T153°C +70°C)NEC / CEC Class / DivClass I Div 1 Group ABCD T3C Ta -55°C to +80°C (DC only)Class I Div 1 Group ABCD T4 Ta -55°C to +55°C (AC: T4A +55°C) Class II Div 1 Group EFG T4 Ta -55°C to +80°C (AC: +40°C)Class III Div 1 Ta -55°C to +80°C (AC: +40°C)IECEx / ATEXII 2G Ex db IIC T3 Gb Ta -55°C to +80°C (AC: +65°C)II 2G Ex db IIC T4 Gb Ta -55°C to +45°CII 2D Ex tb IIIC T146°C Db Ta -55°C to +80°C (AC: T139°C +70°C)Specificatio nSource:Xenon StrobeEnergy:15 Joules (15Ws)Flash rates:1Hz flash (60 fpm)1.3Hz flash (80 fpm)1.5Hz flash (90 fpm)Double flash (120 fpm)Eff. Intensity cd:98.61cd UL1638 Private mode fireEff. Intensity cd:731.71cd measured ref to I.E.SEff. Intensity cd:750 cd – calculated from energy (J)Peak Candela:1,500,000 cd – calculated from energy (J)Lens colours:Amber, Blue, Clear, Green, Magenta, Red & Yellow Voltage DC:24V dc (20-28Vdc), 48Vdc (42-54Vdc)Voltage AC:115Vac (110-120Vac), 230Vac (220-240Vac)In-rush:753mA within 6ms @ 24Vdc, 1958mA within 4.3ms @ 48VdcSafety Integrity Level:Product version A: SIL1 and SIL2 Route 2HProduct version S: SIL2 Route 1H with diagnostics SFF: >99% See install manual for reliability & functional safety dataIngress protection:IP rating per EN60529:IP66/67Type rating per UL50E/NEMA250:4/4X/3R/13Lens material:High impact Borosilicate glassEnclosurematerial:Marine grade LM6 aluminium alloyEnclosure colour:Red or Grey, custom colours available on request Enclosure finish:Chromate & powder coated finishCable entries:Side: 2 × 3/4"NPT & 2 x M20x1.5mmPendant: 1 × 3/4"NPTStopping plugs includedStopping plugs:Brass, Nickel Plated or Stainless SteelTerminals:0.5 – 2.5mm² (20-14AWG) – 12AWG solid core conductorDuplicated terminalsLine monitoring:Blocking diode includedEOL Min. 500 Ohm 2W, or 3k3 Ohm 0.5W resistoror diode (DC versions) can be fittedGround/Earthstud:M5Enclosure volume:<2 litresInstallation temp:-55 to +80°C [-67° to +176°F]Storage temp:-55 to +80°C [-67° to +176°F]Relative humidity:95% – Additional tropicalisation is recommended forapplications where both high relative humidity and highambient temperatures existMTBF DC:198.88 years / 1,742,161 hours – MIL 217MTBF AC:253.68 years / 2,222,223 hours – MIL 217Weight: 3.2kg/7.1Ibs*All candela data is representative of performance with clear lens at optimum voltage.Part Co desPar t Cod e:Id en ti fi er:Descr i p ti on:Product type:D1xB2Type:X15Xenon Strobe Beacon 15 JouleVoltage:DC024DC048AC115AC23024Vdc (20-28Vdc)48Vdc (42-54Vdc)115Vac (110-120Vac)230Vac (220-240Vac)Cable entries: [e]MBE2 × 3/4"NPT, 2 x M20, 1 × 3/4"NPT2 × 1/2"NPT – adaptors, 2 × 3/4"NPT, 1 ×3/4"NPT1 × 1/2"NPT – adaptors, 1 x M20,2 × 3/4"NPT,1 × 3/4"NPTStopping plug/adaptor material:[m]BNSBrassNickel plated brassStainless steelGuard material:[s]13A4 316 Stainless SteelA4 316 St/St with Equip. TagProduct version:[v]ASUL, cUL, ULC, IECEx, ATEXCCCEx, Ex EAC, PESO, CSFM – SIL1 & SIL2 Route2HUL, cUL, ULC, IECEx, ATEX,CCCEx, Ex EAC, PESO, CSFM (24Vdc only) – SIL2Route 1H with diagnostics SFF: >99% Product option:[o]1TXStandard productTropicalisationCustom configuration – contact E2S Enclosure colour:[x]RGSRedGreySpecial colour – contact E2SLens colour: [y]ABCGMRYAmberBlueClearGreenMagentaRedYellowA ccessor i es:SP77-0001-A4-RSP77-0001-A4-GSP65-0001-A4SP65-0003-A4Multi angle bracket A4 (316) for Red enclosureMulti angle bracket A4 (316) for Grey enclosurePole Mount Bracket Kit 2" St/St A4 (316)Sunshade – St/St A4 (316)Sp ar es:SP77-0002SP77-0015-RSP77-0015-GXenon flash tube assemblyPack of 2 x Mounting Lugs – Red enclosurePack of 2 x Mounting Lugs – Grey enclosureCurrent Co nsumptio nNom i n al Vol tage:Vol tager an ge:Nom i n alcu r r en t:M ax.cu r r en t:In-r u sh:24Vdc20-28Vdc853mA920mA753mA <6ms48Vdc42-54Vdc330mA360mA1958mA <4.3ms115Vac110-120Vac 50/60Hz310mA420mA-230Vac220-240Vac 50/60Hz170mA230mA-AssembliesThe D1xB2X15 is available as a plated assembly configured with a D1x type alarm horn sounder and additionalD1x type Xenon strobe or LED beacons with or without a D1xJ2 Ex d junction box. Contact E2S for further information.E2S Warning S ignals s ales@ No liability is accepted for any consequence of the use of this document. The technical specification of this unit is subject to chang e without notice due to our policy of continual product development. All dimensions are approximate. This unit is sold subject to our standard conditions of sale, a copy of which is available on request.9 Ju l 2023。

The SPARTAN series of explosion protected luminaires are specialist devices, certified for use in specific operating environments.The units must be installed in accordance with these instructions, must be correctly certified for the specific operating environment and must be installed by suitably qualified personnel.If you have any queries about the installation or the certification of the unit – please contact Raytec for immediate assistance and advice.Important information0920-D -00042-R e v DSPARTANLinear Range - Installation GuideSPX/SPZCML14ATEX3119 & IEC Ex CML 15.0001 & CML21UKEX3105 CML15ATEX4138 & IEC Ex CML15.0068 & CML21UKEX4104 CML16ATEX1130 & IEC Ex CML16.0052 & CML21UKEX1100This installation guide provides instructions for installing SPARTAN series of explosion protected linear luminaires.Text in italics is specific for emergency variants.Overview1Safety Instructions 2 Installation 3 Maintenance 4 T echnical Specification 5Declaration of ConformityUK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 99901. Safety instructions1. Read this leaflet carefully before commencing to install the SPARTAN unit and retain it for future use. Installation can only be carried out by suitably qualified personnel.2. Check the certification to ensure that the hazardous zone, mains supply, ambient temperature present and ‘T’ rating are is suitable for the environment the unit is being installed in.3. If the SPARTAN unit is to be installed in areas of high vibration, please consult with Raytec.4.Externally the SPARTAN unit housing is constructed from marine grade aluminium and polycarbonate outer optic, stainless steel brackets/fasteners and silicone gaskets, internally there are many non metallic components. The end user must ensure that these materials are suitable for the environment the SPARTAN unit will be installed in; Zone 1 or Zone 2 Hazardous areasPlastic components may be cleaned with water containing a small amount of detergent, followed by a clean water wash. Chemicals/ oils that come into contact with plastic parts may cause stress cracking and premature component failure.5.SPARTAN units are designed to withstand marine environments and are tested in accordance with IEC60068-2-52. However if the SPARTAN unit is to be installed in a very high corrosive environment such as coastal and offshore the following good practice should be followed:During installing ensure there are no scratches, chips or defects in external paint surface that would allow ingress of water to bare aluminium. If so touch up with suitable paintDuring installation apply an anti corrosive jointing compound to screw threads such as PSU cover and external earth points.During installation ensure exterior surface of the product is not in direct contact with a dissimilar metal such as galvanised steel. If so fit a nylon barrier to prevent galvanic corrosion.During maintenance regularly wash down external surface of fitting with clean, fresh water to remove any deposits of mineral salts on the exterior surface.5.Check certification nameplate on cover of luminaire to ascertain type of threaded cable entry on the luminaire. Select suitably certified ATEX/IEC Ex/ UKEX cable glands and stopper plugs, these must be parallel thread, have a minimum of 5 full thread engagement and be of a medium/fine tolerance to ISO965-1 and ISO965-3. The cable entry devices selected must maintain the IP rating of the luminaire7.The incoming mains cable should not exceed a temperature rise of 27C above the ambient conditions; select suitable cable.8. When the unit is installed correctly and in accordance with these installation instructions it will not harm humansor animals.9. Before installing emergency luminaires please check the last charge date of the battery. This is shown on theexternal product packaging and also on the battery label, alternatively consult date shown on the declaration at the back of this leaflet. If the last charge date was in excess of 3 months (if stored at 5°C to 25°C) or 1 month (if stored outside this range) from date of installation, please consult Raytec document 0010-D-00001 Battery3UK / Europe T el: +44 (0) 1670 520055Americas Tel: +1 613 270 99902. InstallationMounting SPARTAN Unit1. T o meet the requirements of certification a MINIMUM of 2 fixing points must be used,the fixing points must be suitable for the conditions of use.2. The rear of the unit has 3 blind sets of M8/M6 fixing points, a full range of mountingaccessories are available including a range of pole clamps, ceiling mount brackets, various wall mount brackets, outreach bracket and chain mount eyelets. Please consult for further details. The spigot mount version of the product is provided with a pole mount system and 2xM6 A4 SS Grub Screws for mounting onto 32-43mm diameter poles. Once mounted tighten grub screws to 15Nm.3. When installing the SPARTAN luminaire vertically where possible, the cable glandsshould be kept to the bottom of the luminaire.1370 FOR WL168 EMER400 FOR WL84700 FOR WL168/WL168-15004UK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 9990Wire the Mains cable into the terminal block. Provision has been made for this and identified as the E (Earth), L1 (Live switched), L2 (Live permanent) and N (Neutral) terminals. There are two pairs of contacts for each of these to facilitate a mains cable that can be looped in and out of the unit, an identical terminal block is also available at the other end of the luminaire to allow the unit to be through wired. The L2 terminals on a standard unit is not electrically connected but allows them to be used on the same circuits as emergency luminaires.Typical wiring diagram - WL168-HOTypical wiring diagram - Emergency Variants5 UK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 9990OperationThe light fitting will carry out the following function automatically after installation:• Commissioning Cycle • Function test •Self-testA tri-colour LED indicator displays the light fitting status. The indication colours are shown in table 1.a. Commissioning Cycle • Starts automatically after 24 hours of uninterrupted charging. If there is a mains failure in this time the count resets for another 24 hours.• 3 charge/discharge cycles to optimise battery’s full capacity.• Battery is charged for 24 hours before each discharge cycle.•No need for manual commissioningSpartan Intelligent Emergency Operation Guide4.Installer should earth the unit separately – an internal and external earth point are provided as standard at each end of the luminaire 5. Connect wires to mains supply.6. If the unit is opened for any reason, disconnect mains – On emergency luminairesthere may be more than one mains supply7. All SPARTAN luminaires have terminal blocks suitable for looping 4mm2 cable, onlyone cable should be connected to each terminal block connection8. The battery fuse is located in the compartment that contains the battery, the fuse isdisconnected after final manufacturing testing. When installing the linear the battery fuse will need to be reconnected and the unit charged for 24 hours and then discharged (repeated 3 times) to bring the battery up to peak capacity. (Unless an ‘EMX’ intelligent emergency variant – see notes below)9. If a 4 core cable is used on emergency luminaires – L1, L2, N and E the link cable at thefront of the terminal block between L1 and L2 should be removed10. During emergency operation the light output and duration will be determined by thevariant purchased11. Once wiring is complete replace terminal enclosure covers. Ensure gasket is located neatlyin channel and no wires are trapped between cover and body. Tighten screws to 3Nm12. If carrying out Insulation Resistance tests the normal method of insulation testing is toconnect Live and Neutral together and test between this point and Earth to prevent the risk of damage to the electronic control gear.6UK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 9990Notes• The luminaire will switch off momentarily (<0.5sec) during the transition between a test and normal operation.•If a test was interrupted by a mains failure, the test will be halted, and the unit will enter emergency mode. Once the mains supply is back, the unit will allow 24 hours to recharge the battery before continuing the tests.• The self-test is carried out at a random time to eliminate the possibility of having more than one unit undergoing the test at the same time.b. Function T est • Carried out every 7 days.• Checks the function of the battery, lamp and power supply.•Lasts for few minutes only.c. Self-test • Carried out at a random time every 3 months.• Checks the battery’s capacity and lamp’s condition.• Performs self-recovery for the battery if not at peak capacity.• Is carried out at 100% load•Discharges only 2/3 of the battery’s capacity.LED indication7UK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 99903. Maintenance1.It is essential that all SPARTAN units are maintained in accordance with the requirements of the EN60079-17 standard: (Electrical apparatus for explosive gas atmospheres – other than mines).2.IMPORTANT . No modifications are permitted to the unit, all spare parts must be purchased from the manufacturer, unauthorized modifications or spare parts will invalidate certification and make the equipment dangerous.3.Isolate the SPARTAN unit from the mains supply and allow to cool before carrying out any maintenance work.• For Emergency variants, battery must be isolated/ connected when a hazardous environment is NOT present prior to carrying out any maintenance work.4.In the unlikely event of a number of LED’s failing, the light engine assembly must be replaced. This is achieved by removing the outer polycarbonate cover and then releasing the M3 bolts that hold the LED assembly in place, disconnect the white and red/white cable to the power supply and pull the light engine PCB clear. Re fitting a light engine is a reversal of the above procedure.•For emergency variants, battery must be isolated/ connected when a hazardous environment is NOT present prior to carrying out any maintenance work.5.The unit has either 1 or 2 independent power supplies located in the terminal chamber covers, in the event that a power supply needs to be replaced the terminal chamber cover should be removed, the cables disconnected and the dog clip can then be detached from the cover. Fitting a new power supply is a reversal of the above procedure.6.Disposal of packaging, SPARTAN unit and old LED assemblies/power supplies should be carried out in accordance with national regulations.Protection ConceptsCML14ATEX3119 or IEC Ex CML15.0001 or CML21UKEX3105 CML15ATEX4138 or IEC Ex CML15.0068 or CML21UKEX4104CML16ATEX1130 or IEC Ex CML16.0052 or CML21UKEX1100Standard variantsII 2 GD Ex eb mb IIC T4 Gb Ex tb IIIC T80°C Db -40°C to +60°CStandard variantsII 3 GD Ex ec mc IIC T4 Gc Ex tc IIIC T80°C Dc -40°C to +60°CStandard variantsII 2 D Ex tb IIIC T80°C Db -40°C to +60°CEmergency variantsII 2 GD Ex eb mb IIC T4 Gb Ex tb IIIC T76°C Db -20°C to +50°CEmergency variantsII 3 GD Ex ec mc IIC T4 Gc Ex tc IIIC T75°C Dc -20°C to +50°CEmergency variantsII 2 D Ex tb IIIC T76°C Db -20°C to +50°CUK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 99904. Technical SpecificationInrush Current Typical Curve9 UK / Europe T el: +44 (0) 1670 520055Americas Tel: +1 613 270 9990UK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 9990ManufacturerRaytec LtdUnit 15, Wansbeck Business Park Rotary Parkway AshingtonNorthumberland NE63 8QWUnited KingdomDescription of EquipmentSpartan range of linear luminaires – standard and emergencyCertification BodyCMLNew Port Road Ellesmere Port CH65 4LZCertificate numbersCML14ATEX3119 & IECExCML15.0001 & CML21UKEX3105 CML15ATEX4138 & IEC Ex CML15.0068 & CML21UKEX4104 CML16ATEX1130 & IEC Ex CML16.0052 & CML21UKEX1100ATEX Quality Assurance Notification CSA BV (2813)UKCA Quality Assurance Notification CSA UK (0518)Declaration Of ConformityWith The Atex Directive 2014/34/EU& UK Directive SI 2016 No. 1107 (as amended)Raytec Ltd. declares under our sole responsibility that the product(s) listed below conform with the relevant provisions of directive 2014/34/EU of 20th April 2016 and UK Directive SI 2016 No. 1107 (as amended)CML14ATEX3119 or IEC Ex CML15.0001 or CML21UKEX3105 CML15ATEX4138 or IEC Ex CML15.0068 or CML21UKEX4104Standard variantsII 2 GD Ex eb mb IIC T4 Gb Ex tb IIIC T80°C Db -40°C to +60°CStandard variantsII 3 GD Ex ec mc IIC T4 Gc Ex tc IIIC T80°C Dc -40°C to +60°C Emergency variantsII 2 GD Ex eb mb IIC T4 Gb Ex tb IIIC T76°C Db -20°C to +50°CEmergency variantsII 3 GD Ex ec mc IIC T4 Gc Ex tc IIIC T75°C Dc -20°C to +50°C UK / Europe T el: +44 (0) 1670 520055Americas T el: +1 613 270 9990Compliance with the Essential Health and Safety Requirements has been assessed by reference to the following standards -EN 60079-0 : 2018 EN 60079-31 : 2014EN 60079-7: 2015+A1:2018 EN 60079-18:2015+A1:2017And also 2014/35/EU – Low Voltage Directive, 2014/30/EU – EMC DirectiveSignedName Barry ThompsonPosition DirectorDatedSerial numberCML16ATEX1130 or IEC Ex CML16.0052 or CML21UKEX1100Standard variants II 2 D Ex tb IIIC T80°C Db -40°C to +60°C Emergency variants II 2 D Ex tb IIIC T76°C Db -20°C to +50°CIP66 & IP67110V-254V AC or 18-48V AC/18-69V DCRaytec Global (excluding Americas)Tel: +44 (0) 1670 520055*******************Raytec Ltd.Unit 15 Wansbeck Business Park, Rotary Parkway Ashington, Northumberland, NE63 8QW, United Kingdom Raytec AmericasTel: +1 613 270 9990*********************Raytec Systems Inc.800-300 Terry Fox Drive, Ottawa, Ontario 2K 0E3, Canada。

led防爆说明书一、产品概述本产品是一种LED防爆灯,具有防爆、防火、节能环保等特点。

适用于石油、化工、制药等易燃易爆场所的照明需求。

本说明书旨在向用户提供正确的使用方法和注意事项,确保用户在使用过程中的安全性。

二、安全操作指南1. 产品安装(1) 在安装过程中,请确保断电,避免电击事故发生。

(2) 确保安装位置稳固,以防产品摇晃或倾斜。

(3) 请根据产品安装图纸正确安装灯具,确保电线无短路现象。

(4) 安装前,请检查产品及配件是否完好,若有损坏请及时更换。

2. 电气连接(1) 在电气连接之前,务必要切断电源,以免触电。

(2) 根据产品连接图正确进行接线,确保接线牢靠,并用绝缘胶带包好。

(3) 如需更换电源线,请选择符合国家标准的电线并由专业人员进行更换。

3. 使用注意(1) 产品仅适用于室内使用,禁止在水中或潮湿场所使用。

(2) 避免阳光直射,防止灯具过热,影响寿命。

(3) 非专业人员请勿拆卸产品,如需维修,请联系专业售后服务。

(4) 如发现产品出现漏电、异味或其他异常情况,请立即停止使用并联系售后服务。

4. 维护保养(1) 定期清洁产品及透明罩,保持灯具的光效。

(2) 检查产品外壳是否存在损坏,如有请及时更换。

(3) 不得使用尖锐物品敲击或碰撞产品,以避免产品损坏。

三、技术参数1. 防爆等级:Exd II CT62. 防护等级:IP653. 电源电压:AC100-240V4. 色温范围:5000-6000K5. 光通量:1000lm6. 使用寿命:50000小时四、故障排除故障现象:产品无法正常亮起。

故障排除方法:请检查电源连接是否正确,确保连接牢固无松动。

如仍无法解决故障,请联系售后服务。

故障现象:产品亮度降低。

故障排除方法:可能是灯珠老化,建议更换LED灯珠。

若更换后仍有问题,请联系售后服务。

故障现象:产品发出异味。

故障排除方法:请立即停止使用,并联系售后服务。

五、注意事项1. 本产品仅供专业人员安装和维修,非专业人员请勿私自拆卸。

矿用隔爆型照明灯说明书1 产品概述矿用隔爆型照明灯(以下简称灯具),是煤矿井下巷道、硐室等有甲烷场所使用的灯具,严禁使用于采掘工作面。

主要特点是:具有隔爆型防爆型式,能在煤矿井下易燃易爆场所安全工作;采用高强度气体放电灯作光源,光效高、寿命长;外壳采用特殊轻质合金材料,强度高,抗冲击性能好;优良的结构设计和最新的表面处理工艺,防水、防尘,确保灯具在各种恶劣的环境中可靠工作;重量轻、体积小、安装简单方便,可采用座式、壁挂式、吊顶式等多种安装方式。

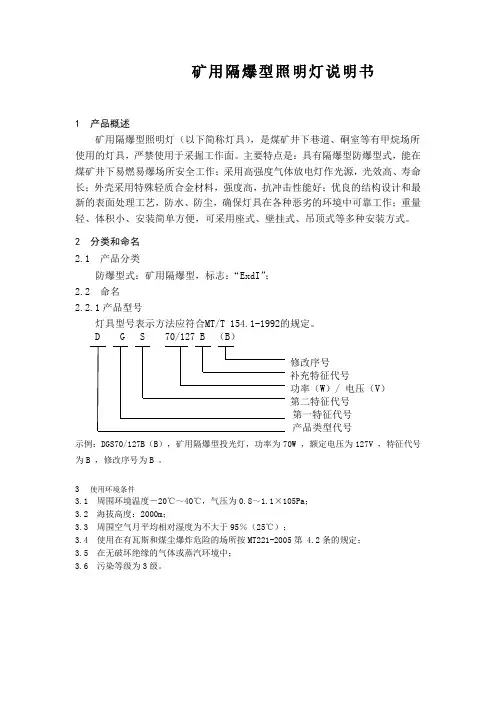

2 分类和命名2.1 产品分类防爆型式:矿用隔爆型,标志:“ExdI”;2.2命名2.2.1产品型号灯具型号表示方法应符合MT/T 154.1-1992的规定。

D G S 70/127 B (B)修改序号补充特征代号功率(W)/ 电压(V)第二特征代号第一特征代号产品类型代号示例:DGS70/127B(B),矿用隔爆型投光灯,功率为70W ,额定电压为127V ,特征代号为B ,修改序号为B 。

3使用环境条件3.1 周围环境温度-20℃~40℃,气压为0.8~1.1×105Pa;3.2 海拔高度:2000m;3.3 周围空气月平均相对湿度为不大于95%(25℃);3.4 使用在有瓦斯和煤尘爆炸危险的场所按MT221-2005第4.2条的规定;3.5 在无破坏绝缘的气体或蒸汽环境中;3.6 污染等级为3级。

4 基本性能参数见表.4.5 结构特征和工作原理5.1 灯具的外壳为隔爆型外壳,能在煤矿易燃易爆场所安全工作;5.2 采用高效气体放电作为光源,光效高、寿命长;5.3 外壳采用特殊轻质合金材料(ADC12),强度高、抗冲击性能好;5.4 优良的结构设计和最新的表面处理工艺,防水、防尘,确保灯具在各种恶劣的环境中可靠工作;5.5 重量轻、体积小、安装简单方便,可采用座式、壁挂式、吊顶式等多种安装方式。

6 安装与调试6.1 首先根据工作现场的实际情况,确定灯具的安装位置和方式,再根据灯具到电源接点的距离,准备相应长度的φ8~φ10mm的三芯电缆线。

LED 投光灯说明书LED投光灯是本公司新开发的一种新型集光照明灯具,该灯采用铝合金压铸底壳,进口材料面罩,超高亮度LED光源,具有外观时尚,坚固可靠,防水防尘,亮度高,光线柔和,节能环保等特点。

灯具特点:灯具特点1、单色性好,光线柔和,发光效率高。

2、冷光源、无热幅射、无有害金属汞、绿色环保。

3、功率低、耗电小、寿命长、稳定性好、可靠性高。

4、消耗能量较同光效的白炽灯减少80%。

5、工作温度可达-30℃~40℃,低温启动正常,响应速度快。

6、灯体采用金属制成,抗冲击性好,面罩采用PC材料,光线均匀柔和,坚固耐用。

7、灯体设计新颖别致,典雅美观,具有现代照明灯具特点,安装简单,调节方便。

技术参数:技术参数光源组成:超高亮白色大功率LED输入电压:AC85~264V频率范围:47~63HZ额定亮度:>0.9发光亮度:≥53Lux(6m),≥30Lux(8m),≥18Lux(10m),≥13Lux(12m)安装高度:6~12米使用寿命:≥30.000小时工作温度:-30℃~40℃灯体与灯罩材质:铝合金和pc材料防护等级:IP65净重:2.5Kg使用说明:使用说明根据灯具的安装位置,预先埋好灯杆,将灯具安装到灯杆上,接好电源线即可。

造用场所:造用场所造合花园,小区,园林,道路等场所的照明。

大功率LED投光灯系列产品简介大功率LED投光灯系列产品主要规格有30W、50W、70W、100W、140W等,还可根据用户要求开发特殊规格的产品,该灯具还可用作高速公路隧道照明灯、广告牌射灯、厂矿照明灯、庭院灯和路灯。

该产品的主要特点有:发光强度高,,照射距离远1、发光强度高目前LED的发光效率已经达到120Lm/W,已远远超过高压钠灯(80 Lm/W)、日光灯(60 Lm/W)和其他光源,而且LED发光角度为160º~180º,所有光能量可以全部投射到被照物表面,其他光源的发光角度均为360º,所以通常只有一半光能量投射到被照物表面,因此在同样光效的情况下,LED灯的发光强度(单位角度内的光通量)比其他灯具要高一倍,因此LED灯的发光强度(即通常人们感知的灯光亮度)比其他光源高得多。

PAK-L83-250L-AD-LN户外投光灯(防爆) 销售电话133384443272 PAK-L83-250L-AD-LN户外投光灯(防爆)适用场所:本公司结合部队、铁路、电力、公安、工矿等企事业单位际,研制开发生产的新一代大功率泛光工作灯,广泛应用于夜间作业、维护抢修、抢险救灾等现场移动照明需要。

结构特性:逆变功能:在停电或无市电的工作现场,可为家用电器、电动工具、拍摄仪器和办公设备提供功率为500W的交流200V或110V应急工作电源(客户可根据实际需求选配此项功能)。

防水性能:全密封性工艺设计,可置于水中正常工作,特制合金外壳确保产品能经受强力碰撞和冲击。

高效性能:选用特殊气体放电光源,发光效率高,光通量为3200Lm,是同功率卤素灯泡的5倍,照度是100W卤素灯泡的3倍,灯泡寿命长10000小时;是普通卤素灯泡的5-10倍;在相同亮度指示下,所消耗的电量是普通卤素灯泡的50%,并有低压过放电保护,可靠的保护电池,延长电池使用寿命。

4、使用方便:独特的灯头结构设计,照明角度可任意调节。

如选购气压三脚支架,还能在1.2-3米高度范围内任意升降。

灯箱装有轮子方便移动,工作时简单、轻松。

技术参数:A(HID光源)额定电压:24V额定容量:20Ah特制灯泡工作电压:24V额定功率:35W光通量:3200lm使用寿命:10000h放电时间:>11h充电时间:正常使用:12h电池耗尽:≥16h电池寿命:约1000次循环外形尺寸:270x228x600mm三角支架:3000mm重量:15Kg外壳防护等级:IP65PAK-L83-250L-AD-LN户外投光灯(防爆) 销售电话133384443272。

BCS系列防爆手电筒适用范围◆适用于1区、2区危险场地。

◆适用于ⅡA、ⅡB、ⅡC类,温度组别为T1-T5的爆炸性气体环境。

技术参数■ 执行标准:GB3836.1-2000、GB3836.2-2000、GB3836.3-2000、GB3836.4-2000、IEC60079■ 防爆标志: Exeib ⅡCT6■ 防护等级:IP65■ 防腐等级:WF2产品特点■ 壳体采用铝合金压铸成型,表面高压静电喷塑;■ 高效的反光碗;■ 透光率好,抗冲击能力强;■ 具有调焦装置,可以进行散光和聚光调节;■ 内置式开关,有良好的防水防尘性能;■ 维修时需采用专用工具,以保护安全;■ 具有独特设计的弯筒式结构,并配有卡扣,便于携带,结构紧凑,外形美观。

BXD6016/JW7300/CBW6100微型防爆电筒一、概况本公司顺应市场对微型照明灯具的要求,采用最新型光源技术,开发生产出微型防爆电筒。

本产品可适用于警察,部队和工矿企业及各种野外工作现场做移动照明和信号指示。

二、性能特点1、安全性能:本产品经国家权威机构防爆认证,具有本安型防爆等级及优良的防静电效果。

2、工作性能:光源采用特制超高亮度白色LED,可视距离达5000米;具有照明、点动频闪和远距离信号指示功能,连续照明时间10小时,而充电时间仅要4.5小时。

3、配置科学:高能无记忆电池容量大,寿命长,自放电率低,经济环保;LED光源耗材能少,寿命长,使用寿命可达10万小时。

4、适用性强:精选用进口高硬度合金材料做外壳,确保产品抗强力冲击和碰撞;防水及耐高低温、高湿性能好,可在各种恶劣环境和气候条件下使用。

5、智能保护:电筒内配置有过放、过充及短路保护电路,可靠的保护电池,延长电筒使用寿命;智能型充电吕设有过充、短路保护及充电显示装置。

6、灵活方便:本产品结构精巧,轻盈美观,体积小,重量轻。

外壳尺寸Φ25x120mm,重量仅0.128Kg,可挎在腰间或放在口袋中,携带十分方便。

使用说明1产品使用工作电压:AC100V~240V 50/60Hz。

勿超出工作电压。

2.储存环境温度-60℃~+50℃,工作温度:-30℃~+50℃,最佳工作环境温度-0℃~+30℃3.由于灯具有玻璃配件,在搬运,储存的时候请注意轻拿轻放,勿重压。

安装说明1.通过产品安装支架上的安装孔位可直接用螺丝固定与安装杆或者安装面上。

2.固定好产品后,可将调节角度螺丝调松,然后转换支架的角度,也就是相当于调节灯具的安装角度。

3.安装灯具时,接线与接线处封闭好,防漏电,外接电源时,必须采取相应的防水措施。

4.该灯具使用时不能违反任何防火法规,不能覆盖灯具表面。

5.安装请找专业的安装人员。

6.要定期对灯具表面进行清洁,清洁前请确定已经断电,清洁时不能用水或者腐蚀性强的溶剂进行清洁,最好用干抹布。

LED Flood light installation instructionsInstructions for use:1. Using working voltage:AC100V~240V 50/60Hz,do not exceed the operating voltage range.2.Storage environment temperature:-60 ℃ ~+50 ℃, the working temperature: -30 ℃ ~+50 ℃, the optimum temperature of working environment: -0 ℃~+30 ℃.3. As a result of the light with glass lamp fittings, when carry, please pay attention to handling gently, don't stressThe installation diagram1. Through the mounting hole on the mounting bracket to be directly fixed withscrews and the installation rod or mounting surface.2. After products fixed, to loose adjustable screw, then transform the bracket angle, which is to adjust the installation angle of the lamp.3. Installation of lamps, wiring and wiring goods sealing good to prevent leakage. Using external power must be take measures for waterproof.4. The lamp be used can’t violate for any of fire regulation, can’t cover the surface of the product.5. Please find professional installer to installation.6. Please regular cleaning of the lamp body surface, and please be sure the power is cut off before cleaning. Do not use water or strong corrosion of solvent to cleaning, preferably with a dry cloth.7.。

救生圈自亮浮灯(本安型)使用说明书一、概述FBQD2救生圈自亮浮灯是一种本质安全型救生圈灯,可用于危险场所zone 0、zone 1、zone 2,适用于海上石油钻井平台,石油、液化气等易燃易爆品运输船配备,安装方便,使用安全可靠。

本产品符合GB3836.1-2000爆炸性气体环境用电气设备第1部份:通用要求;GB3836.4-2000 爆炸性气体环境用电气设备第4部份:本质安全型“i”;和1974年SOLAS公约1996修正案、MSC.81(70)相关要求。

二、结构特点1.灯具壳体采用密闭结构,由改性PC注塑而成,灯罩采用透明PC材料,耐腐蚀,耐冲击,坚固耐用,坠落或与其它物体相碰时不会产生火花,安全可靠。

2.光源采用特制白光发光二极管,控制电路采用恒流升压芯片,光效高,性能稳定可靠;电源通断由干簧管和磁性材料组成的开关结构控制,圈灯倒置时为关闭状态,圈灯处于正立位置即发出闪光信号。

三、主要参数1. 电源:2节1#碱性电池(可用电池:劲量Energizer:E95;金霸王Duracell:MN1300)2.光源:1W白光发光二极管3.适应环境温度:-30℃~65℃4.工作温度:-1℃~30℃5.工作时间:≥ 2 hours6.发光强度:≥ 2 cd7.发光型式:闪光8.防爆等级:Ex iaⅡC T49.防爆证号:GYB09130110.有效期:CCS为3年11.外形尺寸:Ф100×295四、使用及注意事项1.特别警告:已装电池的圈灯应确保处于倒置状态,更换电池必须在安全场所进行。

2.安装电池:旋开灯罩,取出电池架组件,装上新电池(只能使用2节劲量或金霸王电池,电池不可混用,极性见电池架内图示),装入电池架组件,检查一下密封圈及外涂硅脂是否完好,否则换备用密封圈,旋紧灯罩确保水密,检查一下圈灯正立位置是否正常点亮。

3.圈灯安装:用2只M5×12螺钉将圈灯固定架安装到合适位置,固定架的安装应确保圈灯处于倒置状态,可随救生圈顺利释放,建议安装高度不要超过水面30米。

![10W投光灯使用说明书[1]](https://uimg.taocdn.com/7bfcf219fad6195f312ba615.webp)

10W投光灯使用说明书

一.用途

格天照明LED投光灯是采用高效能的电子恒流源的半导体照明灯具,是一种新型节能、环保、长寿命照明光源。

主要用于大面积作业场矿、建筑物轮廓、体育场、立交桥、纪念碑、公园和花坛等。

二.特点

电子恒流源半导休照明灯具有高光效,寿命长,开启响应快,省电,显色指数高,无频闪,可适应全球电网电压的实际情况,在相同的照明效果时的用电量比荧光灯省电70%以上,是节能和绿色工程的理想的绿色灯具。

三.外形尺寸

四.主要性能参数

五.安装方法

1.如图2所示,用螺丝把固位脚固定在所需安装的位置。

2.按图3所示把控制开关安装在所需开启灯具的位置。

3.如图3所示,把灯具的输入线红线接到控制开关的“输出”接线端,控制开关的“输入”接线端连到电网的L线,灯具输入蓝线接到电网N线,黄绿线接到电网接地线。

图2

控制开关

图3

五、使用注意事项

1、安装及更换灯具时,必须切断电源,保证安全。

2、灯具的使用环境温度为-30°~55°,在通风条件好的环境中使用,不宜在密封的地方使用。

3、如发现灯具异常(不亮,闪烁,很暗)应请专业人员先检查灯具的接线是否良好,或反馈我司售后服务电话

4、灯具禁止在腐蚀强度高的环境使用。

5、高空安置的灯具应将紧固件锁紧,确保紧固,防止发生安全事故。

led防爆说明书LED防爆说明书第一章:前言1.1 概述随着科技的进步和社会的发展,LED(Light Emitting Diode)发光二极管已经成为照明行业的主流产品。

LED灯具具有能耗低、寿命长、光效高等特点,受到广大用户的青睐。

然而,在一些特殊环境下,如油气、矿山、化工等行业,存在爆炸危险。

为了满足这些特殊环境的需求,LED防爆灯应运而生。

1.2 目的本说明书主要介绍LED防爆灯的特点、优势、使用方法、注意事项、安装注意事项等内容,旨在帮助用户正确、安全地使用LED防爆灯,避免事故发生。

第二章:LED防爆灯的特点和优势2.1 特点(1)防爆性能:LED防爆灯能够在易爆气体或粉尘环境中工作,并且能够防止火花或高温引起的爆炸。

(2)能耗低:LED防爆灯采用高效LED光源,能效高,相较于传统灯具能够达到更好的节能效果。

(3)寿命长:LED防爆灯的光源寿命长,能够达到几万小时,相较于传统灯具更为耐用。

(4)光效高:LED防爆灯的光效高,照明效果好,能够提供良好的照明体验。

(5)耐用性好:LED防爆灯采用高质量材料制作,具有良好的抗震、抗压、抗腐蚀性能,能够适应恶劣的环境。

2.2 优势(1)高安全性:LED防爆灯具有优越的防爆性能,能够确保在危险环境中的安全使用。

(2)高可靠性:LED防爆灯由优质材料制作,具有较长的使用寿命和良好的可靠性,能够满足用户的需求。

(3)节能环保:LED防爆灯使用LED光源,能耗低,相较于传统灯具更为节能环保。

(4)易维护:LED防爆灯的光源寿命长,不需要经常更换,维护成本低。

(5)适用范围广:LED防爆灯适用于石油、天然气、矿山、化工等行业,满足不同环境下的照明需求。

第三章:使用方法3.1 准备工作(1)仔细阅读本说明书,并了解LED防爆灯的特点、优势。

(2)根据使用环境选择适当的型号和规格的LED防爆灯。

(3)选择合适的安装位置,并确保其可以稳固地安装在悬挂装置或支架上。

防爆道路灯使用方法及注意事项1、根据工作现场的实际照明需要,确定灯具及镇流器的安装位置和方式,然后按灯具到镇流器接点的距离和镇流器到220V电源接点的距离备好相应长度的三芯电缆线(距离不超过2米可用随灯配备的电缆线)。

2、当灯具到镇流器接点的距离超过2米时,需要更换三芯电缆线。

即用内六角扳手旋下灯外壳六个内六角螺栓,将灯体部分拔出后,拆下灯具自带的三芯电缆线,然后按原来的接线方式接好所备的三芯电缆线。

3、用套筒扳手拧下镇流器箱盖上的紧固螺栓,取下箱盖,将灯具的三芯电缆线一端通过镇流器输出口的引入装置引进镇流器腔内,把红线、黑线(或蓝线)、黄绿线分别接到镇流器的4、5、6号接线端子上,然后把压紧螺母拧紧。

4、将准备好的三芯电源电缆线一端通过镇流器输入口的引入装置,引进镇流器腔内,然后将L线(火线)、N线(中线)、地线分别接到镇流器的1、2、3号位的接线端子上,并把压紧螺母旋紧。

5、合上镇流器箱盖并拧紧紧固螺栓,最后再把三芯电缆线另一端按防爆要求接通220V电源。

6、更换灯泡时,先切断电源,检查吊链是否挂好,然后用内六角扳手旋开灯外壳上的六个内六角螺栓,小心将灯体部分向下拉,使灯体与灯头壳分离,旋下旧灯泡换上新灯泡。

注意事项1、安装和维护灯具时,必须切断电源。

2、使用时,灯具表面有一定温升,属正常现象,透明件中心温度较高,不得触摸。

3、必须使用本公司配备的镇流器。

4、灯具启动电流为正常工作电流的2.5倍,250W灯具启动电流为2.8A。

5、灯头壳内装有减震泡沫,第一次安装使用时务必取出。

警告:1、严禁带电打开灯具。

2、安装灯具时务必将灯外壳接地,并使其牢固。

防爆道路灯使用方法及注意事项(2)防爆道路灯是一种能够在爆炸性环境中保持安全的照明设备。

它广泛应用于石油、化工、煤矿等易燃易爆场所,以确保工作人员的安全。

本文将介绍防爆道路灯的使用方法及注意事项。

一、防爆道路灯的使用方法:1. 场地评估:在安装防爆道路灯之前,首先需要对场地进行评估。

防爆 LED 线性灯具EXLUX 6002/4 系列使用说明书其他语种 DEENFRITESRUNLDKSEFIPTGRPLCZSKHUSLROBGLVLTEECHKRCN内容目录2防爆 LED 线性灯具EXLUX 6002/4 系列内容目录1总体信息...............................................................................................................31.1制造商..................................................................................................................31.2使用说明书信息....................................................................................................31.3其他文档...............................................................................................................31.4标准和规定的符合性.............................................................................................32符号说明...............................................................................................................42.1本使用说明书中的符号.........................................................................................42.2警告提示...............................................................................................................42.3设备上的符号.......................................................................................................53安全提示...............................................................................................................53.1使用说明书的存放................................................................................................53.2安全使用...............................................................................................................53.3设计用途...............................................................................................................63.4改造和改装...........................................................................................................64功能和设备设计....................................................................................................64.1功能......................................................................................................................64.2设备设计...............................................................................................................75技术数据...............................................................................................................96运输和仓储.........................................................................................................157安装与装配.........................................................................................................157.1尺寸信息/固定尺寸...........................................................................................157.2去除保护膜.........................................................................................................177.3安装/拆卸,使用位置........................................................................................187.4装配....................................................................................................................218调试....................................................................................................................289维护、保养、修理..............................................................................................289.1维护和保养.........................................................................................................299.2修理....................................................................................................................299.3退回....................................................................................................................3010清洁....................................................................................................................3011废弃物处置 (3012)配件和备件 (31)286437 / 6002603002102022-03-03·BA00·III·zh·04总体信息3防爆 LED 线性灯具EXLUX 6002/4 系列1总体信息1.1制造商1.2使用说明书信息原版使用说明书是英文版。

1 用途与适用范围1.1用途投光灯主要适用于爆炸性气体环境中1区或2区危险区域,为ⅡB类或ⅡC类T4组及以下爆炸危险场所,在交流50Hz、额定电压至220V的线路中,作钻井架、平台等室外场所的远距离照明之用。

1.2正常工作条件:投光灯,应在下列条件下能够可靠工作:a)安装地点的海拔不超过2000m;b)周围环境温度为-20℃~+40℃,且24小时内的平均值不超过+35℃;c)安装地点的最高温度为+40℃时,空气相对湿度不超过50%;在较低的温度下允许有较高的相对湿度;d)在Ⅱ类含有爆炸性气体环境场所;e)污染等级为3级;f)安装类别为Ⅱ类。

2 产品型号含义及基本参数2.1 产品型号含义:汞灯 Z:自镇汞灯 N:钠灯 L:金属卤灯2.2产品分类按形式分:a)ExdⅡBT4 b)ExdⅡCT4 3主要技术参数4包装包装箱内随同产品携带的技术文件有:a)检验合格证;b)使用说明书;5运输及贮存5.1操作柱在运输过程中,应有防雨雪侵袭的措施。

5.2操作柱应贮存在空气流通,空气相对湿度不大于90%温度不高于40℃,不低于-25℃的仓库中。

6定货须知6.1定货时请注明完整型号、名称及数量。

6.2设备如有故障请及时与厂方联系。

7外形尺寸************有限公司地址:****电话:**************传真:**************全国免费电话:************* ********ExBA T防爆投光灯防爆合格证号:********使用说明书使用前请认真阅读本说明书!********************。

LED免维护防爆投光灯的参数特点是怎样的?

LED免维护防爆投光灯适用于性气体环境1区、2区;IIA、IIB、IIC级性气体环境;温度组别为T1-T4的环境;适用于石油采炼、储存、化工、医药、军工及军事设施等性危险环境;用作厂区或道路照明;

三种规格产品可选:泛光(照明)灯、投光灯和马路灯

技术参数

防爆标志ExdIICT4

额定电压220V

外壳防护IP65

额定功率50W70W100W120W

防腐等级WF1

进线口螺纹G3/4

距高比0.4

外形尺寸9-14mm

光源LED

LED免维护防爆投光灯的特点

1.采用高亮度LED光源,配合高效率恒流驱动电源,比气体放电灯节电达百分之60;LED组件全部密封,防水防尘,无需内部清洁和维护;

电路基板热阻低,专门设计的模块电路,每单元故障不会影响其余组件的正常工作。

2.电源模块:

高效率恒流驱动电源配合智能型功率调整器;具有光通量补偿功能,减少光衰,保证LED光源的光效;具有过压保护、过电流保护及突波电流保护功能。

3.防爆灯外壳采用铝合金高压铸造成型,表面经抛丸后高压静电喷塑,有效提高了壳体的散热性能;针对每种灯具类型专门设计的配光元件,充分发挥灯具的使用性能

4.无紫外线辐射,能为长时间在室内工作的用户提供优质照明与健康保障;

电路基板紧贴铝合金壳体,可将点热源瞬间转换为面热源,散热面积成倍增加,利于热量迅速分散,提高散热效率;壳体有散热功能,借助空气流动带走热量。

5.光源与电源采用一体式结构,电源腔设有铰链,灯具安装更方便;

6.本系列灯具属于免维护产品,节能环保;

7.壁式安装旋转角度可调,电缆布线,吸顶式、嵌入式安装可采用电缆或钢管布线。

We appreciate your purchase!Please read the instruction manual before installation and keep it handy for future reference.High purity light cast aluminum heatsink, high brightness, Nichia SMD chip, with a Mean Well driver. Design of the PCB LED for medium and high height in industry: production, diaphanous warehouses with shelves at half height, workshops, gas stations, shopping centers, markets, highway tolls and similar applications..ProblemPossible causeSolutionsLEDs stop working The powerline is improperly connectedConnect the power cable The power plug is loose Firming plug the power in The LED driver malfunctions Replace with a new driverThe LED chip is damaged It can be repaired only by Venalsol. LEDs flash on and off The output of the driver is abnormalReplace with a new driverThe LED chip breaks downIt can be repaired only by Venalsol.Venalsol guarantees its products, within the general conditions of supply, provided it is a manufacturing or material defect for a period of five years from the date of purchase. The guarantee consists in the repair / replacement of the parts or assemblies that are considered defective. Therefore, it will not apply to items that show damage as a result of not following the instructions for use correctly, or when the installation has been carried out by non-specialized personnel. Likewise, the damages caused by improper use of the device and faults produced during transport are excluded.To make a warranty claim, you must notify your seller in writing, provide a purchase invoice and comply with the other warranty requirements. It will always be necessary to return the damaged product with its original identification plate of Venalsol Smart Light and its serial number. Transportation costs are excluded.1. The decision as to whether the product is defective will be taken by Venalsol, who will check the malfunction of theproduct. If Venalsol verifies that the product is defective, it will decide if it has to be repaired or replaced by a new one. Venalsol reserves the right to use new or repaired products in the process of repair or replacement of the product under warranty. The product that has been repaired or replaced will be guaranteed during the original warranty period remaining. The cost of personnel and the cost of the machinery necessary for the replacement is excluded. The total responsibility of Venalsol regarding the defective product will always be limited to the money paid by the buyer for that product originally.2. In case of request of a product in good condition, prior to the shipment of the defective product, in order to facilitatethe substitution work, Venalsol may accept to supply it and this will be billed. This invoice will be paid, if applicable, once the allegedly damaged product is received and verified. If the warranty requirements are not met, or the damaged material is not received, 60 days after the previous replacement, the invoice will be charged.The guarantee will not cover the following circumstances:1. Damages caused by force majeure such as wars, riots, sabotages, cyclones, earthquakes, floods, explosions, fires, etc.2. Damages caused by improper use during the delivery period, defects caused by its misuse, wrong treatment or destruction of the machinery.3. Disassembly, modification or improper maintenance of repaired products without the authorization of the supplier.4. Damage caused by the buyer or installer using low quality wiring or other components not compatible with the product.5. This warranty is not valid if the product is used for different purposes for which it is originally designed.Read the instructions carefully before you start using the product.50W - 100W - 150W - 200WVenalsol Smart Light S.L.C/ Garbí nº15. - Polígono Industrial Palma de Gandía - 46724 - Palma de Gandía Valencia (España) - Customer service: +34 962 808 219 *****************< PRODUCT DATA SHEETTodos los derechos reservados - Copyright © 2019Instructions Control by DALI9. If the wiring of the luminaire itself is damaged, it can only be replaced by VenalsolApplicable regulationsIt has passed the tests and verifications necessary to obtain the CE Marking. This product complies withthe application standards on Low Voltage (LVD) 2014/35 / EU: EN60598-1: 2015, EN60598-2-24: 2013,EN60598-2-1: 1989, EN62031: 2008, EN62471: 2008, EN62493: 2010 and Electromagnetic Compatibility(EMC) 2014/30 / EU: EN61000-3-2: 2014, EN61000-3-3: 2013, EN61547: 2009, EN55015: 2013.This symbol indicates that the product at the end of its useful life should be removed separately fromother waste, since it is identified as an appliance for electrical use or domestic appliance according toRoyal Decree 208/2005. Therefore, at the end of the use, you must take charge of delivering theproduct to a selective collection center or to an authorized waste manager. Venalsol is registered in theNational Registry of Electrical and Electronic Devices with registration number 3493 and is attached to aWaste Management System for Electrical and Electronic Devices for products with the category of"lighting devices".LED Venalsol luminaires are respectful with the environment. They do not contain mercury and theelectronic components used comply with the provisions of the RoHS regulations transposing RoyalDecree 208/2005.Technical ParametersProduct specifications 50W 100W 150W 200WInput voltage AC100-277V 50/60Hz Clase I (Needs grounding)CRI Ra80Beam angle 30ºX70º, 50ºX90º, 120º, 40ºX120º, 90ºClassification IP IP65Dimensions (mm) 280x137x102mm 486x137x102mm 718x137x102mm 948x137x102mmLuminaire net weight 1.9 ±0.3kg 3.4 ±0.3kg 4.7 ±0.3kg 5.7 ±0.3kgPower factor >0.93Useful life ≥50000Hrs (LM70@35°C)Working temperature -30- +50°COperating humidity 15%~90%RHStoring temperature -40- +70°CB. Adjustable surface installationDimensions2. Push1. Press1. Insert1. Enter loopBrownYellow/GreenBlueCABBrownBlueCONNECTION DALI.。

MANUALHLL Series LED Explosion-protected Luminaire3. Safety InstructionsThis product should be installed, inspected, and maintained by a qualifiedelectrician only, in accordance with national regulation, including the relevantstandard and, where applicable, in acc. With IEC 60079-17 on electrical apparatus for explosive atmospheres.The national safety rules and regulations for prevention of accidents and the following safety instructions in these operating instructions, will have to be observed!The luminaire must not be operated in Zone0 and in Zone20!When using in Zone21,Zone22, the requirements of IEC/EN 60079-14 relating to temperature must be observed. The indicated surface temperatures are not related to a layers above 5 mm thickness.Do not install where the marked operating temperature exceed the ignition temperature of the hazardous atmosphere.Do not operate in ambient temperatures above those indicated on the luminaire nameplate.The luminaires shall be operated as intended and only in undamaged and perfect conditions! And Keep tightly closed when in operation! The technical data indicated on the luminaire are to be observed!!connection cable. Following their manufacturer instructions.Fig.1Ceiling mounting 1. DIMENSIONSFig.2Wall mountingFig.3Pipe mounting2. Technical dataHazardous area specificationType of protection:Ex d, e, i,m, tIEC Certification Marking:Ex db eb mb IIC Gb(Normal with switch)Ex db eb ib mb IIC Gb(EM with switch)Ex eb mb IIC Gb(Normal without switch)Ex eb ib mb IIC Gb(EM without switch)Ex tb IIIC T80℃DbATEX Certification Marking:II2 G Ex db eb mb op is IIC T6 Gb(Normal with switch)II2 G Ex db eb ib mb op is IIC T6 Gb(EM with switch)II2 G Ex eb mb op is IIC T6 Gb(Normal w/o switch)II2 G Ex eb ib mb op is IIC T6 Gb(EM without switch)II2 D Ex tb op is IIIC T80℃DbAmbient temperature:-40ºC~+55ºC/-25ºC~+55ºC Temperature class:T6IECEx Certificate No.:IECEx CQM 16.0030X temperature is -40ºC~+55ºC or -25ºC~+55ºC . Refer to the luminaire nameplate, For specific information, corresponding operating temperature(T-Code).The enclosure materials used, including any external metal parts, are High quality materials that ensure a corrosion resistance and resistance to chemical substances according to the requirements for use in a “normal“ industrial atmosphere. In case of use in an extremely aggressive atmospheres, please refer to manufacture.5. Conformity with standardsThis explosion protection floodlight meet the requirements of IEC/EN 60079-0, IEC/EN 60079-1, IEC/EN 60079-7, IEC 60079-11, IEC 60079-18, IEC/EN 60079-31. It also complies with the EC Directives for “Apparatus and protective system for use in explosion atmospheres” (2014/34/EU). It has been designed, manufactured and tested in accordance to the state of the art and according to ISO 9001:2008. The luminaires are suitable for use in explosive atmospheres, Zone1, Zone2 according to IEC60079-10-1 and dust area Zone21 and Zone22 according to IEC60079-10-2.7. Type configuration and Max. Ambient and Temperature RatingsStd. Cat No.ColorTemp.SystempowerLEDQty.T Class(Gas)T ℃(Dust)Voltage(V)Tamb.(ºC)Weight(kg)HLL-2-W-2L-D-*-*-*-*3000K4000K30W28T680110-240Vac50-60Hz108-250Vdc-40~+556HLL-2-W-2L-D-EM*-*-*-*-25~+557HLL-2-3L-D-*-*-*-*5000k5700K6500K -40~+556HLL-2-3L-D-EM*-*-*-*-25~+557HLL-4-W-4L-D-*-*-*-*3000K4000K60W56-40~+5510HLL-4-W-4L-D-EM*-*-*-*-25~+5512HLL-4-5L-D-*-*-*-*5000k5700K6500K -40~+5510HLL-4-5L-D-EM*-*-*-*-25~+55128. Installation8.1GeneralThe respective national regulations IEC/EN 60079-14 as well as the general rules of engineering which apply to the installation and operation of explosion protected apparatus will have to be observed!The improper installation and operation may result in the explosion protection and invalidation of the guarantee. 8.2 Mounting luminaire8.2.1 Mounting the bracketOnly use the accompanying mounting bracket! Securely fasten the mounting bracket to a suitable base with sufficient load-bearing capacity. The mounting should be secured with M8 bolts and relative lock washers, nuts should be used.The minimum distance between the luminaire and illuminated surface, directly in front of the luminaire, is 0.5 meter. The lamp must not be illuminated when at a distance of less than 0.5m from inflammable material8.3 Cable entries/Plugs and Breathing valve The “Increased safety (Exe)" properties must be preserved when select and mount cable entry/plug and breathing valve. Unused holes must be closed with certified plug to establish the Exe protection category. The cable glands/plugs and breathing valve should be Ex tb certified if the whole product is Ex tb certified also. Cable entries sealing washer(if required by manual of cable gland/plug) must be used to obtain IP66.The authoritative mounting guidelines for the cable glands and breathing valve used must be observed. Mounting the selected cable entries acc. type and dimensions of the main connection cable following their manufacturer instructions. The cable temperatures are given as the rise over the max. rated ambient (Tamb). This allows the user to adjust the cable specification for actual maximum site ambient. Only heat resistant cable according to the data on the type label may be used! The max. conductor size is 6mm². The standard looping cable size is 4mm².8.4 Opening/closing the luminaire8.4.1 GeneralThe opening of luminaire always shall be without voltage! All gasket seals must be clean and undamaged before closing the luminaire. Make sure the luminaires is well closed before operation!8.4.2 Exe chamber coverOpen the buckles and remove the PC cover. And carry out the steps in reverse order to close the luminaire. Check all buckles to ensure a secure fit during operation .8.5 Electrical connectionThe electrical connection of the lamp must only be established by qualified electricians.Make sure the supply voltage is the same as the luminaire voltage! Use proper supply wiring as specified on the nameplate of the luminaire and in this instructions! Excessive tightening may affect or damage the connection.8.5.1 Wire connectionThe conductors shall be connected with special care inorder to maintain the explosion category.The conductor itself shall not be damaged.The connectible min. and max. conductor cross-sections shall be observed (see technical data). Allterminals, used and unused, shall be fully tightened toprevent incorrect selection between 1.2Nm for Exe T6P and 1.5~1.8Nm for MBK. Main connection: Seewiring diagram. See Fig.4 for details.9. Putting into operationPrior to putting the apparatus into operation, the testsspecified in the relevant national regulations shall becarried out. Insulation measurements may only becarried out between PE and the external conductor L1(L2, L3) as well as between PE and N.-Measurement voltage: Max. 1.5 KV AC-Measurement current: Max.5 mA-The luminaire may only be operated when closed.-It is generally recommended (see IEC/EN 60079-14)that you ensure the type of protection of theconstruction is not impaired during installation.10. Maintenance/Servicing10.1 GeneralThe relevant national regulations which apply to themaintenance/servicing of electrical apparatus inexplosive atmospheres, shall be observed (EN/IEC60079-17). The interval between maintenance dependsupon the ambient conditions and the hours ofoperation. The recommendations given within EN/IEC60079-17 for recurring checks must be observed.10.2 ChecksThe equipment must be de-energised before openingVisual inspection should be carried out at a minimumof 12 monthly intervals and more frequently ifconditions are severe, refer to EN/IEC 60079-17. Thetime between lamp changes could be very infrequentand this is too long a period without inspection.10.3 Routine ExaminationDuring maintenance, the parts affecting the level ofprotection must be checked in particular:-Ensure the lamp is lit when energised and examine theenclosure and glass for any signs of cracks and damage.-When de-energised and left to cool, there should be nosignificant sign of internal moisture. If there are signs ofwater ingress, the luminaire should be opened up, driedout, and any likely ingress points eliminated by re-gasketing, re-greasing or other replacement.-Check the gasket of pc cover and LED housing for anydamage or permanent set and replace as required.-Terminal, screw glands and blanking plugs for securefitting.-To maintain the light output, clean the protective pccover periodically with a damp cloth or a mild cleaningfluid.-If this product is used in the combustible dust area,outside of enclosure must be cleaned on a regular basis toprevent accumulation of dust.-The cable connections should be checked for tightness.The gasket should be checked for cracks or lack ofelasticity, and if necessary, replaced.-Check that mountings are secure and the adjusting boltsare tight.-If it has been suspected that the luminaire has mechanicaldamage, a stringent workshop overhaul will be required.Where spares are needed, these must be replaced withfactory specified parts.No modifications should be made without the knowledgeand approval of the manufacturer.Cleaning the joint of housing assy. and pc cover use adamp cloth or a mild cleaning fluid.11. Repair/Overhaul/Modifications11.1 GeneralThe national regulations EN/IEC60079-19 have to beobserved! Repairs and overhaul may only be carried outwith genuine Eaton Crouse-Hinds spare parts.In the case of battery failure, the battery pack must bereplaced as a complete unit from the manufacture.Before replacing or disassembling individual parts, observethe following:Disconnect the power supply to the equipment beforemaintenance/repair.Make sure that there is no explosive atmosphere whenopening the equipment. See section 8.4 for notes onopening and closing the lamp.Only use original spare parts. If the luminaire waspreviously in operation then wait to cool enough beforeopening. Repairs that affect the explosion protection,may only be carried out by Eaton Crouse-Hinds or aqualified electrician in compliance with the applicablenational rules. Modifications to the device or changes toits design are not permitted.After carrying out repair or overhaul work, ensure thatthe “Exde" properties have not been affected.Assistance may also be obtained through CooperElectronic Technologies (Shanghai) Co., Ltd. Sales Servicedepartment,955 ShengLi Road, Pudong Shanghai 201201Phone (86) 21-2899394312. Disposal/RecyclingWhen the apparatus is disposed of, the respective nationalregulations on waste disposal will have to be observed. Fig4。

——使用本产品前请仔细阅读使用说明书

防爆投光灯

使用说明书

BTd系列防爆投光灯使用说明书

1、用途、工作条件

1.1用途:

BTd系列防爆投光灯(以下简称防爆灯),适用于含有II类A级、B级,T3组以下级别、组别含有爆炸性气体混合物的危险场所。

1.2工作条件

a.海拔不超过2000m;

b.周围环境温度为+40℃,不低于-20℃;

c.空气相对湿度不大于90%(+25℃时);

d.在露天场所最大降雨强度50㎜/10min;

e.无显著摇动和剧烈冲击振动的地方;

f.最大辐射强度1.4cal/cm2.min;

2、结构与特点

2.1型号含义

B Td 36 -□□

额定功率

光源类型

设计序号

灯具

防爆

2.2主要技术参数

2.3结构概述

a.防爆灯按照GB3836-2000,IEC600079标准规定要求设计制造,经国家指定检验机关检验合格,并颁发合格证;

b.防爆灯采用间隙隔爆原理,即当壳内发生爆炸时,不致引起周围环境的爆炸;

c.玻璃罩采用高硼硅玻璃,经钢化处理后,能承受规定冲击强度和温差试验,防爆灯外壳和接线盒或镇流器采用铝合金压铸成型;

d.防爆灯设有“严禁带电开盖”的警告牌,告知切断电源后才能启盖维修;

3、外形及安装尺寸见图:例

4、安装与维修

4.1 安装时必须检查铭牌上的技术数据是否与实际使用情况相符,电缆应穿过橡胶密封圈,金属垫圈,用压螺母压紧,保证密封及电缆不得松动;

4.2安装时须有良好的内外接地;

4.3为保证防爆灯正常工作,用户必须定期检查。

发现金属零部件有油漆脱落或腐蚀等现象,应用细砂布磨光擦净后,涂上防锈油。

检查电气性能是否处于良好状态,隔爆面应严禁磕碰、划伤,并涂204-1防锈油;

4.4紧固件不得松动,如发现松动须加以紧固;

4.5非专业人员不准打开防爆灯;

4.6更换灯泡时必须在切断电源后进行操作。

5、订货须知

订货时须说明投光灯的完整型号、名称、规格及订货数量:。